Study on Initial Fracture Characteristics of the Main Roof in Fully Mechanized Caving Mining of Inclined Coalbed

Abstract

:1. Introduction

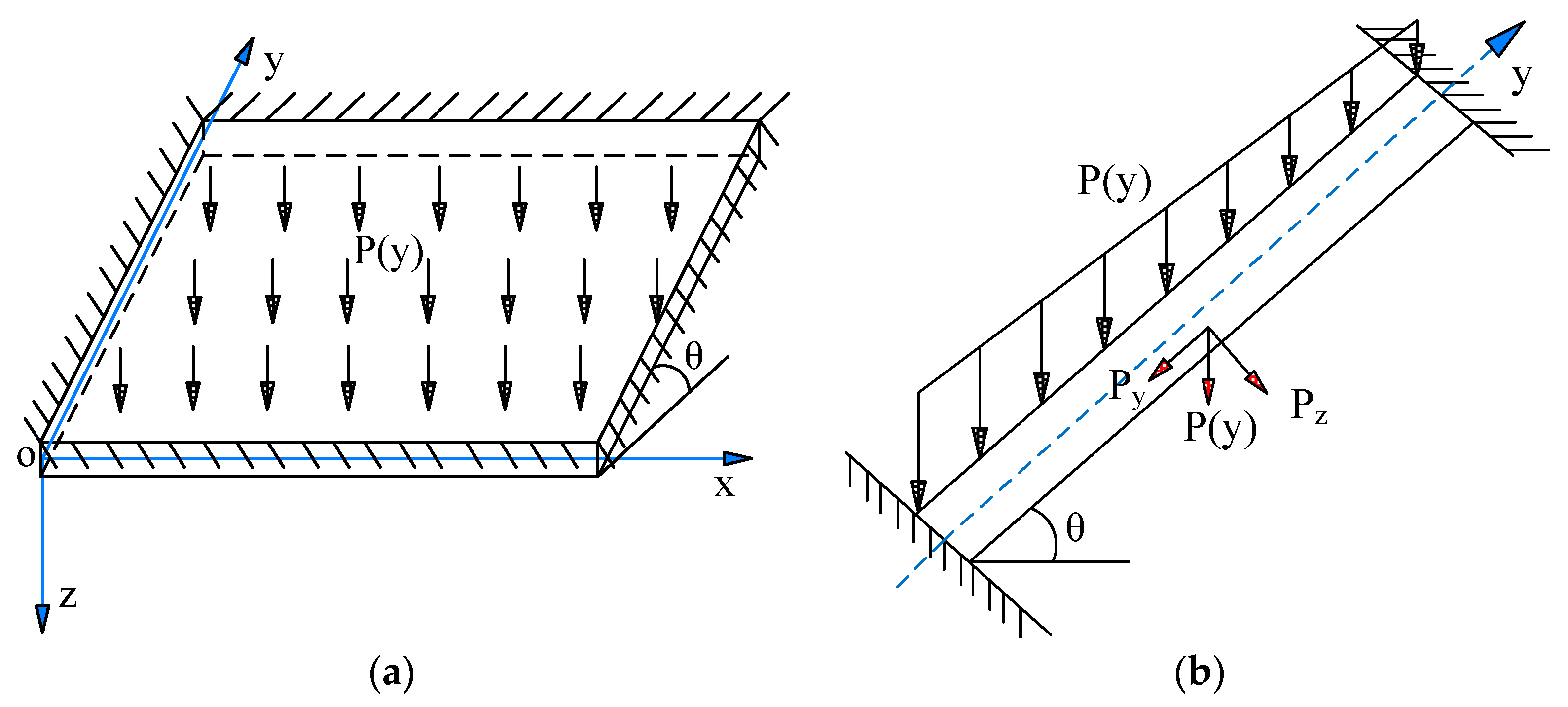

2. Mechanical Analysis of Primary Fracture in Inclined Coalbed Mining

2.1. Mechanical Model of Primary Top Failure

2.2. Main Roof Stress Equation of State

3. The Evolution Law of the Primary Failure of the Main Roof of the Inclined Coalbed

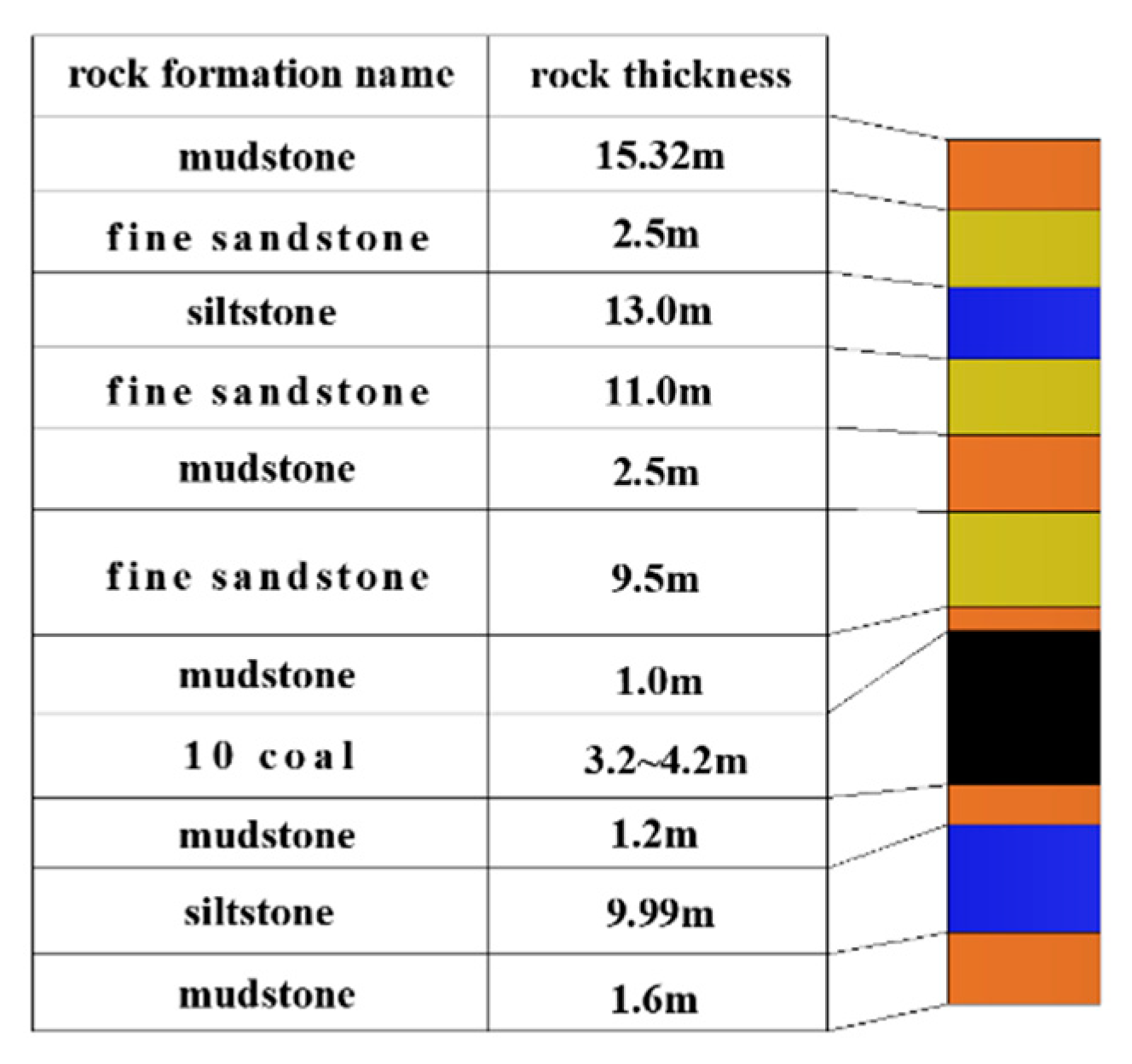

3.1. Engineering Background

