Analyzing Reliability and Maintainability of Crawler Dozer BD155 Transmission Failure Using Markov Method and Total Productive Maintenance: A Novel Case Study for Improvement Productivity

Abstract

:1. Introduction

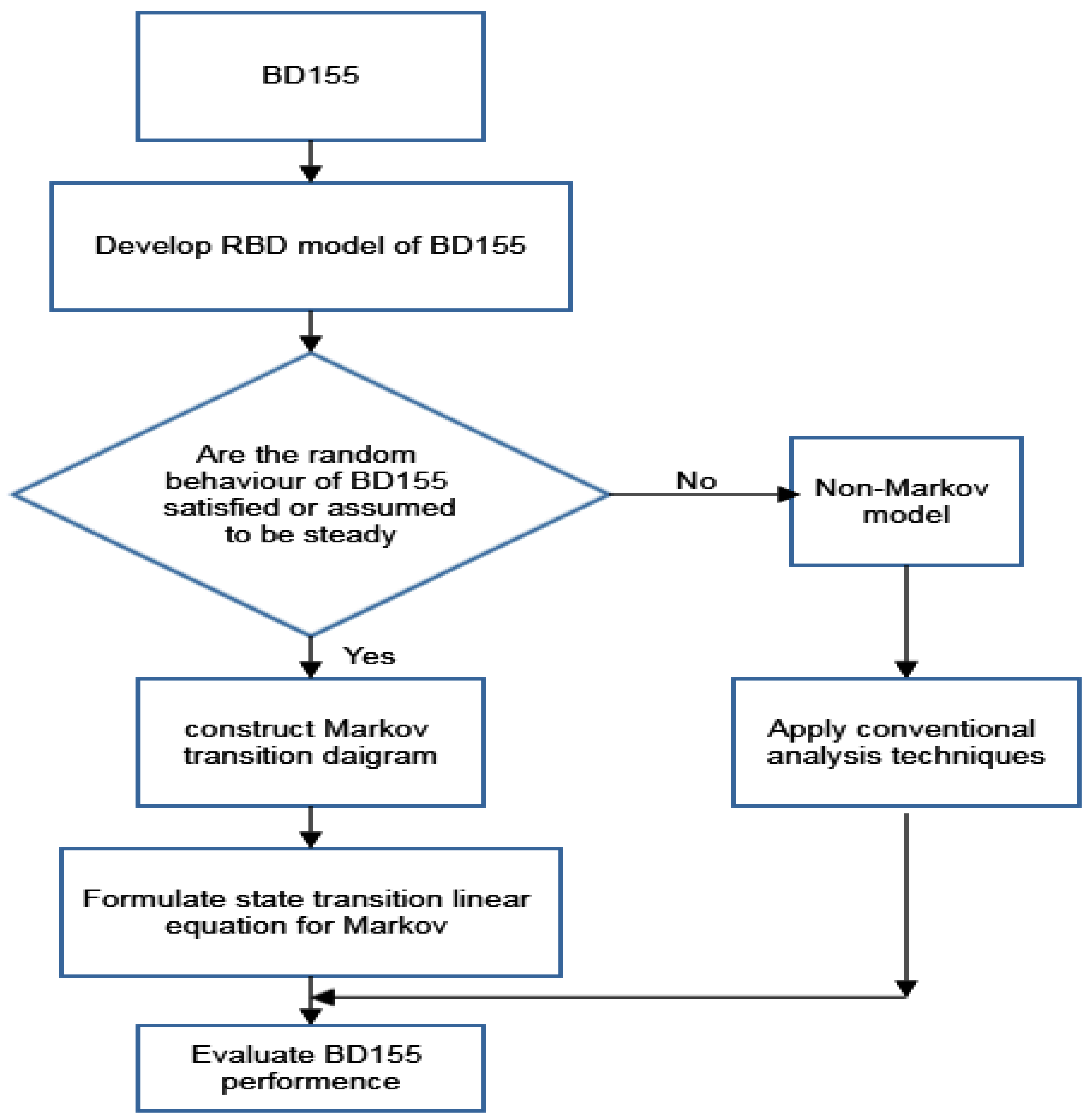

2. Research Methodology

3. BD155 Crawler Dozer Transmission: At a Glance

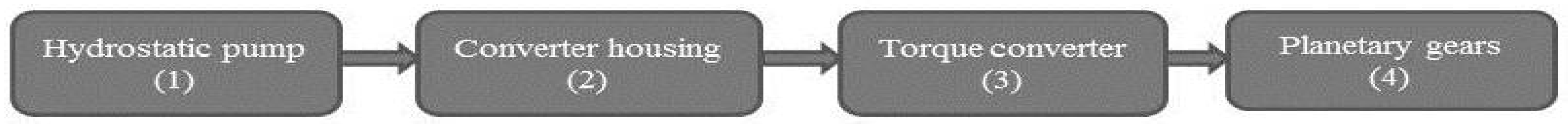

Subsystems of BD155 Crawler Dozer

4. Reliability Analysis of Dozer Transmission (BD155)

4.1. Markov Modeling

- S = system and U = groups of up states

- Rsi (t, t +∆t) = Pr {system up in [t, t + ∆t], Zi is entered at t = 0, Zi ϵ U (in general)

- Rsi (∆t) = Pr {system up in [t, t + ∆t], in steady-state for t →∞

- [31]

4.1.1. Reliability Block Diagram (RBD) of BD155 Transmission

4.1.2. Assumptions of Markov Modeling for BD155 Transmission

- For all subsystems of the BD155 transmission, the rates of repair (µ) and failure (µ) are independent statistically and constant concerning time.

- Mean time to repair (MTTR) and mean time to failure (MTTF) have exponential distributions.

- Repairing damaged or repairable BD155 components should restore their original functionality. Worn-out parts are replaced with newer ones in the BD155.

- There are no immediate subsystem breakdowns, and there is no likelihood that there will be one or more breakdowns and restorations in a specific amount of time. Due to the harsh operating and loading conditions, failures are frequent and make it challenging to locate all of the BD155 transmission’s subsystems supported by housings or cases.

