Masonry in the Context of Sustainable Buildings: A Review of the Brick Role in Architecture

Abstract

1. Introduction and Background

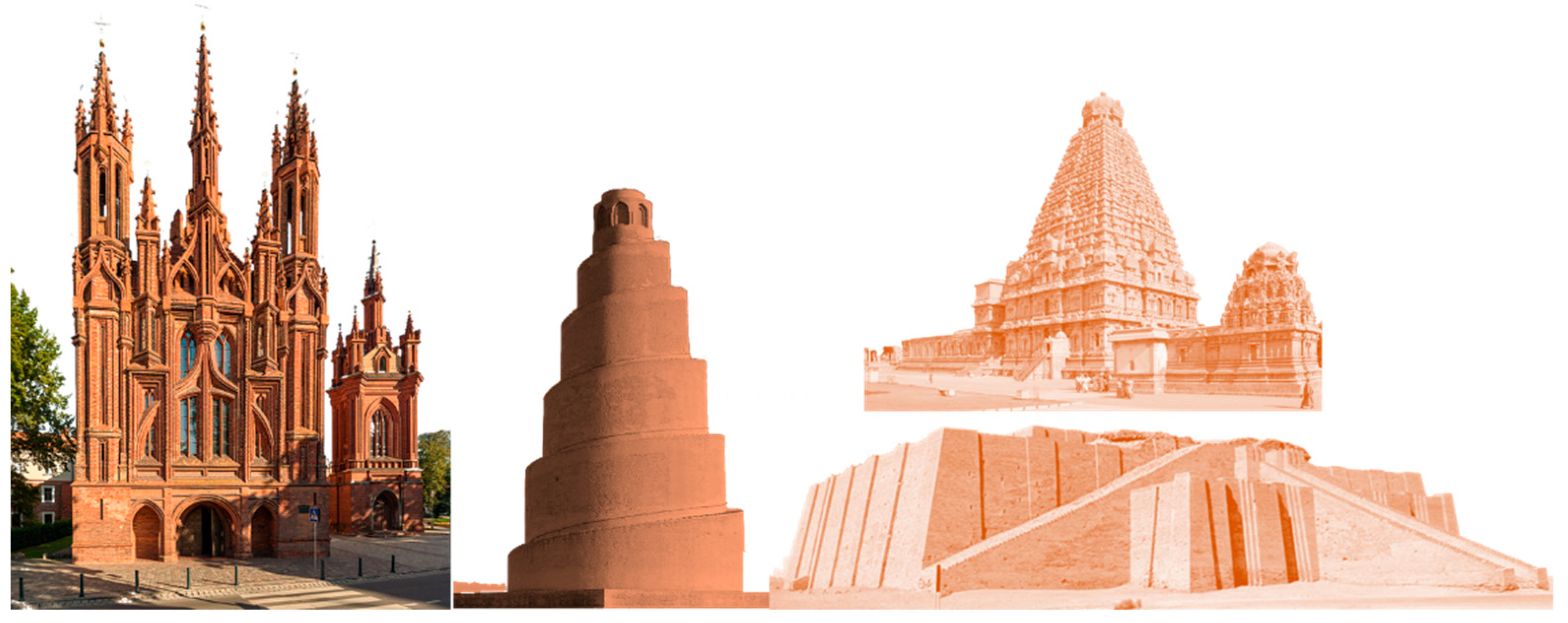

2. History—The Evolution from BC to AD

2.1. Ancient Civilizations—Rome, Mesopotamia, Greece, and China

2.2. Medieval Times

3. The Contemporary Brick Masonry Techniques

3.1. Masonry in the Application and Conceptual Framework

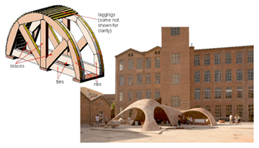

3.2. Masonry within the Architectural Model

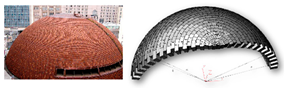

3.3. Brick Working Model

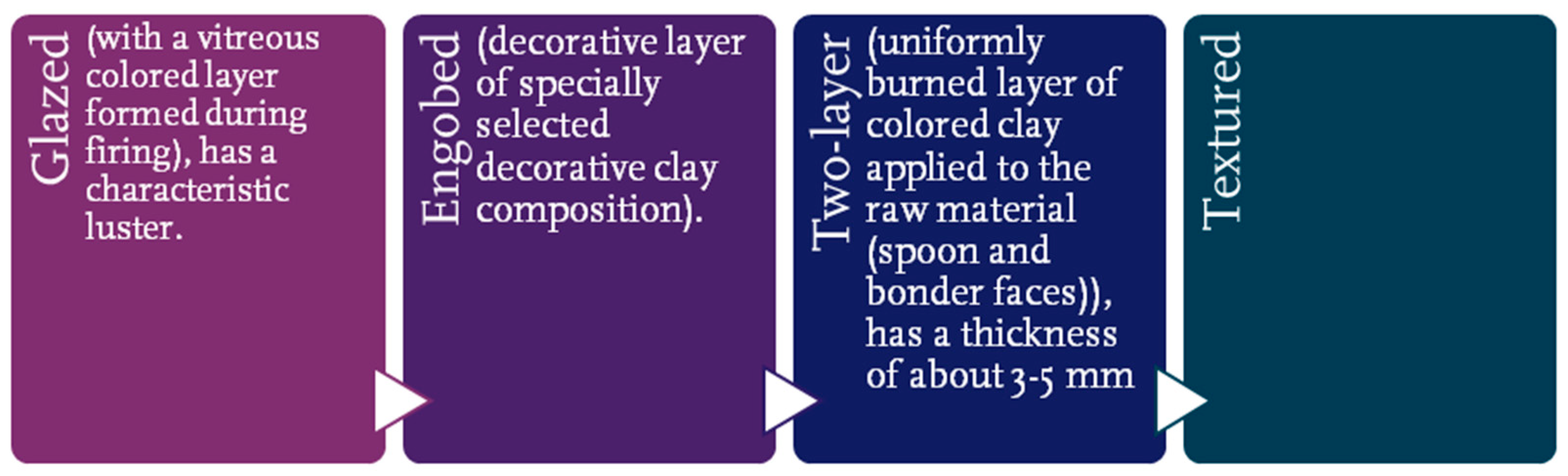

3.4. The Special Form of Masonry (Polychrome Brickwork)

3.5. Masonry & Quality-Control Process

4. Contemporary Masonry Construction Standards and Model

4.1. Masonry Working Standards

4.2. Masonry, Form, Colors, and Selection Platform

4.3. ABC and Sustainability

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tamás, H.; Nagy, D.U.; Pál, R.W. Adobe bricks can help identify historic weed flora—A case study from south-western Hungary. Plant Ecol. Divers. 2016, 9, 113–125. [Google Scholar] [CrossRef]

- Dipasquale, L.; Rovero, L.; Fratini, F. Ancient stone masonry constructions. In Nonconventional and Vernacular Construction Materials; Woodhead Publishing: Sawston, UK, 2020; pp. 403–435. [Google Scholar]

