Abstract

Controlling environmental noise and reducing excessive noise is necessary to protect human health and provide auditory comfort. People are frequently exposed to traffic noise in their daily life and traffic noise is a considerable problem on the city scale. This study investigates the sound absorption coefficient in asphalt pavements so as to reduce traffic and environmental noise. The important parameters affecting the sound absorption coefficient in asphalt pavement, such as the use of porous asphalt pavements, clogging pores, the mixture content change, the thickness change, and getting wet, were identified. It is stated that the sound absorption coefficient in the asphalt layer can be increased with the use of a porous asphalt layer, and by changing the thickness and mixture content. In addition, with the effects of global warming, water supply problems are observable in cities. In this context, the use of rainwater is of vital importance. Permeability of the asphalt layer and storage of rainwater in the lower layer are recommended. The accumulation of rainwater with the aid of drainage in porous asphalt pavements has been investigated and the use of rainwater within the scope of recycling is explored. Within the scope of the research, the construction of porous asphalt pavements is suggested in a system that can store water, reuse rainwater with a new system proposal, and reduce environmental noise by increasing sound absorption performance. Accordingly, it will be possible to reduce the environmental noise level and to use rainwater within the scope of recycling. According to varying thicknesses, porous asphalt pavements were modeled using the finite element method, and the Von Mises stress and vertical deformation results of different thicknesses were compared.

1. Introduction

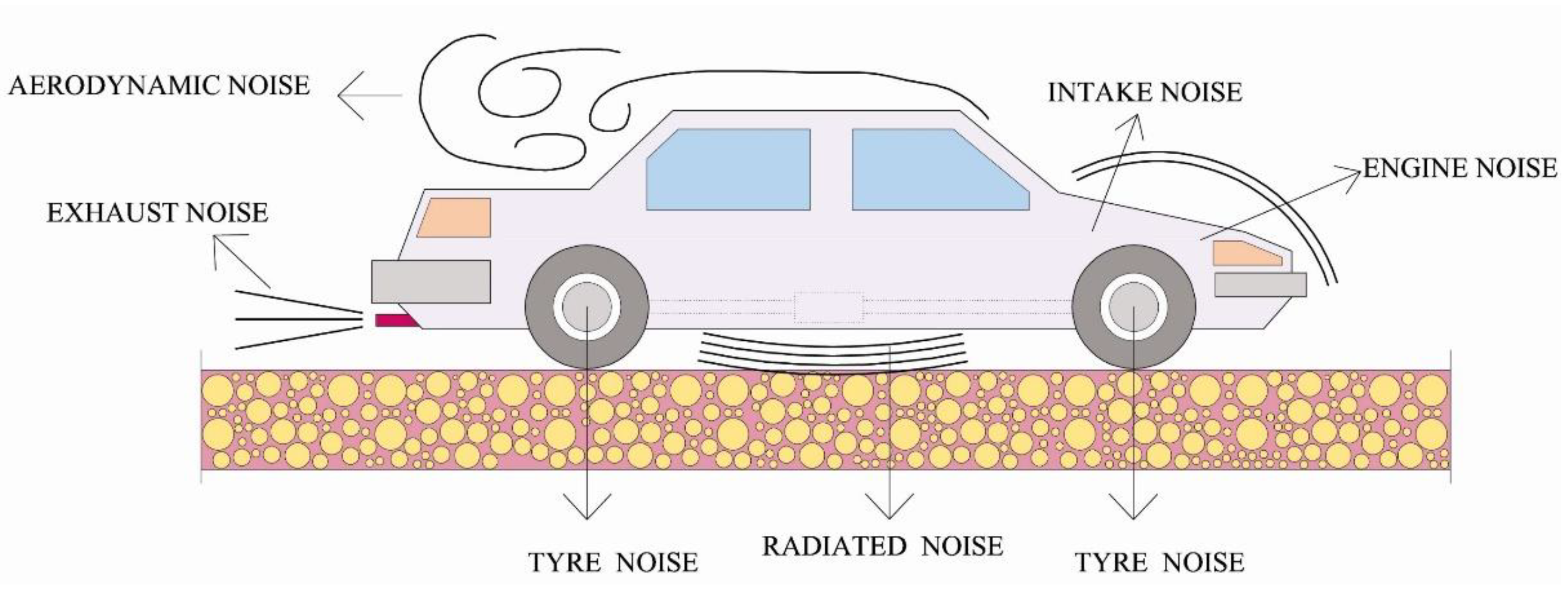

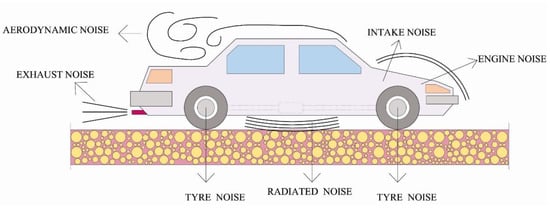

Noise pollution is becoming a major problem with the increasing population. Especially in crowded cities, noise pollution affects our daily life, and controlling the level of noise is one of the most important requirements. Auditory comfort conditions are an important parameter to provide healthy living spaces. Excessive noise has negative physiological and psychological effects on human health [1]. Additionally, long-term exposure to excessive noise can cause hearing loss (as stated in the research of Christa et al. [2], Miao et al. [3], and Zaw et al. [4]). Bozkurt and Demirkale [1] mentioned that environmental noise can significantly affect public health and human activities and environmental noise control should be mandatory to provide auditory comfort conditions. The World Health Organization has defined environmental noise as the second leading environmental effect that has a negative impact on human health [5,6]. The first environmental problem that negatively affects human health is air pollution, followed by noise pollution [5,6]. Among environmental noises, one of the most frequent noises is that originating from transportation. Noises from transportation can be classified as highway noise, railway noise, and airway noise. Asphalt coating is frequently used in all transportation systems. In Figure 1, the significant sources of noise related to the highway are displayed. Highway noise can include engine noise, intake noise, exhaust noise, aerodynamic noise, tire noise, radiated noise, and horn noises. Noise originating from highways is also prevalent in all residential areas, and asphalt systems are often used. For this reason, it is of great importance to examine the acoustic properties of asphalt pavements and to reduce the number of people exposed to excessive noise due to highways. Che et al. [7] mentioned that highway traffic noise, which affects the quality of life and can cause discomfort, is one of the ‘‘city diseases” observed with an increased volume of vehicles. Kleizienė et al. [8] found that traffic noise causes cardiovascular disease in at least 1 million Europeans every year. In the research of Gilani and Mir [9], it is stated that poor sleep quality can be observed when excessive traffic noise exists. Barros et al. [10] explained that long-term exposure to road traffic noise can cause health problems such as cardiovascular diseases, cognitive dysfunction, and sleep disorder. For the determined reasons, it is imperative for urban health to reduce and manage transportation noise.

Figure 1.

Highway noise sources (effective to increase environmental noise).

It is of great importance to improve the sound absorption performance of the asphalt layer in order to reduce environmental noise. If the sound absorption performance of the asphalt pavement can be increased, the traffic noise can be reduced. Kotzen and English [11] emphasized in their book that an important noise reduction strategy is to use sound-absorbing surfaces for roads and they stated that porous asphalt as a sound-absorbing surface is used frequently in Europe. In Figure 1, the interaction of road asphalt surface and traffic noise sources is observed. Increasing the sound absorption performance of the asphalt surface coating ensures a reduction in the traffic noise level. In the literature, it seems that one of the noise reduction strategies is to use porous asphalt. For this reason, this research focuses on porous asphalt systems, and porous asphalt systems were examined. Increasing the sound absorption coefficient of asphalt surface coatings is an important noise reduction strategy. In the research of Barros et al. [10], it was shown that a reduction of 2.8 dB in noise exposure utilizing porous asphalt type was determined in the daytime and nighttime measurements. Bozkurt [5] explained that road pavements are an important parameter in reducing environmental noise and mentioned that material-based research improving acoustic properties is a very wide research subject.

Noise mapping processes are explained in directive 2002/49/EC of the European Parliament [12], and it is explained that the noise reduction measures to be determined after strategic noise mapping should be defined. In directive 2002/49/EC of the European Parliament [12], noise improvement decisions are classified as action plans, which consist of noise reduction strategies in the noise mapping process. If the sound absorption coefficient of asphalt road pavements can be increased, the number of people exposed to noise can be reduced. In this context, asphalt pavements with an increased sound absorption coefficient can be used as an important noise improvement proposal in noise mapping studies at the urban scale.

In the literature, porous asphalt pavements can be used for drainage. It can be beneficial to use a porous asphalt system on rainy days due to the drainage system properties. The fact that water does not accumulate on the asphalt and is transmitted directly to the lower layers can also positively affect driving safety. One of the reasons for choosing the porous asphalt type in the application is that it provides drainage. Alber et al. [13] stated that the design of porous asphalt is favored for having good drainage. Chu and Fwa et al. [14] note that porous asphalt pavements have been employed to improve skid resistance.

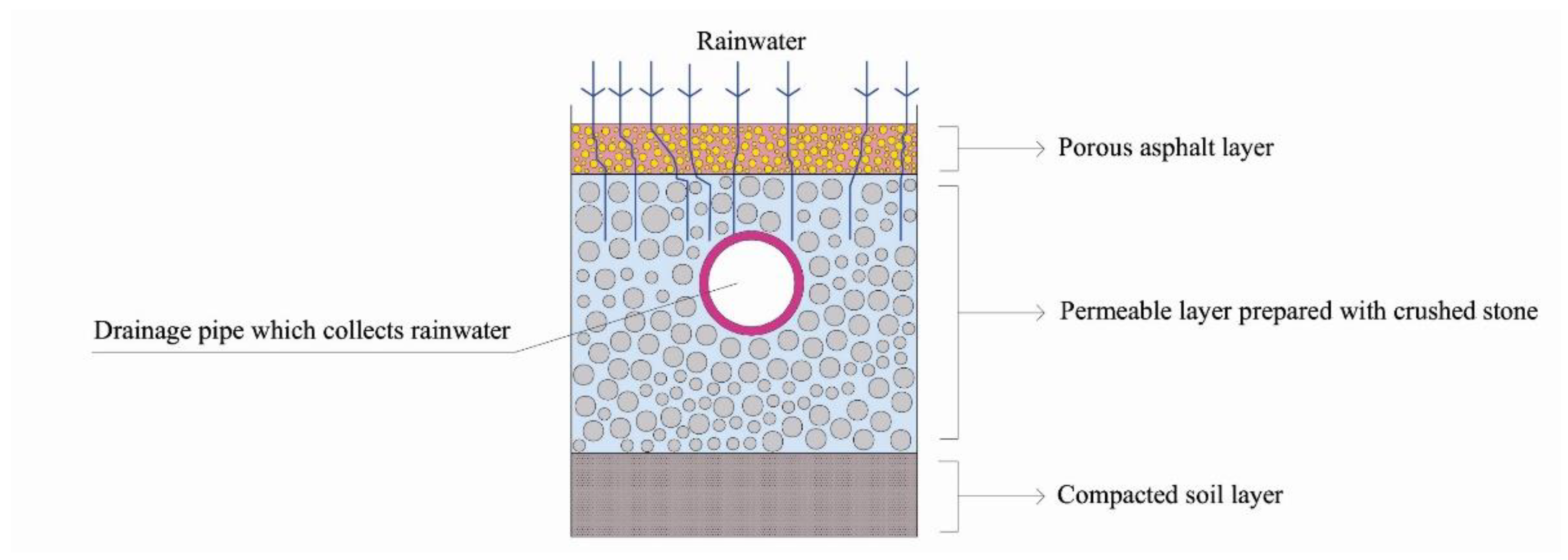

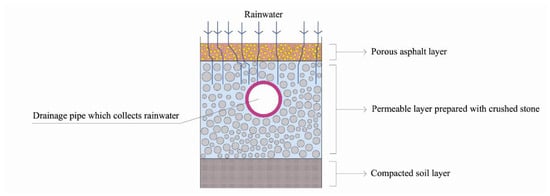

Asphalt roads play an important role in the transmission of rainwater to the lower layer in cities with dense construction. The recycling of rainwater without it being transmitted to the sewer line should be considered an important factor. In cities located near to the sea, it can also be observed that rainwater can flow towards the sea due to the impermeability of the city cover. In this context, the management of rainwater is of vital importance for providing a sustainable environment. It is estimated that water supply problems may increase with global warming. If the rainwater can be collected and stored and used for urban water consumption, the annual water consumption will decrease. In order to achieve this, it is essential to choose construction systems that transmit water to the lower layers and can store water. Porous asphalt systems can transmit water to the lower layers due to their permeability feature. With the drainage system to be built on the asphalt road sub-layers, water can be collected in the underground tanks. In this research, the use of a porous asphalt pavement system is suggested, which was integrated with the drainage system and can be considered within the scope of recycling. The drainage system design suggestion, which is integrated with a porous asphalt layer, is shown in Figure 2. In addition, sustainable development goals were announced by the United Nations and information was provided to draw attention to the problems that the world may face in the near future. The United Nations has declared 17 sustainable development goals in order to make the world more livable, and the main issues to be tackled in this direction were explained [15]. The protection of water resources is important in this context, and the use of rainwater in the city’s water consumption will reduce the total amount of water consumed.

