Design and Employing of a Non-Linear Response Surface Model to Predict the Microbial Loads in Anaerobic Digestion of Cow Manure: Batch Balloon Digester

Abstract

:1. Introduction

1.1. Common Types of Available Biodigesters

1.1.1. Fixed-Dome Biodigester

1.1.2. Floating-Drum Digester

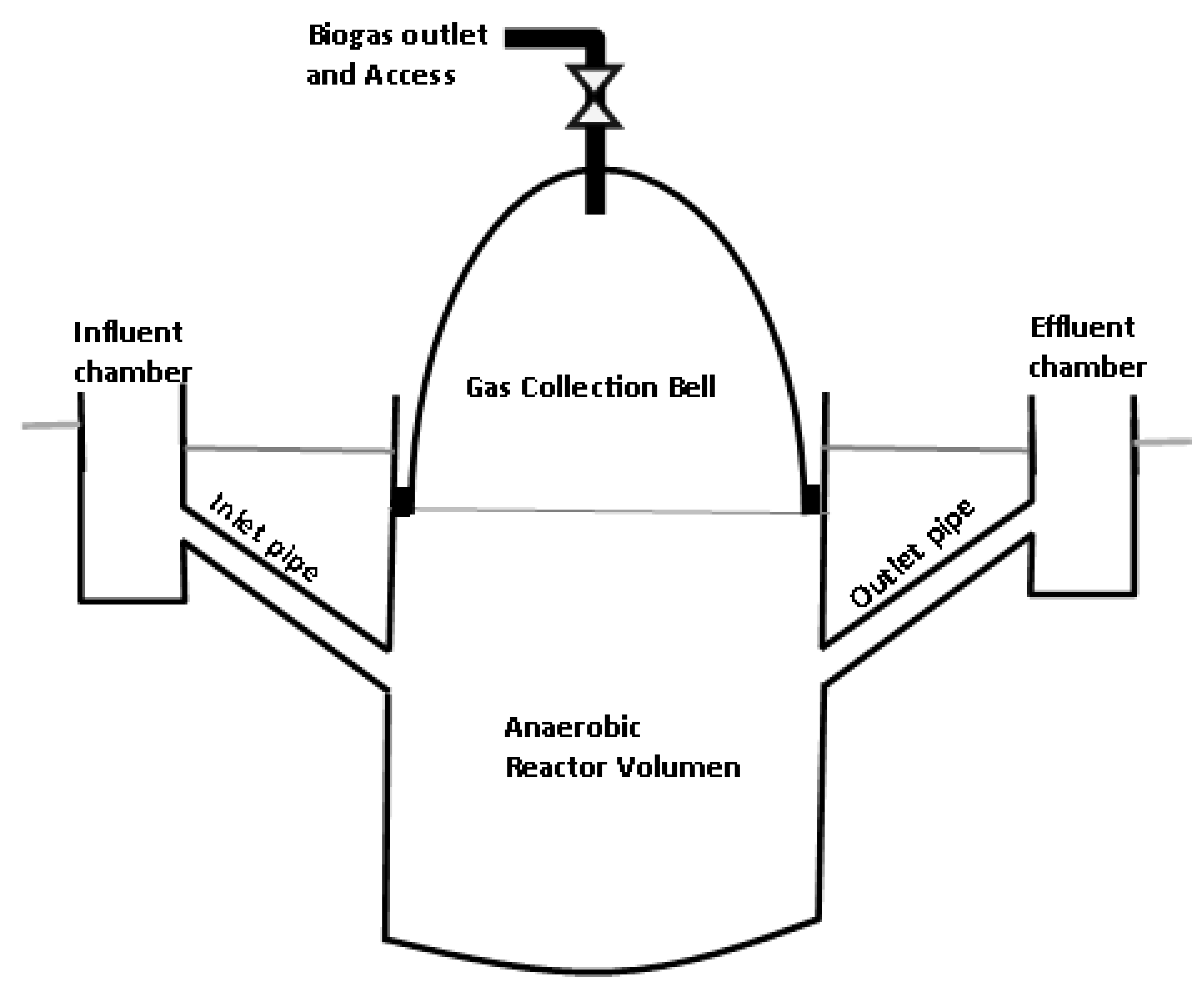

1.1.3. Balloon Digester

1.2. Factors Contributing to the Yield of Biogas in a Biodigester

1.2.1. Carbon/Nitrogen (C/N) Ratio

1.2.2. Slurry Temperature

1.2.3. pH Value

1.2.4. Dilution and Consistency of Input

1.2.5. Loading Rate

1.2.6. Hydraulic Retention Time

1.2.7. Toxicity

1.3. Aim and Objectives of the Study

- To design a data acquisition system to enable the investigation of the correlation between the total viable bacteria counts with predictors (number of days, daily slurry temperatures and pH).

