Abstract

The main objective of this study is to investigate the effect of granite waste powder on the behavior of compacted clay soil in both field and laboratory environments. Samples were collected from clay soil exposed at Karak, Khyber Pakhtunkhwa, Pakistan. The sampled soils contain kaolinite, illite, and montmorillonites. The samples were mixed with various quantities, i.e., 10%, 20%, 30%, and 40% by weight of granite waste powder collected from various stone industries in district Mansehra, Khyber Pakhtunkhwa, Pakistan. They were then subjected to a variety of geotechnical testing in both the laboratory and the field, following the standard ASTM procedures. The results show that mixing with granite-cutting waste enhances the quality of the soil in both the field and laboratory settings by increasing its bearing capacity (BC), dry density (DD), California-bearing ratio (CBR), unconfined compressive strength (UCS), penetration resistance, and angle of internal friction and by reducing the optimum moisture content, cohesion, porosity, void ratio, and saturation potential. The resulting improvement is mainly due to the stronger, denser, and less hydrophilic character of the constituents of the added rock powders than the raw soil. It is observed that adding 40% granite waste powder produces the best outcome. However, there is a significant difference in the magnitude of the impact on soil quality between the laboratory and field testing. Owing to differences in the testing environment, soil volume, and compaction effort and energy, the amount of improvement is higher in laboratory testing than in field testing.

1. Introduction

In civil engineering projects, certain soil types are suitable in their natural form for building, while others, i.e., the so-called problematic soils, are not suitable due to their complex behavior [1]. Expansive soil is one of the problematic soil types for it is sensitive to volume change on exposure to water since it swells (heaves) by absorbing water and shrinks (hogges) by losing water [2]. Expansive soils are found all over the world except the polar areas [1]. The expansive clay offers considerably less stability to foundations as compared to gravel and sand [3]. That is why geotechnical and pavement experts have long battled to remediate such soils [4]. To withstand the applied loads from overlying structures, these soils must be either removed or replaced, or else their properties improved. For the past few years, soil stabilization techniques have been used with the goal of making substandard soils capable of fulfilling the requirements for infrastructural projects. Fly ash, lime, cement [5], and a variety of stone waste powders are often used as admixtures for soil stabilization [6,7,8]. Such a technique improves durability, deformation, toughness, and other mechanical and physical properties of soil. However, the fly ash, lime, and cement admixtures are not cost-effective and have detrimental environmental consequences during manufacturing [9,10,11,12]. On the other hand, stone industrial waste material is a preferable alternative for stabilization of soil since it is a waste product and hence inexpensive [13]. The appropriate utilization of this waste material is important since its poor management produces negative impacts on the environment [7], while environmental safety is very important for any developmental project [14,15]. During dry weather, stone dust particles lift in the air, fly, and settle on plants and crops, causing a negative impact on environmental and local systems [16]. Stone dust dumped along riversides and near manufacturing plants reduces the porosity and permeability of the topsoil, causing water logging. Furthermore, fine particles induce a rise in alkalinity, thus reducing soil fertility [17], which can lead to serious health problems. Other serious environmental impacts include the loss of vegetation cover, regional topographic disturbances, soil degradation, and landscape disorder. Granitic rocks constitute one of the most famous stone types due to their extensive usage as building, decorative, and foundation material throughout the world.

The Mansehra district of the Hazara division in the Khyber Pakhtunkhwa Province, Pakistan is regarded as a hub for different types of granitic rocks, including the Mansehra granite, Hakale granite, pegmatites, and leucogranite [18,19]. The main Mansehra granite, which is whitish grey, jointed, and assumes a rounded appearance due to mass-exfoliation [20], is widely used in the construction industry as a building and decorative stone. The granite stone industries in the district are mostly located along riversides because the production process involves intensive water usage. River water is utilized for cooling the cutting equipment and cleaning the resulting dirt and dust. In addition, the granite cutting industries generate large volumes of waste in the form of powder or fine aggregates, larger stone pieces and cobbles, and damaged blocks or slabs. The granite industrial waste is dumped into the rivers or landfills without any pretreatment, which adversely affects the water quality and causes severe environmental and economic drawbacks. Hence, a proper utilization of the granite processing waste is imperative for avoiding the associated detrimental environmental impacts.

The current work is designed to utilize the granite industrial waste for stabilizing weak compacted clay soils. The geotechnical quality of the resulting mixtures was assessed in two ways: (1) laboratory testing and (2) field testing. Evaluation of results from most of the previously performed stabilization studies is based on testing in the laboratory only. Hence, direct application of the resulting data is limited since knowledge of the possible differences in the values of the measured parameters between laboratory and field tests is lacking. Additionally, determination of some key parameters, e.g., porosity, void ratio, degree of saturation, and bearing capacity, which is important for understanding the behavior of stabilized soil in both the laboratory and field settings, is also uncommon in the relevant published literature [7]. To fill these gaps in soil stabilization studies and properly utilize granite--cutting waste, the present work focuses on a detailed comparison between the results obtained from the laboratory testing with the actual stabilization done in the field. For this purpose, granite-cutting waste from the industries in Mansehra was mixed with soil in different proportions, and the resulting mixtures were subjected to a variety of geotechnical tests in both the laboratory and the field. The values of porosity, void ratio, and degree of saturation are also determined and discussed in the present study. This work also provides the basic methodology for how to use the admixtures for soil stabilization in the field following testing in the laboratory. The outcomes are expected to be advantageous to the civil engineering industry for cost- effective structure designing.

2. Materials and Methods

To build a strong correlation, the procedures are discussed in a systematic manner to develop a better relationship between the soil admixtures from laboratory and field soil samples.

2.1. Granite Waste Samples

Granite-cutting waste samples were obtained from several granite-stone-processing facilities in the district of Mansehra, Khyber Pakhtunkhwa, Pakistan. The gathered samples include fine aggregates, bigger (cobble size) fragments, and fractured blocks; all these are deemed trash since they can no longer be used further in the building business. Thin sections of the granite waste samples were prepared and analyzed under a polarizing microscope in the Department of Earth Sciences, COMSATS University Islamabad, Abbottabad campus, while the geotechnical parameters, e.g., water absorption, specific gravity, and unconfined compressive strength, were determined using corresponding standards provided in ASTM D6473 [21] and ASTM D7012 [22], respectively. To carry out further laboratory investigations, all the samples were crushed to finer fractions and passed through a #40 sieve.

2.2. Clay Soil

A 252.929 m2 area consisting of loose clay in Karak, Khyber Pakhtunkhwa, Pakistan was selected. To guarantee systematic data collection, four samples were collected from the grid’s corners and one from the grid’s center point. All the obtained samples were subjected to sieve analysis and hydrometer examination in the laboratory in accordance with ASTM C136 [23] and ASTM D7928 [24] standards, respectively, to ensure that all the samples have identical grain size and clay concentration and are well-mixed for use in further testing. To determine mineralogical composition, x-ray diffraction (XRD) analysis was performed on the soil samples using a Bruker D8-Advance x-ray diffractometer. The XRD results show that the soil is predominantly made up of kaolinite, illite, and montmorillonite. Finally, the Atterberg limits were determined according to ASTM D4318 [25] to classify the soil sample following the unified classification system.

2.3. Samples Preparation for Laboratory Testing

Five samples were prepared by adding granite waste powder to dry soil in four different proportions (Table 1 and Table 2). The proctor compaction test was performed on all the prepared samples in accordance with ASTM D638 [26] to ensure correct compaction and recording of the maximum dry density (MDD) and optimum moisture content (OMC). The geotechnical properties, including cohesion, angle of internal friction, specific gravity (SG), California-bearing ratios (CBR), and unconfined compressive strength (UCS) of all the compacted samples were determined by following the corresponding standards mentioned in ASTM D3080 [27], ASTM D854 [28], ASTM D1863 [29], and ASTM D2166 [30], respectively. The results of direct shear box parameters (cohesion and angle of internal friction) and MDD were further utilized to determine the allowable bearing capacities for various shallow foundations with the application of the Terzaghi equations [31] given below:

for strip footings

for square footings

for circular footings

where Qu refers to the ultimate bearing capacity, C is the cohesion, γ is the dry density of the soil (the MDD value was used), D is the depth of the footing (the depth of the test pit was used from where the soil sample was extracted), B is the width of the footing (the width of the test pit was used from where the soil sample is extracted), Nc, Nq, and Nγ are the bearing-capacity factors that were determined using Terzaghi’s published chart. For an allowable bearing capacity, Qu is divided by the factor of safety (FOS). The FOS used in this study is 3.

Table 1.

Proctor compaction and Gs data used in the three-phase relationships for determining porosity, void ratio, and degree of saturation.

Table 2.

Field density and Gs data used in the three-phase relationships for determining porosity, void ratio, and degree of saturation.

The geotechnical parameters, including porosity, void ratio, and saturation potential, were calculated following the procedure outlined in Shah et al. 2021 [7] using the three phase-derived relationships described by Budhi (2001) [32]. For a better understanding, the complete methodology is also explained here.

- Results from proctor compaction and specific gravity tests were employed in three phase-derived relationships (Table 1).

- To determine the void ratios, the following equation was used.

- 3.

- To determine Vv the derived relation is

- 4.

- To determine the solid volume (Vs), the equation is given as

- 5.

- To determine the porosity, the following equation was used.

- 6.

- To determine the degree of saturation, the following derived weight–volume relationship was utilized

2.4. In Situ Soil Sampling and Laboratory Testing

For in situ soil sampling, five test pits (1 m3 each) were dug in the site from where the soil samples were collected for laboratory testing. The granite waste powder was mixed with the excavated soil from each test pit in exactly the same percentages as used in laboratory testing (Table 1). The soil samples were then allowed to dry naturally, and OMC according to the percentage of admixture already determined in the laboratory was added to each of them. These newly formed mixes were then poured back into the pits and compacted with a compaction vibrator. The field density tests were conducted on all the pits according to ASTM D 1586 [33] to calculate the dry density of the soil. The same compaction procedure was maintained, and multiple field density tests were performed until maximum compaction was attained so that the dry density of the soil did not change any further. Undisturbed soil samples were then collected from all the pits and laboratory tests, including direct shear box, UCS, CBR, and SG, were performed on all the samples in accordance with the ASTM standards mentioned above. The standard penetration test was also conducted on all the pits to determine the infield soil-bearing capacity using Bowle’s equation [34]:

where Qa is the allowable bearing capacity in kips/ft2, N = penetration resistance, K = 1 + 0.33 (D/B), B is the width of footing (i.e., the width of the test pit), and D is depth of footing (i.e., depth of the test pit).