- There are two possible states for BD155 subsystems: operating and not functioning. When a system changes from a nonfunctioning state (downstate) to an operating condition (upstate), it indicates that the necessary repairs or replacements have been made. In contrast, when it changes from an operational state (upstate) to a nonfunctioning state (downstate), it designates that a subsystem has failed. The initial state does not impact how likely it is to move into the subsequent state [33].

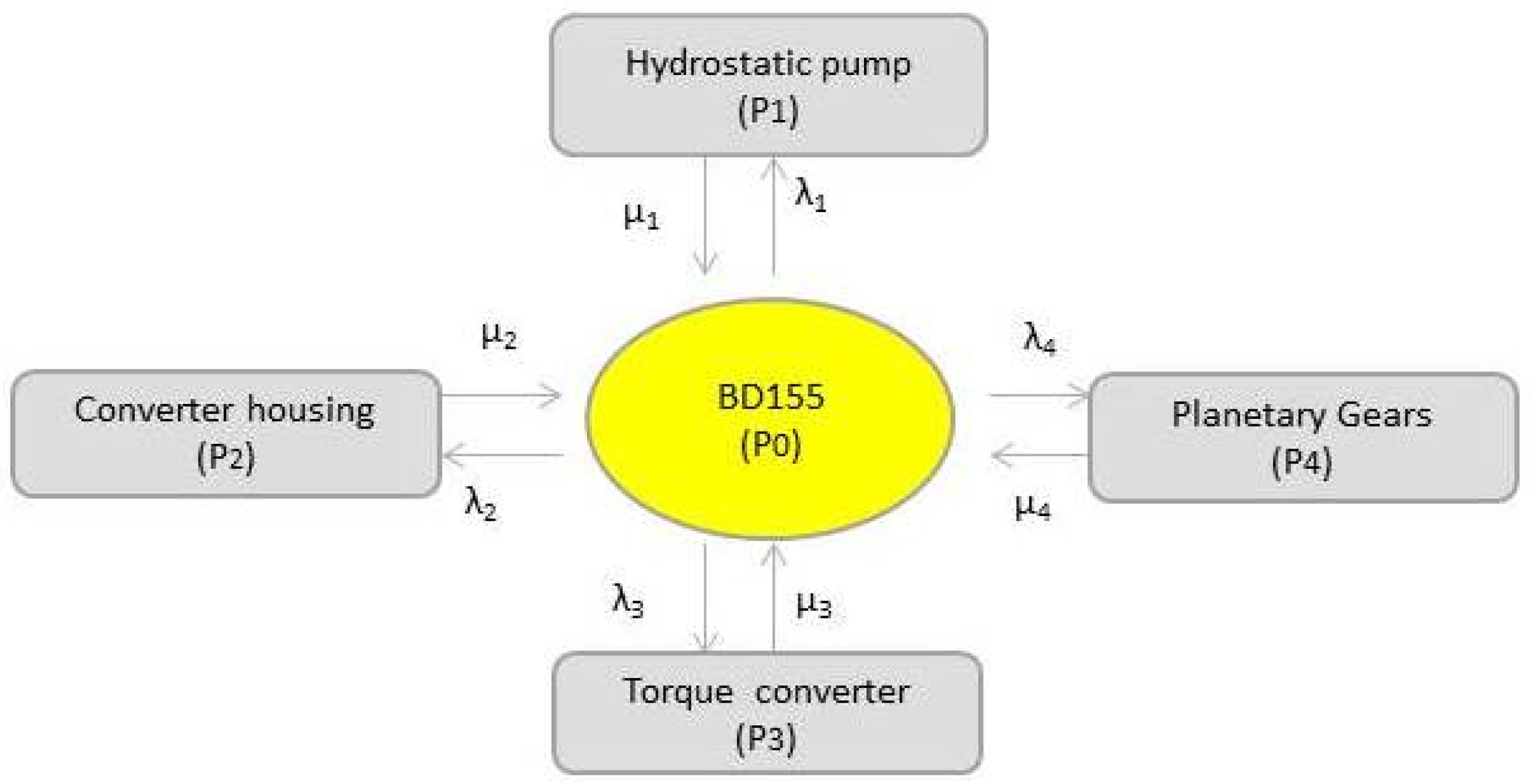

4.1.3. Transition Diagram and Markov Modeling for BD155

5. Discussions on Analysis

6. Conclusions

- Due to its complicated operation, BD155 transmission faults are relatively frequent. All of the BD155’s subsystems are interconnected in series, and their effects on R(t), M(t), and A(t) were studied to increase reliability. TPM policies and preventive maintenance (PM) techniques are used.