Figure 2.

The drainage system design suggestion which integrated with the porous asphalt layer (the drainage system that can recycle and reuse rainwater).

Collecting rainwater and using it for recycling will be very useful in case of major disasters. When clean water connections in cities are damaged during high-intensity earthquakes, the stored water can be used very effectively. By storing rainwater at important points in the city, emergency water requirements in disaster situations can be met. In the Kobe earthquake observed in Japan in 1995, it was observed that the roads collapsed and vehicle transportation could not be provided to some regions. In addition, since the clean water connection lines of the city were damaged during the earthquake, clean water connections to certain areas could not be provided. It was seen that in the fires that broke out after the Kobe earthquake, the fire could not be handled because the fire trucks could not reach certain areas and the clean water connection lines were cut. In the literature prepared by Chung et al. [16], Shimazu et al. [17], Scawthorn et al. [18], and Balaei et al. [19], the processes encountered after the Kobe earthquake were explained in detail. To solve water problems in significant disasters such as earthquakes, there is a great need to build underground water tanks where rainwater can be collected in certain parts of the city.

The accumulation of water on asphalt pavement surfaces reduces the contact between the wheel and pavement surface and poses a danger to driving safety. In addition, porous asphalt coatings on the surface can contribute to reducing the level of environmental noise by increasing the sound absorption coefficient. One of the most important features that distinguish porous asphalt pavements from other asphalt pavements is that it has a higher void ratio. A high void ratio can significantly increase sound absorption. Porous asphalt pavements have an open porous material structure, which provides interaction in the material cross-section; thus, high sound absorption performance can be achieved. Porous asphalt pavements are also detailed in Section 2.

In this study, investigations were carried out on increasing the sound absorption properties of asphalt pavements, and investigations were made on how to increase the sound absorption coefficient in asphalt pavements. In addition, this research investigated the use of a porous asphalt layer integrated with the drainage system in order to use rainwater. This research examined not only the reduction in environmental noise but also the recycling of rainwater. The prepared article presents a system in which porous asphalt pavement can be beneficial in controlling urban noise and using rainwater within the scope of recycling.

The effect of ground absorption on the environmental noise level is explained in the Section 2 of the research article; then, the basic parameters that are effective in increasing the sound absorption coefficient in asphalt pavements are detailed. The discussion is provided in the Section 3 of the article and the main parameters that are effective in porous asphalt pavement are examined; furthermore, the reasons for the preference of porous asphalt pavement are explained. In addition, porous asphalt pavements were modeled using the finite element method according to the different thicknesses; the effect of varying thicknesses on the analysis results was examined. In the Section 4, the conclusion is presented, the study is summarized and the important findings of the study are explained.

2. The Improvement of Asphalt Pavement Sound Absorption Properties

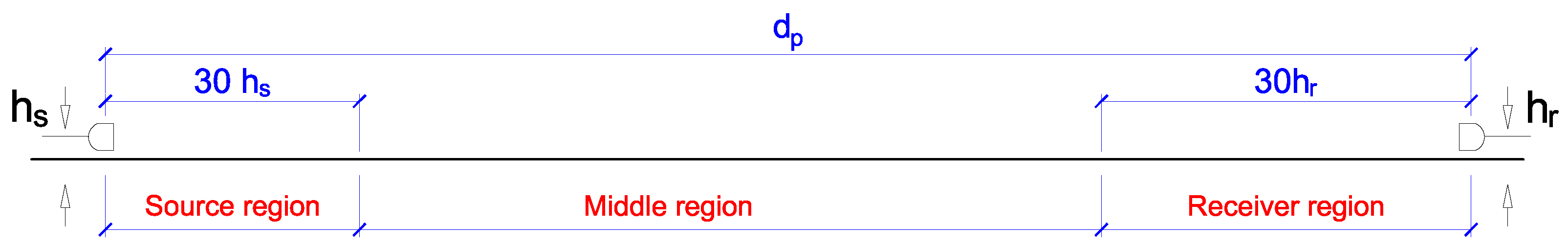

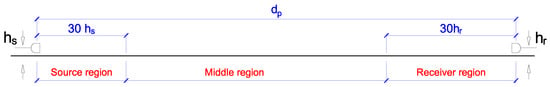

Environmental noise control aims primarily to resolve the noise at the source, and to reduce the noise between the receiver and the source path. Highway noise may not be completely reduced at the noise source. In such cases, the path, in which sound is transferred to the receiver, is an important factor to reduce noise levels. The attenuation of sound during propagation outdoors has been clarified in the ISO 9613-2:1996 standard [20]. The attenuation level observed during the propagation of sound outdoors is calculated as demonstrated in Equation (1) [20]. The attenuations observed during the propagation of the sound outdoors are as shown in Equation (2) [20]. The attenuations in outdoor sound propagation are acquired due to geometrical divergence, ground effect, a barrier effect, and other miscellaneous effects. The attenuation due to the ground effect is demonstrated in Equation (3) [20]. The ground effect is related to ground absorption properties. In Equation (3), the parameters As, Ar and Am are related to different regions (source, receiver, and middle region, respectively), and the regions are clarified in Figure 3 according to the ISO 9613-2:1996 standard. Table 1 shows the frequency-dependent ground attenuation formulas and it is understood that the G factor is an important parameter. The G value is between 0 and 1, and if the ground is reflective, the G value is close to 0, while if the ground is absorbent, the G number is close to 1. In the ISO 9613-2:1996 standard, it is understood that noise levels can be reduced if the sound absorption properties of outdoor ground coverings are increased. In this context, increasing the sound absorption coefficient of outdoor ground coverings is an important parameter.

Lft(DW) = Lw + Dc − A

Figure 3.

Different regions related to ground effect (regions used in the calculation of ground absorption), (hs: source height, hr: receiver height), (retrieved from ISO 9613-2 [20]).

Table 1.

Formulation of ground attenuation contributions As, Ar, and Am [20].

Lft(DW) = the equivalent continuous downwind octave-band sound pressure level at a receiver location;

Lw = is the octave-band sound power level, in decibels, produced by point source;

Dc = the directivity correction (for an omnidirectional point sound source radiating into free space, Dc = 0 dB);

A = the octave- band attenuation, in decibels.

A = Adiv + Aatm + Agr + Abar + Amisc

Adiv = the attenuation due to geometrical divergence;

Aatm = the attenuation due to atmospheric absorption;

Agr = the attenuation due to ground effect;

Abar = the attenuation due to a barrier;

Amisc = the attenuation due to a miscellaneous other effect (the attenuation due to propagation through foliage, industrial sites and areas of houses).

Agr = As + Ar + Am

As = the attenuation due to source region ground effect;

Ar = the attenuation due to receiver region ground effect;

Am = the attenuation due to middle region ground effect;

Table 1 presents the formulas of As, Ar, and Am values according to frequencies. The attenuation due to ground effect can be calculated with the help of Table 1 [20].

The formulas of a′(h), b′(h), c′(h), d′(h), and q presented in Table 1 are provided, respectively, in Equations (4)–(8) [20].

where dp is the source to receiver distance, in meters (Figure 3).

Increasing ground absorption according to the ISO 9613-2:1996 standard contributes to reducing environmental noise levels. Ground absorption is an important factor in reducing traffic noise. Asphalt road pavements constitute a large area on the city scale. If the sound absorption performance of floor coverings is increased, the environmental noise level decreases. Hence, on the urban scale, the sound absorption of asphalt pavement surfaces is an important parameter for environmental noise control. In this section, the strategies that can be used to increase the sound absorption performance of asphalt pavements are examined.

In the literature, the sound-absorbing properties of the asphalt layer are investigated using different methods. It is observed in the literature that the normal incidence sound absorption coefficient of different asphalt samples is measured by the impedance tube method. The normal incidence sound absorption performance of different asphalt samples can be measured in accordance with the ISO 10534-2 standard [21]. The diffuse incidence sound absorption coefficient can be obtained in the reverberation room in accordance with the ISO 354 standard [22]. The close-proximity method is generally used for long-term traffic noise analysis in the literature. In the ISO 11819-2 standard [23], the measurement of the influence of road surfaces on traffic noise is determined and the close-proximity method is clarified. By means of the close-proximity method, long-term traffic noise can be analyzed. Vuye et al. [24] carried out long-term research in which the close-proximity method was used to analyze the 34-month time period after construction; they stated that acoustic deterioration caused noise reductions at a maximum of 1 dB(A) after three years. Andriejauskas et al. [25] conducted a tire/road noise spectrum analysis of ageing low-noise pavements according to the close-proximity method and they showed that the largest sound level increase at higher frequencies (800–3150 Hz) in a long term analysis was observed for porous asphalt pavements due to the clogged pores in the pavement. Morcillo et al. [26] investigated modifications of stone mastic asphalt mixes for improving the noise attenuation of asphalt pavements in Seville. They used the close-proximity method for analyzing different asphalt pavement types and they stated that modified asphalt systems provide a reduction in the environmental noise level. Additionally, the close-proximity method was used to analyze the mixture’s acoustic properties in the research of Gardziejczyk et al. [27].

In the literature, modeling studies that have been prepared recently to determine sound absorption are available. There are many parameters that affect the sound absorption in asphalt pavements. This is observed in the model study of Chen et al. [7], Kleizienė et al. [8], and Ciaburro et al. [28]. In both experimental and numerical analysis studies, it is seen in the literature that there are many parameters that affect the sound absorption coefficient of asphalt pavements. Some of the most important issues related to sound absorption performance of asphalt pavements in the literature are explained in the sub-titles of this research. The important parameters affecting the sound absorption coefficient of asphalt pavements are listed below.

- The effect of the use of porous asphalt type pavements;

- The effect of clogging pores;

- The effect of the mixture content change;

- The effect of the thickness change;

- The effect of becoming wet and climate conditions.

2.1. The Effect of the Use of Porous Asphalt Type Pavements

In the literature, it is observed that using a porous asphalt type can enhance the sound absorption properties of the asphalt system. Chen et al. [7] explained that porous asphalt mixture pavement is used in order to reduce traffic noise. Chu and Fwa [14] stated that porous asphalt pavements have been used in a number of applications as a form of quiet pavement to reduce tire–pavement noise in many developed countries. Alber et al. [29] mentioned that the design of porous asphalt can be selected based on good drainage and acoustic noise-reducing properties. In summary, it is seen that the porous asphalt type can be used as a strategy to reduce environmental noise.