The results of the infield bearing capacities were then compared with the bearing capacities obtained from laboratory testing and on pit samples through direct shear box parameters. The weight–volume relationships, mentioned above, were used to determine porosity, void ratio, and degree of saturation of the pits on the field. Here, the parameters of the field density test using the core cutter method were used in calculations instead of Proctor compaction results (Table 2). In laboratory testing, for example, the value of water content was substituted with OMC, but in this case, the value of water content acquired in the field density test was used instead of OMC. Similarly, the volume of proctor mould was replaced with the volume of core cutter for measuring the total volume of soil, and the weight of dry soil in core cutter was used for determining the weight of soil solids (γs). All the other procedures are already outlined in the section on Samples Preparation for Laboratory Testing.

3. Results

The results of the field and laboratory analyses are summarized in this section. The section is separated into the following headings to simplify the findings.

3.1. Characterization

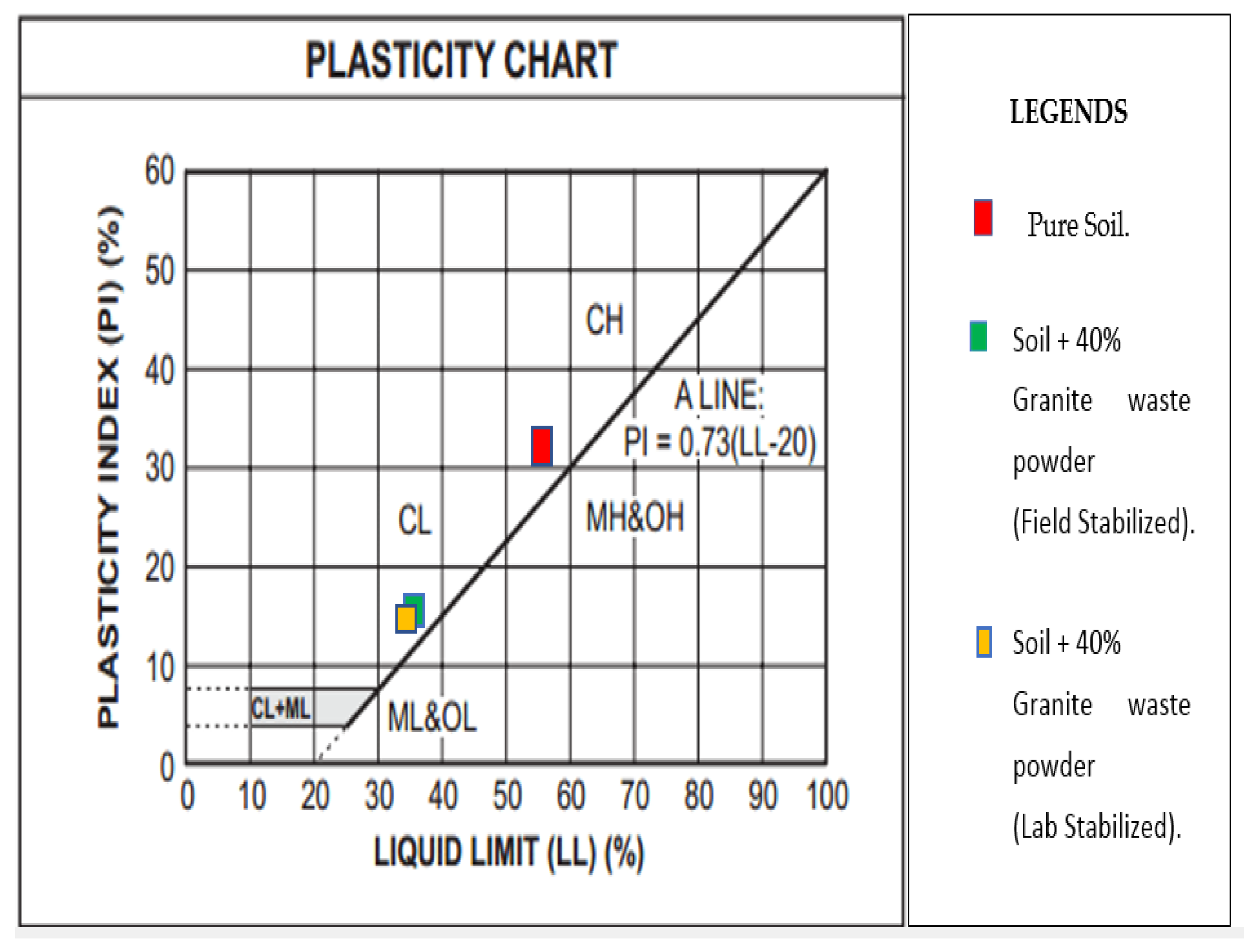

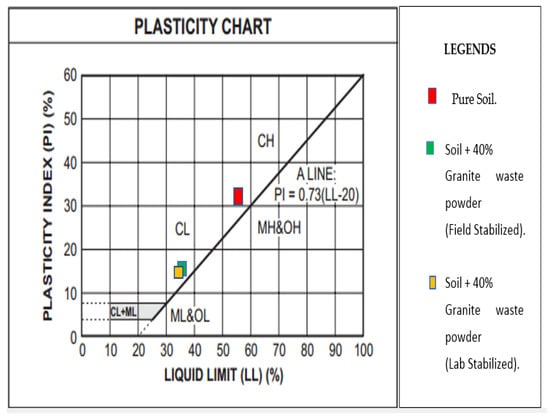

According to the unified soil classification system, which is based on the soil liquid limit and plasticity index, the soil used in the present study is classified as CH type (Figure 1).

Figure 1.

Characterization of the untreated and variously treated laboratory and field stabilized soil samples.

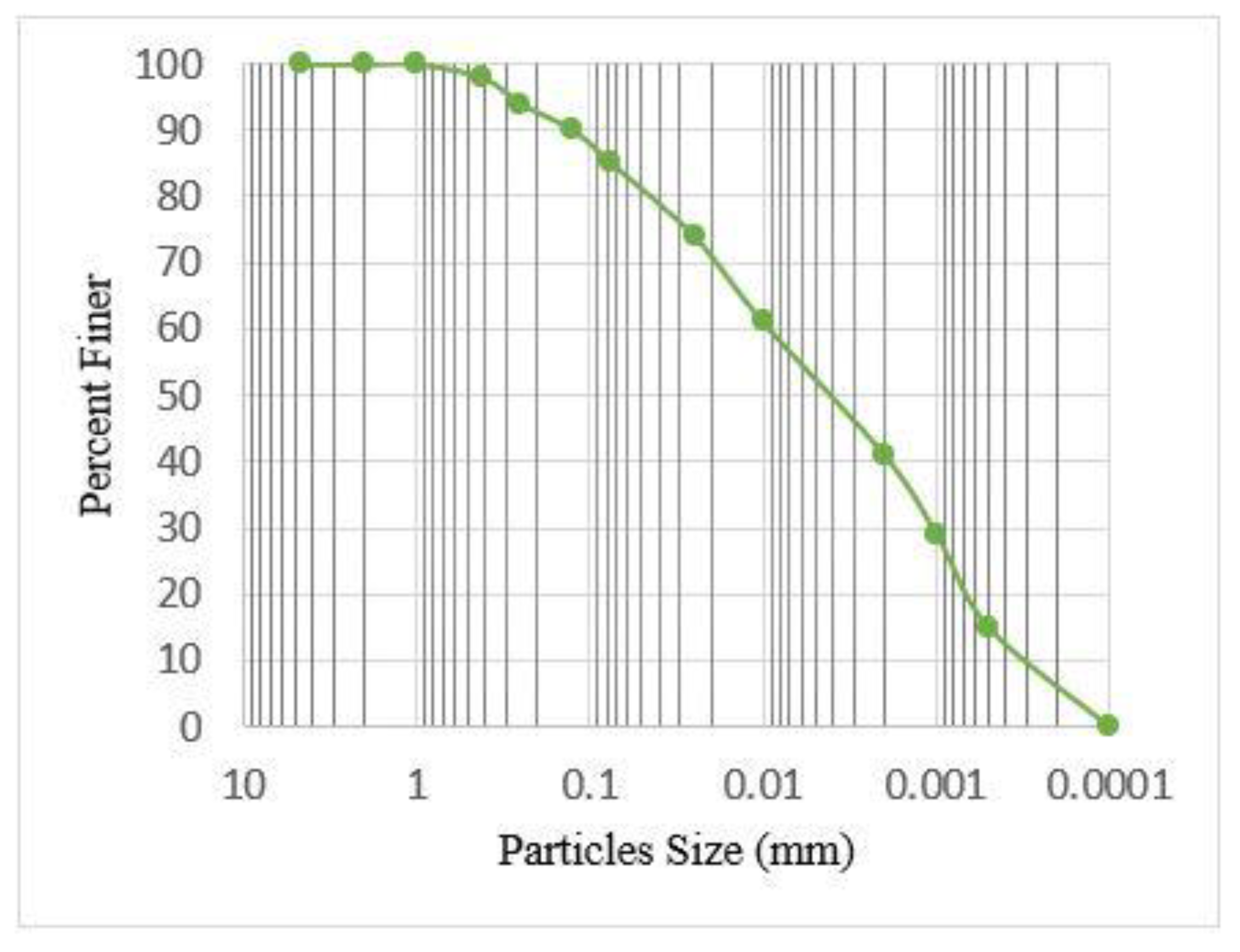

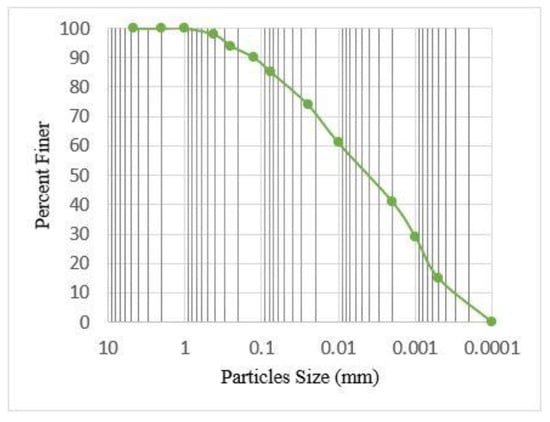

3.2. Particle Size and Mineralogical Composition

As shown in Figure 2, more than 80 percent of the soil particles are finer than the #200 (0.075 mm) sieve opening. Soils with such a grain size are considered as fine-grained soils according to the unified soil classification system. The soil particles dominantly comprise of quartz, feldspar, calcite, kaolinite, illite, and montmorillonites, according to the XRD test results.

