Urban Rail Transit Rolling Stock Scheduling Optimization with Shared Depot

Abstract

:1. Introduction

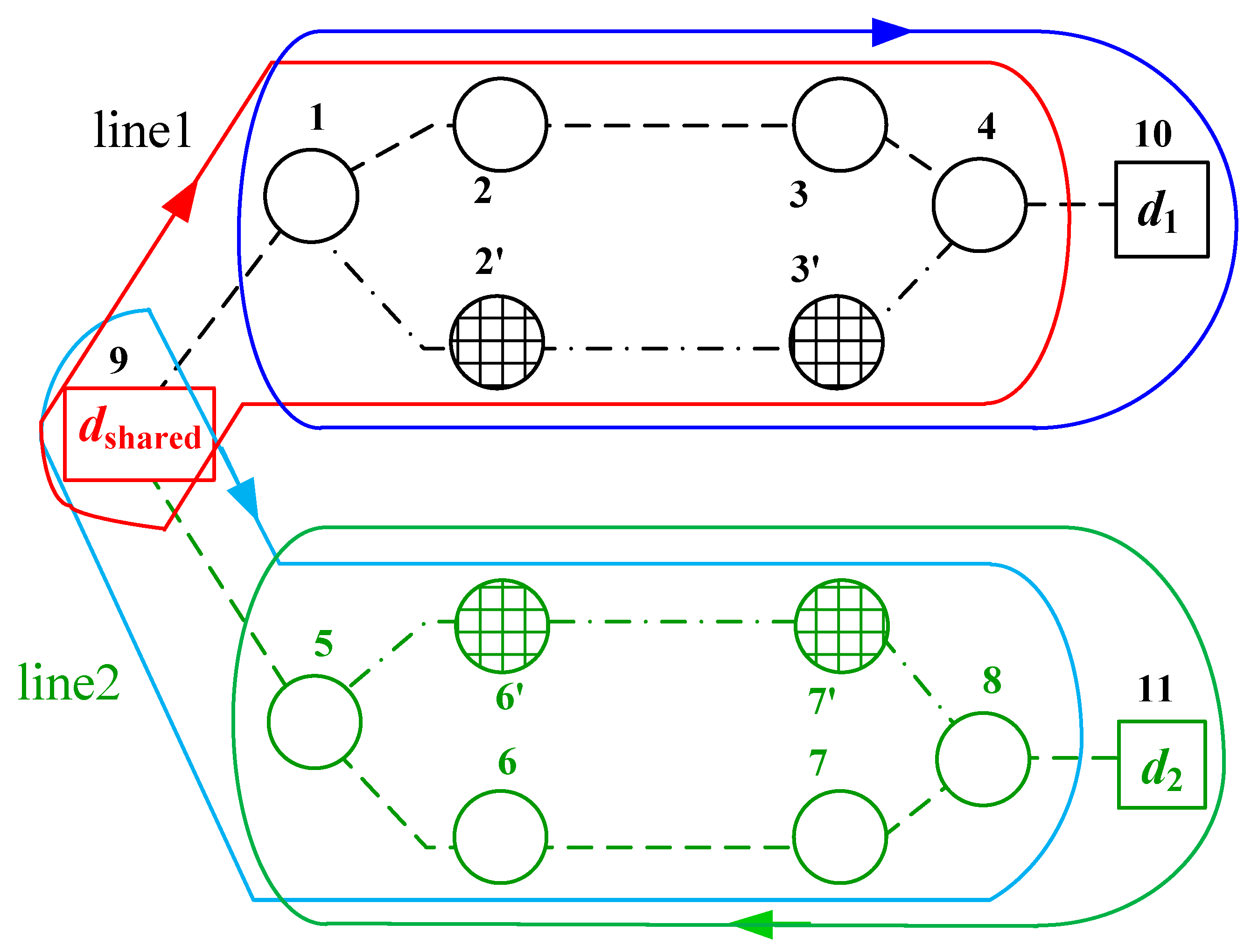

2. Problem Description

3. Rolling Stock Scheduling Model of Urban Rail Transit with Shared Depot

- (1)

- Undertake the task of running under an inseparable train between the starting station and the ending station;

- (2)

- The continuation task, which mainly considers the time or space required to complete the rolling stock operation.