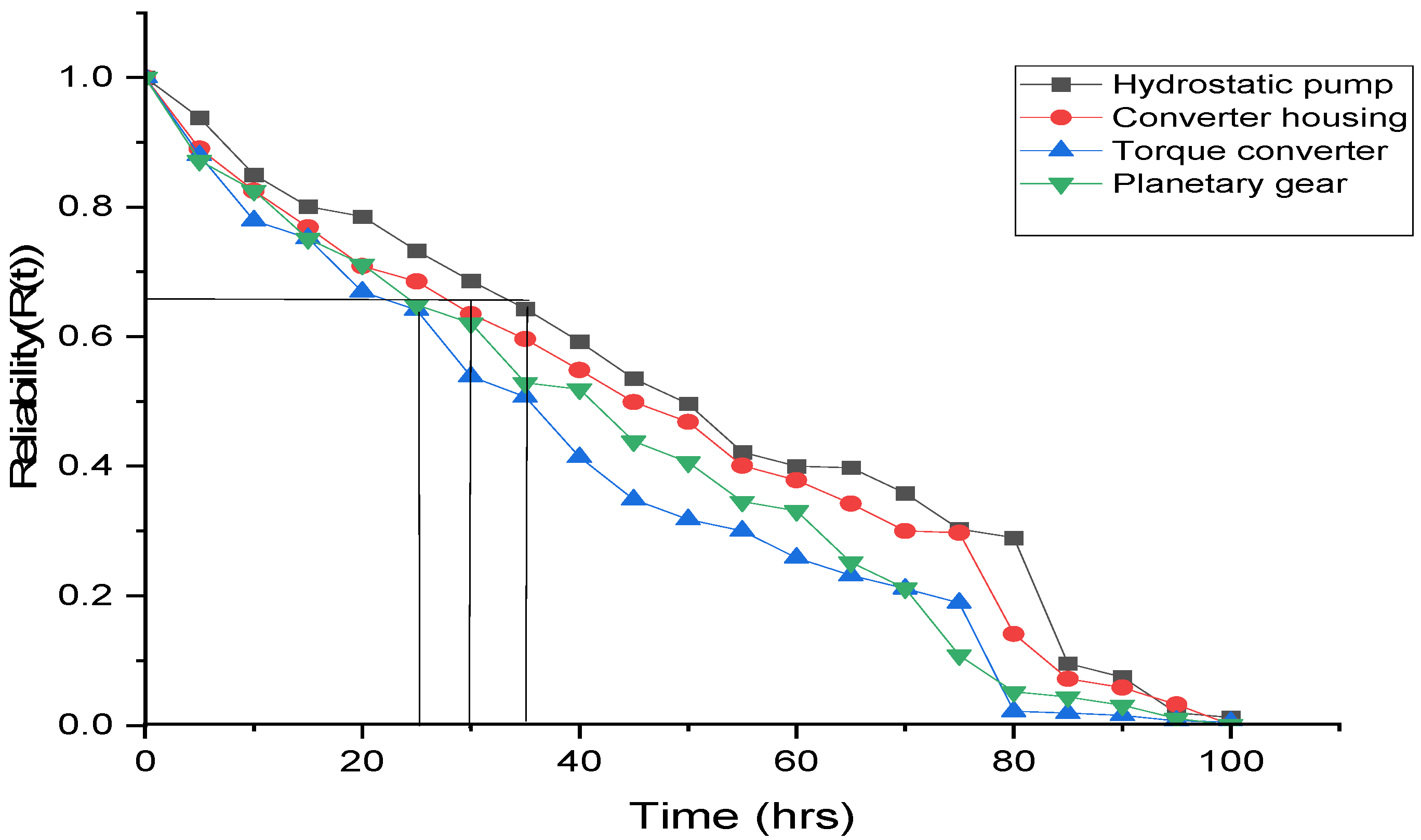

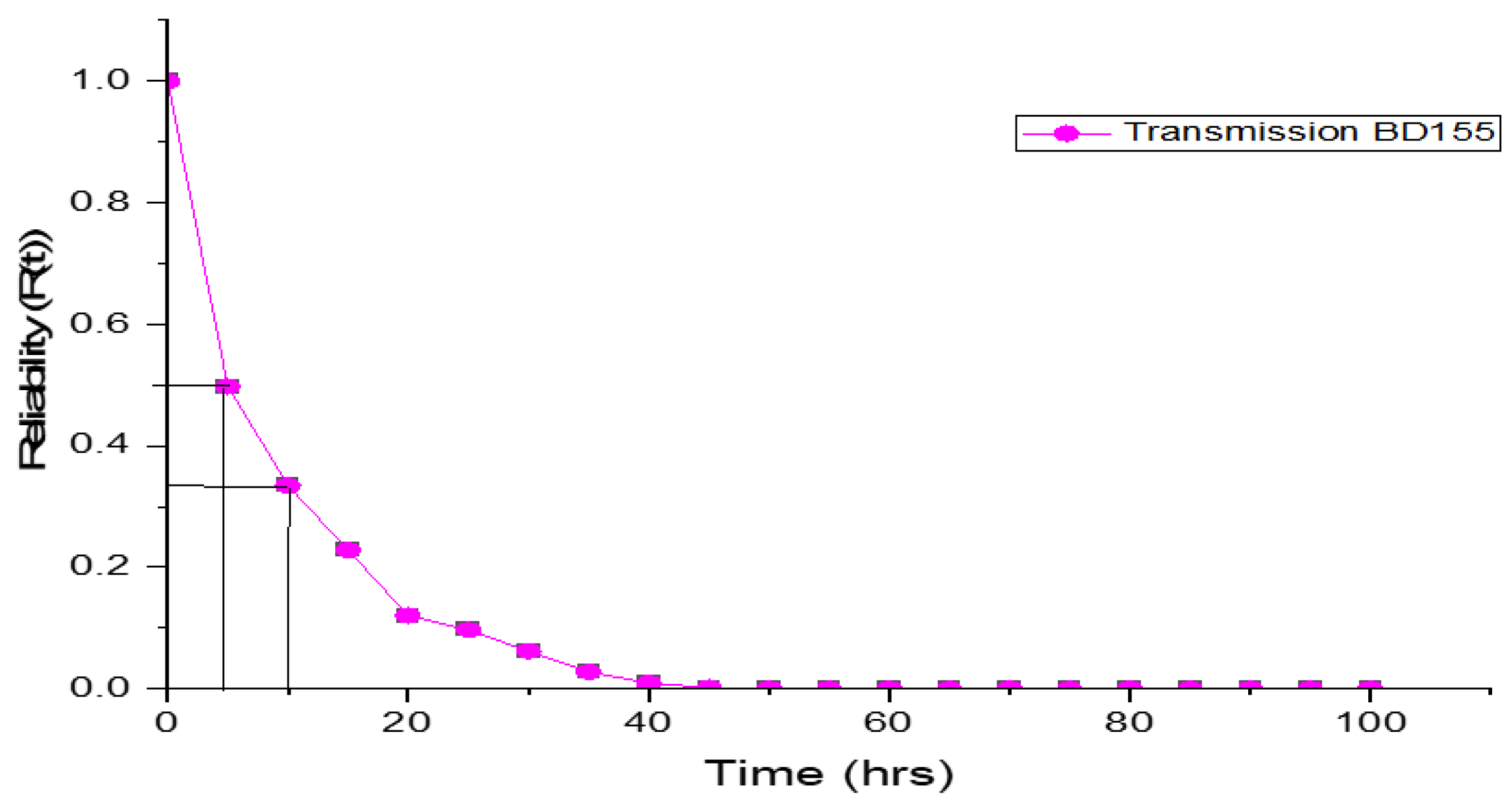

- It is apparent that the reliability R(t) of the BD155 subsystem is deteriorating with time. Since each subsystem is coupled to the others in a series, overall reliability is a function of each subsystem. Additionally, Rs(5) = 0.5 and Rs(10) = 0.33 clearly show that R (t) of BD155 has decreased.