- Nicolas Durand, H.; Monger, C.; Matthew, G.C. 9-Calcium Carbonate Features. In Interpretation of Micromorphological Features of Soils and Regoliths; Elsevier: Amsterdam, The Netherlands, 2010; pp. 149–194. [Google Scholar] [CrossRef]

- Manzanilla, L.; López, C.; Freter, A. Dating Results from Excavations in Quarry Tunnels Behind the Pyramid of the Sun at Teotihuacan. Anc. Mesoam. 1996, 7, 245–266. [Google Scholar] [CrossRef]

- Bahobail, M.A. The mud additives and their effect on thermal conductivity of adobe bricks. J. Eng. Sci. 2012, 40, 21–34. [Google Scholar] [CrossRef]

- Lambourn, E. Brick, Timber, and Stone: Building Materials and the Construction of Islamic Architectural History in Gujarat. Muqarnas 2006, 23, 191–217. [Google Scholar] [CrossRef]

- Peter, J.L.; Paul, J.S. Decagonal and Quasi-Crystalline Tilings in Medieval Islamic Architecture. Science 2007, 315, 1106–1110. [Google Scholar] [CrossRef]

- Hamburg, J.; Lorenzon, M. Before Meeting the Greeks: Kutaisi Influence in Late Bronze and Early Iron Age Colchian Settlements. J. Field Archaeol. 2022, 47, 13–31. [Google Scholar] [CrossRef]

