How Do Technologies Based on Cyber–Physical Systems Affect the Environmental Performance of Products? A Comparative Study of Manufacturers’ and Customers’ Perspectives

Abstract

:1. Introduction

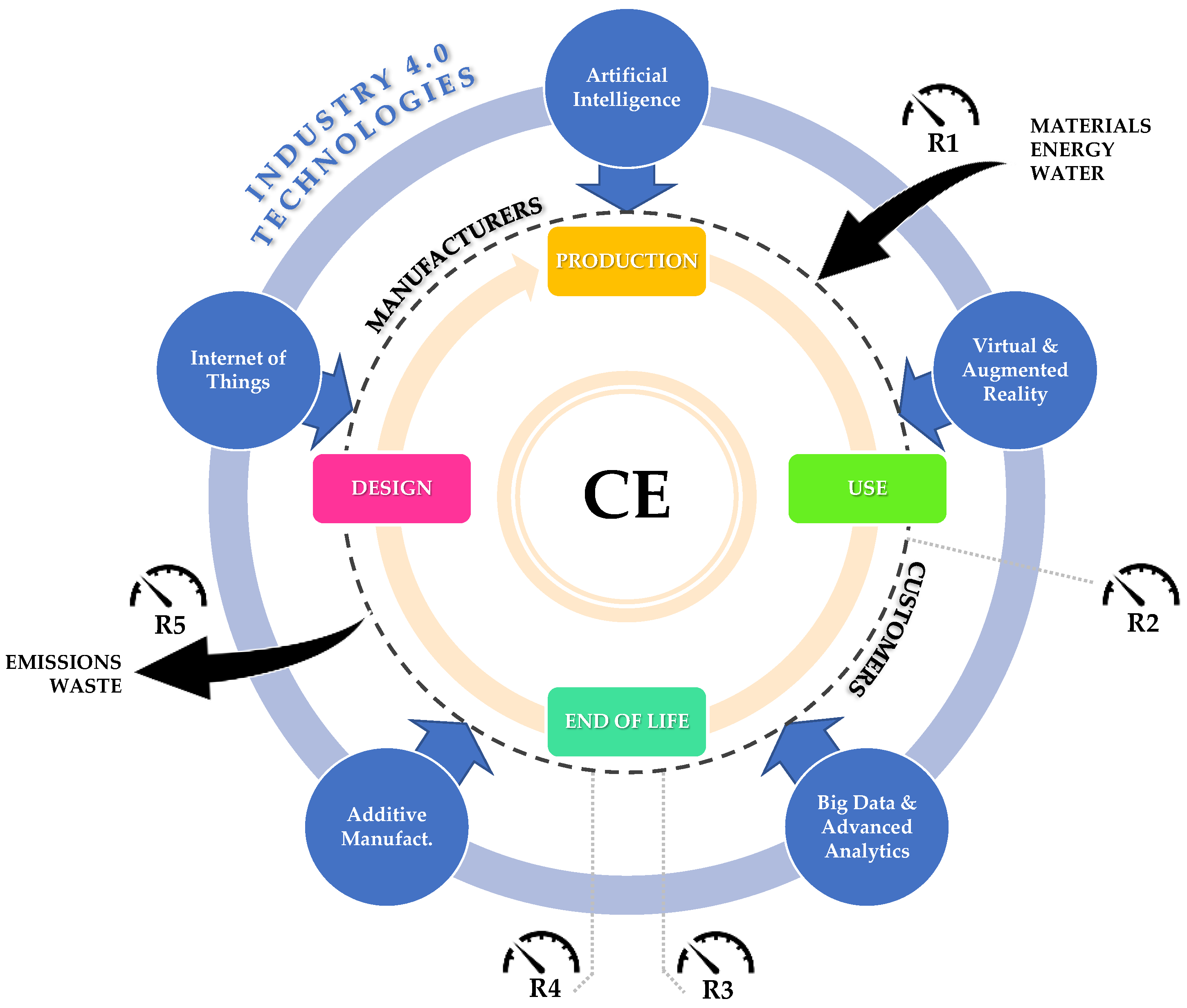

- Assessing the actual contribution of each technology to system circularity from the perspective of manufacturers and customers. This includes an analysis of the direct influence of each technology on each phase of the product life cycle, as well as the influence of the I40Ts in each of the key circularity indicators of the CE model (R1, R2, R3, R4 and R5);

- Identifying the importance given by both manufacturers and customers to the circularity of resources in the selection process of I40Ts.

2. Literature Review

2.1. Circular Economy Strategies

- Reduce (R1): Perhaps the most important R of the three [26]. It is about reducing the amount of waste produced while reducing input consumption, such as materials, energy and water.

- Reuse (R2): This is based on reusing objects and resources to give them a second useful life. This focuses on the reuse of products or components of the same type of product discarded by another consumer after they fulfil their original function.

- Recycle (R3): Perhaps one of the most popular methods: through separate collection and recycling, the need for new materials is reduced, but energy is required for their transformation and reuse. It would, therefore, be the last option to consider.

- Recover (R4): This consists of finding solutions to recover products that appear non-recyclable, such as energy or water.

- Reduce waste and emissions (R5): This is a consequence of the other R. It should focus on resource recovery. At the end of the process, CE requires a waste and emission management strategy that should seek to reinforce the recirculation of resources, minimising environmental consequences.

2.2. Industry 4.0 Technologies

- Additive manufacturing (AM): This is based on the 3D printing of plastic, metallic or other materials; 3D printing is called as such because of the process of adding to an object layer by layer [50].

- Artificial intelligence (AI): As indicated by Boden [51], AI technology can be understood as intelligence performed by "intelligent machines" so that they have reasoning capacity and the ability to develop psychological capabilities. For example, developing perception, associating, announcing, planning and motor control.

- Virtual and augmented reality (VR/AR): This is a set of computer techniques that allow the creation of images, the integration of virtual objects in real space, and the development of interfaces in which the user uses glasses or helmets made by the manufacturer [52]. Some authors share this view and add energy consumption and reducing material resources to the potential capabilities of I40Ts [53].

- Big data and advanced analytics (BD/AA): Large data sets (big data or macro data) that are commonly found in research or business practices should be managed through advanced analytics. In big data, the three dimensions of data management or “3V” (volume, variety and velocity) are defined as variety, velocity and size [54].

- Internet of Things (IoT): This refers to the interaction of objects with the environment and the immediate response to changes [55]. In this way, IoT technology and smart devices help to improve decision-making in usage decisions by providing real-time responses.

2.3. Circular Economy and Industry 4.0

- What is the actual contribution of each technology in each of the key circularity indicators of the CE model (R1, R2, R3, R4 and R5)?

- To what extent does each technology directly influence each phase of the product life cycle?

- How important is resource circularity in the selection process of I40Ts for both manufacturers and risk customers?