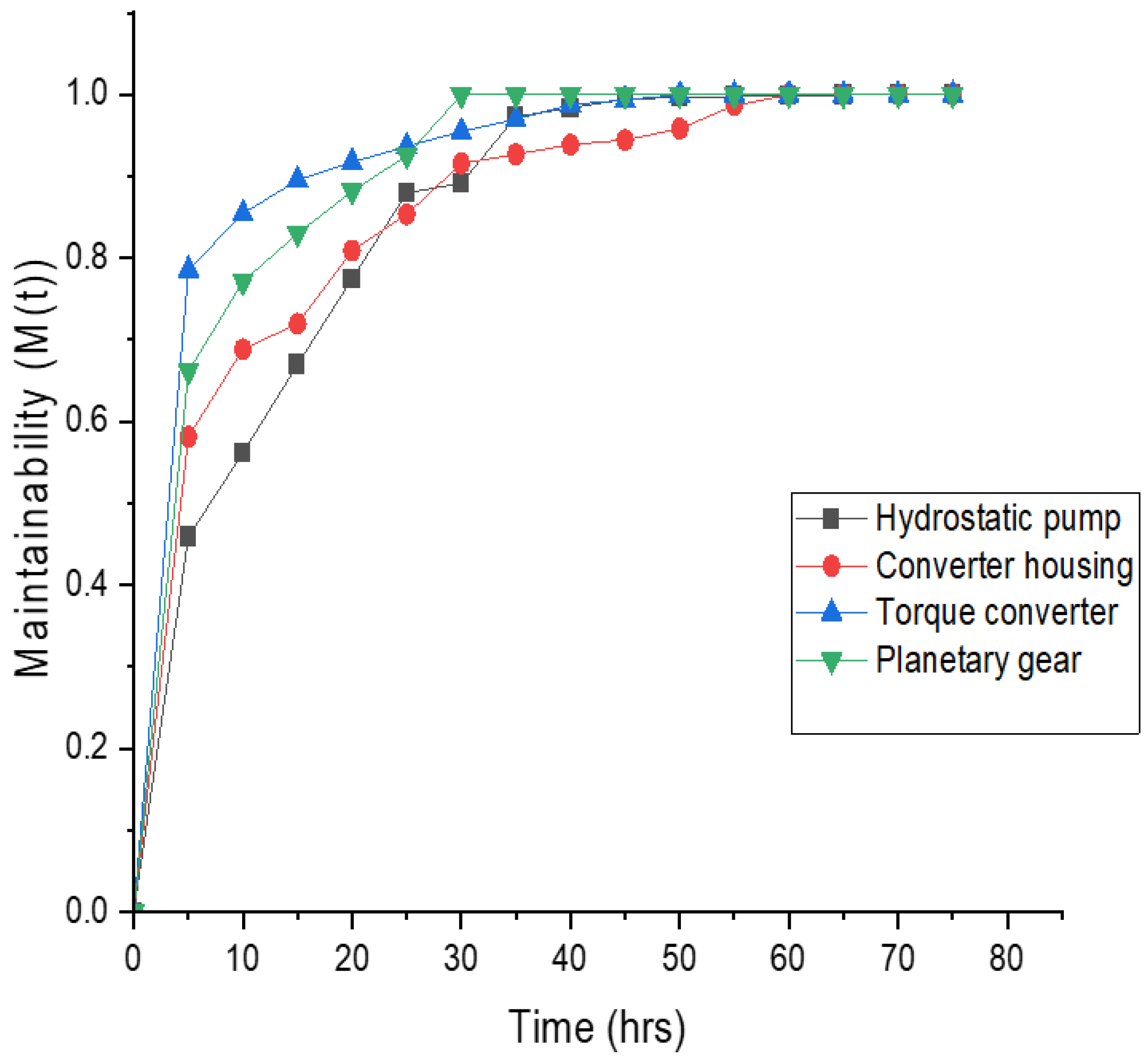

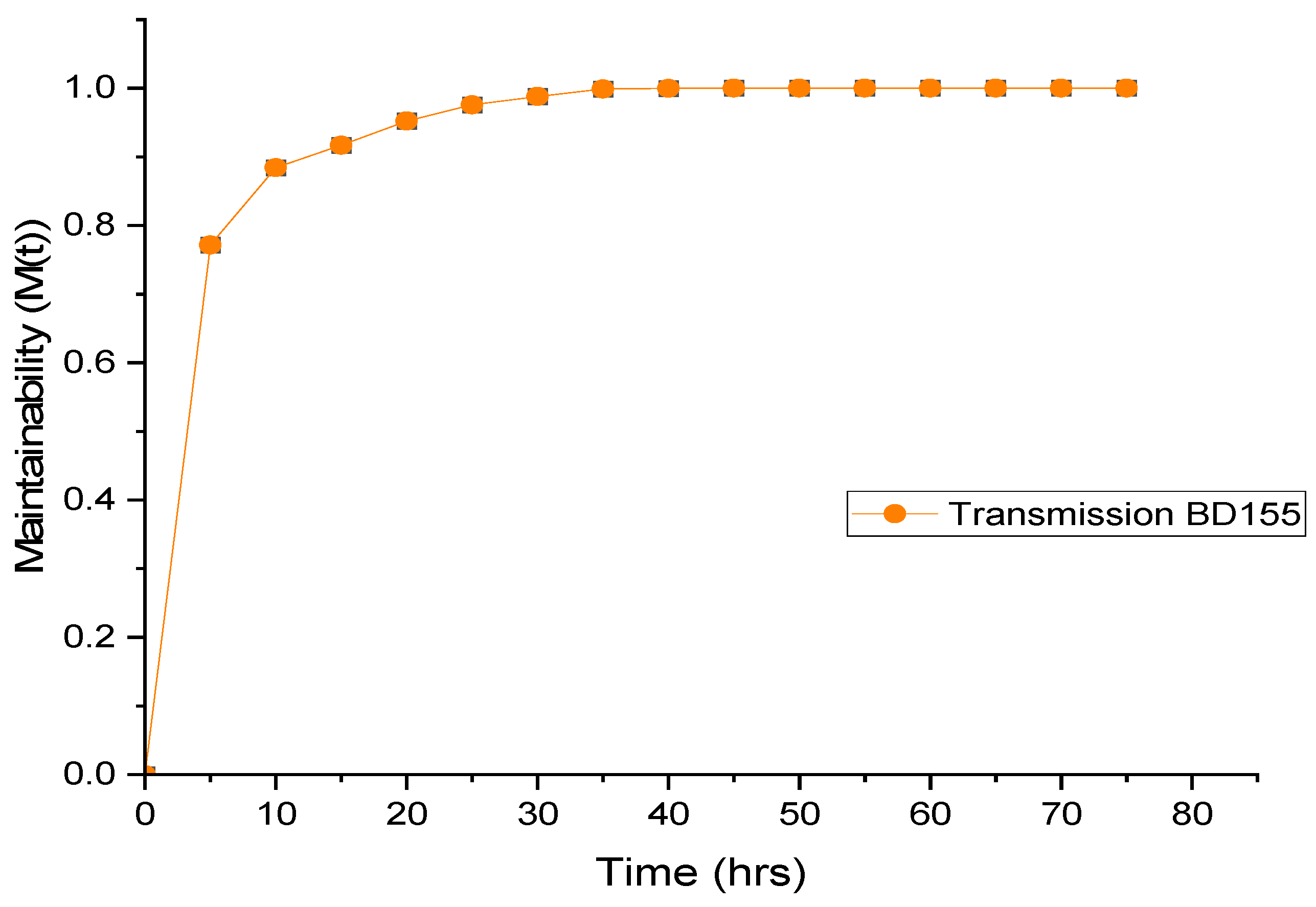

- The transmission of the BD155’s subsystems’ maintainability M (t) is improving over time. In contrast, the converter housing needs the greatest time to regain early efficacy (55 h). Planetary gears have a superior maintainability Ms(t) than other subsystems and are ready for use after only 30 h of maintenance (Ms(30) = 0.999). The key factor contributing to the lengthy maintainability is the lack of original replacement parts. The result of 35 h of maintenance procedures is the transmission system’s return to its original state.

