Applications of Solar Panel Waste in Pavement Construction—An Overview

Abstract

1. Introduction

2. Research Methodology

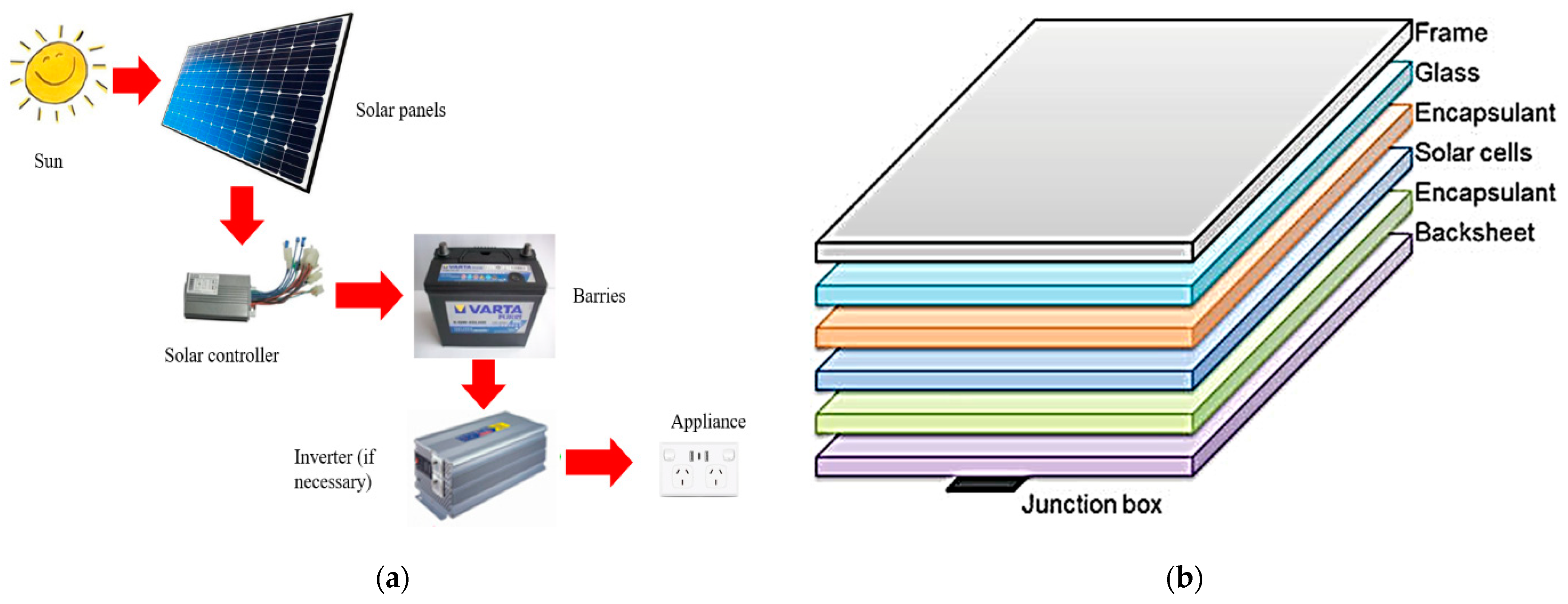

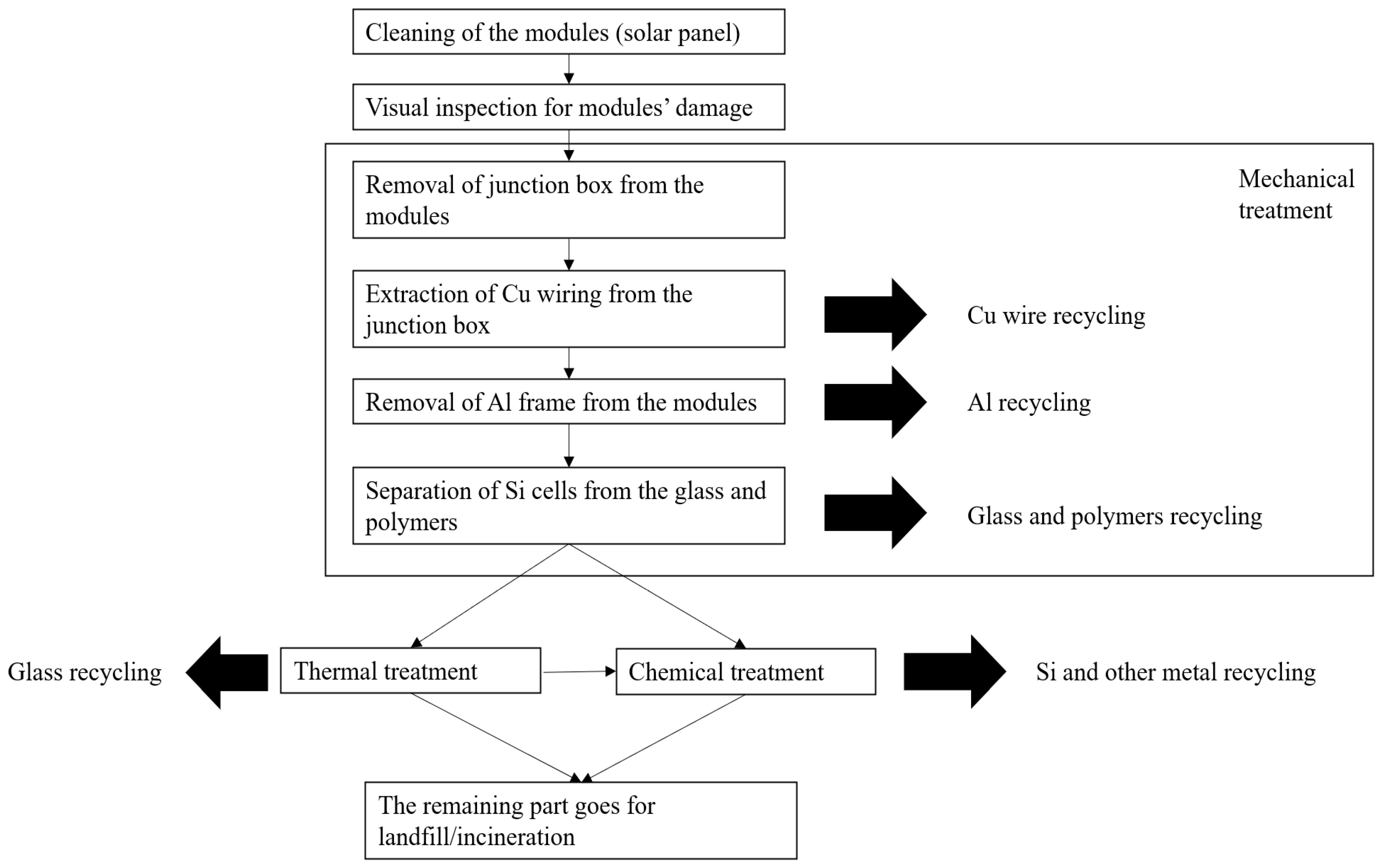

3. Composition and Material Properties of a Solar Panel

4. Concrete Pavement Applications

4.1. Waste Glass as an Aggregate

4.2. Waste Glass as a Cement Replacement Material

4.3. Waste Glass Together as an Aggregate and Cement Replacement Material

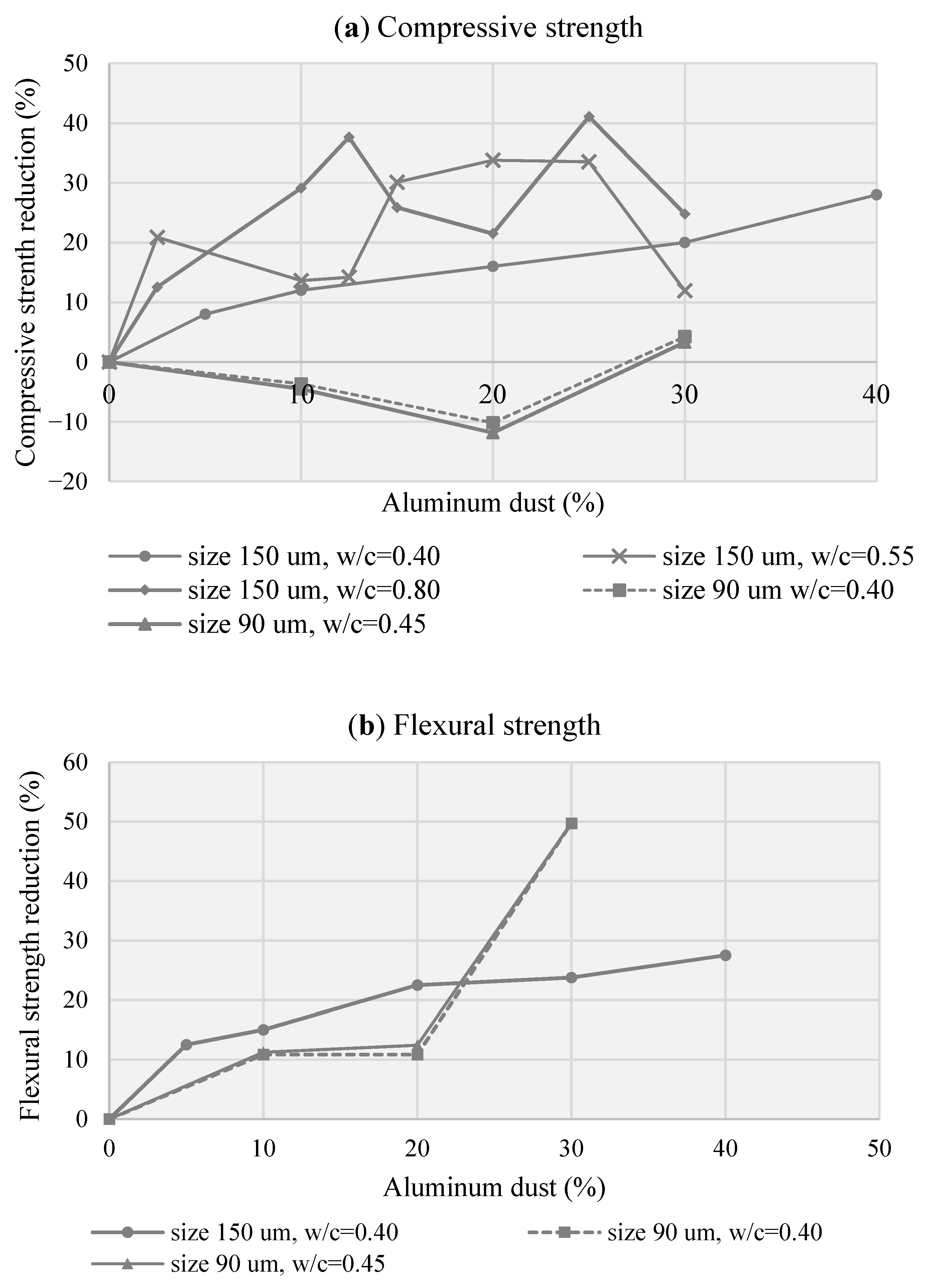

4.4. Aluminium (Al) Waste in Concrete

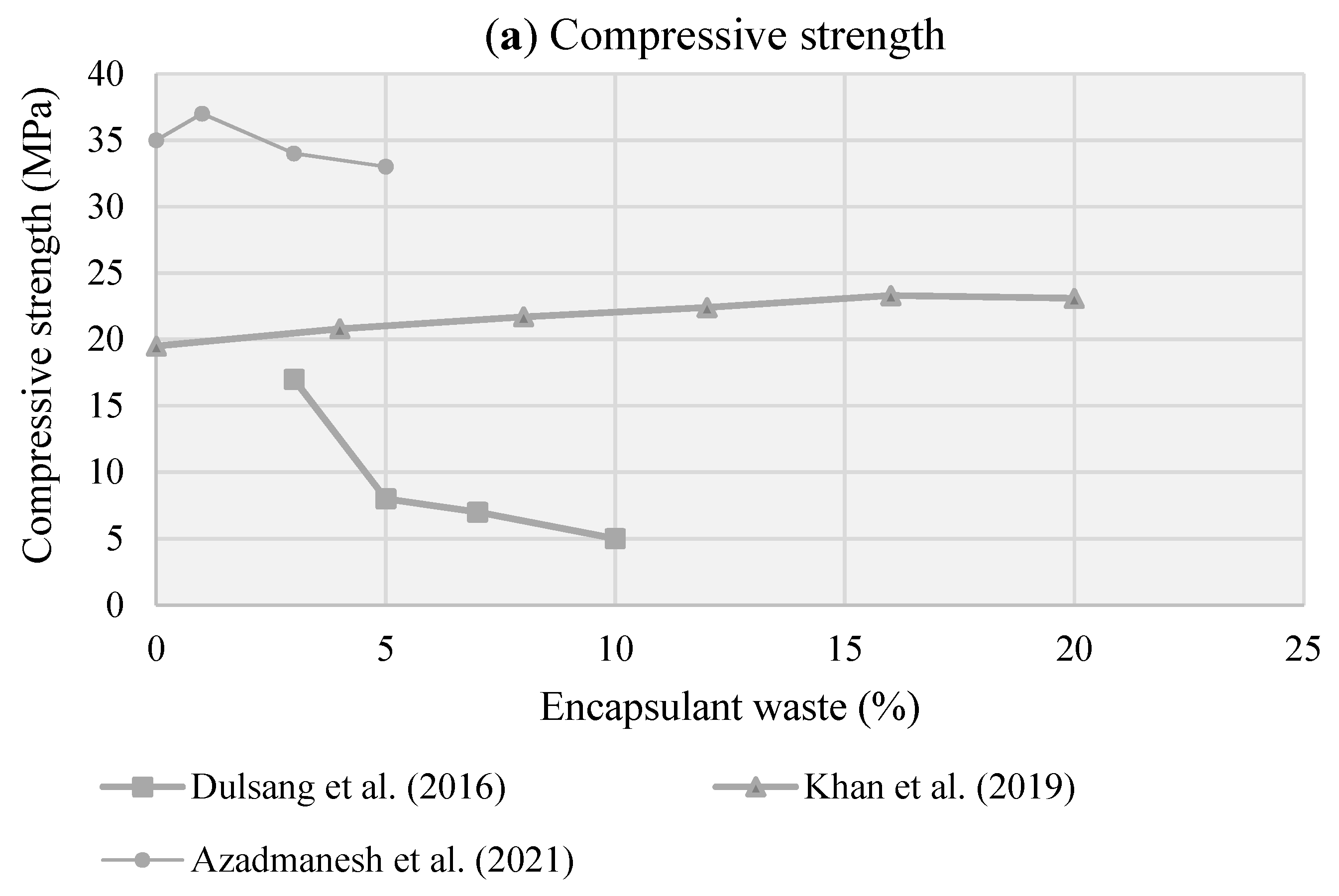

4.5. Polymer Waste in Concrete

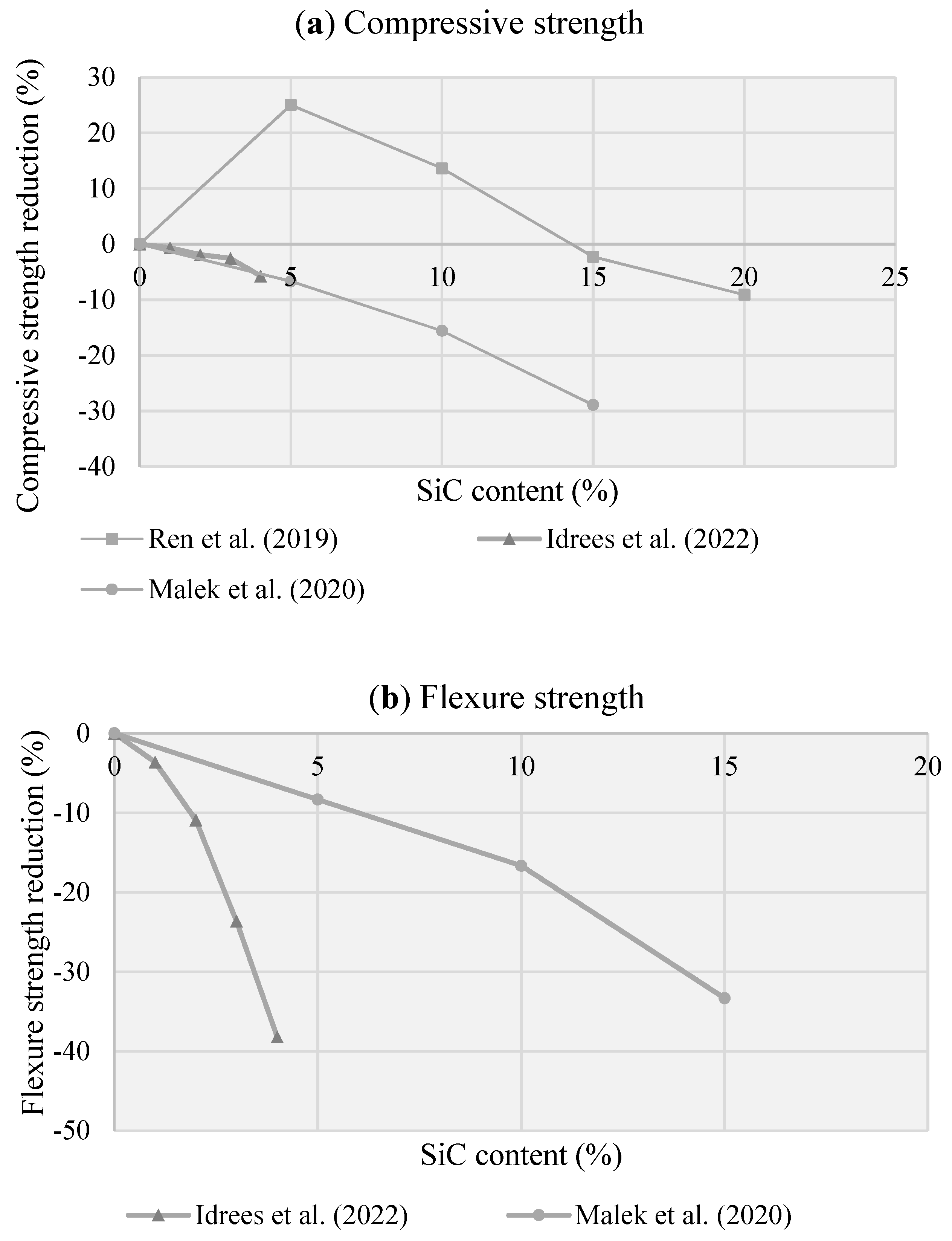

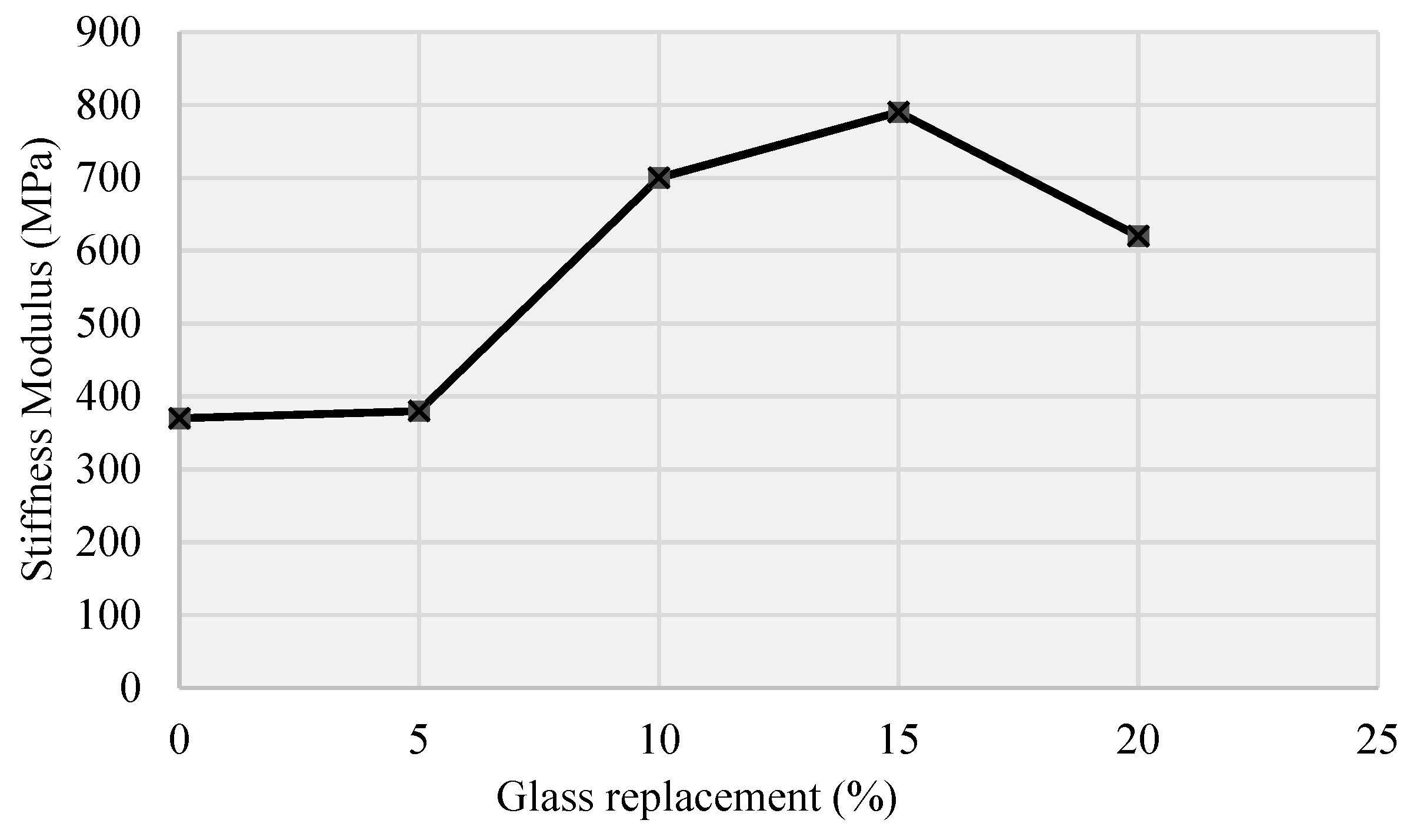

4.6. Silicon Waste in Concrete

5. Asphalt Pavement Applications

6. Impediments and Drivers of Using Solar Panel Waste as a Pavement Material

7. Conclusions and Future Research

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Varun; Prakash, R.; Bhat, I.K. Energy, economics and environmental impacts of renewable energy systems. Renew. Sustain. Energy Rev. 2009, 13, 2716–2721. [Google Scholar] [CrossRef]

- Xu, Y.; Li, J.H.; Tan, Q.Y.; Peters, A.L.; Yang, C.R. Global status of recycling waste solar panels: A review. Waste Manag. 2018, 75, 450–458. [Google Scholar] [CrossRef] [PubMed]

