Abstract

This paper presents a comprehensive overview on the current status of solid oxide fuel cell (SOFC) energy systems technology with a deep insight into the techno-energy performance. In recent years, SOFCs have received growing attention in the scientific landscape of high efficiency energy technologies. They are fuel flexible, highly efficient, and environmentally sustainable. The high working temperature makes it possible to work in cogeneration, and drive downstream bottomed cycles such as Brayton and Hirn/Rankine ones, thus configuring the hybrid system of a SOFC/turbine with very high electric efficiency. Fuel flexibility makes SOFCs independent from pure hydrogen feeding, since hydrocarbons can be fed directly to the SOFC and then converted to a hydrogen rich stream by the internal thermochemical processes. SOFC is also able to convert carbon monoxide electrochemically, thus contributing to energy production together with hydrogen. SOFCs are much considered for being supplied with biofuels, especially biogas and syngas, so that biomass gasifiers/SOFC integrated systems contribute to the “waste to energy” chain with a significant reduction in pollution. The paper also deals with the analysis of techno-energy performance by means of ad hoc developed numerical modeling, in relation to the main operating parameters. Ample prominence is given to the aspect of fueling, emphasizing fuel processing with a deep discussion on the impurities and undesired phenomena that SOFCs suffer. Constituent materials, geometry, and design methods for the balance of plant were studied. A wide analysis was dedicated to the hybrid system of the SOFC/turbine and to the integrated system of the biomass gasifier/SOFC. Finally, an overview of SOFC system manufacturing companies on SOFC research and development worldwide and on the European roadmap was made to reflect the interest in this technology, which is an important signal of how communities are sensitive toward clean, low carbon, and efficient technologies, and therefore to provide a decisive and firm impulse to the now outlined energy transition.

1. Introduction

Energy production and its environmental impact are currently among the most important and discussed issues around the world. Electrical power is still mainly supplied by conventional power generation technologies based on the combustion of fossil fuels, with the generation of various polluting emissions. However, the most pressing and immediate problem is global warming, which is directly linked to greenhouse gas emissions into the atmosphere. At the end of the last decade, globally, about 40 Gtoneq CO2 have been produced, which means that a narrow gap has remained before reaching the temperature rise to within two Celsius degrees, as agreed during the Paris Agreement [1].

Due to increasing demand for energy and the depletion of fossil resources, efficient energy systems and new energy conversion processes are urgently needed, enabling the shift from a fossil fuel-based economy to a new paradigm. Therefore, an energy transition is now more mandatory than ever. In 1997, the United States Department of Energy launched its Vision 21st program [2,3], which aimed to conduct conceptual feasibility studies for the evaluation of high-efficiency fossil fuel power plants and then develop the technologies for a fleet that is fuel-flexible.

Currently, governments are adopting rules to limit the emissions of carbon dioxide and other greenhouse gases on a large scale. Various methods can be adopted to mitigate pollutant emissions such as imposing taxes on carbon emissions or on gasoline, so that individuals and companies have a greater incentive to save energy and pollute less [4].

In the last decade, renewable energy production has grown exponentially, going from an installed power of 110 GW (2011) to 280 GW (2020) [5], indicating a new way for decarbonization. The total decarbonization of some sectors such as transport, industry, and uses with a high requirement of heat, which is currently difficult to achieve only by means of electrification. This challenge could be addressed by using hydrogen technologies. The report of the International Renewable Energy Agency (IRENA) presents a technology outlook for the energy transition [6] and many publications have focused on the energy transition toward hydrogen energy [7,8,9,10,11] as being the cleanest fuel. Hydrogen energy represents the new energy paradigm, in which hydrogen has the main role of an energy carrier, being a transformation gas that can be stored and used by occurrence, thus producing non pollutant emissions. Hydrogen is unequivocally connected to fuel cells, which are the main electrochemical devices that convert it into energy at high efficiency.

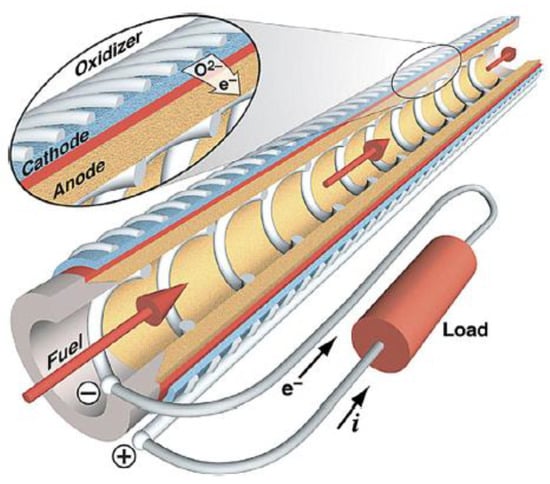

In this regard, this paper reviews and provides an overview of high temperature solid oxide fuel cell (SOFC) energy systems, notoriously considered by the scientific and industrial communities due to the strength shown. The SOFC fuel cell is constructed from anode and cathode electrodes that sandwich a solid oxide electrolyte. Its operating principle is based on semi-electroreactions occurring at the electrodes. The fuel is fed to the anode where the hydrogen oxidation reaction (HOR) occurs, while air is fed to the cathode where the oxygen reduction reaction (ORR) takes place [12]. HOR generates the production of electrons by means of hydrogen reacting with oxygen ions. Electrons circulate into an external circuit closed to the cathode at which they accomplish the oxygen ions of the ORR by encountering the entering oxygen. Oxygen ions are then transported by the electrolyte, which is selective for these anions, to the anode where they continue progressing the life cycle of SOFC electrochemical processes.

The electrochemical processes occurring are highly exothermic, thus raising the temperature to very high levels that can be operated in SOFCs due to the constitutive elements employed. This makes it possible to work in cogeneration and deliver high quality heat. The high temperature exhaust gases can be processed in heat recovery devices, thus delivering thermal energy. Moreover, by integrating absorption cooling machines, the SOFC-based energy systems extend themselves to trigenerative systems.

SOFC systems offer high efficiency pathways to produce electricity from fuels. Their peculiarity consists in being flexible in fuels and high efficiency with regard to the generation of electric energy, also delivering a valid contribution to the issue of environmental sustainability when fed with biofuels.

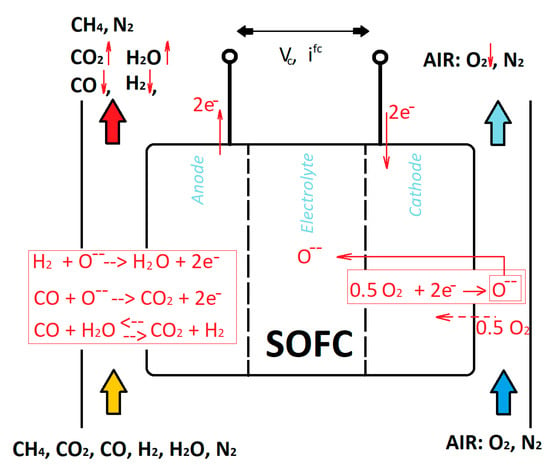

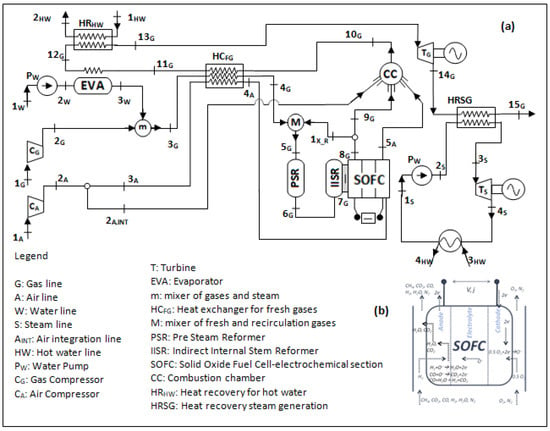

The big difference between SOFCs and the other types of fuel cells is hence the fuel flexibility that makes SOFCs independent from pure hydrogen feeding. This is a great strength, since hydrogen is not immediately available in the environment. Hydrocarbons fed to SOFC are subsequently converted to a hydrogen rich stream by the internal thermochemical processing (reforming and CO-shift processes), favored by the internal thermodynamic condition [13,14,15,16]. The resulting process gas is a current of H2, CO, CO2, H2O, N2, and CH4 in different proportions, depending on the primary source treated and on the thermodynamic conditions. SOFC is also able to convert carbon monoxide electrochemically, thus contributing to energy production together with hydrogen [17,18,19]. Figure 1 reports the processes occurring in a SOFC by feeding it with a reformate or syngas stream.

Figure 1.

Thermo-electrochemical processes occurring in a SOFC core by feeding with a reformate or syngas stream.

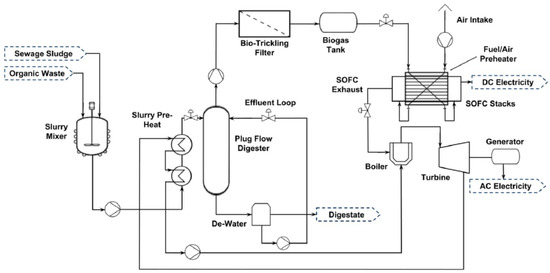

Given the above, SOFC has attracted increasing attraction in the scientific panorama of “green and clean energy technologies”. Several studies have been involved in “waste biomass to energy” by investigating the integration of a biomass gasifier with SOFC energy systems [20,21,22,23,24]. In particular, biogas and syngas have been studied intensively as supply fluids for SOFC.

