Solar PV-Based Electric Vehicle Charging Station for Security Bikes: A Techno-Economic and Environmental Analysis

Abstract

:1. Introduction

1.1. General

1.2. Research Contribution

- The proposed system addresses economic and technological aspects, while also offering solar PV-based energy solutions for EV charging.

- In the targeted location, it also recommends hybrid EV charging stations that are profitable.

- The proposed system investigates the performance of unknown variance using sensitivity analysis.

- The illustrated study also compares the environmental benefits of the new system to the old system in terms of GHG (CO2, CO, SO2, and NOX) emissions.

- The suggested scheme addresses the policy implications of the proposed standalone hybrid charging model.

2. Methodology

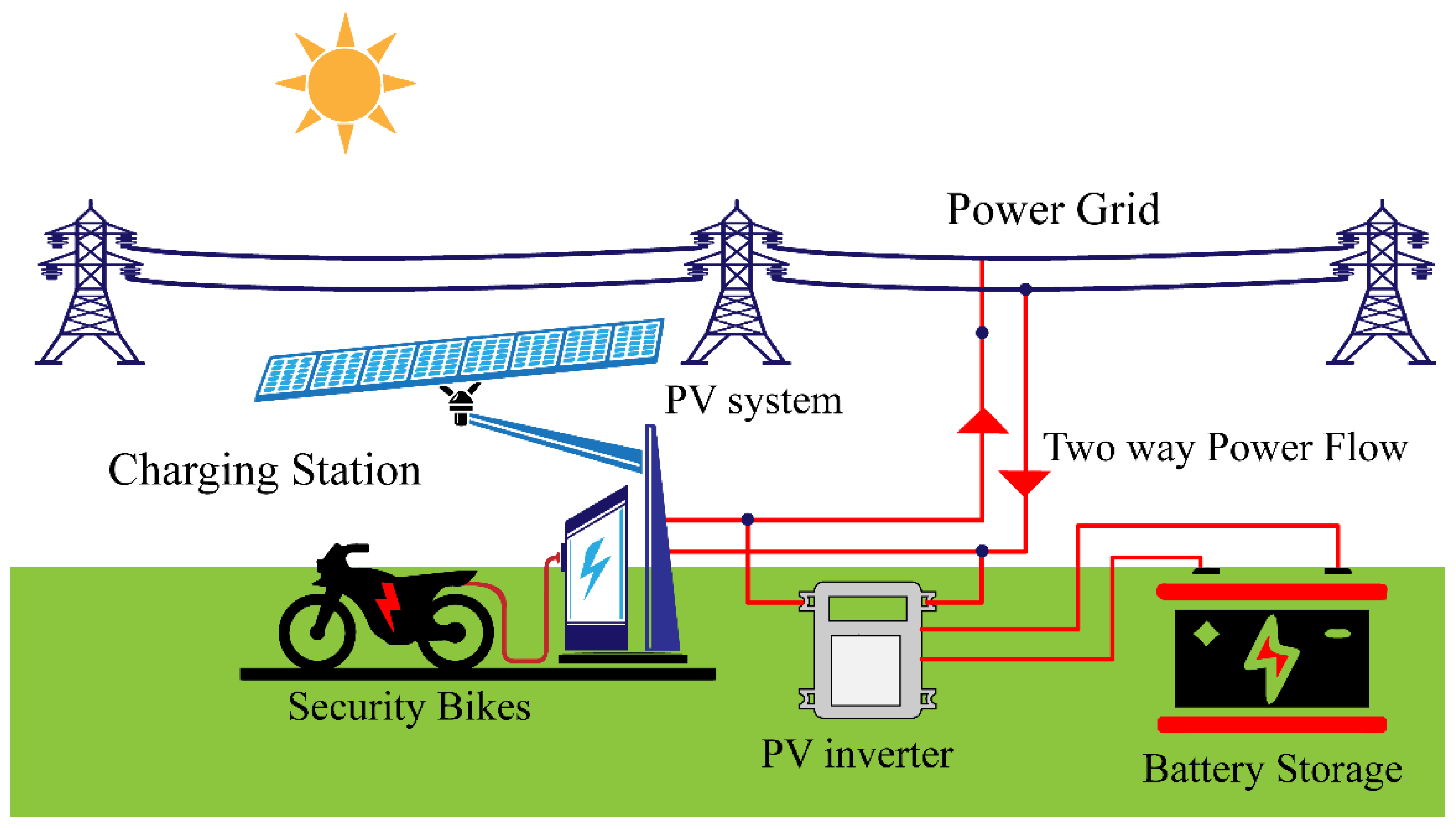

2.1. Site Description and System Model

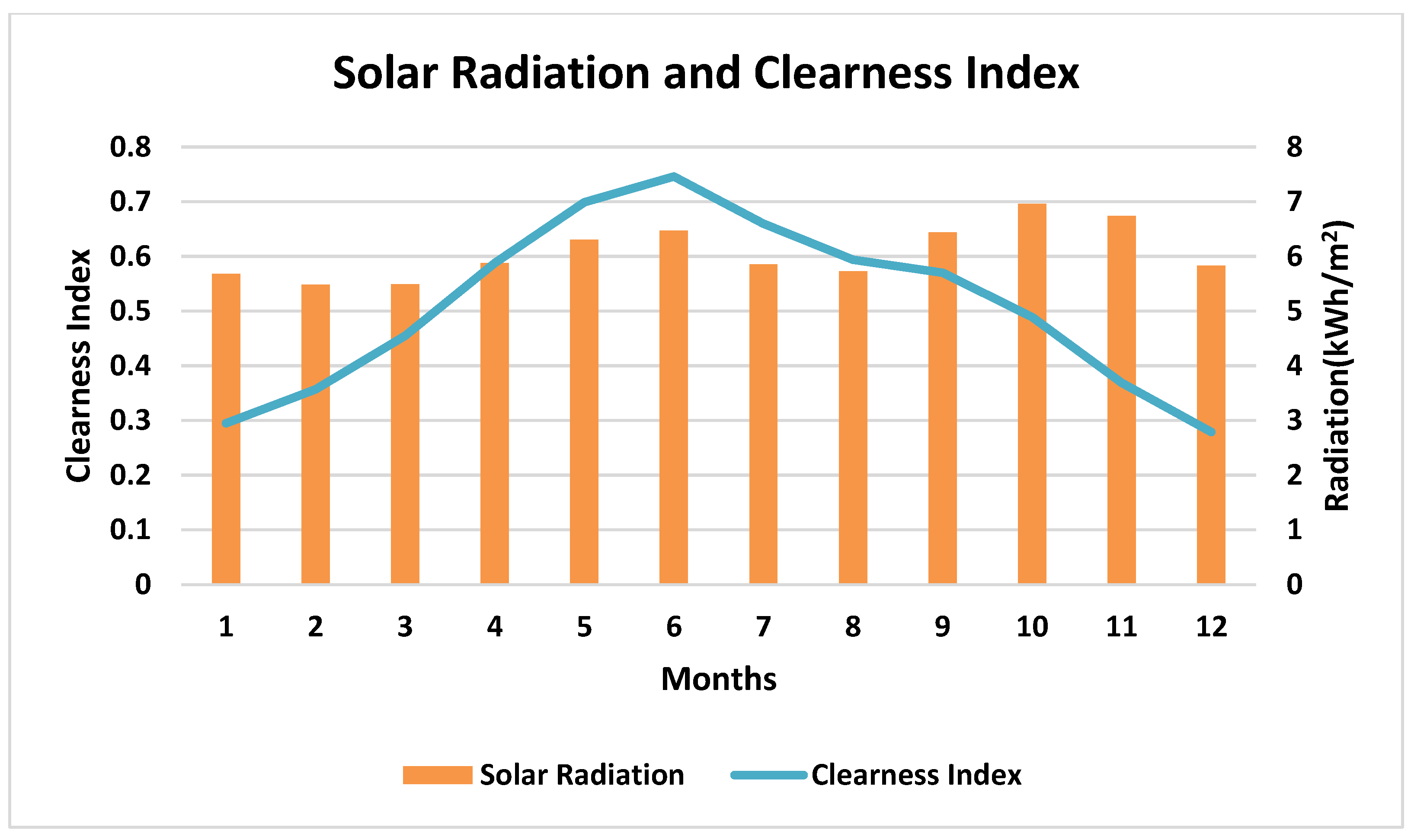

2.2. Solar Resources

2.3. Initial Assessment

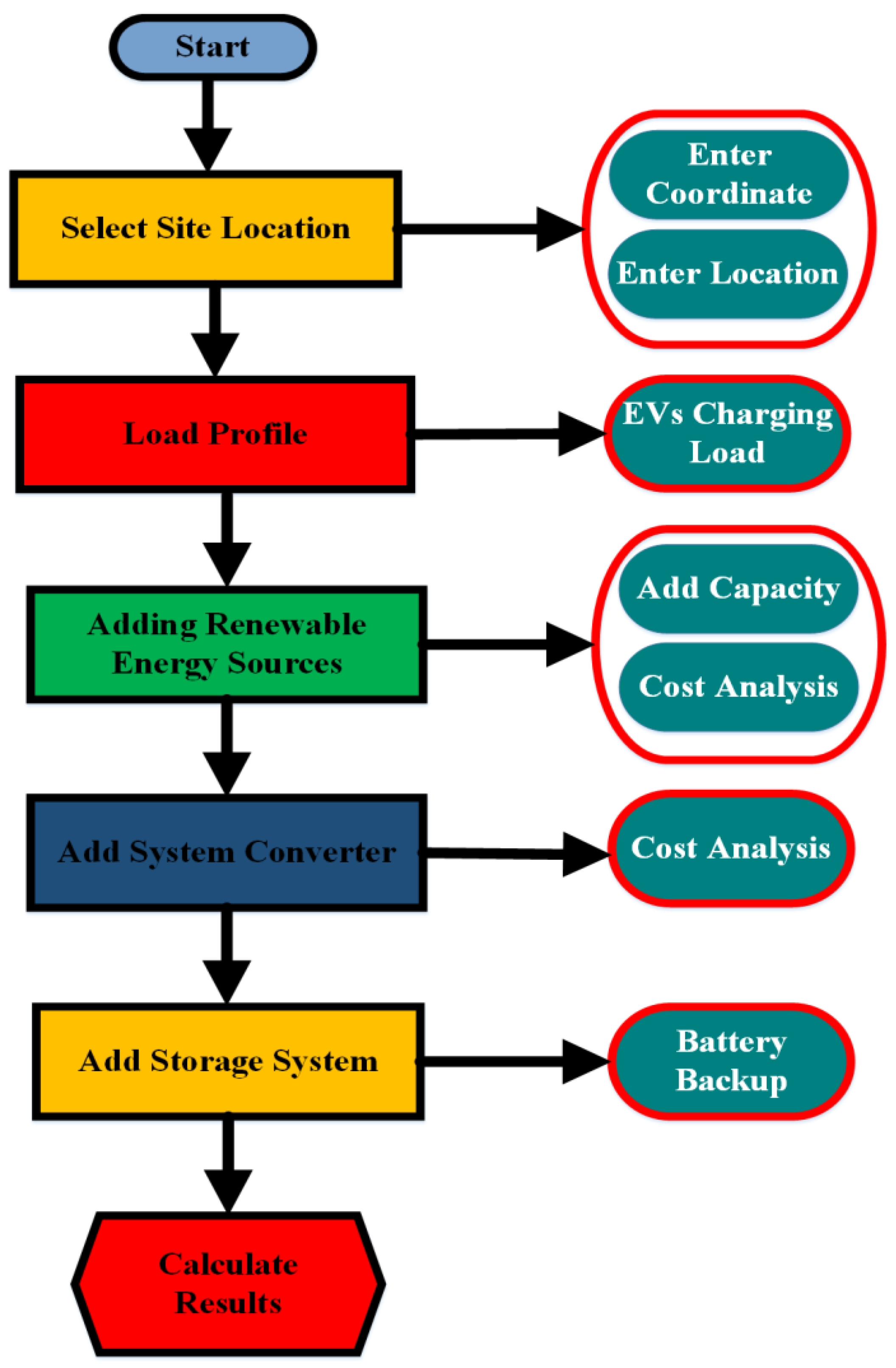

2.4. Flow Chart

3. Results and Discussions

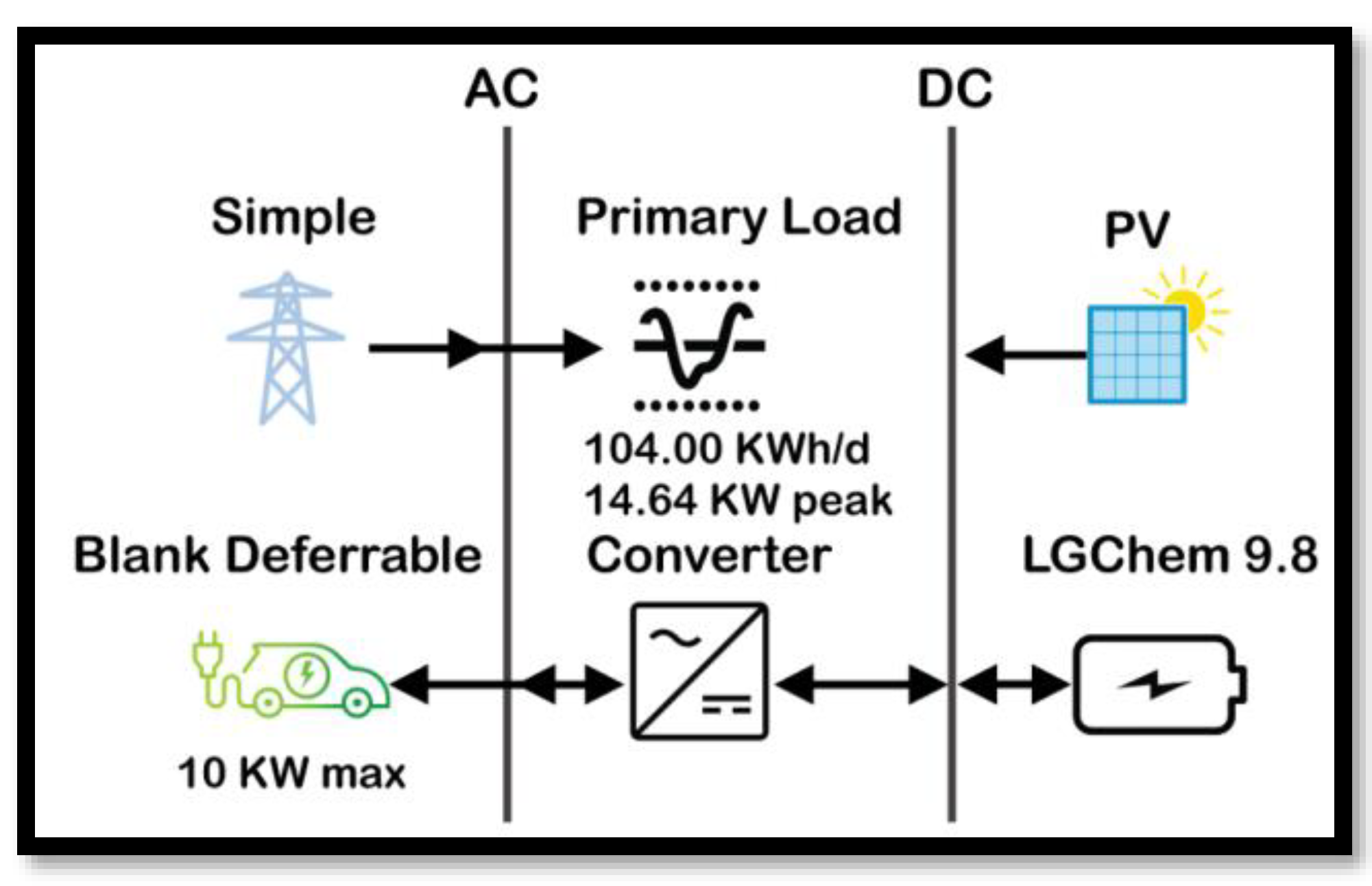

3.1. System Architecture

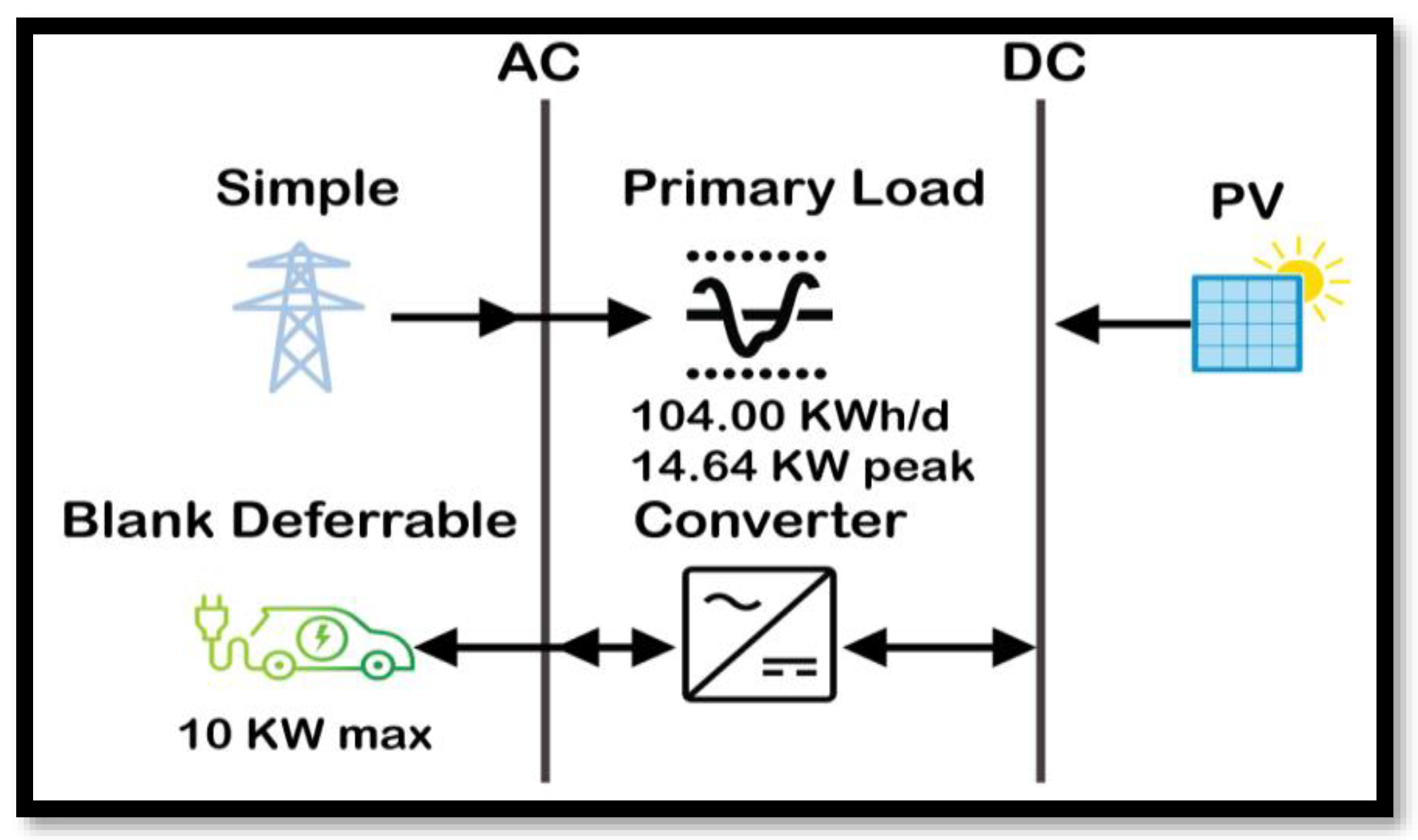

3.1.1. With Storage

3.1.2. Without Storage

3.2. Net Present Cost

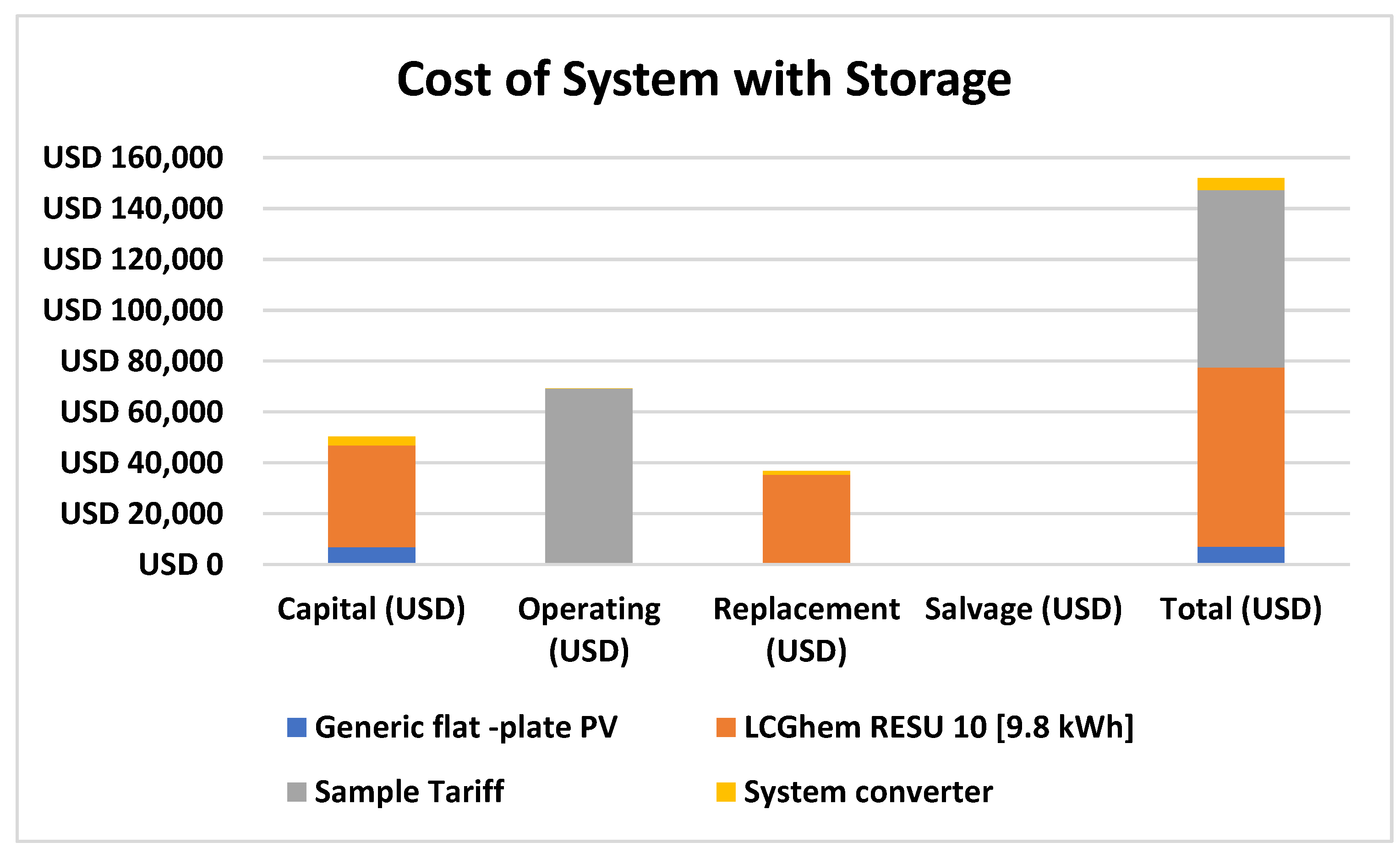

3.2.1. With Storage

3.2.2. Without Storage

3.3. Annualized Cost

