Product-Service Systems for Circular Supply Chain Management: A Functional Approach

Abstract

:1. Introduction

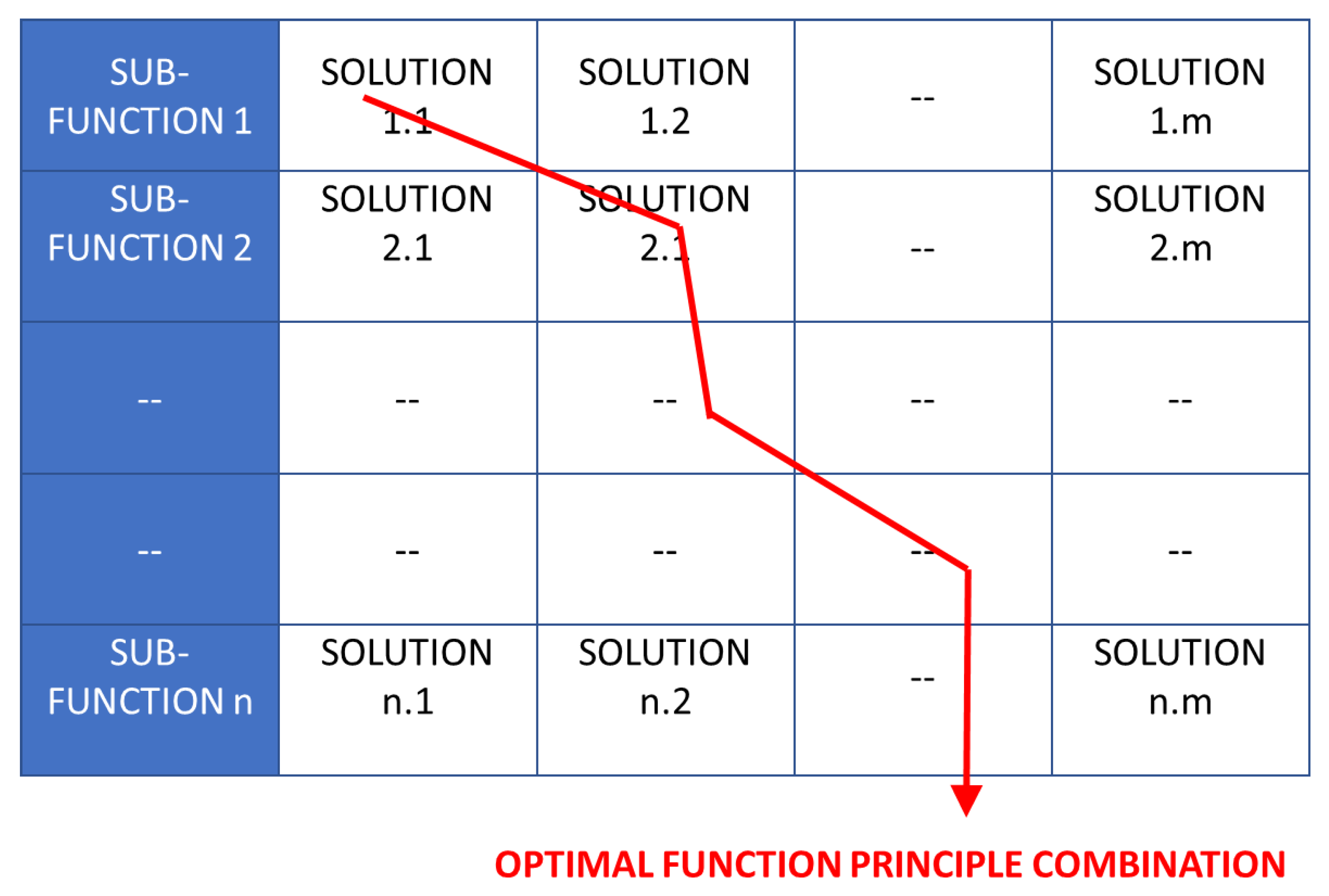

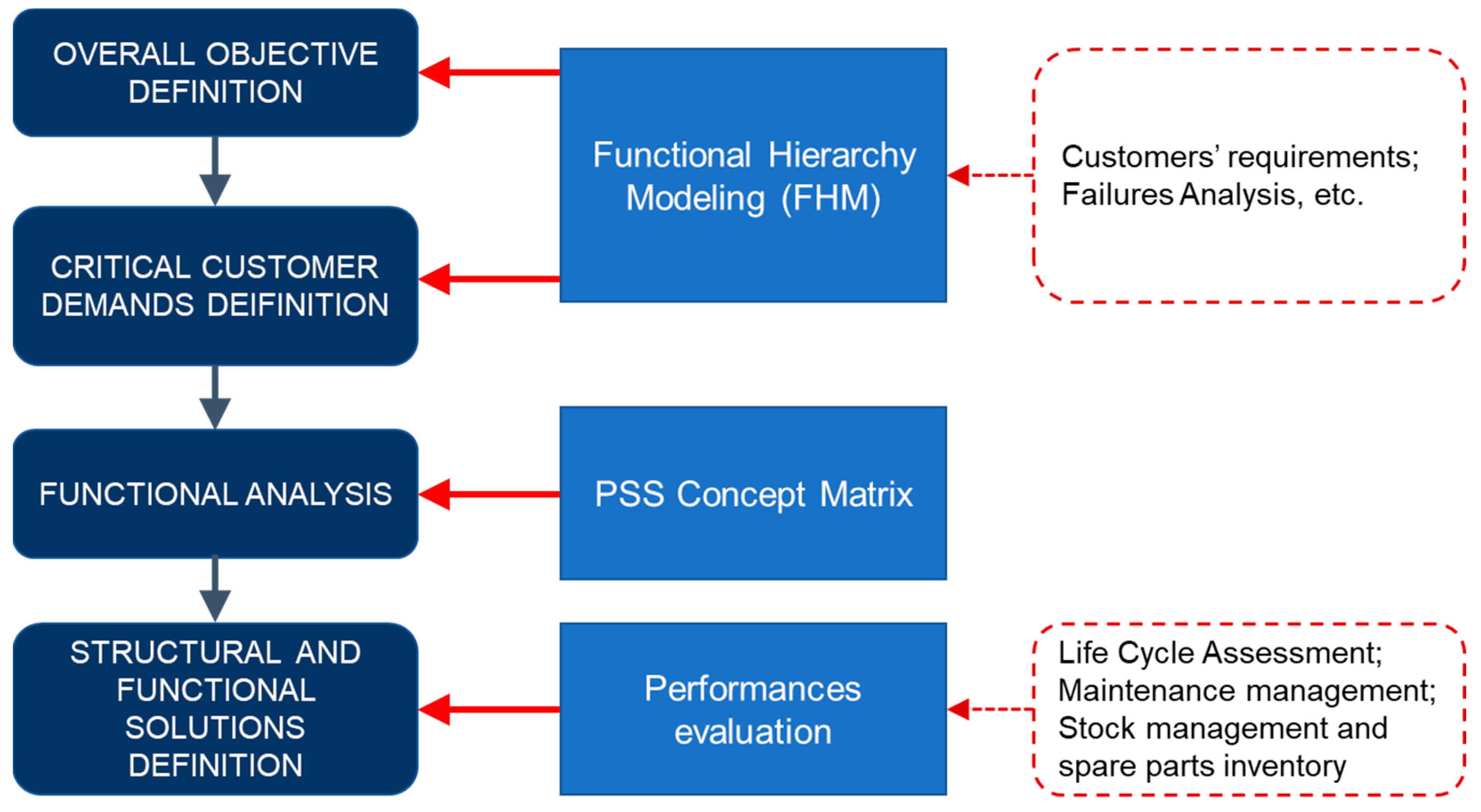

2. Materials and Methods

- Customer demands level,

- Functional level,

- Structural level.

- 4.

- Overall objective definition,

- 5.