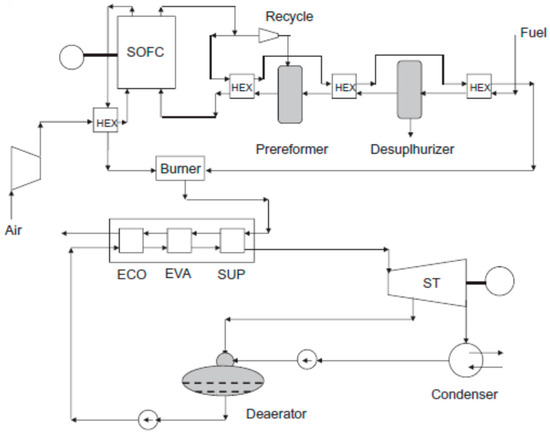

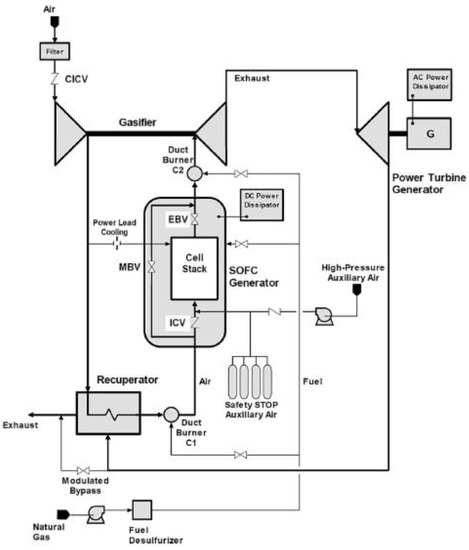

One further advantage of SOFCs is the possibility of configuring hybrid systems by combining them with a steam or gas turbine, thus grafting a bottomed Rankine or Brayton cycle. High temperature operation, and therefore the utilization of high-quality heat and residual fuel outgoing from the SOFC, can further improve the efficiency of the system. It is possible to implement a Rankine/Hirn cycle by recovering the exhaust heat in the downstream bottomed process while a Brayton cycle is implementable by integrating the SOFC inside the Brayton process, substituting the central combustor with the SOFC itself. This allows the SOFC system to enhance the overall electric efficiency due to the additional electric power generation of the bottomed process [25,26,27,28].

Regarding the materials making up the stack, current SOFC models make use of Y2O3 and stabilized ZrO2 (yttria-stabilized zirconia (YSZ)) over a nickel matrix (YSZ/Ni) for anodes, YSZ for electrolytes, and LaxSryMnO3 (typically La0.8Sr0.2MnO3—LSM) for cathodes [29]. Ordinary solid oxide fuel cells must work at temperatures of 800–1000 °C [30] in order to provide the optimal electrolyte and electrode performance as well as technical ones [31]. The SOFC system electric efficiency is around 45–50%, which increases to around 60% in the case of hybrid systems.

On the other hand, the high working temperature can also bring some disadvantages as it leads to material degradation and incurs high maintenance costs, thus hindering their economic feasibility. Moreover, great attention has been paid to the thermomechanical behavior of the various elements to avoid drawbacks related to the difference between the thermal expansion coefficients that can induce joint and sealing problems. This opens up the challenge versus the material addressing sealing and degradation, searching for novel materials that are highly resistant and efficient. The subsequent challenge is that of researching how to lower the operating temperatures to an intermediate range (500–800 °C), in order to reduce the costs and improve the stability [32,33,34] by trying to keep the strength in energy performance. Electrodes, seals, interconnections, and other parts of the fuel cell (necessary to the overall functional aggregation of the device) must therefore be manufactured with special materials and by special techniques, which are suitable for the delicate working environment.

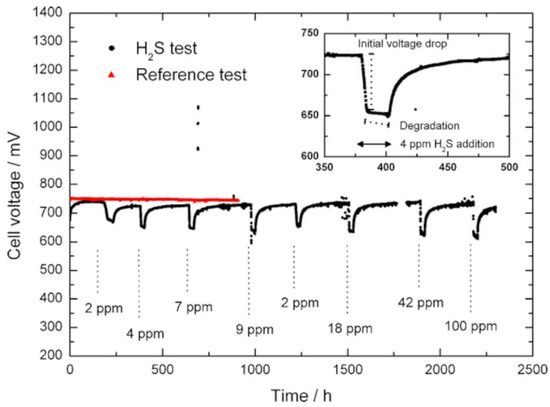

In addition, there are also problems related to: undesired phenomena that lead to a degradation of energy performance as well as to a physical degradation of the electrodes that can become irreversible and thus damage the device; the impurities contained in the fuel; and the carbon deposition. Raw fuels can contain impurities such as sulfur compounds and others that can entail catalyst malfunction and microstructure degradation [35,36,37,38]. Carbon rich fuels can cause carbon formation on the reaction surface, with resulting obstruction of porous electrocatalytic sites, implying rapid and irreversible performance degradation of the SOFC [39,40,41].

SOFC systems have been reviewed over time [42,43,44,45,46], with particular attention to the constituent materials and the fabrication techniques [47,48,49]. The SOFC/turbine hybrid system has also attracted a lot of attention and produced extensive research [50,51,52], which has contributed to an ever better understanding of this technology and has identified future challenges to be faced in order to improve it.

Contribution

This paper aimed at presenting a comprehensive understanding of the current status of SOFC energy systems technology with a deep insight into the techno-energy performance of SOFC systems.

The study begins by describing the results of an in-depth parametric numerical analysis based on the influence of operational factors, starting from the basic principle of the thermo-electrochemistry. For this purpose, a numerical model developed ad hoc by the authors of the present paper was used. The model allowed us to simulate the behavior of the SOFC core, taking into account the concurrent thermo-electrochemical processes.

A review on the constituent materials follows to circumscribe the optimal packing of elements in order to satisfy the electric and the thermo-mechanical requisites.

The constructive geometries adopted and the balance of plant for self-sustained functioning is then illustrated. SOFC fuel processing is presented and discussed extensively by describing the various processes that bring about the generation of a hydrogen rich stream. The topic is then completed with numerical simulations to analyze the steam reforming performance.

A great deal of attention is devoted to analyzing the carbon formation and deposition phenomena in order to detect the thermodynamic conditions to be adopted in order to operate safely.

In this paper, for the sake of completeness, a wide and deepened analysis on the impurities in the SOFC feed is reported and the possible fuels that can be converted into energy are examined.

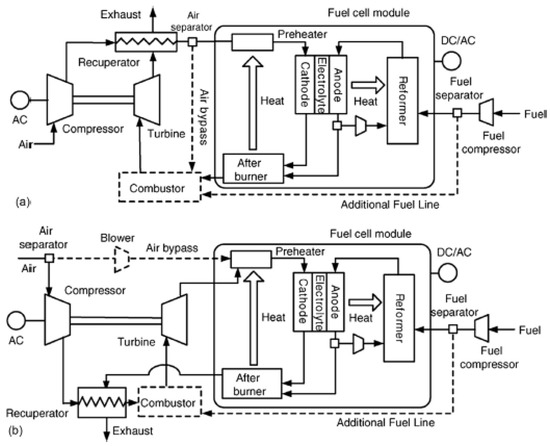

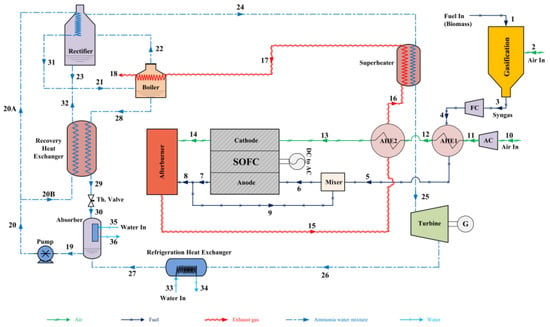

Moreover, an overview on the status of the research in the field of SOFC/turbine hybrid power plants is reported, illustrating all the existing matchings and configurations to converge to the real installations worldwide. The topic continues with the analysis of the integrated systems of a biomass gasifier/SOFC, presenting the basic principles and focusing on the technology behind it, with particular emphasis on plants based on biogas and syngas.

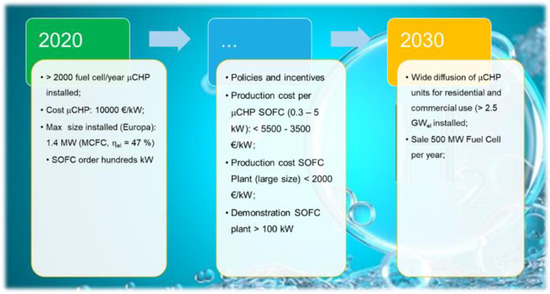

Finally, after having produced a list of the main manufacturers and commercial companies of SOFC systems worldwide, the European roadmap 2020–2030 is presented.

SOFC technology has been advancing at a rapid rate over the last two decades. Many review and research papers have been published. Significant papers have appeared in the meantime, but each of them has always and only deepened a specific aspect. Even the reviews themselves, although quite complete, did not submit a comprehensive coverage of the subject. The present paper has the purpose of filling the remaining gaps by addressing a complete discussion that also takes into account the multi-disciplinarity around the connections of the SOFC technology for power generation. The advancements of the present review compared to those already published rely on the originality of the approach used. This paper overviews the technology by means of the analysis of the results provided by a numerical model, built up ad hoc, and validated, also deepening the techno-energy performance of SOFC systems and all the ways to manage a SOFC system by changing the exercise parameters. Moreover, from the basic to the most varied applications, the review presents the European roadmap for the diffusion of SOFC technology, therefore, the great international interest that surrounds it in the now traced route of the energy and ecological transition, in which SOFC systems can be the main protagonist.

This review is believed to provide detailed up-to-date information for researchers, engineers, and designers who are going to make SOFCs commercial in the near future, in efficient power stations and in novel applications.

2. Thermo-Electrochemistry

Fuel cells are excellent electrochemical devices for the energy conversion of hydrogen by means of its electro-oxidation, producing water and electricity. A first classification of the technology is given by the type of electrolyte used, therefore, by the ionic species exchanged in it. A second categorization is given by the operating temperature, however, it is strictly related to the kind of material used to constitute the electrolyte. For the SOFC supply chain, the electrolyte used is selective toward the O− ions. As for the material used for the ion exchange selectivity, this is analyzed later, in the next section. In the SOFC, the H2 electro-oxidation occurs at the anode side, as in Equation (1). This is accompanied by the oxygen reduction reaction, as shown in Equation (2), occurring at the cathode side, where oxygen anions are produced by means of the electrons produced at the anode, then they are transported to the anode via the electrolyte.

The SOFC flexibility also allows for a mixture of gas that is rich in carbon monoxide, steam, carbon dioxide as well hydrogen, as will be discussed in detail in the next section. Therefore, the electro-oxidation of carbon monoxide and the CO-shift reaction (or water gas shift) occurring in parallel are also considered together to that of hydrogen, as shown in Equations (3) and (4), when a carbon rich fuel is fed.