- Zappa, W.; Van Den Broek, M. Analysing the potential of integrating wind and solar power in Europe using spatial optimisation under various scenarios. Renew. Sustain. Energy Rev. 2018, 94, 1192–1216. [Google Scholar] [CrossRef]

- Mahmoudi, S.; Huda, N.; Behnia, M. Photovoltaic waste assessment: Forecasting and screening of emerging waste in Australia. Resour. Conserv. Recycl. 2019, 146, 192–205. [Google Scholar] [CrossRef]

- Sandanayake, M.; Lokuge, W.; Zhang, G.; Setunge, S.; Thushar, Q. Greenhouse gas emissions during timber and concrete building construction—A scenario based comparative case study. Sustain. Cities Soc. 2018, 38, 91–97. [Google Scholar] [CrossRef]

- Sandanayake, M.; Zhang, G.; Setunge, S. A comparative method of air emission impact assessment for building construction activities. Environ. Impact Assess. Rev. 2018, 68, 1–9. [Google Scholar] [CrossRef]

- Kuruvachalil, L.; Sandanayake, M.; Kumanayake, R.; Radhakrishna. Carbon Emission and Cost Analysis of Using Hybrid Fibre White Topping Overlays & mdash;A Road Rehabilitation Feasibility Study. Future Transp. 2022, 2, 263–280. [Google Scholar]