In the literature, it is determined that the sound absorption performance of porous asphalt can be high and it is understood that the asphalt layer porosity ratio and air void ratio can affect sound absorption performance. Wang et al. [30] investigated the idealized pore structure parameters (pore radius, pore length, and porosity) to enhance the sound absorption coefficient in porous asphalt concrete. The authors showed that when porosity increases without a change in the pore radius, the sound absorption coefficient in the frequency range between 100 Hz and 400 Hz can be enhanced. In the research of Liu et al. [31], the relationship between the change of the sound absorption coefficient and air void ratio of the pavement surfacing was clarified and it was understood that when the air void ratio increases, the sound absorption coefficient also increases. Zhang et al. [32] researched the noise reduction characteristics of asphalt pavement. In the research, it was seen that the air void ratio affects the sound absorption coefficients, and increasing the air void ratio can enhance sound absorption coefficients. Kalauni and Pawar [33] provide explanations on porous asphalt surface coating in their research and they stated that porous asphalt is used for noise reduction due to its pores. Gao et al. [34] showed that the sound absorption coefficient of porous asphalt concrete specimens has a good linear correlation with the measured air voids; additionally, when the air void ratio increases, sound absorption performance enhances in general. Mikhailenko et al. [35] explained that sound absorption is affected mostly by the air void content which is related to the porosity ratio. Sun et al. [36] determined that the porosity is small in densely graded road surfaces and that most of the sound waves are directly reflected in the environment, causing noise pollution. Furthermore, they clarified that the pore microstructure of asphalt pavement, which involves its depth, irregularity, and pore length, can improve the ability of noise reduction. In the research of Xu et al. [37], it was mentioned that air voids have a good correlation with the average value of the sound absorption coefficient. In the literature, it is seen that porosity properties and the air void ratio affect sound absorption performance.

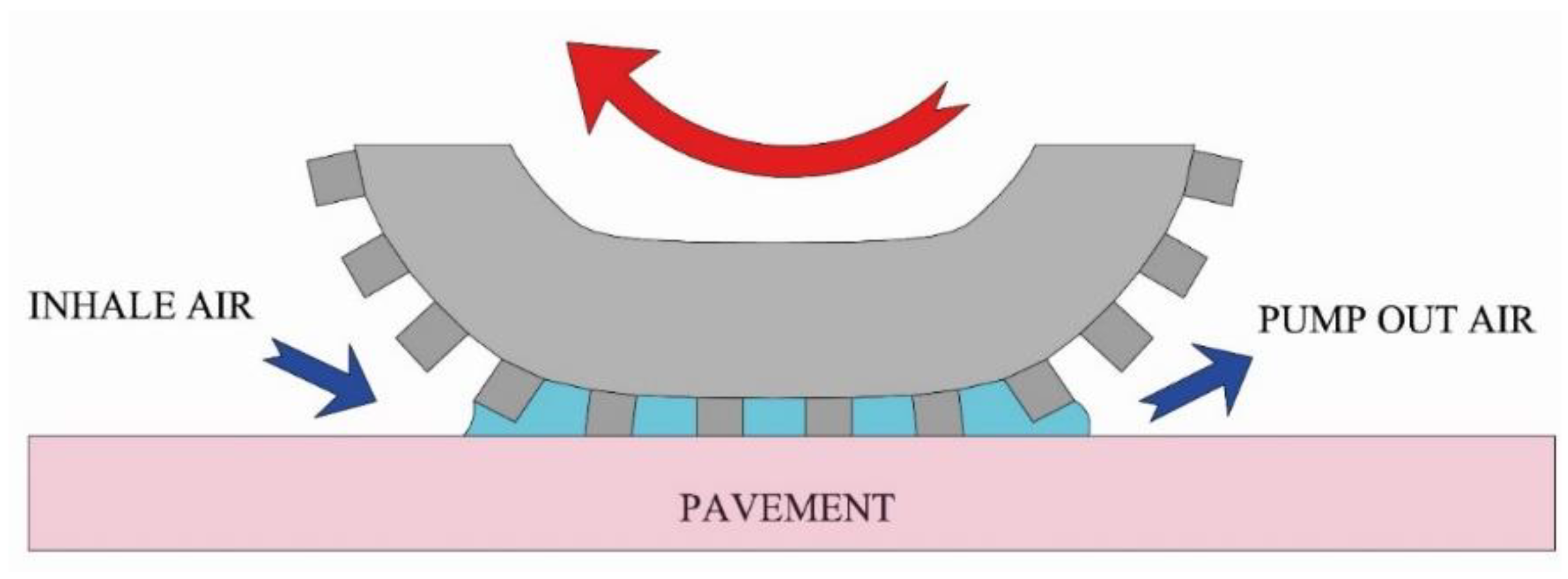

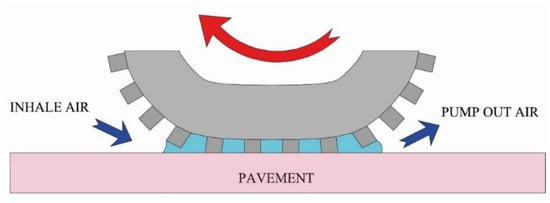

Porosity and void ratio in asphalt pavements are effective in reducing the noise caused by the air pumping effect. The air pumping effect causes increased noise in highways and the air pumping process is illustrated in Figure 4. During wheel–road contact, the wheel changes form during movement due to the rubber material contained in the wheels. Air is trapped in the channels between the rubber surface. As a result, the compressed air moves towards the region where the pressure is low. As a result of wheel movement, the tires change in size and the trapped air is released again. This event, which takes place in a short time, causes a noise for which the frequency range is around 1000 Hz in the middle frequency range [38]. This event is called the “air pumping effect”. Lai et al. [38] found that high-speed driving causes air pumping noise.

Figure 4.

Air pumping effect (effective in increasing the noise level).

The sound absorption performance of porous asphalt pavements according to frequencies was investigated. For the porous asphalt layer, the frequency ranges where high sound absorption performance is achieved were investigated. Li et al. [39] identified that according to existing studies, improving sound absorption performance is an effective method for tire–road noise reduction in the frequency range between 800 Hz and 1600 Hz on porous asphalt layers. Vaitkus et al. [40] demonstrated that an increase in porosity can provide better sound absorption and a reduction in the tire/road noise at high frequencies (over 1000 Hz). Vaitkus et al. [41] researched three different asphalt types, namely asphalt concrete, stone mastic asphalt, and porous asphalt. In their research, using the optimal binder content, the maximum sound absorption in the frequency range between 600 Hz and 2000 Hz was obtained with the porous asphalt type. However, it was observed that the stone mastic asphalt type can be more effective at frequencies lower than 600 Hz. Ding and Wang [42] investigated the comparisons of sound pressure levels on non-porous and porous pavement surfaces in their study and the sound pressure levels demonstrated that porous pavement surfaces generally decreases tire–pavement noise at high frequencies. It can be observed in the literature studies that a high sound absorption performance at low frequencies cannot be obtained in porous asphalt pavements. In order to increase the low-frequency efficiency in porous asphalt pavements, it can be necessary to change the layer thickness or to change the mixture content by using additives. In the following sections, changes in the layer thickness and mixture content are detailed.

2.2. The Effect of Clogging Pores

One of the biggest problems of porous asphalt roads is the clogging of their pores over time. Filling the pores of the sound-absorbing asphalt pavement can adversely affect the sound-absorption performance. Chu and Fwa [14] stated that clogging, which can severely reduce the sound absorption capability, is a prevalent problem and they showed in their research that clogging the pores of asphalt covering can reduce sound absorption performance. Andriejauskas et al. [25] investigated porous asphalt over a long time period, and they underlined that the largest sound level increase occurred at the frequency range of between 800 Hz and 3150 Hz. Furthermore, they predicted that this situation could be related to clogged pores in the pavement. Ciaburro et al. [28] found that the asphalt layer accrued dirt over the studied period. In this research, the measurement results of the dirty asphalt samples were compared with the undirtied condition and it was shown that there was a decrease in sound absorption performance in general when the asphalt layer contained dirt. Alber et al. [29] investigated the clogging of pores in asphalt pavement; artificial soiling tests were performed to examine the soiling mechanisms of porous asphalt, and it was demonstrated that stronger soiling can cause a significant decrease in the sound absorption ratio. Chu et al. [43] analyzed the effect of porous asphalt clogging on sound absorption; they produced different samples according to the porous asphalt clogging ratio (0%, 28% 53%, 76%, and 100% clogged). In this research, the minimum sound absorption performance was acquired from the sample with the maximum porous asphalt clogging ratio (100% clogged). Additionally, the clogging of porous asphalt negatively affected the sound absorption performance. Furthermore, Chu et al. [44] showed that the sound absorption coefficient can be decreased when the pervious concrete clogging ratio increases. Trematerra and Lombardi [45] investigated the contamination of roads over time and it was shown in their research that the pollution of asphalt pavements over time can adversely affect the sound absorption performance. Mahmud et al. [46] researched the sound absorption properties of porous asphalt subjected to progressive clogging and they showed that the sound absorption performance of porous asphalt at an 800 Hz frequency decreases with the clogging of porous asphalt. Lou et al. [47] stated that voids-clogging in porous asphalt pavements can cause an increase in noise at the low-frequency and high-frequency bands. In the literature, it is seen that the soiling of pores is a severe problem and it is understood that precautions should be taken against soiling.

Periodic cleaning is required to reduce the clogging of the pores. It is recommended within the scope of this research to wash the porous asphalt pavements with pressurized water at least once every 6 months. If the porous asphalt pavement is washed regularly with an adjustable-pressure water jet cleaner, the clogging of the pores can be reduced. Using the adjustable-pressure water jet cleaner leads to additional maintenance costs. However, this is necessary for improving sound absorption performance and water recycling. Periodic maintenance and cleaning of porous asphalt pavements are essential in order to recycle water and keep the sound absorption performance as high as possible.

2.3. The Effect of the Mixture Content Change

It is understood from the literature research that the sound absorption coefficient can be improved by changing the mixture content of the asphalt pavement. The aggregate type and aggregate particle size are effective for the sound absorption performance in asphalt pavements. In the research of Gardziejczyk et al. [27], it was mentioned that the poroelastic asphalt mixture including an aggregate of a maximum particle size of 5 mm is characterized by better acoustic properties than mixtures with a maximum aggregate particle size of 8 mm. Shen et al. [48] state that porous asphalt aggregate types, including those listed as crushed stone and basic oxygen furnace slag, were used in their research. It was observed in the research that the utilization of a basic oxygen furnace slag aggregate instead of a crushed stone aggregate can increase the sound absorption performance of porous asphalt. Kolodziej et al. [49] investigated two different aggregate gradations which are related to different applications across countries, and they showed that when the aggregate gradation content changes, the sound absorption coefficient may increase. In the research of Elmagarhe et al. [50], the addition of recycled aggregate to the granite aggregate mixture reduced the sound absorption performance of the porous asphalt mixture. Changing the aggregate type or decreasing the maximum aggregate particle size (from 8 mm to 5 mm) can improve the sound absorption coefficient.

It is observed in the literature that the sound absorption coefficient can be improved with the additive material added into the asphalt mixture. In this context, it is seen that crumb rubber additive material is frequently used. Morcillo et al. [26] stated that waste materials, such as rubber crumbs from end-of-life tires and plastics can improve the acoustic properties of asphalt mixtures. In the study of Mavridou and Kehagia [51], it was demonstrated that pavements of the rubberized asphalt mixture can reduce environmental noise by about 1–3 dB. Vázquez et al. [52] researched crumb rubber addition to improve the sound absorption of asphalt pavement. A gap-graded mixture containing crumb rubber added by the wet process, for which crumb rubber addition was 20% by weight of bitumen, was prepared. Asphalt mixture type containing crumb rubber additive and normal asphalt mixture type, which does not contain crumb rubber additive, were compared. It was observed in the research that crumb rubber additives increase sound absorption in the frequency range between 200 Hz and 500 Hz. In the study of Xu et al. [37], it was stated that the addition of crumb rubber to the mixture can enhance the sound absorption capacity at frequencies of 500–1000 Hz in porous asphalt coatings. It is seen that the crumb rubber additive material can increase the sound absorption coefficient of frequencies above 200 Hz. In the asphalt mixtures, the use of fibers as additive material is observed in the literature. In the research of Wang et al. [53], it was observed that the utilization of the basalt fiber additive in the asphalt pavement can enhance the sound absorption coefficient. The sound absorption coefficient can be improved by using additives in the mixture content, and this is one of the most extensive research topics in asphalt pavements.