3.1. Objective Function

3.2. Constraint Condition

3.2.1. Uniqueness Constraint

3.2.2. Rolling Stock Consistency Constraint

3.2.3. Constraint for Empty Running

3.2.4. Spatial–Temporal Constraint of Rolling Stocks

3.2.5. Constraint of the Total Number of Rolling Stocks in Depots

3.3. Improved Minimum Ant Colony Algorithm

- (1).

- Basic data preparation and data pretreatment

- (2).

- Internal circulation process

- (3).

- External circulation process

4. Results

4.1. Number of Rolling Stock

4.2. Application Evaluation Index

4.3. Sensitivity Analysis

- (1).

- Explanation of the empirical results on the distributions of unit connection cost

- (2).

- Understanding the influence mechanism of rolling stock purchase cost on fixed cost

5. Discussion

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| No. of Rolling Stocks | Train Numbers |

|---|---|

| 1 | X-81002-81035-81040-81119-81118-81339-81334-81415-81414-81453-81454- 51437-X |

| 2 | X-51001-51014-51043-51072-51113-51138-51163-51180-51201-51218-51239- 51256-51277-51298-51341-51380-51391-51416-X |

| 3 | Y-51003-51016-51045-51074-51115-51140-51165-51182-51205-51222-51243- 51260-51281-51306-51337-51376-51387-51414-Y |

| 4 | X-51018-51047-51078-51119-51142-51167-51184-51207-51224-51245-51262- 51283-51310-51343-51382-51393-51418-X |

| 5 | X-51007-51020-51051-51082-51123-51144-51169-51186-51209-51226-51247- 51264-51285-51314-51345-51384-51395-51424-X |

| 6 | X-51009-51022-51055-51088-51129-51148-51171-51188-51211-51228-51251- 51268-51295-51328-51357-51390-51401-51422-X |

| 7 | X-51002-51027-51050-51091-51122-51149-51168-51191-51208-51229-51246- 51267-51284-51315-51352-51373-51402-51411-51430-X |

| 8 | X-51004-51029-51052-51093-51124-51151-51170-51195-51212-51233-51250- 51271-51288-51323-51362-51379-51406-51413-51434-X |

| 9 | X-81011-81012-81059-81064-81143-81132-81189-81188-81223-81224-81255- 81256-81289-81290-81345-81348-51369-51398-51407-51426-X |

| 10 | X-51006-51031-51054-51095-51126-51153-51174-51197-51214-51235-51252- 51273-51294-51327-51366-51381-51408-51415-51436-X |

| 11 | X-81006-81043-81050-81133-81130-81363-81358-81431-81432-81467-81468-X |

| 12 | X-51008-51035-51060-51101-51130-51155-51172-51193-51210-51231-51248- 51269-51286-51317-51354-51375-51404-51417-51438-X |

| 13 | X-81008-81049-81056-81131-81120-81183-81182-81215-81216-81247-81248- 81279-81280-81325-81328-81409-81408-51409-51428-X |

| 14 | Y-51011-51026-51063-51094-51133-51152-51175-51192-51213-51230-51253- 51270-51291-51324-51353-51388-51403-51440-Y |

| 15 | X-51010-51037-51070-51111-51136-51161-51178-51199-51216-51237-51254- 51275-51296-51329-51368-51383-51410-51419-51442-X |