- Sandanayake, M.; Law, D.; Sargent, P. A new framework for assessing the environmental impacts of circular economy friendly soil waste–based geopolymer cements. Build. Environ. 2022, 210, 108702. [Google Scholar] [CrossRef]

- Maghool, F.; Arulrajah, A.; Ghorbani, B.; Horpibulsuk, S. Strength and permanent deformation properties of demolition wastes, glass, and plastics stabilized with foamed bitumen for pavement bases. Constr. Build. Mater. 2022, 320, 126108. [Google Scholar] [CrossRef]

- Senanayake, M.; Arulrajah, A.; Maghool, F.; Horpibulsuk, S. Evaluation of rutting resistance and geotechnical properties of cement stabilized recycled glass, brick and concrete triple blends. Transp. Geotech. 2022, 34, 100755. [Google Scholar] [CrossRef]

- Luo, W.; Sandanayake, M.; Zhang, G.; Tan, Y. Construction Cost and Carbon Emission Assessment of a Highway Construction—A Case towards Sustainable Transportation. Sustainability 2021, 13, 7854. [Google Scholar] [CrossRef]

- Sherwani, A.; Usmani, J. Life cycle assessment of solar PV based electricity generation systems: A review. Renew. Sustain. Energy Rev. 2010, 14, 540–544. [Google Scholar] [CrossRef]

- Chowdhury, M.S.; Rahman, K.S.; Chowdhury, T.; Nuthammachot, N.; Techato, K.; Akhtaruzzaman, M.; Tiong, S.K.; Sopian, K.; Amin, N. An overview of solar photovoltaic panels’ end–of–life material recycling. Energy Strategy Rev. 2020, 27, 100431. [Google Scholar] [CrossRef]

