1. Introduction

The Sixth Assessment Report of the Intergovernmental Panel on Climate Change highlights the challenges that society needs to face to deal with the impacts of climate change. In most of them, engineering is a tool to adapt structures and make them more resilient. From an engineering perspective, sustainable development should focus on reducing key assets’ exposure to climate-induced impacts, such as changes in runoff, floods, wildfires, heatwaves, and sea level rises [

1].

However, all these adaptation actions require engineering constructions, either in existing structures or in new projects. This need is associated with the natural development of populations and technology making the demand for mineral exploration grow exponentially [

2]. Thus, the two leading principles for the sustainability of industrial processes are the reuse of industrial waste and the efficient use of by-products [

2]

In the mining context, the large volume of tailings generated indicate the consequential requirement for safe disposal structures [

3,

4,

5,

6]. Additionally, using this material outside the mine area as a construction material has several benefits, such as the reduction of the implementation, maintenance, and instrumentation costs of disposal structures; establishment of the waste-free concept [

7]; and reduction in the effect on vegetation areas [

8].

The challenge lies in the complexity of the structure of the tailings and the absence of a theory to guide the general behavior of these materials, such as Soil Mechanics [

9]. In dealing with mining waste, it is also necessary to be aware that there may be various components that can be re-processed or could be harmful to the environment. The presence of these components can lead to adverse effects such as expansion, contraction, heating, etc., which must be mapped in experimental campaigns [

2].

Geotechnical techniques need to be applied to make tailings in landfills possible. The fundamental improvement technique is compaction, which allows an increase in resistance by generating a more stable structure. This may not be sufficient, and additional processes such as stabilization and reinforcement may be required [

10,

11,

12,

13].

From stabilization, the objective is the formation of new composites based on man-made waste from mining with an internal structure more stable than the pure tailings. The aim is to create a new or secondary crystalline structure, significantly increasing the mechanical properties of the tailings [

2]. The stabilization of bauxite tailings from sugarcane bagasse ash and carbide lime was proposed by [

14], demonstrating the effectiveness of the alternative binder. In [

15], showed that 5% geopolymer stabilizing gold ore tailings resulted in a higher mechanical strength than those stabilized with ordinary Portland cement. Additionally, [

16] investigated the mix design ratio between gold tailing (GT) and granulated blast furnace slag (GBFS) as sustainable backfill material, demonstrating an optimum strength of 0.9 MPa from 20% GBFS and 80% GT. Several studies have shown that including a reinforcing element improves the stress–strain behavior, unconfined compression strength, and ductility of geotechnical materials [

17,

18,

19].

Polypropylene fiber-reinforced gold ore tailings under cyclic shear response were assessed by [

10,

20], indicating that both monotonic and cyclic stress paths led to the same strength parameters. The chemical stabilization of soil-mine tailing mixtures was investigated by [

21], resulting in mechanical gains and the immobilization of heavy metals in the residue. These findings are consistent with the [

22] authors’ report on cement-stabilized tailing. The substitution of cement by iron ore tailings in mortars was investigated by [

5], indicating that not only the mechanical but the thermal behavior needs to be taken into account. From an extensive characterization program [

23], it was demonstrated that the inclusion of ore tailings in concrete decreases the pore size by micro-CT, resulting in gains in compressive strength.

From all the previous research, ore tailings’ mechanical behavior has been the focus of investigations [

11]. Even so, ore tailings are a challenging material, and an in-depth understanding of their properties and their ability to interact with chemical stabilizers is a current gap in enabling their safe application as a civil construction material [

24].

In this sense, microstructural analyses are powerful techniques to develop tailings mechanics and validate their hypotheses since they are non-invasive, non-destructive, require only minimal material, and provide meaningful analysis [

25]. The authors of [

26] pointed out that using these techniques allows for more detailed and accurate material characterization. They are powerful techniques for assessing a solid materials’ structure, texture, and physical-chemical interactions. Utilizing the experimental mechanical results, conclusions about the composite’s behavior can be drawn more completely.