Figure 2.

Particle size distribution in the studied soil samples.

3.3. Geotechnical and Mineralogical Parameters of the Granite-Cutting Waste

The water absorption, SG, and UCS values of the granite used in this study are 0.71%, 2.73, and 61 MPa, respectively. Mineralogically, the granite waste samples contain 45.9% quartz, 31.4% alkali feldspar, 6% plagioclase, 13% biotite, and 3.7% opaque minerals.

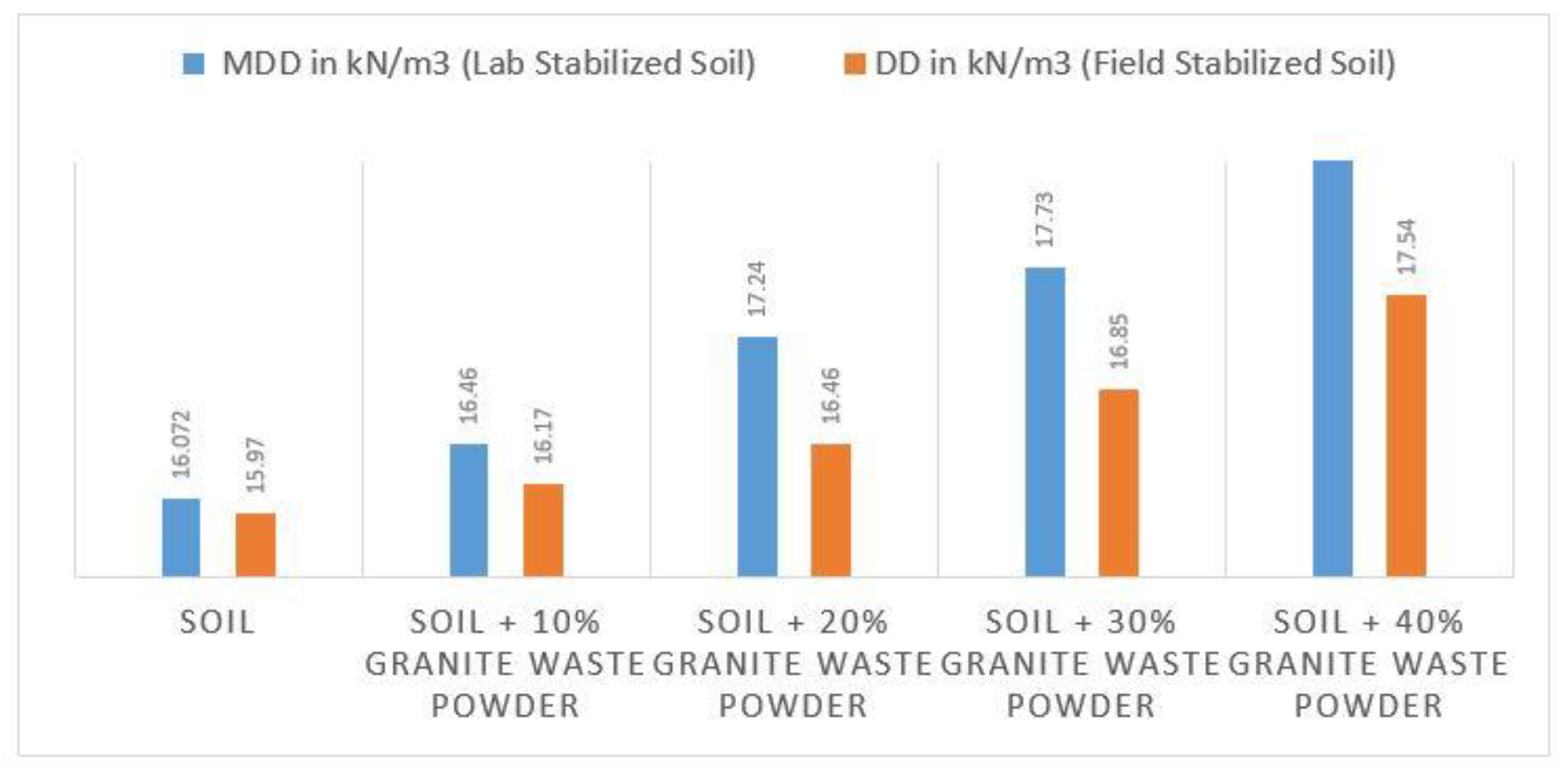

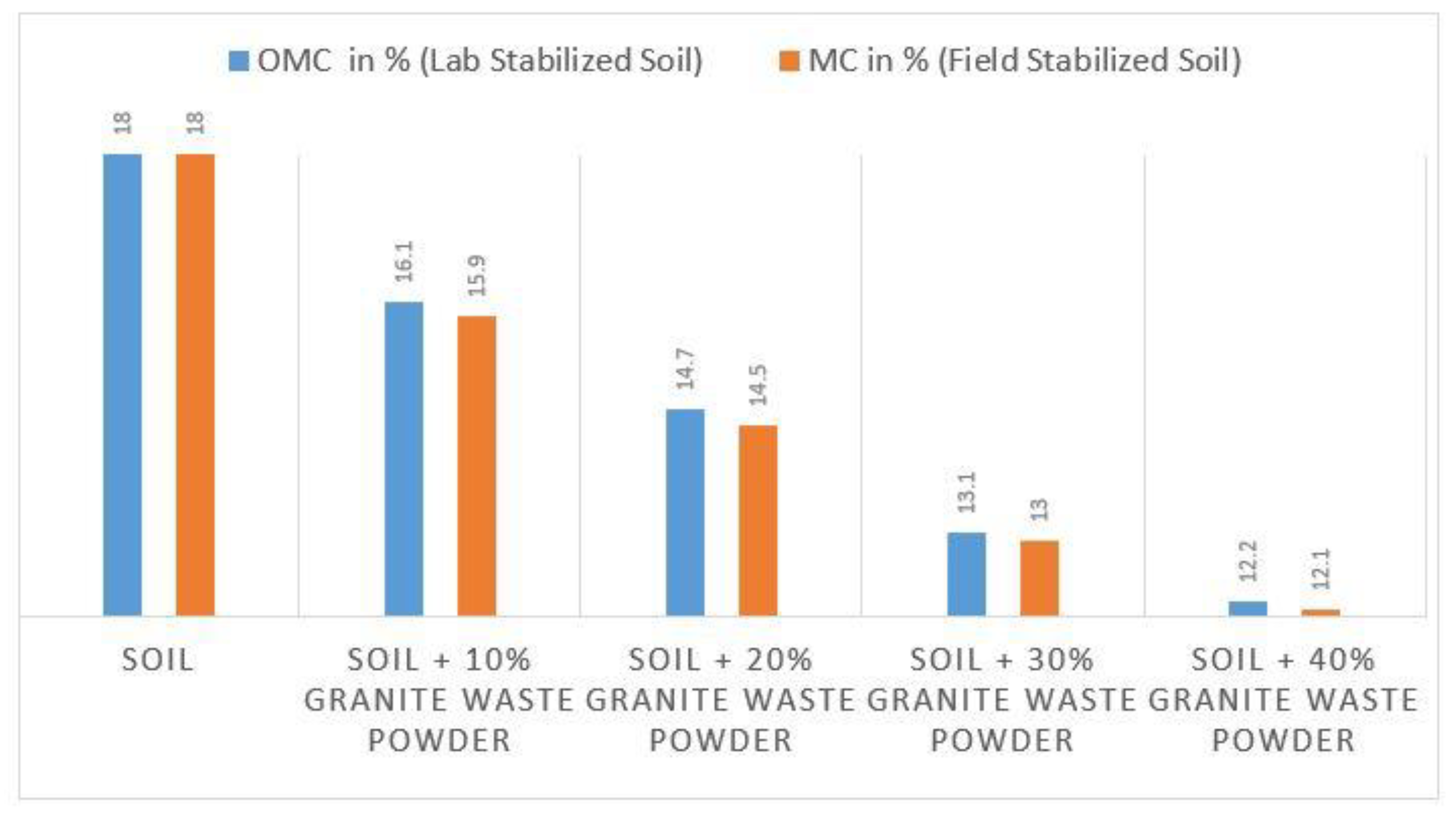

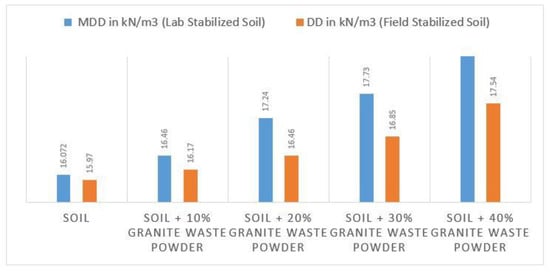

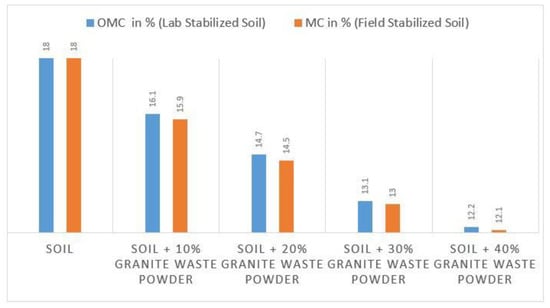

3.4. Compaction Parameters

Figure 3 and Figure 4 provide data on compaction parameters, including MDD and OMC, for the laboratory-stabilized samples, and dry density and moisture contents for the field-stabilized soil samples. The addition of granite powder as an admixture improved densities and moisture contents of both the laboratory- and field-stabilized soils, i.e., densities increased, and moisture contents reduced. Moreover, the level of improvement is higher for the laboratory-stabilized soils than the field-stabilized ones.