- Weckend, S.; Wade, A.; Heath, G.A. End of Life Management: Solar Photovoltaic Panels; National Renewable Energy Lab (NREL): Golden, CO, USA, 2016. [Google Scholar]

- Jung, B.; Park, J.; Seo, D.; Park, N. Sustainable system for raw-metal recovery from crystalline silicon solar panels: From noble–metal extraction to lead removal. ACS Sustain. Chem. Eng. 2016, 4, 4079–4083. [Google Scholar] [CrossRef]

- Tao, M.; Fthenakis, V.; Ebin, B.; Steenari, B.M.; Butler, E.; Sinha, P.; Corkish, R.; Wambach, K.; Simon, E.S. Major challenges and opportunities in silicon solar module recycling. Prog. Photovolt. Res. Appl. 2020, 28, 1077–1088. [Google Scholar] [CrossRef]

- Lunardi, M.M.; Alvarez–Gaitan, J.P.; Bilbao, J.I.; Corkish, R. A Review of Recycling Processes for Photovoltaic Modules. In Solar Panels and Photovoltaic Materials; Intech Open: London, UK, 2018; pp. 9–27. [Google Scholar]

- Chang, N.L.; Ho–Baillie, A.W.Y.; Vak, D.; Gao, M.; Green, M.A.; Egan, R.J. Manufacturing cost and market potential analysis of demonstrated roll–to–roll perovskite photovoltaic cell processes. Sol. Energy Mater. Sol. Cells 2018, 174, 314–324. [Google Scholar] [CrossRef]