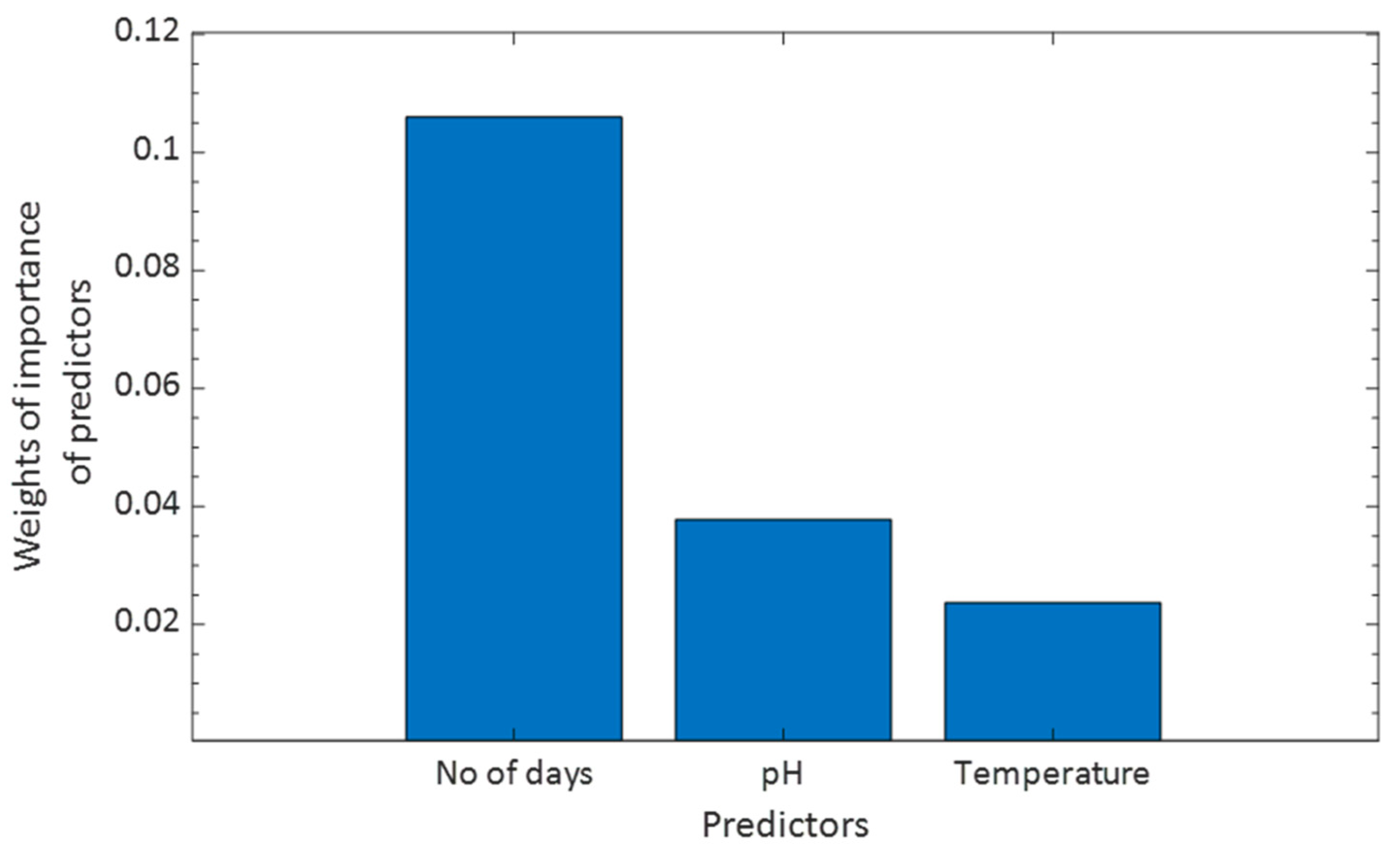

- To employ the reliefF statistical test in ranking of the predictors into weights of importance to the total viable bacteria counts.

- To develop a non-linear response surface model to predict the total viable bacteria counts with the number of days, daily slurry temperatures and pH as the predictors.

- To simulate the variation in the total viable bacteria counts with each of the predictor, whereas the other input parameters are held constant using the 2D multi-contour surface plots.

- To perform a robust validation of the developed model used in the prediction of the total viable bacteria counts.

1.4. Research Questions of the Study

- Can a data acquisition system be designed and built to measure the ambient and physicochemical parameters, quality, and quantity of potential biogas production in a balloon-type digester?

- Can the input parameters (number of days, slurry temperature, and pH) influence the total bacteria counts, and is it possible to rank them according to their weights of importance?

- Can a response surface model be developed that could be used to predict the total bacteria counts in a balloon digester using the number of days, slurry temperature and pH as the predictors.

- Can a 2D multi-contour surface plots be generated to simulate the variation in each of the input parameter with the model output while the others are held constant?

- Can the derived response surface model of the balloon digester fed with cow waste be accurately validated?

1.5. Delineation of the Study

2. Methodology of the Study

2.1. Materials and Experimental Setup

2.2. Methods

2.2.1. Raw Anaerobic Digestion Material (Cow Manure)

2.2.2. Physicochemical Analysis of the Slurry Samples

- Calculation of the ammonium (NH4) level of the sample

- ii.

- Determination of percentage of moisture content of samples

- iii.

- Determination of percentage of dry matter (total solids)

- iv.

- Determination of percentage of volatile solid content and ash content

- v.

- Determination of pH, ambient temperature, slurry temperature and biogas yield

- vi.