The asphalt binder ratio is one of the important factors which influence asphalt sound absorption performance. Li et al. [54] demonstrated that the increase in the asphalt binder ratio can reduce the level of the peak point where the maximum sound absorption occurs in the sound absorption curve graph. It was understood that when the asphalt content decreases, the sound absorption performance can be enhanced in porous asphalt pavements.

The asphalt layer mixture content affects the density of the asphalt layer. It is seen that the density change of the asphalt pavement is also effective for the sound absorption performance. Zhang et al. [32] mentioned that the density of the asphalt mixture is found to be negatively correlated with the noise reduction performance. Poulikakos et al. [55] demonstrated in their research that the sound absorption coefficient of semi-dense asphalt is considerably higher than that of the dense asphalt. It is understood that if the density of the asphalt pavement increases, the sound absorption performance may decrease.

In the literature, it is seen that the improvement of the sound absorption coefficient in transportation methods other than asphalt pavement has been investigated. It can also be useful to consider the research on the materials produced with the mortar mixture. Zhao et al. [56] researched the porous sound-absorbing concrete slabs used in the railways and analyzed the sound absorption coefficient to reduce environmental noise. To increase the sound absorption coefficient, different aggregate particle sizes were examined, and this showed that using a very small aggregate particle size could reduce the sound absorption coefficient. It has also been shown that the use of lightweight aggregate type and the utilization of a polypropylene fiber additive can improve the sound absorption coefficient. Oancea et al. [57] investigated the sound absorption performance of sustainable concrete with different waste replacements. Five different types of sustainable concrete including polystyrene granules, polyethylene terephthalate granules, corn cob granules, shredded sunflower stalks, and balls made of sheep wool were examined. Oancea et al. found that each sustainable concrete has sound absorption coefficients that are higher than those of conventional concrete in the cities. They determined that sustainable concrete types can be used to reduce noise problems and waste materials. Mortar mixture research was performed in the literature to enhance sound absorption coefficients. Bozkurt and Demirkale [58] investigated historical plasters’ sound absorption properties. In this research direction, they investigated the sound absorption properties of mortars prepared with hydraulic lime and river sand aggregate. They stated that the increase in the binder ratio and the use of very fine aggregates can negatively affect the sound absorption coefficient [59]. It was depicted in the research that the use of the flax fiber additive and the use of crumb rubber additive can enhance sound absorption [59,60,61]. In addition, it has been explained that the use of a lightweight aggregate type in the mortar mixture can increase the sound absorption coefficient [60,61].

Increasing the sound absorption coefficient by changing the mixture content is a very broad and important research topic. It is considered an important research topic that can help to increase low-frequency sound absorption performance, especially in porous asphalt pavements.

2.4. The Effect of the Thickness Change

Sound insulation of low frequencies at the building element scale can be costly and more difficult than high frequencies. In the books prepared by Ginn [62], Metha et al. [63], Barron [64], Beranek and Ver [65], Everest and Pohlmann [66], and Jaramillo and Stell [67], sound insulation principles in the building element scale are clarified. In these books, it was shown that to increase the sound insulation level of low frequencies, it can be necessary to increase the section density of the building element or increase the section thickness of the building element. The sound insulation problem of low frequencies at the building scale is frequently encountered in windows. If environmental noise is not kept under control at the urban scale, it may be necessary to use thick sections and heavy window systems in building facades. Finding solutions to sound insulation problems at the scale of building elements can be considerably more expensive than at the urban scale. For this reason, it is an important design decision to prevent the noise of low frequencies at the urban scale. The spectrum characteristics of traffic noise are specified in the ISO 717-1 standard [68]. It is understood from the standard that traffic noise is effective at low frequencies. In the research of Mikhailenko et al. [35], they demonstrated the sound absorption coefficient to be up to 1200 Hz in their asphalt pavement research and they described traffic noise as being effective at low frequencies. Increasing the low-frequency sound absorption performance in asphalt pavement is one of the important parameters to reduce traffic noise.

In the literature, the sound absorption performance of low frequencies in asphalt pavements is frequently investigated and the affecting parameters are detailed. One of the important parameters is the effect of the thickness increase in the asphalt pavement on the sound absorption performance. In the literature, increasing the asphalt thickness can increase the sound absorption coefficient at low frequencies. In the research of Chu et al. [43], Shen et al. [48], Wang et al. [69], and Peng et al. [70], it is observed that the sound absorption coefficients of low frequencies can increase when the asphalt layer increases. In the study of Li et al. [71], the effect of thickness on porous asphalt pavements was analyzed, the sound absorption performance of 25 mm, 40 mm, and 50 mm thick porous asphalt pavements was examined, and it was shown that the sound absorption performance can increase with the increase in asphalt thickness. In addition, it can be observed in the literature that the sound absorption coefficient of low frequencies can be increased as a result of the mixture content change.

2.5. The Effect of Getting Wet and Climate Condition

In the literature, it was observed that the sound absorption performance of the asphalt layer is adversely affected when the asphalt layer is exposed to water for a long time. Ciaburro et al. [28] investigated the sound absorption performance of the wet and dry asphalt sample; the wet samples were left in water for a long time and it was demonstrated that dry asphalt samples’ sound absorption performance can be higher than wet asphalt samples. In the research of Trematerra and Lombardi [45], it was stated that the sound absorption coefficient of the asphalt pavement may decrease by keeping the asphalt pavement in water for a long time.

The climate condition is an important parameter for designing asphalt pavements. Vaitkus et al. [72] stated in their research that the design of low noise asphalt mixtures strongly depends on climate conditions and severe climate conditions can reduce the lifetime of low noise asphalt mixtures. Sirin et al. [73] conducted an acoustic performance evaluation of dense-graded asphalt. They mentioned that the acoustic performance of pavements in Qatar deteriorates faster compared to US and European countries due to harsh climatic conditions during summer. Hence, they indicated that there is a need to design an alternative asphalt mixture in Qatar and the Arabian Gulf.

The effect of temperature on the sound absorption coefficient of asphalt pavements is considered a subject that requires long-term comprehensive study. The effect of different temperatures on the noise level of porous asphalt pavements is an important research topic that needs to be investigated.

3. Results and Discussion

All factors affecting the sound absorption performance of asphalt pavements are explained together in this section. In light of the literature studies, it is necessary to increase the asphalt coating thickness or change the mixture content in order to increase the sound absorption performance at low frequencies. It is understood that the sound absorption performance at medium and high frequencies can be increased by changing the asphalt mixture content. When different types of asphalt pavements are compared, it can be stated, as demonstrated in the literature, that the sound absorption performance of the porous asphalt pavement type can be high. For example, Lou et al. [47] found that the use of the porous asphalt type can provide a better noise reduction capability than the stone mastic asphalt type. It has been observed that porous asphalt pavements can increase sound absorption performance at medium frequencies of between 800 Hz and 1600 Hz. The clogging of the pores of the porous asphalt can significantly affect the sound absorption performance at medium frequencies. If the asphalt pavement is exposed to water for a long time, a decrease in sound absorption performance can be observed in all frequency ranges. The important factors affecting sound absorption performance are presented in Table 2 in line with the studies in the literature. In Table 2, the literature studies are summarized and the methods used in the literature to increase the sound absorption performance are shown.

Table 2.

Literature studies related with asphalt pavements (increasing sound absorption performance in or reducing environmental noise) (X: method type used).

In the literature, flax fiber, polypropylene fiber and crumb rubber additives are used in mortar mixtures, the sound absorption performances of different mixtures are examined and the crumb rubber additive is found to be generally more effective at low-frequency values. Additionally, in the literature, it is observed that the use of additives in asphalt can make a significant contribution to its strength or fatigue life. It is seen that basalt fiber and rubber additives can be effective in asphalt pavements. It is observed that rubber materials may be preferred over other additives in terms of contributing to the sound absorption feature of asphalt coating as well as durability. The utilization of additives for durability in asphalt pavement can be observed in the literature research prepared by Morova [74], Zheng et al. [75], Wang et al. [76], Zhao et al. [77], Li et al. [78], Guo et al. [79], and Hui et al. [80].

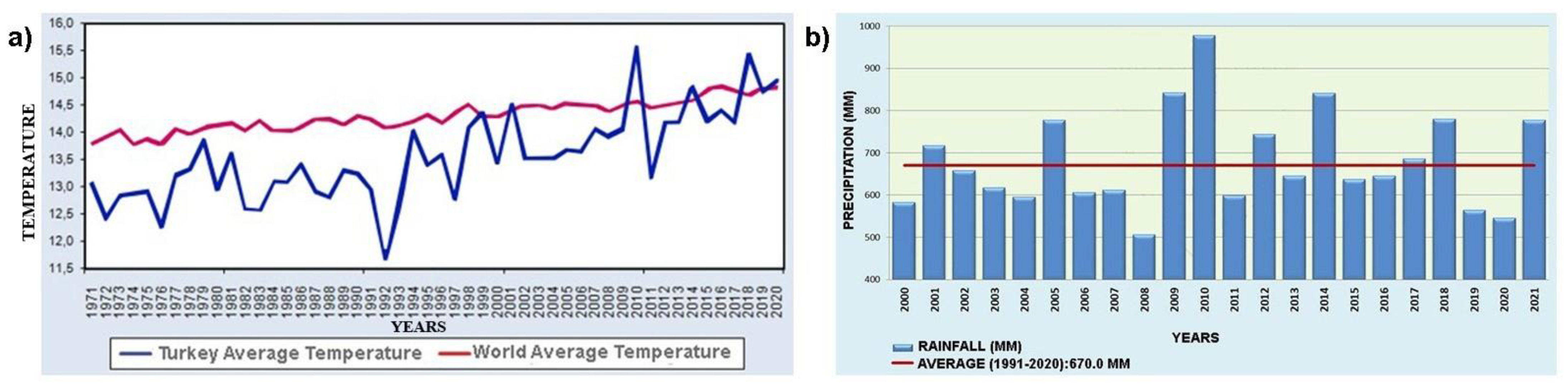

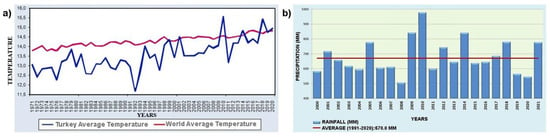

In recent years, global climate change has been found to negatively affect urban life in terms of environmental factors. In particular, the increase in drought and the change in precipitation patterns can also cause disaster problems. Natural disasters such as floods caused by changes in the climate can occur at certain periods of the year. Flood problems can cause loss of life and property, especially in unplanned urbanizations where the population density and building stock are high. Flood waters that cause natural disasters cannot be evaluated due to the lack of sustainability. Rainwater can flow into the sea as sustainability cannot be achieved in coastal cities. In order to prevent this situation, it should be possible to use flood waters in terms of sustainability in urban planning, and in this context, it should be possible to use rainwater in a controlled manner. Porous asphalt pavements have the ability to drain water better than other asphalt road pavements. It is suggested in this study that porous asphalt pavement is preferable in terms of water storage and reuse in terms of sustainability in urban roads with light vehicle traffic and in areas with dense building stock. In the study, the annual precipitation values of the city of Istanbul, which is one of the largest cities in the world, where the population and building stock are dense, were examined. It is shown in Figure 5a [81] that the average temperature values in Turkey may increase with global climate change. Temperature changes in the 30 years between 1971 and 2020 can have an effect on annual precipitation amounts. In Figure 5b [82], the average annual precipitation values of the Marmara region, where Istanbul is located, are provided. It is observed that precipitation after 1999 has decreased in general compared to the average over the last 30 years (Figure 5b). In addition, in Figure 5b, it is demonstrated that there can be great changes in annual precipitation averages. It can be observed that in the last 30 years, there has been a decrease in precipitation due to the effect of global climate change in the province of Istanbul, and for this reason, daily precipitation can reach a record level. In terms of sustainability, the storage of sudden rains in underground and aboveground dams through drainage is important in terms of their reuse. Since asphalt coatings, which are easy to apply and economical in terms of maintenance and repair, are widely used in urban transportation, it would be appropriate to use porous asphalt coatings for the evaluation of water.