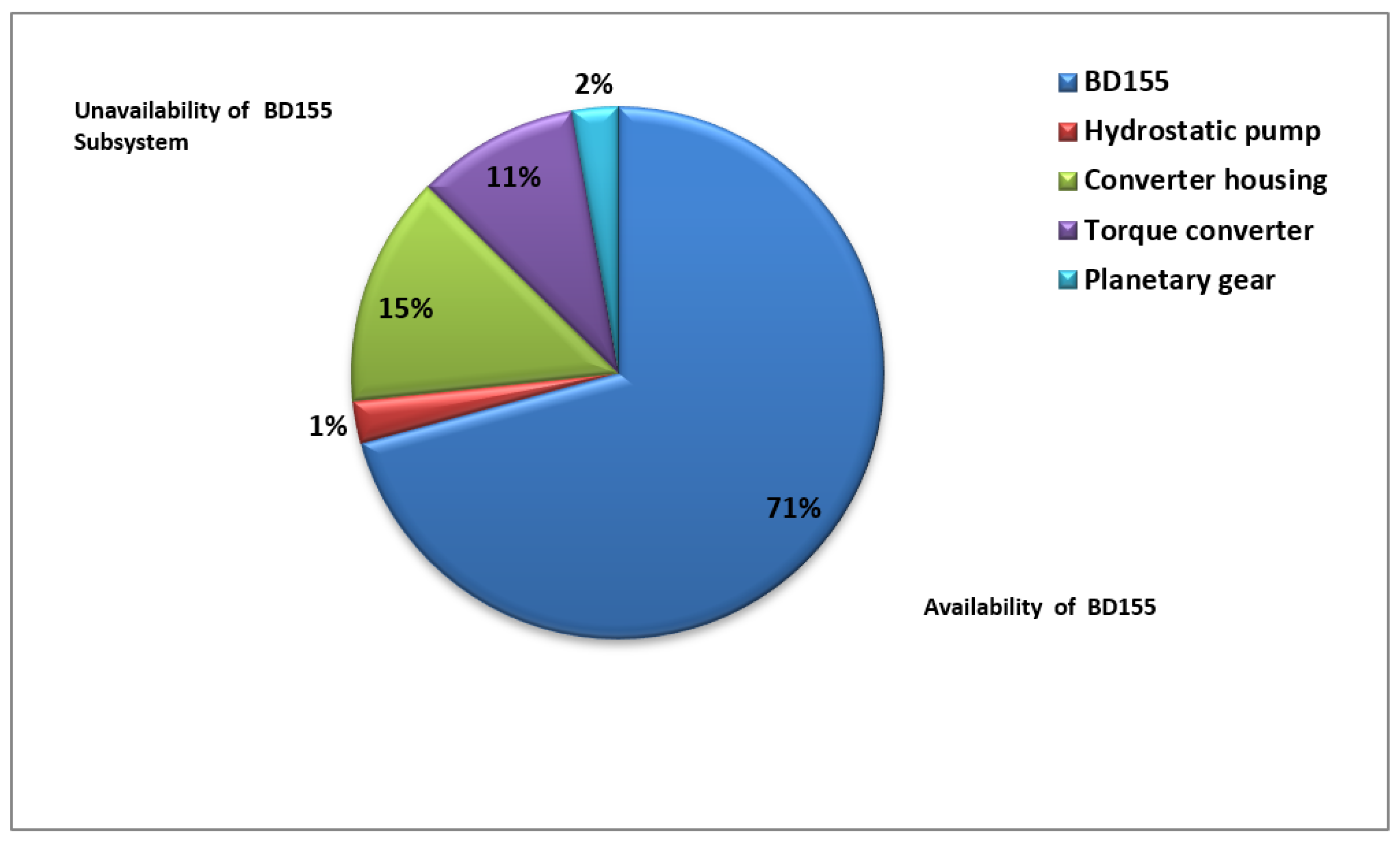

- Compared to others, BD155’s availability A(t) is about 62%, which seems to be a low percentage. Due to poor reliability and maintenance, 38% of transmission subsystems are not functional. According to Markov analysis, there is a 2%, 18%, 15%, and 3% corresponding unavailability for the hydrostatic pump, converter housing, torque converter, and planetary gear.

- The total productive maintenance (TPM) approach has been used to boost reliability and decrease downtime. Considering that TPM’s primary activity is preventive maintenance (PM), it is possible to undertake a TPM PM analysis as well. This process starts by identifying the issue and its scope. It entails ground research, equipment restoration, performance, and malfunction mapping for the study of previous performance.

- Mathematical analyses have shown that the MTTRPM is 1.5 times the typical MTTF without changing the MTTR.

- Additionally, the MTTF increased while the MTTR remained the same. The availability of the BD155 has increased from 62% to 71%, while the unavailability of the hydrostatic pump, converter housing, torque converter, and planetary gears has fallen to 1%, 15%, 11%, and 2%, respectively. This demonstrates the influence of TPM.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- O’Connor, P.; Kleyner, A. Practical Reliability Engineering; John Wiley & Sons: Chichester, UK, 2012. [Google Scholar]

- Avizienis, A.; Laprie, J.-C.; Randell, B. Fundamental concepts of dependability. Department of Computing Science Technical Report Series. Newcastle upon Tyne. 2001. Available online: http://www.cs.ncl.ac.uk/publications/trs/papers/739.pdf (accessed on 3 October 2022).

- Nichols, H.L., Jr. Moving the Earth: The Workbook of Excavation; McGraw-Hill Education: New York, NY, USA, 2005. [Google Scholar]

- Nick, V.; Wu, X. Maintenance and reliability analysis of a fleet of load-haul-dump vehicles in an un-derground hard rock mine. Int. J. Min. Reclam. Environ. 2009, 23, 227–238. [Google Scholar]

- Kumar, N.S.H.; Choudhary, R.P.; Murthy, C.S.N. Model based reliability analysis of shovel—Dumper system’s mechanical failures used in the surface coal mine: A case study. Saf. Reliab. 2020, 39, 215–229. [Google Scholar] [CrossRef]