Figure 3.

Variations in densities of raw and laboratory- and field-stabilized soil samples.

Figure 4.

Variations in the moisture contents of raw and laboratory- and field-stabilized soil samples.

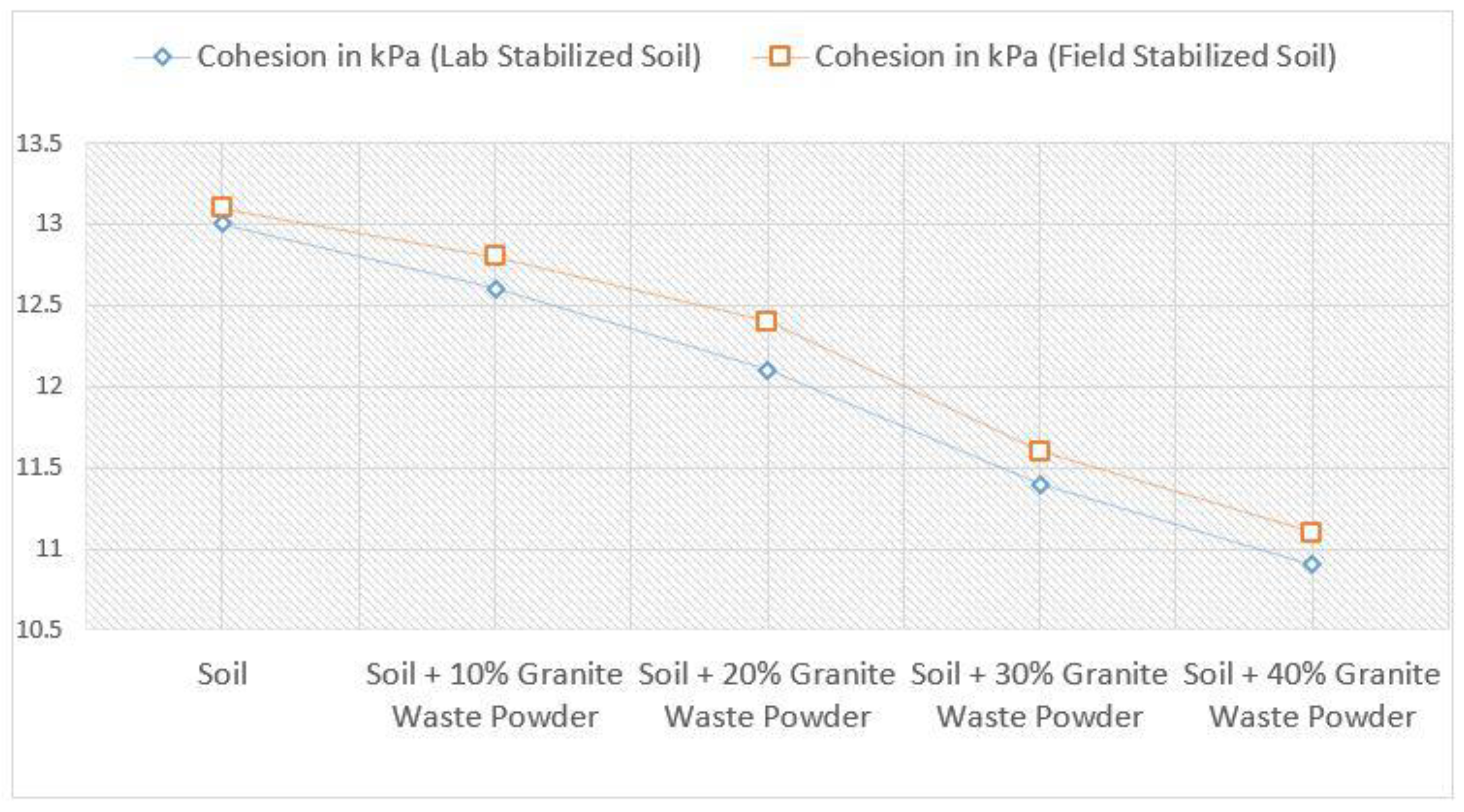

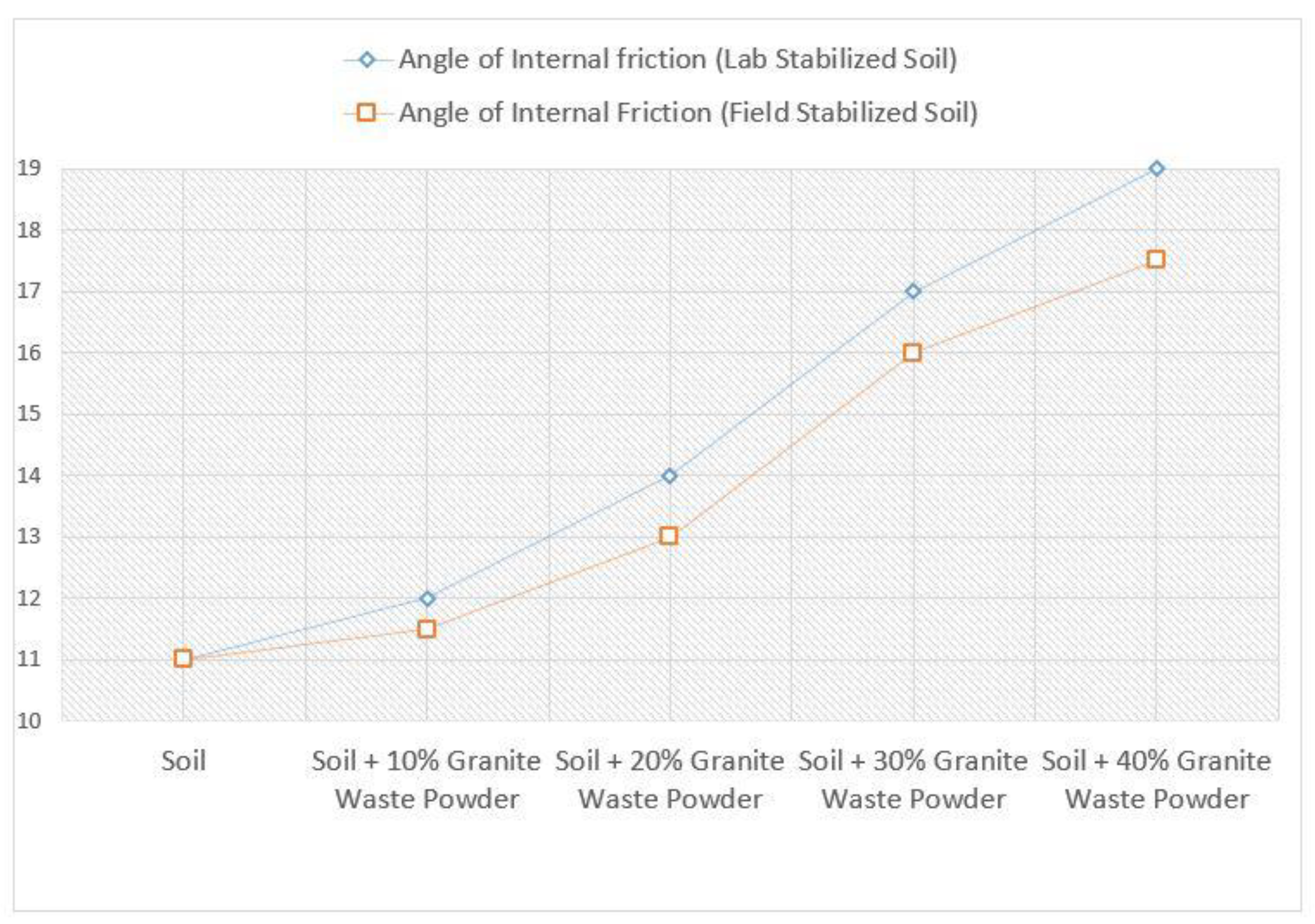

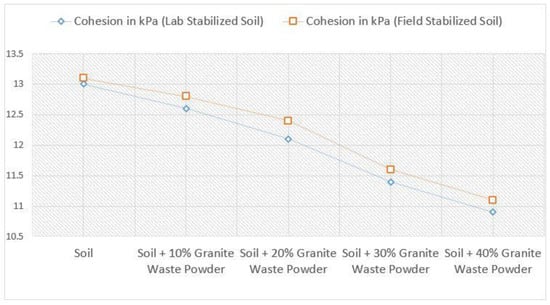

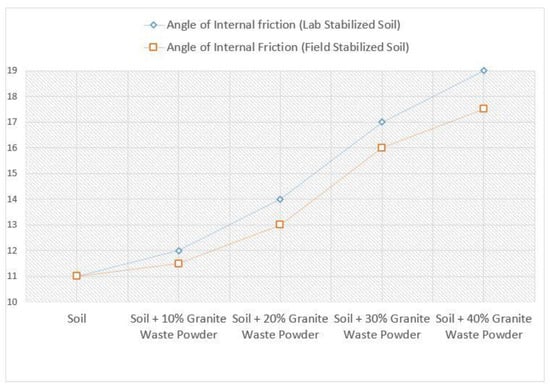

3.5. Shear Strength Parameters

The shear strength parameters, i.e., cohesion and angle of internal friction are very important to determine the ultimate and allowable bearing capacities of soils. The addition of granite powder improved the angle of internal friction in both the laboratory and the field and decreased cohesion values (Figure 5 and Figure 6). However, the decrease in cohesiveness is modest and has no influence on the overall performance of the soil. Overall, the impact of granite waste powder on laboratory-stabilized samples is greater than those treated in the field.