Notwithstanding the advantages reported by the current literature, few works have jointly explored the microstructure and mechanical behavior of polymer-stabilized and fiber-reinforced tailings composites. Thus, this work was conducted to achieve the goals: (1) characterize the pure gold ore tailings from XRD, XRF, TGA/DTG, and SEM analysis; (2) verify the effect of polymeric stabilization and fiber reinforcement on the tailing’s microstructure using μCT tests; (3) obtain comparative mechanical responses from the pure tailings and the reinforced and stabilized composites. The present research focuses on contributing to the knowledge of tailings composite through microstructural analysis and its feasibility as construction material by mechanical tests. Based on promising findings and the initial study’s limitations, the hydraulic and mechanical behavior of stabilized and reinforced gold ore tailings composites from permeability tests, indirect tensile strength (ITS), and direct shear tests are planned for future stages of the study.

2. Materials and Methods

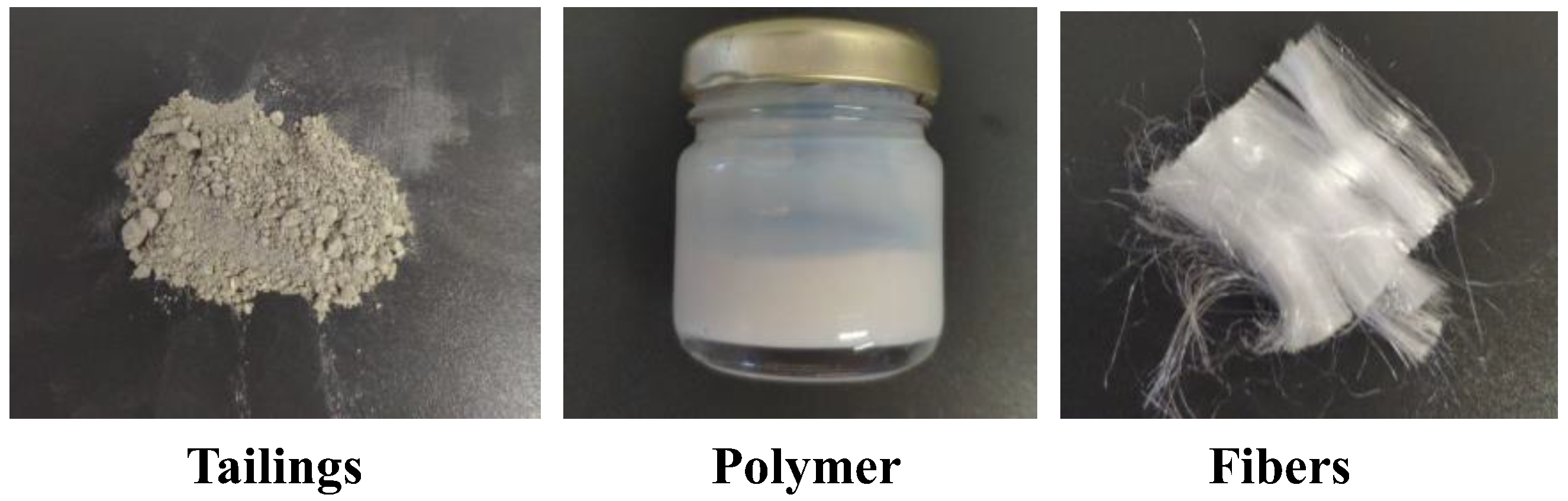

The materials used in this research were gold ore tailings, polypropylene fibers, and polymer solution, as in

Figure 1. The gold ore tailing was extracted from the Morro do Ouro deposit in Minas Gerais State, Brazil.

The deposit is located in the carbonaceous phyllites of the Paracatu Formation. It is geologically composed by an association of detrital metasedimentary rocks characterized by layers of grey phyllites with quartz intercalations [

27].