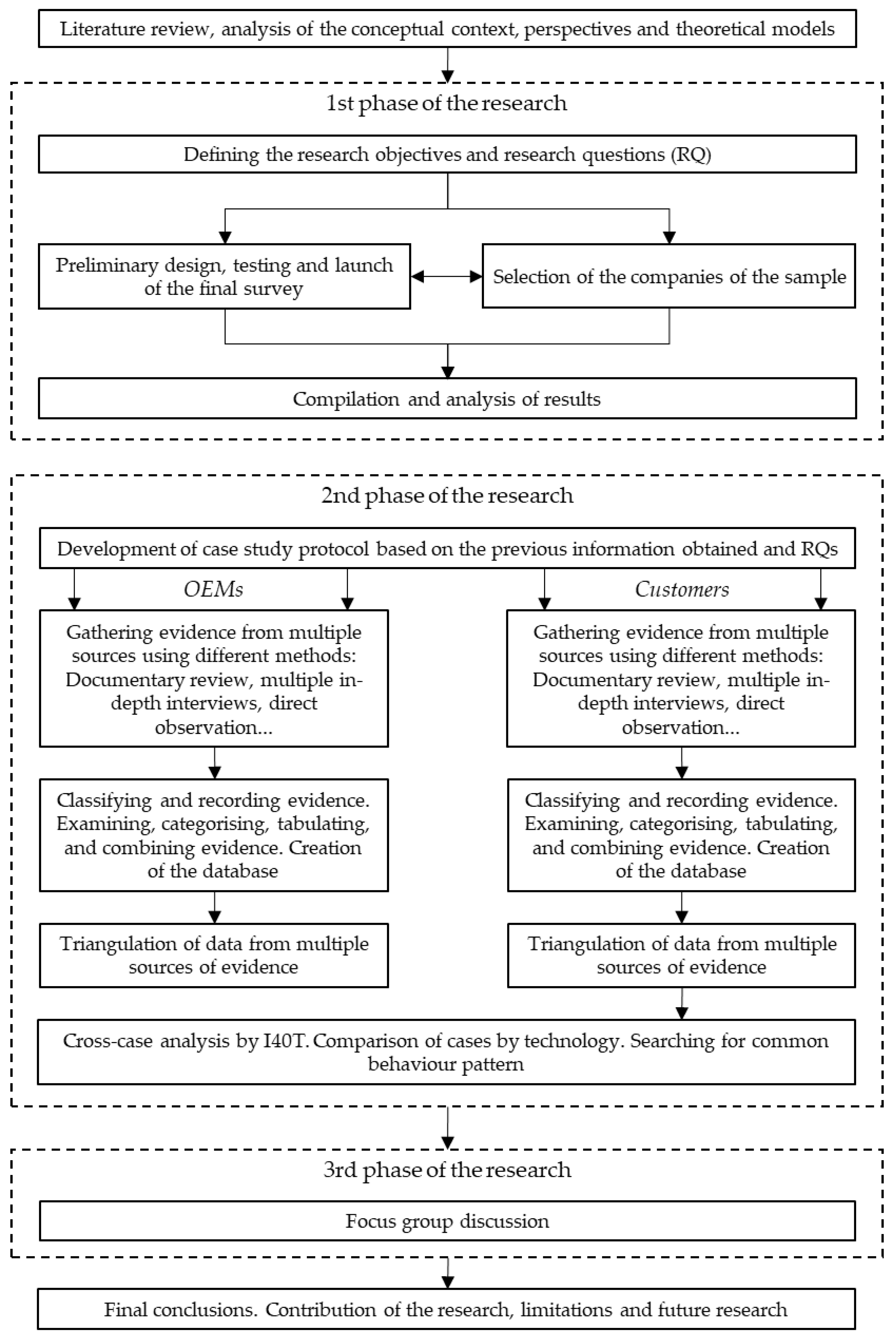

3. Materials and Methods

4. Results and Discussion

4.1. Environmental Influence of I40Ts on 5Rs

4.2. Influence of I40Ts on Each Life Cycle Phase

4.3. Importance of Resource Circularity in the Process of Technology Selection

5. Conclusions

- I40 technologies have a positive impact on sustainability and CE indicators.

- Its greater precision, speed of information, greater flexibility and greater energy efficiency mainly reduce consumption.

- In general, the 5Rs are considered to be appropriate variables. However, they must be adapted to each case, and their measurement is complicated because the necessary information and resources are not available in the companies. This is because they are not normally considered a priority.

- The environmental benefit offered by I40Ts depends on their use and the type of technology.

- Benefits are mainly concentrated in the manufacturing, logistics and transport phases and, to a lesser extent, in the use, maintenance and end-of-life phases.

- AM seems to be the technology with the greatest potential to influence the 5Rs of the CE, exerting a medium-to-high influence on all of them.

- The greatest influence exerted by these technologies is on R1 (reducing materials consumption).

- They do not consider environmental aspects to be critical variables in their decision-making processes.

- CE benefits are limited to the importance given by the customers to other critical variables such as cost, safety and quality.

- CE benefits do not contribute to improving market penetration.

- A decisive boost from public administrations to enforce compliance with requirements related to the circular economy would be a key factor to foster market penetration.

- Customers share the opinion that AM is the technology that most influences the 5Rs, but they also highlight the influence of VR/AR. In their opinion, both technologies have a high or very high influence on the 5Rs.

- They consider R1 an essential variable, since the reduction in consumption serves them, in turn, to improve critical variables in their market positioning, as well as reducing costs.

- Environmental benefits cannot compromise the requirements of their products in relation to quality, safety or cost.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Reliability | |

| Design |

|

| Case selection |

|

| Data collection |

|

| Data analysis |

|

| Internal validity | |

| Design |

|

| Case selection |

|

| Data collection |

|

| Data analysis |

|

| Construct validity | |

| Design |

|

| Case selection | N/A |

| Data collection |

|

| Data analysis |

|

| External validity | |

| Design |

|

| Case selection |

|

| Data collection | N/A |

| Data analysis | N/A |

References

- de Sousa Jabbour, A.B.L.; Jabbour, C.J.C.; Filho, M.G.; Roubaud, D. Industry 4.0 and the circular economy: A proposed research agenda and original roadmap for sustainable operations. Ann. Oper. Res. 2018, 270, 273–286. [Google Scholar] [CrossRef]

- European Union. New Circular Economy Action Plan. 2020. Available online: https://environment.ec.europa.eu/strategy/circular-economy-action-plan_en#:~:text=The%20new%20action%20plan%20announces,for%20as%20long%20as%20possible (accessed on 4 April 2022).