- Suzan, E.A.K.; Peta, J.M. Palynological records of climate and oceanic conditions in the late Pleistocene and Holocene of the nile cone, southeastern Mediterranean. Egypt Palynol. 2009, 33, 1–24. [Google Scholar] [CrossRef]

- Chen, M. Harappa Civilization. In China and the World in the Liangzhu Era. Liangzhu Civilization; Springer: Singapore, 2022. [Google Scholar] [CrossRef]

- Binici, H.; Binici, F.; Akcan, M.; Yardim, Y.; Mustafaraj, E.; Corradi, M. Physical–Mechanical and Mineralogical Properties of Fired Bricks of the Archaeological Site of Harran, Turkey. Heritage 2020, 3, 1018–1034. [Google Scholar] [CrossRef]

- Almusaed, A.; Almssad, A. Introductory Chapter: Overview of a Competent Sustainable Building. In Sustainable Buildings—Interaction Between a Holistic Conceptual Act and Materials Properties; IntechOpen: London, UK, 2018; Available online: https://www.intechopen.com/chapters/61634 (accessed on 17 September 2022). [CrossRef]

- Almusaed, A.; Almssad, A.; Najar, K. An Innovative School Design Based on a Biophilic Approach Using the Appreciative Inquiry Model: Case Study Scandinavia. Adv. Civ. Eng. 2022, 2022, 8545787. [Google Scholar] [CrossRef]

- Homod, R.Z.; Almusaed, A.; Almssad, A.; Jaafar, M.K.; Goodarzi, M.; Sahari, K.S.M. Effect of different building envelope materials on thermal comfort and air-conditioning energy savings: A case study in Basra city, Iraq. J. Energy Storage 2021, 34, 101975. [Google Scholar] [CrossRef]

- Dhandhukia, P.; Goswami, D.; Thakorb, P.; Thakker, J.N. Soil property apotheosis to corral the finest compressive strength of unbaked adobe bricks. Constr. Build. Mater. 2013, 48, 948–953. [Google Scholar] [CrossRef]

- Han, L.C.; Mirasa, A.K.B.; Saad, I.; Bolong, N.B.; Asman, N.S.A.B.; Asrah, H.B.; Abdullah, E.S.R.B. Use of Compressed Earth Bricks/Blocks in Load-Bearing Masonry Structural Systems: A Review. Mater. Sci. Forum 2020, 997, 9–19. [Google Scholar] [CrossRef]

- Adamo, N.; Al-Ansari, N. Babylon in a New Era: The Chaldean and Achaemenid Empires (330–612 BC). J. Earth Sci. Geotech. Eng. 2020, 10, 87–111. [Google Scholar]

- Almusaed, A.; Asaad Alasadi Almssad, A. A Research on the Biophilic Concept upon School’s Design from Hot Climate: A Case Study from Iraq. Publ. Adv. Mater. Sci. Eng. 2022, 2022, 7994999. [Google Scholar] [CrossRef]

- Almusaed, A.; Yitmen, I.; Almssad, A.; Homod, R.Z. Environmental profile on building material passports for hot climates. Sustainability 2020, 12, 3720. [Google Scholar] [CrossRef]

- CultroneItziar, G.; Carmen, A.; Casado, C.; Arizzi, A. Sawdust recycling in the production of lightweight bricks: How the amount of additive and the firing temperature influence the physical properties of the bricks. Constr. Build. Mater. 2020, 235, 117436. [Google Scholar] [CrossRef]

- Rossi, C. On Measuring Ancient Egyptian Architecture. J. Egypt. Archaeol. 2020, 106, 229–238. [Google Scholar] [CrossRef]

- Almusaed, A.; Almssad, A. Building materials in eco-energy houses from Iraq and Iran. In Case Studies in Construction Materials Journal; Elsevier: Amsterdam, The Netherlands, 2015; Volume 1, pp. 452–454. [Google Scholar] [CrossRef][Green Version]

- Shu, C.X.; Cantisani, E.; Fratini, F.; Rasmussen, K.L.; Rovero, L.; Stipo, G.; Vettori, S. China’s brick history and conservation: Laboratory results of Shanghai samples from 19th to 20th century. Constr. Build. Mater. 2017, 151, 789–800. [Google Scholar] [CrossRef]