The original sample presented a high moisture content with a large amount of gravel. The material was sieved with a 2.00 mesh to use the sand fraction of the tailings in this research [

28] as a result of the high applicability of this fraction in geotechnical projects and the need to look for alternative materials to be used as sand due to the excessive sand extraction environmental problem [

29]. The particle size distribution of the pure tailing was obtained using laser granulometry using a PENTAPYC 5200e pycnometer [

30], which is presented in

Figure 2. Additionally, tailing specific gravity and particle-size distribution properties are shown in

Table 1.

Despite being classified as silt, it was observed using visual-tactile analysis that the material has low or no plasticity. This may be because the geological process of soil formation has not formed such materials. This suggests that making inferences from the classification of the soils for the tailings is perhaps not appropriate.

The supplier provided the polymer stabilizer used in this research. It consists of an organic acrylic-styrene copolymer obtained randomly and presented in the form of an aqueous emulsion of anionic character. The polymer has a pH of 8.0–9.0, a density of 0.98–1.04 g/cm³, a viscosity of 3.000–10.000 centipoise (cP), and is completely soluble in water. CHN Elemental Analysis showed that the polymer comprises 69.03% carbon, 7.01% hydrogen, and 0.52% nitrogen. The product is frequently used for pavement sealing and as a soil stabilizer.

Polypropylene fiber with 25 mm length, 0.023 mm diameter, and a specific gravity of 0.91 g/cm³ was selected, according to information provided by the supplier. The tensile strength and Young Modulus are 300 MPa and 3000 MPa, respectively [

31]. The fibers present high resistance to acid environments and, therefore, are suitable for assembly tailings composites.

2.1. Composites Assembly

In addition to pure gold ore tailings evaluation, two composites are proposed in this research: (i) tailings-polymer; (ii) tailings-polymer-fibers. The first composite is formed by the tailings matrix and stabilized by a polymer solution (GT_P). Based on compaction tests using a standard Proctor compaction (600 kJ/m³), two dry unit weights, 1.7 g/cm³, and 1.8 g/cm³, with an optimum moisture content of 15%. Two polymer contents were used, 6% and 9%, and added to the total mass of the tailings.

The second composite is formed by the tailings matrix, the same polymeric solutions content, and polypropylene fibers (GT_PF). The reinforcement was added in a content of 0.5% by matrix mass since this amount has been satisfactorily used in several studies in the literature [

13,

17,

32,

33,

34]. The mixture was made in a systematic process, alternating layers of tailings and fibers, and pulverizing the polymer solution, after which the mixture was homogenized until uniformity was visually observed.

Table 2 summarizes the experimental conditions evaluated in the study and the abbreviations adopted.

For the unconfined compression tests, samples of 5 cm in diameter and 10 cm in height were prepared. They were molded from by compaction in three layers in a metal cylinder. In each layer, the dry specific weight was verified and the top layer was scarified for better adherence to the others. At the end of the process, the sample was removed from the mold and immediately weighed, measured, and placed for curing.

The samples were considered suitable for testing if they met the following tolerances: dry unit weight ± 1% of the target value; moisture contest within ±0.5% of the optimum moisture content; diameter within ±0.5 mm; and height ± 1 mm [

35]. After checking the eligibility of the samples, they were subjected to curing for 7 and 28 days. The curing process was performed by exposing them to air at a controlled temperature of 24 °C.

The mixing of the polymer with the tailings was performed following a systematic method, considering that all the granular material had been previously crushed and dried: (i) separation of the mass of tailings for a specimen; (ii) weighing on a precision scale of the amount of solution to be added to reach the proposed moisture content; (iii) spraying of the solution on the mass of tailings arranged on a flat surface; (iv) mixing for approximately 1 min. A moisture sensor was inserted in at least three points of the mass to check the homogeneous distribution of the polymer solution.

For the case of the second composite, the polypropylene fibers were detached to avoid clumping. Then, the methodology was followed: (i) weighing of fiber content for a specimen; (ii) separation in three equal parts referring to each one of the specimen layers; (iii) manual insertion in layers for each one of the parts.

2.2. Experimental Program

2.2.1. Unconfined Compression Strength Test

The unconfined Compression Strength Test is a simple, fast, and reliable alternative to evaluate chemical stabilization efficiency or assess the most relevant factors in composite strength. Therefore, this is the most widely used test in the experimental programs reported in the literature related to stabilization and reinforcement [

11].