- McDowall, W.; Geng, Y.; Huang, B.; Bartekova, E.; Bleischwitz, R.; Turkeli, S.; Kemp, R.; Domenech, T. Circular Economy Policies in China and Europe. J. Ind. Ecol. 2017, 21, 651–661. [Google Scholar] [CrossRef] [Green Version]

- Ludger-Anselm, V.; Mann, T.; Schomerus, T. Kreislaufwirtschaftsgesetz; C.H. Beck: Munich, Germany, 2012. [Google Scholar]

- Ogunmakinde, O.E. A review of circular economy development models in China, Germany and Japan. Recycling 2019, 4, 27. [Google Scholar] [CrossRef] [Green Version]

- Fitch-Roy, O.; Benson, D.; Monciardini, D. All around the world: Assessing optimality in comparative circular economy policy packages. J. Clean. Prod. 2021, 286, 125493. [Google Scholar] [CrossRef]

- Schandl, H.; Fischer-Kowalski, M.; West, J.; Giljum, S.; Dittrich, M.; Eisenmenger, N.; Geschke, A.; Lieber, M.; Wieland, H.; Schaffartzik, A.; et al. Global Material Flows and Resource Productivity: Forty Years of Evidence. J. Ind. Ecol. 2018, 22, 827–838. [Google Scholar] [CrossRef]

- United Nations (UN). From the Perspective of Transforming Our World: The 2030 Agenda for Sustainable Development; United Nations: New York, NY, USA, 2016; pp. 485–508. [Google Scholar]

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the circular economy: An analysis of 114 definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Ghobakhloo, M. The future of manufacturing industry: A strategic roadmap toward Industry 4.0. J. Manuf. Technol. Manag. 2018, 29, 910–936. [Google Scholar] [CrossRef] [Green Version]

- Rosa, P.; Sassanelli, C.; Urbinati, A.; Chiaroni, D.; Terzi, S. Assessing relations between Circular Economy and Industry 4.0: A systematic literature review. Int. J. Prod. Res. 2020, 58, 1662–1687. [Google Scholar] [CrossRef] [Green Version]

- Li, L. China’s manufacturing locus in 2025: With a comparison of “Made-in-China 2025” and “Industry 4.0”. Technol. Forecast. Soc. change 2018, 135, 66–74. [Google Scholar] [CrossRef]

- Council for Science, Technology and Innovation Cabinet Office (CSTICO). Report on the 5th Science and Technology Basic Plan; Government of Japan: Tokyo, Japan, 2015.

- Bundesministerium für Bildung und Forschung (BMBF). The High-Tech Strategy 2025. Research and Innovation that Benefit the People; Government of Germany: Berlin, Germany, 2018.

- Government of United States of America (USA). Advanced Manufacturing Partnership. The White House. Office of the Press Secretary, United States of America. 2014. Available online: https://obamawhitehouse.archives.gov/the-press-office/2011/06/24/president-obama-launches-advanced-manufacturing-partnership (accessed on 18 January 2022).

- Jean-Claude, A.; Jean-Michel, B.; Gilles, L.; Francis, V.; Florence, L. La nouvelle france industrielle: Présentation des feuilles de route des 34 plans de la nouvelle France industrielle; Ministère de l’Économie: Paris, France, 2014.

- Agrawal, R.; Wankhede, V.A.; Kumar, A.; Upadhyay, A.; Garza-Reyes, J.A. Nexus of circular economy and sustainable business performance in the era of digitalization. Int. J. Product. Perform. Manag. 2022, 71, 748–774. [Google Scholar] [CrossRef]

- Chiarini, A. Industry 4.0 technologies in the manufacturing sector: Are we sure they are all relevant for environmental performance? Bus. Strategy Environ. 2021, 30, 3194–3207. [Google Scholar] [CrossRef]

- Dubey, T. Waste Toxicity and New Circular Economy: National and International Legal Perspectives. Indian JL Pub. Pol’y 2019, 6, 1. [Google Scholar]

- Bonilla, S.H.; Silva, H.R.; Terra da Silva, M.; Franco Gonçalves, R.; Sacomano, J.B. Industry 4.0 and sustainability implications: A scenario-based analysis of the impacts and challenges. Sustainability 2018, 10, 3740. [Google Scholar] [CrossRef] [Green Version]

- Massaro, M.; Secinaro, S.; Dal Mas, F.; Brescia, V.; Calandra, D. Industry 4.0 and circular economy: An exploratory analysis of academic and practitioners’ perspectives. Bus. Strategy Environ. 2021, 30, 1213–1231. [Google Scholar] [CrossRef]

- Garcia-Muiña, F.E.; González-Sánchez, R.; Ferrari, A.M.; Volpi, L.; Pini, M.; Siligardi, C.; Settembre-Blundo, D. Identifying the Equilibrium Point between Sustainability Goals and Circular Economy Practices in an Industry 4.0 Manufacturing Context Using Eco-Design. Soc. Sci. 2019, 8, 241. [Google Scholar] [CrossRef] [Green Version]

- Ünal, E.; Sinha, V.K. Understanding Circular Economy Trade-offs. AOM 2021, 2021, 13775. [Google Scholar] [CrossRef]

- Nascimento, D.L.M.; Alencastro, V.; Quelhas, O.L.G.; Caiado, R.G.G.; Garza-Reyes, J.A.; Rocha-Lona, L.; Tortorella, G. Exploring Industry 4.0 technologies to enable circular economy practices in a manufacturing context. J. Manuf. Technol. Manag. 2019, 30, 607–627. [Google Scholar] [CrossRef]

- Yin, R.K. Case Study Research and Applications: Design and Methods; Sage: Thousand Oaks, CA, USA, 2018. [Google Scholar]

- Stahel, W.R. The circular economy. Nature 2016, 531, 435–438. [Google Scholar] [CrossRef] [Green Version]

- Bocken, N.M.P.; Olivetti, E.A.; Cullen, J.M.; Potting, J.; Lifset, R. Taking the Circularity to the Next Level: A Special Issue on the Circular Economy. J. Ind. Ecol. 2017, 21, 476–482. [Google Scholar] [CrossRef]

- Lieder, M.; Rashid, A. Towards circular economy implementation: A comprehensive review in context of manufacturing industry. J. Clean. Prod. 2016, 115, 36–51. [Google Scholar] [CrossRef]

- Hollander, M.C.; Bakker, C.A.; Hultink, E.J. Product Design in a Circular Economy: Development of a Typology of Key Concepts and Terms. J. Ind. Ecol. 2017, 21, 517–525. [Google Scholar] [CrossRef]

- Tavera Romero, C.A.; Castro, D.F.; Ortiz, J.H.; Khalaf, O.I.; Vargas, M.A. Synergy between circular economy and industry 4.0: A literature review. Sustainability 2021, 13, 4331. [Google Scholar] [CrossRef]

- Prieto-Sandoval, V.; Jaca-García, C.; Ormazabal-Goenaga, M. Economía circular: Relación con la evolución del concepto de sostenibilidad y estrategias para su implementación. Mem. Investig. Ing. 2017, 15, 85–95. [Google Scholar]

- McKinsey. Towards a Circular Economy: Business Rationale for an Accelerated Transition; Ellen MacArthur Foundation: Isle of Wight, UK, 2015. [Google Scholar]