Figure 5.

Climatic data which are affected by global warming; (a) average temperature data of Turkey and the world [81]; (b) precipitation values of Marmara region where Istanbul is located [82].

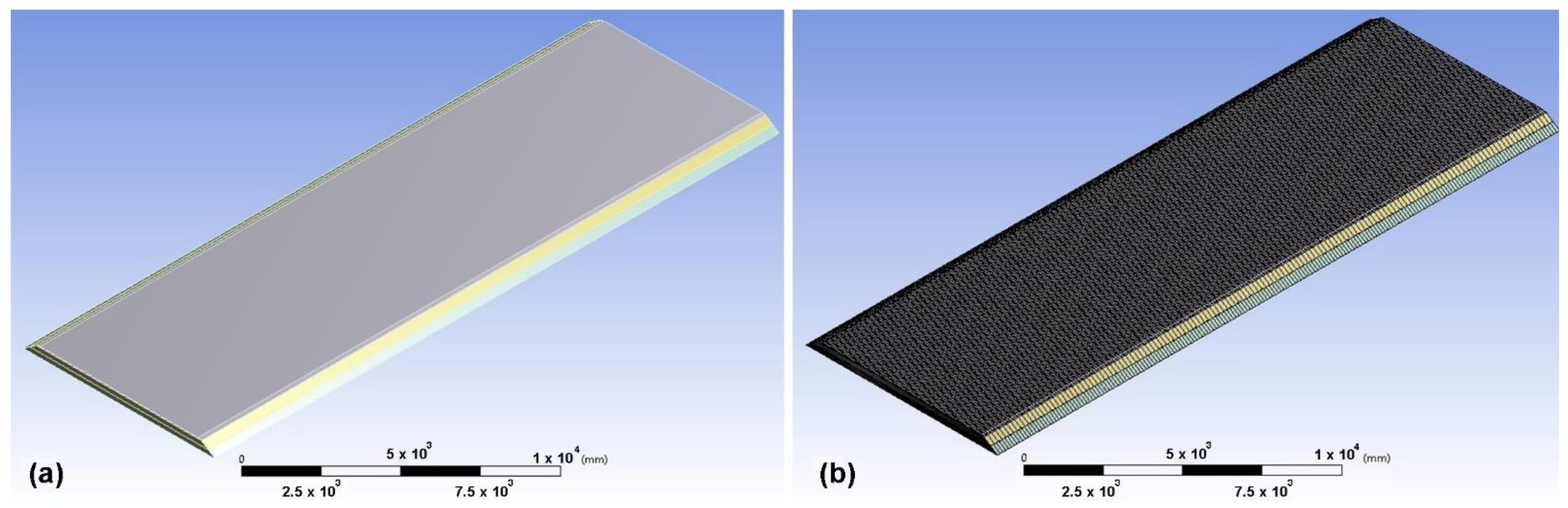

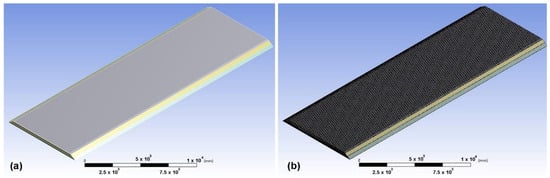

In the literature studies, it is observed that numerical analyses in asphalt pavements can be carried out by using the ANSYS program [83,84,85,86]. A similar research process was conducted in this study. A numerical analysis of porous asphalt pavements was made and the numerical analysis of porous asphalt pavements was carried out using the finite element method. Numerical analyses were performed using the ANSYS R16.2 program and numerical models of asphalt pavements of different thicknesses were modeled in the ANSYS program. In the ANSYS program, asphalt thicknesses of 4 cm, 7 cm, and 9 cm were modeled, and the durability properties of varying thicknesses were examined. In addition, literature studies were examined, and it was observed that the Young modulus of porous asphalt pavements can reach 4000 mPa [87,88], the Poisson’s ratio could reach 0.35 [89], and the density value of porous asphalt pavements could reach 1.8 g/cm3 [90]. The specified values were used in the modeling process of porous asphalt pavements in the ANSYS program. In the models prepared in the ANSYS program, the axle load applied to the porous asphalt pavement was defined as 2559 N. The model of the analyzed porous asphalt pavement is displayed in Figure 6a. Numerical model analyses were conducted at a thermal temperature of 22 degrees. Mesh assignment was performed while the model was being prepared, and it is shown in Figure 6b.

Figure 6.

Prepared model for 4 cm porous asphalt pavement (Numerical model in ANSYS software), (a) road superstructure design, (b) model view with mesh assignment.

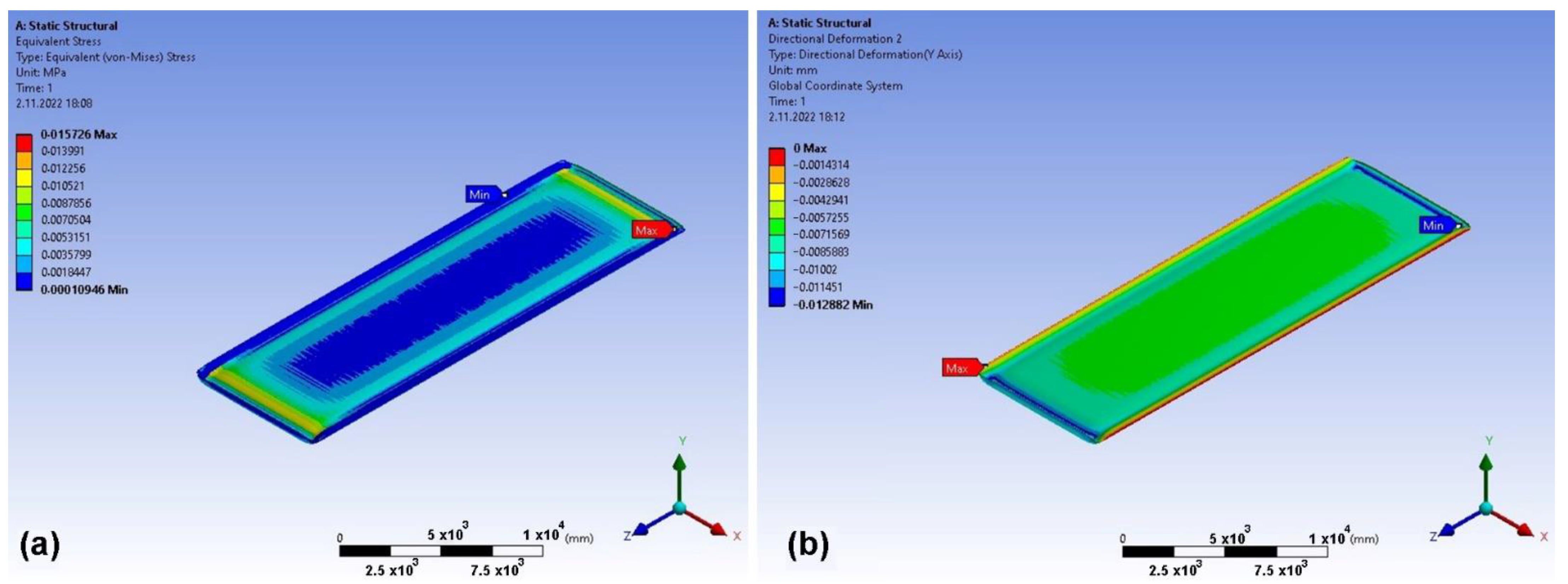

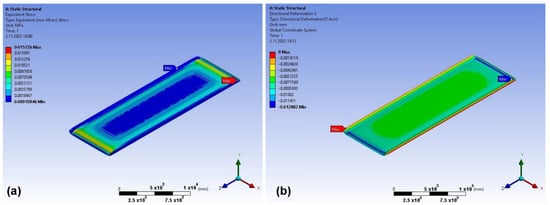

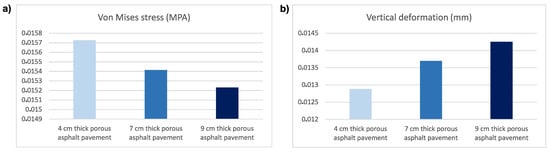

Von Mises stress and vertical deformation analyses were carried out for porous asphalt pavements of 4 cm, 7 cm, and 9 cm thicknesses. Granular base and sub-base layers were designed as 20 cm thick. The Von Mises stress (Figure 7a) and vertical deformation (Figure 7b) results for the 4 cm porous asphalt pavement are presented in Figure 7.

Figure 7.

The results of the Von Mises stress and vertical deformation for the 4 cm porous asphalt pavement (numerical model analysis in ANSYS software), (a) Von Misses stress, (b) vertical deformation (y-axis).

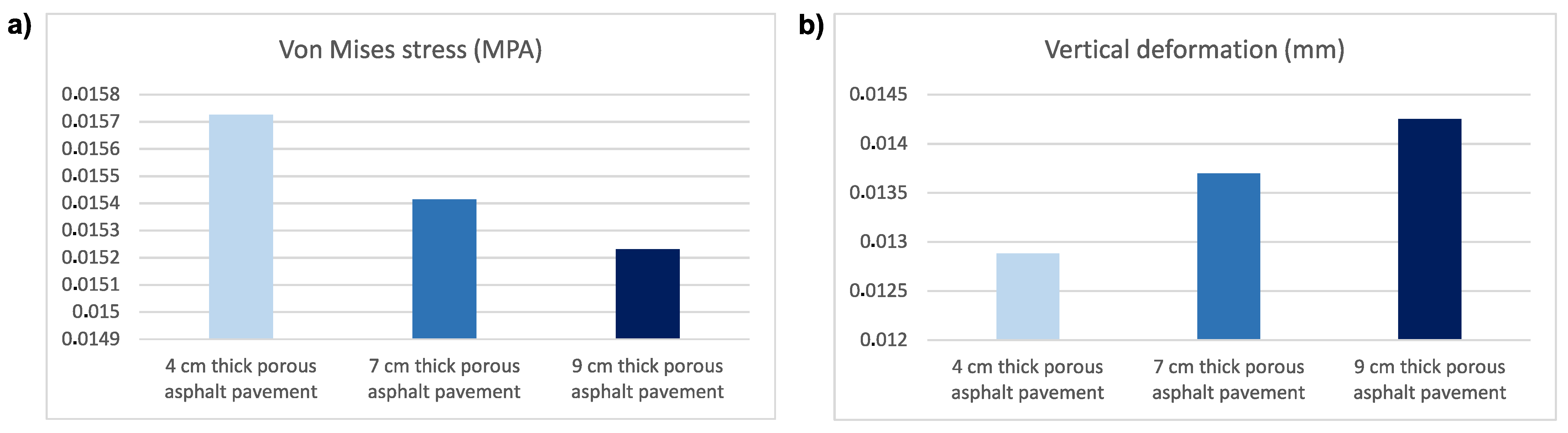

The Von Mises stress results obtained according to the asphalt thicknesses of 4 cm, 7 cm, and 9 cm are presented in Figure 8a and Table 3. In addition, the results of the vertical deformation in the direction of the load according to different thicknesses are provided in Figure 8b and Table 3. It can be seen from Figure 8a and Table 3 that as the asphalt thickness increases, the von Mises stresses can decrease. It was observed that the vertical deformation in the load direction increased as the asphalt thickness increased (Figure 8b and Table 3). It was determined that the increase in thickness affects the vertical deformation rate and it was understood that vertical deformation can increase as the thickness increases.