3.3.1. With Storage

3.3.2. Without Storage

3.4. Production Summary

3.4.1. With Storage

3.4.2. Without Storage

3.5. Consumption Summary

3.5.1. With Storage

3.5.2. Without Storage

3.6. EV Charging

3.7. Economic Comparison

- a

- Base Case Electric bill

- b

- Predicted Electric bill

- c

- Annualized Cost

- d

- Base Case Electric Bill

- e

- Predicted Case Electric Bill

3.8. Economic Comparison

3.8.1. Without Storage

3.8.2. With Storage

3.9. Polluting Gas Emissions

3.10. Comparison with Existing Work

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- ReferencesNanaki, E.A.; Xydis, G.A. Deployment of Renewable Energy Systems: Barriers, Challenges, and Opportunities. In Advances in Renewable Energies and Power Technologies; Elsevier: Amsterdam, The Netherlands, 2018; pp. 207–229. [Google Scholar]

- Podder, A.K.; Supti, S.A.; Islam, S.; Malvoni, M.; Jayakumar, A.; Deb, S.; Kumar, N.M. Feasibility Assessment of Hybrid Solar Photovoltaic-Biogas Generator Based Charging Station: A Case of Easy Bike and Auto Rickshaw Scenario in a Developing Nation. Sustainability 2021, 14, 166. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, Q.; Farnoosh, A.; Chen, S.; Li, Y. GIS-Based Multi-Objective Particle Swarm Optimization of charging stations for electric vehicles. Energy 2019, 169, 844–853. [Google Scholar] [CrossRef]