- Pan, S.; Du, M.A.; Huang, I.; Liu, I.; Chang, E.; Chiang, P. Strategies on implementation of waste-to-energy (WTE) supply chain for circular economy system: A review. J. Clean. Prod. 2015, 108, 409–421. [Google Scholar] [CrossRef]

- Potting, J.; Hekkert, M.P.; Worrell, E.; Hanemaaijer, A. Circular Economy: Measuring Innovation in the Product Chain; PBL Netherlands Assessment Agency: Den Haag, The Netherlands, 2017. [Google Scholar]

- Goyal, S.; Chauhan, S.; Mishra, P. Circular economy research: A bibliometric analysis (2000–2019) and future research insights. J. Clean. Prod. 2021, 287, 125011. [Google Scholar] [CrossRef]

- Bag, S.; Gupta, S.; Kumar, S. Industry 4.0 adoption and 10R advance manufacturing capabilities for sustainable development. Int. J. Prod. Econ. 2021, 231, 107844. [Google Scholar] [CrossRef]

- Vermeulen, W.J.V.; Witjes, S.; Reike, D. Advies over een Raamwerk voor Impactmeting voor Circulair Inkopen; Copernicus Institute of Sustainable Development: Utrecht, The Netherlands, 2014. [Google Scholar]

- Singh, J.; Ordoñez, I. Resource recovery from post-consumer waste: Important lessons for the upcoming circular economy. J. Clean. Prod. 2016, 134, 342–353. [Google Scholar] [CrossRef]

- Merli, R.; Preziosi, M.; Acampora, A. How do scholars approach the circular economy? A systematic literature review. J. Clean. Prod. 2018, 178, 703–722. [Google Scholar] [CrossRef]

- Morseletto, P. Restorative and regenerative: Exploring the concepts in the circular economy. J. Ind. Ecol. 2020, 24, 763–773. [Google Scholar] [CrossRef]

- Gudde, C. Circulaire Economie: Van wens naar Uitvoering. Raad voor de Leefomgeving en Infrastructuur, Dutch Government. 2015. Available online: https://library.wur.nl/WebQuery/groenekennis/2093657 (accessed on 18 January 2022).

- Evans, P.C.; Annunziata, M. Industrial internet: Pushing the boundaries. Gen. Electr. Rep., Boston, United States of America. 2012. Available online: chrome-extension://efaidnbmnnnibpcajpcglclefindmkaj/http://www.cse.tkk.fi/fi/opinnot/T-109.4300/2015/luennot-files/Industrial.pdf (accessed on 17 March 2022).

- Culot, G.; Nassimbeni, G.; Orzes, G.; Sartor, M. Behind the definition of Industry 4.0: Analysis and open questions. Int. J. Prod. Econ. 2020, 226, 107617. [Google Scholar] [CrossRef]

- Dalenogare, L.S.; Benitez, G.B.; Ayala, N.F.; Frank, A.G. The expected contribution of Industry 4.0 technologies for industrial performance. Int. J. Prod. Econ. 2018, 204, 383–394. [Google Scholar] [CrossRef]

- Kagermann, H.; Lukas, W.; Wahlster, W. Industry 4.0: With the internet of things on the way to the 4th industrial revolution. VDI News, 2011; 13. [Google Scholar]

- Tjahjono, B.; Esplugues, C.; Ares, E.; Pelaez, G. What does Industry 4.0 mean to Supply Chain? Procedia Manuf. 2017, 13, 1175–1182. [Google Scholar] [CrossRef]

- Awan, U.; Sroufe, R.; Shahbaz, M. Industry 4.0 and the circular economy: A literature review and recommendations for future research. Bus. Strategy Environ. 2021, 30, 2038–2060. [Google Scholar] [CrossRef]

- Saturno, M. Proposal for new automation architecture solutions for Industry 4.0. LogForum 2018, 14, 185–195. [Google Scholar] [CrossRef]

- Javaid, M.; Haleem, A.; Singh, R.P.; Suman, R.; Gonzalez, E.S. Understanding the adoption of Industry 4.0 technologies in improving environmental sustainability. Sustain. Oper. Comput. 2022, 3, 203–217. [Google Scholar] [CrossRef]

- Stock, T.; Seliger, G. Opportunities of Sustainable Manufacturing in Industry 4.0. Procedia CIRP 2016, 40, 536–541. [Google Scholar] [CrossRef] [Green Version]

- Boden, M.A. Artificial Intelligence; Oxford University Press: Oxford, UK, 2016. [Google Scholar]

- Torres Vega, M.; Liaskos, C.; Abadal, S.; Papapetrou, E.; Jain, A.; Mouhouche, B.; Kalem, G.; Ergüt, S.; Mach, M.; Sabol, T.; et al. Immersive Interconnected Virtual and Augmented Reality: A 5G and IoT Perspective. J. Netw. Syst. Manag. 2020, 28, 796–826. [Google Scholar] [CrossRef]

- Javaid, M.; Haleem, A.; Singh, R.P.; Suman, R. Artificial Intelligence Applications for Industry 4.0: A Literature-Based Study. J. Ind. Integr. Manag. Innov. Entrep. 2022, 7, 83–111. [Google Scholar] [CrossRef]

- Mark, B.; Laney, D. The Importance of ‘Big Data’: A Definition; Gartner: Stamford, CT, USA, 2012; pp. 2014–2018. [Google Scholar]

- Witkowski, K. Internet of Things, Big Data, Industry 4.0—Innovative Solutions in Logistics and Supply Chains Management. Procedia Eng. 2017, 182, 763–769. [Google Scholar] [CrossRef]

- Kamble, S.S.; Gunasekaran, A.; Gawankar, S.A. Sustainable Industry 4.0 framework: A systematic literature review identifying the current trends and future perspectives. Process. Saf. Environ. Prot. 2018, 117, 408–425. [Google Scholar] [CrossRef]

- Chang, M.M.L.; Ong, S.K.; Nee, A.Y.C. Approaches and Challenges in Product Disassembly Planning for Sustainability. Procedia CIRP 2017, 60, 506–511. [Google Scholar] [CrossRef]

- Bloomfield, M.; Borstrock, S. Modeclix. The additively manufactured adaptable textile. Mater. Today Commun. 2018, 16, 212–216. [Google Scholar] [CrossRef]

- Marconi, M.; Germani, M.; Mandolini, M.; Favi, C. Applying data mining technique to disassembly sequence planning: A method to assess effective disassembly time of industrial products. Int. J. Prod. Res. 2019, 57, 599–623. [Google Scholar] [CrossRef]

- Lahrour, Y.; Brissaud, D. A Technical Assessment of Product/Component Re-manufacturability for Additive Remanufacturing. Procedia CIRP 2018, 69, 142–147. [Google Scholar] [CrossRef]