The test was carried out on an automatic loading machine with a maximum capacity of 50 kN. The tests were performed in triplicates using randomly chosen samples for the respective curing times (7 days and 28 days). They were tested in unsaturated conditions. The rate of displacement adopted was 1.27 mm/min.

The response variable of this test is compressive strength (qu). To analyze the influence of more than two factors and the interaction between them, the 2k Factorial Experimental Design was chosen. Therefore, two levels of dry unit weight, polymer content, and curing period were established. In total, 48 specimens were made for the unconfined compression strength test. As an acceptance criterion for UCS tests, it was established that the strength of the replicates, molded with the same characteristics, should not deviate more than 10% from the average strength.

2.2.2. X-ray Diffraction (XRD)

XRD is one of the primary methods for the microstructural characterization of crystalline materials. To use this technique, the pure tailings and composite samples were oven dried at 105 °C and sieved on a 0.074 mm mesh. The analysis was performed in a Rigaku diffractometer under a voltage of 35 kV and 15 mA. The experiment tests were conducted considering an angular amplitude of 2θ, measurement range between 2 and 100°, and velocity of 0.05°/min. The mineralogical identification was carried out using the JADE 9.0 software database reference standards.

2.2.3. X-ray Fluorescence Spectrometry (XRF/EDX)

The X-ray fluorescence technique can quickly evaluate chemical species qualitatively and quantitatively with low operating costs and easy sample preparation. EDX/XRF is an analytical technique based on the measurement of the characteristic X-ray intensities emitted by the elements that constitute the sample. The emitted X-rays are detected using a silicon detector that generates an intensity spectrum as a function of energy.

The test was performed in a Shimadzu model EDX 720HS spectrometer, which analyzes the range of elements from sodium (11Na) to uranium (92U), with X-ray tubes with a rhodium (Rh) anode. Powder samples were dried in the oven at 105 °C for 24 h before the analysis.

2.2.4. Thermogravimetric Analysis (TGA/DTG)

The thermogravimetric analysis (TGA/DTG) was obtained from the Shimadzu DTG-60H model using oven-dried powder samples. The experiments were conducted in an inert atmosphere (N2), with a heating rate of 10 °C/min and a 30 mL/min gas flow from room temperature to 800 °C in a platinum pan.

2.2.5. Optical Microscopy (OM)

The optical microscope is an instrument that uses the refraction of light coming from a series of lenses to magnify images of objects. In this research, images were obtained on the same samples used for SEM to compare analysis scales. The equipment used was an electron microscope model SLQ-M-003 for 10-times magnification.

2.2.6. Scanning Electron Microscopy (SEM)

The Scanning Electron Microscope (SEM) uses a small-diameter, high-energy electron beam to generate signals on the surface of solid samples. The sample is analyzed point by point with successive lines. The signals are collected by detectors and reveal information of interest, such as the sample’s external morphology and chemical composition. The data are collected from a selected area and a two-dimensional image is formed.

The tests were accomplished using an SEM Zeiss EVO MA10 model, which operates in a high vacuum or VP mode. It is equipped with secondary electron (SE) and backscattered electron (BSD) detectors and an Oxford model 51-ADD0048 energy dispersive X-ray spectroscopy (EDS) detector.

Square samples of 1 cm × 1 cm were prepared with two different dry unit weights (1.7 and 1.8 g/cm³). The samples were covered with gold impregnation to become conductive and allow for analysis. For this, the Leica EM SCD050 equipment was used.

2.2.7. X-ray Micro-Computed Tomography (μCT)

X-ray micro-tomography is a powerful microstructural analysis technique since it is non-invasive, non-destructive, and generates high-resolution images. This technique has been used for many years, especially in research in medicine and geology [

36,

37,

38]. The numerous captured images are reconstructed and transformed into a three-dimensional model, allowing a qualitative visual analysis and determining structural properties such as porosity. Thus, the μCT technique is a valuable option for evaluating the structure of composites with tailings [

39].

