Cellulose Textiles from Hemp Biomass: Opportunities and Challenges

Abstract

:1. Introduction

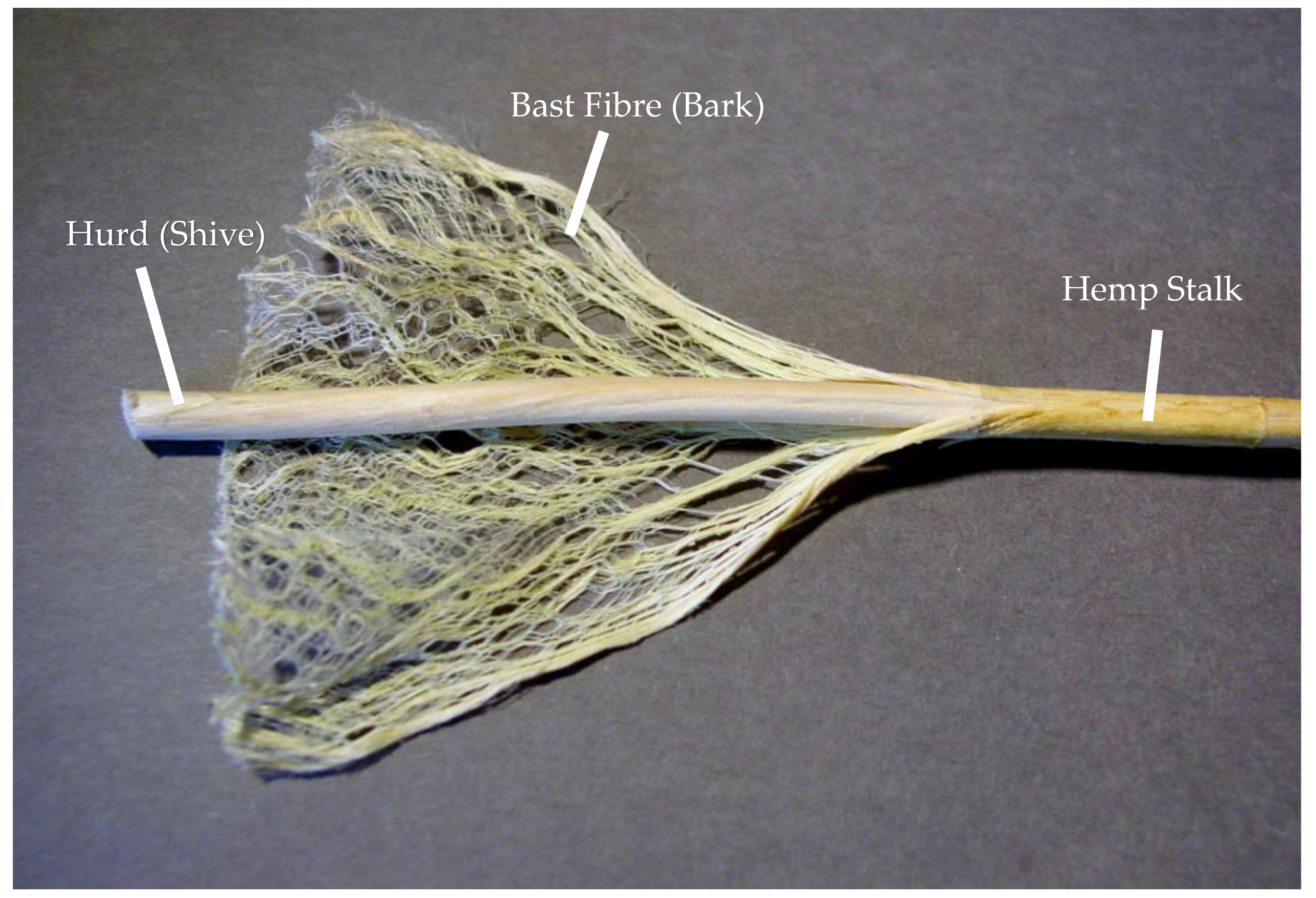

2. Environmental Challenges and MMCF

3. Hemp Biomass Feedstock for MMCF

4. Agricultural Opportunities and Challenges

- Cultivation in temperate, subtropical, and tropical climates;

- Increased global cultivation (49% increase by country from 2021–2022) at a CAGR of 16.8% (2022–2030);

- Hemp fibre yield 25–500% higher than that of cotton;

- Low pesticide, herbicide, and water consumption requirements;

- High biomass yields in 90 days (4× that of equivalent 25-year tree stand);

- Whole plant utilization.