- James, T.; Goodrich, A.; Woodhouse, M.; Margolis, R.; Ong, S. Building-Integrated Photovoltaics (BIPV) in the Residential Sector: An Analysis of Installed Rooftop System Prices; National Renewable Energy Lab (NREL): Golden, CO, USA, 2011. [Google Scholar]

- Ganescu, V.; Pascu, A. A study on prevalent factors behind efficiency deterioration of a typical low power solar panel. In Proceedings of the International Symposium on Microelectronics: International Microelectronics Assembly and Packaging Society, Orlando, FL, USA, 30 September–3 October 2013; pp. 384–388. [Google Scholar]

- Paiano, A. Photovoltaic waste assessment in Italy. Renew. Sustain. Energy Rev. 2015, 41, 99–112. [Google Scholar] [CrossRef]

- KEI. Management Status and Improvement Plans of Waste Solar Panels; Korea Environment Institute: Seoul, Korea, 2018. [Google Scholar]

- Rai, A.K.; Singh, G.; Tiwari, A.K. Comparative study of soil stabilization with glass powder, plastic and e–waste: A review. Mater. Today Proc. 2020, 32, 771–776. [Google Scholar]

- Gueli, A.M.; Pasquale, S.; Tanasi, D.; Hassam, S.; Lemasson, Q.; Moignard, B.; Pacheco, C.; Pichon, L.; Stella, G.; Politi, G. Weathering and deterioration of archeological glasses from late Roman Sicily. Int. J. Appl. Glass Sci. 2020, 11, 215–225. [Google Scholar] [CrossRef]

- Rajmohan, K.V.S.; Ramya, C.; Viswanathan, M.R.; Varjani, S. Plastic pollutants: Effective waste management for pollution control and abatement. Curr. Opin. Environ. Sci. Health 2019, 12, 72–84. [Google Scholar] [CrossRef]

- Shinzato, M.C.; Hypolito, R. Effect of disposal of aluminum recycling waste in soil and water bodies. Environ. Earth Sci. 2016, 75, 1–10. [Google Scholar] [CrossRef]

- Borggaard, O.K.; Gimsing, A.L. Fate of glyphosate in soil and the possibility of leaching to ground and surface waters: A review. J. Pest Manag. Sci. Former. Pestic. Sci. 2008, 64, 441–456. [Google Scholar] [CrossRef]

- Jaishankar, M.; Tseten, T.; Anbalagan, N.; Mathew, B.B.; Beeregowda, K.N. Toxicity, mechanism and health effects of some heavy metals. Interdiscip. Toxicol. 2014, 7, 60–72. [Google Scholar] [CrossRef]

- Rosseland, B.O.; Eldhuset, T.D.; Staurnes, M. Environmental effects of aluminium. Environ. Geochem. Health 1990, 12, 17–27. [Google Scholar] [CrossRef] [PubMed]

- Pandey, G.; Madhuri, S. Heavy metals causing toxicity in animals and fishes. Res. J. Anim. Vet. Fish. Sci. 2014, 2, 17–23. [Google Scholar]

- Sevigné-Itoiz, E.; Gasol, C.M.; Rieradevall, J.; Gabarrell, X. Environmental consequences of recycling aluminum old scrap in a global market. J. Resour. Conserv. 2014, 89, 94–103. [Google Scholar] [CrossRef]

- Elgharbawy, A.S.A.A. Review on corrosion in solar panels. Int. J. Smart Grid 2018, 2, 218–220. [Google Scholar]

- Zhang, J.; Lv, F.; Ma, L.Y.; Yang, L.J. The status and trends of crystalline silicon PV module recycling treatment methods in Europe and China. Adv. Mater. Res. 2013, 724–725, 200–204. [Google Scholar] [CrossRef]

- Pagnanelli, F.; Moscardini, E.; Granata, G.; Atia, T.A.; Altimari, P.; Havlik, T.; Toro, L. Physical and chemical treatment of end of life panels: An integrated automatic approach viable for different photovoltaic technologies. Waste Manag. 2017, 59, 422–431. [Google Scholar] [CrossRef]

- Huang, B.; Zhao, J.; Chai, J.; Xue, B.; Zhao, F.; Wang, X. Environmental influence assessment of China’s multi-crystalline silicon (multi-Si) photovoltaic modules considering recycling process. Solar Energy 2017, 143, 132–141. [Google Scholar] [CrossRef]

- Elinwa, A.U.; Mbadike, E. The use of aluminum waste for concrete production. J. Asian Archit. Build. Eng. 2011, 10, 217–220. [Google Scholar] [CrossRef]

- Mbadike, E.M.; Osadere, N. Effect of incorporation of aluminium waste in concrete matrix using different mix ratio and water cement ratio. Biotechnol. Adv. 2014, 2, 58–74. [Google Scholar] [CrossRef]

- Mailar, G.; Sreedhara, B.; Manu, D.; Hiremath, P.; Jayakesh, K. Investigation of concrete produced using recycled aluminium dross for hot weather concreting conditions. Resour. Effic. Technol. 2016, 2, 68–80. [Google Scholar] [CrossRef]

- Ardente, F.; Latunussa, C.E.; Blengini, G.A. Resource efficient recovery of critical and precious metals from waste silicon PV panel recycling. Waste Manag. 2019, 91, 156–167. [Google Scholar] [CrossRef] [PubMed]

- Imteaz, M.A.; Ali, M.Y.; Arulrajah, A. Possible environmental impacts of recycled glass used as a pavement base material. Waste Manag. Res. 2012, 30, 917–921. [Google Scholar] [CrossRef]

- Panditharadhya, B.J.; Sampath, V.; Mulangi, R.H.; Shankar, A.U.R. Mechanical properties of pavement quality concrete with secondary aluminium dross as partial replacement for ordinary portland cement. IOP Conf. Ser. Mater. Sci. Eng. 2018, 431, 032011. [Google Scholar] [CrossRef]

- Idrees, M.; Chaudhary, H.; Akbar, A.; Mohamed, A.; Fathi, D. Effect of Silicon Carbide and Tungsten Carbide on Concrete Composite. Materials 2022, 15, 2061. [Google Scholar] [CrossRef]

- Jain, S.; Joshi, Y.; Goliya, S. Design of rigid and flexible pavements by various methods & their cost analysis of each method. Int. J. Eng. Res. Appl. 2013, 3, 119–123. [Google Scholar]

- Schmidt, A.; Saia, W. Alkali–aggregate reaction tests on glass used for exposed aggregate wall panel work. ACI Mater. J. 1963, 60, 1235–1236. [Google Scholar]

- Polley, C.; Cramer, S.M.; Cruz, R.V.d.l. Potential for using waste glass in Portland cement concrete. J. Mater. Civ. Eng. 1998, 10, 210–219. [Google Scholar] [CrossRef]

- Zheng, K. Pozzolanic reaction of glass powder and its role in controlling alkali–silica reaction. J. Cem. Concr. Compos. 2016, 67, 30–38. [Google Scholar] [CrossRef]

- Topcu, I.B.; Canbaz, M. Properties of concrete containing waste glass. Cem. Concr. Res. 2004, 34, 267–274. [Google Scholar] [CrossRef]