Therefore, the synthesis gas feed, which is also rich in carbon monoxide contributes to the concurrent electro-oxidation. It is known that almost 25–30% of carbon monoxide reacts compared to the reacted hydrogen [53,54,55].

The study of the operating principles of a fuel cell is based on thermodynamic and chemical considerations. It is demonstrated that the maximum electrical work () that can be extracted from a cell, under ideal conditions of reversibility, is equal to the variation in the free energy of Gibbs (, dependent on the temperature and pressure), as shown in expression (5).

If the process of electrochemical reactions taking place in the fuel cell is reversible, there are no losses in the cell and all the Gibbs free energy supplied by the reaction is converted into electrical work as in (6), where is the electrons exchanged, is the Faraday constant, and is the reversible voltage.

Therefore, the reversible voltage is determined as in (7), from which the Nernst voltage is calculated.

For the hydrogen reaction, the Nernst equation is written explicitly as in (8), where the partial pressure (p) of the reaction gases involved are evident, where and represent the perfect gas constant and the temperature, respectively.

In fact, the reality of the phenomena involves the rise in losses of chemical and electric nature that diminish the Nernst value to a real one, as expressed in (9).

These losses are of the polarization type and rise when the fuel cell is working. These are activation , ohmic , and concentration type.

Activation overpotentials rise when the electrochemical reaction is about to trigger. They are associated with the energy needed to establish the reaction of hydrogen with oxygen ions at the anode side and electrons and oxygen at the cathode side. The base of the calculation is given by the Butler–Volmer Equation (10), which highlights the electric current density () as a function of the activation polarization ().

The entity of cell activation losses is strongly conditioned by the value of the current exchange density of each electrode, , of which they are a function. This parameter can be considered as an estimate of the direct and inverse reaction rate for the reactions at the electrodes (oxidation and reduction). In fact, high values of the exchange current density involve high rates of electrochemical reactions, which result in lower activation losses and hence a high fuel cell performance. is strictly dependent on the properties of the electrode microstructure and operating conditions (gas composition, temperature, and operating pressure). The exchange current density was estimated for the anode and the cathode using the Arrhenius law. Instead, is an empirical value.

The ohmic polarization losses are mainly caused by the resistance to ion conduction through the electrolyte and by the resistance encountered by electrons to flow through the electrodes. This kind of loss is determined by (11),

where k is the index for the k-th element (anode, cathode, electrolyte). is the electric conductivity of the element, while is the thickness of the element.

Concentration losses occur at high current density values and are heavily influenced by the phenomena of the diffusion of gaseous substances in porous electrodes and, of course, by the concentrations of the species that take part in the processes occurring within the fuel cell.

Concentration losses are given by the sum of the concentration losses that occur at the anode and at the cathode. They are defined according to the partial pressure in the bulk of the species involved in cell global reactions (, functions of the molar fractions X), and to partial pressures of the same substances, but at the reaction sites (). For example, the hydrogen reaction concentration losses at the anode diffusion are expressed as in (12). (13) reports the cathodic concentration losses.

The calculation accounts for the effective diffusion coefficient of the diffusing species (oxygen, hydrogen, water) in porous electrodes and in the gaseous mixture at the reaction site. This requires making use of an effective diffusion coefficient, which is obtained by combining the ordinary diffusion coefficient and the Knudsen diffusion coefficient, since both diffusion types occur at the same time.

This brief discussion on the thermo-electrochemistry on SOFC is addressed as the main direct electro-oxidation occurring to the fuel cell, but obviously, calculations have to be extended to the concurrent electro-oxidation of carbon monoxide, as discussed above.

More details on thermo-electrochemistry and modeling are reported in the paper [56].

2.1. Influence of Operational Parameters on Performance

The trend of the voltage of a fuel cell is influenced by the operating parameters of the same such as temperature, pressure, electric current density, the utilization of reactants as well as other factors such as gas composition and the possible presence of impurities (on which the next section is dedicated to its discussion). The assessment of how temperature and pressure affect the value of the ideal cell potential, Erev, can be made, based on the variation in the Gibbs free energy. In particular, the relation expressing the variation in the reversible potential as a function of temperature is given by Equation (14).

Given that a reaction in which H2 and O2 react, the variation of entropy is negative, and from Equation (14), it can be deduced that the curve Erev = f(T) has a negative slope, and therefore Erev decreases with the increasing temperature.

In the real operation of a fuel cell, an increase in temperature produces positive effects such as a reduction in the ohmic polarization due to the increase in ionic conductivity in the electrolyte, a reduction in the activation polarization due to the improvement in the electrode kinetics, and a reduction in the concentration polarization since an increase in temperature improves the transport phenomena and the tolerance to impurities present in the feed gas, so there is more efficient recovery of the heat produced.

For SOFCs the maximum temperature is limited to 1000/1050 °C. The maximum value is, in fact, limited by the acceleration of some phenomena that causes damage to the cell, which arise as corrosion phenomena, problems of sintering, and crystallization of the catalysts.

Regarding the pressure influence, the variation in the reversible cell potential as a function of the pressure is given by Equation (15). As can be observed, the ideal potential increases with increasing pressure.

In the actual operation of a fuel cell, pressure has a significant influence on the efficiency. In fact, an increase results in a corresponding increase in efficiency due to higher partial pressures of the reactant gases, greater solubility of the reacting gases, and higher mass transfer rates. However, the benefits deriving from an increase in pressure are opposed by problems related to the higher stress and corrosivity of materials. Hence, there is the need to minimize differential pressures to also avoid the escape of the reacting gases through the electrolyte and seals. SOFCs are devoted to hydrocarbon fuels such as methane, hence, the SOFC feed is often a fuel to be converted in a reforming process. This implies that the pressurized operations also account for the fuel processing. Operations at higher pressure imply a higher tendency for the formation of methane in the combustible gas with inefficient fuel conversion as well as the deposition of carbon, an undesired phenomenon, as will be seen in detail in the fuel processing section. Moreover, by considering the balance of plant, the pressurized operation of the cell determines an increase in the parasitic power absorbed by the pumps and compressors. This implies searching for a condition of compromise.

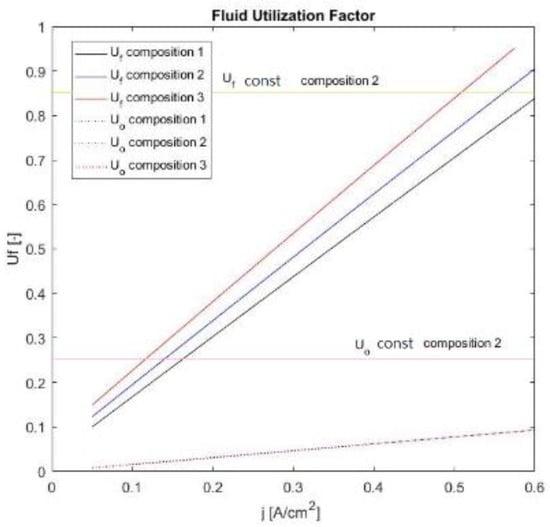

Other factors considered in fuel cell operations are the reactant utilization coefficient (16) (where and are the reactant at inlet and output), the fuel utilization factor made explicit in (17), Uf, and the oxidant utilization factor made explicit in (18), Uo. In the equations, is the electric current operated by the fuel cell, is the flow rate [g·s−1], and is the molecular weight.

Depending on the gas-feed management, the gas utilization factor can be set to a fixed value (gas feeding is proportional to the electric current required) or kept free and variable (gas feeding fixed to the nominal value independently of the electric current required).

In any case, it is not convenient to push the conversion of the fuel over 85–90% due to the onset of some losses that are related to the poor concentration of the reactants. Therefore, it is necessary to maintain a certain amount of non-oxidized fuel. This is why the percentage of unreacted fuel is indispensable to provide energy to the fuel treatment system (if the fuel cell system considers it) and to avoid an abrupt fall in the voltage curve. Regarding the oxidant utilization factor, this should be managed between 0.2 and 0.5 as it is necessary to avoid the occurrence of high losses as well as allow for efficient cooling of the cell by exploiting the flow of excess air.

2.2. Efficiency

The evaluation of the performance is based on the electric and thermal efficiencies derived from the SOFC operations. Equations (19)–(24) report the package of equations used for the calculations, starting from the initial concept to the final expression, giving evidence of the main parameters through which a fuel cell can be managed. The electric power (generated ‘gen’) is given in (19) by the product of the voltage () and the electric current () of the single fuel cell (fc). Considering a stack, the number of cells composing the stack have to be computed (). The thermal power is given in (20). Making explicit the terms, it is a function of the electric current (), the reaction enthalpy of the fuel fed (), and of the voltage (). Other terms represent the number of electrons involved in the electrochemical process () and the Faraday constant ().

The electric efficiency is also given in (21), weighted on the chemical power of the entering fuel (), and is made explicit in (22), highlighting the hydrogen contribution of the fuel. The term F represents a molar flow rate [mol·s−1].

The thermal efficiency is given in (23), and is made explicit in (24), highlighting the hydrogen contribution over the fuel.

As can be seen, the efficiencies are the function of the fuel utilization factor (). represents the molecular weight, is the fraction of hydrogen contained in the feeding fuel, while represents the reaction heat.