- Al-Fakih, A.; Mohammed, B.S.; Liew, M.S.; Nikbakht, E. Incorporation of waste materials in the manufacture of masonry bricks: An update review. J. Build. Eng. 2019, 21, 37–54. [Google Scholar] [CrossRef]

- Wu, Y.; Bao, P. Experimental study on the properties of modern blue clay brick for Kaifeng People’s Conference Hall. Sci. Rep. 2021, 11, 20631. [Google Scholar] [CrossRef]

- Nadali, D. Esarhaddon’s glazed bricks from Nimrud: The Egyptian campaign depicted. Iraq 2006, 68, 109–119. [Google Scholar] [CrossRef]

- Dabaieh, M.; Heinonen, J.; El-Mahdy, D.; Hassan, D.M. A comparative study of life cycle carbon emissions and embodied energy between sun-dried bricks and fired clay bricks. J. Clean. Prod. 2020, 275, 122998. [Google Scholar] [CrossRef]

- Arnaud, B.; Benoit, R. L’industrie Cistercienne (XIIe-XXIe siècle). Actes du Colloque International, Troyes, Abbaye de Clairvaux, Abbaye de Fontenay, Somogy, éditions d’art, 1er-5 Septembre 2015, pp. 14–15, Paris. Available online: https://www.academia.edu/38986164/Lindustrie_cistercienne_XIIe_XXIe_si%C3%A8cle_Actes_du_colloque_international_Troyes_Abbaye_de_Clairvaux_Abbaye_de_Fontenay_1er_5_septembre_2015_ (accessed on 17 September 2022).

- Stefanidou, M.; Papayianni, I.; Pachta, V. Analysis and characterization of Roman and Byzantine fired bricks from Greece. Mater. Struct. 2015, 48, 2251–2260. [Google Scholar] [CrossRef]

- Hvattum, M. Panoramas of Style. J. Soc. Archit. Hist. 2011, 70, 190–209. [Google Scholar] [CrossRef][Green Version]

- Yakovlev, D.; Trushnikova, A.; Antipov, I. The cross-cultural interaction in the Baltic region in the fifteenth century: The vaults of the Faceted Palace in Novgorod the Great and Brick Gothic architecture. J. Balt. Stud. 2020, 51, 553–568. [Google Scholar] [CrossRef]

- Brotherson, D. The fortification of Angkor Wat. Antiquity 2015, 89, 1456–1472. [Google Scholar] [CrossRef]

- Joseph, P.; Tretsiakova-McNally, S. Sustainable Non-Metallic Building Materials. Sustainability 2010, 2, 400–427. [Google Scholar] [CrossRef]

- Fiala, J.; Junior, J.; Mikolas, M. Special brick products and their application. In World Multidisciplinary Earth Sciences Symposium (WMESS 2019), Proceedings of the Earth and Environmental Science, Prague, Czech Republic, 9–13 September 2019; IOP Publishing Ltd.: Prague, Czech Republic, 2019; Volume 362, p. 362. [Google Scholar]

- Cases, I. Appartenir aux classes populaires: L’exemple du pub dans l’Angleterre victorienne. Cah. Victoriens Et Edouardiens 2008, 67, 103–114. [Google Scholar] [CrossRef]

- Clark, K. The Landscape of Industry: Patterns of Change in the Ironbridge Gorge. In The Landscape of Industry: Patterns of Change in the Ironbridge Gorge; Routledge: London, UK, 1993; p. 192. [Google Scholar]

- Boerefijn, W. About the Ideal Layout of the City Street in the Twelfth to Sixteenth Centuries: The Myth of the Renaissance in Town Building. J. Urban Hist. 2016, 42, 938–952. [Google Scholar] [CrossRef]

- Debonne, V. Brick Production and Brick Building in Medieval Flanders January 2014. In Proceedings of the European Association of Archaeologists (EAA) Meeting, Helsinki, Finland, 29 August–1 September 2012. [Google Scholar]

- Kulakov, A.I.; Ri, A.U. Ceramics in architecture. IOP Conf. Ser. Earth Environ. Sci. 2021, 751, 012052. [Google Scholar] [CrossRef]

- Ali, M.M.; Al-Kodmany, K. Tall Buildings and Urban Habitat of the 21st Century: A Global Perspective. Buildings 2012, 2, 384–423. [Google Scholar] [CrossRef]

- Almusaed, A. Biophilic and Bioclimatic architecture. In Analytical Therapy for the Next Generation of Passive Sustainable Architecture; Springer-Verlag London Limited: London, UK, 2011; pp. 123–130. Available online: https://www.springer.com/gp/book/9781849965330 (accessed on 17 September 2022).