Figure 5.

Variations in cohesion of raw and laboratory- and field-stabilized soil samples.

Figure 6.

Variations in the angle of internal friction of raw and laboratory- and field-stabilized soil samples.

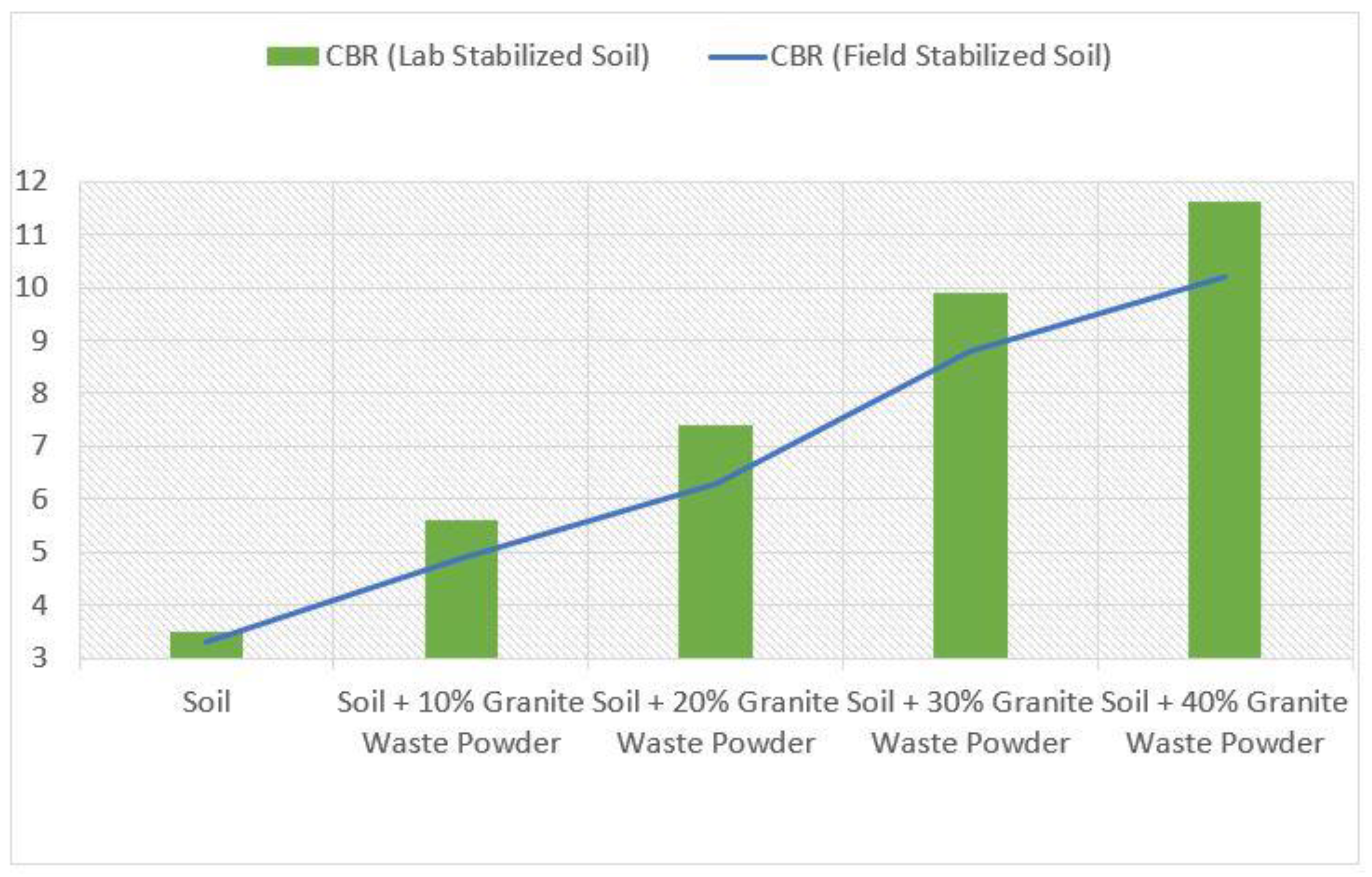

3.6. SG, UCS, and CBR

The values of SG, UCS, and CBR for the laboratory- and field-stabilized samples are shown in Figure 7 and Figure 8 and Table 1 and Table 2. As illustrated, increasing the amount of granite waste powder progressively improves the SG, UCS, and CBR values. The level of the observed improvement is lower for field-stabilized samples than the laboratory-stabilized ones.

Figure 7.

Variations in CBR of raw and laboratory- and field-stabilized soil samples.

Figure 8.

Variations in UCS of raw and laboratory- and field-stabilized soil samples.