2.3. Thermo-Electrochemical Performance Evaluation

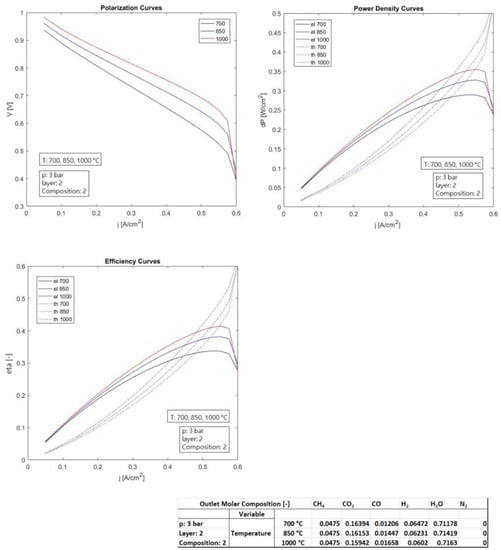

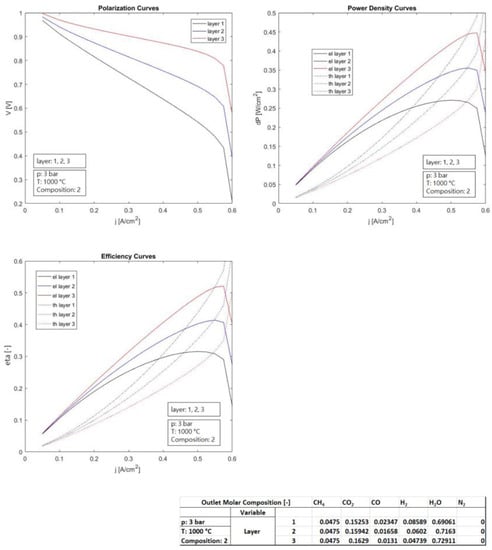

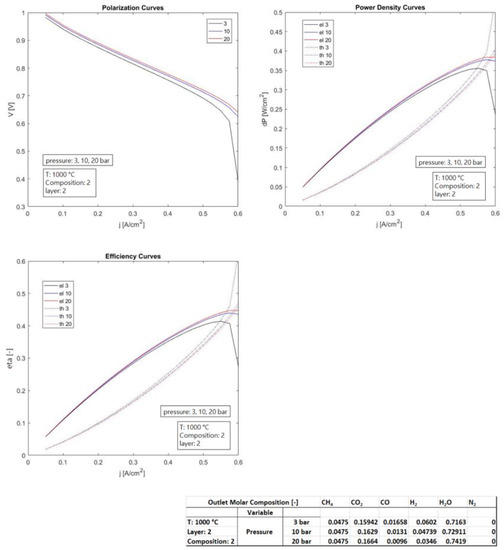

The present section reports the performance assessment of a SOFC electrochemical single cell, conducted by means of a numerical simulation model developed ad hoc by the authors of this paper [56]. It reports the performance variations, based on the change in the main operating parameters and of the layer thickness of the electrolyte, in order to detect how they influence the behavior. Table 1 reports the settings of the simulations in detail. The main exercise parameters analyzed were the temperature, pressure, and fluid supply considering its composition, while the layer influence was assessed by means of the change in the thickness of the electrolyte.

Table 1.

The parameters and operation condition settings.

Two main methods of SOFC cell management were investigated. The first method analyzed consisted of constant feeding with the electric current of the anodic and cathodic fluid, therefore, with variable fuel and oxidant utilization with the electric current. The second method analyzed consisted of the variable and proportional feeding with the electric current of anodic and cathodic fluid, therefore with the fuel and oxidant utilization constant with the electric current. The simulations were based on the electric current change.

The temperature changed in the range 700–1000 °C, while the pressure was in the range of 3–20 bar. Three thicknesses of electrolyte were considered in the range 8–60 × 10−4 cm. The operating temperatures considered (700–1000 °C) were to evaluate the feasible range that can be operated and therefore discuss it. The pressure range considered (3–20 bar) is to evaluate possible operations as non-pressurized and pressurized. Three bar reflects a “non-pressurized” operation: three bar is the usual operative pressure for inlet gases, since the SOFC operates at a value of pressure slightly higher than the atmospheric one. More than 3 bar (i.e., 10, 20 bar) was used to evaluate the possible pressurized operation, for instance, those that can be operated when SOFC is coupled to gas turbines in hybrid systems (more details are shown in Section 10). The three compositions of the anodic fuel feeding reflect three possible synthesis gases derived from a reforming fuel processor that processes methane, natural gas, or biogas, consisting of a mixture of CH4, CO2, CO, H2, H2O, and N2. The layer of the electrodes and of the electrolyte were those of a typical SOFC cell. The thicker thickness reflects the electrode that supports the cell.

The fixed parameters consisted of the anode and cathode layer, respectively, 240 × 10−4 cm, and 40 × 10−4 cm, while the cell active area was 100 cm2. The material of the anode was Ni–YSZ, the cathode was (LSM) La0.8Sr0.2MnO3, and the electrolyte was (YSZ) ZrO2-Y2O3 (a complete overview about the constituent materials is reported in the next section).

The first four case analyses were based on the method of managing (method 1) the SOFC with constant anodic and cathodic flow rates, therefore, with fuel and oxidant utilization factors that are variable with the electric current.

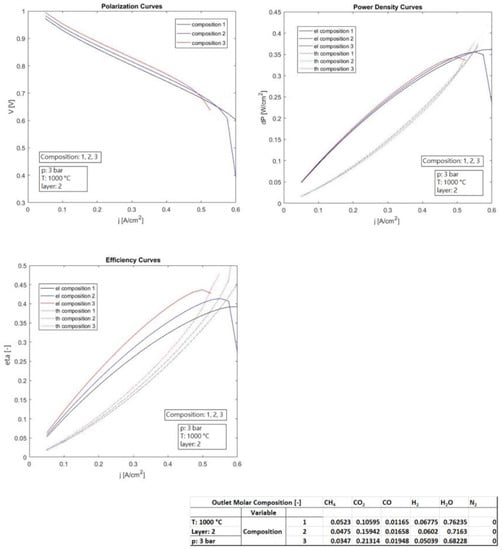

The first case analysis was set based on the variation in the temperature in the range of 700–1000 °C, keeping fixed the parameters pressure (set at 3 bar), electrolytic layer (set at 34 × 10−4 cm), and anodic composition (set as n.2). The second case analysis was set based on the variation in the electrolyte layer in the range 8–60 × 10−4 cm, keeping fixed the parameters temperature (set at 1000 °C), pressure (set at 3 bar), and anodic composition (set as n.2). The third case analysis was set on the variation in the pressure in the range of 3–20 bar, keeping fixed the parameters temperature (set at 1000 °C), electrolytic layer (set at 34 × 10−4 cm), and anodic composition (set as n.2). The fourth case analysis was set based on the variation in the composition of the anodic gas supply (1–3), keeping fixed the parameters temperature (set at 1000 °C), electrolytic layer (set at 34 × 10−4 cm), and pressure (set at 3 bar).

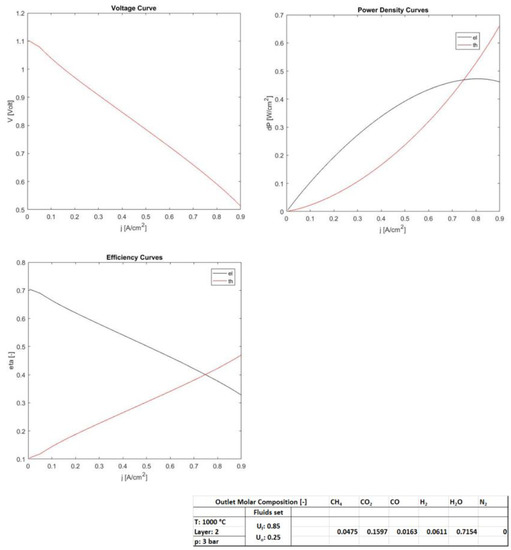

The fifth case completed the analyses, since it considered the method of managing the SOFC according to a variable anodic and cathodic feeding, proportional to the electric current generated. This implies fixing of the fuel and oxidant utilization factors, set at Uf: 0.85 and Uo: 0.25, respectively.

The other parameters set were the following: temperature (set at 1000 °C), electrolytic layer (set at 34 × 10−4 cm), pressure (set at 3 bar), and composition (set as n.2).

The simulations aimed to investigate how the influence of the above discussed parameters impacted on the thermo-electrochemical performance of the SOFC single cell. The outcomes assessed involved the voltage, the electric and thermal power densities, and the electric and thermal efficiencies. Each case analysis was completed with the calculation of the output composition at the anodic exhaust in order to understand that the fuel processing occurred in the thermo-electrochemical sites. Figure 2, Figure 3, Figure 4, Figure 5, Figure 6 and Figure 7 illustrate the results and the plots over the electric current density.

Figure 2.

Influence of the temperature on the thermo-electrochemical performance (constant anodic inlet flow rate).

Figure 3.

Influence of the electrolyte thickness on the thermo-electrochemical performance (constant anodic inlet flow rate).

Figure 4.

Influence of the pressure on the thermo-electrochemical performance (constant anodic inlet flow rate).

Figure 5.

Influence of the anodic composition on the thermo-electrochemical performance (constant anodic inlet flow rate).

Figure 6.

The thermo-electrochemical performance considering the anodic and cathodic inlet flow rate proportional to the electric current (constant Uf and Uo).

Figure 7.

Plots of the fluid utilization factors regarding the cases assessed.

As can be seen from the graphs, the voltage curve over the electric current showed a decreasing trend with it. As known, and as can be detected from the same graphs, at low electric current, the first drop in voltage was due to the activation polarization, the middle and linear zone of the plot were mainly affected by the ohmic polarization, which impacted the slope of the curve, while the last zone, at high electric currents, was affected by the concentration polarization that caused an abrupt fall in the voltage. As a consequence, the electric power had a parabolic trend, while the thermal one showed a parabolic ramp. Regarding the electric and thermal efficiencies, their trends depended strongly on the type of cell management regardless of whether the fuel utilization factor was variable or constant. When the fuel utilization factor was variable (proportional to electric current), the electric efficiency showed a parabolic profile with a maximum at high currents and mostly approximated the shape of the electric power. When the fuel utilization factor was constant, the electric efficiency showed a decreasing profile with higher values at low currents and mostly approximated the shape of the voltage curve. Regarding the thermal efficiency, it reflected the opposite profile since the thermal recovery is based on the irreversibility of the reactions. However, a more detailed discussion on the profile of the efficiencies is made at the end of this section.

Figure 2 illustrates the influence of the temperature on the thermo-electrochemical performance (constant anodic inlet flow rate).