- Microbial analysis of samples

2.2.3. Statistical Analysis

2.2.4. Development of Non-Linear Response Surface Model

2.3. Measurement Accuracies and Uncertainties

3. Results and Discussion

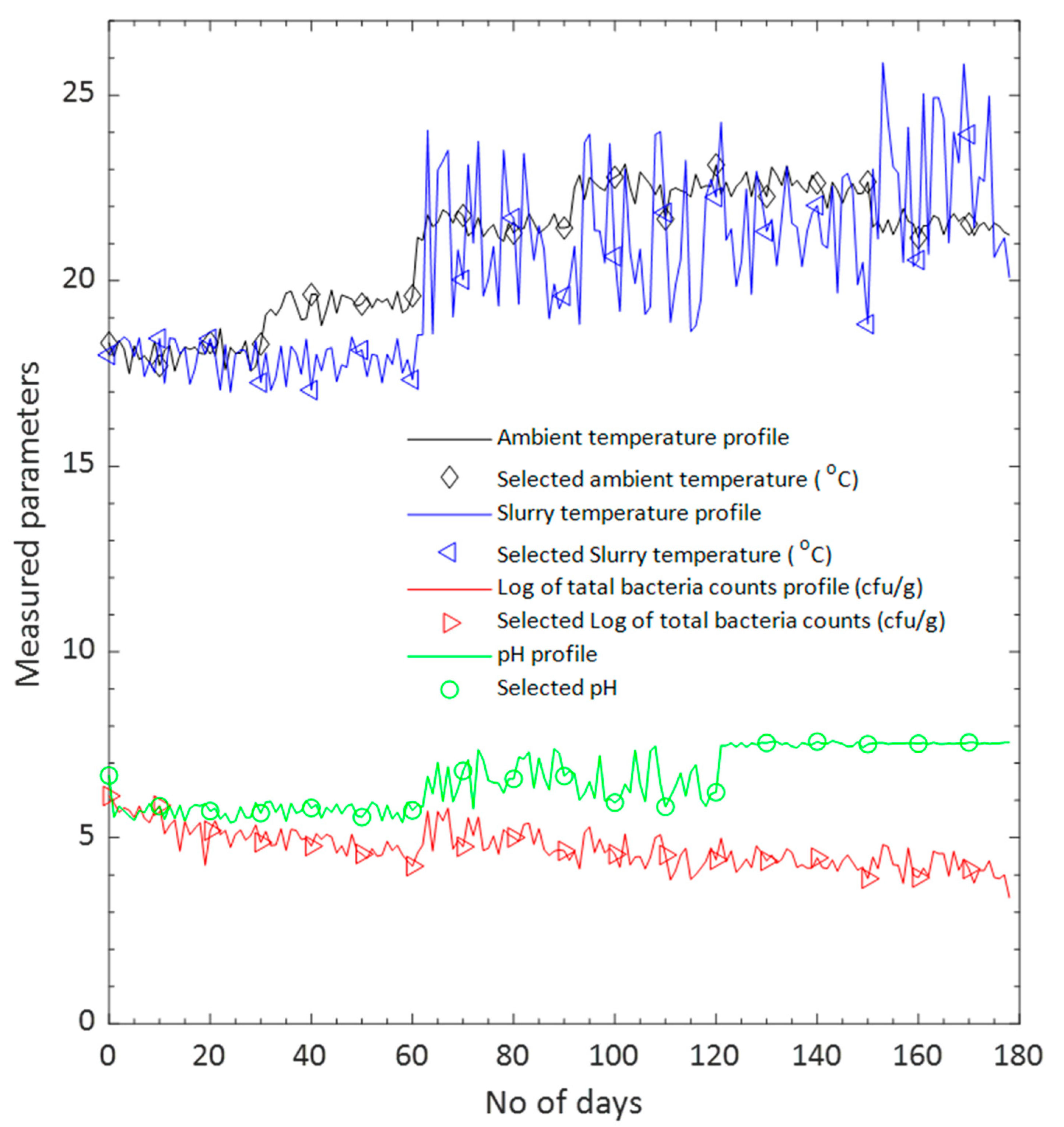

3.1. Profiles of Ambient Temperature, Input and Output Parameters during Anaerobic Digestion

3.2. Characteristics of the Cow Manure and Variation of Physicochemical Parameters

3.3. ReliefF Test Used in Weight Ranking of the Predictors to the Total Viable Counts

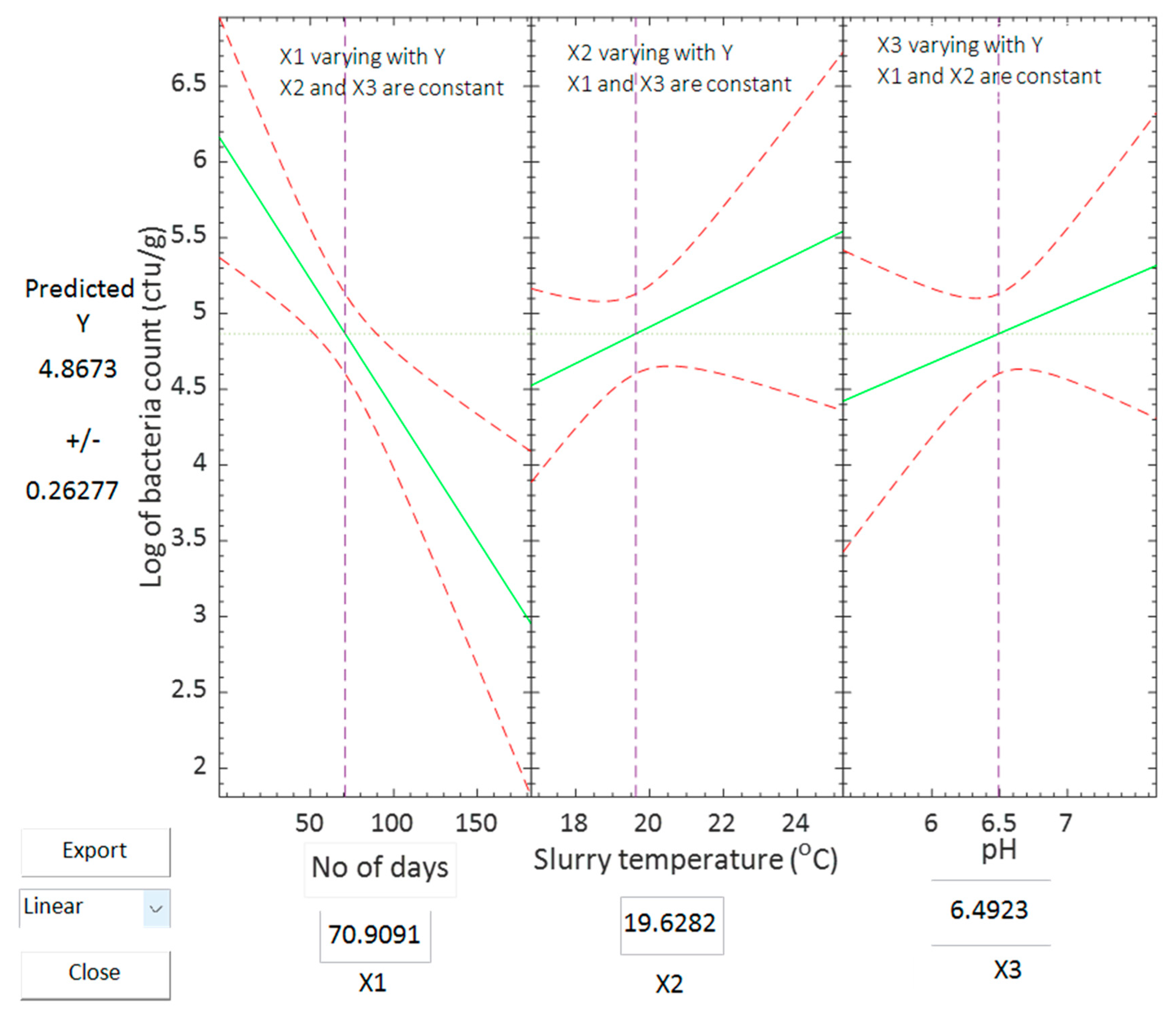

3.4. 2D Multi-Contour Surface Plots to Simulate the Variation in the Response with Each Predictor

Two-Dimensional Multi-Contour Plots with the Developed Non-Linear Response Surface Model