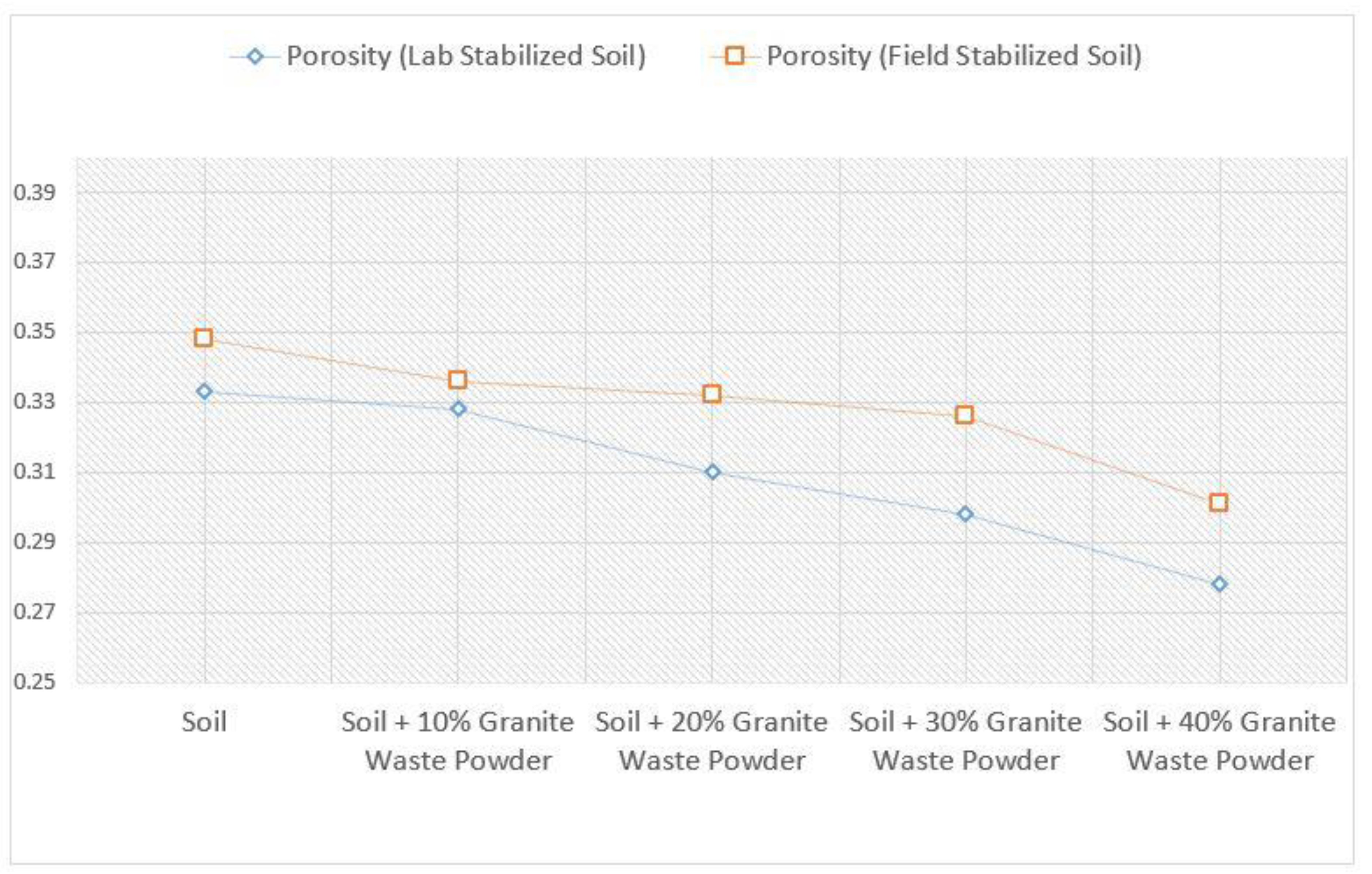

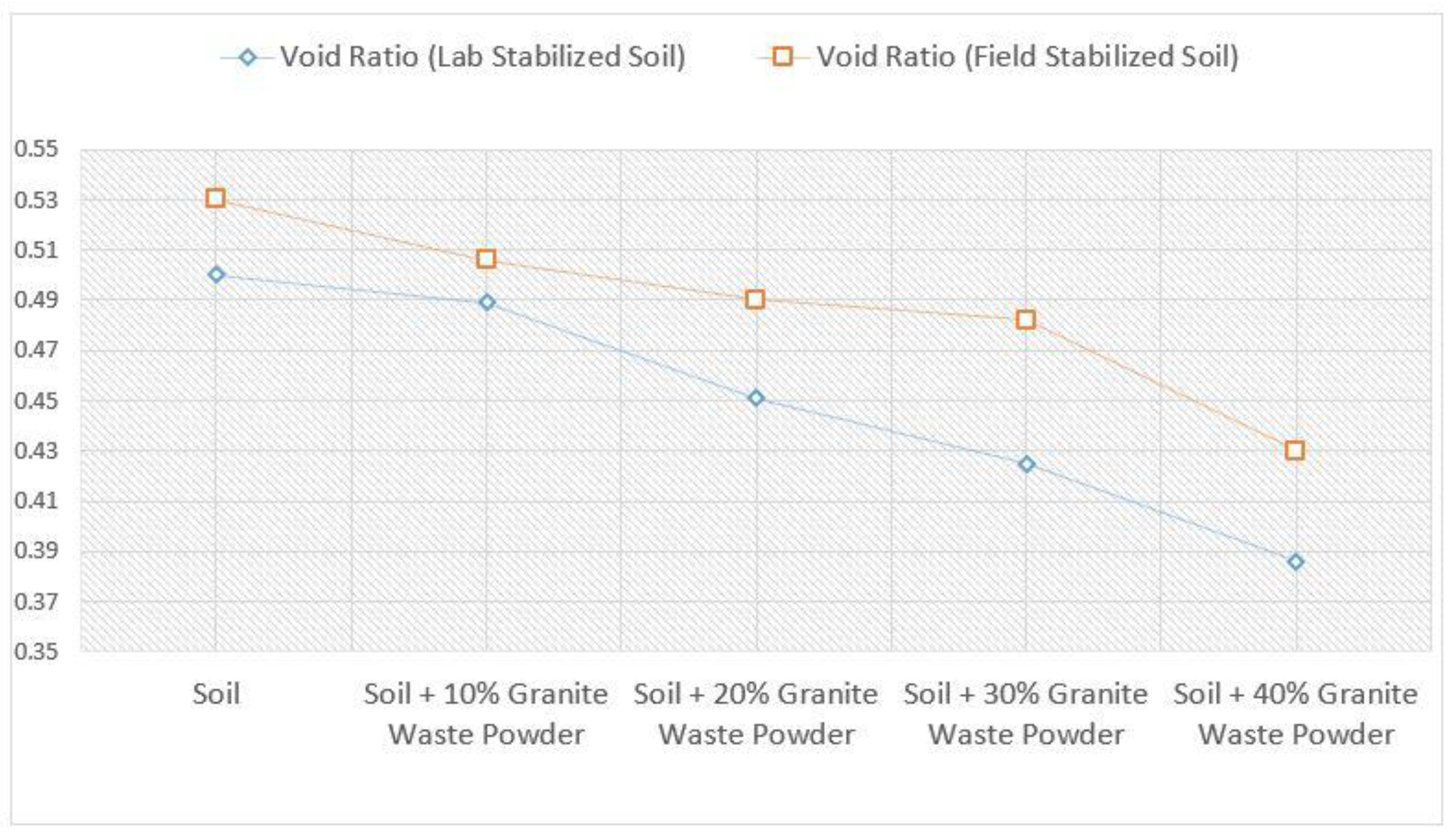

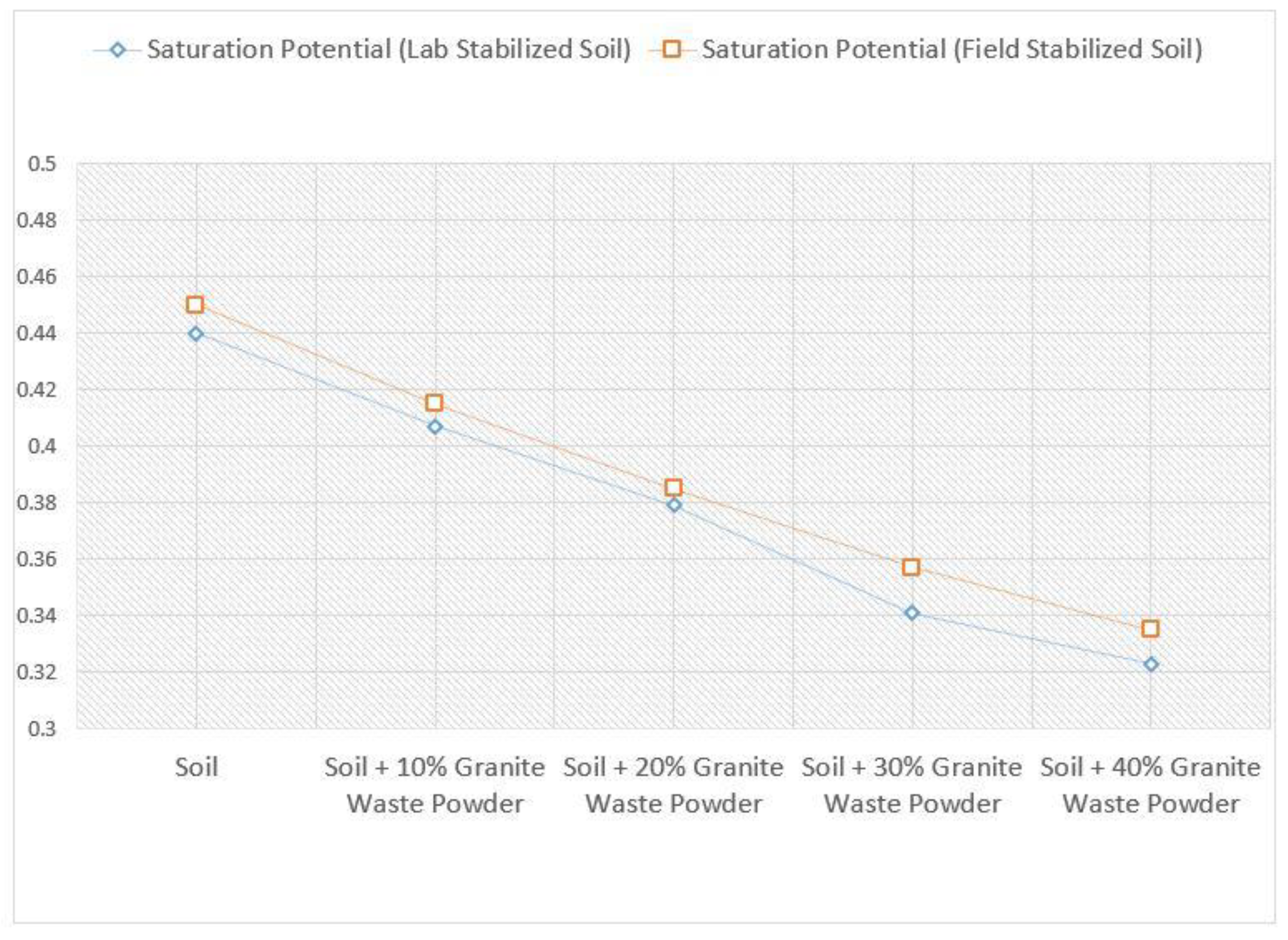

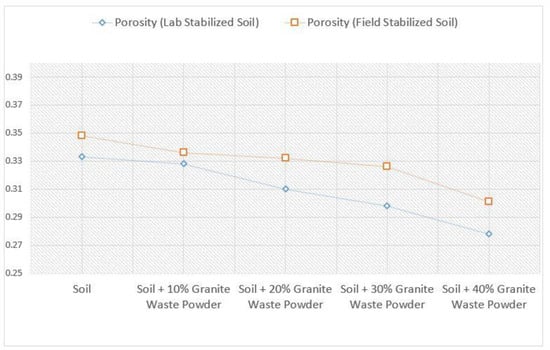

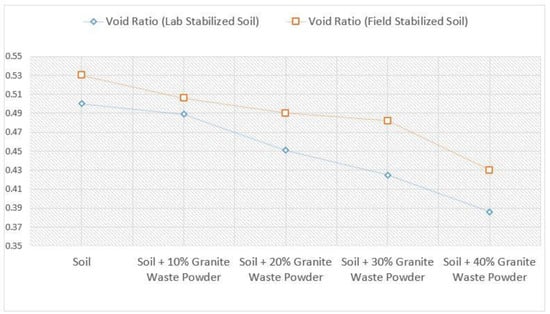

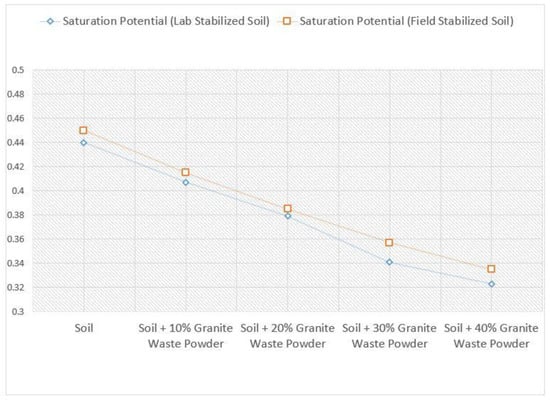

3.7. Porosity, Void Ratio, and Saturation Potential

The values of porosity, void ratio, and saturation potential for laboratory- and field-stabilized soils are demonstrated in Figure 9, Figure 10 and Figure 11. The addition of granite powder in varied amounts significantly lowered all these values, which is a clear indicator of favorable improvement. The observed impact on laboratory-stabilized soils is greater than on the field-stabilized soils.

Figure 9.

Variations in porosity of raw and laboratory- and field-stabilized soils.

Figure 10.

Variations in void ratio of raw and laboratory- and field-stabilized soils.

Figure 11.

Variations in the saturation potential of raw and laboratory- and field-stabilized soils.