- Iqbal, S.; Jan, M.U.; Rehman, A.U.; Shafique, A.; Rehman, H.U.; Aurangzeb, M. Feasibility Study and Deployment of Solar Photovoltaic System to Enhance Energy Economics of King Abdullah Campus, University of Azad Jammu and Kashmir Muzaffarabad, AJK Pakistan. IEEE Access 2022, 10, 5440–5455. [Google Scholar] [CrossRef]

- Halabi, L.M.; Mekhilef, S.; Olatomiwa, L.; Hazelton, J. Performance analysis of hybrid PV/diesel/battery system using HOMER: A case study Sabah, Malaysia. Energy Convers. Management 2017, 144, 322–339. [Google Scholar] [CrossRef]

- Miceli, R.; Viola, F. Designing a Sustainable University Recharge Area for Electric Vehicles: Technical and Economic Analysis. Energies 2017, 10, 1604. [Google Scholar] [CrossRef] [Green Version]

- Habib, S.; Khan, M.M.; Abbas, F.; Ali, A.; Hashmi, K.; Shahid, M.U.; Bo, Q.; Tang, H. Risk Evaluation of Distribution Networks Considering Residential Load Forecasting with Stochastic Modeling of Electric Vehicles. Energy Technol. 2019, 7, 1900191. [Google Scholar] [CrossRef]

- Iqbal, S.; Habib, S.; Khan, N.H.; Ali, M.; Aurangzeb, M.; Ahmed, E.M. Electric Vehicles Aggregation for Frequency Control of Microgrid under Various Operation Conditions Using an Optimal Coordinated Strategy. Sustainability 2022, 14, 3108. [Google Scholar] [CrossRef]

- Dai, Q.; Liu, J.; Wei, Q. Optimal Photovoltaic/Battery Energy Storage/Electric Vehicle Charging Station Design Based on Multi-Agent Particle Swarm Optimization Algorithm. Sustainability 2019, 11, 1973. [Google Scholar] [CrossRef] [Green Version]

- Ilieva, L.M.; Iliev, S.P. Feasibility assessment of a solar-powered charging station for electric vehicles in the North Central region of Bulgaria. Renew. Energy Environ. Sustain. 2016, 1, 12. [Google Scholar] [CrossRef]

- Pan, A.; Zhao, T.; Yu, H.; Zhang, Y. Deploying Public Charging Stations for Electric Taxis: A Charging Demand Simulation Embedded Approach. IEEE Access 2019, 7, 17412–17424. [Google Scholar] [CrossRef]

- John, S.; Vincent, G. PV fed Electric Vehicle Charging Station with Power Backup. In Proceedings of the 2021 13th IEEE PES Asia Pacific Power & Energy Engineering Conference (APPEEC), Karela, India, 21–23 November 2021; pp. 1–6. [Google Scholar] [CrossRef]

- Filote, C.; Felseghi, R.; Raboaca, M.S.; Aşchilean, I. Environmental impact assessment of green energy systems for power supply of electric vehicle charging station. Int. J. Energy Res. 2020, 44, 10471–10494. [Google Scholar] [CrossRef]

- Ahmad, F.; Khalid, M.; Panigrahi, B.K. An enhanced approach to optimally place the solar powered electric vehicle charging station in distribution network. J. Energy Storage 2021, 42, 103090. [Google Scholar] [CrossRef]

- Niccolai, A.; Bettini, L.; Zich, R. Optimization of electric vehicles charging station deployment by means of evolutionary algorithms. Int. J. Intell. Syst. 2021, 36, 5359–5383. [Google Scholar] [CrossRef]

- Khan, W.; Ahmad, F.; Alam, M.S. Fast EV charging station integration with grid ensuring optimal and quality power exchange. Eng. Sci. Technol. Int. J. 2019, 22, 143–152. [Google Scholar] [CrossRef]

- ur Rehman, A.; Ali, M.; Iqbal, S.; Shafiq, A.; Ullah, N.; Otaibi, S.A. Artificial Intelligence-Based Control and Coordina-tion of Multiple PV Inverters for Reactive Power/Voltage Control of Power Distribution Networks. Energies 2022, 15, 6297. [Google Scholar] [CrossRef]

- Xu, M.; Meng, Q. Optimal deployment of charging stations considering path deviation and nonlinear elastic demand. Transp. Res. Part B Methodol. 2020, 135, 120–142. [Google Scholar] [CrossRef]

- Yan, D.; Ma, C. Stochastic planning of electric vehicle charging station integrated with photovoltaic and battery systems. IET Gener. Transm. Distrib. 2020, 14, 4217–4224. [Google Scholar] [CrossRef]

- Wang, W.; Huang, S.; Zhang, G.; Liu, J.; Chen, Z. Optimal Operation of an Integrated Electricity-heat Energy System Considering Flexible Resources Dispatch for Renewable Integration. J. Mod. Power Syst. Clean Energy 2021, 9, 699–710. [Google Scholar] [CrossRef]

- Bhatti, A.R.; Salam, Z.; Sultana, B.; Rasheed, N.; Awan, A.B.; Sultana, U.; Younas, M. Optimized sizing of photovoltaic grid-connected electric vehicle charging system using particle swarm optimization. Int. J. Energy Res. 2019, 43, 500–522. [Google Scholar] [CrossRef] [Green Version]

- Nishanthy, J.; Raja, S.C.; Praveen, T.; Nesamalar, J.J.D.; Venkatesh, P. Techno-economic analysis of a hybrid solar wind electric vehicle charging station in highway roads. Int. J. Energy Res. 2022, 46, 7883–7903. [Google Scholar] [CrossRef]

- Hafez, O.; Bhattacharya, K. Optimal design of electric vehicle charging stations considering various energy resources. Renew. Energy 2017, 107, 576–589. [Google Scholar] [CrossRef]

- Iqbal, S.; Xin, A.; Jan, M.U.; Salman, S.; Zaki, A.U.M.; Rehman, H.U.; Shinwari, M.F.; Abdelbaky, M.A. V2G Strategy for Primary Frequency Control of an Industrial Microgrid Considering the Charging Station Operator. Electronics 2020, 9, 549. [Google Scholar] [CrossRef] [Green Version]

- Mouli, G.R.C.; Bauer, P.; Zeman, M. System design for a solar powered electric vehicle charging station for workplaces. Appl. Energy 2016, 168, 434–443. [Google Scholar] [CrossRef] [Green Version]

- Iqbal, S.; Xin, A.; Jan, M.U.; Abdelbaky, M.A.; Rehman, H.U.; Salman, S.; Aurangzeb, M.; Rizvi, S.A.A.; Shah, N.A. Improvement of Power Converters Performance by an Efficient Use of Dead Time Compensation Technique. Appl. Sci. 2020, 10, 3121. [Google Scholar] [CrossRef]