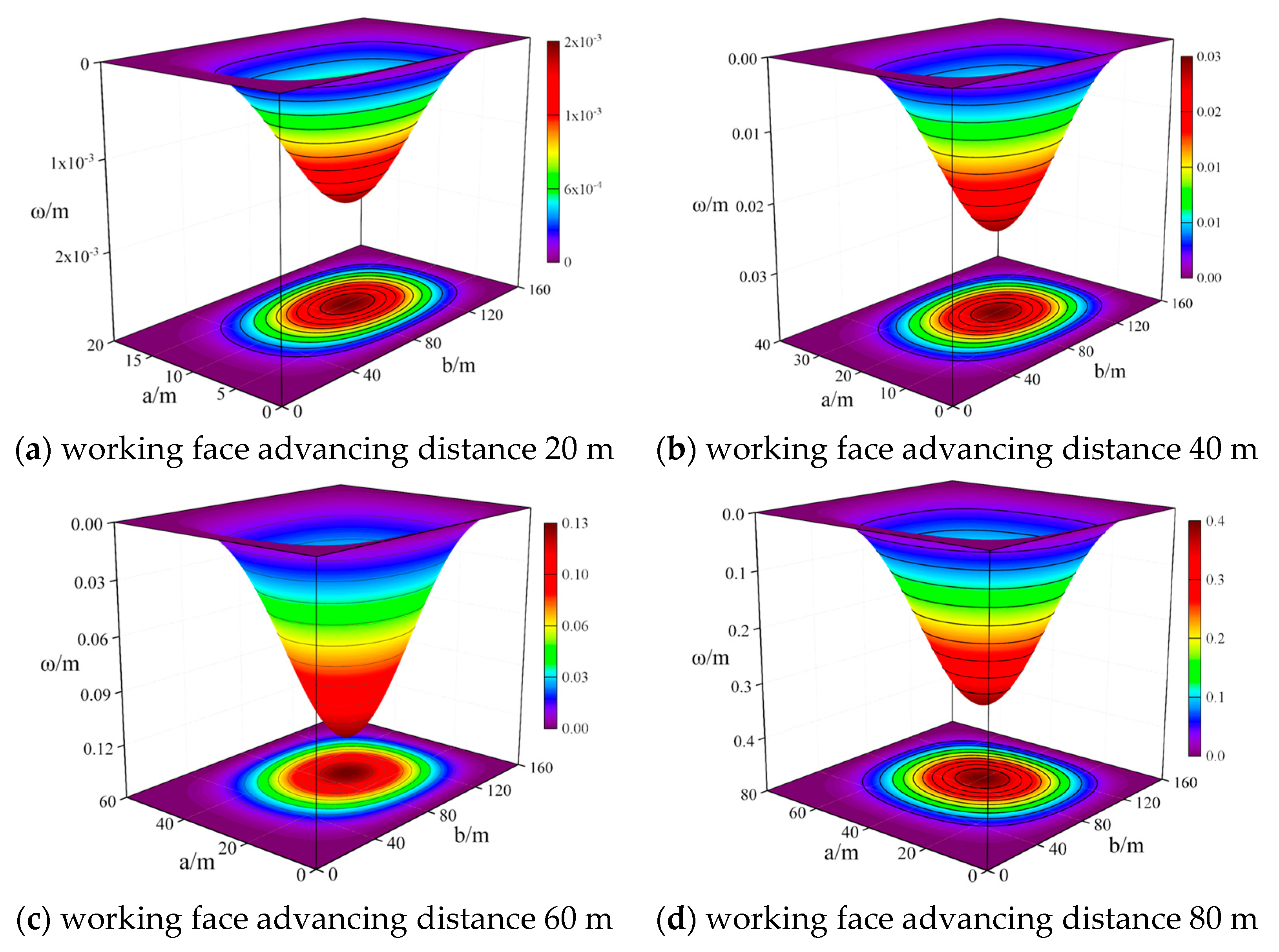

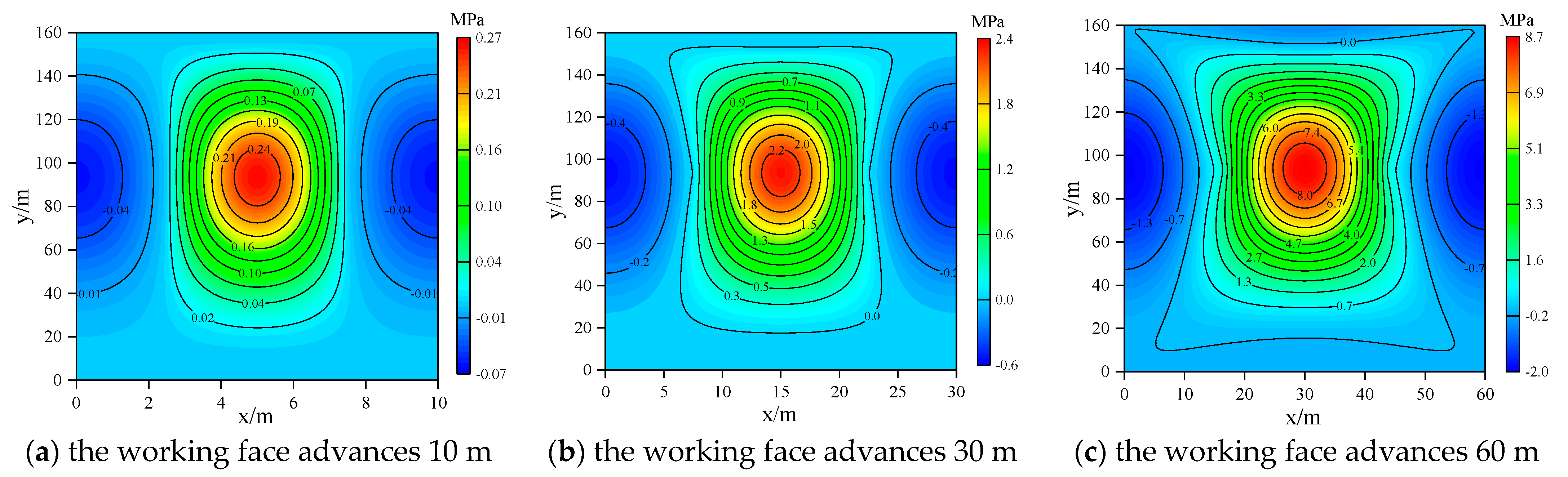

3.2. Fundamental Top First Break Deflection Parameter Analysis

3.3. Analysis of Stress Distribution Parameters of Primary Top Breaking

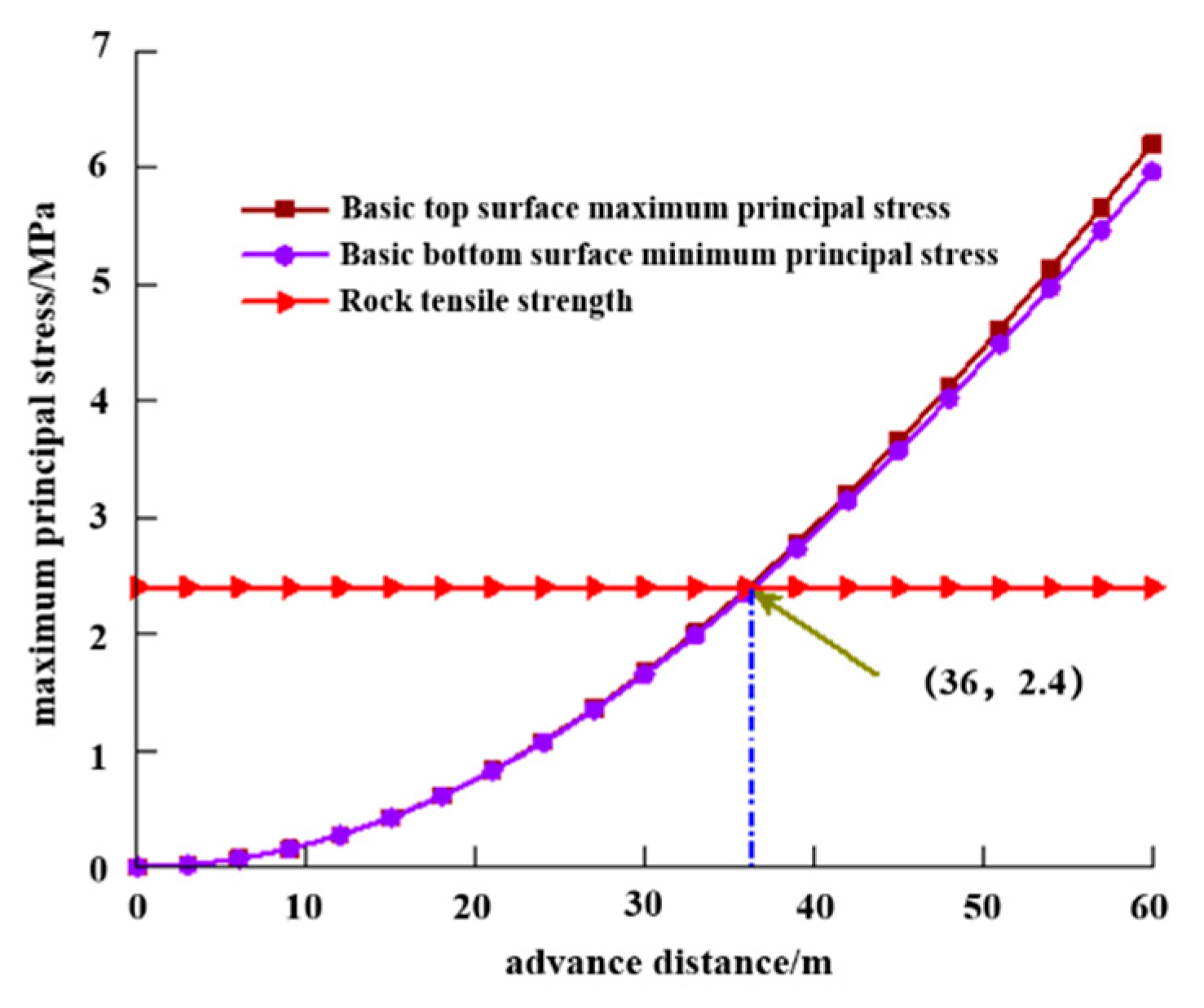

3.4. Main Roof First Break Step Distance Analysis

4. Simulation Analysis of Stress Variation in High Dip Coal Seam Working Face

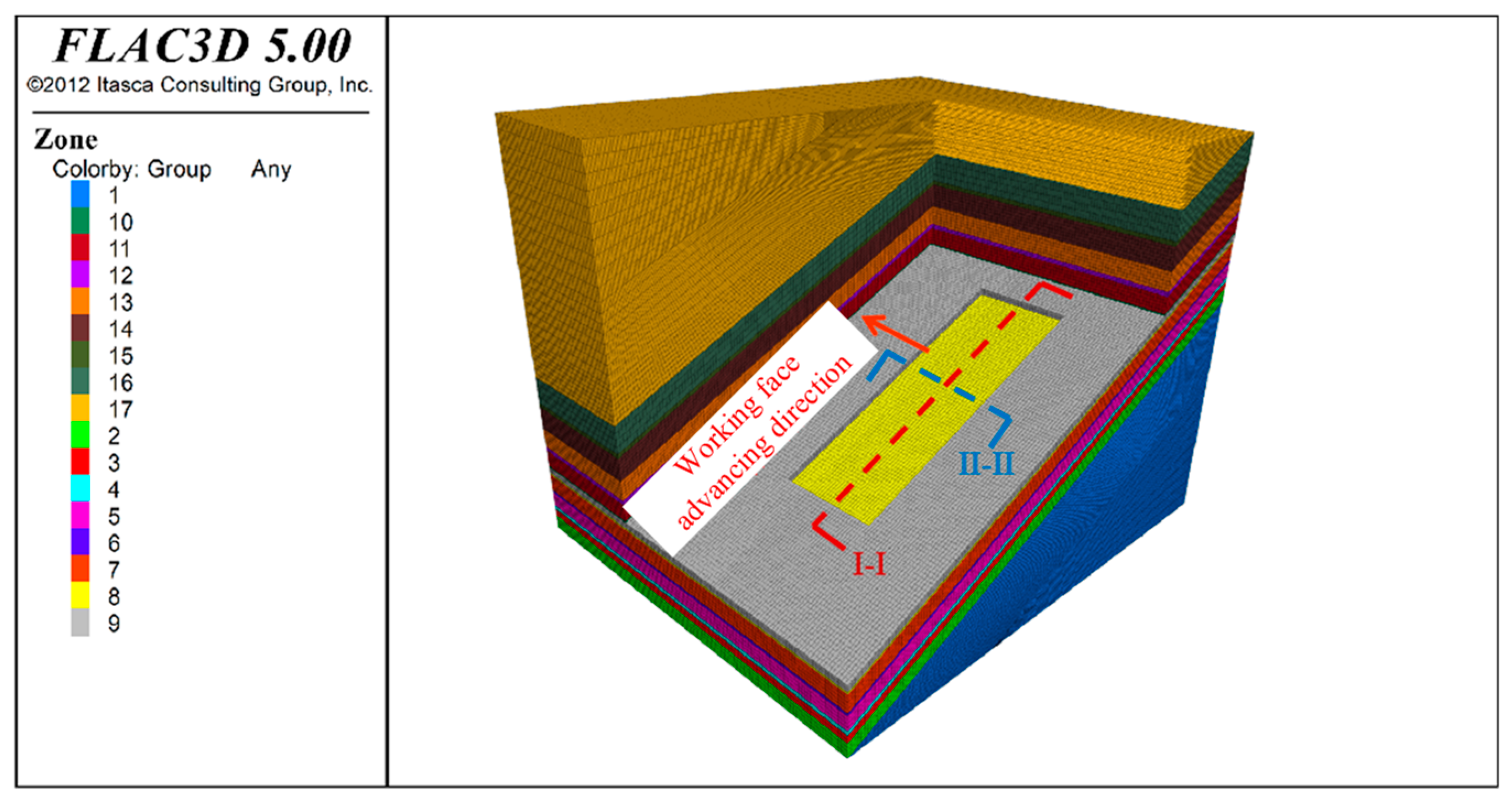

4.1. Numerical Model Building