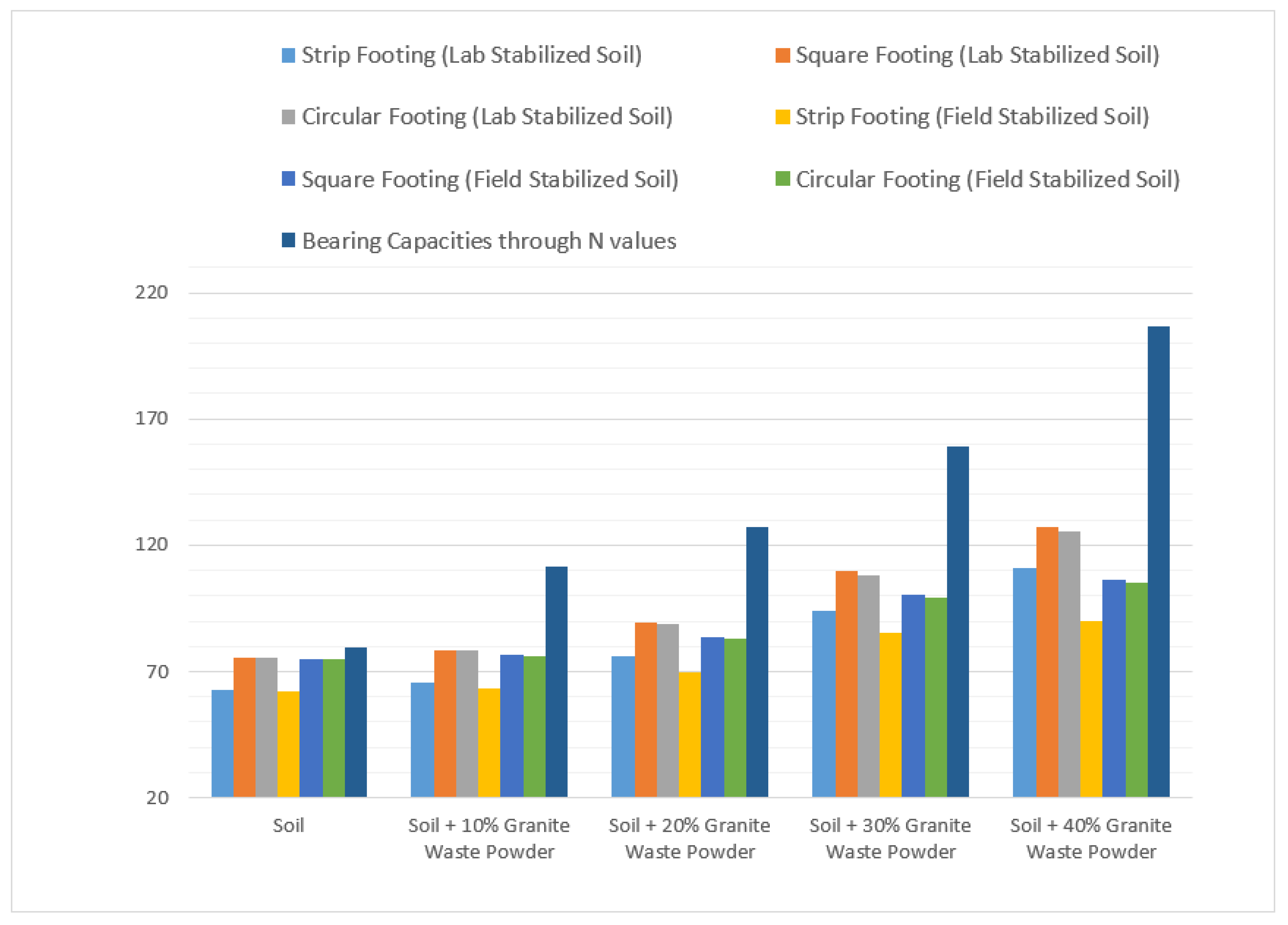

3.8. Foundation Analysis

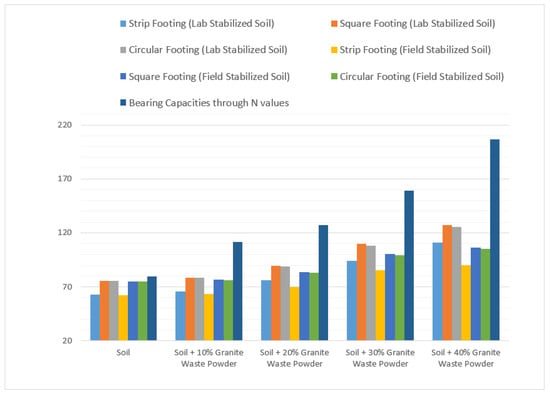

The primary goal of all the soil investigations is to develop appropriate foundations for construction operations. The influence of granite waste powder addition on bearing capabilities of different shallow foundations, including strip footing, square footing, and circular footing, is investigated in this study. The general bearing capacities were also determined through penetration resistance by using Bowles equation. The results demonstrate that the granite waste powder greatly increases the bearing capabilities in both field and laboratory testing and that the rise in bearing capacity is greater in the laboratory-treated samples (Figure 12).

Figure 12.

Bearing capacities in kPa of three different types of shallow foundations with raw and variously treated laboratory- and field-stabilized soil.

4. Discussion

A thorough investigation of the geotechnical characteristics of soil is critical before undertaking any sort of construction project since they influence the behavior of clay under applied loads [35,36]. The raw soil studied in the current research possesses high LL, PI, OMC, porosity, void ratio, degree of saturation, and poor CBR, UCS, density, and bearing capacities, thus making it unsuitable for constructional operations unless significant improvement is achieved through stabilization. The unified soil classification characterizes the examined raw clay soil as “CH” type (fat soil) (Figure 1). The presence of kaolinite, illite, and montmorillonite in clay is the principal cause of the observed undesirable features since montmorillonite may absorb and keep a substantial amount of moisture in its inter-ionic layers, causing expansion and changes in the interlayer spacing [36,37,38,39]. The addition of granite waste in various proportions to the raw clay soil lowered its LL, PI, OMC, and cohesion in both the laboratory and field tests. This is because the water-holding capacity of granite is significantly low since it predominantly consists of quartz, feldspar, and mica. The water absorption capacity of the granite employed in this study is less than 1%, and the activity values of quartz and mica are 0 and 0.25, respectively [40]. Therefore, the progressive addition of granite increased the relatively proportions of less active, non-cohesive, and less-absorptive components (e.g., quartz, mica) in clay, thus diluting the abundance of highly active, cohesive, and more absorptive clay minerals (kaolinite, illite, and montmorillonite), lowering the values of the corresponding geotechnical parameters, e.g., LL and PI, thus elevating the originally CH-type soil to the level of CL-type, which is a low plasticity soil (Figure 1). Ogbonnaya and David [41], Sivrikaya et al. [42], and Shah et al. [7] observed similar improvements in clays through the addition of different rock powders.

The treatment with granite resulted in increasing the CBR, UCS, DD, and bearing capacities of the resulting mixtures for usage in a variety of shallow foundations through both laboratory and field tests. The addition of granite enhanced the bearing capacity (BC) values for all the shallow foundations, including strip, square, and circular footings. This is obviously because granitic rocks have higher specific gravity than soil. Accordingly, the granite waste powder is significantly denser than the clay soil, thus making its addition suitable for enhancement in the relevant parameters, i.e., the CBR, UCS, DD, and BC. The values of BC derived from Terzaghi equations, which are based on shear strength parameters and dry density, were also compared to BC values derived from Bowle’s equation that employs penetration resistance values. The BC is raised in both cases; however, the values obtained through the Bowle’s equation are larger than those obtained through the Terzaghi equations. The explanation for the observed difference might be that the Bowle’s equation solely considers stresses and does not take into account the DD values, whereas the Terzaghi equations incorporate both stresses and DD.

Furthermore, the influence of granite waste powder on several other important parameters, e.g., the soil porosity, void ratio, and saturation potential, is investigated through testing in both the field and laboratory settings. These metrics are generally determined on the job, but their determination in the lab is lacking [7]. Owing to elevated porosity, void ratio, and saturation, clays generally have high-swelling potential. The addition of granite significantly reduces these metrics, thus enhancing the soil’s overall performance. The observed improvement is obviously due to higher density of the added granite.

The most important component of the present study is to compare the outcomes of laboratory testing with those from field testing. An understanding of whether the laboratory results are completely obtainable in the field is required. The degree of improvement in the laboratory setting is higher than in the field in all the evaluated criteria with the range of variance lying between 2 and 12%. There might be several factors that could have contributed to significantly better outcomes from testing in the laboratory than in the outdoors. One of the primary reasons is that laboratory testing provides a more regulated and well-defined environment than field testing. In the case of laboratory testing, the granite stabilizer is mixed with a smaller volume of soil to meet the requirements of the test, but the stabilizer is mixed with soil excavated from 1 m3 test pits for testing in the field. Consequently, the volume of soil used in field testing is much larger. This could be another reason for the observed difference in test results since the mixing is easier and much more thorough in case of smaller than larger volumes. Furthermore, since most of the examined attributes were assessed after maximum compaction, variation in compaction might also be a factor. The results show that the density is higher in laboratory testing than in in situ testing, which may be attributed to differences in compaction energy, compaction effort, soil thickness, and contact pressure. Standard equipment is designed to obtain the greatest dry density for a given soil inside the laboratory. In contrast, several options (e.g., rolling, tamping, or vibration) are available for soil compaction in the field. In other words, there is no standard apparatus that could be used to achieve maximum soil compaction in the field. In such situations, vibrators are usually utilized to compact the earth to the greatest possible extent in the field. The reason for selecting a vibrator over other available equipment is its low cost and ready availability. Other field equipment, e.g., different types of rollers, can be used to increase the soil density, but such an exercise is likely to increase the project cost that cannot be readily afforded by the general public in underdeveloped countries.

The level of improvement in all the measured soil parameters is influenced by the variance in densities in both the laboratory and the field owing to differences in compaction. The density is higher and the degree of improvement in the examined parameters is likewise greater in the laboratory than in the field testing. This demonstrates that it is extremely difficult to achieve exactly the same results through testing in the field as obtained under controlled conditions in the laboratory. Therefore, it is highly recommended to consider a safety factor of about 2–12 percent in the laboratory testing results before applying them in the field. Such a practice will make the foundation design more efficient and improve the overall constructional process.

5. Conclusions

Results from laboratory and field experiments led to the following conclusions:

- Adding up to 40% granite-cutting waste significantly improves the quality of compacted clay in both the field and laboratory setting by (a) enhancing bearing capacity, CBR, UCS, SG, DD, angle of internal friction, and penetration resistance and (b) greatly reducing porosity, void ratio, saturation potential, OMC, and PI. Hence, granite-cutting waste powder is recommended for use as an admixture in the geotechnical industry to stabilize clay so that harmful environmental concerns could be avoided.