A higher temperature is beneficial to thermo-electrochemical performance and has positive repercussions on the losses: they improve the kinetics of the processes and improve the ionic conduction, which is reflected in a lower ohmic loss. The slope of the curve is gentler at high temperatures. As a result, the electric power density, and thus the electric efficiency, was higher. The opposite behavior was shown by the thermal performance. The electric efficiency passed from 33% at 700 °C to 43% at 1000 °C. Therefore, a gain of about 10 points percentage was attained. The thermal efficiency passed from about 50% at 700 °C to 42% at 1000 °C. The values were considered in correspondence with the electric current at which the maximum efficiency occurs. From reading the outlet composition of the exhaust gas (the values are considered in correspondence with the electric current at which the maximum efficiency occurs), it can also be deduced that the higher temperature implies a minor negative repercussion on the fuel processing. In fact, the reverse water gas shift reaction has more force at higher temperature, consuming CO2 and H2 in favor of CO and H2O. Therefore, it can be deduced that CO2 passed from 16.4% (700 °C) to 15.9% (1000 °C), while CO passed from 1.2% to 1.6%. However, the influence of temperature on performance was more than positive, even if some minor negative effects occurred.

Figure 3 illustrates the influence of the electrolyte thickness on thermo-electrochemical performance (constant anodic inlet flow rate). It can be understood immediately that a lower thickness of the layer implies a higher performance. In fact, one challenge of the manufacturing industry is to create thinner and thinner layers, thus reducing the tri-phase-boundary (TPB). The electric efficiency was almost 32% at a thickness of 60 × 10−4 cm, while it reached 53% at the lowest thickness of 8 × 10−4 cm. Consequently, the thermal efficiency was in contrast to the electric efficiency (about 55–25%). Moreover, a lower thickness permitted pushing a higher electric current, therefore reaching a higher energy density, which is beneficial for the compactness of the device.

Figure 4 illustrates the influence of the pressure on the thermo-electrochemical performance (constant anodic inlet flow rate). Higher pressures are also beneficial to the performance, although with less importance compared to the change discussed above. A pressure increase directly reflects an increase in the Nernst voltage, which implies an offset of the entire voltage curve. However, as the pressure increases, the increase in electric performance is less and less incisive. The electric efficiency (42–45/46%) gained only three and four percentage points passing from 3 to 10 bar and from 3 to 20 bar. Clearly, it has to be underlined again that these simulations only concern the electrochemical section. For a complete system, other parts with a mechanical nature (e.g., compressors) have to be considered that require more energy at a higher pressure as well as considering the fuel processing, which is disadvantaged at a pressure higher than the atmospheric one (as will be discussed in next paragraphs). Although pressure implies a slight increase in the SOFC stack/cell electric performance; considering this, the overall balance of the plant performance decreases, without considering this, the effort on and of the seals to pressurized operations increases. Pressurized operations are required when coupling SOFCs with gas turbines.

Figure 5 illustrates the influence of three different anodic compositions of the feeding gas on the thermo-electrochemical performance (constant anodic inlet flow rate), keeping fixed the other parameters as specified in the box. Compositions 1, 2, and 3 were used to feed the anodic compartment. The compositions were very similar, since they derived from a reforming fuel processing of methane rich gas, exercised at different conditions.

It can be deduced that composition 3 implies the highest electric efficiency, of about 45%, although at the lowest electric current (0.5 A/cm2). Composition 2 shows the mid performance, while composition 3 showed the worst with 40% of electric efficiency, but at the highest electric current of 0.6 A/cm2. In contrast, composition 3 can account for much higher thermal efficiencies, and so much higher total efficiencies. In general (not only for this last case), an adequate techno-feasibility analysis is necessary to assess whether it is better working at higher electric current, thus benefiting from compactness and losing a few percentage points in electric efficiency, rather than working at lower currents, preferring higher electrical efficiencies at the expense of greater plant dimensions.

The last case of analysis considered the cell operations with a constant fuel utilization factor. This means working with the anode flow rate in supply proportional to the electric current. Therefore, the mathematical model calculates, according to an iterative computational process, the incoming flow as a function of the fixed outputs. Figure 6 reports the results and the table illustrates the set parameters as well as the output composition. The graphs of the voltage and the power density curves presented almost the same trend, where the big difference was instead highlighted in the graph of the efficiency curves. The electric efficiency reflected a decreasing profile with electric current, very similar in shape to the voltage trend. The thermal efficiency, instead, had the opposite behavior. The electric efficiency presented high values at low electric currents, and lower values when increasing in electric current. Therefore, the question on how to operate the fuel cell arises, and therefore the criterion in which to manage it. A criterion could be that of letting the SOFC work around the point of the maximum electric power, in order to establish a compromise between the efficiency and compactness, thus setting the cell design. For example, in this case, the SOFC could be operated around 0.6 A/cm2, presenting an electric efficiency of about 48–50%, with a consequent thermal efficiency of 35%. This way of management opens to off design work and partial load operations, still maintaining a very high performance. From observing the output molar composition of the anodic gas, presenting low amounts of undepleted fuels, the good utilization of the entering gas can be confirmed.

The graph in Figure 7 illustrates the fluid utilizations for the cases discussed above. Clearly, when managing at constant input flow rates (anodic and cathodic), the fuel and oxidant utilization factors are proportional and increase with the electric current. The fuel utilization factors, however, depend on the gas fed at the anodic section, and could be different in the function of processable gases (H2 and CO) in the anode compartment. Uf and Uo reflect compositions 1–3 used in this analysis. Conversely, from the management with fluids (anodic and cathodic), which are strictly calculated as proportional to the electric current desired, the fluid utilization factors must remain constant, and in this case, were fixed at 0.85 regarding the fuel utilization, and 0.25 for the oxygen utilization.

For the sake of completeness, a description of how the two management methods of SOFC reflect the two different trends and shapes of electric and thermal efficiency is opportune.

Analyzing the basic analytical expressions of the electric (22) and thermal (24) efficiency, it can be easily demonstrated that they can be written as expressions (25) and (26), respectively, where kel, kth1, and kth2 are numeric constants.

Equations (25) and (26) indicate that the electric and thermal efficiencies are the function of the fuel utilization factor Uf and of the fuel cell voltage Vcfc. By substituting the functions or the values of Uf and Vcfc, respectively, for the two methods of management, it can easily be demonstrated why the shape of the electric efficiency was parabolic for the first case (Uf variable), and decreased in the voltage shape for the second case (Uf constant). The thermal efficiency was consequently demonstrated.

Table 2 reports the conclusion of the analyses conducted. The increase in temperature produces an important gain in performance. Clearly, the constraint on the maximum value achievable has to be related to the material strength and to the thermo-mechanical stresses that arise. An increase in pressure is slightly beneficial at lower values, since beyond a specific value, the energy expenditure of the BoP is greater than the gain. However, pressurized operations are required in the case of combined systems. Regarding the anodic composition, its influence mainly depends on the grade of hydrogen, but also on the entire composition in relation to the thermodynamic conditions of the working environment. The first method of management (Uf variable) was not designed to be adopted by operating at partial loads, which is in contrast to the second method.

Table 2.

Influence on the performance.

3. On the Constituent Material

The thermo-electrochemical process of SOFC must take place safely and efficiently and, therefore, the cell components involved must be made of suitable materials. This section examines with particular care all of the materials that are currently used for the construction of SOFCs.

A solid oxide fuel cell is a sandwich structure consisting of three elements (anode, cathode, and electrolyte), joined by a metal matrix, which also has the function of collecting the electric current to be delivered to an external circuit and the sealants.

The anode is the site of the electrochemical fuel oxidation, the cathode is the site of the oxidant reduction, and the electrolyte is the selective bridge carrying oxygen anions from the cathode to anode. The delicate work environment requires the presence of particular constituent materials such as nickel, oxides, ceramics, and perovskite, which are currently the most widely adopted [57,58].

3.1. Solid Electrolyte

The electrolyte has to meet several criteria for its good performance: dense and leak-tight, selective for oxygen anions at the operating temperatures, high strength to thermal shocks, chemical inertness with electrode elements, and economics. The first requirement is possessed by materials with crystal structures that show a large interionic open space [57] such as the cubic fluorite structure. Materials exhibiting this property are oxides such as ZrO2, CeO2, Bi2O3, LaGaO3-based perovskite, and others [59].

Over the years, different materials have been tested, but due to their good anionic conduction properties, the focus has always been on zirconia-based matrices such as zirconia doped with magnesia, yttria, or calcium oxide. Amongst these, yttria-stabilized zirconia (YSZ: ZrO2-Y2O3) is the most common for high temperature solid oxide fuel cells. Nernst investigated the characteristics of zirconia and found its ability to be an insulator at room temperature, ionic conductor from 600 °C to 1000 °C, and an electronic and ionic conductor at about 1500 °C [60]. As an oxide material, zirconia conducts oxide ions and has numerous advantages that make it ideal for this application such as abundance and chemical stability, moreover, it is non-toxic and inexpensive. In contrast, some drawbacks are evident such as the high coefficient of thermal expansion and the problems of joining and sealing the material.

Yttria is the main stabilizer, currently, it is used in about 15% in weight [60]; scandia and ytterbia, on the other hand, are more expensive and provide better ionic conductivity.

The most commonly used manufacturing method is electrochemical vapor deposition [60].

3.2. Anode

The main requirements that must be met by the anode are to allow for a rapid and clean reaction with the fuel and to provide good electronic conduction to the interconnector. Thermomechanical properties and the chemical inertia of the materials with which the anode is made must be similar to those of the closest components. These can be metals and or carbon-based materials such as, for example, platinum, iron, cobalt, nickel, and graphite. Generally, among these materials, the choice has always fallen on nickel for economic reasons. However, it presents some drawbacks such as a different thermal coefficient (13.3 ×10−6 K−1) compared to the electrolyte (11 × 10−6 K−1), which can cause flaking off [60], and the propensity to coke by covering itself with a carbon layer, thus risking the rupture by pushing the nickel particles apart and inhibiting the gas reaction [61]. However, flaking off is minimized by depositing a variable concentration of YSZ in the nickel matrix with the aim to obtain, near the interface, an expansion coefficient similar to that of the electrolyte [62,63]. This solution also improves the adhesion of the anode to YSZ. The problem of coking is inhibited by adding 5% of ceria and 1% of molybdena (percentages in weight) to the Ni + YSZ cermet [60].