- Purici, Ş.; Mareci Sabol, H. From Beautification to Ennobling: The Exterior Mural Mosaics from Suceava of the Socialist Era. Societies 2022, 12, 107. [Google Scholar] [CrossRef]

- Lainez JM, C.; Verdejo JR, J.; Macias, B.S.-M.; Calero, J.I.P. The Key-role of Eladio Dieste, Spain and the Americas in the Evolution from Brickwork to Architectural Form. J. Asian Archit. Build. Eng. 2009, 8, 355–362. [Google Scholar] [CrossRef][Green Version]

- De Lorenzis, L.; Teng, J.G. Near-surface mounted FRP reinforcement: An emerging technique for strengthening structures. Compos. Part B Eng. 2007, 38, 119–143. [Google Scholar] [CrossRef]

- Artioli, G. 3 Materials and case studies: How to meet the needs. In Scientific Methods and Cultural Heritage: An Introduction to the Application of Materials Science to Archaeometry and Conservation Science; Oxford Academic: Oxford, UK, 2010. [Google Scholar] [CrossRef]

- Reade, J. Alexander the Great and the Hanging Gardens of Babylon; British Institute for the Study of Iraq: London, UK, 2000; Volume 62, pp. 195–217. [Google Scholar] [CrossRef]

- Ferrari, E.P. From Soil to Domes: Vernacular Architecture and Construction Techniques in Esfahak, South Khurasan. J. Br. Inst. Persian Stud. 2022, 60. [Google Scholar] [CrossRef]

- Foyle, J. Some Examples of External Colouration on English Brick Buildings, c. 1500–1650 », Bulletin du Centre de Recherche du Château de Versailles [En ligne], | 2002, mis en Ligne le 12 juin 2008, Consulté le 18 août 2022. Available online: http://journals.openedition.org/crcv/125 (accessed on 20 October 2022). [CrossRef]

- Gencel, O. Characteristics of fired clay bricks with pumice additive. Energy Build. 2015, 102, 217–224. [Google Scholar] [CrossRef]

- Auld, H.; Klaassen, J.; Comer, N. Weathering of Building Infrastructure and the Changing Climate: Adaptation Options. In Proceedings of the 2006 IEEE EIC Climate Change Conference, Ottawa, ON, Canada, 10–12 May 2006; pp. 1–11. [Google Scholar] [CrossRef]

- Getachew, K.; Mosisa, A. Laboratory Investigation of Locally Produced Clay Brick Quality and Suitability for Load Bearing Element in Jimma Area, Ethiopia. Int. J. Eng. Res. Technol. 2017, 6, 809–817. [Google Scholar]

- Müller, A.H.N.S.; Day, P.M.; Kilikoglou, V. Thermal conductivity of archaeological ceramics: The effect of inclusions, porosity, and firing temperature. Thermochim. Acta 2008, 480, 35–42. [Google Scholar] [CrossRef]

- Patel, A.L.M.A. Towards sustainable bricks production: An overview. Constr. Build. Mater. 2018, 165, 112–125. [Google Scholar] [CrossRef]

- Hermawan, H.; Švajlenka, J. Building Envelope and the Outdoor Microclimate Variable of Vernacular Houses: Analysis on the Environmental Elements in Tropical Coastal and Mountain Areas of Indonesia. Sustainability 2022, 14, 1818. [Google Scholar] [CrossRef]

- Zahra, T.; Thamboo, J.; Asad, M. Compressive strength and deformation characteristics of concrete block masonry made with different mortars, blocks, and mortar bedding types. J. Build. Eng. 2021, 38, 102213. [Google Scholar] [CrossRef]

- Cmglee. Comparison of Typical Face Brick Sizes of Assorted Countries with Isometric Projections with Dimensions in mm. 2022. Available online: https://commons.wikimedia.org/wiki/File:Comparison_house_brick_size.svg (accessed on 20 October 2022).