| 16 | Y-51013-51028-51065-51098-51135-51154-51177-51194-51215-51232-51255- 51272-51297-51330-51359-51396-51405-Y |

| 17 | X-81010-81057-81062-81147-81144-81323-81318-81397-81398-81447-81448- 51431-X |

| 18 | X-51015-51030-51067-51100-51137-51156-51179-51196-51217-51234-51261- 51278-51305-51340-51367-51400-51427-X |

| 19 | X-81016-81065-81070-81153-81150-81197-81196-81227-81228-81259-81258- 81291-81292-81349-81352-51433-X |

| 20 | X-81013-81020-81077-81082-81167-81164-81203-81204-81235-81236-81267- 81268-81305-81306-81377-81382-51423-X |

| 21 | Y-81018-81071-81076-81159-81156-81331-81326-81407-81406-81449-81456- 51439-Y |

| 22 | X-51012-51039-51066-51107-51134-51159-51176-51203-51220-51241-51258- 51279-51302-51333-51372-51385-51412-51435-X |

| 23 | Y-81003-81024-81083-81086-81169-81168-81205-81206-81237-81238-81271- 81272-81307-81308-81381-81386-81441-81440-81475-81476-Y |

| 24 | Y-81005-81030-81095-81098-81175-81174-81209-81210-81241-81244-81275- 81276-81313-81316-81393-81396-51421-Y |

| 25 | X-81022-81079-81014-81165-81152-81309-81314-81405-81404-51397-X |

| 26 | X-51017-51032-51071-51102-51141-51160-51181-51198-51219-51236-51257- 51274-51299-51334-51361-51392-51425-X |

| 27 | Y-51019-51036-51077-51108-51145-51164-51185-51202-51223-51240-51263- 51280-51311-51348-51371-Y |

| 28 | X-51021-51038-51079-51114-51147-51166-51187-51204-51225-51242-51265- 51282-51313-51350-51377-X |

| 29 | Y-81026-81087-81090-81319-81320-81399-81400-51429-Y |

| 30 | X-81007-81032-81101-81104-51347-51386-81459-81460-X |

| 31 | X-81009-81072-81157-81154-81199-81198-81229-81230-81261-81262-81299- 81300-81365-81368-81435-81438-81473-81474-X |

| 32 | X-81023-81028-81089-81092-81171-81172-81207-81208-81239-81240-81273- 81274-81311-81312-81385-81392-X |

| 33 | X-81004-81041-81046-81123-81114-81295-81294-81353-81356-51399-51420-X |

| 34 | X-51024-51057-51090-51131-51150-51173-51190-51221-51238-51259-51276- 51301-51336-51363-51394-81465-81466-X |

| 35 | Y-81017-81042-81125-81122-81315-81310-81387-81394-81445-81446-81481- 81480-Y |

| 36 | X-81015-81034-81105-81108-81179-81178-81213-81214-81245-81246-81277- 81278-81317-81322-81403-81402-81455-81458-X |

| 37 | X-51034-51073-51104-51139-51158-51189-51206-51249-51266-51287-51318- 51349-X |

| 38 | X-81067-81094--81097-81112-81153-81158-81162-81181-81148-81213-81322- 81367-81374-X |

| 39 | X-51042-51083-51116-51157-51316-51351-X |

| 40 | Y-81036-81107-81110-81347-81342-81423-81424-81461-81462-Y |

| 41 | Y-51044-51085-51118-51331-51370-81463-81464-Y |

| 42 | X-81031-81048-81129-81128-81187-81186-81219-81220-81251-81252-81285- 81288-81337-81340-X |

| 43 | Y-81039-81038-81115-81116-81185-81184-81217-81218-81249-81250-81281- 81282-81329-81332-81413-81412-Y |

| 44 | X-81047-81044-81127-81126-81283-81284-81333-81336-81417-81416-X |

| 45 | X-51046-51087-51120-51339-51378-81471-81472-X |

| 46 | X-81051-81054-81137-81134-81343-81338-81419-81418-81457-81470-X |

| 47 | X-81019-81060-81145-81140-81193-81192-81225-81226-81257-81260-81293- 81296-81357-81360-81433-81434-81469-81478-X |