- Barabady, J.; Kumar, U. Reliability analysis of mining equipment: A case study of a crushing plant at Jajarm Bauxite Mine in Iran. Reliab. Eng. Syst. Saf. 2008, 93, 647–653. [Google Scholar] [CrossRef]

- Vagenas, N.; Kumar, U.; Rönnkvist, E. Analysis of truck maintenance characteristics in a Swedish open pit mine. Int. J. Surf. Mining Reclam. Environ. 1994, 8, 65–71. [Google Scholar] [CrossRef]

- Kumar, U.; Klefsjö, B.; Granholm, S. Reliability investigation for a fleet of load haul dump machines in a Swedish mine. Reliab. Eng. Syst. Saf. 1989, 26, 341–361. [Google Scholar] [CrossRef] [Green Version]

- Morad, A.M.; Pourgol-Mohammad, M.; Sattarvand, J. Application of reliability-centered mainte-nance for productivity improvement of open pit mining equipment: Case study of Sungun Copper Mine. J. Cent. South Univ. 2014, 21, 2372–2382. [Google Scholar] [CrossRef]

- Barabady, J. Reliability and maintainability analysis of crushing plants in Jajarm Bauxite Mine of Iran. In Proceedings of the Annual Reliability and Maintainability Symposium, Alexandria, VA, USA, 24–27 January 2005; pp. 109–115. [Google Scholar]

- Vidyasagar, D.; Kishorilal, D.B. Maintenance and performance analysis of draglines used in mines. Int. J. Comput. Eng. Res. 2016, 6, 24–27. [Google Scholar]

- Mohammadi, M.; Rai, P.; Gupta, S. Improving productivity of dragline through enhancement of re-liability, inherent availability and maintainability. Acta Montan. Slovaca 2016, 21, 1–8. [Google Scholar]

- Pandey, P.; Mukhopadhyay, A.K.; Chattopadhyaya, S. Reliability analysis and failure rate evaluation for critical subsystems of the dragline. J. Braz. Soc. Mech. Sci. Eng. 2018, 40, 50. [Google Scholar] [CrossRef]

- Fan, Q.; Fan, H. Reliability Analysis and Failure Prediction of Construction Equipment with Time Series Models. J. Adv. Manag. Sci. 2015, 3, 203–210. [Google Scholar] [CrossRef] [Green Version]

- Acuña, G.; Curilem, M.; Araya, B.; Cubillos, F.; Miranda, R.; Garrido, F. Predictive Models Applied to Heavy Duty Equipment Management; Springer: Cham, Switzerland, 2014. [Google Scholar] [CrossRef]

- Washimkar, P.V.; Deshpande, V.S.; Modak, J.P.; Nasery, A.V. Formulation of Preventive Maintenance Schedule for Dragline System. Int. J. Eng. Technol. 2011, 3, 396–399. [Google Scholar] [CrossRef]