Cylindrical samples molded at an optimum compaction condition, presenting 14.97 mm high and 14.95 mm in diameter, were analyzed using a Bruker SkyScan 1172 MicroCT system throughout 2501 images. They were obtained with a 1000 ms exposure time and an imaging resolution of 5.98 μm, with a source voltage and source current of 40 kV and 250 μA for the pure tailing sample, and 100 kV and 100 μA for the composite. The reconstruction of the three-dimensional model was performed in the NRecon software.

3. Results and Discussion

3.1. Polymer-Tailings Composite

The stress–strain curves of the stabilized and reinforced composites presented in

Figure 3 show a significant increase in compressive strength compared to the pure tailings. The brittle behavior is common for all curing times and dry unit weight. However, polymer hardening has an initial stiffness gain, leading to smaller axial strains for the composites with a longer curing time. The rupture of the composites at 28 days occurs with an axial strain of 2% and 3%, while those at 7 days occur between 3 and 4% for the lower polymer content. For the 9% content, the peak strains at 28 days are between 3% and 4.5%, and for 7 days, between 4% and 5.5%.

The improvement in the mechanical behavior of the tailings by the insertion of polymer can be demonstrated by the tenacity, the property of the material that expresses the energy absorbed by it when deformed. This study assessed tenacity using the strain energy absorption capacity (Edef), a quantity numerically equal to the area under the stress x variation strain curve, until the material rupture (

Figure 4).

The presence of polymer promotes an increase of the energy-absorbing capacity of the composite, in which both the increase of the amount and the curing period promote significant gains in this property. Statistical analysis was performed to evaluate the factors’ influence on the response variable based on the 2k Factorial Experiment Design. The objective was to generate a regression model from which the effects of each factor can be accounted for and thus allow predictions in experimental space. An ANOVA analysis considering third-order effects showed that the controllable factors (dry unit weight, curing time, and polymer content) are significant in determining the qu at a significance level of 0.001. The results are presented in

Table 3. The Shapiro–Wilk test was used to test normality, and the Breush-Pagan test was applied for the homoscedasticity test. The data met both assumptions.

As all factors are significant, it is interesting to evaluate all interactions graphically (uncoded).

Figure 5 shows the interaction between the specific mass and polymer content for the two curing periods. Comparing the increase in strength due to curing with density, it is observed that for 6% polymer, the increase was 40.3% and 104.5% for 1.7 and 1.8 g/cm³, indicating that the denser the structure, the greater the gain obtained. However, when increasing the amount of polymer to 9%, this increase was 219.9% and 246.9%, respectively, demonstrating that increasing the polymer reduces the effect of densifying the composite strength.

The influence of polymer content and curing period on compressive strength is shown in

Figure 6. It can be observed that the behavior of the curve is polynomial, with the establishment of a maximum strength value for the 7 days of curing, which seems to be a maximum strength relative to the percentage of cure in that period. Even if there were more polymers, the composite would undergo the same chemical reactions at 7 days, and thus have the same ultimate strength. In this sort of chemical stabilization, curing has high importance.

3.2. Polymer-Fibers-Tailings Composite

By adding a reinforcing element to the tailings-polymer composites, the expectation was fibers develop resisting forces and anchor the mass when forces in weak zones overcome composite resistance.

This effect happened, as shown by the curves in

Figure 7. The post-peak compression strength drop was attenuated in all cases compared to the GT_P composites (

Figure 3). Moreover, it is observed that the performance of the fibers is benefited from a more stable structure, with a dry unit weight of 1.8 g/cm³. This mechanism facilitates their anchorage, which increases the post-peak strength.

It can be observed that the portion of additional strength given by the fibers even allows a reduction of polymer in the composites since close values of compression strength were obtained for both contents. For the GT_PF6_1.8_28D composite, a qu value of approximately 2200 kPa was obtained, compared to 1900 kPa for the GT_PF9_1.8_28D composite. From these results, it is possible to conclude that from the mobilization of tensile stresses in the fibers, the GT_PF composite becomes more ductile than the GT_P.