| 48 | X-81021-81058-81141-81138-81335-81330-81411-81410-81451-81452-X |

| 49 | Y-51048-51089-51128-51289-51320-51355-Y |

| 50 | Y-81052-81139-81136-81191-81190-81231-81232-81263-81264-81301-81302- 81369-81372-Y |

| 51 | X-81001-51432-X |

| 52 | Y-51005-51304Y |

| 53 | X-81025-81102-81177-81176-81211-81212-81243-81254-81287-81298-81361- 81364-81439-81442-81477-81482-X |

| 54 | X-81055-81066-81151-81148-81391-81388-X |

| 55 | Y-81063-81068-81163-81160-81201-81200-81233-81234-81265-81266-81321- 81324-81421-81420-Y |

| 56 | X-81027-81080-81173-81180-81221-81222-81253-81270-81373-81376-81437- 81436-81479-X |

| 57 | Y-51025-51058-51099-51132-81443-81444-X |

| 58 | X-51033-51062-51103-51146-51293-51326-51365-X |

| 59 | X-81029-81170-81269-81286-81341-81346-81425-81426-X |

| 60 | X-51041-51076-51117-51360-X |

| 61 | X-51056-51097-51312-81395-81390-X |

| 62 | X-51064-51105-51332-81427-81428-X |

| 63 | X-81069-81074-81155-81142-81195-81194-81297-81304-81429-81430-X |

| 64 | X-81078-81161-81158-51321-51358-X |

| 65 | X-81075-81084-81181-81202-51325-51364-X |

| 66 | X-51049-51080-51121-51346-X |

| 67 | X-81088-51309-51344-X |

| 68 | X-81094-81327-81344-X |

| 69 | X-81085-81096-51303-51338-X |

| 70 | X-81093-81100-81303-81354-X |

| 71 | X-51053-51084-51125-51290-51335-X |

| 72 | X-51059-51092-51307-51342-X |

| 73 | Y-51061-51096-81401-81422-Y |

| 74 | X-81053-81106-51069-51106-81383-81380-X |

| 75 | X-81033-81112-81099-81124-X |

| 76 | Y-81166-81375-81374-Y |

| 77 | X-51075-51110-81351-81350-X |

| 78 | X-51109-51300-81379-81378-X |

| 79 | X-81135-81146-81037-81162-81359-81370-X |

| 80 | X-81117-81242-51068-51127-51292-81389-81384-X |

| 81 | X-81061-81362-81045-81366-X |

| 82 | X-51086-51308-81371-81450-X |

| 83 | X-81109-51304-81355X |

| 84 | Y-51023-51040-51081-51112-51143-51162-51183-51200-51227-51244-51319-51356-51389-Y |

References

- Mao, B.; Gao, Z. Progress of operational resources sharing methods for urban rail networks. J. Transp. Syst. Eng. Inf. Technol. 2018, 18, 1–8. [Google Scholar]

- Huisman, D.; Kroon, L.G.; Lentink, R.M.; Vromans, M.J.C.M. Operations research in passenger railway transportation. Stat. Neerl. 2005, 59, 467–497. [Google Scholar] [CrossRef] [Green Version]

- Haahr, J.; Lusby, R.M. Integrating rolling stock scheduling with train unit shunting. Eur. J. Oper. Res. 2017, 259, 452–468. [Google Scholar] [CrossRef] [Green Version]

- Lin, Z.; Kwan, R.S.K. A branch-and-price approach for solving the train unit scheduling problem. Transp. Res. Part B Methodol. 2016, 94, 97–120. [Google Scholar] [CrossRef]

- Peeters, M.; Kroon, L. Circulation of railway rolling stock: A branch-and-price approach. Comput. Oper. Res. 2008, 35, 538–556. [Google Scholar] [CrossRef] [Green Version]

- Fioole, P.-J.; Kroon, L.; Maróti, G.; Schrijver, A. A rolling stock circulation model for combining and splitting of passenger trains. Eur. J. Oper. Res. 2006, 174, 1281–1297. [Google Scholar] [CrossRef] [Green Version]

- Cacchiani, V.; Caprara, A.; Toth, P. A Lagrangian heuristic for a train-unit assignment problem. Discret. Appl. Math. 2013, 161, 1707–1718. [Google Scholar] [CrossRef]