- Analysis of critical customers’ demand,

- 6.

- Definition of the environment-centric function,

- 7.

- Definition of the solution-centric function.

- An investigation of customers’ requirements based on the last two years of requests received by the company’s customer care service.

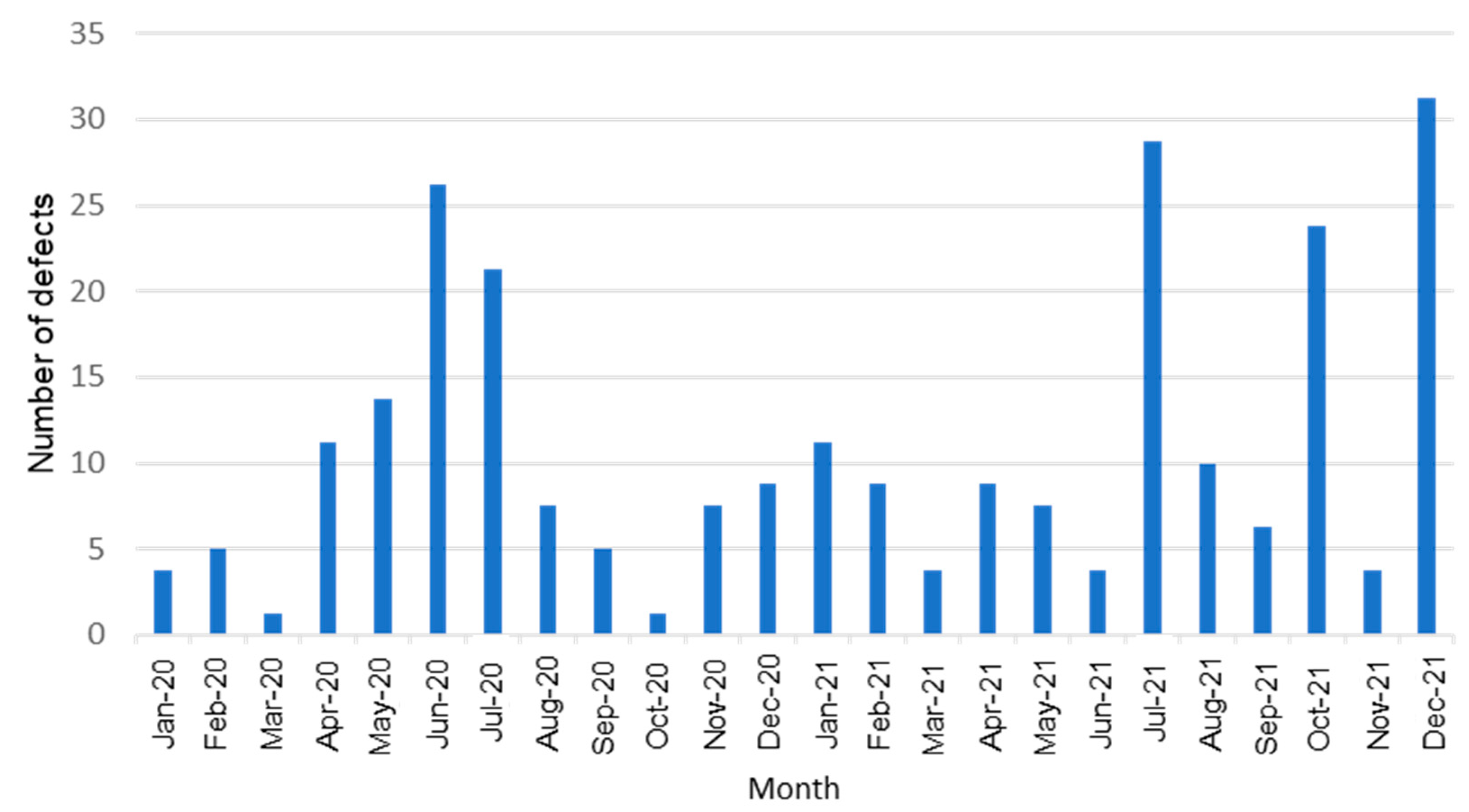

- A failure analysis based on customers’ requests for intervention, which is aimed at optimizing the spare parts and maintenance provisions in a coordinated manner.

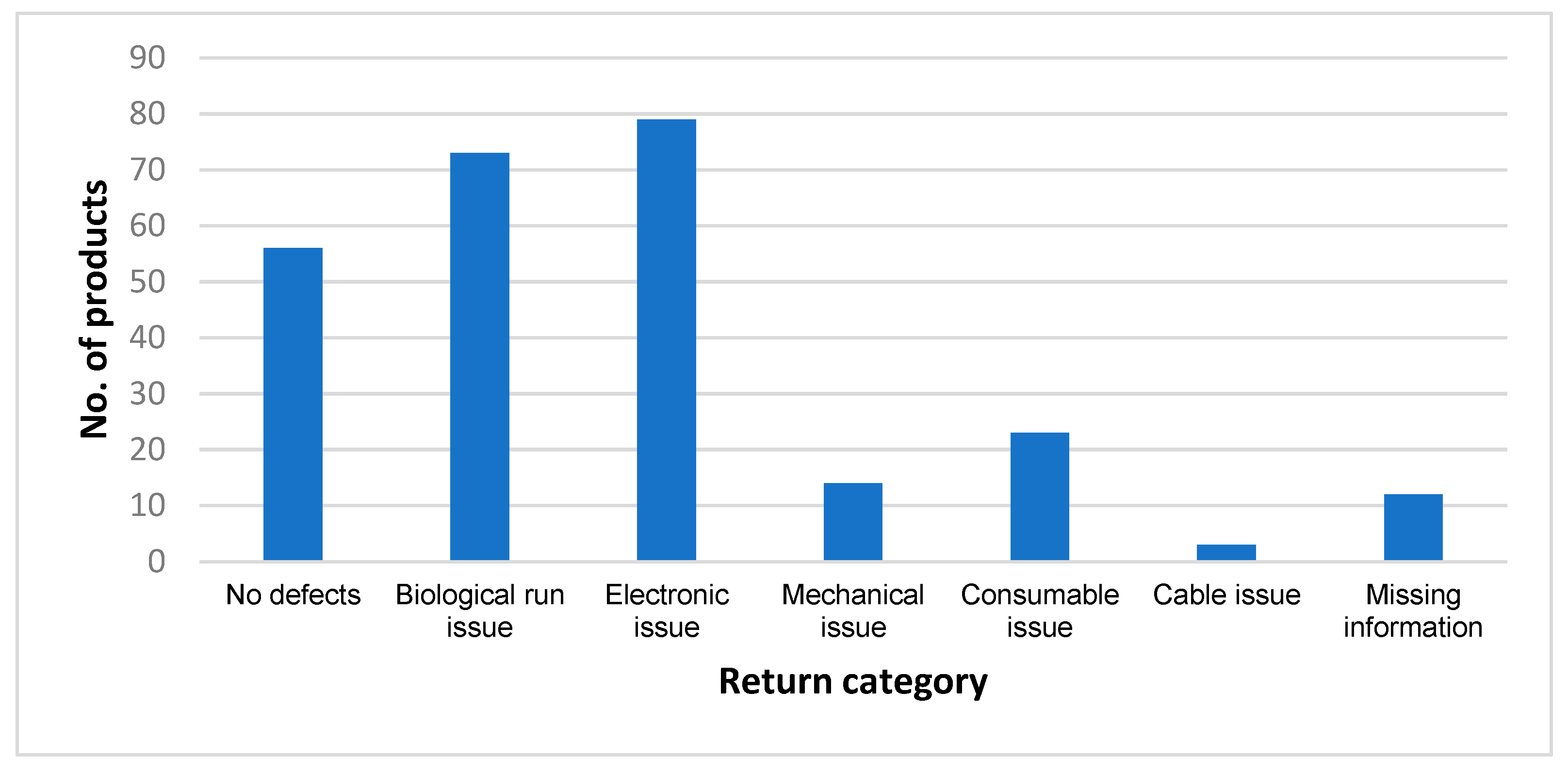

- An analysis of returned units after the end of the contract, which is aimed at establishing what type of components can be restored and reused, as well as the number of materials that can be recycled.