Figure 8 depicts the reinforced composite’s ability to absorb strain energy up to failure. It can be observed that the fibers promote an increase of the absorbed energy for all experimental conditions when compared to pure tailings and tailings-polymer composite. In addition, similar results were seen for the tailings-polymer-fiber composites with 6% and 9% of the polymer, in which the density of the composite is the most significant factor. This behavior is associated with greater fiber performance capacity in more densified matrices [

17].

Statistical analysis was performed to evaluate the factors’ influence on this composite’s response variable. ANOVA analysis demonstrated that the controllable factors of curing time and dry unit weight are significant for determining compressive strength at a significance level of 0.001. The results are presented in

Table 4. The polymer content for this composite is not meaningful from the statistical point of view, as expected. The Shapiro–Wilk test was used to test normality, and the Breush-Pagan test was applied for the homoscedasticity test. The data met both assumptions.

An analysis of the interaction between polymer content and specific mass is presented in

Figure 9. It can be seen that for the 6% and 9% contents, there is an increase in the compression strength of approximately 1000 kPa for 1.8 g/cm³, and a drop of 200 kPa to 1.7 g/cm³ when compared with the curing time.

As already observed in the GT_P composites, the polymer offers maximum resistance at seven days. The residual moisture in the matrix does not collaborate with the fibers’ anchorage, which is why the composites presented close results.

At 28 days, the polymer content of 6% brings the most benefits from the increase of dry unit weight. It is understood that this would be the optimal content to ensure the cohesive effect between the finer particles and create an anchoring structure for the fibers, thus collaborating with their tensile strength.

In

Figure 10 the relationship between curing time and polymer content is shown. As in all cases mentioned, at seven days, there is a stabilization of the compressive strength. At 28 days, the curves show a polynomial behavior, with a slight decrease of the qu for the 9% content and the 6% content for the highest dry unit weight.

In the case of the tailings-polymer-fiber composite, the results corroborate those presented by [

40] for cemented soils reinforced with glass fibers. In the authors’ case, the composites formed with a lower stabilizer (cement) content showed better results when reinforced.

On the other hand, for GT_P composites, the higher polymer content was more beneficial for compressive strength. However, when fibers are inserted, a type of linear reinforcement, a polymer content higher than 6% does not contribute to their anchorage in the matrix.

As [

28] presents, the primary type of rupture of fiber-reinforced composites is in the anchorage. Thus, knowing that the polymer is a viscous material, the friction angle is smaller in the anchorage contact because it becomes mostly fiber-polymer and not a fiber-tailings particle.

3.3. Chemical Characterization

3.3.1. X-ray Diffraction (XRD)

The mineralogical analysis is presented in

Figure 11. For the pure tailings, it indicated the presence of quartz (SiO

2), Muscovite (KAl

2(Si

3Al)O

10(OH

1F)

2, and Kaolinite (Al

2Si

2O

2(OH)

4), in agreement with the composition reported by Festugato et al. [

20]. In the composite (GT_P), a portion of gypsum was identified in addition to the reduction of the frequency of minerals identified for pure waste (CaSO

4H

2O).

Although gypsum belongs to the class of hydrated sulfates and is the most abundant mineral in this class, the composite did not generate a new mineral. Its presence is due to the classification technique, which consults the mineral database through the JADE 9.0 software.

Each crystalline structure produces a characteristic diffraction pattern. Therefore, a database is used to interpret the results, and a comparison is made with the patterns produced by known, previously analyzed structures. In this case, the polymer was classified as isostructural to the gypsum. Although it is not possible to characterize the polymer, it is possible to observe its presence together with the tailings minerals.

3.3.2. X-ray Fluorescence Spectrometry (XRF/EDX)

The chemical composition of the pure tailing is presented in

Table 5. The elements identified in the x-ray fluorescence spectrometry agree with previously reported mineral results, wherein the percentage of silicon, aluminum, and potassium were the most representative elements, given the presence of quartz, muscovite, and kaolinite. It is essential to mention that the results on the composite showed no differences since the polymer is mainly composed of carbon, and this element is not detected in this test.