5. Manufacturing Opportunities and Challenges

6. Economic Opportunities

- Personal Protective Equipment (PPE): The current worldwide market for commercial PPE is valued at $52.7 B, with $140 M serviceable towards flame resistant (FR) PPE in oil/gas, mining, electrical, and construction applications [110]. The PPE market is expected to increase to $92.5 B by 2025 [110] and $110.85 B by 2029 [111]. The NA market for commercial PPE is $2.9 B, from which $83 M serviceable towards FR PPE applications [112]. Targeted market for FR hemp-based L-MMCF at commercialization is initially estimated at $12.5 M worldwide and $2 M in NA, increasing at scale-up production of hemp-based L-MMCF.

- Filtration media/Disposable Consumer Products: Single-use disposable non-wovens (e.g., facemasks, gowns, flushable wipes, hygiene/sanitation products) are a high-demand commodity. The global non-woven medical textiles market is estimated to exhibit a CAGR of 3.9% with $27.7 B in sales by 2030 [113]. Targeted market for L-MMCF from hemp and post-consumer cellulosic textiles at commercialization for use in filtration media/disposable consumer products is estimated at $23 B worldwide and $8.3B in NA [114], increasing at scale-up. Consumption of cotton, other natural fibres, wood pulp, and rayon fibres for nonwoven applications in NA in 2021 was estimated at 1 million tonnes [115]. Considering a CAGR of 3.9%, the estimated consumption for L-MMCF staple fibres for nonwoven applications in NA at commercialization is 1.2 million tonnes.

- Apparel: The current global hemp apparel market is estimated to be $23.02 B by 2031 (CAGR of 27.1%), with NA and Europe accounting for 65% of global consumption ($15 B by 2030) [116]. The global L-MMCF market for apparel is approximately $447 M US (45% of currently L-MMCF market share) [117]. The global ethical fashion market size is estimated to grow from $6.35 B in 2019 to $15.7 B in 2030 with a CAGR of 9.1% [118]. Targeted market for L-MMCF from hemp and post-consumer cellulosic textiles at commercialization for use in apparel at commercialization is estimated between $6.9 B globally ($4.5 NA) and $10.2 B globally ($6.6 NA).

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Niinimäki, K.; Peters, G.; Dahlbo, H.; Perry, P.; Rissanen, T.; Gwilt, A. The Environmental Price of Fast Fashion. Nat. Rev. Earth Environ. 2020, 1, 189–200. [Google Scholar] [CrossRef] [Green Version]

- Bevilacqua, M.; Ciarapica, F.E.; Mazzuto, G.; Paciarotti, C. Environmental Analysis of a Cotton Yarn Supply Chain. J. Clean. Prod. 2014, 82, 154–165. [Google Scholar] [CrossRef]

- Textile Exchange. Preferred Fiber and Materials Market Report 2022. Available online: https://textileexchange.org/wp-content/uploads/2022/10/Textile-Exchange_PFMR_2022.pdf (accessed on 5 November 2022).

- Jiang, X.; Bai, Y.; Chen, X.; Liu, W. A Review on Raw Materials, Commercial Production and Properties of Lyocell Fiber. J. Bioresour. Bioprod. 2020, 5, 16–25. [Google Scholar] [CrossRef]

- Sayyed, A.J.; Deshmukh, N.A.; Pinjari, D.V. A Critical Review of Manufacturing Processes Used in Regenerated Cellulosic Fibres: Viscose, Cellulose Acetate, Cuprammonium, LiCl/DMAc, Ionic Liquids, and NMMO Based Lyocell. Cellulose 2019, 26, 2913–2940. [Google Scholar] [CrossRef]

- Briggs, J. Hemp Paper vs. Tree Paper. Available online: https://hempfrontiers.com/hemp-paper-vs-tree-paper/ (accessed on 13 September 2022).

- Chua, J.M. Amazon Pledges to Rid Private-Label Brands of Forest-Harming Viscose. Sourc. J. 2020. Available online: https://sourcingjournal.com/topics/raw-materials/amazon-private-label-canopystyle-deforestation-sustainable-viscose-2022-219512/ (accessed on 13 September 2022).