- Terro, M.J. Properties of concrete made with recycled crushed glass at elevated temperatures. Build. Environ. 2006, 41, 633–639. [Google Scholar] [CrossRef]

- Sopov, V.; Korkh, O.; Izbash, M.Y. A study of the alkali–silica reaction in recycled glass concrete. IOP Conf. Ser. Mater. Sci. Eng. 2020, 907, 012062. [Google Scholar] [CrossRef]

- Yuan, Z.; Jia, Y.; Materials, B. Mechanical properties and microstructure of glass fiber and polypropylene fiber reinforced concrete: An experimental study. J. Constr. 2021, 266, 121048. [Google Scholar] [CrossRef]

- Omoding, N.; Cunningham, L.S.; Lane–Serff, G.F. Effect of using recycled waste glass coarse aggregates on the hydrodynamic abrasion resistance of concrete. Constr. Build. Mater. 2021, 268, 121177. [Google Scholar] [CrossRef]

- Turgut, P.; Yahlizade, E. Research into concrete blocks with waste glass. Int. J. Civ. Environ. Eng. 2009, 3, 186–192. [Google Scholar]

- de Castro, S.; de Brito, J. Evaluation of the durability of concrete made with crushed glass aggregates. J. Clean. Prod. 2013, 41, 7–14. [Google Scholar] [CrossRef]

- Keryou, A.B.; Ibrahim, G.J. Effect of using windows waste glass as coarse aggregate on some properties of concrete. Eng. Technol. J. 2014, 32. [Google Scholar]

- Serpa, D.; De Brito, J.; Pontes, J. Concrete made with recycled glass aggregates: Mechanical performance. ACI Mater. J. 2015, 112, 29–39. [Google Scholar] [CrossRef]

- Park, S.B.; Lee, B.C.; Kim, J.H. Studies on mechanical properties of concrete containing waste glass aggregate. Cem. Concr. Res. 2004, 34, 2181–2189. [Google Scholar] [CrossRef]

- Shayan, A.; Xu, A. Stainless steel reinforcement to increase durability in concrete structures. In Proceedings of the Australian Small Bridges Conference, Sydney, NSW, Australia, 12–13 October 2005. [Google Scholar]

- Ismail, Z.Z.; Al-Hashmi, E.A. Recycling of waste glass as a partial replacement for fine aggregate in concrete. Waste Manag. 2009, 29, 655–659. [Google Scholar] [CrossRef] [PubMed]

- Kou, S.C.; Poon, C.S. Properties of self-compacting concrete prepared with recycled glass aggregate. Cem. Concr. Compos. 2009, 31, 107–113. [Google Scholar] [CrossRef]

- Du, H.; Tan, K.H. Effect of particle size on alkali–silica reaction in recycled glass mortars. Constr. Build. Mater. 2014, 66, 275–285. [Google Scholar] [CrossRef]

- Dhir, R.; Dyer, T.; Tang, M. Expansion due to alkali–silica reaction (ASR) of glass cullet used in concrete. In Proceedings of the 2003 International Symposium “Advances in Waste Management and Recycling”, Dundee, UK, 9–11 September 2003; pp. 751–760. [Google Scholar]

- Du, H.; Tan, K.H. Waste glass powder as cement replacement in concrete. J. Adv. Concr. Technol. 2014, 12, 468–477. [Google Scholar] [CrossRef]

- Shao, Y.; Lefort, T.; Moras, S.; Rodriguez, D. Studies on concrete containing ground waste glass. Cem. Concr. Res. 2000, 30, 91–100. [Google Scholar] [CrossRef]

- Maas, A.J.; Ideker, J.H.; Juenger, M.C. Alkali silica reactivity of agglomerated silica fume. J. Cem. Concr. Res. 2007, 37, 166–174. [Google Scholar] [CrossRef]

- Pan, Z.; Tao, Z.; Murphy, T.; Wuhrer, R. High temperature performance of mortars containing fine glass powders. J. Clean. Prod. 2017, 162, 16–26. [Google Scholar] [CrossRef]

- Doni, A.; Dughiero, F. Electrothermal heating process applied to c-Si PV recycling. In Proceedings of the 2012 38th IEEE Photovoltaic Specialists Conference, Austin, TX, USA, 3–8 June 2012; pp. 757–762. [Google Scholar]

- Shayan, A.; Xu, A. Value-added utilisation of waste glass in concrete. Cem. Concr. Res. 2004, 34, 81–89. [Google Scholar] [CrossRef]

- Shi, C.; Wu, Y.; Riefler, C.; Wang, H. Characteristics and pozzolanic reactivity of glass powders. Cem. Concr. Res. 2005, 35, 987–993. [Google Scholar] [CrossRef]

- Schwarz, N.; Cam, H.; Neithalath, N. Influence of a fine glass powder on the durability characteristics of concrete and its comparison to fly ash. Cem. Concr. Compos. 2008, 30, 486–496. [Google Scholar] [CrossRef]

- Khmiri, A.; Samet, B.; Chaabouni, M. A cross mixture design to optimise the formulation of a ground waste glass blended cement. Constr. Build. Mater. 2012, 28, 680–686. [Google Scholar] [CrossRef]

- AL–Zubaid, A.B.; Shabeeb, K.M.; Ali, A.I. Study the effect of recycled glass on the mechanical properties of green concrete. Energy Procedia 2017, 119, 680–692. [Google Scholar] [CrossRef]

- Taha, B.; Nounu, G. Properties of concrete contains mixed colour waste recycled glass as sand and cement replacement. Constr. Build. Mater. 2008, 22, 713–720. [Google Scholar] [CrossRef]

- Wang, H.-Y.; Huang, W.-L. Durability of self-consolidating concrete using waste LCD glass. Constr. Build. Mater. 2010, 24, 1008–1013. [Google Scholar] [CrossRef]

- Paktiawal, A.; Alam, M. An experimental study on effect of aluminum composite panel waste on performance of cement concrete. Ain Shams Eng. J. 2021, 12, 83–98. [Google Scholar] [CrossRef]

- Hay, R.; Ostertag, C.P. On utilization and mechanisms of waste aluminium in mitigating alkali-silica reaction (ASR) in concrete. J. Clean. Prod. 2019, 212, 864–879. [Google Scholar] [CrossRef]

- Rahim, N.L.; Ibrahim, N.M.; Salehuddin, S.; Che Amat, R.; Mohammed, S.A.; Hibadullah, C.R. The Utilization of Aluminum Waste as Sand Replacement in Concrete; Trans Tech Publications: Bäch, Switzerland, 2014; Volume 594. [Google Scholar]

- Muwashee, R.S.; Al-Jameel, H.A.; Jabal, Q.A. Investigating the behavior of concrete and mortar reinforced with Aluminum waste strips. Int. J. Eng. Technol. 2018, 7, 211–213. [Google Scholar] [CrossRef]