- Li, L.-L.; Lv, C.-M.; Tseng, M.-L.; Sun, J. Reliability measure model for electromechanical products under multiple types of uncertainties. Appl. Soft Comput. 2018, 65, 69–78. [Google Scholar] [CrossRef]

- Katsitadze, J.; Karkashadze, N.; Kutelia, G. Indicators of reliability of plows working in mountainous conditions of Georgia. Ann. Agrar. Sci. 2018, 16, 210–212. [Google Scholar] [CrossRef]

- Wang, Q.; Fang, H. Reliability analysis of tunnels using an adaptive RBF and a first-order reliability method. Comput. Geotech. 2018, 98, 144–152. [Google Scholar] [CrossRef]

- Esmaeili, M.; Bazzazi, A.A.; Borna, S. Reliability analysis of a fleet of loaders in Sangan irons mine. Arch. Min. Sci. 2011, 56, 629–640. [Google Scholar]

- Xu, Y.; Xi, Y.; Li, D.; Zhou, Z. Traffic Signal Control Based on Markov Decision Process. IFAC-Pap. Online 2016, 49, 67–72. [Google Scholar] [CrossRef]

- Samanta, B.; Sakar, B.; Mukherjee, S.K. Reliability modelling and performance analyses of an LHD system in mining. J. S. Afr. Inst. Min. Metall. 2004, 104, 1–8. [Google Scholar]

- Murthy, V.M.S.R.; Ghose, A.K.; Jethwa, J.L. Improving roadheader performance in Indian coal mines—A systems development approach and field investigations. J. Mines Met. Fuels 1997, 45, 66–80. [Google Scholar]

- Lalropuia, K.; Gupta, V. Modeling cyber-physical attacks based on stochastic game and Markov processes. Reliab. Eng. Syst. Saf. 2019, 181, 28–37. [Google Scholar] [CrossRef]

- Ossai, C.I.; Boswell, B.; Davies, I. Markov chain modelling for time evolution of internal pitting corrosion distribution of oil and gas pipelines. Eng. Fail. Anal. 2016, 60, 209–228. [Google Scholar] [CrossRef] [Green Version]

- Agrawal, A.K.; Murthy, V.; Chattopadhyaya, S. Investigations into reliability, maintainability and availability of tunnel boring machine operating in mixed ground condition using Markov chains. Eng. Fail. Anal. 2019, 105, 477–489. [Google Scholar] [CrossRef]

- D’Urso, D.; Chiacchio, F.; Borrometi, D.; Costa, A.; Compagno, L. Dynamic failure rate model of an electric motor comparing the Military Standard and Svenska Kul-lagerfabriken (SKF) methods. Procedia Comput. Sci. 2021, 180, 456–465. [Google Scholar] [CrossRef]

- Yadav, G.; Joshi, D.; Gopinath, L.; Soni, M.K. Reliability and Availability Optimization of Smart Microgrid Using Specific Configuration of Renewable Resources and Considering Subcomponent Faults. Energies 2022, 15, 5994. [Google Scholar] [CrossRef]

- Odeyar, P.; Apel, D.B.; Hall, R.; Zon, B.; Skrzypkowski, K. A Review of Reliability and Fault Analysis Methods for Heavy Equipment and Their Components Used in Mining. Energies 2022, 15, 6263. [Google Scholar] [CrossRef]

- Cox, D.R. The analysis of non-Markovian stochastic processes by the inclusion of supplementary variables. Math. Proc. Camb. Philos. Soc. 1955, 51, 433–441. [Google Scholar] [CrossRef]

- Birolini, A. Reliability Engineering: Theory and Practice; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Chiacchio, F.; Aizpurua, J.I.; Compagno, L.; Khodayee, S.M.; D’Urso, D. Modelling and Resolution of Dynamic Reliability Problems by the Coupling of Simulink and the Stochastic Hybrid Fault Tree Object Oriented (SHyFTOO) Library. Information 2019, 10, 283. [Google Scholar] [CrossRef] [Green Version]

- Khoshalan, H.A.; Torabi, S.R.; Maleki, D. RAM Analysis of Hydraulic System of Earth Pressure Balance Tunnel Boring Machine. Indian J. Sci. Technol. 2015, 8, 28. [Google Scholar] [CrossRef]

- Kumar, D.; Pandey, P.C. Maintenance planning and resource allocation in a urea fertilizer plant. Qual. Reliab. Eng. Int. 1993, 9, 411–423. [Google Scholar] [CrossRef]

- Borris, S. Total Productive Maintenance; McGraw-Hill: New York, NY, USA, 2006. [Google Scholar]

- Sun, R.; Wang, J.; Cheng, Q.; Mao, Y.; Ochieng, W.Y. A new IMU-aided multiple GNSS fault detection and exclusion algorithm for integrated navigation in urban environments. GPS Solutions 2021, 25, 147. [Google Scholar] [CrossRef]

- Ni, T.; Liu, D.; Xu, Q.; Huang, Z.; Liang, H.; Yan, A. Architecture of Cobweb-Based Redundant TSV for Clustered Faults. IEEE Trans. Very Large Scale Integr. VLSI Syst. 2020, 28, 1736–1739. [Google Scholar] [CrossRef]

| Net Torque: | 1456 N-m (148.5 kg-m) @ 1400 rpm | ||

| Torque Converter: | Type 3 element, Single Stage and Single phase | ||

| Stall ratio: 2.4 | |||

| Transmission Type: | 3F/3R, Planetary Power shift Transmission | ||

| Final Drive: | Type-Spur gearing, Double reduction | ||

| Lubrication Type: Splash | |||

| Total Reduction: 40.104 | |||

| Speeds m/sec (km/h): | Range | Forward | Reverse |

| 1st | 0–1.03 (0–3.07) | 0–1.25 (0–4.50) | |

| 2nd | 0–1.89 (0–6.80) | 0–2.30 (0–8.20) | |

| 3rd | 0–3.28 (0–11.8) | 0–3.81 (0–13.7) |

| Operational Status | Rate of Failure λi/h | Rate of Repair µi/h | Working State Probability | Failed State Probability |