3.3. Cathode

The cathode as well as the anode must satisfy a series of requirements such as high electronic conductivity, chemical compatibility with other components, cost effectiveness, etc.

The material choice over the years has fallen on perovskite-based oxides with the general formula ABO3 (LaMnO3, LaCoO3, LaFeO3) [64]. The most widely used material is constituted of lanthanum manganite LaMnO3, doped with a dopant substance to achieve a good compromise between a high electronic conductivity and thermal expansion coefficient. Typically, it is lanthanum manganite doped with strontium La1-xSrxMnO3 (LSM) [65]. A higher dopant level improves the conductivity at the cost of worsening the thermal expansion, reasonably the compromise is La0.8Sr0.2MnO3, which exhibits a high conductivity and good mechanical and chemical stability at operational temperatures. Other materials such as lanthanum cobaltite are even better than lanthanum manganite, but are unstable with zirconia [66]. In contrast, LSM becomes unstable above 1400 °C. The first layer of the cathode at the electrolyte side is made up of LSM powder with YSZ powder in a 50/50 proportion to enlarge the three-phase boundary. Various methods have been used for its application on electrolytes such as electrochemical vapor deposition and screen printing.

3.4. Interconnections

Interconnections are necessary to collect the electric current and transfer it to an external circuit. They have strict characteristics. Since they sandwich the three elements, they have to possess similar thermo-mechanical characteristics to be stable in oxidizing and reducing environments.

Lanthanum chromite (LaCrO3) has been adopted to carry out this function at a operating temperature close to 1000 °C. Doping with strontium at 20% mol permits achieving the same thermal expansion as YSZ [67]. For applications at lower temperature such as 700–850 °C, metallic alloys are more appropriate as the constituent material (ferritic stainless steel).

3.5. Sealants

The sealant material plays a key role in avoiding any leakages of either fuel and air from their respective chambers, thus preventing their possible mixing. The conditions of oxidizing and reducing environment impose very stringent characteristics to be fulfilled such as hermeticity, similarity in the coefficient of thermal expansion with the anode and cathode, inert environment and chemical stability, resistance to hydrogen embrittlement, no ionic and electronic conductivity, and low cost. It has to be underlined that sealing strictly refers to the geometry, for example, sealing is not a serious problem for tubular design (the cell-tube can be seal-less: the gas seals are just applied far from electrochemical sites with the possibility of using conventional metals), while it has to be deepened in the case of planar geometry. There are various types of sealant materials for high temperatures such as metal, glass-ceramic, brazing, and mica-based composites. Multiple sealant materials are also used when required. Regarding sealing methods, there are two standard methods: compressive (without tight fix) sealing or glass joining and rigid sealing. The category of compressive sealing is divided into metal and mica-based sealings. Since metals are susceptible of oxidation, the choice is restricted to noble metals such as platinum, gold, and silver. Generally, to satisfy the cost-effective requirement, silver is the best choice. Unfortunately, silver suffers the solubility of both hydrogen and oxygen with the risk of forming water. To overcome this problem, silver is combined with mica. The mica-based category is very appropriate to tolerate high thermal stresses, but mica has to be combined with glass and silver to increase the hermeticity capacity, also infiltrating bismuth nitrate [68]. A rigid sealant is produced by glass-ceramic and brazing alloy materials and offers advantages in terms of economics over the previous method. In this regard, alkaline earth silicate glasses are commonly used.

SOFCs can also be categorized according to the type of the cell support (i.e., anode, cathode, electrolyte, or porous substrate supported). The anode-supported cell design is the most common in this respect. The electrolyte-supported SOFCs, however, have relatively strong structures and are less susceptible to mechanical failure. In early designs of SOFC, the anode was primarily present for its electrode function. In these cases, the anode could be a relatively thin layer. The actual anode itself needs to be about 15–30 μm thick as the electrochemistry generally takes place very close to the electrolyte interface [69]. It is in this layer that the requirements of good ionic conductivity, high electrocatalytic activity, and high affinity with the electrolyte material are required. Compared to the mechanical properties of the other cell materials, researchers and manufacturers share the decision to attribute the burden of the load-bearing structure to the anode (mainly in planar design, the tubular Siemens–Westinghouse is cathode supported since the air is fed externally via the tube). Hence, the anode-supported cell became the prevalent design. An important aspect of the anode support is the current collection and distribution between the anode and the contact points of the interconnection. Numerous production routes have been utilized to fabricate anode-supported cells, finding a suitable thickness of 250–2000 μm [70].

4. SOFC Architecture

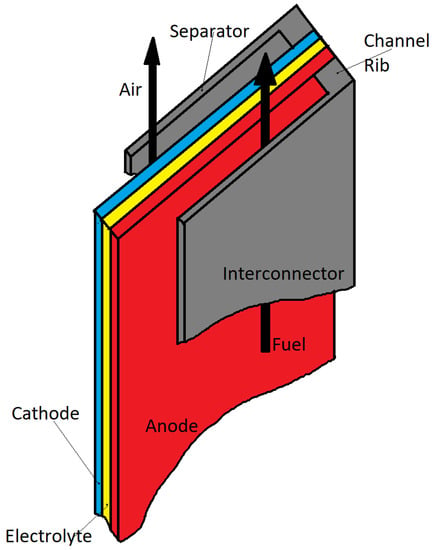

It is also possible to classify SOFCs according to the cell geometry. Two major SOFC design configurations are used: tubular geometry and planar geometry. Tubular design sees the three layers wrapped around themselves, as shown in Figure 8.

Figure 8.

Typical anode supported tubular design SOFC, reprinted with permission from [71]. Copyright 2007 Elsevier B.V.

Although this type of cell is difficult both to design and build and it has a low power density, it shows some advantageous compared to the planar type when a stack of cells must be produced, thanks to the easy way in which both the gas sealing and the interconnections can be accomplished. Other advantages are the possibility of using thin electrolyte layers; the greater simplicity in fuel and air distribution manifolds; the higher ability to cope with higher thermal stresses; the faster response to load variations; and, finally, the higher tolerance to fuel feeding variations [72,73].

On the other hand, the planar type requires easier fabrication, and can also exhibit a power density higher than the tubular type (tubular design involves a long current collection path, which reflects a structural disadvantage regarding the power density). The interconnections in the planar design were composed of a channel separator and a channel rib, also acting as a distributor for the gas flow between the cells (see Figure 9). In this regard, recently, the planar SOFC, rather than the tubular type, has been studied and developed in two forms of radial and flat types [74].

Figure 9.

Scheme of the planar SOFC design.

Table 3 reports the comparison between the two geometries, taken from Timurkutluk et al. [75].

Table 3.

A comparison of the tubular and planar designs.

In general, the planar design is the typical geometry employed by most types of fuel cells and received much attention to its simple cell geometry and manufacturing process. The electrolyte is sandwiched between the electrodes.

Tubular SOFC can have an anode or cathode in the internal part of the tube. The main advantage of the tubular design is related to the sealing, since it does not require seals like the planar design, for which sealing is the main issue. On the other hand, the current collection is more challenging for the tubular design, especially when the anode is on the inside of the tube [76,77].

In general, layer structuring is made by means of the plasma spray process, implying a fast deposition rate and easy masking for the deposition of patterned structures; other film formation processes considered are electrochemical vapor deposition (EVD), sol–gel methods, and sputtering [78].

Concerning the tubular SOFC fabrication methods, in the last decade, many traditional techniques have been demonstrated to be usable, mainly including plastic extrusion [79], slip casting [80], and dip coating [81].

Planar SOFC stacks are produced by different methods. Two of the most widely used methods are dry pressing and screen printing [82].

The literature confirms an ever growing consideration of the micro-tubular SOFC design. This architecture presents several advantages over other types of SOFC architectures such as high volumetric power density, good endurance against thermal cycling, less robust sealing between fuel and air, and low costs [83,84]. The reduced dimensions of the components forming the microtubular SOFCs (diameters ranging from the millimeter scale to the sub-millimeter scale) make the latter suitable for small applications.

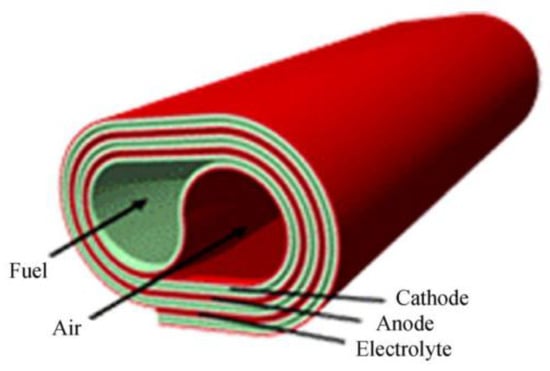

Other designs consist of the roll design and monolithic design. The roll design configuration is prepared using a tape-casting process, with each element of the fuel cell being cast individually as an easily manipulated, flexible tape. The anode, electrolyte, and cathode components are laminated jointly and arranged to give the preferred geometry (see Figure 10). Regarding the fuel supply, it can be introduced into both the anode and cathode (core) through stainless steel tubes [85].

Figure 10.

Roll design.

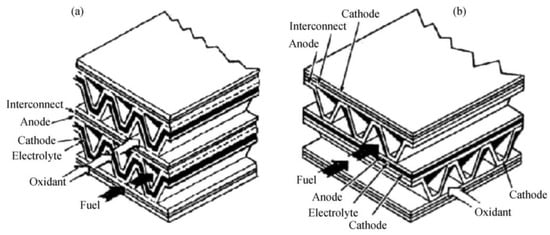

SOFC’s monolithic design is based on the design of a primary structure comparable to that of a heat exchanger. Aside from the cathode and anode separated by the dense electrolyte, it includes the interconnection and current collectors put into a channeled structure together. Two distinct arrangements for this design are possible: gas co-flow and gas crossflow (Figure 11) [85].

Figure 11.

Monolithic design: (a) co-flow, (b) cross-flow.