Figure 8.

Von Mises stress and vertical deformation of porous asphalt pavements for different thicknesses (Numerical model analysis results in ANSYS software), (a) Von Misses stress, (b) vertical deformation (y-axis).

Table 3.

Von Mises stress and vertical deformation results according to different porous asphalt pavement thicknesses (numerical model analysis results in ANSYS software).

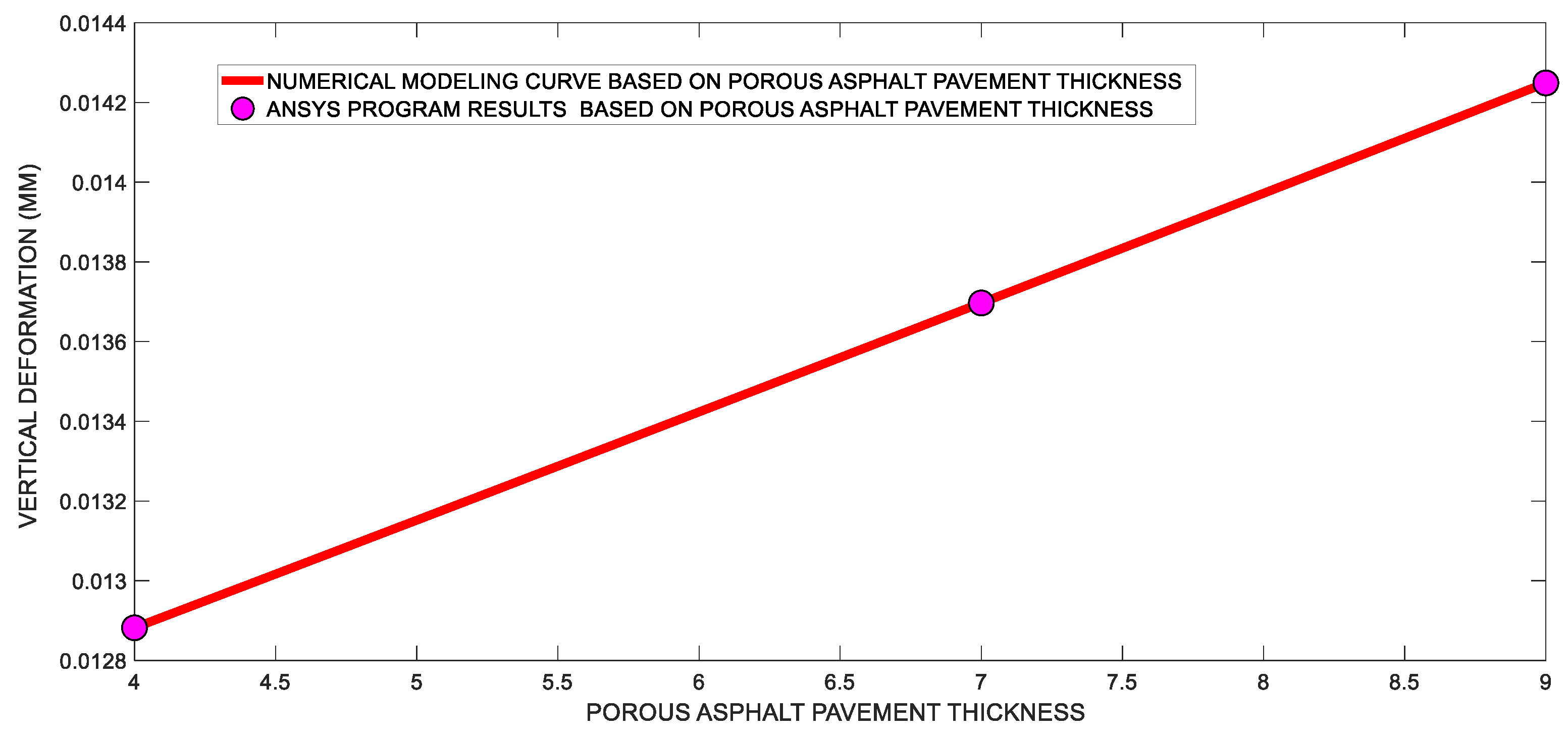

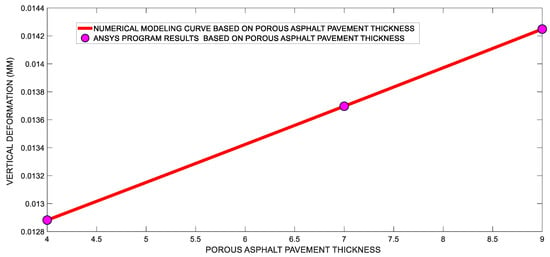

The properties of the material used in the super-structure of the road, for which the model was applied in the ANSYS program, were defined as solid elements which have linearly elastic and isotropic behavior. The finite element method was applied in numerical analysis studies in ANSYS software. In the finite element method, the results of stress and vertical deformations were obtained by applying the least squares method. The vertical deformation (mm) results obtained with the ANSYS 16.2 software were transferred to the MATLAB R2020b program according to varying porous asphalt thicknesses. A mathematical model was created by transferring the vertical deformation results according to the varying porous asphalt pavement thicknesses to the MATLAB software. A mathematical model was developed using the polynomial curve fitting method in MATLAB software. According to the varying asphalt thicknesses, the numerical model curve was derived by using the Poly2 curve fitting method. The numerical model curve fitted to the varying porous asphalt thickness is presented in Figure 9. With the numerical model curve graph provided in Figure 9, the vertical deformation of the porous asphalt pavements in the range of 4 to 9 cm thickness is approximately estimated according to the varying intermediate thickness value. In addition, the equation of the numerical model curve of the vertical deformation values of porous asphalt pavements of different thicknesses is provided in Equation (9).

x = porous asphalt pavement thickness (cm).

Vertical deformation (mm) = 0.00000008667x2 + 0.0002621x + 0.01182

Figure 9.

Vertical deformation curve model prepared for porous asphalt pavements (between 4 and 9 cm) (curve model prepared with MATLAB software).

It is understood that the porous asphalt pavement vertical deformation ratio increases when the asphalt pavement thickness increases. Due to the high vertical deformation rate, it is predicted that the durability performance of thick asphalt coatings will be lower than thin asphalt coatings. However, it has been observed in the literature that it might be necessary to increase the asphalt thickness to increase the sound absorption performance of porous asphalt pavements at low frequencies. For these reasons, it is recommended to use high-thickness porous asphalt pavements in light vehicle traffic.

As a result of the literature review, it was understood that new studies are needed to improve the sound absorption coefficient performance of porous asphalt pavements. Increasing the sound absorption performance of porous asphalt pavements according to different mixture contents is a broad research topic. According to different additives and different aggregate size ranges in porous asphalt pavements, increasing the sound absorption performance and material strength properties should be investigated. The number of studies about porous asphalt should be increased. In addition, the sound absorption performance of porous asphalt pavements due to temperature change is a research subject that needs to be investigated. In future studies, the authors plan to use recycled aggregate in porous asphalt pavements and to investigate new mixture contents to increase sound absorption performance.

4. Conclusions

Excessive noise adversely affects human health and environmental noise should be kept under control to provide healthy living spaces. For this purpose, the sound absorption coefficient of surfaces is an important parameter in controlling environmental noise. Since highway asphalt surfaces have a large area at the urban scale, it is necessary to improve their sound absorption performance. The improvement of sound absorption performance contributes to urban noise control. Recycling rainwater is one of the other important points for environmental issues. Dense urbanization leads to a decrease in green areas and non-waterproof urban surface coatings can prevent the recycling of rainwater. In this context, increasing the sound absorption coefficient in the asphalt layer and obtaining a water-permeable asphalt layer were investigated. In porous asphalt pavements, the collection and storing of water with the help of a drainage system is important, which can be used within the scope of recycling. In addition, an investigation on how to increase the sound absorption coefficient and reduce environmental noise was conducted in relation to the porous structure. In this direction, the basic parameters affecting the sound absorption coefficient have been examined in detail. The effective parameters are briefly described below.

- The use of porous asphalt type pavements can generally enhance sound absorption in the frequency range between 800 Hz and 1600 Hz. However, it may be necessary to change the asphalt mixture content in order to increase the low-frequency sound absorption performance. In the porous asphalt system, water can be transmitted to the lower layers. If the water transferred to the lower layer can be collected in the drainage system and collected at certain points, the recycling of rainwater can be achieved.

- It is understood that the clogging of pores significantly affects the sound absorption coefficient. Especially in porous asphalt pavements, the clogging of the pores can significantly reduce the sound absorption performance ratio. In addition, the closure of the pores adversely affects water drainage and storage. The clogging of the pores prevents the use of rainwater within the scope of recycling. For this reason, it is necessary to reduce the clogging of the pores. Regular maintenance is required to reduce the clogging of the pores. To prevent pore clogging, cleaning with an adjustable-pressure water jet cleaner at least once every 6 months is recommended.

- The sound absorption coefficient can be increased by changing the mixture content in asphalt pavements. It is understood that the low-frequency spectrum content is highly effective in controlling traffic noise; furthermore, it is important to increase the sound absorption performance at low frequencies in asphalt pavements. For this purpose, in porous asphalt pavements, the mixture content of the asphalt layer can be changed to increase the low-frequency sound absorption performance. It is found that the use of additives, including crumb rubber, flax fiber, basalt fiber, etc., can enhance the low frequency sound absorption coefficient.

- Increasing the asphalt coating thickness can increase the sound absorption coefficient. In particular, increasing the asphalt coating thickness can increase the sound absorption performance of low frequencies.

- Exposing the asphalt pavement to water for a long time period can adversely affect the sound absorption performance. In order to increase the sound absorption performance, the asphalt should not be kept in water for a long time and should be dried quickly. In this context, the rapid transmission of water to the lower layers and its storage by transferring it to the drainage system contribute to the rapid drying of the asphalt coating. In this way, the sound absorption performance can be increased by means of designing a drainage system. Finally, it is depicted that harsh climatic conditions may negatively affect the sound absorption performance.

Within the scope of the research, the Von Mises stress and vertical deformation analyses of porous asphalt pavements were performed with the finite element method. As a result of the numerical analysis, it was observed that the Von Mises stress decreased but the vertical deformation increased as the thickness increased in porous asphalt pavements. Since the increase in thickness increases the vertical deformation, it is predicted that the durability performance may decrease as the thickness increases. However, as the thickness of asphalt pavements increases, sound absorption performance at low frequencies can increase. For this reason, it is recommended to increase the thickness of porous asphalt pavements in areas with light traffic.

Using porous asphalt pavement and rainwater with the help of drainage will contribute to the more efficient use of water resources. In addition, increasing the sound absorption coefficient in porous asphalt pavements can alleviate the environmental noise level. Future research should aim to increase the service life of porous asphalt pavements, store rainwater and evaluate it within the scope of recycling, and improve the sound absorption coefficient. In this direction, the design of porous asphalt pavements and the determination of the mixture content properties by considering the sound absorption performance is a promising research topic. This study also provides ideas for scientific research and academic studies.