Approximately 1% of the elements found in the gold ore tailings are heavy metals, i.e., Ti, As, Mn, Cr, Zn, and Sr, which has been a notorious environmental problem investigated by the literature [

41,

42,

43].

3.3.3. Thermogravimetric Analysis

Thermogravimetric analysis was conducted for the pure tailings and the composite.

Figure 12 shows the results evaluating the mass loss in percentage (TGA), its derivate curve (DrTGA), and the DTA curve.

The TGA analysis relates to mass changes due to interaction with the atmosphere, vaporization, and decomposition. Both samples showed a slight mass loss in the analyzed value range (0 °C–800 °C), approximately 4.1% for the pure tailings and 6.2% for the composite. This indicates thermal stability.

On the other hand, DTA analysis looks at physical and chemical processes involving energy variation. The maximum peaks in the graph indicate the occurrence of exothermic processes, with heat release and temperature increase. Some exothermic processes include oxidation in the air, the presence of oxygen, polymerization, adsorption, and crystallization [

44].

In contrast, the minimal peaks observed are due to endothermic processes, in which the sample absorbs heat. Some examples include melting, vaporization, absorption, and desorption.

The DTA curve of the samples is characterized by two thermal events, a maximum and minimum peak. In the pure tailings, the maximum occurs at approximately 250 °C and in the composite at approximately 350 °C. This event is associated with mass loss in both cases, as shown in the derived DrTGA curve.

As these peaks occur in both samples, they must be related to the tailings matrix. One possibility would be the roasting reaction, in which sulfides in the sample are burned. The minimum peak of the curves occurs at 600 °C. The literature indicates that this endothermic reaction may be related to the crystalline transformation of the quartz present in the tailings [

45].

The analysis of the DrTGA curve is interesting to evaluate the three main temperature points for polymers: glass transition, melting, and boiling. As can be observed, this curve of the composite presents some well-defined points, which does not happen in the pure sample. Thus, the glass transition temperature for this polymer can be observed at approximately 100 °C, the melting temperature at approximately 400 °C, and the boiling temperature near 600 °C.

3.4. Morphological Analysis

3.4.1. Optical Microscopy (OM)

Figure 13 shows an optical microscopy image at 10× magnification for the pure tailings and the composite. Firstly, it is possible to observe the fine grain size of the material and the conglomerates formed by the polymer. Additionally, it is interesting to note that there is a natural attraction between the tailing particles and the polypropylene fibers. This may be related to electrostatic forces. The tailings particles, as well as the clays, are superficially charged with negative charges. These are then attracted to the fibers that have cationic potential.

It is important to note that a limitation of optical microscopy is that it does not allow the analysis of the grain-polymer interface due to the size of the material’s grains requiring other techniques.

3.4.2. Scanning Electron Microscopy (SEM)

Figure 14 shows the morphological analysis obtained by SEM. It can be seen that the pure tailings are composed of a lamellar isotextural structure, randomly oriented and with tightly interlocking packets. The author of [

46] suggests that micromorphology and texture can be used to support mineral identification. In comparison with other authors, it is observed that kaolinite and muscovite are detected in agreement with the XRD analyses [

47].

The tendency to form aggregates in the composite, shown in

Figure 14b, is directly related to particle size and surface area availability [

47]. However, the lamellar packages in the pure tailing decrease the surface area for polymer contact, which can lead to brittle behavior.

The SEM analysis also showed the anchoring mechanism of the fiber in the matrix, as shown in

Figure 15a. Efficient anchoring is related to the ratio between fiber length and fiber diameter. This parameter, combined with the actuating stresses, will determine if the rupture will occur by fiber breakage or fiber pullout [

48].

Furthermore, in

Figure 15b, the effect of the increased porosity in the fiber-reinforced composites is possible. Although compaction minimizes this effect, the fiber generates surrounding voids.