- Lee, D.; Park, J.; Shin, H.; Choi, Y.; Lee, H.; Choi, J. Microgrid Village Design with Renewable Energy Resources and Its Economic Feasibility Evaluation. In Proceedings of the 2009 Transmission & Distribution Conference & Exposition: Asia and Pacific, Seoul, Korea, 26–30 October 2009; pp. 1–4. [Google Scholar] [CrossRef]

- Biya, T.S.; Sindhu, M.R. Design and Power Management of Solar Powered Electric Vehicle Charging Station with Energy Storage System. In Proceedings of the 2019 3rd International Conference on Electronics, Communication and Aerospace Technology (ICE-CA), Coimbatore, India, 12–14 June 2019; pp. 815–820. [Google Scholar] [CrossRef]

- Biswas, S.; Kabir, M.A.; Rabby, M.F.; Nazmi, N.N.; Faiz, R. Solar Powered Tea Harvester with Isolated Charging Station in Sylhet, Bangladesh. In Proceedings of the 2021 2nd International Conference on Robotics, Electrical and Signal Processing Techniques (ICREST), 5–7 January 2021; pp. 259–262. [Google Scholar] [CrossRef]

- Habib, S.; Khan, M.M.; Abbas, F.; Numan, M.; Ali, Y.; Tang, H.; Yan, X. A framework for stochastic estimation of electric vehicle charging behavior for risk assessment of distribution networks. Front. Energy 2020, 14, 298–317. [Google Scholar] [CrossRef]

- Hu, J.; Liu, X.; Shahidehpour, M.; Xia, S. Optimal Operation of Energy Hubs with Large-Scale Distributed Energy Resources for Distribution Network Congestion Management. IEEE Trans. Sustain. Energy 2021, 12, 1755–1765. [Google Scholar] [CrossRef]

- Wei, Z.; Quan, Z.; Wu, J.; Li, Y.; Pou, J.; Zhong, H. Deep Deterministic Policy Gradient-DRL Enabled Multiphysics-Constrained Fast Charging of Lithium-Ion Battery. IEEE Trans. Ind. Electr. 2022, 69, 2588–2598. [Google Scholar] [CrossRef]

- Liu, K.; Wei, Z.; Zhang, C.; Shang, Y.; Teodorescu, R.; Han, Q.-L. Towards Long Lifetime Battery: AI-Based Manufactur-ing and Management. IEEE/CAA J. Autom. Sin. 2022, 9, 1139–1165. [Google Scholar] [CrossRef]

- Jaganath, M.M.; Ray, S.; Choudhury, N.B.D. Techno-enviro-economic optimization of renewable energy potential in North Eastern India. Int. J. Ambient Energy 2022. [Google Scholar] [CrossRef]

- Praveenkumar, S.; Agyekum, E.B.; Ampah, J.D.; Afrane, S.; Velkin, V.I.; Mehmood, U.; Awosusi, A.A. Techno-economic optimization of PV system for hydrogen production and electric vehicle charging stations under five different climatic conditions in India. Int. J. Hydrogen Energy 2022. [Google Scholar] [CrossRef]

- Li, C.; Shan, Y.; Zhang, L.; Zhang, L.; Fu, R. Techno-economic evaluation of electric vehicle charging stations based on hybrid renewable energy in China. Energy Strategy Rev. 2022, 41, 100850. [Google Scholar] [CrossRef]

- Minh, P.V.; Quang, S.L.; Pham, M.-H. Technical Economic Analysis of Photovoltaic-Powered Electric Vehicle Charging Stations under Different Solar Irradiation Conditions in Vietnam. Sustainability 2021, 13, 3528. [Google Scholar] [CrossRef]

- Lin, Y.; Fu, L. A Study for a Hybrid Wind-Solar-Battery System for Hydrogen Production in an Islanded MVDC Network. IEEE Access 2022, 10, 85355–85367. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, Y.; Li, T.; Jiang, L.; Li, K.; Yin, H.; Ma, C.L. A Hierarchical Distributed Energy Management for Multiple PV-Based EV Charging Stations. In Proceedings of the IECON 2018-44th Annual Conference of the IEEE Industrial Electronics Society, Washington, DC, USA, 21–23 October 2018; pp. 1603–1608. [Google Scholar] [CrossRef]

- Jahangiri, M.; Nematollahi, O.; Haghani, A.; Raiesi, H.A.; Shamsabadi, A.A. An optimization of energy cost of clean hybrid solar-wind power plants in Iran. Int. J. Green Energy 2019, 16, 1422–1435. [Google Scholar] [CrossRef]

- Yoomak, S.; Ngaopitakkul, A. Development of Sustainable Nanogrid Road Lighting Systems. IEEE Trans. Intell. Transp. Syst. 2021, 22, 6682–6699. [Google Scholar] [CrossRef]

- Xie, Z.; Qi, W.; Huang, C.; Li, H. Effect Analysis of EV Optimal Charging on DG Integration in Distribution Network. In Proceedings of the 2019 IEEE 8th International Conference on Advanced Power System Automation and Protection (APAP), Xi’an, China, 21–24 October 2019; pp. 525–528. [Google Scholar] [CrossRef]

- Almehizia, A.A.; Al-Masri, H.M.K.; Ehsani, M. Feasibility Study of Sustainable Energy Sources in a Fossil Fuel Rich Country. IEEE Trans. Ind. Appl. 2019, 55, 4433–4440. [Google Scholar] [CrossRef] [Green Version]