- Al-Assadi, F.I.; Al-Dewachi, M.H. The Role of Brick in Determining Features of Iraqi Architecture. IOP. Conf. Ser. Mater. Sci. Eng. 2020, 881, 012018. [Google Scholar] [CrossRef]

- Araya-Letelier, G.; Antico, C.; Federico, W.; María, J.; Gonzalez Retamal, R. Eco-bricks: A sustainable substitute for construction material. Rev. Construcción 2017, 16, 518–526. Available online: https://www.redalyc.org/articulo.oa?id=127654962016 (accessed on 17 August 2022).

- Spence, C. Senses of place: Architectural design for the multisensory mind. Cogn. Res. 2020, 5, 46. [Google Scholar] [CrossRef] [PubMed]

- Hnaihen, K.H. The Appearance of Bricks in Ancient Mesopotamia. Athens J. Hist. 2020, 6, 73–96. [Google Scholar] [CrossRef]

- Roof, C.; Bricks, F.S. Mortar Joints in Masonry—Here Are the Top 10 Types. 2022. Available online: https://gosmartbricks.com/types-mortar-joints/ (accessed on 19. October 2022).

- Wang, C.; Forth, J.P.; Nikitas, N.; Sarhosis, V. Retrofitting of masonry walls by using a mortar joint technique; experiments and numerical validation. Eng. Struct. 2016, 117, 58–70. [Google Scholar] [CrossRef]

- Karaman, S.; Gunal, H.; Gokalp, Z. Variation of Clay Brick Colors and Mechanical Strengthas Affected by Different Firing Temperatures. Sci. Res. Essays 2012, 7, 4208–4212. [Google Scholar]

- Attalla, R. The Technology of Mudbricks from the Sacred Architecture in Ancient Egypt to the Green House Revolution (Case Study of Luxor City, Egypt). Int. J. Adv. Sci. Technol. 2020, 29, 1264–1277. [Google Scholar]

- Villeda-Muñoz, G.; Castañeda-Miranda, A.; Pless, R.C.; Vega-Durán, J.T.; Pineda-Piñón, J. Clay-Brick Firing in a High-Temperature Solar Furnace. Ing. Investig. Tecnol. 2011, 12, 395–408. [Google Scholar] [CrossRef]

- Achik, M.; Moumni, B.; Benmoussa, H.; Oulmekki, A.; Touache, A.; Álvaro, G.G.; Rivera, F.G.; Infantes-Molina, A.; Eliche-Quesada, D.; Kizinievic, O. Towards the Use of Yellow Clay in Fired Bricks. In Clay and Clay Minerals; Intechopen: London, UK, 2021. [Google Scholar]

- Smith, A.S.; Bingel, P.; Bown, A. Sustainability of Construction Materials. In Woodhead Publishing Series in Civil and Structural Engineering, 2nd ed.; Woodhead Publishing: Sawston, UK, 2016; pp. 245–282. [Google Scholar] [CrossRef]

- Švajlenka, J.; Kozlovská, M.; Pošiváková, T. Analysis of Selected Building Constructions Used in Industrial Construction in Terms of Sustainability Benefits. Sustainability 2018, 10, 4394. [Google Scholar] [CrossRef]

- Švajlenka, J.; Kozlovská, M. Perception of User Criteria in the Context of Sustainability of Modern Methods of Construction Based on Wood. Sustainability 2018, 10, 116. [Google Scholar] [CrossRef]

- Akinyele, J.O.; Oyelakin, S.K. Assessment of the properties of bricks made from stone dust and molten plastic for building and pedestrian pavement. Int. J. Pavement Res. Technol. 2021, 14, 771–777. [Google Scholar] [CrossRef]

- Boriesab, C.; Borredon, M.; Vedrenne, E.; Vilarem, G. Review Development of eco-friendly porous fired clay bricks using pore-forming agents: A review. J. Environ. Manag. 2014, 143, 186–196. [Google Scholar] [CrossRef] [PubMed]

- Dakhli, Z.; Lafhaj, Z.; Shukla, S.K. Robotic mechanical design for brick-laying automation. Cogent Eng. 2017, 4, 1. [Google Scholar] [CrossRef]

| Form and Image | Description |

|---|---|

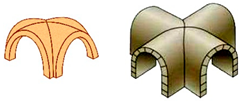

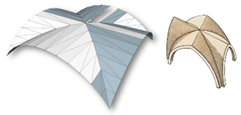

Folded arch | Based on the folded fake coupons, the Romans invented the real vaulted coupons in the 2nd century BC [45]. The coupon can be understood as the basic element of the arch. Single-story arched structures, such as arched doors and windows in the walls, are coupons. |