3.5. X-ray Micro-Computed Tomography Analysis

3.5.1. Acquisition Characteristics

The microtomography analysis enabled several aspects to understand the behavior of the pure tailings and the composite. First, by clearly verifying the edge effect in the samples through the color chart presented in

Figure 16. These acquisitions were made using a filter (Cu, 0.038 mm + Al, 1 mm). However, the polymer and fiber detections were later changed to a filterless analysis and lower energy for the composites.

According to Bugani et al. [

49], it is not always possible to identify the polymer directly in the reconstructed images due to three factors: (i) normal spatial resolution; (ii) the low contrast given by the focal spot size of the source; (iii) low attenuation of X-rays by the water repellent.

As observed, under the regions near the mold (blue), a lower density is indicated by the colors green and yellow. The rest of the specimen consists of elements with density indicated by the orange color, the denominated matrix, with encrusted rock clasts in purple. This analysis concluded that the size of the edge effect is 4.95% of the total sample width.

3.5.2. Porosity

The two-dimensional porosity analysis evaluated the total, the open, and the closed pores (

Figure 17). The openness of the pores refers to the interconnection between them. Therefore, it was found that the two-dimensional analysis is unsuitable for checking the open pores since the grouping of the 2D images cannot reconstruct the pore’s connections.

Regarding total porosity, a range of 7–10% was obtained for the pure tailings and much lower values, 0.5–1.5%, for the composite GT_P. Intermediate values of porosity were found in GT_PF composites at approximately 4–6%. The same trend was identified by the number of closed pores found in the materials (

Figure 18), in the order of 20,000 for the pure tailing, an average of 7000 for the GT_P, and 15,000 for GT_PF.

This analysis shows that the polymer acts with a cohesive effect by filling the voids in the sample, connecting the particles, and, consequently, decreasing the medium’s permeability. It is consistent with the literature that identified the development of interconnection bonds between grains, adhesion between adjacent grains, and coating grains with a thin polymer film by SEM tests [

50,

51]. Nevertheless, the fiber addition promoted increased porosity due to the voids formed around the fiber [

52].

In the three-dimensional analysis, it is possible to evaluate the volumes of each component that constitutes the materials. Pure tailings comprise pores, a matrix, clasts, and heavy minerals. In the GT_P composite, besides the elements mentioned, there is the polymer portion, and in the GT_PF composite there are fibers in addition to the others.

The heavy minerals possess a density greater than 3 g/cm² and are found in the tailings, mainly associated with the clasts. The details of each representative volume are presented in

Figure 19 for pure tailings, GT_P, and GT_PF, respectively.

From the information presented, it is possible to see a reduction of porosity from 8.77% to 0.85% in the case of the GT_P. On the other hand, GT_PF presents a porosity of 4.19%. A more detailed analysis, illustrated in

Figure 20, shows the sample’s open and closed pores distribution.

The reduction of porosity observed in the composite GT_P is equivalent to the volume of polymer found, which is 5.43%. This again indicates that the polymer fills the voids, decreases permeability, and connects the particles. From this image, it is also possible to see the uniform distribution of the polymer and the fiber in the sample, confirming that the mixing process is adequate.

Figure 21,

Figure 22 and

Figure 23 show this in detail.

The pore size distribution is shown in

Figure 24. It is found that the majority (46.74%) of the pores in the pure tailings are between 0.018 and 0.030 mm in size. In the composite GT_P, the majority (74.20%) of the pores are smaller, between 0.006 and 0.018 mm.

3.5.3. Heavy Minerals Analysis

The heavy minerals are 1% in the GT_P sample and 1.37% in the case of the pure tailings. The same percentage of heavy minerals was identified in the XRF analyses, thus demonstrating the convergence of results from different analysis methodologies and validating the CT technique in identifying heavy metals in ore tailings studies.

Since the polymer acts as a binder, a more detailed analysis of the heavy minerals was performed to assess whether the polymer could immobilize these elements during a leaching process. According to

Figure 25, it can be seen that the polymer acts as a barrier to heavy minerals. This may immobilize these elements. This is an interesting finding from an environmental point of view since these heavy minerals may contain metals with toxicological potential.