- Environmental assessment carried out using the eco-indicator method [51];

- Maintenance operations management;

- Stock management and spare parts inventory management, including the evaluation of distribution lead times.

3. Case Study

3.1. Overview

3.2. Product Presentation

- Fluidic components: parts that come into contact with the patient’s sample and are behind its mixing with reagents, control samples and other biological solutions.

- Electro-mechanical components: responsible for the moving parts of the product, i.e., gears, motors, pressing plates, etc.

- Structural components: mainly aluminum and stainless-steel sheets as well as plastic pieces that compose the chassis and maintain the structural integrity of the product.

- Optical components: mainly imaging modules that serve for diagnostic purposes via the optical characteristics of the samples.

- Electronics: microcontrollers and processors behind analysis intelligence.

- Peripherals and accessories: access and control monitor, ethernet cables, ferrites, and fuses among others. In other words, the additional items needed to operate the product and ensure its correct functionality and security.

3.3. Current Market Status and Product Feedback

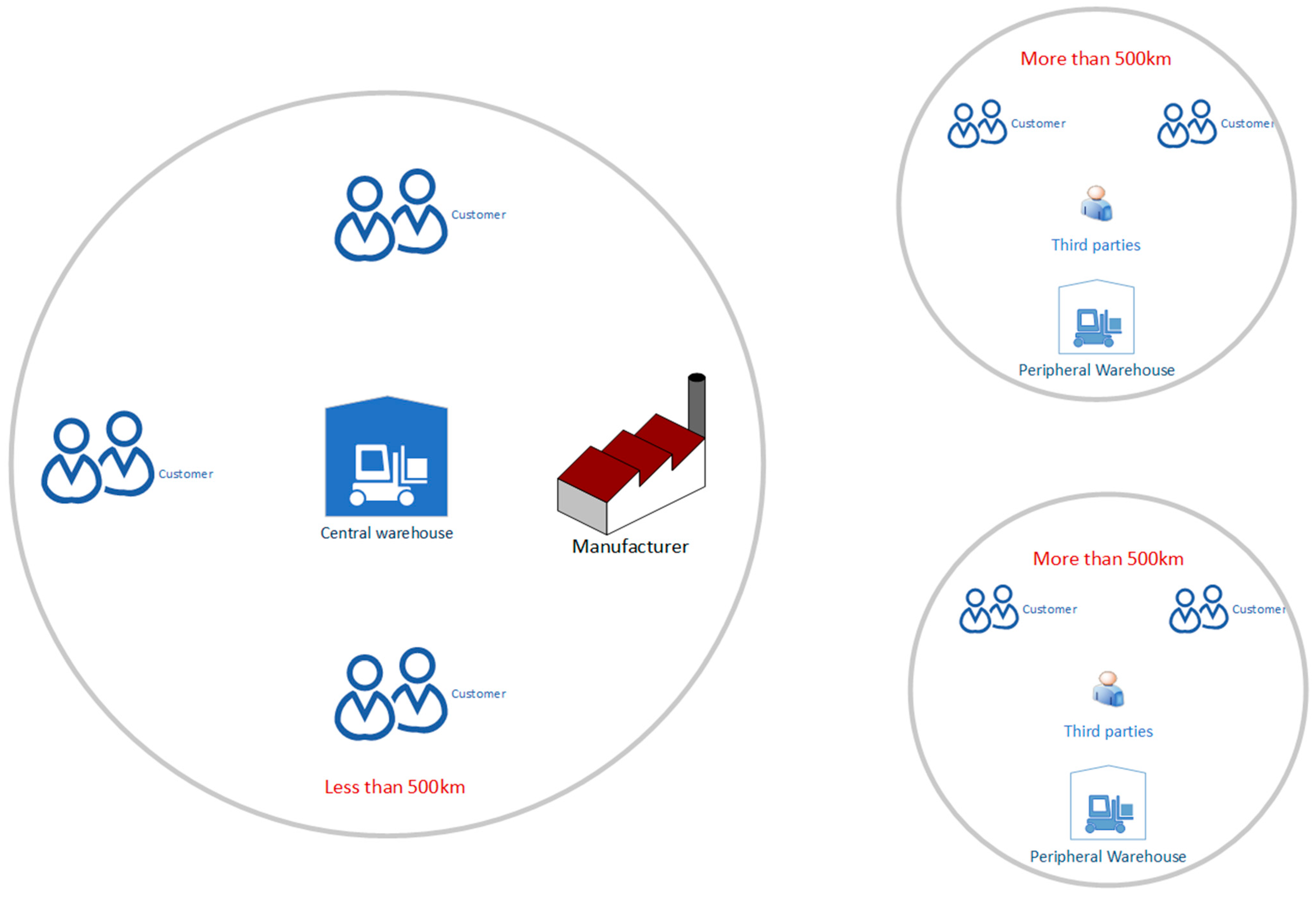

- Customer locations within a 500 km radius are handled by the manufacturer’s team directly.

- Customer locations outside this distance (>500 km) are handled by authorized third parties and suppliers. Peripheral (secondary) warehouses are available for this purpose (Figure 5).