- Wu, M.; Li, Z.; Fan, J. Selection of new energy vehicles using hybrid approach: A case study of China. IFS 2021, 40, 11967–11980. [Google Scholar] [CrossRef]

| Month | Clearness Index | Radiation (kWh/m2) | Temp (°C) |

|---|---|---|---|

| January | 0.568 | 2.950 | 5.450 |

| February | 0.548 | 3.570 | 7.030 |

| March | 0.549 | 4.550 | 12.040 |

| April | 0.588 | 5.880 | 17.700 |

| May | 0.630 | 6.990 | 23.630 |

| June | 0.647 | 7.460 | 27.430 |

| July | 0.585 | 6.600 | 26.430 |

| August | 0.573 | 5.940 | 24.460 |

| September | 0.644 | 5.700 | 22.030 |

| October | 0.696 | 4.890 | 17.270 |

| November | 0.674 | 3.690 | 12.150 |

| December | 0.583 | 2.790 | 7.840 |

| Average | 0.607 | 5.08 | 16.96 |

| Components | Name | Size | Unit |

|---|---|---|---|

| PV | Generic flat-plate PV module | 19.8 | kW |

| Storage | LGChem RESU10 [9.8 kWh] | 1 | Strings |

| System converter | System converter | 10.0 | kW |

| Component | Name | Size | Unit |

|---|---|---|---|

| PV | Generic flat-plate PV module | 20.0 | kW |

| System converter | System Converter | 10.0 | kW |

| Name | Capital (USD) | Operating (USD) | Replacement (USD) | Salvage (USD) | Total (USD) |

|---|---|---|---|---|---|

| Generic flat-plate PV LCGhem RESU 10 [9.8 kWh] | 6916 40,000 | 25.89 64.64 | 0.00 35,338 | 0.00 −4791 | 7026 70,611 |

| Sample Tariff | 0.00 | 69,095 | 0.00 | 0.00 | 69,633 |

| System converter | 3500 | 12.93 | 1485 | 279.48 | 4718 |

| System | 50,416 | 69,198 | 36,822 | 279.48 | 151,366 |

| Name | Capital (USD) | Operating (USD) | Replacement (USD) | Salvage (USD) | Total (USD) |

|---|---|---|---|---|---|

| Generic flat-plate PV | 7000 | 25.86 | 0.00 | 0.00 | 7026 |

| Simple Tariff | 0.00 | 69,633 | 0.00 | 0.00 | 69,633 |

| System Converter | 3500 | 12.93 | 1485 | −279.48 | 4718 |

| System | 10,500 | 69,672 | 1485 | −279.48 | 81,378 |

| Name | Capital (USD) | Operating (USD) | Replacement (USD) | Savage (USD) | Total (USD) |

|---|---|---|---|---|---|

| Generic flat-plate PV | 534.98 | 1.98 | 0.00 | 0.00 | 536.96 |

| LCGhem RESU 10 [9.8 kWh] | 3094 | 5.00 | 2734 | −370.62 | 5462 |

| System converter | 270.74 | 1.0 | 114.87 | −21.62 | 364.99 |

| Simple tariff | 0.00 | 5345 | 0.00 | 0.00 | 5345 |

| System | 3900 | 5353 | 2848 | −392.24 | 11,709 |

| Name | Capital (USD) | Operating (USD) | Replacement (USD) | Salvage (USD) | Total (USD) |

|---|---|---|---|---|---|

| Generic flat-plate PV | 541.48 | 2.00 | 0.00 | 0.00 | 543.48 |

| Sample tariff | 0.00 | 5.386 | 0.00 | 0.00 | 5386 |

| System Converter | 270.74 | 1.00 | 114.87 | −21.62 | 364.99 |

| System | 812.22 | 5389 | 114.87 | −1.62 | 6295 |

| Component | Production (kWh) | Percent |

|---|---|---|

| Generic flat-plate PV | 33,448 | 49.8 |

| Grid purchases | 33,690 | 50.2 |

| Total | 67,139 | 100 |

| Component | Production (kWh) | Percent |

|---|---|---|

| Generic flat-plate PV | 33,855 | 47.1 |

| Grid purchases | 33,055 | 52.9 |

| Total | 71,910 | 100 |

| Consumption | Consumption (kWh) | Percent |

|---|---|---|

| AC primary load | 37,960 | 62.0 |

| Grid purchases | 12,311 | 20.1 |

| EV charger served | 10,950 | 17.9 |

| Total | 61,221 | 100 |

| Component | Consumption (kWh) | Percent |

|---|---|---|

| AC primary load | 37,960 | 58.0 |

| Grid sales | 16,510 | 25.2 |

| EV charger served | 10,950 | 16.2 |

| Total | 65,420 | 100 |

| Charging Station | Session per Year | Annual Energy Saved (kWh) | Energy per Session | Session per Day |

|---|---|---|---|---|

| Blank deferrable EV charger | 3650 | 10,950 | 3.00 | 10.0 |

| Costs | Base System | Predicted System |

|---|---|---|

| CAPEX | USD 0.00 | USD 50,416 |

| OPEX | USD 12,228 | USD 7809 |

| Annual energy change | USD 12,228 | USD 5345 |

| LCDE iper | USD 0.250 | USD 0.191 |

| CO2 emailed | 30,911 kg/yr | 21,292 kg/yr |

| Net present cost | USD 158,071 | USD 151,366 |

| January | February | March | April | May | June | July | August | September | October | November | December | Annual | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Energy charge (USD) | 1044 | 919.42 | 1051 | 1014 | 1109 | 1014 | 1031 | 1061 | 1007 | 1032 | 992.42 | 1042 | 12,227 |

| Energy purchased (USD) | 4177 | 3678 | 4203 | 4055 | 4708 | 4056 | 4124 | 4244 | 4029 | 4129 | 3970 | 4168 | USD 49,541 |

| January | February | March | April | May | June | July | August | September | October | November | December | Annual | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Energy charge (USD) | 574.26 | 472.44 | 508.12 | 416.11 | 363.15 | 375.13 | 405.82 | 400.43 | 471.67 | 373.20 | 438.32 | 559.72 | 5345 |

| Energy purchased (kWh) | 3055 | 2613 | 2955 | 2756 | 2697 | 2708 | 2736 | 2918 | 2739 | 2728 | 2778 | 3008 | 33,690 |

| Energy sold (kWh) | 758 | 724 | 923 | 1091 | 1244 | 1221 | 1113 | 1031 | 1137 | 1286 | 1042 | 769 | 12,311 |

| Base System | Processed System | |

|---|---|---|

| Net present Cost | USD 158,071 | USD 51,378 |

| CAPEX | USD 0.00 | USD 10,500 |

| OPEX | USD 12,228 | USD 5483 |

| Annual energy charge | USD 12,228 | USD 5386 |

| LCOE per kWh | USD 0.250 | USD 0.0962 |

| CO2 emitted | 30,911 kg/yr | 24,051 kg/yr |

| January | February | March | April | May | June | July | August | September | October | November | December | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Energy Charge (USD) | 1044 | 919,42 | 1051 | 1019 | 1014 | 1031 | 1061 | 1007 | $1031 | 992.44 | 1042 | 12,222 |

| Energy purchased (kWh) | 4177 | 3678 | 4203 | 4055 | 4078 | 4056 | 4124 | 4244 | 4029 | 4129 | 3970 | 4168 |