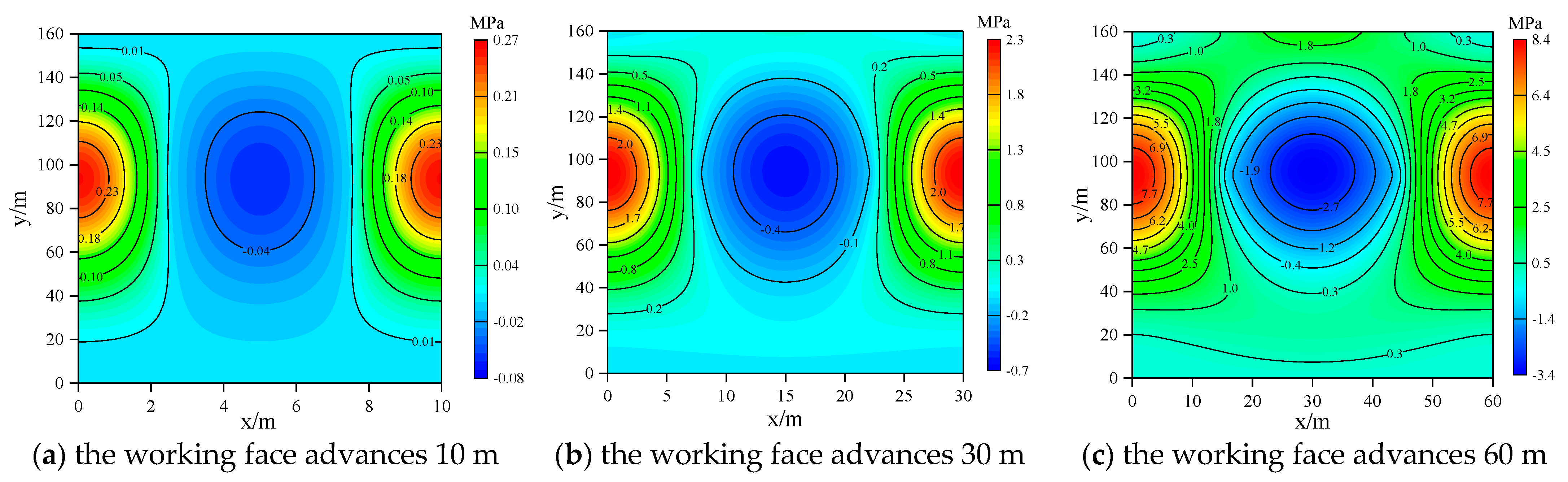

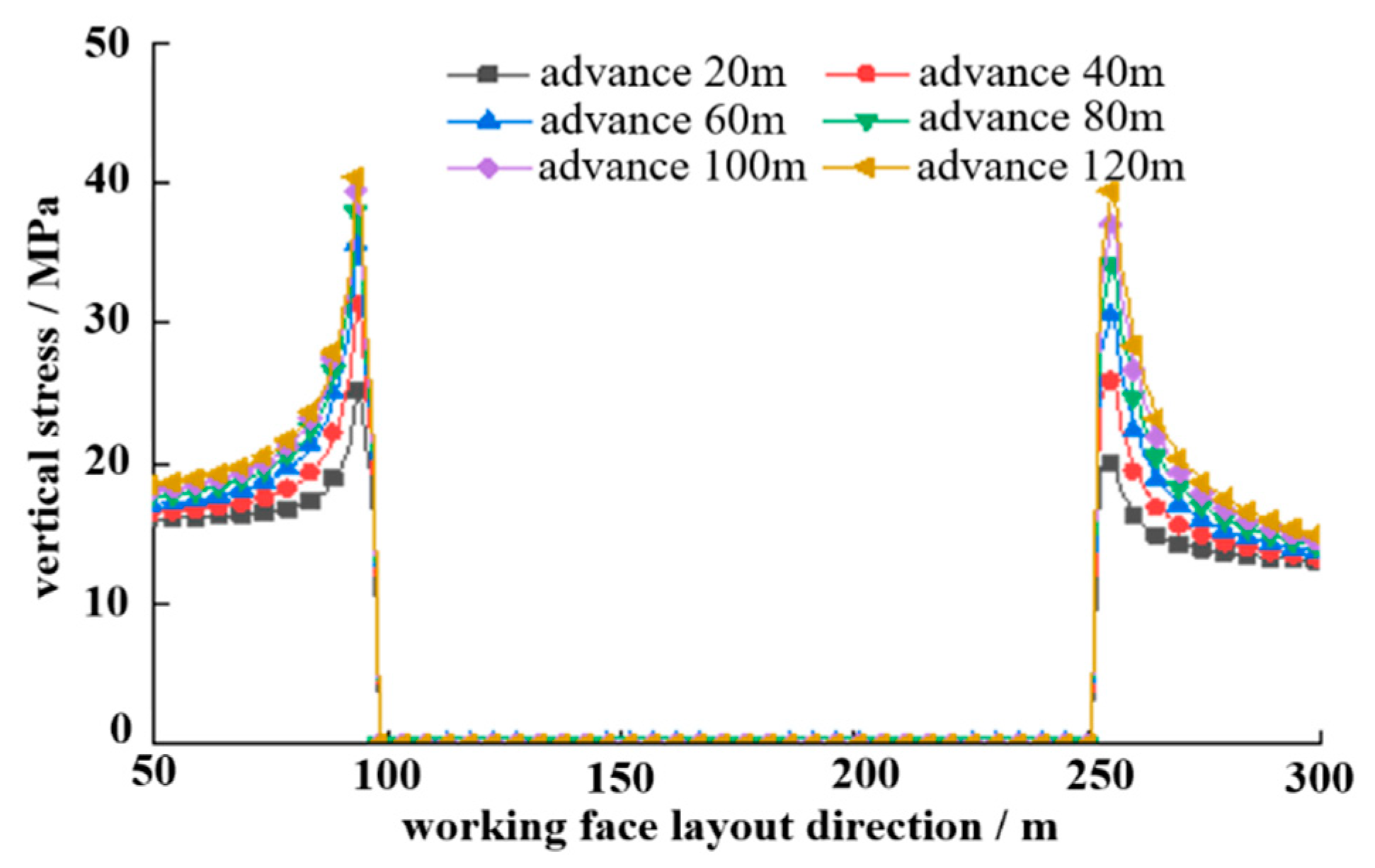

4.2. Analysis of Support Stress in Stope of Large Dip Angle Coal Seam

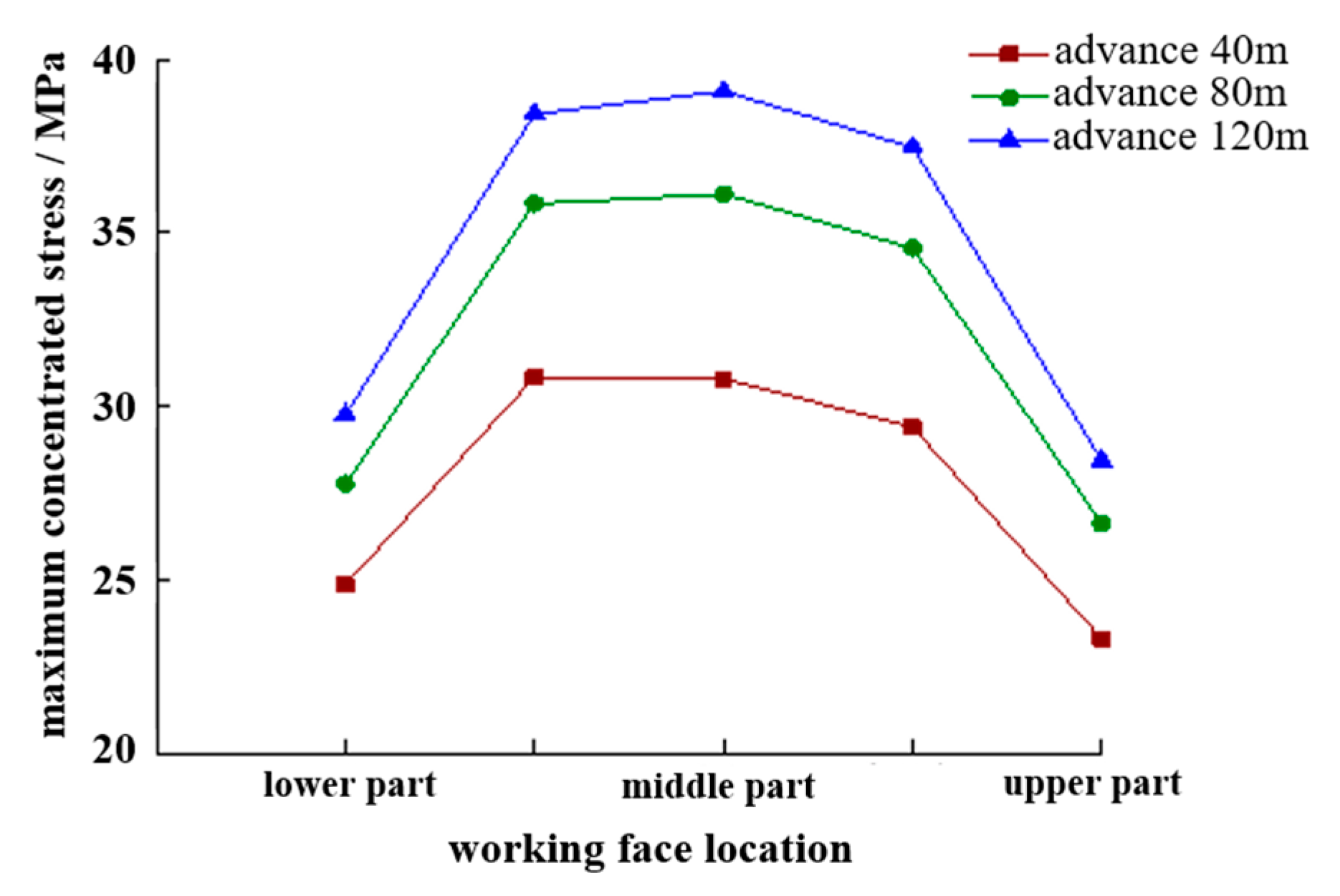

4.3. Comparative Analysis of Stress at Different Positions of Working Face Inclination

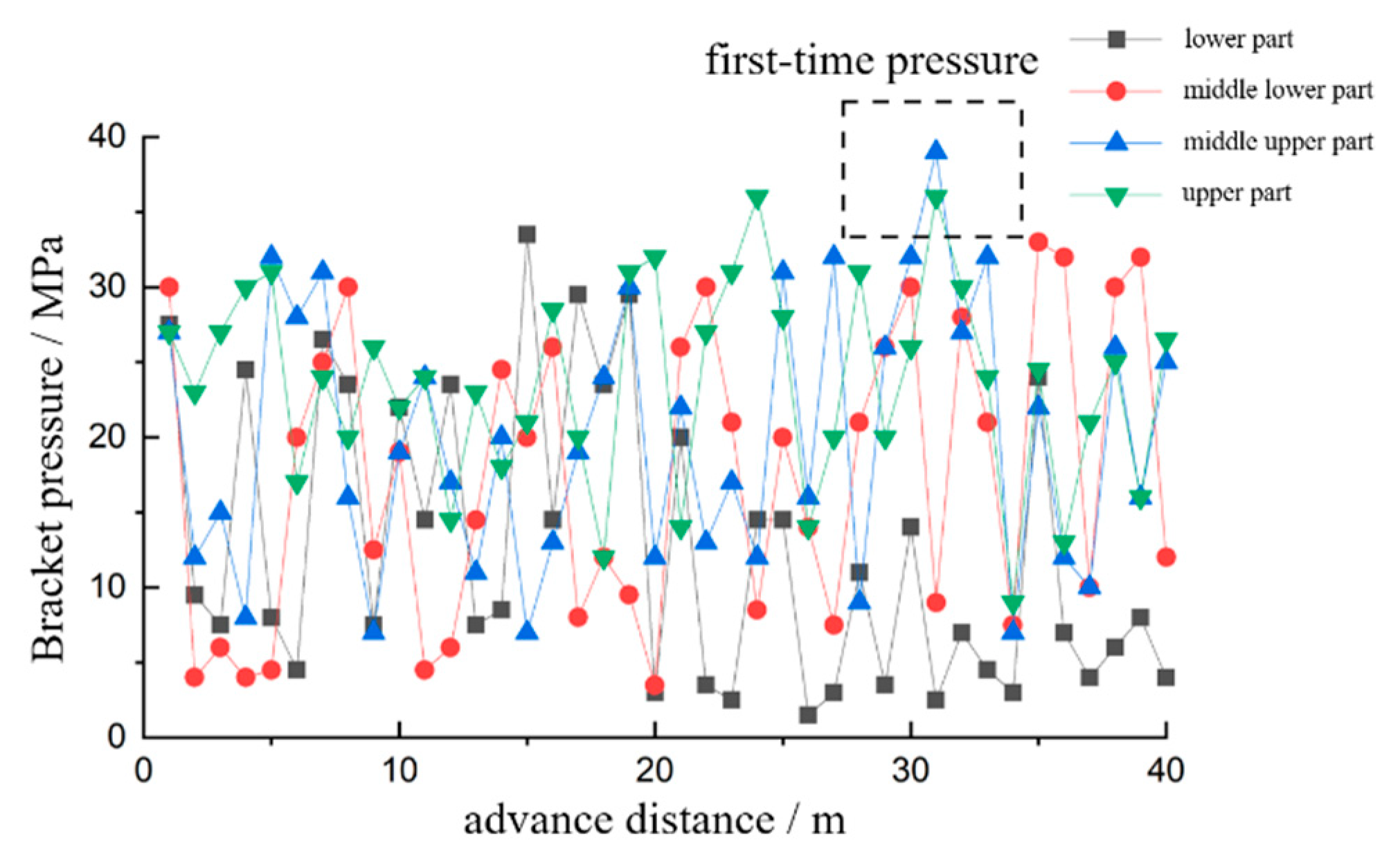

5. Analysis on the Appearance of Rock Pressure at the First Fracture of the Main Roof

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kang, X.; Yang, S.; Zhan, P.; Li, L. Simulation