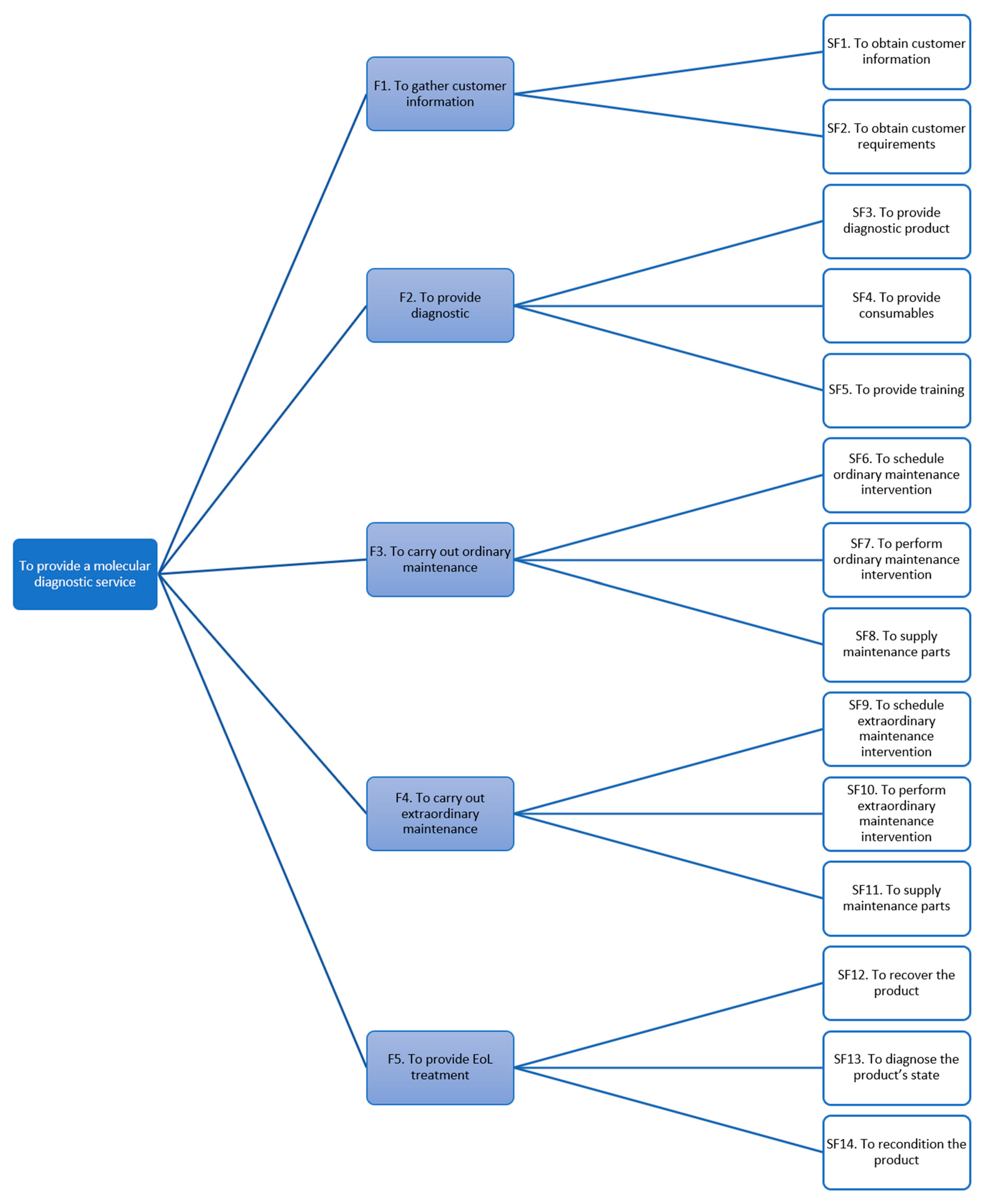

3.4. The PSS Solution

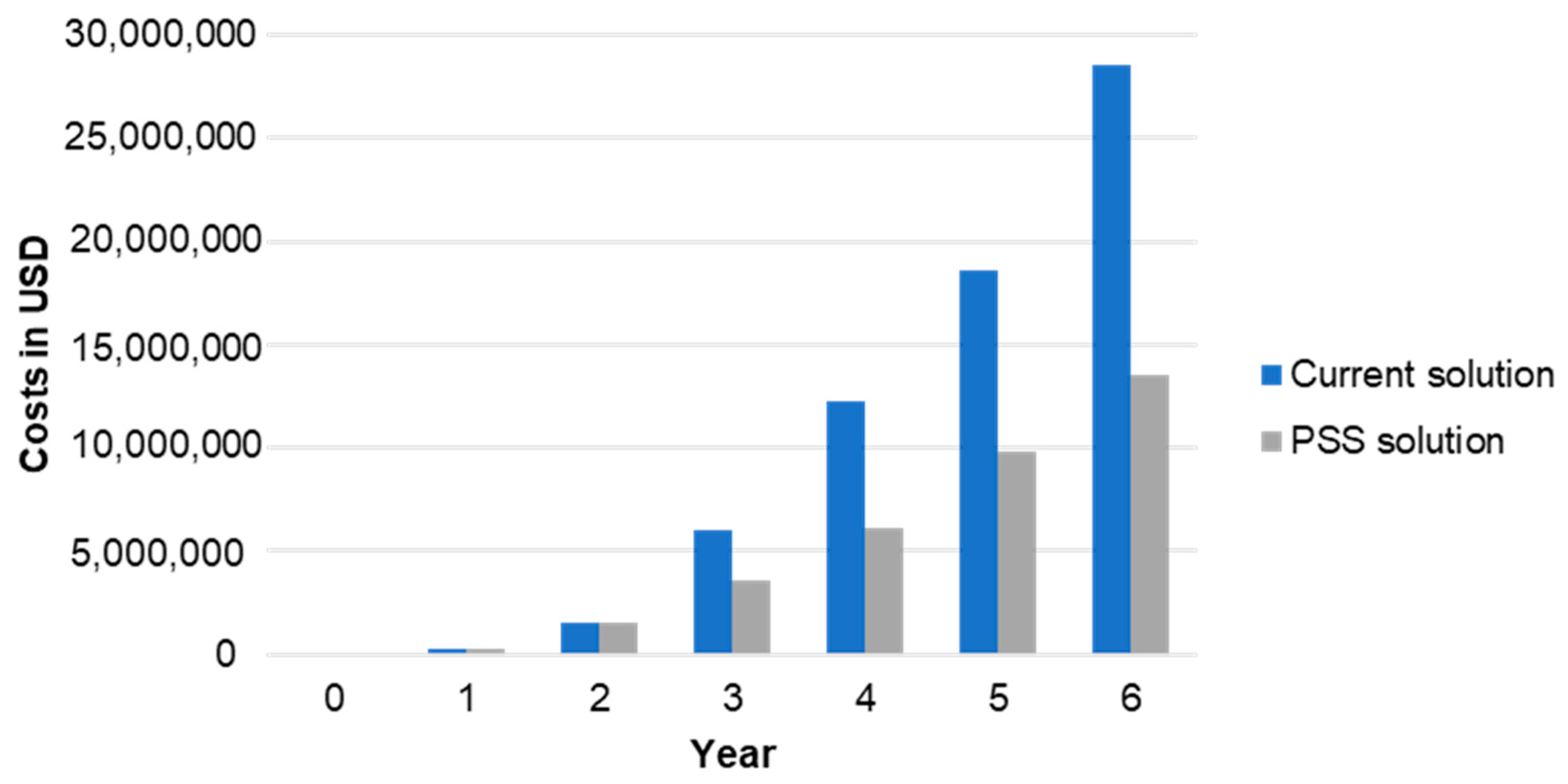

3.5. PSS Evaluation

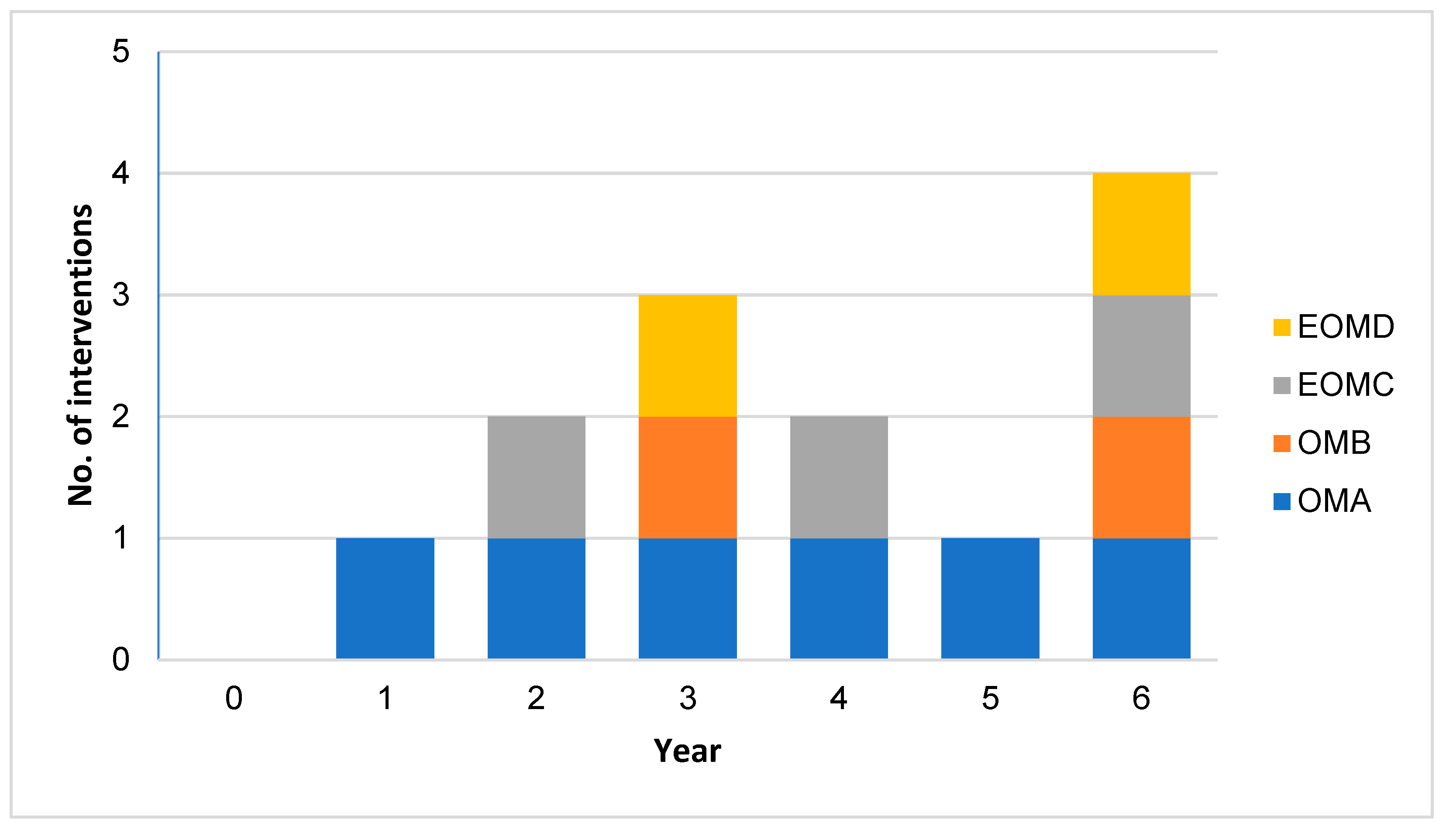

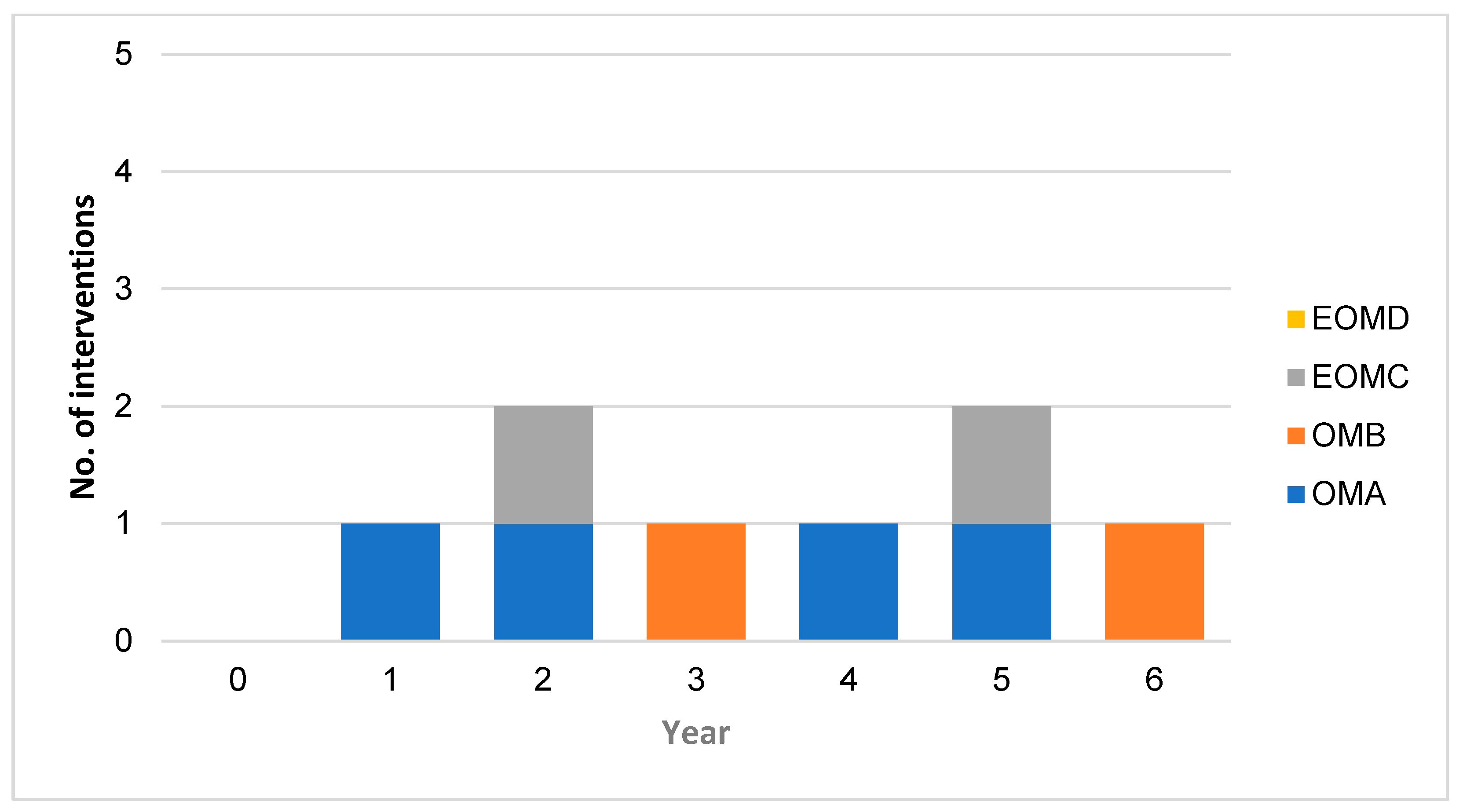

3.5.1. Maintenance Interventions Management

- Production output: 576 equipment/year

- Product lifespan: 3 years

- Operational hours: 1750 h/year

- Ordinary maintenance operations A (OMA): mainly concern software plugin updates, thorough cleaning, heat sensors, and mechanical triggers. These occur every 1500 h of use on average.

- Ordinary maintenance operations B (OMB): mostly relate to electronic components replacement, gear replacement, thorough cleaning, sampling motor replacement, and solenoid valve replacement. They take place after approximately 4500 h of use.

- Extraordinary maintenance operations C (EOMC): predominantly comprises the replacement of the excitation module and the replacement of the heater module. The manufacturer’s engineers estimate this occurring between 3500 and 4000 h of use on average

- Extraordinary maintenance operations D (EOMD): commonly consist of the motherboard replacement, fuse replacement, and the replacement of the power supply components. The collected information from the manufacturer shows the incidence at nearly 5000 h of use.