- Laskurain-Iturbe, I.; Arana-Landín, G.; Landeta-Manzano, B.; Uriarte-Gallastegi, N. Exploring the influence of industry 4.0 technologies on the circular economy. J. Clean. Prod. 2021, 321, 128944. [Google Scholar] [CrossRef]

- Leino, M.; Pekkarinen, J.; Soukka, R. The Role of Laser Additive Manufacturing Methods of Metals in Repair, Refurbishment and Remanufacturing—Enabling Circular Economy. Phys. Procedia 2016, 83, 752–760. [Google Scholar] [CrossRef] [Green Version]

- Wittbrodt, P.; Lapunka, I.; Marek-Kolodziej, K. Industry 4.0—future of Production Systems; Varazdin Development and Entrepreneurship Agency (VADEA): Varazdin, Hrvatska, 2018; pp. 461–467. [Google Scholar]

- Gallastegi, U.N.; Manzano, L.B.; Landin, A.G.; Iturbe, L.I. Environmental benefits and weaknesses of additive manufacturing processes in the business sector. Key players influencing the environmental impact of digital manufacturing technologies. DYNA 2020, 95, 587–590. [Google Scholar] [CrossRef]

- Berman, B. 3-D printing: The new industrial revolution. Bus. Horiz. 2012, 55, 155–162. [Google Scholar] [CrossRef]

- Hermann, M.; Pentek, T.; Otto, B. Design Principles for Industrie 4.0 Scenarios. In Proceedings of the 2016 49th Hawaii International Conference on System Sciences (HICSS), Koloa, HI, USA, 5–8 January 2016; pp. 3928–3937. [Google Scholar]

- Müller, J.M.; Kiel, D.; Voigt, K. What Drives the Implementation of Industry 4.0? The Role of Opportunities and Challenges in the Context of Sustainability. Sustainability 2018, 10, 247. [Google Scholar] [CrossRef] [Green Version]

- Yuan, Z.; Qin, W.; Zhao, J. Smart Manufacturing for the Oil Refining and Petrochemical Industry. Engineering 2017, 3, 179–182. [Google Scholar] [CrossRef]

- Mellor, S.; Hao, L.; Zhang, D. Additive manufacturing: A framework for implementation. Int. J. Prod. Econ. 2014, 149, 194–201. [Google Scholar] [CrossRef] [Green Version]

- Oettmeier, K.; Hofmann, E. Additive manufacturing technology adoption: An empirical analysis of general and supply chain-related determinants. J. Bus. Econ. 2016, 87, 97–124. [Google Scholar] [CrossRef]

- Campbell, T.; Garrett, B.; Ivanova, O.; Williams, C. Could 3D Printing Change the World? Technologies, Potential, and Implications of Additive Manufacturing; Atlantic Council: Washington, DC, USA, 2011; p. 3. [Google Scholar]

- Kellens, K.; Baumers, M.; Gutowski, T.G.; Flanagan, W.; Lifset, R.; Duflou, J.R. Environmental Dimensions of Additive Manufacturing: Mapping Application Domains and Their Environmental Implications. J. Ind. Ecol. 2017, 21, S49–S68. [Google Scholar] [CrossRef] [Green Version]

- Rejeski, D.; Zhao, F.; Huang, Y. Research needs and recommendations on environmental implications of additive manufacturing. Addit. Manuf. 2018, 19, 21–28. [Google Scholar] [CrossRef] [Green Version]

- Kamarul Bahrin, M.A.; Othman, M.F.; Nor Azli, N.H.; Talib, M.F. Industry 4.0: A review on industrial automation and robotic. Jurnal teknologi. A, Pembuatan, bahan termaju, tenaga dan pengangkutan. J. Teknol. 2016, 78. [Google Scholar] [CrossRef] [Green Version]

- Rüßmann, M.; Lorenz, M.; Gerbert, P.; Waldner, M.; Justus, J.; Engel, P.; Harnisch, M. Industry 4.0: The Future of Productivity and Growth in Manufacturing Industries; bcg Perspectives; The Boston Consulting Group: Boston, MA, USA, 2015. [Google Scholar]

- Shrouf, F.; Ordieres, J.; Miragliotta, G. In Smart factories in Industry 4.0: A review of the concept and of energy management approached in production based on the Internet of Things paradigm. In Proceedings of the 2014 IEEE International Conference on Industrial Engineering and Engineering Management, Selangor, Malaysia, 9–12 December 2014; pp. 697–701. [Google Scholar]

- Tao, F.; Wang, Y.; Zuo, Y.; Yang, H.; Zhang, M. Internet of Things in product life-cycle energy management. J. Ind. Inf. Integr. 2016, 1, 26–39. [Google Scholar] [CrossRef]

- Wan, J.; Tang, S.; Yan, H.; Li, D.; Wang, S.; Vasilakos, A.V. Cloud robotics: Current status and open issues. Access 2016, 4, 2797–2807. [Google Scholar] [CrossRef]

- Lotfi, R.; Kargar, B.; Gharehbaghi, A.; Hazrati, H.; Nazari, S.; Amra, M. Resource-constrained time–cost-quality-energy-environment tradeoff problem by considering blockchain technology, risk, and robustness: A case study of healthcare project. Environ. Sci. Pollut. Res. 2022, 1–17. [Google Scholar] [CrossRef]

- Lotfi, R.; Kargar, B.; Gharehbaghi, A.; Afshar, M.; Rajabi, M.S.; Mardani, N. A data-driven robust optimization for multi-objective renewable energy location by considering risk. Environ. Dev. Sustain. 2022, 1–22. [Google Scholar] [CrossRef]

- Rodič, B. Industry 4.0 and the New Simulation Modelling Paradigm. Organizacija 2017, 50, 193–207. [Google Scholar] [CrossRef] [Green Version]

- Prause, G.; Atari, S. On sustainable production networks for Industry 4.0. Entrep. Sustain. Issues 2017, 4, 421–431. [Google Scholar] [CrossRef]

- Jamwal, A.; Agrawal, R.; Sharma, M.; Giallanza, A. Industry 4.0 Technologies for Manufacturing Sustainability: A Systematic Review and Future Research Directions. Appl. Sci. 2021, 11, 5725. [Google Scholar] [CrossRef]

- Piscitelli, G.; Ferazzoli, A.; Petrillo, A.; Cioffi, R.; Parmentola, A.; Travaglioni, M. Circular economy models in the industry 4.0 era: A review of the last decade. Procedia Manuf. 2020, 42, 227–234. [Google Scholar] [CrossRef]

- Eisenhardt, K.M. Building Theories from Case Study Research. Acad. Manag. Rev. 1989, 14, 532–550. [Google Scholar] [CrossRef]

- Patton, M.Q. Qualitative Research & Evaluation Methods: Integrating Theory and Practice; Sage: Thousand Oaks, CA, USA, 2014. [Google Scholar]

- European Commission. European Enterprise Promotion Awards. 2019. Available online: https://single-market-economy.ec.europa.eu/smes/supporting-entrepreneurship/european-enterprise-promotion-awards_en (accessed on 4 April 2022).