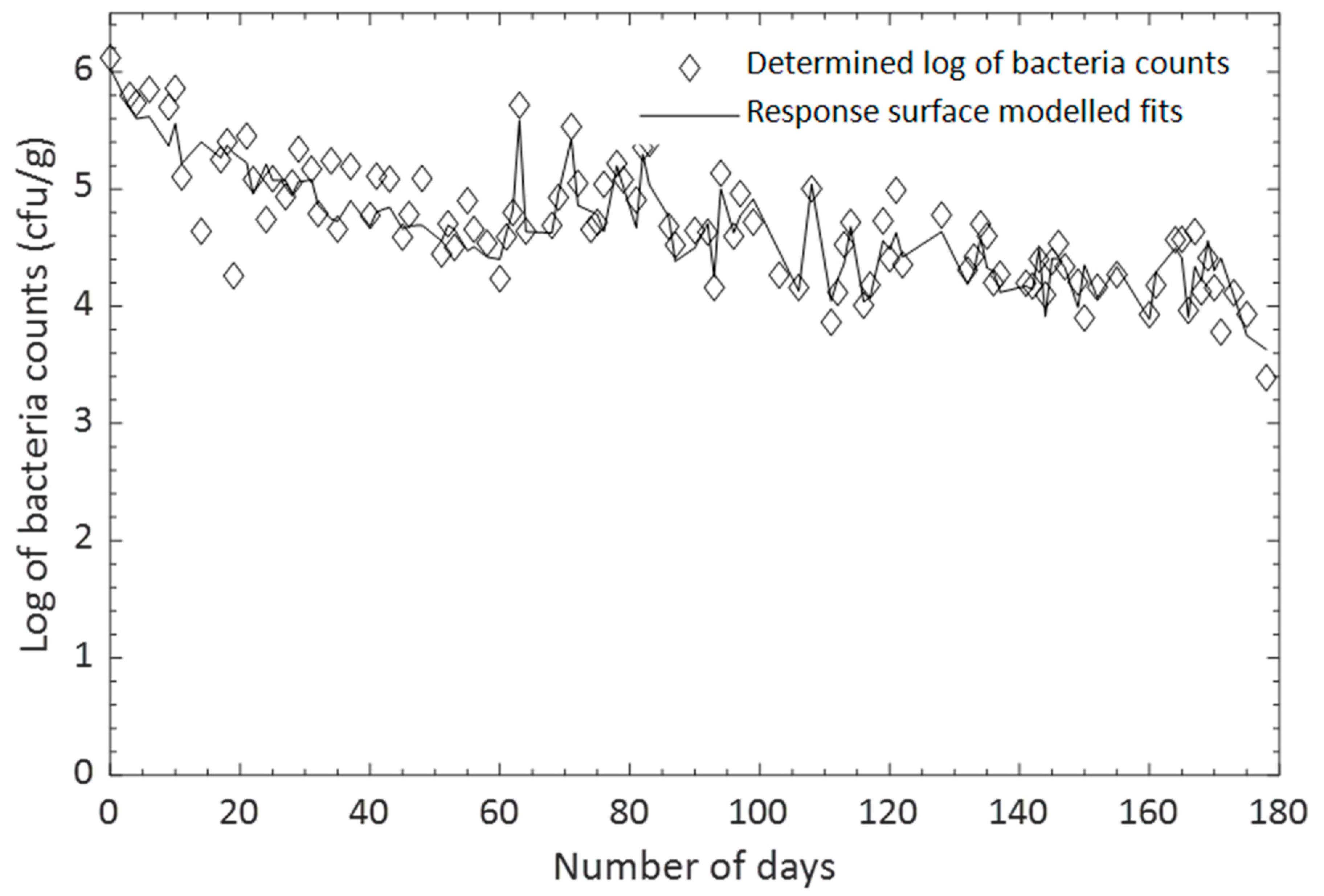

3.5. Testing of the Accuracy of the Developed Model

3.5.1. Testing of the Accuracy of the Developed Non-Linear Response Surface Model

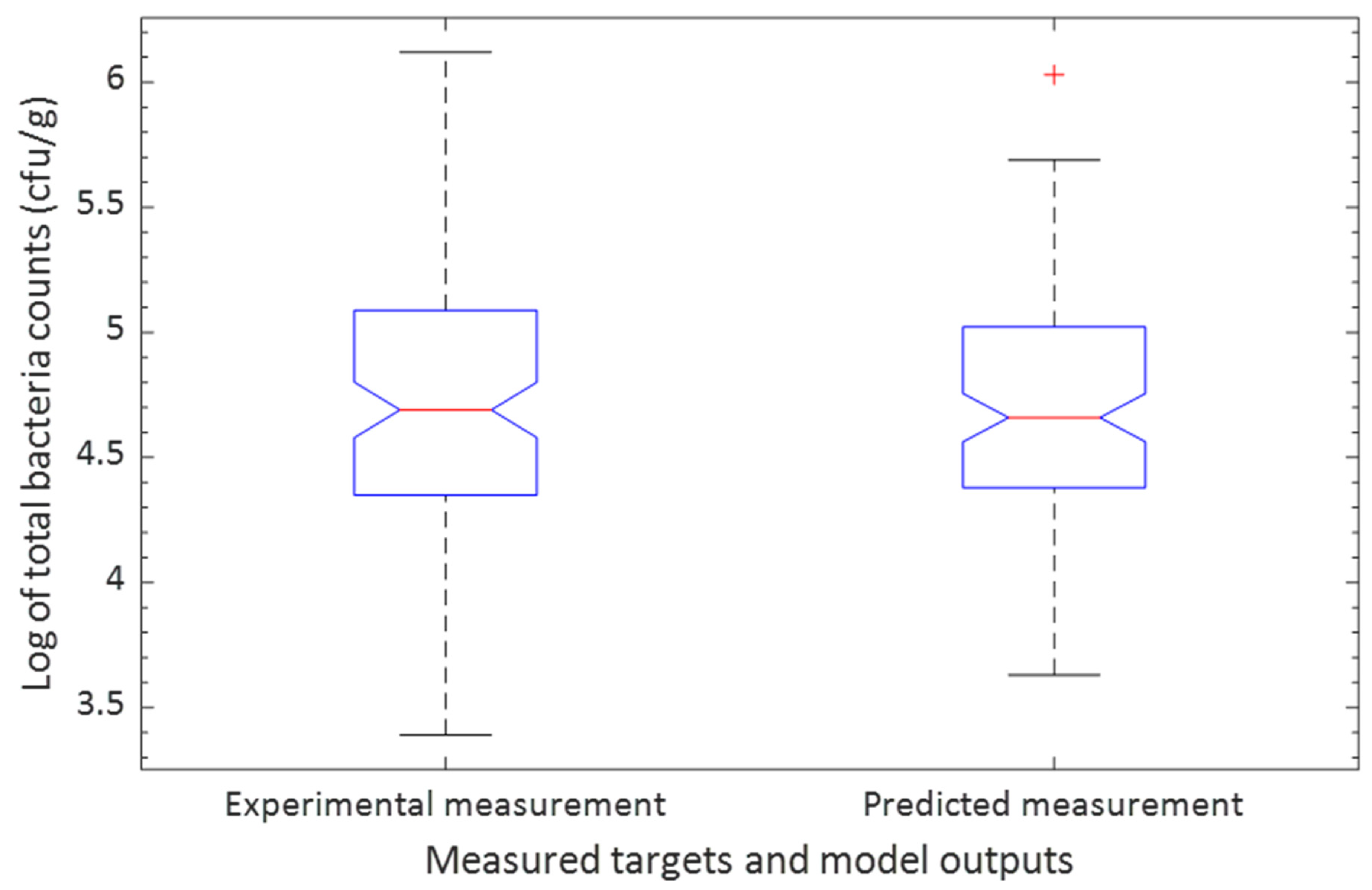

3.5.2. ANOVA Statistics to Confirm the Accuracy of Developed Non-Linear Response Surface Model Using Testing Data Set

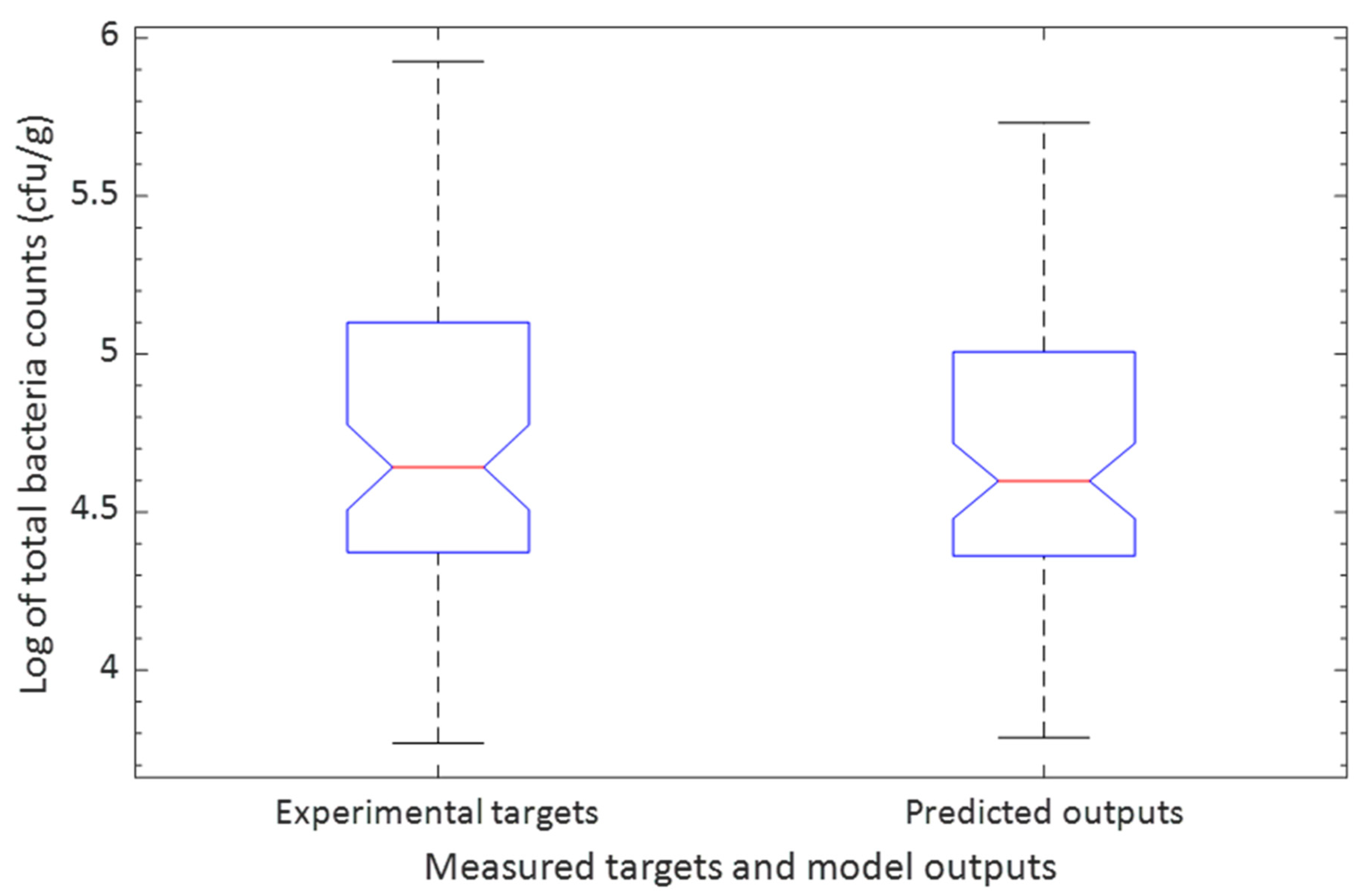

3.6. Validation of the Developed Non-Linear Response Surface Model

ANOVA Statistics to Confirm Accuracy of the Response Surface Model with Validation Data Set

4. Conclusions

5. Recommendation for Future Study

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Lu, Y.; Khan, Z.A.; Alvarez-Alvarado, M.S.; Zhang, Y.; Huang, Z.; Imran, M. A critical review of sustainable energy policies for the promotion of renewable energy sources. Sustainability 2020, 12, 5078. [Google Scholar] [CrossRef]

- Abanades, S.; Abbaspour, H.; Ahmadi, A.; Das, B.; Ehyaei, M.A.; Esmaeilion, F.; El Haj Assad, M.; Hajilounezhad, T.; Jamali, D.H.; Hmida, A.; et al. A critical review of biogas production and usage with legislations framework across the globe. Int. J. Environ. Sci. Technol. 2021, 19, 3377–3400. [Google Scholar] [CrossRef]

- Kemausuor, F.; Adaramola, M.S.; Morken, J. A review of commercial biogas systems and lessons for Africa. Energies 2018, 11, 2984. [Google Scholar] [CrossRef] [Green Version]

- Ayilara, M.S.; Olanrewaju, O.S.; Babalola, O.O.; Odeyemi, O. Waste management through composting: Challenges and potentials. Sustainability 2020, 12, 4456. [Google Scholar] [CrossRef]

- Garfí, M.; Martí-Herrero, J.; Garwood, A.; Ferrer, I. Household anaerobic digesters for biogas production in Latin America: A review. Renew. Sustain. Energy Rev. 2016, 60, 599–614. [Google Scholar] [CrossRef] [Green Version]

- Manyi-Loh, C.E.; Mamphweli, S.N.; Meyer, E.L.; Okoh, A.I.; Makaka, G.; Simon, M. Microbial anaerobic digestion (bio-digesters) as an approach to the decontamination of animal wastes in pollution control and the generation of renewable energy. Int. J. Environ. Res. Public Health 2013, 10, 4390–4417. [Google Scholar] [CrossRef] [Green Version]

- Wilkie, A.C. Anaerobic digestion of dairy manure: Design and process considerations. In Dairy Manure Management: Treatment, Handling, and Community Relations; Cornell University: Ithaca, NY, USA, 2005; Volume 301, pp. 301–312. [Google Scholar]