- Lai, Y.; Wang, S.; Huang, K. Optimized train-set rostering plan for Taiwan high-speed rail. IEEE Trans. Autom. Sci. Eng. 2017, 14, 286–298. [Google Scholar] [CrossRef]

- Tomiyama, T.; Sato, T.; Okada, K.; Wakamiya, T.; Murata, T. Railway rolling-stock-assignment-scheduling algorithm for minimizing inspection cost. IAENG Int. J. Appl. Math. 2018, 48, 228–237. [Google Scholar]

- Canca, D.; Sabido, M.; Barrena, E. A rolling stock circulation model for railway rapid transit systems. Transp. Res. Procedia 2014, 3, 680–689. [Google Scholar] [CrossRef] [Green Version]

- Luis, C.; Ángel, M. Robust rolling stock in rapid transit networks. Comput. Oper. Res. 2011, 38, 1131–1142. [Google Scholar]

- Giacco, G.L.; D’Ariano, A.; Pacciarelli, D. Rolling stock rostering optimization under maintenance constraints. J. Intell. Transp. Syst. 2014, 18, 95–105. [Google Scholar] [CrossRef]

- Zheng, L.; Song, R.; Xiao, Y.; Liu, J. Optimization method for working out vehicle scheduling plan of urban rail transit under network operation. China Railw. Sci. 2014, 35, 104–110. [Google Scholar]

- Yue, Y.; Han, J.; Wang, S.; Liu, X. Integrated train timetabling and rolling stock scheduling model based on time-dependent demand for urban rail transit. Comput.-Aided Civ. Infrastruct. Eng. 2017, 32, 856–873. [Google Scholar] [CrossRef]

- Wang, Y.; Tang, T.; Ning, B.; Meng, L. Integrated optimization of regular train schedule and train circulation plan for urban rail transit lines. Transp. Res. Part E Logist. Transp. Rev. 2017, 105, 83–104. [Google Scholar] [CrossRef]

- Zhang, M.; Wang, Y.; Su, S.; Tang, T.; Ning, B. A short turning strategy for train scheduling optimization in an urban rail transit line: The case of Beijing Subway Line 4. J. Adv. Transp. 2018, 2018, 5367295. [Google Scholar] [CrossRef]

- Zhong, Q.; Zhang, Y.; Dian, W.; Zhong, Q.; Wen, C.; Peng, Q. A mixed integer linear programming model for rolling stock deadhead routing before the operation period in an urban rail transit line. J. Adv. Transp. 2020, 2020, 3809734. [Google Scholar] [CrossRef]

- Placido, A.; D’Acierno, L. A methodology for assessing the feasibility of fleet compositions with dynamic demand. Transp. Res. Procedia 2015, 10, 595–604. [Google Scholar] [CrossRef] [Green Version]

- Samà, M.; D’Ariano, A.; Pacciarelli, D.; Corman, F. Lower and upper bound algorithms for the real-time train scheduling and routing problem in a railway network. IFAC-PapersOnLine 2016, 49, 215–220. [Google Scholar] [CrossRef]

- D’Ariano, A.; Meng, L.; Centulio, G.; Corman, F. Integrated stochastic optimization approaches for tactical scheduling of trains and railway infrastructure maintenance. Comput. Ind. Eng. 2019, 127, 1315–1335. [Google Scholar] [CrossRef]

- van Hövell, M.E.M.A.; Goverde, R.M.P.; Bešinović, N.; de Weerdt, M.M. Increasing the effiectiveness of the capacity usage at rolling stock service locations. J. Rail Transp. Plan. Manag. 2022, 21, 10297. [Google Scholar]

| Publications | Object | Infrastructure | Model Structure | Solution Algorithms | ||||