Study of the Roof Fracture Pattern of a Horizontal Sublevel Caving in a Steeply Inclined Thick Coal Seam. Adv. Civ. Eng. 2020, 2020, 8370634. [Google Scholar] [CrossRef]

- Wang, H.; Qin, Y.; Wang, H.; Chen, Y.; Liu, X. Process of overburden failure in steeply inclined multi-seam mining: Insights from physical modelling. R. Soc. Open Sci. 2021, 8, 210275. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Wang, Z.; Zhang, J. Stability of roof structure and its control in steeply inclined coal seams. Int. J. Min. Sci. Technol. 2017, 27, 359–364. [Google Scholar] [CrossRef]

- Çelik, A.; Özçelik, Y. Investigation of the efficiency of longwall top coal caving method applied by forming a face in horizontal thickness of the seam in steeply inclined thick coal seams by using a physical model. Int. J. Rock Mech. Min. Sci. 2021, 148, 104917. [Google Scholar] [CrossRef]

- Wang, H.; Wu, Y.; Jiao, J.; Cao, P. Stability Mechanism and Control Technology for Fully Mechanized Caving Mining of Steeply Inclined Extra-Thick Seams with Variable Angles. Min. Metall. Explor. 2021, 38, 1047–1057. [Google Scholar]

- Zhang, H.; Hu, G.; Zhao, G. Research on the Movement Law of Roof Structure in Large-Inclined Coal Seam Working Face: A Case Study in Liu.Pan.Shui. Mining Area. Shock Vib. 2022, 2022, 6328851. [Google Scholar] [CrossRef]

- Wang, S.; Dou, L.; Mu, Z.; Cao, J.; Li, X. Study on Roof Breakage-Induced Roadway Coal Burst in an Extrathick Steeply Inclined Coal Seam. Shock. Vib. 2019, 2019, 2969483. [Google Scholar] [CrossRef] [Green Version]

- Wu, Y.; Liu, W.; Xie, P.; Tian, S. Stress Evolution and Roof Breaking Characteristics of Surrounding Rock in Oblique Longwall Mining Area of Steeply Dipping Seam. J. Coal 2020, 51, 222–227. [Google Scholar]

- Wu, Y.; Wang, H.; Xie, P. Analysis of surrounding rock macro stress arch-shell of longwall face in steeply dipping seam mining. J. Coal 2012, 37, 559–564. [Google Scholar]