- Dulsang, N.; Kasemsiri, P.; Posi, P.; Hiziroglu, S.; Chindaprasirt, P. Characterization of an environment friendly lightweight concrete containing ethyl vinyl acetate waste. Mater. Des. 2016, 96, 350–356. [Google Scholar] [CrossRef]

- Khan, K.A.; Ahmad, I.; Alam, M. Effect of ethylene vinyl acetate (EVA) on the setting time of cement at different temperatures as well as on the mechanical strength of concrete. Arab. J. Sci. Eng. Technol. J. 2019, 44, 4075–4084. [Google Scholar] [CrossRef]

- Azadmanesh, H.; Hashemi, S.A.H.; Ghasemi, S.H. The effect of styrene-butadiene rubber and ethylene vinyl acetate polymers on the mechanical properties of Engineered Cementitious Composites. Compos. Commun. 2021, 24, 100656. [Google Scholar] [CrossRef]

- Ren, Q.; Jiang, Z.; Li, H.; Zhu, X.; Chen, Q. Fresh and hardened properties of self-compacting concrete using silicon carbide waste as a viscosity–modifying agent. Constr. Build. Mater. 2019, 200, 324–332. [Google Scholar] [CrossRef]

- Małek, M.; Jackowski, M.; Życiński, W.; Łasica, W.; Owczarek, M.J.M.T. Influence of silicone carbide additions on the mechanical properties of concrete. Mater. Technol. 2020, 54, 595–599. [Google Scholar]

- Jiang, Z.; Ren, Q.; Li, H.; Chen, Q. Silicon carbide waste as a source of mixture materials for cement mortar. Front. Environ. Sci. Eng. 2017, 11, 1–8. [Google Scholar] [CrossRef]

- Fernández, L.J.; Ferrer, R.; Aponte, D.; Fernandez, P. Recycling silicon solar cell waste in cement–based systems. Sol. Energy Mater. Sol. Cells 2011, 95, 1701–1706. [Google Scholar] [CrossRef]

- Kandhal, P.S. Waste Materials in Hot Mix Asphalt—An Overview; Report No: NCAT Report No. 92–6; National Center for Asphalt Technology: Auburn, AL, USA, 1992. [Google Scholar]

- Su, N.; Chen, J. Engineering properties of asphalt concrete made with recycled glass. Resour. Conserv. Recycl. 2002, 35, 259–274. [Google Scholar] [CrossRef]

- Arabani, M. Effect of glass cullet on the improvement of the dynamic behaviour of asphalt concrete. Constr. Build. Mater. 2011, 25, 1181–1185. [Google Scholar] [CrossRef]

- Issa, Y. Effect of adding crushed glass to asphalt mix. Arch. Civ. Eng. 2016, 62, 35–44. [Google Scholar] [CrossRef]

- Salem, Z.T.A.; Khedawi, T.S.; Baker, M.B.; Abendeh, R. Effect of waste glass on properties of asphalt concrete mixtures. Jordan J. Civ. Eng. 2017, 11, 117–131. [Google Scholar]

- Moses Ogundipe, O.; Segun Nnochiri, E. Evaluation of the effects of waste glass in asphalt concrete using the Marshall test. Eng. Rev. 2020, 40, 24–33. [Google Scholar] [CrossRef]

- Marandi, S.M.; Ghasemi, M. Laboratory studies of the effect of recycled glass powder additive on the properties of polymer modified asphalt binders. Int. J. Eng. 2013, 26, 1183–1190. [Google Scholar]

- Lachance-Tremblay, É.; Vaillancourt, M.; Perraton, D. Evaluation of the impact of recycled glass on asphalt mixture performances. Road Mater. Pavement Des. 2016, 17, 600–618. [Google Scholar] [CrossRef]

- Shafabakhsh, G.; Sajed, Y. Investigation of dynamic behavior of hot mix asphalt containing waste materials; case study: Glass cullet. Case Stud. Constr. Mater. 2014, 1, 96–103. [Google Scholar] [CrossRef]

- Federal Highway Administration, U.S.D.O.T. User Guidelines for Waste and Byproduct Materials in Pavement Construction: Waste Glass. Available online: http://www.fhwa.dot.gov/publications/research/infrastructure/pavements/97148/068.cfm (accessed on 5 July 2022).

- Wu, S.; Yang, W.; Xue, Y. Preparation and properties of glass-asphalt concrete. Wuham China Key Lab. Silic. Mater. Sci. Eng. Minist. Educ. Wuham Univ. Technol. 2004. Available online: https://www.researchgate.net/publication/237644653_Preparation_and_Properties_of_Glass-asphalt_Concrete (accessed on 5 July 2022).

- Rahma, A.; El Naber, N.; Issa Ismail, S. Effect of glass powder on the compression strength and the workability of concrete. Cogent Eng. 2017, 4, 1373415. [Google Scholar] [CrossRef]

- Jain, S.; Sharma, T.; Gupta, A.K. End–of–life management of solar PV waste in India: Situation analysis and proposed policy framework. Renew. Sustain. Energy Rev. 2022, 153, 111774. [Google Scholar] [CrossRef]

- Jiang, W. Logistic Challenges of Large-Scale Solar Projects. Available online: https://www.solarfeeds.com/mag/logistic–challenges–of–large–scale–solar–projects/ (accessed on 20 January 2022).

- Sharma, H.B.; Vanapalli, K.R.; Barnwal, V.K.; Dubey, B.; Bhattacharya, J. Evaluation of heavy metal leaching under simulated disposal conditions and formulation of strategies for handling solar panel waste. Sci. Total Environ. 2021, 780, 146645. [Google Scholar] [CrossRef]

- Gautam, A.; Shankar, R.; Vrat, P. End–of–life solar photovoltaic e–waste assessment in India: A step towards a circular economy. Sustain. Prod. Consum. 2021, 26, 65–77. [Google Scholar] [CrossRef]

| No | Material | Weight (%) | Price, USD | Reference/s |

|---|---|---|---|---|

| 1 | Glass | 74–76 | 0.10/kg | [14,16] |

| 2 | Polymer (Encapsulant and back sheet foil) | 10 | 37/m2 (encapsulant) 20/m2 (back–sheet foil) | [18,19] |

| 3 | Al | 8–10 | 2/kg | [14,16] |

| 4 | Si | 3–5 | 0.95/kg | |

| 5 | Cu | 0.6–1 | 5.00/kg | |

| 6 | Ag | 0.06–0.1 | 574.23/kg | |

| 7 | Others (Sn, Pb, etc.) | <0.1 | – |

| Concrete Mix | Concrete Properties | Reference/s | |||||

|---|---|---|---|---|---|---|---|

| w/c * | S/A * | Cement Type * | Glass Content * (%) | Glass Resources | Compressive Strength Degradation | Flexure Strength Degradation | |

| Coarse aggregate | |||||||

| 0.48 | 0.60 | CEM I | 10–100 | Waste bottle | 1.3% to 23.8% | – | Terro [48] |

| 0.35 | – | CEM I | 10–30 | – | −7.2% to −34.0% | −10.6% to −15.2% | Turgut and Yahlizade [52] |