|---|---|---|---|---|---|---|---|---|

| Single Line | Multi Line | Single Depot | Multi Depots | Shared Depot | ||||

| Cadarso [11] | SR | √ | √ | MCFM | CPLEX | |||

| Ciacco [12] | SR | √ | √ | MILP | BD | |||

| Zheng [13] | URT | √ | √ | MIP | Tabu research | |||

| Yue [14] | URT | √ | √ | Bi-level model | CPLEX/SA | |||

| Wang [15] | URT | √ | √ | MILP | CPLEX | |||

| Zhang [16] | URT | √ | √ | MILP | CPLEX | |||

| Zhong [17] | URT | √ | √ | MILP | CPLEX | |||

| Samà [19] | R | √ | MILP | LB/UB/CPLEX | ||||

| D’Ariano [20] | R | √ | √ | MILP | CPLEX | |||

| Our work | URT | √ | √ | √ | MIP | ACO | ||

| Rolling Stock Number of Depot | Whether Rolling Stock Belongs to the Depot | Capacity Utilization | Flexibility | Management Complexity | |

|---|---|---|---|---|---|

| Fixed depot rolling stock operation mode | Fixed | Yes | Lower | Lower | Lower |

| Cycle/beat type rolling stock operation mode | Fixed | Yes | Average | Average | Average |

| Variable rolling stock operation mode | Fixed | No | Higher | Higher | Higher |

| Parameters | |

|---|---|

| set of rolling stocks, | |

| rolling stock | |

| set of train number nodes, | |

| set of depot nodes, | |

| set of both train number and depot nodes | |

| train number | |

| depot | |

| unit connection cost | |

| connect time between train numbers and | |

| the departure time of train number | |

| the arrive time of train number | |

| the standard continuous time standard between node and node | |

| the standard time for the passenger operation process of rolling stock | |

| the standard time for turn-back operation of rolling stock | |

| the departure station of train number node | |

| the arrive station of train number node | |

| Fixed operation cost for a day of one rolling stock | |

| the parking capacity of depot | |

| 0–1 decision variable, 1 represents rolling stock coming from depot departing from node to node , otherwise is 0, |

| Running Section | X–A | X–B | X–C | X–D | X–E | Y–E |

|---|---|---|---|---|---|---|

| Running time (seconds) | 926 | 1651 | 306 | 336 | 2280 | 210 |

| No. | Running Time | The Application Efficiency | The Daily Utilization Efficiency | No. | Running Time | The Application Efficiency | The Daily Utilization Efficiency |