| Total (USD) | 1044 | 919.42 | 1051 | 1014 | 1019 | 11,014 | 1031 | 1061 | 1007 | 1032 | 992.44 | 1042 |

| January | February | March | April | May | June | July | August | September | October | November | December | Annual | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Energy Charge (USD) | 579.88 | 477.54 | 511.49 | 418.28 | 363.89 | 369.89 | 405.47 | 471.01 | 405.63 | 382.79 | 437.18 | 562.90 | 5386 |

| Energy Purchased (kWh) | 3372 | 2613 | 2955 | 2756 | 2697 | 2707 | 2736 | 2918 | 2739 | 2778 | 2728 | 3008 | 33,600 |

| Energy Sold (kWh) | 1053 | 1010 | 1277 | 1456 | 1628 | 1600 | 1507 | 1404 | 1458 | 1638 | 1354 | 1095 | 16,510 |

| Months | Energy Purchased (kWh) | Energy Sold (kWh) | Net Energy Purchased (kWh) | Peak Load (kW) | Energy Charge (USD) | Total (USD) |

|---|---|---|---|---|---|---|

| January | 3372 | 1053 | 2320 | 13.9 | 579.88 | 579.88 |

| February | 2921 | 1010 | 1910 | 13.7 | 477.54 | 477.54 |

| March | 3323 | 1277 | 2046 | 14.6 | 511.49 | 511.49 |

| April | 3129 | 1456 | 1673 | 13.6 | 418.28 | 418.28 |

| May | 3083 | 1628 | 1454 | 12.8 | 363.58 | 363.58 |

| June | 3080 | 1600 | 1480 | 12.9 | 363.89 | 369.89 |

| July | 3128 | 1507 | 1622 | 12.9 | 405.47 | 405.47 |

| August | 3391 | 1404 | 1887 | 12.8 | 471.81 | 471.81 |

| September | 3110 | 1488 | 1623 | 12.3 | 405.63 | 405.63 |

| October | 3170 | 1638 | 1531 | 12.2 | 382.79 | 471.81 |

| November | 3103 | 1354 | 1749 | 13.5 | 437.18 | 405.63 |

| December | 3346 | 1095 | 2252 | 13.2 | 562.90 | 382.79 |

| Annual | 38,055 | 16,510 | 21,546 | 14.6 | 5386 | 562.90 |

| Months | Energy Purchased (kWh) | Energy Sold (kWh) | Net Energy Purchased (kWh) | Peak Load (kW) | Energy Charge (USD) | Total (USD) |

|---|---|---|---|---|---|---|

| January | 2055 | 758 | 2297 | 13.9 | 574.20 | 574.26 |

| February | 2613 | 724 | 1890 | 13.7 | 472.44 | 472.44 |

| March | 2955 | 923 | 2032 | 14.6 | 508.12 | 508.12 |

| April | 2756 | 1091 | 1664 | 12.6 | 416.11 | 416.11 |

| May | 2697 | 1244 | 1453 | 12.8 | 363.15 | 363.15 |

| June | 2707 | 1221 | 1486 | 12.9 | 371.53 | 371.53 |

| July | 2736 | 1113 | 1623 | 12.9 | 405.82 | 405.82 |

| August | 2018 | 1031 | 1887 | 12.8 | 471.67 | 471.67 |

| September | 2739 | 1137 | 1602 | 12.3 | 400.43 | 400.43 |

| October | 2778 | 1286 | 1493 | 12.2 | 373.20 | 373.20 |

| November | 2728 | 1014 | 1713 | 13.5 | 428.32 | 428.32 |

| December | 2008 | 769 | 2239 | 13.2 | 559.72 | 559.72 |

| Annual | 33,690 | 12,311 | 21,379 | 14.6 | 5345 | 5345 |

| Quantity | Value | Units |

|---|---|---|

| Carbon Dioxide | 24,051 | kg/yr |

| Sulfur dioxide | 104 | kg/yr |

| Nitrogen oxides | 51 | kg/yr |

| Reference | Existing Work | Proposed Work |

|---|---|---|

| [35] | PV system for hydrogen production and EV charging in India | PV system for EV charging with different storage backup |

| [36] | Techno-economic analysis for EV charging station in China | Techno-economic and environmental impact of EV charging stations in Pakistan |

| [37] | Technical and environmental impact of EVs charging stations with different solar irradiance | Impact study with the same irradiance condition |

| [38] | Hydrogen production by means of solar, wind, and storage based systems | System discusses the power production instead of hydrogen production |

| [39] | Energy management of the distributed charging stations | Energy management based on production |

| [40] | Clean energy production in Iran | Energy production in Pakistan utilizing clean energy resources |

| [41] | Road lightening system based on PV system | Charging station based on PV system |

| [42] | Technical effects of EV charging station | Technical and economical effects |

| [43] | Feasibility study for the countries which are rich in fossil fuel | Feasibility study for a country that lacks fossil fuel resources |

| [44] | Effect of EV charging in China. | EV-based charging stations in Pakistan. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shafiq, A.; Iqbal, S.; Habib, S.; ur Rehman, A.; ur Rehman, A.; Selim, A.; Ahmed, E.M.; Kamel, S. Solar PV-Based Electric Vehicle Charging Station for Security Bikes: A Techno-Economic and Environmental Analysis. Sustainability 2022, 14, 13767. https://doi.org/10.3390/su142113767

Shafiq A, Iqbal S, Habib S, ur Rehman A, ur Rehman A, Selim A, Ahmed EM, Kamel S. Solar PV-Based Electric Vehicle Charging Station for Security Bikes: A Techno-Economic and Environmental Analysis. Sustainability. 2022; 14(21):13767. https://doi.org/10.3390/su142113767

Chicago/Turabian StyleShafiq, Aqib, Sheeraz Iqbal, Salman Habib, Atiq ur Rehman, Anis ur Rehman, Ali Selim, Emad M. Ahmed, and Salah Kamel. 2022. "Solar PV-Based Electric Vehicle Charging Station for Security Bikes: A Techno-Economic and Environmental Analysis" Sustainability 14, no. 21: 13767. https://doi.org/10.3390/su142113767

APA StyleShafiq, A., Iqbal, S., Habib, S., ur Rehman, A., ur Rehman, A., Selim, A., Ahmed, E. M., & Kamel, S. (2022). Solar PV-Based Electric Vehicle Charging Station for Security Bikes: A Techno-Economic and Environmental Analysis. Sustainability, 14(21), 13767. https://doi.org/10.3390/su142113767