Author Contributions

Conceptualization, T.S.B. and A.S.K.; investigation, T.S.B. and A.S.K.; Supervision, T.S.B. and A.S.K.; writing—original draft preparation, T.S.B.; writing—review and editing, T.S.B. and A.S.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Bozkurt, T.S.; Demirkale, S.Y. The field study and numerical simulation of industrial noise mapping. J. Build. Eng. 2017, 9, 60–75. [Google Scholar] [CrossRef]

- Christa, L.; Themann, C.L.; Masterson, E.A. Occupational noise exposure: A review of its effects, epidemiology, and impact with recommendations for reducing its burden. J. Acoust. Soc. Am. 2019, 146, 3879. [Google Scholar] [CrossRef]

- Miao, L.; Zhang, J.; Yin, L.; Pu, Y. Hearing loss and hypertension among noise-exposed workers: A pilot study based on baseline data. Int. J. Environ. Health Res. 2022. [Google Scholar] [CrossRef] [PubMed]

- Zaw, A.K.; Myat, A.M.; Thandar, M.; Htun, Y.M.; Aung, T.H.; Tun, K.M.; Han, Z.M. Assessment of Noise Exposure and Hearing Loss Among Workers in Textile Mill (Thamine), Myanmar: A Cross-Sectional Study. Saf. Health Work 2020, 11, 199–206. [Google Scholar] [CrossRef] [PubMed]

- Bozkurt, T.S. Preparation of Industrial Noise Mapping and Improvement of Environmental Quality. Curr. Pollut. Rep. 2021, 7, 325–343. [Google Scholar] [CrossRef] [PubMed]

- World Health Organization. Environmental Noise Guidelines for the European Region; World Health Organization: Geneva, Switzerland, 2018; ISBN 978-92-890-5356-3.

- Chen, D.; Ling, C.; Wang, T.; Su, Q.; Ye, A. Prediction of tire-pavement noise of porous asphalt mixture based on mixture surface texture level and distributions, Construction and Building. Materials 2018, 173, 801–810. [Google Scholar] [CrossRef]

- Kleizienė, R.; Šernas, O.; Vaitkus, A.; Simanavičienė, R. Asphalt Pavement Acoustic Performance Model. Sustainability 2019, 11, 2938. [Google Scholar] [CrossRef]

- Gilani, T.A.; Mir, M.S. A study on the assessment of traffic noise induced annoyance and awareness levels about the potential health effects among residents living around a noise-sensitive area. Environ. Sci. Pollut. Res. 2021, 28, 63045–63064. [Google Scholar] [CrossRef]

- Barros, G.D.A.; Kampen, J.K.; Vuye, C. The Impact of Thin Asphalt Layers as a Road Traffic Noise Intervention in an Urban Environment. Sustainability 2021, 13, 12561. [Google Scholar] [CrossRef]

- Kotzen, B.; English, C. Environmental Noise Barriers, 2nd ed.; Taylor & Francis Group: Abingdon, UK, 2009. [Google Scholar]

- European Union. Directive 2002/49/EC of the European Parliament and the Council of 25 June 2002 relating to the assessment and management of environmental noise. Off. J. Eur. Comm. 2002, L 189, 12–25. [Google Scholar]

- Alber, S.; Ressel, W.; Liu, P.; Hu, J.; Wang, D.; Oeser, M.; Uribe, D.; Steeb, H. Investigation of microstructure characteristics of porous asphalt with relevance to acoustic pavement performance. Int. J. Transp. Sci. Technol. 2018, 7, 199–207. [Google Scholar] [CrossRef]

- Chu, L.; Fwa, T.F. Functional sustainability of single-and double-layer porous asphalt pavements. Constr. Build. Mater. 2019, 197, 436–443. [Google Scholar] [CrossRef]

- United Nation. Sustainable Development Goals. Available online: https://www.un.org/sustainabledevelopment/ (accessed on 25 November 2021).

- Chung, R.; Madrzykowski, D.; Stone, W.C.; Lew, H.S. The January 17, 1995 Hyogoken-Nanbu (Kobe) Earthquake: Performance of Structures, Lifelines, and Fire Protection Systems (NIST SP 901); National Institute of Standards and Technology: Gaithersburg, MD, USA, 1996. [CrossRef]

- Shimazu, T.; Shimazu, N.; Shimazu, H. Regional assessment of earthquake hazard (part 2 lifeline and transportation) 2003. In Proceedings of the Advancing Mitigation Technologies and Disaster Response for Lifeline Systems, Long Beach, CA, USA, 10–13 August 2003; pp. 819–828. [Google Scholar] [CrossRef]

- Scawthorn, C.; Eidinger, J.M.; Schiff, A.J. Fire Following Earthquake; Technical Council on Lifeline Earthquake Engineering (TCLEE) Monograph 26; American Society of Civil Engineers (ASCE): Reston, VA, USA; NFPA: Quincy, MA, USA, 2005; ISBN 13: 978-0-7844-0739-4/10: 0-7844-0739-8. [Google Scholar]

- Balaei, B.; Wilkinson, S.; Potangaroa, R.; Adamson, C.; Alavi-Shoshtari, M. Social factors affecting water supply resilience to disasters. Int. J. Disaster Risk Reduct. 2019, 37, 101187. [Google Scholar] [CrossRef]

- ISO 9613–2:1996; Acoustics, Attenuation of Sound during Propagation Outdoors, Part 2: General Method of Calculation. ISO—International Organization for Standardization: Geneva, Switzerland, 1996.

- ISO 10534-2:1998; Acoustics—Determination of Sound Absorption Coefficient and Impedance in Impedance Tubes—Part 2: Transfer-Function Method. ISO—International Organization for Standardization: Geneva, Switzerland, 1998.

- ISO 354:2003; Acoustics—Measurement of Sound Absorption in a Reverberation Room. ISO—International Organization for Standardization: Geneva, Switzerland, 2003.

- EN ISO 11819-2:2017; Acoustics—Measurement of the Influence of Road Surfaces on Traffic Noise, Part 2: The Close-Proximity Method. ISO—International Organization for Standardization: Geneva, Switzerland, 2017.

- Vuye, C.; Bergiers, A.; Vanhooreweder, B. The Acoustical Durability of Thin Noise Reducing Asphalt Layers. Coatings 2016, 6, 21. [Google Scholar] [CrossRef]

- Andriejauskas, T.; Vaitkus, A.; Čygas, D. Tyre/Road Noise Spectrum Analysis of Ageing Low Noise Pavements. In Proceedings of the Euronoise, Crete, Greece, 27–31 May 2018; pp. 2733–2740. [Google Scholar]

- Morcillo, M.A.; Hidalgo, M.E.; Pastrana, M.d.C.; García, D.; Torres, J.; Arroyo, M.B. Life soundless: New Generation of Eco-Friendly Asphalt with Recycled Materials. Environments 2019, 6, 48. [Google Scholar] [CrossRef]

- Gardziejczyk, W.; Jaskula, P.; Ejsmont, J.A.; Motylewicz, M.; Stienss, M.; Mioduszewski, P.; Gierasimiuk, P.; Zawadzki, M. Investigation of Acoustic Properties of Poroelastic Asphalt Mixtures in Laboratory and Field Conditions. Materials 2021, 14, 2649. [Google Scholar] [CrossRef]

- Ciaburro, G.; Iannace, G.; Ali, M.; Alabdulkarem, A.; Nuhait, A. An artificial neural network approach to modelling absorbent asphalts acoustic properties. J. King Saud Univ. Eng. Sci. 2021, 33, 213–220. [Google Scholar] [CrossRef]

- Alber, S.; Ressel, W.; Liu, P.; Wang, D.; Oeser, M. Influence of soiling phenomena on air-void microstructure and acoustic performance of porous asphalt pavement. Constr. Build. Mater. 2018, 158, 938–948. [Google Scholar] [CrossRef]

- Wang, H.; Ding, Y.; Liao, G.; Ai, C. Modeling and Optimization of Acoustic Absorption for Porous Asphalt Concrete. J. Eng. Mech. 2016, 142, 04016002. [Google Scholar] [CrossRef]

- Liu, M.; Huang, X.; Xue, G. Effects of double layer porous asphalt pavement of urban streets on noise reduction. Int. J. Sustain. Built Environ. 2016, 5, 183–196. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, Z.; Meng, X. Noise reduction characteristics of asphalt pavement based on indoor simulation tests. Constr. Build. Mater. 2019, 215, 285–297. [Google Scholar] [CrossRef]

- Kalauni, K.; Pawar, S.J. A review on the taxonomy, factors associated with sound absorption and theoretical modeling of porous sound absorbing materials. J. Porous Mater. 2019, 26, 1795–1819. [Google Scholar] [CrossRef]

- Gao, L.; Wang, Z.; Xie, J.; Wang, Z.; Li, H. Study on the sound absorption coefficient model for porous asphalt pavements based on a CT scanning technique. Constr. Build. Mater. 2020, 230, 117019. [Google Scholar] [CrossRef]

- Mikhailenko, P.; Piao, Z.; Kakar, M.R.; Athari, S.; Bueno, M.; Poulikakos, L.D. Effect of waste PET and CR as sand replacement on the durability and acoustical properties of semi dense asphalt (SDA) mixtures. Sustain. Mater. Technol. 2021, 29, e00295. [Google Scholar] [CrossRef]

- Sun, J.; Zhang, H.; Wu, G.; Liu, G.; Feng, Y. Micro-structural analysis of noise reduction mechanism of porous asphalt mixture based on FEM. Multidiscip. Model. Mater. Struct. 2021, 17, 1154–1167. [Google Scholar] [CrossRef]

- Xu, L.; Ni, J.; Zhang, Y.; Sun, D.; Zheng, Y.; Hu, M. Porous asphalt mixture use asphalt rubber binders: Preparation and noise reduction evaluation. J. Clean. Prod. 2022, 376, 134119. [Google Scholar] [CrossRef]

- Lai, F.; Huang, Z.; Guo, F. Noise Reduction Characteristics of Macroporous Asphalt Pavement Based on A Weighted Sound Pressure Level Sensor. Materials 2021, 14, 4356. [Google Scholar] [CrossRef]

- Li, M.; Keulen, W.N.; Tijs, E.; Ven, M.V.D.; Molenaar, A. Sound absorption measurement of road surface with in situ technology. Appl. Acoust. 2015, 88, 12–21. [Google Scholar] [CrossRef]

- Vaitkus, A.; Čygas, D.; Vorobjovas, V. Andriejauskas, T.; Traffic/Road Noise Mitigation under Modified Asphalt Pavements. Transp. Res. Procedia 2016, 14, 2698–2703. [Google Scholar] [CrossRef]

- Vaitkus, A.; Andriejauskas, T.; Vorobjovas, V.; Jagniatinskis, A.; Fiks, B.; Zofka, E. Asphalt wearing course optimization for road traffic noise reduction. Constr. Build. Mater. 2017, 152, 345–356. [Google Scholar] [CrossRef]

- Ding, Y.; Wang, H. FEM-BEM analysis of tyre-pavement noise on porous asphalt surfaces with different textures. Int. J. Pavement Eng. 2019, 20, 1090–1097. [Google Scholar] [CrossRef]

- Chu, L.; Fwa, T.F.; Tan, K.H. Evaluation of wearing course mix designs on sound absorption improvement of porous asphalt pavement. Constr. Build. Mater. 2017, 141, 402–409. [Google Scholar] [CrossRef]

- Chu, L.; Fwa, T.F.; Tan, K.H. Laboratory Evaluation of Sound Absorption Characteristics of Pervious Concrete Pavement Materials. Transp. Res. Record. 2017, 2629, 91–103. [Google Scholar] [CrossRef]

- Trematerra, A.; Lombardi, I. Acoustic Properties of Absorbent Asphalts. IOP Conf. Ser. Mater. Sci. Eng. 2017, 225, 012081. [Google Scholar] [CrossRef]