3.5.2. Spare Parts Inventory Evaluation

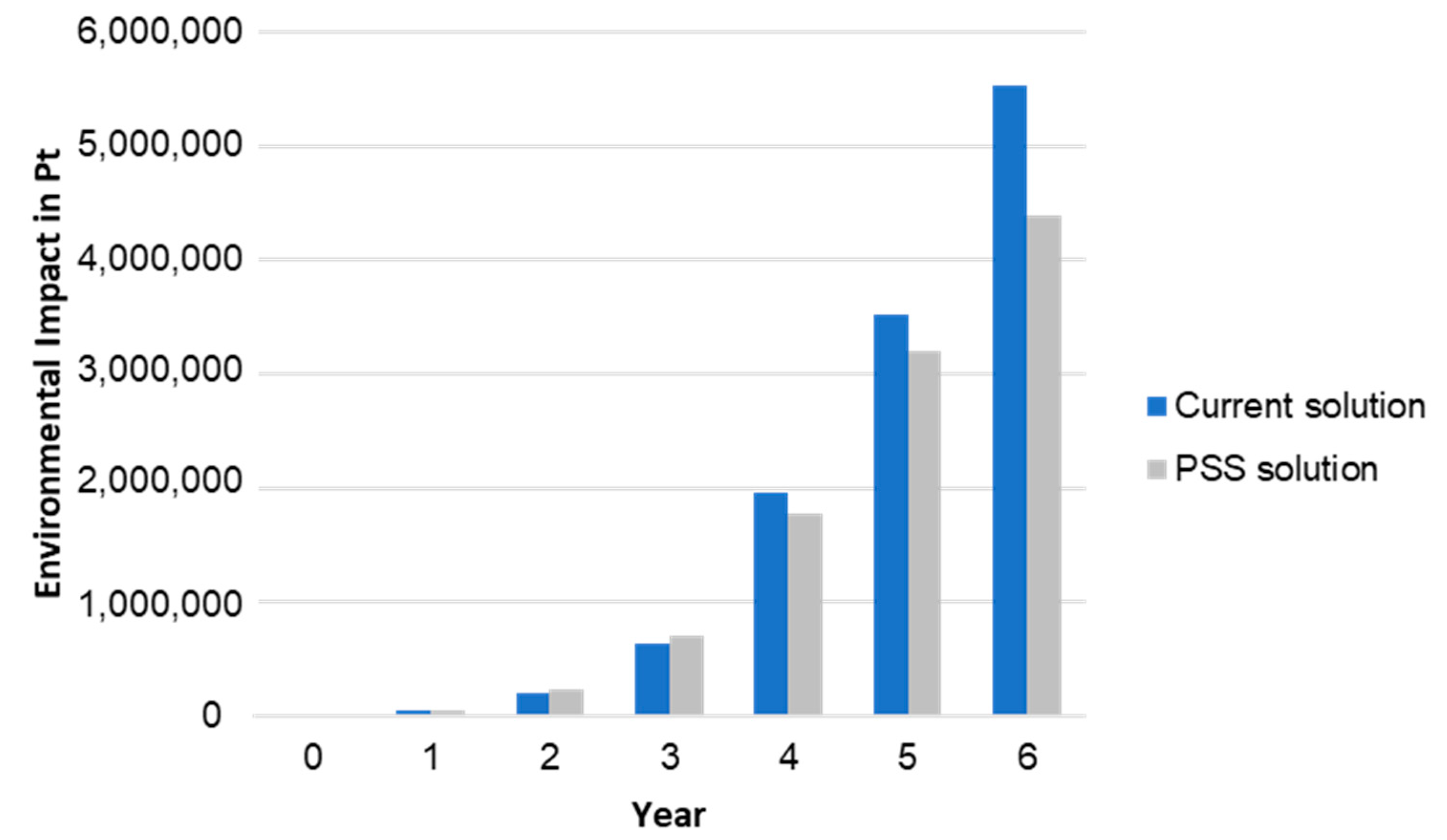

3.5.3. Environmental Impact

4. Discussion of Results

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Qu, M.; Yu, S.; Chen, D.; Chu, J.; Tian, B. State-of-the-art of design, evaluation, and operation methodologies in product service systems. Comput. Ind. 2016, 77, 1–14. [Google Scholar] [CrossRef]

- Haber, N.; Fargnoli, M. The management of customer requirements in a product-service system context: A case study in the medical equipment sector. Int. J. Serv. Oper. Manag. 2020, 37, 145–169. [Google Scholar] [CrossRef]

- He, B.; Luo, T.; Huang, S. Product Sustainability Assessment for Product Life Cycle. J. Clean. Prod. 2019, 206, 238–250. [Google Scholar] [CrossRef]

- Zheng, P.; Lin, T.J.; Chen, C.H.; Xu, X. A systematic design approach for service innovation of smart product-service systems. J. Clean. Prod. 2018, 201, 657–667. [Google Scholar] [CrossRef]

- Wiesner, S.; Hauge, J.B. Review of Factors Influencing Product-Service System Requirements Along the Life Cycle. In IFIP Advances in Information and Communication Technology; Dolgui, A., Bernard, A., Lemoine, D., von Cieminski, G., Romero, D., Eds.; Springer: Cham, Switzerland, 2021; Volume 633, pp. 138–145. [Google Scholar] [CrossRef]

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the circular economy: An analysis of 114 definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Demirel, P.; Danisman, G.O. Eco-Innovation and Firm Growth in the Circular Economy: Evidence from European SMEs. Bus. Strategy Environ. 2019, 28, 1608–1618. [Google Scholar] [CrossRef]

- Bocken, N.M.P.; de Pauw, I.; Bakker, C.; van der Grinten, B. Product design and business model strategies for a circular economy. J. Ind. Prod. Eng. 2016, 33, 308–320. [Google Scholar] [CrossRef] [Green Version]

- George, D.A.R.; Lin, B.C.B.; Chen, Y. A circular economy model of economic growth. Environ. Model. Softw. 2015, 73, 60–63. [Google Scholar] [CrossRef]

- Tukker, A. Eight Types of Product-Service System: EightWays to Sustainability? Experiences from SusProNet. Bus. Strategy Environ. 2004, 13, 246–260. [Google Scholar] [CrossRef]

- Kjaer, L.L.; Pigosso, D.C.A.; Niero, M.; Bech, N.M.; McAloone, T.C. Product/service-systems for a circular economy: The route to decoupling economic growth from resource consumption? J. Ind. Ecol. 2019, 23, 22–35. [Google Scholar] [CrossRef] [Green Version]

- Haber, N.; Fargnoli, M. Design for product-service systems: A procedure to enhance functional integration of product-service offerings. Int. J. Prod. Dev. 2017, 22, 135–164. [Google Scholar] [CrossRef]

- den Hollander, M.C.; Bakker, C.A.; Hultink, E.J. Product design in a circular economy: Development of a typology of key concepts and terms. J. Ind. Ecol. 2017, 21, 517–525. [Google Scholar] [CrossRef]

- Burke, H.; Zhang, A.; Wang, J.X. Integrating product design and supply chain management for a circular economy. Prod. Plan. Control 2021, 1–17. [Google Scholar] [CrossRef]

- Williams, A. Product service systems in the automobile industry: Contribution to system innovation? J. Clean. Prod. 2007, 15, 1093–1103. [Google Scholar] [CrossRef]

- Pigosso, D.C.A.; Mcaloone, T.C. Maturity-based approach for the development of environmentally sustainable product/service-systems. CIRP J. Manuf. Sci. Technol. 2016, 15, 33–41. [Google Scholar] [CrossRef] [Green Version]

- Reim, W.; Parida, V.; Örtqvist, D. Product–Service Systems (PSS) business models and tactics—A systematic literature review. J. Clean. Prod. 2015, 97, 61–75. [Google Scholar] [CrossRef]

- Fargnoli, M.; Haber, N.; Tronci, M. Case Study Research to Foster the Optimization of Supply Chain Management through the PSS Approach. Sustainability 2022, 14, 2235. [Google Scholar] [CrossRef]

- Jain, S.; Jain, N.K.; Metri, B. Strategic Framework towards Measuring a Circular Supply Chain Management. Benchmarking 2018, 25, 3238–3252. [Google Scholar] [CrossRef]

- Nag, U.; Sharma, S.K.; Govindan, K. Investigating drivers of circular supply chain with product-service system in automotive firms of an emerging economy. J. Clean. Prod. 2021, 319, 128629. [Google Scholar] [CrossRef]

- Xie, W.M.; Zhao, Y.X.; Jiang, Z.B.; Chow, P.S. Optimizing product service system by franchise fee contracts under information asymmetry. Ann. Oper. Res. 2016, 240, 709–729. [Google Scholar] [CrossRef]

- Erkoyuncu, J.A.; Roy, R.; Shehab, E.; Cheruvu, K. Understanding service uncertainties in industrial product–service system cost estimation. Int. J. Adv. Manuf. Technol. 2011, 52, 1223–1238. [Google Scholar] [CrossRef]

- Kim, S.-H.; Cohen, M.A.; Netessine, S. Performance Contracting in After-Sales Service Supply Chains. Manag. Sci. 2007, 53, 1843–1858. [Google Scholar] [CrossRef] [Green Version]

- Michail, N.A.; Melas, K.D. Shipping markets in turmoil: An analysis of the Covid-19 outbreak and its implications. Transp. Res. Interdiscip. Perspect. 2020, 7, 100178. [Google Scholar] [CrossRef]

- Michail, N.A.; Melas, K.D. Geopolitical Risk and the LNG-LPG Trade. Peace Econ. Peace Sci. Pub. Pol. 2022, 28, 243–265. [Google Scholar] [CrossRef]