|---|---|---|---|---|

| Hydrostatic pump | 0.060 | 1.512 | P0 | P1 |

| Converter housing | 0.190 | 0.619 | P0 | P2 |

| Torque converter | 0.312 | 1.193 | P0 | P3 |

| Planetary gear | 0.042 | 0.979 | P0 | P4 |

| Subassembly of BD155 Transmission | |||||

|---|---|---|---|---|---|

| Time (h) | Hydrostatic Pump | Converter Housing | Torque Converter | Planetary Gear | Trans (BD155) |

| 0 | 1.0000 | 1.0000 | 1.0000 | 1.0000 | 1.0000 |

| 5 | 0.9378 | 0.8901 | 0.8798 | 0.8715 | 0.4977 |

| 10 | 0.8501 | 0.8251 | 0.7791 | 0.8254 | 0.3347 |

| 15 | 0.8005 | 0.7689 | 0.7517 | 0.7512 | 0.2281 |

| 20 | 0.7854 | 0.7091 | 0.6691 | 0.7114 | 0.1209 |

| 25 | 0.7323 | 0.6854 | 0.6413 | 0.6489 | 0.0972 |

| 30 | 0.6859 | 0.6351 | 0.5385 | 0.6207 | 0.0621 |

| 35 | 0.6431 | 0.5965 | 0.5071 | 0.5287 | 0.0279 |

| 40 | 0.5923 | 0.5484 | 0.4139 | 0.5189 | 0.0095 |

| 45 | 0.5355 | 0.4991 | 0.3485 | 0.4387 | 0.0021 |

| 50 | 0.4965 | 0.4684 | 0.3179 | 0.4062 | 0.0001 |

| 55 | 0.4219 | 0.4010 | 0.3005 | 0.3454 | 0.0001 |

| 60 | 0.4001 | 0.3785 | 0.2587 | 0.3312 | 0.0000 |

| 65 | 0.3979 | 0.3423 | 0.2317 | 0.2518 | 0.0000 |

| 70 | 0.3582 | 0.3001 | 0.2109 | 0.2117 | 0.0000 |

| 75 | 0.3030 | 0.2971 | 0.1894 | 0.1084 | 0.0000 |

| 80 | 0.2897 | 0.1413 | 0.0217 | 0.0521 | 0.0000 |

| 85 | 0.0959 | 0.0719 | 0.0189 | 0.0438 | 0.0000 |

| 90 | 0.0743 | 0.0585 | 0.0155 | 0.0312 | 0.0000 |

| 95 | 0.0197 | 0.0324 | 0.0073 | 0.0105 | 0.0000 |

| 100 | 0.0124 | 0.0011 | 0.0000 | 0.0001 | 0.0000 |

| Subassembly of BD155 Transmission | |||||

|---|---|---|---|---|---|

| Time (h) | Hydrostatic Pump | Converter Housing | Torque Converter | Planetary Gear | Trans (BD155) |

| 0 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 |

| 5 | 0.4592 | 0.5814 | 0.7857 | 0.6615 | 0.7715 |

| 10 | 0.5618 | 0.6886 | 0.8543 | 0.7714 | 0.8844 |

| 15 | 0.6697 | 0.7195 | 0.8954 | 0.8298 | 0.9169 |

| 20 | 0.7747 | 0.8091 | 0.9174 | 0.8819 | 0.9523 |

| 25 | 0.8798 | 0.8534 | 0.9367 | 0.9254 | 0.9758 |

| 30 | 0.8914 | 0.9157 | 0.9548 | 0.9999 | 0.9879 |

| 35 | 0.9729 | 0.9269 | 0.9699 | 0.9999 | 0.9989 |

| 40 | 0.9835 | 0.9387 | 0.9877 | 1.0000 | 0.9999 |

| 45 | 0.9944 | 0.9444 | 0.9934 | 1.0000 | 1.0000 |

| 50 | 0.9966 | 0.9584 | 0.9999 | 1.0000 | 1.0000 |

| 55 | 0.9975 | 0.9868 | 1.0000 | 1.0000 | 1.0000 |

| 60 | 0.9981 | 0.9999 | 1.0000 | 1.0000 | 1.0000 |

| 65 | 0.9999 | 1.0000 | 1.0000 | 1.0000 | 1.0000 |

| 70 | 1.0000 | 1.0000 | 1.0000 | 1.0000 | 1.0000 |

| 75 | 1.0000 | 1.0000 | 1.0000 | 1.0000 | 1.0000 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bhushan, K.; Chattopadhyaya, S.; Sharma, S.; Sharma, K.; Li, C.; Zhang, Y.; Eldin, E.M.T. Analyzing Reliability and Maintainability of Crawler Dozer BD155 Transmission Failure Using Markov Method and Total Productive Maintenance: A Novel Case Study for Improvement Productivity. Sustainability 2022, 14, 14534. https://doi.org/10.3390/su142114534

Bhushan K, Chattopadhyaya S, Sharma S, Sharma K, Li C, Zhang Y, Eldin EMT. Analyzing Reliability and Maintainability of Crawler Dozer BD155 Transmission Failure Using Markov Method and Total Productive Maintenance: A Novel Case Study for Improvement Productivity. Sustainability. 2022; 14(21):14534. https://doi.org/10.3390/su142114534

Chicago/Turabian StyleBhushan, Kartick, Somnath Chattopadhyaya, Shubham Sharma, Kamal Sharma, Changhe Li, Yanbin Zhang, and Elsayed Mohamed Tag Eldin. 2022. "Analyzing Reliability and Maintainability of Crawler Dozer BD155 Transmission Failure Using Markov Method and Total Productive Maintenance: A Novel Case Study for Improvement Productivity" Sustainability 14, no. 21: 14534. https://doi.org/10.3390/su142114534