- Forza, C. Survey research in operations management: A process-based perspective. Int. J. Oper. Prod. Manag. 2002, 22, 152–194. [Google Scholar] [CrossRef] [Green Version]

- Ivankova, N.V.; Creswell, J.W.; Stick, S.L. Using Mixed-Methods Sequential Explanatory Design: From Theory to Practice. Field Methods 2006, 18, 3–20. [Google Scholar] [CrossRef]

- Yu, C.H. Book Review: Creswell, J.; Plano Clark, V. Designing and Conducting Mixed Methods Research. Thousand Oaks, CA: Sage. Organ. Res. Methods 2009, 12, 801–804. [Google Scholar] [CrossRef]

- Glaser, B.G.; Strauss, A.L. Discovery of Grounded Theory: Strategies for Qualitative Research; Routledge: London, UK, 2017. [Google Scholar]

- Miles, M.B.; Huberman, A.M.; Saldana, J. Qualitative Data Analysis: A Methods Sourcebook, 3rd ed.; Sage: Thousand Oaks, CA, USA, 2014. [Google Scholar]

- Denzin, N.K.; Lincoln, Y.S. Strategies of Qualitative Inquiry; Sage Publications: Los Angeles, CA, USA, 2008. [Google Scholar]

- Gibbert, M.; Ruigrok, W.; Wicki, B. What passes as a rigorous case study? Strateg. Manag. J. 2008, 29, 1465–1474. [Google Scholar] [CrossRef]

- Thurmond, V.A. The Point of Triangulation. J. Nurs. Scholarsh. 2001, 33, 253–258. [Google Scholar] [CrossRef]

- Nyumba, T.; Wilson, K.; Derrick, C.J.; Mukherjee, N.; Geneletti, D. The use of focus group discussion methodology: Insights from two decades of application in conservation. Methods Ecol. Evol. 2018, 9, 20–32. [Google Scholar] [CrossRef] [Green Version]

- Bai, C.; Dallasega, P.; Orzes, G.; Sarkis, J. Industry 4.0 technologies assessment: A sustainability perspective. Int. J. Prod. Econ. 2020, 229, 107776. [Google Scholar] [CrossRef]

- Oláh, J.; Aburumman, N.; Popp, J.; Khan, M.A.; Haddad, H.; Kitukutha, N. Impact of Industry 4.0 on environmental sustainability. Sustainability 2020, 12, 4674. [Google Scholar] [CrossRef]

- Ghadge, A.; Mogale, D.G.; Bourlakis, M.; Maiyar, L.M.; Moradlou, H. Link between Industry 4.0 and green supply chain management: Evidence from the automotive industry. Comput. Ind. Eng. 2022, 169, 108303. [Google Scholar] [CrossRef]

- Umar, M.; Khan, S.A.R.; Yusliza, M.Y.; Ali, S.; Yu, Z. Industry 4.0 and green supply chain practices: An empirical study. Int. J. Product. Perform. Manag. 2022, 71, 814–832. [Google Scholar] [CrossRef]

- Lotfi, R.; Nazarpour, H.; Gharehbaghi, A.; Sarkhosh, S.M.H.; Khanbaba, A. Viable closed-loop supply chain network by considering robustness and risk as a circular economy. Environ. Sci. Pollut. Res. 2022, 1–20. [Google Scholar] [CrossRef]

- Tang, Y.M.; Chau, K.Y.; Fatima, A.; Waqas, M. Industry 4.0 technology and circular economy practices: Business management strategies for environmental sustainability. Environ. Sci. Pollut. Res. Int. 2022, 29, 49752–49769. [Google Scholar] [CrossRef]

- Mitchell, G.J.; Cody, W.K. The role of theory in qualitative research. Nurs. Sci. Q. 1993, 6, 170–178. [Google Scholar] [CrossRef]

- Lincoln, Y.S.; Guba, E.G. Naturalistic Inquiry; Sage: Thousand Oaks, CA, USA, 1985. [Google Scholar]

- Peräkylä, A. Validity and reliability in research-based tapes and transcripts. In Qualitative Analysis; Issues of Theory and Method; Sage: Thousand Oaks, CA, USA, 1997; pp. 201–220. [Google Scholar]

- Flick, U. (Ed.) Designing for Multimodal Data and Mixed Methods within a Qualitative Framework; The SAGE Handbook of Qualitative Research Design; Sage: Thousand Oaks, CA, USA, 2022; Volume 2, p. 604. [Google Scholar]

- LeCompte, M.D.; Goetz, J.P. Problems of reliability and validity in ethnographic research. Rev. Educ. Res. 1982, 52, 31–60. [Google Scholar] [CrossRef]

- Griggs, S. Analysing Qualitative Data. J. Mark. Res. Soc. 1987, 29, 1. [Google Scholar]

- Campbell, J.C. Catherine Marshall Gretchen B. Rossman Designing Qualitative Research 1989 Sage Publications New-berry Park, CA 153 pages. J. Prof. Nurs. 1990, 6, 313. [Google Scholar] [CrossRef]

- Riege, A.M. Validity and reliability tests in case study research: A literature review with "hands-on" applications for each research phase. Qual. Mark. Res. 2003, 6, 75–86. [Google Scholar] [CrossRef] [Green Version]

- Blome, C.; Schoenherr, T. Supply chain risk management in financial crises—A multiple case-study approach. Int. J. Prod. Econ. 2011, 134, 43–57. [Google Scholar] [CrossRef]

| Authors | Year | Ref. No. | Research Gap | Main Contributions |

|---|---|---|---|---|

| Rosa et al. | 2020 | [11] | Connection between CE and I40. | It reveals how different I40Ts could support CE strategies and organisations. |

| Agrawa et al. | 2022 | [17] | Future research directions at the nexus of CE and sustainable business in the context of digitisation | Digitalisation could be of great help in developing sustainable circular products. Customer involvement is necessary to create innovative sustainable circular products. |

| Chiarini et al. | 2021 | [18] | Contribution of each technology to the overall environmental performance of manufacturing companies. | Sensors, radio frequency identification, artificial intelligence and analytics are most relevant to improve environmental performance. Simulation software contributes moderately. Additive manufacturing, cobots, robots, automated mobile robots and automated guided vehicles had a negative effect. Augmented reality had no effect and other technologies indirectly affected environmental performance. Lack of knowledge and scepticism about the application of technologies such as artificial intelligence and augmented reality. |

| Bonilla et al. | 2018 | [20] | The effect on the environmental sustainability of physical and virtual infrastructures inherent to I40. | Predominance of positive impacts that can be considered as positive side effects resulting from I40 activities. |

| Garcia-Muiña et al. | 2019 | [22] | Ecodesign as a tool to define the balance point between sustainability and circular economy. | Empirical validation of a circular business model as an operational tool to promote the competitiveness of enterprises. |