- Mehariya, S.; Patel, A.K.; Obulisamy, P.K.; Punniyakotti, E.; Wong, J.W. Co-digestion of food waste and sewage sludge for methane production: Current status and perspective. Bioresour. Technol. 2018, 265, 519–531. [Google Scholar] [CrossRef]

- Howarth, R.W.; Santoro, R.; Ingraffea, A. Methane and the greenhouse-gas footprint of natural gas from shale formations. Clim. Chang. 2011, 106, 679–690. [Google Scholar] [CrossRef] [Green Version]

- Manyi-Loh, C.; Mamphweli, S.; Meyer, E.; Okoh, A. Characterizing Bacteria and Methanogens in a Balloon-Type Digester Fed with Dairy Cattle Manure for Anaerobic Mono-Digestion. Pol. J. Environ. Stud. 2019, 28, 1287–1293. [Google Scholar] [CrossRef]

- Hagos, K.; Zong, J.; Li, D.; Liu, C.; Lu, X. Anaerobic co-digestion process for biogas production: Progress, challenges and perspectives. Renew. Sustain. Energy Rev. 2017, 76, 1485–1496. [Google Scholar] [CrossRef]

- Manyi-Loh, C.E.; Mamphweli, S.N.; Meyer, E.L.; Makaka, G.; Simon, M.; Okoh, A.I. An overview of the control of bacterial pathogens in cattle manure. Int. J. Environ. Res. Public Health 2016, 13, 843. [Google Scholar] [CrossRef] [Green Version]

- Tangwe, S.L.; Simon, M. Evaluation of performance of air source heat pump water heaters using the surface fitting models: 3D mesh plots and 2D multi contour plots simulation. Therm. Sci. Eng. Prog. 2018, 5, 516–523. [Google Scholar] [CrossRef]

- Dincer, I.; Acar, C. A review on clean energy solutions for better sustainability. Int. J. Energy Res. 2015, 39, 585–606. [Google Scholar] [CrossRef]

- Morgan, H.M., Jr.; Xie, W.; Liang, J.; Mao, H.; Lei, H.; Ruan, R.; Bu, Q. A techno-economic evaluation of anaerobic biogas producing systems in developing countries. Bioresour. Technol. 2018, 250, 910–921. [Google Scholar] [CrossRef]

- Pérez, I.; Garfí, M.; Cadena, E.; Ferrer, I. Technical, economic and environmental assessment of household biogas digesters for rural communities. Renew. Energy 2014, 62, 313–318. [Google Scholar] [CrossRef]

- Hamid, R.G.; Blanchard, R.E. An assessment of biogas as a domestic energy source in rural Kenya: Developing a sustainable business model. Renew. Energy 2018, 121, 368–376. [Google Scholar] [CrossRef] [Green Version]

- Werner, U.; Stöhr, U.; Hees, N. Biogas Plants in Animal Husbandry; Deutsches Zentrum für Entwicklungstechnologien: Eschborn, Germany, 1989. [Google Scholar]

- Nzila, C.; Dewulf, J.; Spanjers, H.; Tuigong, D.; Kiriamiti, H.; Van Langenhove, H. Multi criteria sustainability assessment of biogas production in Kenya. Appl. Energy 2012, 93, 496–506. [Google Scholar] [CrossRef]