- March, D.; Metcalfe, K.; Tintoré, J.; Godley, B.J. Tracking the global reduction of marine traffic during the COVID-19 pandemic. Nat. Commun. 2021, 12, 2415. [Google Scholar] [CrossRef]

- Visnjic, I.; Jovanovic, M.; Neely, A.; Engwall, M. What brings the value to outcome-based contract providers? Value drivers in outcome business models. Int. J. Prod. Econ. 2017, 192, 169–181. [Google Scholar] [CrossRef]

- Yang, M.; Smart, P.; Kumar, M.; Jolly, M.; Evans, S. Product-service systems business models for circular supply chains. Prod. Plan. Control 2018, 29, 498–508. [Google Scholar] [CrossRef] [Green Version]

- Resta, B.; Gaiardelli, P.; Cavalieri, S.; Dotti, S. Enhancing the design and management of the product-service system supply chain: An application to the automotive sector. Serv. Sci. 2017, 9, 302–314. [Google Scholar] [CrossRef]

- Aminoff, A.; Kettunen, O. Sustainable Supply Chain Management in a Circular Economy—Towards Supply Circles; Springer: Berlin/Heidelberg, Germany, 2016; pp. 61–72. [Google Scholar] [CrossRef]

- Lahcen, B.; Eyckmans, J.; Rousseau, S.; Dams, Y.; Brusselaers, J. Modelling the circular economy: Introducing a supply chain equilibrium approach. Ecol. Econ. 2022, 197, 107451. [Google Scholar] [CrossRef]

- Brissaud, D.; Sakao, T.; Riel, A.; Erkoyuncu, J.A. Designing value-driven solutions: The evolution of industrial product-service systems. CIRP Annals 2022, 71, 553–575. [Google Scholar] [CrossRef]

- Kimita, K.; Brambila-Macias, S.A.; Tillman, A.M.; Sakao, T. Failure analysis method for enhancing circularity through systems perspective. J. Ind. Ecol. 2021, 25, 544–562. [Google Scholar] [CrossRef]

- Haber, N.; Fargnoli, M. Designing Product-Service Systems: A Review Towards a Unified Approach. In Proceedings of the International Conference on Industrial Engineering and Operations Management, Rabat, Morocco, 11–13 April 2017; pp. 817–837. [Google Scholar]

- Xu, Z.; Elomri, A.; Zhang, Q.; Liu, C.; Shi, L. Status review and research strategies on product-service supply chain. Proc. IMechE Part B J. Eng. Manuf. 2020, 234, 1075–1086. [Google Scholar] [CrossRef]

- Ding, K.; Jiang, P.; Zheng, M. Environmental and economic sustainability-aware resource service scheduling for industrial product service systems. J. Intell. Manuf. 2017, 28, 1303–1316. [Google Scholar] [CrossRef]

- Costantino, F.; Di Gravio, G.; Patriarca, R.; Petrella, L. Spare parts management for irregular demand items. Omega 2018, 81, 57–66. [Google Scholar] [CrossRef]

- Duran, O.; Afonso, P.S.L.P. An activity based costing decision model for life cycle economic assessment in spare parts logistic management. Int. J. Prod. Econ. 2020, 222, 107499. [Google Scholar] [CrossRef]

- Engin, B.E.; Martens, M.; Paksoy, T. Lean and Green Supply Chain Management: A Comprehensive Review. In Lean and Green Supply Chain Management; Paksoy, T., Weber, G.-W., Huber, S., Eds.; Springer International Publishing: Cham, Switzerland, 2019; pp. 1–38. ISBN 978-3-319-97510-8. [Google Scholar]

- Tseng, M.L.; Wu, K.J.; Chiu, A.S.F.; Lim, M.K.; Tan, K. Service innovation in sustainable product service systems: Improving performance under linguistic preferences. Int. J. Prod. Econ. 2018, 203, 414–425. [Google Scholar] [CrossRef]

- Labbate, R.; Silva, R.F.; Rampasso, I.S.; Anholon, R.; Quelhas, O.L.G.; Leal Filho, W. Business models towards SDGs: The barriers for operationalizing Product-Service System (PSS) in Brazil. Int. J. Sustain. Dev. World Ecol. 2021, 28, 350–359. [Google Scholar] [CrossRef]

- Haber, N.; Fargnoli, M. Sustainable Product-Service Systems Customization: A Case Study Research in the Medical Equipment Sector. Sustainability 2021, 13, 6624. [Google Scholar] [CrossRef]

- Cavalieri, S.; Pezzotta, G. Product service systems engineering: State of the art and research challenges. J. Clean. Prod. 2012, 63, 278–288. [Google Scholar] [CrossRef]

- Fargnoli, M.; Haber, N.; Sakao, T. PSS modularisation: A customer-driven integrated approach. Int. J. Prod. Res. 2019, 57, 4061–4077. [Google Scholar] [CrossRef] [Green Version]

- Damha, L.G.; Trevisan, A.H.; Costa, D.G.; Costa, J.M.H. How are end-of-life strategies adopted in product-service systems? A systematic review of general cases and cases of medical devices industry. In Proceedings of the Design Society: International Conference on Engineering Design, Delft, The Netherlands, 5–8 August 2019; Volume 1, pp. 3061–3070. [Google Scholar] [CrossRef]

- De los Rios, I.C.; Charnley, F. Skills and Capabilities for a Sustainable and Circular Economy. J. Clean. Prod. 2017, 160, 109–122. [Google Scholar] [CrossRef]

- Song, W. Requirement management for product-service systems: Status review and future trends. Comput. Ind. 2017, 85, 11–22. [Google Scholar] [CrossRef]

- Van Ostaeyen, J.; van Horenbeek, A.; Pintelon, L.; Duflou, J.R. A refined typology of product–service systems based on functional hierarchy modeling. J. Clean. Prod. 2013, 51, 261–276. [Google Scholar] [CrossRef]

- Hubka, V.; Eder, W.E. Engineering Design; Heurista: Zürich, Switzerland, 1992. [Google Scholar]

- Li, H.; Ji, Y.; Li, Q.; Yang, M.; Evens, S. A methodology for module portfolio planning within the service solution layer of a product–service system. Int. J. Adv. Manuf. Technol. 2018, 94, 3287–3308. [Google Scholar] [CrossRef]

- Goedkoop, M.; Spriensma, R. The Eco-indicator 99: A Damage Oriented Method for Life Cycle Impact Assessment—Methodology Annex, 3rd ed.; PRé Consultants BV: Amersfoort, The Netherlands, 2001. [Google Scholar]

- Vezzoli, C.; Ceschin, F.; Diehl, J.C.; Kohtala, C. New design challenges to widely implement ‘Sustainable Product–Service Systems’. J. Clean. Prod. 2015, 97, 1–12. [Google Scholar] [CrossRef] [Green Version]

- Feng, D.; Fu, X.; Jiang, S.; Jing, L. Conceptual Solution Decision Based on Rough Sets and Shapley Value for Product-Service System: Customer Value-Economic Objective Trade-Off Perspective. Appl. Sci. 2021, 11, 11001. [Google Scholar] [CrossRef]

- Moultrie, J.; Sutcliffe, L.; Maier, A. A maturity grid assessment tool for environmentally conscious design in the medical device industry. J. Clean. Prod. 2016, 122, 252–265. [Google Scholar] [CrossRef]

- Cong, L.; Zhao, F.; Sutherland, J.W. A Design Method to Improve End-of-Use Product Value Recovery for Circular Economy. J. Mech. Des. 2019, 141, 044502–044511. [Google Scholar] [CrossRef]

- Cong, L.; Zhao, F.; Sutherland, J.W. Integration of dismantling operations into a value recovery plan for circular economy. J. Clean. Prod. 2017, 149, 378–386. [Google Scholar] [CrossRef]

- Alamerew, Y.A.; Brissaud, D. Circular economy assessment tool for end of life product recovery strategies. J. Remanufact. 2019, 9, 169–185. [Google Scholar] [CrossRef] [Green Version]