| Nascimento et al. | 2019 | [24] | Integration of emerging I40Ts with CE practices. | Positive influence on improving business sustainability by re-integrating waste into the supply chain. Recommendation of a circular model to reuse discarded electronic devices, integrating web technologies, reverse logistics and AM. |

| Prieto-Sandoval et al. | 2017 | [31] | Direct connection of CE with the goal of this paradigm: sustainability. | CE is not a “fad”, it is a paradigm of action that has resulted from the evolution of the concept of sustainability and its application in the economy, society, and the necessary care of the environment around us. |

| Laskurain-Iturbe et al. | 2021 | [61] | I40 influence on CE. | Environmental impact improvements related to reducing material, energy consumption, waste generation and emissions. Important differences between the potential impacts of each technology. |

| Uriarte Gallastegi et al. | 2020 | [64] | Environmental implications of the technologies covered by AM. | Neither companies nor experts confirm an increase in energy consumption highlighted in the literature. Higher material consumption efficiency compared with traditional subtractive technologies. Low level of noise generated by AM. Possibility of integrating AF in environments where medium–high concentration tasks are carried out. |

| Campbell et al. | 2011 | [71] | AM geopolitical, economic, social, demographic, environmental, and security implications. | AM manufacturing:

|

| Kellens et al. | 2017 | [72] | Environmental dimensions and impacts related to AM manufacturing processes. | Parts made with AM can be beneficial for very small batches, or in cases where AM-based redesigns offer substantial functional advantages during the use phase of the product. |

| Rejeski et al. | 2018 | [73] | Environmental implications of AM. | There is a need for research:

Regulatory implications of bioprinting. |

| Shrouf et al. | 2014 | [76] | How IoT will improve energy efficiency. | Approach to adopt the IoT paradigm at production level to support energy management and increase the energy efficiency of production systems in smart factories (I40). |

| Tao et al. | 2016 | [77] | IoT applications in product life cycle’s energy management. | IoT techniques can accompany the entire product lifecycle for better energy management. |

| Jamwal et al. | 2021 | [83] | Future research potential of Industry 4.0 technologies to achieve manufacturing sustainability. | Industry 4.0 has a significant impact on the sustainability of manufacturing at different stages. Very few studies discuss the relationship between sustainability and Industry 4.0 factors for business practices. AI and machine learning approaches are helping industries to achieve sustainability in manufacturing as well as the implementation of Industry 4.0. In blockchain-enabled supply chains, few studies have addressed environmental issues. Big data offers several opportunities for manufacturing industries in terms of production tracking and real-time optimisation. |

| Tavera Romero et al. | 2021 | [30] | Challenges and impacts on society and individuals for the transition from a linear to a circular economy. | Few studies address the impacts on individuals and society of a transition to CE supported by I40, and what strategies are available to avoid societal failure. |

| Awan et al. | 2021 | [47] | How IoT can be part of managing the circular economy. | IIoT plays a crucial role in value creation, but there are few studies on the requirements of I40 to incorporate the circular economy of the supply chain. The literature has focused on digitisation as an enabler of the circular economy. |

| Piscitell et al. | 2020 | [84] | How to I40 can unlock the circularity resources within organisations. | This research topic is still in its early stage of attention and the full potential has not yet been fully explored. The choice to implement the CE model ultimately depends on the field of application of the I40 system. |

| Bag et al. | 2021 | [36] | Effect of I40 adoption on advanced manufacturing capabilities and its outcome on sustainable development (10R). | Companies with a high degree of I40 implementation lead to a positive development of 10R advanced manufacturing capabilities. 10R advanced manufacturing capabilities have a positive influence on sustainable development results. The I40 delivery system has a moderating effect on the degree of relationship of I40 adoption and 10R advanced manufacturing capabilities. |

| Massaro et al. | 2021 | [21] | How I40 can foster the impact of CE in companies. | Use of smart services in waste management, resource efficiency and collaboration, new business models and the mission of companies. |

| This research | How EC can benefit from I40Ts. Perspectives of the two main actors (manufacturers and customers). | Benefits are mainly concentrated in the manufacturing, logistics and transport phases. Manufacturers and customers do not consider environmental aspects to be critical variables in their decision-making processes, even though they give them a medium to high importance. Manufacturers and customers point out that the greatest influence exerted by these technologies is on R1 (reducing material consumption). Manufacturers: AM has a high or very high influence on the 5Rs. Customers: AM and VR/AR have a high or very high influence on the 5Rs. |

| Code—Brief Description | Source of Evidence | ||

|---|---|---|---|

| Interviews 1 | Visits 2 | Docs. 3 | |

| AM1—Printing metal and plastic material for aircraft manufacturer suppliers | M, T, EM | ✓ | 7 |

| AM2—Minimization of biological waste in the food industry through atomic-level applications | T, SM | ✓ | 2 |

| AM3—Special coating using nanotechnology in the manufacture of brake discs | M | ✓ | 3 |

| AM4—Consultancy to implement AM in industrial processes | M | ✓ | 2 |

| AI1—Monitoring the construction of a wind farm using satellite-free images | T | 2 | |

| AI2—Voice recognition technology for operators to search for or write down procedures | M | ✓ | 2 |

| AI3—Analysis of the data (heating, air conditioning) of the buildings/factories | M | ✓ | 3 |

| AI4—Analysis of camera data to optimize procedures | T | 2 | |

| AV1—Quality inspection system for plastic film production | M, T | ✓ | 5 |

| AV2—Automation of parts inspection in industrial processes (mainly automotive parts) | M | 4 | |

| BDAA1—Data processing to optimize the use of industrial machines | M, T | ✓ | 4 |

| BDAA2—Use of information systems to manage and optimize the factory | M | ✓ | 5 |

| BDAA3—Massive data analysis to optimize production machine indicators | T, SM | 4 | |

| IoT1—Devices for monitoring the supply chain | T, SM | 5 | |

| IoT2—Monitoring through sensors in the lube oil of the wind turbines | M | ✓ | 4 |

| IoT3—Data capture from industrial machines using sensors | M | ✓ | 3 |

| IoT4—Sensorization of industrial machines to optimize mainly energy consumption | T | 2 | |

| IoT5—Use of wireless sensors to control the entire value chain (from supplier to customer) | T | 3 | |

| IoT6—Movement control of workers by sensors to optimize routes and movements | T | 3 | |

| Code—Brief Description | Source of Evidence | ||

|---|---|---|---|

| Interviews 1 | Visits 2 | Docs. 3 | |

| AM1—Private foundation for the creation and promotion of connections between people, companies, and initiatives in the context of the use of ICT. | M, T, EM | ✓ | 5 |