5. From Cell to Stack to Balance of Plant

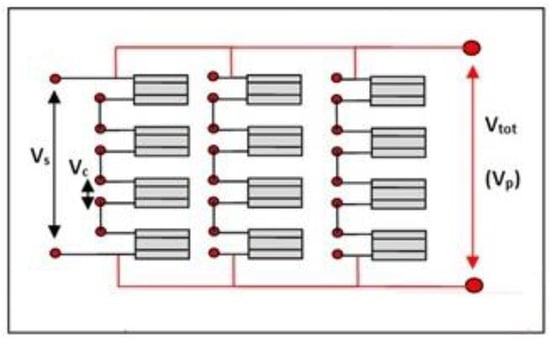

As previously illustrated, a single cell can be used individually to generate an electric current or voltage, in this section, however, it will be illustrated how the single cell can be considered the basic element with which to build much more powerful and complex modular systems called “stacks”. A stack can be created simply by connecting several cells in series. The stack, in turn, being modular, can be assembled in series or in parallel with other stacks in order to deliver the required voltage and current (see Figure 12).

Figure 12.

Cell modularity, series, and parallels.

However, this packaging cannot work alone. Extra components are required to operate the fuel cells by constituting the so called balance of plant (BoP). Air, fuel, and fluids need to be circulated through the stacks, so compressors, pumps, and blowers are necessary to move them. Electric motors, which drive these components, are a vital part of the fuel cell system. Therefore, part of the electric power generated by the same system will be destined for electric motors. The supply of hydrogen is also a very critical issue due to its lack in nature, so its storage is nowadays a very important problem. This has pushed technology to produce hydrogen in situ, directly from the available hydrocarbon, therefore, some form of fuel processing system is needed (as will be discussed in detail in the next section).

Where direct supply from the grid is not possible, it is necessary to have a system for the storage and purification (i.e., desulfurization) of the upstream fuel. Fuel processing in most cases is based on reforming, requiring a high content of heat. In this regard, the BoP considers a heat recovery system.

Fuel cells need electric current processing for a DC/AC conversion for the electric loads following. Power conditioning is nearly always needed to set and fix the load working point (the control of output voltage is more delicate for the power quality of SOFC [86]). Obviously, equipment such as control valves as well as pressure regulators are usually needed. In most cases, a control system is present to coordinate the parts of the system.

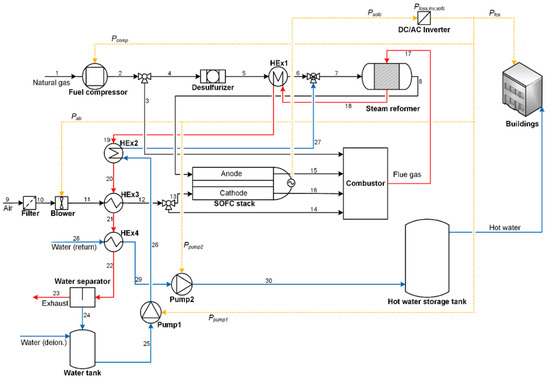

Figure 13 shows a technically complete balance of plant of a SOFC power plant, based on fuel processing via steam reforming. The plant scheme reported refers to a complex layout whose stream lines are subjected to various processes to accomplish the overall self-sustenance. As can be seen, there are three main streamlines: the fuel line, the water line, and the air line. These three streams are moved by proper compressors (CG, CA) and pumps for water (PW), which can regulate the pressure in the case of pressurized plant operations. Aside from the SOFC, which represents the core system in which the electro-chemical processes occur (Figure 13b), the plant in the case is, however, based on antecedent fuel processing and on a subsequent combustion process. This burns the remaining fuel traces contained in the exhaust stream and energizes it by further increasing its temperature to deliver thermal energy inside and outside the plant. Following the logical and consequential fluid routes, after pressurization, the water stream is soon vaporized by a an evaporator (EVA), which receives heat from a heat exchanger in the exhausted-combusted gas line. In parallel, fuel is pressurized and moved by its compressor. Steam and fuel are mixed in a collector (m) to then obtain a preheating in the HCFG, in parallel with the pressurized air. The heat exchanger is operated due to the high thermal energy amount of combusted gases. The fresh fuel is then mixed with recirculated anode off gases, whose function it is to dilute and further heat up the gas, which is being prepared to be subjected to the endothermic reforming and thus sustain the process thermally (PSR). This step is put into effect frequently in a real installation, since it is beneficial for SOFC performance and safety. In fact, it ensures at the inlet SOFC section, a gas that is rich in hydrogen and well diluted not to be dangerous in the case of undesired carbon deposition on composite materials. The reforming then continues inside the SOFC structure via indirect internal steam reforming (IISR), which completes the fuel transformation to hydrogen. In this, as presented in the next section, the steam plays a central role due to its reforming agent action. In fact, the fuel streams at the SOFC anode inlet section is composed of about 50–60% of hydrogen (if the steam reforming converts pure methane), while the rest is a mixture of steam, carbon monoxide, carbon dioxide, traces of methane, and a possible low content of nitrogen. The rich hydrogen stream is then subjected to exothermic electrochemical processes together with the pressurized air to generate electric and thermal energy. Apart from those that are recirculated, the rest of the anode exhaust gases are then sent to the combustion chamber (CC) together with the exhaust air that burns the remaining undepleted fuels (hydrogen, carbon monoxide, and unconverted methane), where the high amount of thermal energy possessed is finally yielded externally through a hot water based heat recovery system (HRHW).

Figure 13.

Balance of plant of a SOFC power plant (the authors reserve the right to use the scheme in Figure 13 for a future paper). Power plant (a); SOFC core (b).

Clearly, the balance of plant can be extended by adding a gas turbine (TG), which operates on the SOFC exhausted combusted gas, recreating a Brayton cycle. It can further be completed by adding a steam turbine (TS) in a downstream Hirn/Rankine cycle in which the steam (or fluid vapor) generation is still possible according to the gas turbine discharge gas still at high temperature. A plant with this typology makes the “hybrid plant SOFC–gas turbines–steam turbines (these will be discussed in detail in the next section).

6. Fuel Processing

The need for fuel processing comes from the impossibility of using pure hydrogen, given its absence over Earth and since direct hydrocarbon feeding has been demonstrated to be unfeasible [87,88,89,90,91,92,93,94,95,96]. Therefore, hydrogen must be produced by fuel processing methods involving chemical compounds that contain it in structure. There are many hydrogen generation methods [97]: water electrolysis [98], through which the water molecule is separated by means of the application of electric energy; water thermolysis, which accomplishes the splitting of the H2O molecule under the effect of thermal energy [99]; pyrolysis, which occurs by splitting the molecule of a hydrocarbon due to the supply of substantial quantities of thermal energy [100]; the photolysis of water, which involves the splitting of H2O molecules by solar radiation with the aid of a photocatalyst [101]; the gasification of coal and biomass [102] through which biomass is treated with an oxidizing media such as water, oxygen, and air and syngas rich in hydrogen is produced; the hydrocarbon reforming, which chemically converts the hydrocarbon into a gaseous stream that is rich in hydrogen by means of thermal energy supply and through the use of a process promoter, and the partial oxidation of hydrocarbons through which hydrocarbons receive heat to be converted into hydrogen, and carbon monoxide by means of the partial oxidation of the primary fuel [103].

Among these, the most widely adopted methods for future large scale hydrogen generation refer to electrolysis [104,105,106,107,108,109,110], and to reforming more specifically for hydrogen industrial production [111,112,113,114,115,116]. In fact, the proper ones to be strictly coupled and integrated with and into SOFC technology refer to reforming [117] and to partial oxidation [118].

The reforming and partial oxidation reactions are typically carried out in a heated furnace over a catalyst, usually nickel based. Several reforming technologies are available for getting the heat into the process. These technologies can be differentiated by the means of heat transfer based on convective heat transfer, radiant heat transfer, and internal combustion. For instance, most industrial hydrogen plants are based on radiant heat transfer in tubular reformers. The furnace consists of a box-type radiant section including the burners if needed, and a convection section to recover the waste heat of the flue gases leaving the radiant section. Clearly, although the principle is similar, reforming-integrated fuel cells differ in the system of delivering heat to the process, whether it is external (ER), direct internal (DIR), and indirect internal (IIR).

The matching with fuel reforming finds its feasibility in the high temperature operation of solid oxide fuel cells in the range of 800–1000 °C. Fuel reforming is a highly endothermic process and it is technically operated at 800 °C, so it can avail of the SOFC waste heat. The motivation of partial oxidation matching with SOFC is in the same fuel used, that is, first burned, thus generating heat at a temperature close to that of the SOFC to accomplish the fuel processing. Both processes deliver at output a resulting stream rich in hydrogen that is at high temperature, thus favoring SOFC electrochemical oxidation. Regarding the above remaining fuel processing methods, the scientific literature does not provide explicit evidence of matching, which is, however, possible but unattractive.

Fuel reforming processing technologies for high temperature fuel cells involve the generation of hydrogen rich fuels by the conversion of gaseous hydrocarbons, or even ammonia, gasoline, ethanol, or methanol. The development of converting hydrocarbon fuels to hydrogen-rich gas products more specifically fall in one of following processes: steam reforming (SR), autothermal reforming-partial oxidation (ATR-PO), CO2 dry reforming (DR), or a combination of two or more.

Steam reforming is a process that converts hydrocarbon into a hydrogen rich stream by means of steam acting as a reforming agent. The heat source is provided from a heat furnace or by recovering waste heat. Autothermal reforming and partial oxidation are quite similar, although some authors are keen to stress that some differences exist [119,120,121,122]. These processes use the same converting hydrocarbon to generate heat through partial oxidation that is then necessary to convert the unburned hydrocarbon to a hydrogen rich stream. CO2 dry reforming is a fuel reforming that uses CO2 as the reforming agent. It has strong rooting, especially by means of the use of biogas as a fuel feed with its copresence of methane and carbon dioxide. More details are reported in the next section.

The challenges and opportunities of the previous fuel reforming technologies for applications in fuel cells have attracted much interest in various scientific reviews in which steam reforming is especially praised [119,120,121,122]. The literature also presents a couple of exhaustive reviews on CO2 reforming and on the production of hydrogen from the steam reforming of ethanol and glycerol, respectively [123,124]. Reviews on the partial oxidation of methane are also available [125,126]. The reforming processes have a delicate role in hydrogen generation, especially integrated in SOFC, since they have to meet stringent requirements such as high activity in hydrocarbon conversion, high activity stability, good heat transfer, low pressure drop, high selectivity to hydrogen, high thermal stability and good mechanical strength, and high resistance to carbon formation, which is a big problem in hydrocarbon processing to hydrogen. Therefore, the catalyst plays a central role.