- Gao, J.; Yao, Y. Service-oriented manufacturing: A new product pattern. J. Intel. Manuf. 2011, 22, 435–446. [Google Scholar] [CrossRef]

- Arifin, R.; Ismail, S.Z. Investigation of inventory record accuracy in product-service system. J. Modern Manuf. Sys. Tech. 2019, 2, 93–105. [Google Scholar] [CrossRef]

- Gabriel, C.A.; Bortsie-Aryee, N.A.; Apparicio-Farrell, N.; Farrell, E. How supply chain choices affect the life cycle impacts of medical products. J. Clean. Prod. 2018, 182, 1095–1106. [Google Scholar] [CrossRef] [Green Version]

- Schumacher, S.; Lüdecke, C.; Ehrentreich-Förster, E.; Bier, F.F. Platform Technologies for Molecular Diagnostics Near the Patient’s Bedside. Adv. Biochem. Eng. Biotechnol. 2013, 133, 75–87. [Google Scholar] [CrossRef] [PubMed]

- Amjad, M. An Overview of the Molecular Methods in the Diagnosis of Gastrointestinal Infectious Diseases. Int. J. Microbiol. 2020, 2020, 8135724. [Google Scholar] [CrossRef]

- Zhang, C.; Gao, W.; Yang, T.; Guo, S. Opportunistic maintenance strategy for wind turbines considering weather conditions and spare parts inventory management. Renew. Energy 2019, 133, 703–711. [Google Scholar] [CrossRef]

- Bader, A.; Kaufmann, J.; Tracht, K. Order Classification in Inventory Planning of Job Shop Production. Proc. Manuf. 2020, 49, 180–184. [Google Scholar] [CrossRef]

- Hübner, A. Lecture Notes in Economics and Mathematical Systems. In Retail Category Management: Decision Support Systems for Assortment, Shelf Space, Inventory and Price Planning; Springer: Berlin/Heidelberg, Germany, 2011; Volume 656. [Google Scholar]

- Tukker, A. Product Services for a Resource-Efficient and Circular Economy—A Review. J. Clean. Prod. 2015, 97, 76–91. [Google Scholar] [CrossRef]

- Linnéusson, G.; Ng, H.C.A.; Aslam, T. Towards strategic development of maintenance and its effects on production performance by using system dynamics in the automotive industry. Int. J. Prod. Econ. 2018, 200, 151–169. [Google Scholar] [CrossRef]

- Darom, N.A.; Hishamuddin, H.; Ramli, R.; Nopiah, Z.M. An inventory model of supply chain disruption recovery with safety stock and carbon emission consideration. J. Clean. Prod. 2018, 197, 1011–1021. [Google Scholar] [CrossRef]

- Tasdemir, C.; Hiziroglu, S. Achieving cost efficiency through increased inventory leanness: Evidence from oriented strand board (OSB) industry. Int. J. Prod. Econ. 2019, 208, 412–433. [Google Scholar] [CrossRef]

- Rosa, M.; Wang, W.M.; Stark, R.; Rozenfeld, H. A Concept Map to Support the Planning and Evaluation of Artifacts in the Initial Phases of PSS Design. Res. Eng. Des. 2021, 32, 189–223. [Google Scholar] [CrossRef]

- Kleber, J.; Cohen, B. Reducing waste and increasing sustainability in health care settings. Am. J. Nurs. 2020, 120, 45–48. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lewandowski, M. Designing the Business Models for Circular Economy—Towards the Conceptual Framework. Sustainability 2016, 8, 43. [Google Scholar] [CrossRef] [Green Version]

- Dente, S.M.R.; Shimizu, T.; Wang, T.; Hashimoto, S. Can Material and Energy Be Saved by Differentiating Water Quality Targets in the Water Purification Process? Sustainability 2020, 12, 8730. [Google Scholar] [CrossRef]

- Song, W.; Sakao, T. A customization-oriented framework for design of sustainable product/service system. J. Clean. Prod. 2017, 140, 1672–1685. [Google Scholar] [CrossRef] [Green Version]

- Kühl, C.; Bourlakis, M.; Aktas, E.; Skipworth, H. How does servitisation affect supply chain circularity?—A systematic literature review. J. Enterp. Inf. Manag. 2019, 33, 703–728. [Google Scholar] [CrossRef]

- Cavalcante, J.; Gzara, L. Cavalcante, J.; Gzara, L. Product-Service Systems Lifecycle Models: Literature Review and New Propositions. Procedia CIRP 2018, 73, 32–38. [Google Scholar] [CrossRef]

- Wang, N.; Ren, S.; Liu, Y.; Yang, M.; Wang, J.; Huisingh, D. An active preventive maintenance approach of complex equipment based on a novel product-service system operation mode. J. Clean. Prod. 2020, 277, 123365. [Google Scholar] [CrossRef]

- Aronson, J.K.; Heneghan, C.; Ferner, R.E. Medical devices: Definition, classification, and regulatory implications. Drug Saf. 2020, 43, 83–93. [Google Scholar] [CrossRef]

| Operation | Options | Current State |

|---|---|---|

| Distribution and customer service coverage | Geographical distribution Customer type distribution Customer importance distribution (number of installed products) | Geographical radius of 500 km |

| Customer and technical support | Assistance by the manufacturer’s field service technicians Assistance by authorized third parties Assistance by independent workshops | Assistance by the manufacturer’s field service technicians Assistance by authorized third parties |

| Spare parts distribution | One level: manufacturer–central warehouse–customer Two levels: manufacturer–central warehouse–peripheral warehouse–customer | Two levels: manufacturer–central warehouse–peripheral warehouse–customer |

| Teleological Chain for the Diagnostic Instrument | |

|---|---|

| Type of application | Provide molecular diagnostic services |

| Overall objective | Enable an efficient and reliable diagnostic service |

| Relevant core customer demands | Number of services per yearIntervention time in case of malfunctioningContinuous update |

| Environment-centric function | Keep the number of diagnostic services near a set number |

| Solution-centric function | Provide a certain number of diagnostic services per year |

| Structural elements | Diagnostic equipment |

| Function | Code | PSS Enabler | PSS Provider | ||||

|---|---|---|---|---|---|---|---|

| To provide molecular diagnostic service | SF1 | Electronic form | Customer contact center | - | Customer | Manufacturer | Third party |

| SF2 | Customer survey | Site visit | - | Customer | Manufacturer | Third party | |

| SF3 | Purchasing | Leasing | - | Customer | Manufacturer | Third party | |

| SF4 | Periodic purchases | Forecast | On-demand | Customer | Manufacturer | Third party | |

| SF5 | Manual (Instructions for use) | On-site training | Remote training | Customer | Manufacturer | Third party | |

| SF6 | Preventive | Risk-based | Condition-based | Customer | Manufacturer | Third party | |

| … | … | … | … | … | … | … | |

| SF14 | Replacement of all critical components | Replacement of degraded components | None (no degradation noted) | Customer | Manufacturer | Third party | |

| Year | 0 | 1 | 2 | 3 | 4 | 5 | 6 |

|---|---|---|---|---|---|---|---|

| Current solution | 0 | 2880 | 8064 | 15,552 | 20,736 | 23,616 | 33,408 |

| PSS solution | 0 | 2880 | 8064 | 11,520 | 14,400 | 19,584 | 23,040 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Haber, N.; Fargnoli, M. Product-Service Systems for Circular Supply Chain Management: A Functional Approach. Sustainability 2022, 14, 14953. https://doi.org/10.3390/su142214953

Haber N, Fargnoli M. Product-Service Systems for Circular Supply Chain Management: A Functional Approach. Sustainability. 2022; 14(22):14953. https://doi.org/10.3390/su142214953

Chicago/Turabian StyleHaber, Nicolas, and Mario Fargnoli. 2022. "Product-Service Systems for Circular Supply Chain Management: A Functional Approach" Sustainability 14, no. 22: 14953. https://doi.org/10.3390/su142214953