| 0.54 | 0.47 | CEM II/B–M 32.5 R | 15–60 | Waste bottle | 8% to 49% | −16% to 33% | Topcu and Canbaz [47] |

| 0.55 | 0.49 | CEM II A–L 42.5 R | 5–20 | – | 0% to 2.5% | – | de Castro and de Brito [53] |

| 0.50 | – | CEM I | 20–30 | Window glass | −5.3% to −28.5% | 10.8% to −21.7% | Keryou and Ibrahim [54] |

| 0.55 | – | CEM II A–L 42.5 | 5–20 | – | 6.5% to 10.5% | 7.2% to 19.3% | Serpa et al. [55] |

| 0.52 | – | CEM II/A–L 42.5 N | 12.5–100 | Waste bottle | 4.4% to 27.0% | – | Omoding et al. [51] |

| Fine aggregate | |||||||

| 0.50 | 0.47 | CEM I | 30–70 | Waste bottle | 0.6% to 13.6% | 3.2% to 18.1% | Park et al. [56] |

| 0.49 | 0.75 | CEM I | 50 | – | 24.1% | 18.1% | Shayan and Xu [57] |

| 0.48 | 0.60 | CEM I | 10–100 | Waste bottle | 1.3% to 41.2% | – | Terro [48] |

| 0.35 | – | CEM I | 10–30 | – | −31.5% to −68.9% | −22.3% to −90.0% | Turgut and Yahlizade [52] |

| 0.53 | – | CEM I | 10–20 | Waste bottle and window | 9.1% to −4.3% | −3.6% to 11.2% | Ismail and Al–Hashmi [58] |

| 0.55–0.58 | 0.49 | CEM II A–L 42.5 R | 5–20 | – | 11.0% to 17.0% | – | de Castro and de Brito [53] |

| 0.55–0.58 | – | CEM II A–L 42.5 | 5–20 | – | 15.3% to 20.5% | 20.9 to 28.1% | Serpa et al. [55] |

| Mix of coarse and fine aggregate | |||||||

| 0.48 | 0.60 | CEM I | 10–100 | Waste bottle | 7.6% to 68.4% | – | Terro [48] |

| 0.47 | – | CEM I | 15–45 | Waste bottle | 1.5% to 8.5% | – | Kou and Poon [59] |

| 0.55–0.58 | 0.49 | CEM II A–L 42.5 R | 5–20 | – | 7.0% to 17.0% | – | de Castro and de Brito [53] |

| 0.55–0.57 | – | CEM II A–L 42.5 | 5–20 | – | 13.7% to 26.7% | 17.9 to 34.8% | Serpa et al. [55] |

| Concrete Mix | Concrete Properties | Reference/s | ||||

|---|---|---|---|---|---|---|

| w/c | Cement Type | Glass Content (%) | Glass Resources | Compressive Strength Degradation | Flexure Strength Degradation | |

| 0.75 | CEM I | 30 | Fluorescent lamps | 9.1% (38–75 µm glass) * to 31.8% (75–150 µm glass) | – | Shao et al. [63] |

| 0.49 | CEM I | 20–30 | – | 21.2% (<10 µm glass) | – | Shayan and Xu [67] |

| 0.49 | CEM I | 20 | Glass beads | 12.5% (30–100 µm glass) | – | Shi et al. [68] |

| 0.42 | CEM I | 10 | Window plate glass | 6.7% (1–100 µm glass) | – | Schwarz et al. [69] |

| 0.57 | CEM I | 30 | Container (green) | 31.9% (<40 µm glass) | – | Khmiri et al. [70] |

| 0.45 | CEM I | 11–15 | Container (green) | 4.1% to 21.0% (18–80 µm glass) | 5.4% to 47.8% | AL–Zubaid, Shabeeb [71] |

| Concrete Mix | Concrete Properties | Reference/s | ||||

|---|---|---|---|---|---|---|

| w/c | Cement Type | Waste Glass Content (%) | Glass Resources | Compressive Strength Reduction | Flexure Strength Reduction | |

| 0.49 | CEM I | 20% for cement; 50% for coarse and fine aggregate | – | 23.9% | – | Shayan and Xu [67] |

| 0.38 | CEM I | 20% for cement; 50% for fine glass aggregate | – | 19.2% | 7.8% | Taha and Nounu [72] |

| 0.38 | CEM I | 20% for cement; 50% for coarse aggregate | – | 22.0% (14 days) 2.0% (56 days) | 15.8% (14 days) 10.3% (56 days) | Wang and Huang [73] |

| Glass Content | Bitumen Content (%) | Flow (mm) | Unit Weight g cm−3 | Air Void (%) | Voids in Mineral Aggregates (%) | Voids Filled with Asphalt (%) | Reference |

|---|---|---|---|---|---|---|---|

| 0 | 4.5 | 2.31 | 2.337 | 4.74 | 13.60 | 65.13 | Arabani [87] |

| 5 | 4.5 | 2.26 | 2.323 | 5.01 | 13.95 | 64.08 | |

| 10 | 4.5 | 2.42 | 2.305 | 5.33 | 14.45 | 63.11 | |

| 15 | 4.5 | 2.63 | 2.331 | 5.03 | 13.31 | 62.22 | |

| 20 | 4.5 | 2.63 | 2.314 | 5.4 | 13.78 | 60.81 | |

| 0 | – | 2.93 | 2.40 | 4.74 | – | – | Issa [88] |

| 5 | – | 2.80 | 2.25 | 4.53 | – | – | |

| 10 | – | 2.87 | 2.13 | 4.30 | – | – | |

| 15 | – | 2.73 | 2.10 | 4.16 | – | – | |

| 0 | 4.32 | 2.213 | 4.2 | 16.5 | 73.5 | Salem et al. [89] | |

| 5 | 4.45 | 2.248 | 2.8 | 15.35 | 81.0 | ||

| 10 | 4.06 | 2.225 | 4.4 | 16.35 | 72.5 | ||

| 15 | 4.57 | 2.24 | 3.5 | 16 | 77.0 | ||

| 20 | 4.11 | 2.247 | 2.5 | 15.2 | 83.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sandanayake, M.; Li, L.; Zhao, J.; Joseph, P. Applications of Solar Panel Waste in Pavement Construction—An Overview. Sustainability 2022, 14, 14823. https://doi.org/10.3390/su142214823

Sandanayake M, Li L, Zhao J, Joseph P. Applications of Solar Panel Waste in Pavement Construction—An Overview. Sustainability. 2022; 14(22):14823. https://doi.org/10.3390/su142214823

Chicago/Turabian StyleSandanayake, Malindu, Le Li, Junhai Zhao, and Paul Joseph. 2022. "Applications of Solar Panel Waste in Pavement Construction—An Overview" Sustainability 14, no. 22: 14823. https://doi.org/10.3390/su142214823

APA StyleSandanayake, M., Li, L., Zhao, J., & Joseph, P. (2022). Applications of Solar Panel Waste in Pavement Construction—An Overview. Sustainability, 14(22), 14823. https://doi.org/10.3390/su142214823