- The impact on clay properties from the granite-cutting waste powder is higher in laboratory stabilization than in stabilization in the field, obviously because of differences in testing environment, soil volume, compaction energy, and efforts.

Author Contributions

Conceptualization, S.H.A.S.; methodology, S.H.A.S.; experiments, S.H.A.S., U.H., Q.u.R. and A.S.; project administration, S.H.A.S.; software, A.M., U.H. and M.A.; funding acquisition, A.M., M.A. and Q.u.R., writing—original draft, S.H.A.S.; writing—review and editing, Q.u.R., A.S., A.M. and M.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

All the data presented in the manuscript.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Steinberg, M. Expansive soils and the geomembrane remedy. In Advances in Unsaturated Geotechnics; American Society of Civil Engineers: Reston, VA, USA, 2000; pp. 456–466. [Google Scholar] [CrossRef]

- Arora, D.K.R. Soil Mechanics and Foundation Engineering, 6th ed.; 170S-B; Nai Sarak: Delhi, India, 2003; p. 903. [Google Scholar]

- Zumrawi, M.; Abdalla, E.A.E. Stabilization of Expansive Soil using Marble Waste Powder. In Second Conference of Civil Engineering in Sudan; University of Khartoum: Khartoum, Sudan, 2018. [Google Scholar]

- Bakhshizadeh, A.; Khayat, N.; Horpibulsuk, S. Surface stabilization of clay using sodium alginate. Case Stud. Constr. Mater. 2022, 16, e01006. [Google Scholar]

- Bahrami, R.; Khayat, N.; Nazarpour, A. Effect of nano-stabilizer on geotechnical properties of leached gypsiferous soil. Geomech. Eng. 2020, 103–113. [Google Scholar] [CrossRef]

- Shah, S.H.A.; Arif, M.; Asif, M.E.; Safdar, M. Influence of granite cutting waste addition on the geotechnical parameters of cohesive soil. Int. J. Eng. Res. Adv. Technol. 2019, 5, 64–74. [Google Scholar] [CrossRef]

- Shah, S.H.A.; Arif, M.; Rehman, Q.; Manzoor, F. Utilization of dolerite waste powder for improving geotechnical parameters of compacted clay soil. Open Geosci. 2021, 13, 1523–1535. [Google Scholar] [CrossRef]

- Shah, S.H.A.; Arif, M.; Sabir, M.A.; Tanoli, J.I.; Asma, S.; Lodhi, H.T. The effect of weathering on the appropriateness of granite for clay stabilization. Acta Geotech. Slov. 2022, 48–56. [Google Scholar]

- Hoy, M.; Rachan, R.; Horpibulsuk, S.; Arulrajah, A.; Mirzababaei, M. Effect of wetting-drying cycles on compressive strength and microstructure of recycled asphalt pavement-fly ash geopolymer. Constr. Build. Mater. 2017, 144, 624–634. [Google Scholar] [CrossRef]

- Latifi, N.; Horpibulsuk, S.; Meehan, C.L.; Abd Majid, M.Z.; Tahir, M.M.; Mohamad, E.T. Improvement of problematic soils with biopolymer—An environmentally friendly soil stabilizer. J. Mater. Civ. Eng. 2016, 29, 04016204–04016211. [Google Scholar] [CrossRef]

- Latifi, N.; Rashis, A.; Siddiqua, S.; Abd Majid, A. Strength measurement and textural characteristics of tropical residual soil stabilization with liquid polymer. Measurement 2016, 91, 46–54. [Google Scholar] [CrossRef]

- Phummiphan, I.; Horpibulsuk, S.; Rachan, R.; Arulrajah, A.; Shen, S.L.; Chindaprasirt, C. High calcium fly ash geopolymer stabilized lateritic soil and granulated blast furnace slag blends as a pavement base material. J. Hazard. Mater. 2018, 341, 257–267. [Google Scholar] [CrossRef]

- Zorluer, I.; Gucek, S. The effects of marble dust and fly ash on clay soil. Sci. Eng. Compos. Mater. 2014, 21, 59–67. [Google Scholar] [CrossRef]

- Yang, W.; Gao, H.; Yang, Y. Analysis of Influencing Factors of Embodied Carbon in China’s Export Trade in the Background of “Carbon Peak” and “Carbon Neutrality”. Sustainability 2022, 14, 3308. [Google Scholar] [CrossRef]

- Yang, W.; Gao, H.; Yang, Y.; Liao, J. Embodied Carbon in China’s Export Trade: A Multi Region Input-Output Analysis. Int. J. Environ. Res. Public Health 2022, 19, 3894. [Google Scholar] [CrossRef]

- Shirazi, E.K. Reusing of stone waste in various industrial activities. In 2nd International Conference on Environmental Science and Development IPCBEE; IACSIT Press: Singapore, 2011; Volume 4. [Google Scholar]

- Montero, M.A.; Jordan, M.M.; Almendro, C.; Sanfeliu, T.; Hernandez-Crespo, M.S. The use of a calcium carbonate residue from the stone industry in manufacturing of ceramic tile bodies. Appl. Clay Sci. 2009, 43, 186–189. [Google Scholar] [CrossRef]

- Shams, F.A. A preliminary account of the geology of the Mansehra area, District Hazara, West Pakistan. Geol. Bull. Univ. Punjab 1961, 1, 57–67. [Google Scholar]

- Ashraf, M. Geology and petrology of acid minor bodied from Mansehra and Batgram area, Hazara district, Pakistan. Geol. Bull. Univ. Punjab 1974, 11, 81–88. [Google Scholar]

- Naeem, M.; Khalid, P.; Anwar, A.W. Construction material prospects of granitic and associated rocks of Mansehra area, NW Himalaya, Pakistan. Acta Geod. Geophys. 2015, 50, 307–319. [Google Scholar] [CrossRef][Green Version]

- ASTM D6473; Standard Test Method for Specific Gravity and Absorption of Rock for Erosion Control. ASTM International: West Conshohocken, PA, USA, 2015.

- ASTM D7012-14; Standard Test Methods for Compressive Strength and Elastic Moduli of Intact Rock Core Specimens under Varying States of Stress and Temperatures. ASTM International: West Conshohocken, PA, USA, 2014.

- ASTM C136/C136M; Standard Test Method for Sieve Analysis of Fine and Coarse Aggregates. ASTM International: West Conshohocken, PA, USA, 2019.

- ASTM D7928; Standard Test Method for Particle Size Distribution (Gradation) of Fine-Grained Soils Using the Sedimentation (Hydrometer) Analysis. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM D4318; Standard test methods for liquid limit, plastic limit and plasticity index of soils. ASTM International: West Conshohocken, PA, USA, 2000.

- ASTM D698; Standard test method for laboratory compaction characteristics of soil using standard effort. ASTM International: West Conshohocken, PA, USA, 2000.

- ASTM D3080/D3080M; Standard Test Method for Direct Shear Test of Soils under Consolidated Drained Conditions. ASTM International: West Conshohocken, PA, USA, 2011.

- ASTM D854; Standard test methods for specific gravity of soil solids by water pycnometer. ASTM International: West Conshohocken, PA, USA, 2014.

- ASTM D1883; Standard test method for CBR (California bearing ratio) of laboratory compacted soils. ASTM International: West Conshohocken, PA, USA, 1999.

- ASTM D2166-06; Standard test method for unconfined compressive strength of cohesive soil. ASTM International: West Conshohocken, PA, USA, 2006.

- Terzaghi, K. Theoretical Soil Mechanics; Wiley: New York, NY, USA, 1925. [Google Scholar]

- Budhi, M. Soil Mechanics and Foundations, 3rd ed.; Wiley & Sons, Inc.: New York, NY, USA, 2010. [Google Scholar]

- ASTM D1556; Standard Test Method for Density and Unit Weight of Soil in Place by the Sand-Cone Method. ASTM International: West Conshohocken, PA, USA, 2007.

- Bowles, J.E. Foundations Analysis and Design, 3rd ed; McGraw-Hill: New York, NY, USA, 1982. [Google Scholar]

- Al-Swaidani, A.; Hammoud, I.; Meziab, A. Effect of adding natural pozzolana on geotechnical properties of lime-stabilized clayey soil. J. Rock Mech. Geotech. Eng 2016, 8, 714–725. [Google Scholar] [CrossRef]

- Shah, S.H.A.; Arif, M.; Sabir, M.A.; Iqbal, J. In-situ stabilization of clays with lime, dolerite and quartzite powders. Acta Geodyn. Geomater. 2020, 3, 341–352. [Google Scholar] [CrossRef]

- Shah, S.H.A.; Arif, M.; Sabir, M.A.; Rehman, Q. Impact of igneous rock admixtures on geotechnical properties of lime stabilized clay. Civ. Environ. Eng. 2020, 16, 329–339. [Google Scholar] [CrossRef]

- Iqbal, J.; Dai, F.; Hong, M.; Tu, X. Failure mechanism and stability analysis of an active landslide in the Xiangjiaba reservoir area, South-west China. J. Earth Sci 2018, 29, 646–661. [Google Scholar] [CrossRef]

- Xu, L.; Dai, F.C.; Chen, J.; Iqbal, J.; Qu, Y. Analysis of a progressive slope failure in the Xiangjiaba reservoir area, Southwest China. Landslides 2014, 11, 55–66. [Google Scholar] [CrossRef]

- Moos, A.V. Geotechnical Properties and Investigation Methods of Loose Rocks; Earthwork Course of E.T.H., No. 4 (Zurich); Faculty of Science, University of London: London, UK, 1938. [Google Scholar]

- Ogbonnaya, I.; Illoabachie, D.E. The potential effect of granite dust on the geotechnical properties of Abakalili clays. Cont. J. Earth Sci. 2011, 6, 23–30. [Google Scholar]

- Sivrikaya, O.; Kıyıldı, R.K.; Karaca, Z. Recycling waste from natural stone processing plants to stabilise clayey soil. Env. Earth Sci. 2014, 71, 4397–4407. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).