- Mahmud, M.Z.H.; Hassan, N.A.; Hainin, M.R.; Ismail, C.R.; Jaya, R.P.; Warid, N.M.; Yaacob, H. Mashros, N. Characterisation of microstructural and sound absorption properties of porous asphalt subjected to progressive clogging. Constr. Build. Mater. 2021, 283, 122654. [Google Scholar] [CrossRef]

- Lou, K.; Xiao, P.; Kang, A.; Wu, Z.; Dong, X. Effects of asphalt pavement characteristics on traffic noise reduction in different frequencies. Transp. Res. Part D Transp. Environ. 2022, 106, 103259. [Google Scholar] [CrossRef]

- Shen, D.-H.; Wu, D.-H.; Du, J.-C. Laboratory investigation of basic oxygen furnace slag for substitution of aggregate in porous asphalt mixture. Constr. Build. Mater. 2009, 23, 453–461. [Google Scholar] [CrossRef]

- Kolodziej, V.M.; Triches, J.S.; Ledezma, G.C.; Carlesso, L.M.; Jardin, L.M.; Knabben, R.M. Functional and Durability Properties Evaluation of Open Graded Asphalt Mixes; Transport Infrastructure and Systems; Taylor & Francis Group: London, UK, 2017; ISBN 978-1-138-03009-1. [Google Scholar]

- Elmagarhe, A.; Lu, Q.; Alharthai, M.; Alamri, M.; Elnihum, A. Performance of Porous Asphalt Mixtures Containing Recycled Concrete Aggregate and Fly Ash. Materials 2022, 15, 6363. [Google Scholar] [CrossRef]

- Mavridou, S.; Kehagia, F. Environmental Noise Performance of Rubberized Asphalt Mixtures: Lamia’s case study. Procedia Environ. Sci. 2017, 38, 804–811. [Google Scholar] [CrossRef]

- Vázquez, V.F.; Terán, F.; Huertas, P.; Paje, S.E. Asphalt Pavement with High Content of Crumb Rubber. Acoustic Assessment, WASTES: Solutions, Treatments and Opportunities. In Proceedings of the 4th International Conference, Washington, DC, USA, 27–29 September 2017. [Google Scholar]

- Wang, W.; Cheng, Y.; Chen, H.; Tan, G.; Lv, Z.; Bai, Y. Study on the Performances of Waste Crumb Rubber Modified Asphalt Mixture with Eco-Friendly Diatomite and Basalt Fiber. Sustainability 2019, 11, 5282. [Google Scholar] [CrossRef]

- Li, X.; Gao, J.; Du, H.; Jia, J.; Zhao, X.; Ling, T. Relationship between the Void and Sound Absorption Characteristics of Epoxy Porous Asphalt Mixture Based on CT. Coatings 2022, 12, 328. [Google Scholar] [CrossRef]

- Poulikakos, L.; Athari, S.; Mıkhaılenko, P.; Pıao, Z.; Kakar, R.K.; Bueno, M.; Pıeren, R.; Heutschi, K. Use of waste and marginal materials for silent roads. In Proceedings of the 23rd International Congress on Acoustics, Aachen, Germany, 9–13 September 2019. [Google Scholar]

- Zhao, C.; Wang, P.; Wang, L.; Liu, D. Reducing railway noise with porous sound-absorbing concrete slabs. Adv. Mater. Sci. Eng. 2014, 2014, 11. [Google Scholar] [CrossRef]

- Oancea, I.; Bujoreanu, C.; Budescu, M.; Benchea, M.; Grădinaru, M.C. Considerations on sound absorption coefficient of sustainable concrete with different waste replacements. J. Clean. Prod. 2018, 203, 301–312. [Google Scholar] [CrossRef]

- Bozkurt, T.S.; Demirkale, S.Y. Laboratory analyses and numerical simulation for sound absorption of plasters in historical buildings. J. Cult. Herit. 2019, 36, 103–117. [Google Scholar] [CrossRef]

- Bozkurt, T.S.; Demirkale, S.Y. The laboratory analyses for the plasters prepared with river sand aggregate and hydraulic lime binder. Constr. Build. Mater. 2018, 190, 691–709. [Google Scholar] [CrossRef]

- Bozkurt, T.S.; Demirkale, S.Y. Investigation and development of sound absorption of plasters prepared with pumice aggregate and natural hydraulic lime binder. Appl. Acoust. 2020, 170, 107521. [Google Scholar] [CrossRef]

- Bozkurt, T.S.; Demirkale, S.Y. The experimental research of sound absorption in plasters produced with perlite aggregate and natural hydraulic lime binder. Acoust. Aust. 2020, 48, 375–393. [Google Scholar] [CrossRef]

- Ginn, K.B. ARCHITECTURAL ACOUSTICS; Brüel δ Kjaer: Nærum, Denmark, 1978; ISBN 87-87355-24-8. [Google Scholar]

- Mehta, M.; Johnson, J.; Rocaford, J. Architectural Acoustics Principles and Design; Prentice Hall: Hoboken, NJ, USA, 1999; ISBN 0-13-793795-4. [Google Scholar]

- Barron, R.F. Industrial Noise Control and Acoustics; Marcel Dekker Inc.: Basel, Switzerland; New York, NY, USA, 2003; ISBN 0-8247-0701-X. [Google Scholar]

- Beranek, L.L.; Ver, I.L. Noise and Vibration Control Engineering Principles and Applications; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2006; ISBN 13: 978-0471-44942-3/10: 0471-44942-3. [Google Scholar]

- Everest, F.A.; Pohlmann, K.C. Master Handbook of Acoustics; McGraw-Hill: New York, NY, USA, 2009; ISBN 978-0-07-160333-1. [Google Scholar]

- Jaramillo, A.M.; Stell, C. Architectural Acoustics; Taylor & Francis Group: London, UK, 2015; ISBN 978-1-315-75284-6 (ebk). [Google Scholar]

- ISO 717-1:2013; Acoustics—Rating of Sound Insulation in Buildings and of Building Elements—Part 1: Airborne Sound Insulation. ISO—International Organization for Standardization: Geneva, Switzerland, 2013.

- Wang, Z.; Xie, J.; Gao, L.; Liu, M.; Liu, Y. Improvement of acoustic model and structural optimization design of porous asphalt concrete based on meso-structure research. Constr. Build. Mater. 2020, 65, 120327. [Google Scholar] [CrossRef]

- Peng, B.; Han, S.; Han, X. Laboratory and field evaluation of noise characteristics of porous asphalt pavement. Int. J. Pavement Eng. 2021, 23. [Google Scholar] [CrossRef]

- Li, B.; Cao, K.; Zhou, J.; Li, A.; Sun, M. Laboratory investigation on influence of mixture parameters on noise reduction characteristics of porous asphalt concrete. Int. J. Pavement Eng. 2022. [Google Scholar] [CrossRef]

- Vaitkus, A.; Andriejauskas, T.; Gražulytė, J.; Šernas, O.; Vorobjovas, V.; Kleizienė, R. Qualitative criteria and thresholds for low noise asphalt mixture design. IOP Conf. Ser. Mater. Sci. Eng. 2018, 356, 012027. [Google Scholar] [CrossRef]

- Sirin, O.; Ohiduzzaman, M.; Kassem, E.; Hassan, W. Acoustic Performance Evaluation of Dense-Graded Asphalt Pavements in Qatar. Adv. Civ. Eng. 2021, 2021, 5520432. [Google Scholar] [CrossRef]

- Morova, N. Investigation of usability of basalt fibers in hot mix asphalt concrete. Constr. Build. Mater. 2013, 47, 175–180. [Google Scholar] [CrossRef]

- Zheng, Y.; Cai, Y.; Zhang, G.; Fang, H. Fatigue property of basalt fiber-modified asphalt mixture under complicated environment. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 2014, 29, 996–1004. [Google Scholar] [CrossRef]

- Wang, W.; Cheng, Y.; Ma, G.; Tan, G.; Sun, X.; Yang, S. Further Investigation on Damage Model of Eco-Friendly Basalt Fiber Modified Asphalt Mixture under Freeze-Thaw Cycles. Appl. Sci. 2019, 9, 60. [Google Scholar] [CrossRef]

- Zhao, H.; Guan, B.; Xiong, R.; Zhang, A. Investigation of the Performance of Basalt Fiber Reinforced Asphalt Mixture. Appl. Sci. 2020, 10, 1561. [Google Scholar] [CrossRef]

- Li, Z.; Shen, A.; Wang, H.; Guo, Y.; Wu, H. Effect of basalt fiber on the low-temperature performance of an asphalt mixture in a heavily frozen area. Constr. Build. Mater. 2020, 253, 119080. [Google Scholar] [CrossRef]

- Guo, Q.; Chen, Z.; Liu, P.; Li, Y.; Hu, J.; Gao, Y.; Li, X. Influence of basalt fiber on mode I and II fracture properties of asphalt mixture at medium and low temperatures. Theor. Appl. Fract. Mech. 2021, 112, 102884. [Google Scholar] [CrossRef]

- Hui, Y.; Men, G.; Xiao, P.; Tang, Q.; Han, F.; Kang, A.; Wu, Z. Recent Advances in Basalt Fiber Reinforced Asphalt Mixture for Pavement Applications. Materials 2022, 15, 6826. [Google Scholar] [CrossRef]

- Republic of Türkiye Ministry of Environment. Urbanization and Climate Change. Available online: https://cevreselgostergeler.csb.gov.tr/en/temperature-i-85993 (accessed on 30 October 2022).

- Turkish State Meteorological Service. Available online: https://mgm.gov.tr/veridegerlendirme/yillik-toplam-yagis-verileri.aspx (accessed on 30 October 2022).

- Karakas, A.S.; Bozkurt, T.S.; Sayin, B.; Ortes, F. An assessment of SBS modified asphalt concrete pavements performance features performing numerical analysis. AIP Conf. Proc. 2017, 1863, 540002. [Google Scholar] [CrossRef]

- Karakas, A.S. Investigation of the Behavior of Stone Mastic Asphalt Coatings in Different Thicknesses by the Finite Element Method. In Proceedings of the VIII INSAC International Congress on Natural and Engineering Sciences (ICNES-2022), Konya, Turkey, 18–20 March 2022; pp. 31–40. [Google Scholar]

- Selsal, Z.; Karakas, A.S.; Sayin, B. Effect of pavement thickness on stress distribution in asphalt pavements under traffic loads. Case Stud. Constr. Mater. 2022, 16, e01107. [Google Scholar] [CrossRef]

- Karakaş, A.S.; Bozkurt, T.S. Investigation of Modified Asphalt Pavement with Different Thicknesses on Stress-Strain and Sound Absorption Performance Characteristics. DUJE Univ. J. Eng. 2022, 13, 319–328. [Google Scholar] [CrossRef]

- Pérez-Acebo, H.; Linares-Unamunzaga, A.; Rojí, E.; Gonzalo-Orden, H. IRI Performance Models for Flexible Pavements in Two-Lane Roads until First Maintenance and/or Rehabilitation Work. Coatings 2020, 10, 97. [Google Scholar] [CrossRef]

- Hong, B.; Lu, G.; Li, T.; Lin, J.; Wang, D.; Liang, D.; Oeser, M. Gene-editable materials for future transportation infrastructure: A review for polyurethane-based pavement. J. Infrastruct. Preserv. Resil. 2021, 2, 27. [Google Scholar] [CrossRef]

- Zhang, H.; Anupam, K.; Skarpas, A.; Kasbergen, C.; Erkens, S. Simple Homogenization-Based Approach to Predict Raveling in Porous Asphalt. Transp. Res. Rec. 2020, 2674, 263–277. [Google Scholar] [CrossRef]

- Setyawan, A. Design and properties of hot mixture porous asphalt for semi-flexible pavement application. Media Teknik Sıpıl. 2005, 41–45. Available online: https://core.ac.uk/download/pdf/12345925.pdf (accessed on 30 October 2022).

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).