| AM2—VR/AR Studio. | M, T | ✓ | 2 |

| AM3—Creation, design, and printing of 3D parts. | M, EM | ✓ | 3 |

| AM4—Goldsmiths and jewellery designers. | T | ✓ | 2 |

| BDAA1—Big Data Research Lab. | M, T | ✓ | 4 |

| BDAA2—Solutions for Internet TV, from the generation and administration of metadata to the complete management of video, interfaces, or user apps. | M | 4 | |

| AI1—Solutions for Internet TV, from the generation and administration of metadata to the complete management of video, interfaces, or user apps. | M | 3 | |

| AV1—Public company to boost economic activity related to the application of cybersecurity and strengthen the professional sector. | M | 3 | |

| AV2—Design of immersive experiences in virtual environments. | M | 2 | |

| IoT1—Solutions for Internet TV, from the generation and administration of metadata to the complete management of video, interfaces or user apps. | M, T | 4 | |

| IoT2—Cybersecurity services covering identification, protection, detection, response, and recovery. | T | 3 | |

| Technology | Stakeholder | Circularity of Materials 1,2 | Strategies | Main findings | |||||

|---|---|---|---|---|---|---|---|---|---|

| R1 | R2 | R3 | R4 | R5 | |||||

| AM | M3 | Impact 3 | ●●◕ | ●●◑ | ●●◕ | ●●● | ●●◑ |

|

|

| Source of evidence 4 | I, D, V (1,2,4) | I, D (1,2,4) | I, D (1,2,3,4) | I, D (1,2,4) | I, D, V (3,4) | ||||

| C | Impact | ●●●◑ | ●●●◑ | ●●●◑ | ●●●◑ | ●●●◑ |

| ||

| Source of evidence | I, D, V (1,2,3,4) | I, D (1,3) | I, D (1,3) | I, D (1,3) | I, D, V (1,3,4) | ||||

| AI | M | Impact | ●●◔ | ●◕ | ●◑ | ●◔ | ● |

|

|

| Source of evidence | I, D, V (1,3,4) | I, D (1,3,4) | I (1,2,3,4) | I (1,3,4) | I, D (2) | ||||

| C | Impact | ●◑ | ●● | ● | ●◑ | ● |

| ||

| Source of evidence | I, D (1) | I (1) | I (1) | I (1) | I, D (1) | ||||

| AV | M | Impact | ●●◕ | ●◔ | ● | ◑ | ◑ |

|

|

| Source of evidence | I, D (1,2) | I (1) | I (2) | I (1) | I, D (2) | ||||

| C | Impact | ●●●● | ●●●● | ●●●● | ●●●◑ | ●●●◑ |

| ||

| Source of evidence | I, D, V (1,2) | I (1,2) | I (1,2) | I (1,2) | I, D, V (1,2) | ||||

| BD/AA | M | Impact | ●●◔ | ●◕ | ●◔ | ●◔ | ● |

|

|

| Source of evidence | I, D (1,2.3) | I, D (1,2) | I (1,2) | I (1,2) | I (1,2) | ||||

| C | Impact | ●●●● | ●●● | ●● | ●● | ●● |

| ||

| Source of evidence | I, D (1,2) | I, D (1) | I (1) | I (1) | I, D (1) | ||||

| IoT | M | Impact | ●◕ | ●◔ | ● | ● | ●◔ |

|

|

| Source of evidence | I, D, V (2,3) | I, D (1,5) | I (1,5) | I (1,5) | I, D, V (3,5) | ||||

| C | Impact | ●●●● | ●●●◑ | ●●● | ●● | ●◑ |

| ||

| Source of evidence | I, D (1,2) | I, V (1) | I (1) | I (1) | I, D (1,2) | ||||

| Technology | Stakeholder | Affected Life Cycle Phase 1 | Strategies | Main Findings | |

|---|---|---|---|---|---|

| AM | M2 | ❶❷❸❹⑤ |

|

| |

| Source of evidence3 | I, D (1,2,3,4) | ||||

| C2 | ①❷❸④⑤ |

| |||

| Source of evidence | I, D, V (1,3,4) | ||||

| AI | M | ①❷❸④⑤ |

|

| |

| Source of evidence | I, D (1,2,3,4) | ||||

| C | ①❷❸❹⑤ | ||||

| Source of evidence | I, D (1) | ||||

| AV | M | ①❷❸④⑤ |

|

| |

| Source of evidence | I, D (1,2) | ||||

| C | ①❷❸❹❺ | ||||

| Source of evidence | I, D, V (1,2) | ||||

| BD/AA | M | ①❷❸❹⑤ |

|

| |

| Source of evidence | I, D (1,2,3) | ||||

| C | ①❷③④⑤ |

| |||

| Source of evidence | I, D (1,2) | ||||

| IoT | M | ①❷❸❹⑤ |

|

| |

| Source of evidence | I, D, V (1,5) | ||||

| C | ①②❸❹⑤ |

| |||

| Source of evidence | I, D, V (1,2) |

| Technology | Stakeholder | Importance of the Environment in Decision-Making 1 | Strategies | Main Findings |

|---|---|---|---|---|

| MA | M2 | ●●● |

|

|

| C2 | ●●●● |

|

| |

| IA | M | ●●●◐ |

|

|

| C | ― 3 |

| ― | |

| VA/RV | M | ― |

| ― |

| C | ●●●● | ― |

| |

| BG/AA | M | ●● |

|

|

| C | ●●●● |

|

| |

| IoT | M | ●●● |

|

|

| C | ●● |

|

|

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Uriarte-Gallastegi, N.; Landeta-Manzano, B.; Arana-Landín, G.; Laskurain-Iturbe, I. How Do Technologies Based on Cyber–Physical Systems Affect the Environmental Performance of Products? A Comparative Study of Manufacturers’ and Customers’ Perspectives. Sustainability 2022, 14, 13437. https://doi.org/10.3390/su142013437

Uriarte-Gallastegi N, Landeta-Manzano B, Arana-Landín G, Laskurain-Iturbe I. How Do Technologies Based on Cyber–Physical Systems Affect the Environmental Performance of Products? A Comparative Study of Manufacturers’ and Customers’ Perspectives. Sustainability. 2022; 14(20):13437. https://doi.org/10.3390/su142013437

Chicago/Turabian StyleUriarte-Gallastegi, Naiara, Beñat Landeta-Manzano, German Arana-Landín, and Iker Laskurain-Iturbe. 2022. "How Do Technologies Based on Cyber–Physical Systems Affect the Environmental Performance of Products? A Comparative Study of Manufacturers’ and Customers’ Perspectives" Sustainability 14, no. 20: 13437. https://doi.org/10.3390/su142013437

APA StyleUriarte-Gallastegi, N., Landeta-Manzano, B., Arana-Landín, G., & Laskurain-Iturbe, I. (2022). How Do Technologies Based on Cyber–Physical Systems Affect the Environmental Performance of Products? A Comparative Study of Manufacturers’ and Customers’ Perspectives. Sustainability, 14(20), 13437. https://doi.org/10.3390/su142013437