Arch coupons | The technique of arch coupons appeared in Mesopotamia as early as in the 4th millennium BC, and was later applied and developed in Babylon, Assyria, India, and Rome [46]. However, arch coupons appeared relatively late in China and went through several development steps of hollow brick beams and slabs, pointed arches, and folding arches, and formed in the early Western Han Dynasty. |

Barrel vault | The barrel vault is an extension of the coupon. Before the invention of concrete, barrel vaults consisted of multiple test blocks side by side. The original barrel-shaped vault was composed of numerous coupons juxtaposed and later developed into interlaced masonry between the coupons and connected into a whole, called a longitudinal barrel vault. |

Dome | The Romans created the dome arch from the tube arch structure, an alienated form of the barrel vault. The construction of domes is a millennias-old architectural tradition that persisted with several local variants worldwide [47]. |

Four-petal arch | Like the quadruple arch, it is also crosscut on the square tube arch, which consists of four identical parts; however, the top forms a more distinct cross shape than the quadruple arch, so the Romans call it a cross arch. |

Cross vaults | Although the cross arch got rid of the load-bearing wall, it could not rely on its own structure to balance the side thrust like the four-petal arch and the barrel vault, so the Romans arranged the cross arch in the longitudinal direction, and the adjacent parts balanced the longitudinal side thrust with each other. |

Rib vaults | The ribbed arch appeared in the late Roman Empire. Compared with the cross arch, the ribbed arch is divided into load-bearing and enclosed parts. The main load is concentrated on the arch, and the rest is enclosed by light bricks slabs, saving materials and lightening the valuts top weight. |

| Type of Mortar Layers | Brief Description | Illustration |

|---|---|---|

| Flush form | Plastering and other final finishes are built using this mortar layer. As a result, these layers are finally concealed. It is somewhat time-consuming and requires a little more work. Water may settle on top of the flush form if it is made in such a way as to stand out from the brickwork. |  |

| Raked form | The mortar is forced slightly inward in the raked jform, leaving it about 2 mm lower than the facing brick. Its ledge, which might enable water or snow to accumulate on top of the brick, makes it unsuitable for external usage. |  |

| Concave form | It is one of the most common forms of mortar owing to the high amount of rainwater it can block, thus avoiding inward leakages. This layer’s ability to keep the mortar tight is due to the employment of a curved steeling tool. |  |

| “V” form | Named as such because of its “V” shape, as seen in the image on the right, this mortar layer offers little protection against water infiltration due to its design. |  |

| Struck form | The struck form works better with interior walls than with exterior ones. This junction has a bottom edge that is recessed and a top edge that is finished flash with a brick edge. Water is drawn in and allowed to settle on the brick thanks to the slope of the layer |  |

| Weather form | This is similar to the struck layer, except that the top edge is recessed, not the bottom. This junction allows the water to drain quickly from the mortar layer because of the slope. Additionally, the mortar in the mortar layer must be adequately bonded to reduce the likelihood of water seeping through its underside. |  |

| Extruded form | No special tooling is needed for this kind of layer. Since excess mortar is naturally squeezed out, and causes an extrusion between the bricks, this effct is generated organically. |  |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Almssad, A.; Almusaed, A.; Homod, R.Z. Masonry in the Context of Sustainable Buildings: A Review of the Brick Role in Architecture. Sustainability 2022, 14, 14734. https://doi.org/10.3390/su142214734

Almssad A, Almusaed A, Homod RZ. Masonry in the Context of Sustainable Buildings: A Review of the Brick Role in Architecture. Sustainability. 2022; 14(22):14734. https://doi.org/10.3390/su142214734

Chicago/Turabian StyleAlmssad, Asaad, Amjad Almusaed, and Raad Z. Homod. 2022. "Masonry in the Context of Sustainable Buildings: A Review of the Brick Role in Architecture" Sustainability 14, no. 22: 14734. https://doi.org/10.3390/su142214734

APA StyleAlmssad, A., Almusaed, A., & Homod, R. Z. (2022). Masonry in the Context of Sustainable Buildings: A Review of the Brick Role in Architecture. Sustainability, 14(22), 14734. https://doi.org/10.3390/su142214734