- Bakar, N.S.A.; Nasir, N.M.; Lananan, F.; Hamid, S.H.A.; Lam, S.S.; Jusoh, A. Optimization of C/N ratios for nutrient removal in aquaculture system culturing African catfish, (Clarias gariepinus) utilizing Bioflocs Technology. Int. Biodeterior. Biodegrad. 2015, 102, 100–106. [Google Scholar] [CrossRef]

- Sreela-Or, C.; Plangklang, P.; Imai, T.; Reungsang, A. Co-digestion of food waste and sludge for hydrogen production by anaerobic mixed cultures: Statistical key factors optimization. Int. J. Hydrogen Energy 2011, 36, 14227–14237. [Google Scholar] [CrossRef]

- Hu, B.; Zhou, W.; Min, M.; Du, Z.; Chen, P.; Ma, X.; Liu, Y.; Lei, H.; Shi, J.; Ruan, R. Development of an effective acidogenically digested swine manure-based algal system for improved wastewater treatment and biofuel and feed production. Appl. Energy 2013, 107, 255–263. [Google Scholar] [CrossRef]

- Mao, C.; Feng, Y.; Wang, X.; Ren, G. Review on research achievements of biogas from anaerobic digestion. Renew. Sustain. Energy Rev. 2015, 45, 540–555. [Google Scholar] [CrossRef]

- Koupaie, E.H.; Lin, L.; Lakeh, A.B.; Azizi, A.; Dhar, B.R.; Hafez, H.; Elbeshbishy, E. Performance evaluation and microbial community analysis of mesophilic and thermophilic sludge fermentation processes coupled with thermal hydrolysis. Renew. Sustain. Energy Rev. 2021, 141, 110832. [Google Scholar] [CrossRef]

- Zhang, T.; Tan, Y.; Zhang, X. Using a hybrid heating system to increase the biogas production of household digesters in cold areas of China: An experimental study. Appl. Therm. Eng. 2016, 103, 1299–1311. [Google Scholar] [CrossRef]

- Akhbari, A.; Kutty, P.K.; Chuen, O.C.; Ibrahim, S. A study of palm oil mill processing and environmental assessment of palm oil mill effluent treatment. Environ. Eng. Res. 2020, 25, 212–221. [Google Scholar] [CrossRef] [Green Version]

- Basumatary, S.; Das, S.; Kalita, P.; Goswami, P. Effect of feedstock/water ratio on anaerobic digestion of cattle dung and vegetable waste under mesophilic and thermophilic conditions. Bioresour. Technol. Rep. 2021, 14, 100675. [Google Scholar] [CrossRef]

- Mahmudul, H.M.; Rasul, M.G.; Akbar, D.; Narayanan, R.; Mofijur, M. A comprehensive review of the recent development and challenges of a solar-assisted biodigester system. Sci. Total Environ. 2021, 753, 141920. [Google Scholar] [CrossRef]

- Zhao, J.; Hou, T.; Lei, Z.; Shimizu, K.; Zhang, Z. Effect of biogas recirculation strategy on biogas upgrading and process stability of anaerobic digestion of sewage sludge under slightly alkaline condition. Bioresour. Technol. 2020, 308, 123293. [Google Scholar] [CrossRef]

- Gaballah, E.S.; Abomohra, A.E.F.; Xu, C.; Elsayed, M.; Abdelkader, T.K.; Lin, J.; Yuan, Q. Enhancement of biogas production from rape straw using different co-pretreatment techniques and anaerobic co-digestion with cattle manure. Bioresour. Technol. 2020, 309, 123311. [Google Scholar] [CrossRef]

- Angenent, L.T.; Sung, S.; Raskin, L. Methanogenic population dynamics during startup of a full-scale anaerobic sequencing batch reactor treating swine waste. Water Res. 2002, 36, 4648–4654. [Google Scholar] [CrossRef]

- Blessy, M.R.D.P.; Patel, R.D.; Prajapati, P.N.; Agrawal, Y.K. Development of forced degradation and stability indicating studies of drugs—A review. J. Pharm. Anal. 2014, 4, 159–165. [Google Scholar] [CrossRef]

- Yadav, D.; Barbora, L.; Bora, D.; Mitra, S.; Rangan, L.; Mahanta, P. An assessment of duckweed as a potential lignocellulosic feedstock for biogas production. Int. Biodeterior. Biodegrad. 2017, 119, 253–259. [Google Scholar] [CrossRef]

- Yu, Q.; Liu, R.; Li, K.; Ma, R. A review of crop straw pretreatment methods for biogas production by anaerobic digestion in China. Renew. Sustain. Energy Rev. 2019, 107, 51–58. [Google Scholar] [CrossRef]

- Bharathiraja, B.; Sudharsana, T.; Jayamuthunagai, J.; Praveenkumar, R.; Chozhavendhan, S.; Iyyappan, J. Biogas production–A review on composition, fuel properties, feed stock and principles of anaerobic digestion. Renew. Sustain. Energy Rev. 2018, 90, 570–582. [Google Scholar] [CrossRef]

- Sreekrishnan, T.R.; Kohli, S.; Rana, V. Enhancement of biogas production from solid substrates using different techniques––A review. Bioresour. Technol. 2004, 95, 1–10. [Google Scholar]

- Gunaseelan, V.N. Anaerobic digestion of biomass for methane production: A review. Biomass Bioenergy 1997, 13, 83–114. [Google Scholar] [CrossRef]

- Ihara, I.; Yano, K.; Andriamanohiarisoamanana, F.J.; Yoshida, G.; Yuge, T.; Yuge, T.; Tangtaweewipat, S. and Umetsu, K. Field testing of a small-scale anaerobic digester with liquid dairy manure and other organic wastes at an urban dairy farm. J. Mater. Cycles Waste Manag. 2020, 22, 1382–1389. [Google Scholar] [CrossRef]

- Ferrer, I.; Garfí, M.; Uggetti, E.; Ferrer-Martí, L.; Calderon, A.; Velo, E. Biogas production in low-cost household digesters at the Peruvian Andes. Biomass Bioenergy 2011, 35, 1668–1674. [Google Scholar] [CrossRef]

- Gupta, P.; Diwan, B. Bacterial exopolysaccharide mediated heavy metal removal: A review on biosynthesis, mechanism and remediation strategies. Biotechnol. Rep. 2017, 13, 58–71. [Google Scholar] [CrossRef]

- Ziganshina, E.E.; Belostotskiy, D.E.; Shushlyaev, R.V.; Miluykov, V.A.; Vankov, P.Y.; Ziganshin, A.M. Microbial community diversity in anaerobic reactors digesting turkey, chicken, and swine wastes. J. Microbiol. Biotechnol. 2014, 24, 1464–1472. [Google Scholar] [CrossRef]

- Manyi-Loh, C.E.; Mamphweli, S.N.; Meyer, E.L.; Okoh, A.I.; Makaka, G.; Simon, M. Investigation into the biogas production potential of dairy cattle manure. J. Clean Energy Technol. 2015, 3, 326–331. [Google Scholar] [CrossRef] [Green Version]