|---|---|---|---|---|---|---|---|

| 1 | 32,760 | 1.25 | 50.56 | 43 | 43,920 | 1.68 | 67.78 |

| 2 | 52,920 | 2.02 | 81.67 | 44 | 25,800 | 0.98 | 39.81 |

| 3 | 52,920 | 2.02 | 81.67 | 45 | 20,340 | 0.78 | 31.39 |

| 4 | 49,980 | 1.91 | 77.13 | 46 | 26,400 | 1.01 | 40.74 |

| 5 | 52,920 | 2.02 | 81.67 | 47 | 50,760 | 1.94 | 78.33 |

| 6 | 49,980 | 1.91 | 77.13 | 48 | 27,000 | 1.03 | 41.67 |

| 7 | 55,860 | 2.13 | 86.20 | 49 | 17,640 | 0.67 | 27.22 |

| 8 | 55,860 | 2.13 | 86.20 | 50 | 36,060 | 1.38 | 55.65 |

| 9 | 55,080 | 2.10 | 85.00 | 51 | 5160 | 0.20 | 7.96 |

| 10 | 55,860 | 2.13 | 86.20 | 52 | 5880 | 0.22 | 9.07 |

| 11 | 29,820 | 1.14 | 46.02 | 53 | 45,120 | 1.72 | 69.63 |

| 12 | 55,860 | 2.13 | 86.20 | 54 | 14,520 | 0.55 | 22.41 |

| 13 | 52,020 | 1.98 | 80.28 | 55 | 38,280 | 1.46 | 59.07 |

| 14 | 52,920 | 2.02 | 81.67 | 56 | 36,660 | 1.40 | 56.57 |

| 15 | 55,860 | 2.13 | 86.20 | 57 | 17,400 | 0.66 | 26.85 |

| 16 | 49,980 | 1.91 | 77.13 | 58 | 20,580 | 0.79 | 31.76 |

| 17 | 32,760 | 1.25 | 50.56 | 59 | 22,560 | 0.86 | 34.81 |

| 18 | 49,980 | 1.91 | 77.13 | 60 | 14,580 | 0.56 | 22.50 |

| 19 | 44,640 | 1.70 | 68.89 | 61 | 13,860 | 0.53 | 21.39 |

| 20 | 47,460 | 1.81 | 73.24 | 62 | 14,460 | 0.55 | 22.31 |

| 21 | 32,760 | 1.25 | 50.56 | 63 | 26,400 | 1.01 | 40.74 |

| 22 | 56,520 | 2.16 | 87.22 | 64 | 14,340 | 0.55 | 22.13 |

| 23 | 55,800 | 2.13 | 86.11 | 65 | 16,560 | 0.63 | 25.56 |

| 24 | 46,860 | 1.79 | 72.31 | 66 | 14,700 | 0.56 | 22.69 |

| 25 | 25,320 | 0.97 | 39.07 | 67 | 11,640 | 0.44 | 17.96 |

| 26 | 49,980 | 1.91 | 77.13 | 68 | 6660 | 0.25 | 10.28 |

| 27 | 44,100 | 1.68 | 68.06 | 69 | 10,920 | 0.42 | 16.85 |

| 28 | 44,100 | 1.68 | 68.06 | 70 | 10,680 | 0.41 | 16.48 |

| 29 | 20,880 | 0.80 | 32.22 | 71 | 14,700 | 0.56 | 22.69 |

| 30 | 21,600 | 0.82 | 33.33 | 72 | 11,760 | 0.45 | 18.15 |

| 31 | 50,160 | 1.91 | 77.41 | 73 | 10,920 | 0.42 | 16.85 |

| 32 | 43,920 | 1.68 | 67.78 | 74 | 13,740 | 0.52 | 21.20 |

| 33 | 28,260 | 1.08 | 43.61 | 75 | 10,680 | 0.41 | 16.48 |

| 34 | 49,740 | 1.90 | 76.76 | 76 | 10,920 | 0.42 | 16.85 |

| 35 | 32,640 | 1.25 | 50.37 | 77 | 10,320 | 0.39 | 15.93 |

| 36 | 50,760 | 1.94 | 78.33 | 78 | 12,900 | 0.49 | 19.91 |

| 37 | 35,280 | 1.35 | 54.44 | 79 | 16,680 | 0.64 | 25.74 |

| 38 | 38,220 | 1.46 | 58.98 | 80 | 17,260 | 0.66 | 26.64 |

| 39 | 17,640 | 0.67 | 27.22 | 81 | 12,000 | 0.46 | 18.52 |

| 40 | 24,180 | 0.92 | 37.31 | 82 | 13,740 | 0.52 | 21.20 |

| 41 | 20,340 | 0.78 | 31.39 | 83 | 8700 | 0.33 | 13.43 |

| 42 | 38,280 | 1.46 | 59.07 | 84 | 35,460 | 1.35 | 54.72 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Feng, J.; Li, G.; Shi, Y.; Li, Z.; Liu, S. Urban Rail Transit Rolling Stock Scheduling Optimization with Shared Depot. Sustainability 2022, 14, 15075. https://doi.org/10.3390/su142215075

Feng J, Li G, Shi Y, Li Z, Liu S. Urban Rail Transit Rolling Stock Scheduling Optimization with Shared Depot. Sustainability. 2022; 14(22):15075. https://doi.org/10.3390/su142215075

Chicago/Turabian StyleFeng, Jia, Guowei Li, Yuxin Shi, Zhengzhong Li, and Shanshan Liu. 2022. "Urban Rail Transit Rolling Stock Scheduling Optimization with Shared Depot" Sustainability 14, no. 22: 15075. https://doi.org/10.3390/su142215075