There are two internal reforming concepts; these are referred to as direct internal reforming (DIR) and indirect internal reforming (IIR).

In the DIR operation, the reforming reaction takes place at the anode of the fuel cell. For instance, heat and steam (which is the reforming agent for steam reforming) are supplied directly from the electrochemical reaction due to the hydrogen electroreaction. The main advantage of this type of operation is that the hydrogen consumption by the electrochemical reaction could directly promote the conversion of methane at the anode side of the fuel cell. Therefore, DIR results in high conversion of the fuel and high efficiency of the process self. However, DIR operations require an anode material exhibiting high catalytic properties, since carbon formation at the anode side could occur, therefore running the risk of the loss of cell performance and poor durability.

For IIR operation, the reforming reaction takes place at the reformer, which is in close thermal contact with the anode side of the fuel cell. IIR has the advantage of good heat transfer between the reformer and the fuel cell. The heat transfer between these two reactors is expected to provide an autothermal operation. However, unlike DIR operation, the reformer part and the anode side for IIR operation are operated separately. Therefore, the catalyst for the reforming reaction at the reformer part and the material for electrochemical reactions at the anode side of the fuel cell can be different and optimized individually.

The main problem of the internal reforming operation is the mismatch between the heat requirement for the reforming reaction and the heat available from the fuel cell section. At SOFC temperatures, the kinetics of the reforming reactions are extremely high. Although they are limited by mass and heat transfer considerations, they are still much higher than the corresponding fuel cell reactions. Therefore, the internal reforming operation could lead to local subcooling around the entrance area of the reformer part (inhomogeneous temperature distributions), which can result in mechanical failure due to thermally induced stresses [127].

A very evident problem related with the direct internal reforming (DIR) is the propensity to form carbon deposition on the anode side, which can occur due to the cracking reaction, favored at high temperature operations. The carbon formation could result in the deactivation of the anode material, which leads to the loss in fuel cell performance. The quantity of carbon deposited on the anode is affected by the operating temperature, the steam to carbon ratio, and other possible diluents such as CO2 and N2 that are present [128]. Clearly, the IIR process can be affected by carbon deposition, but unlike DIR, it does not directly damage the electro-oxidation zone. Another disadvantage of the internal reforming operation compared to external reforming is related to the poisoning by some impurities (e.g., sulfur components) that can be present in the feed fuel that can poison the reaction site, or by sintering the active metal and/or support at high temperature. Therefore, the integration of the combination between the reforming and electrochemical reactions might reduce the flexibility of the fuel cell operation. This disadvantage is likely to be more concerned with DIR operation compared with IIR, which is more protective compared to the latter.

Internal reforming hence presents advantages and disadvantages. For example, it has been demonstrated that internally reforming hydrocarbon fuels in SOFC improved, in addition to compactness, an efficiency of 8% compared to the external reformed fuel cell [129].

As above highlighted, carbon formation is a serious event to be avoided. In this regard, research has been oriented toward the study and the development of materials that show the properties aforementioned, many of which are nickel based. Many researchers have utilized CeO2. Zhan et al. [130] studied the Ru–CeO2 catalyst layer on the Ni cermet anode side for direct internal reforming. Klein et al. studied the Ir–CeO2 catalyst on the Ni–YSZ cermet anode for CH4 processing, which presented a still stable fuel cell operation after 120 h [131,132]. Wang et al. [133] studied the effect of Ru loading on Al2O3 supported catalysts during the activity of partial oxidation, steam reforming, and CO2 reforming. Wang et al. [134,135,136] also studied the effect of promoters such as Li2O, La2O3, CaO, CeO2, Pr2O3, etc. on the Ni–Al2O3 catalyst to monitor coking resistance. It was found that the addition of BaO on the Ni based anode improved the anti-coking properties [137].

Steam reforming is the most popular method to generate hydrogen rich gases inside a solid oxide fuel cell amongst all the reforming processes. The very interesting review of Sengodan et al. [138] presents a wide overview on the catalysts, supports, and methods of preparation in order to ensure high process activity. Clearly, the catalysts were Ni based. Ni/SiO2 prepared by impregnation, Ni/Al2O3, and catalysts based on noble metals such as Ru, Pt, Pd, Ir, etc. were overviewed. For instance, Pd–Rh metal foam (Pd 1.5% wt, Rh 0.16% wt, ZrO2 35%, Al2O3 63.7%) has been shown to exhibit good activity and stability with negligible carbon deposition after 200 h [139]. It has been reported that the commercial Ni/α-Al2O3 catalyst is stable at a steam to carbon ratio of 3, and deactivates rapidly at a steam to carbon ratio of 2, while Ru/γ-Al2O3 shows stability even at a low steam to carbon ratio of 1 [140]. This evidence shows how the operating parameter of the steam to carbon ratio affects the activity of the catalyst during the process. For instance, Sengodan et al. reported these other steam reforming catalyst as good materials: Ni/La2Zr2O7, manufactured by coprecipitation/impregnation and by adopting a steam to carbon ratio of 2 [141]; Ni-Pt/Al2O3 by adopting a steam to carbon ratio of 3 [142]; and Rh/CeO2 by adopting a steam to carbon ratio of 1.2 [143]. Regarding the partial oxidation, the catalysts were similar. Transition metals (Ni, Co, Fe), noble metals, and perovskite oxide-based materials have exhibited good catalytic activity, stability, and resistance to carbon deposition. Co/ZrO2 is reported to be an excellent low cost catalyst [144]. Additionally, for CO2 reforming, Ni- and Co-based catalysts are the best options mostly adopted due to their abundance, high activity, and economically feasible cost. Strengthening to overcome carbon deposition is performed by using the different types of catalysts widely adopted (Ni, Ru, Rh, Pd, Ir, Pt, and Co) on oxide supports such as SiO2, Al2O3, MgO, YiO2, CaO, ZrO2, and La2O3 [145,146].

While steam and CO2 reforming can occur inside the fuel cell architecture, partial oxidation cannot be acted inside a fuel cell depending on its process, but requires an external fuel processor.

Clearly, the only CO-shift process can also occur when feeding a gas mixture rich in CO and H2O. To trigger it, it requires the proper thermodynamic conditions that are favored at low temperatures, around 300 °C. These do not match those of SOFC, therefore, it should be operated externally, with the help of a catalyst, usually nickel based.

6.1. Thermodynamic Briefs on Reforming Fuel Processing

The present section briefly reports on the thermodynamics of the main fuel reforming processes. The equations illustrate the process constant (K) as a function of the partial pressures (p) of the gases involved, with their stoichiometries (m, n). The most adopted, as commonly known, is the steam reforming (SR) of hydrocarbons, whose chemical reactions are shown in Equation set (27). The reactions that strictly refer to steam reforming is the first one. As can be seen, the generic hydrocarbon is treated with a quantity of steam that is also the reforming promoter. The products are carbon monoxide and hydrogen. In fact, the first reaction is accompanied by a second one, which is the co-shift reaction. Undepleted water reacts with carbon monoxide, thus producing carbon dioxide and still hydrogen. For instance, by considering the steam reforming of methane, the potentialities of this process are shown, since four moles of hydrogen are produced by converting a mole of primary fuel.

Equation set (28) shows the PO-ATR reactions, (29) the DR reactions, while set (30) represents the only process of the CO-shift reaction that involves a gaseous stream with the presence of carbon monoxide and steam. The result is an enrichment of the hydrogen stream.

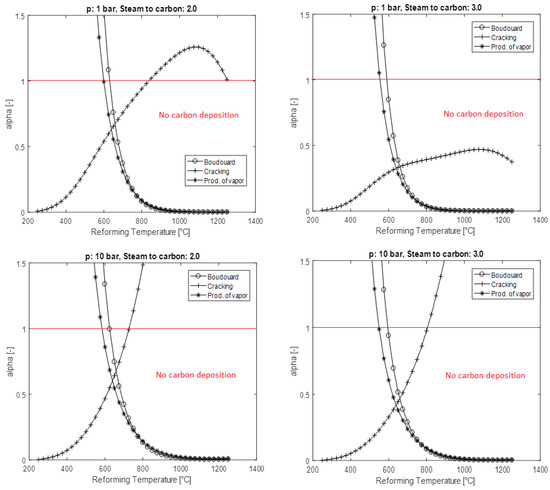

A complete analysis cannot fail to consider the carbon deposition control. This is a problem to be absolutely avoided, since carbon deposits on the reaction sites hinder the encounter between the gaseous reactants [147,148]. Carbon deposition mainly occurs due to methane cracking reactions (C) (31), Boudouard (B) (32), and the production of water vapor (PV) (33). The parameter alpha ‘α’, presented for each of the above carbon activity in the formulations (34–36), provides evidence if the phenomenon has been triggered. If α > 1, carbon deposition occurs [149].

All of the above reactions are accompanied by the process constant, as functions of partial pressure, for the understanding of the generation results by acting on the main parameters as the reforming the promoter content, temperature, and pressure.

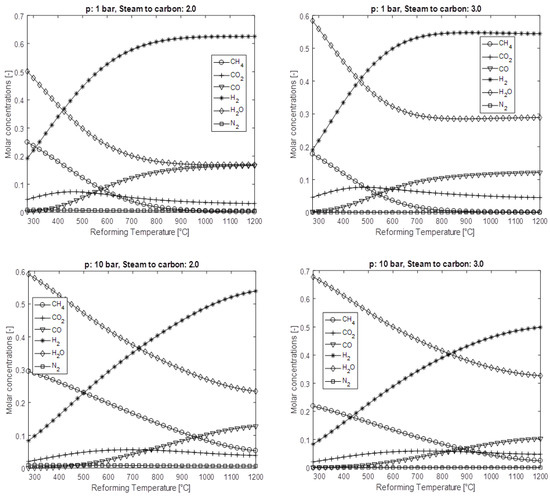

6.2. Steam Methane Reforming Processing Assessment