- Fridh, L.; Volpé, S.; Eliasson, L. An accurate and fast method for moisture content determination. Int. J. For. Eng. 2014, 25, 222–228. [Google Scholar] [CrossRef]

- Bradley, R.L. Moisture and total solids analysis. In Food Analysis; Springer: Boston, MA, USA, 2010; pp. 85–104. [Google Scholar]

- Van Wychen, S.; Laurens, L.M. Determination of Total Solids and Ash in Algal Biomass: Laboratory Analytical Procedure (LAP) (No. NREL/TP-5100-60956); National Renewable Energy Lab. (NREL): Golden, CO, USA, 2016. [Google Scholar]

- Sahlström, L. A review of survival of pathogenic bacteria in organic waste used in biogas plants. Bioresour. Technol. 2003, 87, 161–166. [Google Scholar] [CrossRef]

- Bodhidatta, L.; McDaniel, P.; Sornsakrin, S.; Srijan, A.; Serichantalergs, O.; Mason, C.J. Case-control study of diarrheal disease etiology in a remote rural area in Western Thailand. Am. J. Trop. Med. Hyg. 2010, 83, 1106. [Google Scholar] [CrossRef] [Green Version]

- Valentine, D.T.; Hahn, B. Essential MATLAB for Engineers and Scientists; Academic Press: Cambridge, MA, USA, 2022. [Google Scholar]

- Tangwe, S.; Kusakana, K. Using statistical tests to compare the coefficient of performance of air source heat pump water heaters. J. Energy S. Afr. 2022, 33, 40–51. [Google Scholar] [CrossRef]

- Faggioli, G.; Zendel, O.; Culpepper, J.S.; Ferro, N.; Scholer, F. March. An enhanced evaluation framework for query performance prediction. In European Conference on Information Retrieval; Springer Cham: Cham, Switzerland, 2021; pp. 115–112982. [Google Scholar]

- Reyes, O.; Morell, C.; Ventura, S. Scalable extensions of the ReliefF algorithm for weighting and selecting features on the multi-label learning context. Neurocomputing 2015, 161, 168–182. [Google Scholar] [CrossRef]

- Germec, M.; Turhan, I. Predicting the experimental data of the substrate specificity of Aspergillus niger inulinase using mathematical models, estimating kinetic constants in the Michaelis–Menten equation, and sensitivity analysis. Biomass Convers. Biorefinery 2021, 1–12. [Google Scholar] [CrossRef]

- Tangwe, S.; Kusakana, K. A statistical methodology to compare the performance of residential air source heat pump water heaters. Int. J. Sustain. Energy 2021, 40, 719–738. [Google Scholar]

- Shirani Faradonbeh, R.; Monjezi, M.; Jahed Armaghani, D. Genetic programing and non-linear multiple regression techniques to predict backbreak in blasting operation. Eng. Comput. 2016, 32, 123–133. [Google Scholar] [CrossRef]

- Coleman, H.W.; Steele, W.G. Experimentation, Validation, and Uncertainty Analysis for Engineers; John Wiley & Sons: Hoboken, NJ, USA, 2018. [Google Scholar]

- Horner, I.; Renard, B.; Le Coz, J.; Branger, F.; McMillan, H.K.; Pierrefeu, G. Impact of stage measurement errors on streamflow uncertainty. Water Resour. Res. 2018, 54, 1952–1976. [Google Scholar] [CrossRef] [Green Version]

- Cioabla, A.E.; Ionel, I.; Dumitrel, G.A.; Popescu, F. Comparative study on factors affecting anaerobic digestion of agricultural vegetal residues. Biotechnol. Biofuels 2012, 5, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Poux, X.; Aubert, P.M. An agroecological Europe in 2050: Multifunctional Agriculture for Healthy Eating. Findings from the Ten Years for Agroecology (TYFA) Modelling Exercise. Iddri-AScA, Study. 2018. Available online: https://www.iddri.org/sites/default/files/PDF/Publications/Catalogue%20Iddri/Etude/201809-ST0918EN-tyfa.pdf (accessed on 20 August 2022).

- Zhang, W.; Kong, T.; Xing, W.; Li, R.; Yang, T.; Yao, N.; Lv, D. Links between carbon/nitrogen ratio, synergy and microbial characteristics of long-term semi-continuous anaerobic co-digestion of food waste, cattle manure and corn straw. Bioresource Technol. 2022, 343, 126094. [Google Scholar] [CrossRef] [PubMed]

- Ibrahim, M.H.; Quaik, S.; Ismail, S.A. An introduction to anaerobic digestion of organic wastes. In Prospects of Organic Waste Management and the Significance of Earthworms; Springer: Cham, Switzerland, 2016; pp. 23–44. [Google Scholar]

- Babaee, A.; Shayegan, J.; Roshani, A. Anaerobic slurry co-digestion of poultry manure and straw: Effect of organic loading and temperature. J. Environ. Health Sci. Eng. 2013, 11, 15. [Google Scholar] [CrossRef]

- Rastogi, G.; Ranade, D.R.; Yeole, T.Y.; Patole, M.S.; Shouche, Y.S. Investigation of methanogen population structure in biogas reactor by molecular characterization of methyl-coenzyme M reductase A (mcrA) genes. Bioresour. Technol. 2008, 99, 5317–5326. [Google Scholar] [CrossRef]

- Choorit, W.; Wisarnwan, P. Effect of temperature on the anaerobic digestion of palm oil mill effluent. Electron. J. Biotechnol. 2007, 10, 376–385. [Google Scholar] [CrossRef]

- Tangwe, S.L. Demonstration of Residential Air Source Heat Pump Water Heaters Performance in South Africa: Systems Monitoring and Modelling. Doctoral Dissertation, University of Sunderland, Sunderland, UK, 2018. [Google Scholar]

| ||

| Item | Device and Materials | Quantity |

| 1 | Centrifugal tubes | 10 |

| 2 | Nessler’s reagent | - |

| 3 | Hexios, Thermo-Spectronics Spectrometer | 1 |

| 4 | Distilled water | - |

| 5 | Dish | 1 |

| 6 | Electric oven | 1 |

| 7 | PHH-SD1 pH meter | 1 |

| 8 | TMC6-HD copper pipe temperature sensors | 4 |

| 9 | Portable biogas analyzer, IRCD4 | 1 |

| 10 | Tryptic soy broth medium | - |

| 11 | Physical saline | - |

| 12 | Triplicates of microbiological media (nutrient agar and anaerobic agar) | - |

| 13 | Fridge | 1 |

| 14 | Incubator | 1 |

| 15 | Weight balance | 1 |

| 16 | muffle furnace | 1 |

| ||

| Item | Device and Materials | Quantity |

| 1 | Fabricated balloon digester | 1 |

| 2 | Feedstock of cow waste (slurry) | 2500 L |

| 2 | An open surface concrete structure | 1 |

| 3 | A black wooden board (insulation cover) | 1 |

| 4 | Portable biogas analyzer, IRCD4 | 1 |

| 5 | TMC6-HD copper pipe temperature sensors | 4 |

| 6 | Hobo-UX120 four external channel data logger | 1 |

| 7 | PHH-SD1 pH meter | 1 |

| 8 | Slurry measuring cylinder (250 cm3) | 1 |

| 9 | ZAN-TECHS gas flow meters with data logger | 1 |

| 10 | Control flow valve | 1 |

| 11 | Biogas circulation pump | 1 |

| 12 | Connecting biogas tubing | 1 |

| 13 | Biogas collection chamber | 1 |

| 14 | Weatherproof data loggers’ enclosure | 1 |

| 15 | A zinc roof open structure (re-forcing protection of sensors and system) | 1 |