- Wang, J.; Zhang, J.; Gao, X.; Wen, J.D.; Gu, Y.D. Fracture mode and evolution of main roof stratum above longwall fully mechanized top coal caving in steeply inclined thick coal seam (I)—Initial fracture. J. Coal Sci. 2015, 40, 1353–1360. [Google Scholar]

- Wang, J.; Zhang, J.; Gao, X.; Wen, J.D.; Gu, Y.D. Fracture mode and evolution of main roof stratum above fully mechanized top coal caving longwall coalface in steeply inclined thick coal seam (II): Periodic fracture. J. Coal 2015, 40, 1737–1745. [Google Scholar]

- Zhang, Y.D.; Cheng, J.Y.; Wang, X.X.; Feng, Z.J.; Ji, M. Thin Plate Model Analysis on Roof Break of Up-Dip or Down-Dip Mining Stope. Chin. J. Min. Saf. Eng. 2010, 27, 487–493. [Google Scholar]

- Sun, J.; Liu, X.; Ren, T. Overburden stability of an inclined backfill stope in the context of the nonlinear elastic mechanical properties of the backfill body. Environ. Earth Sci. 2019, 78, 719. [Google Scholar] [CrossRef]

- Sun, J.; Wang, L.; Zhao, G. Failure Characteristics and Confined Permeability of an Inclined Coal Seam Floor in Fluid-Solid Coupling. Adv. Civ. Eng. 2018, 2018, 2356390. [Google Scholar] [CrossRef]

- Jian, S.; Yang, H. Mechanical properties of fixed rectangular thin plates under uniform distribution and hydrostatic pressure. Appl. Mech. 2015, 32, 908–914; 1096–1097. [Google Scholar]

- Xie, P.; Tian, S.; Duan, J. Experimental study on the movement law of roof in pitching oblique mining area of steeply dipping seam. J. Coal 2019, 44, 2974–2982. [Google Scholar]

- Yang, H.; Cui, J.; Liu, H. Quantitative analysis of roof migration of top coal in light caving face of large dip angle coal seam. Coal Eng. 2003, 4, 41–42. [Google Scholar]

- Chai, J.; Du, W.G.; Zhang, D.D.; Lei, W. Study on roof activity law in steeply inclined seams based on BOTDA sensing technology. Chin. J. Rock Mech. Eng. 2019, 38, 1809–1818. [Google Scholar]

- Zhang, Y.; Wang, K. Roof Broken Features at Fully Mechanized Caving Mining Stope in Steep Inclined and Specially Thick Seam. Coal Mine Saf. 2014, 7, 187–191. [Google Scholar]

- Wang, S.; Wang, J.; Dai, Y. Discrete Element Analysis on Movement Law and Failure Mechanism of Top Coal in Fully-mechanized Caving Mining of Thick Coal Seam with Large Dip Angle. J. Univ. Sci. Technol. Beijing 2005, 1, 5–8. [Google Scholar]

- Yang, Z.; Zhang, J.; Lai, X.; Lv, Z. Localized character of strata movement for complicated super-thick water-rich coal seam with large mining height. J. Coal 2010, 35, 1868–1872. [Google Scholar]

- Cheng, W.; Li, J. Stope wall rock activity law of long-wall full-mechanized caving mining on strike of steep dipping seam. China Min. Ind. 2009, 5, 56–58. [Google Scholar]

- Skrzypkowski, K.; Korzeniowski, W.; Duc, T.N. Choice of powered roof support FAZOS-15/31-POz for Vang Danh hard coal mine. Inżynieria Miner. 2019, 21, 175–182. [Google Scholar] [CrossRef]

- Łukasz, H.; Dariusz, J.; Krzyszto, S. Powered Roof Support—Rock Strata Interactions on the Example of an Automated Coal Plough System. Stud. Geotech. Mech. 2018, 40, 46–55. [Google Scholar] [CrossRef]

- Wu, G.; Chen, W.; Jia, S.; Tan, X.; Zheng, P.; Tian, H.; Rong, C. Deformation characteristics of a roadway in steeply inclined formations and its improved support. Int. J. Rock Mech. Min. Sci. 2020, 130, 104324. [Google Scholar] [CrossRef]

| Rock Stratum | Shear Elasticity/GPa | Bulk Modulus/GPa | Cohesion/GPa | Tensile Strength/MPa | Density/kg/m3 | Frictional Angle/° |

|---|---|---|---|---|---|---|

| aleuvite | 2.4 | 4.5 | 3.2 | 2.4 | 2500 | 40 |

| argillite | 1.6 | 3 | 2.2 | 1.2 | 2500 | 30 |

| packsand | 9 | 5.8 | 4.2 | 2.8 | 2800 | 34 |

| 10 coal | 1.2 | 2 | 1.8 | 0.9 | 1600 | 23 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, H.; Xue, Y.; Li, Y.; Yin, J. Study on Initial Fracture Characteristics of the Main Roof in Fully Mechanized Caving Mining of Inclined Coalbed. Sustainability 2022, 14, 13782. https://doi.org/10.3390/su142113782

Zhang H, Xue Y, Li Y, Yin J. Study on Initial Fracture Characteristics of the Main Roof in Fully Mechanized Caving Mining of Inclined Coalbed. Sustainability. 2022; 14(21):13782. https://doi.org/10.3390/su142113782

Chicago/Turabian StyleZhang, Hualei, Yonglin Xue, Yangao Li, and Jiadi Yin. 2022. "Study on Initial Fracture Characteristics of the Main Roof in Fully Mechanized Caving Mining of Inclined Coalbed" Sustainability 14, no. 21: 13782. https://doi.org/10.3390/su142113782