| Parameters | Sample A | Sample B | Sample C | Sample D | Sample E | Mean | Standard Deviation |

|---|---|---|---|---|---|---|---|

| Percentage of moisture content | 89.12 | 91.23 | 91.19 | 89.96 | 90.78 | 90.38 | 0.886 0.396 |

| Percentage of total solids | 10.88 | 8.77 | 8.81 | 10.04 | 9.22 | 9.55 | 0.975 0.436 |

| Percentage of volatile solids | 65.76 | 68.25 | 72.65 | 71.55 | 73.04 | 70.25 | 3.138 1.403 |

| Percentage of ash content | 34.24 | 31.75 | 27.35 | 28.45 | 26.96 | 29.75 | 3.138 1.403 |

| Ammonium (NH4) level (mg/mL) | 2.19 | 2.01 | 2.25 | 2.28 | 2.20 | 2.18 | 0.105 0.046 |

| pH | 6.83 | 6.82 | 6.59 | 6.76 | 6.46 | 6.69 | 0.162 0.072 |

| Input Parameters | Input Symbols | Scaling Attribute | Scaling Values | Output |

|---|---|---|---|---|

| Forcing constant | 1 | Log of total bacteria counts (y) r2 = 0.959, RMSE = 0.197, p-value = 0.602 | ||

| Number of days | x1 | 0.0047 | ||

| Daily slurry temperature | x2 | 0.4947 0.0521 | ||

| pH | x3 | −0.1445 2.2002 |

| Quantity | Type A Uncertainty | Type B Uncertainty | Combined Uncertainty |

|---|---|---|---|

| Ambient temperature (°C) | ±0.200 | ±0.120 | ±0.320 |

| Biogas flow rates measurements (L/min) | ±0.010 | ±0.006 | ±0.016 |

| pH measurements | ±0.130 | ±0.003 | ±0.133 |

| Slurry temperature (°C) | ±0.200 | ±0.120 | ±0.320 |

| % Total solids content | ±0.850 | ±0.105 | ±0.955 |

| % Total volatile content | ±0.850 | ±1.405 | ±2.255 |

| % Ash content | ±0.850 | ±1.203 | ±2.053 |

| Ammonium level (mg/mL) | ±0.060 | ±0.020 | ±0.080 |

| Chosen Input x1 (Number of Days) | Predicted y with Non-Linear Model (Log of Bacteria Counts) | Derived Equation with Non-Linear Model |

|---|---|---|

| 10 | 6.036 | |

| 30 | 5.580 | |

| 50 | 5.188 | |

| 70 | 4.847 | |

| 90 | 4.548 | |

| 110 | 4.284 | |

| 130 | 4.049 | |

| 150 | 3.839 | |

| 170 | 3.649 |

| Chosen Input x2 (Daily Slurry Temperature) | Predicted y with Non-Linear Model (Log of Bacteria Counts) | Derived Equation with Non-Linear Model |

|---|---|---|

| 17 | 4.277 | |

| 18 | 4.482 | |

| 19 | 4.672 | |

| 20 | 4.842 | |

| 21 | 5.010 | |

| 22 | 5.162 | |

| 23 | 5.305 | |

| 24 | 5.438 | |

| 25 | 5.563 |

| Chosen Input x3 (pH) | Predicted y with Non-Linear Model (Log of Bacteria Counts) | Derived Equation with Non-Linear Model |

|---|---|---|

| 5.50 | 4.691 | |

| 5.75 | 4.727 | |

| 6.00 | 4.765 | |

| 6.25 | 4.805 | |

| 6.50 | 4.847 | |

| 6.75 | 4.891 | |

| 7.00 | 4.938 | |

| 7.25 | 4.987 | |

| 7.50 | 5.038 |

| Statistics Based on Targets and Model Outputs with the Response Surface Model | |||||

|---|---|---|---|---|---|

| Source | Sum of Square (SS) | Degree of Freedom (df) | Mean Square (MS) | F | Prob > F |

| Columns | 0.0674 | 1 | 0.0674 | 0.27 | 0.602 |

| Error | 53.2762 | 216 | 0.2467 | ||

| Total | 53.3436 | 217 | |||

| Number of Days (x1) | Slurry Temperature (x2) | pH (x3) | Determined Log of Bacteria Counts (y) | Predicted Log of Bacteria Counts with Non-Linear Model |

|---|---|---|---|---|

| 2 | 18.358 | 5.847 | 5.682 | 5.731 |

| 11 | 17.236 | 5.496 | 5.102 | 5.217 |

| 16 | 17.212 | 5.790 | 5.077 | 5.182 |

| 20 | 18.439 | 5.716 | 5.188 | 5.309 |

| 31 | 18.059 | 5.954 | 5.170 | 5.078 |

| 36 | 18.235 | 5.922 | 5.222 | 5.009 |

| 52 | 18.019 | 5.949 | 4.704 | 4.692 |

| 73 | 23.758 | 7.367 | 5.554 | 5.542 |

| 80 | 21.691 | 6.580 | 5.005 | 4.976 |

| 95 | 23.954 | 6.505 | 5.291 | 5.069 |

| 123 | 24.270 | 7.48 | 4.990 | 4.628 |

| 145 | 22.786 | 7.519 | 4.383 | 4.408 |

| 153 | 25.875 | 7.550 | 4.811 | 4.741 |

| 161 | 25.040 | 7.550 | 4.180 | 4.290 |

| 168 | 23.178 | 7.534 | 4.123 | 4.214 |

| Statistics Based on Targets and Model Outputs with the Response Surface Model | |||||

|---|---|---|---|---|---|

| Source | Sum of Square (SS) | Degree of Freedom (df) | Mean Square (MS) | F Statistic | Prob > F |

| Columns | 0.0966 | 1 | 0.0966 | 0.37 | 0.5434 |

| Error | 36.3955 | 142 | 0.2603 | ||

| Total | 37.0521 | 143 | |||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tangwe, S.; Mukumba, P.; Makaka, G. Design and Employing of a Non-Linear Response Surface Model to Predict the Microbial Loads in Anaerobic Digestion of Cow Manure: Batch Balloon Digester. Sustainability 2022, 14, 13289. https://doi.org/10.3390/su142013289

Tangwe S, Mukumba P, Makaka G. Design and Employing of a Non-Linear Response Surface Model to Predict the Microbial Loads in Anaerobic Digestion of Cow Manure: Batch Balloon Digester. Sustainability. 2022; 14(20):13289. https://doi.org/10.3390/su142013289

Chicago/Turabian StyleTangwe, Stephen, Patrick Mukumba, and Golden Makaka. 2022. "Design and Employing of a Non-Linear Response Surface Model to Predict the Microbial Loads in Anaerobic Digestion of Cow Manure: Batch Balloon Digester" Sustainability 14, no. 20: 13289. https://doi.org/10.3390/su142013289