- Seisl, S.; Hengstmann, R. Manmade Cellulosic Fibers (MMCF)—A Historical Introduction and Existing Solutions to a More Sustainable Production. In Sustainable Textile and Fashion Value Chains: Drivers, Concepts, Theories and Solutions; Matthes, A., Beyer, K., Cebulla, H., Arnold, M.G., Schumann, A., Eds.; Springer International Publishing: Cham, Switzerland, 2021; pp. 3–22. ISBN 978-3-030-22018-1. [Google Scholar]

- Cassman, K.G. Ecological Intensification of Cereal Production Systems: Yield Potential, Soil Quality, and Precision Agriculture. Proc. Natl. Acad. Sci. USA 1999, 96, 5952–5959. [Google Scholar] [CrossRef] [Green Version]

- Ribul, M. Regenerative Textiles: A Framework for Future Materials Circularity in the Textile Value Chain. Sustainability 2021, 13, 13910. [Google Scholar] [CrossRef]

- Janjic, S.; Kostic, M.; Skundric, P. Direct Hemp Cellulose Dissolution in N-Methylmorpoline-N-Oxide. J. Nat. Fibers 2007, 4, 23–36. [Google Scholar] [CrossRef]

- Vosper, J. The Role of Industrial Hemp in Carbon Farming. Available online: https://www.aph.gov.au/parliamentary_business/committees/house_of_representatives_committees?url=ccea/24march2011/subs/sub035.pdf (accessed on 13 September 2022).

- Kosan, B.; Meister, F.; Sigmund, I.; Paulitz, J. Innovative Dissolving Pulps for Application in Cellulose MMF Production. Lenzing. Ber. 2019, 95, 9–14. [Google Scholar]

- Speicher, S. Hemp Is a Strong Option for Sequestering Carbon. Available online: https://www.lancasterfarming.com/news/main_edition/hemp-is-a-strong-option-for-sequestering-carbon/article_29e4d6d0-bcae-5ca6-bb76-0963c470ffc8.html (accessed on 27 October 2022).

- Legal History of Cannabis in Canada. Available online: https://en.wikipedia.org/w/index.php?title=Legal_history_of_cannabis_in_Canada&oldid=1109411917 (accessed on 11 October 2022).

- Lynch, P. Why Was Hemp Banned After World War II? Available online: https://wayofleaf.com/hemp/why-was-hemp-banned-after-world-war-ii (accessed on 11 October 2022).

- Business Wire. Global Lyocell Fabric Market to Reach 745.9 KT by 2027—Coherent Market Insights. Available online: https://www.businesswire.com/news/home/20191125005611/en/Global-Lyocell-Fabric-Market-to-Reach-745.9-KT-by-2027-%E2%80%93-Coherent-Market-Insights (accessed on 12 October 2022).

- Fastmarkets RISI. Synthetics Continue to Lead Fiber Supply in 2021, While Cellulosics Reach an All-Time High in Volume. Sourc. J. 2020. Available online: https://thefiberyear.com/wp-content/uploads/2022/07/NWM_14_2022.pdf (accessed on 11 October 2022).

- El Seoud, O.A.; Kostag, M.; Jedvert, K.; Malek, N.I. Cellulose Regeneration and Chemical Recycling: Closing the “Cellulose Gap” Using Environmentally Benign Solvents. Macromol. Mater. Eng. 2020, 305, 1900832. [Google Scholar] [CrossRef]

- EEA’s European Topic Centre on Waste and Materials in a Green Economy. Plastic in Textiles: Towards a Circular Economy for Synthetic Textiles in Europe—European Environment Agency. Available online: https://www.eea.europa.eu/themes/waste/resource-efficiency/plastic-in-textiles-towards-a (accessed on 11 October 2022).

- Jambeck, J.R.; Geyer, R.; Wilcox, C.; Siegler, T.R.; Perryman, M.; Andrady, A.; Narayan, R.; Law, K.L. Plastic Waste Inputs from Land into the Ocean. Science 2015, 347, 768–771. [Google Scholar] [CrossRef]

- Barnes, D.K.A.; Galgani, F.; Thompson, R.C.; Barlaz, M. Accumulation and Fragmentation of Plastic Debris in Global Environments. Philos. Trans. R. Soc. B Biol. Sci. 2009, 364, 1985–1998. [Google Scholar] [CrossRef] [PubMed]

- Haemmerle, F.M. The Cellulose Gap (the Future of Cellulose Fibres). Lenzing. Ber. 2011, 89, 12–21. [Google Scholar]

- Cherrett, N.; Barrett, J.; Clemett, A.; Chadwick, M.; Chadwick, M.J. Ecological Footprint and Water Analysis of Cotton, Hemp and Polyester; Stockholm Environmental Institute: Stockholm, Sweden, 2005; ISBN 978-91-975238-2-0. [Google Scholar]

- Zhang, X.; Cai, X. Climate Change Impacts on Global Agricultural Land Availability. Environ. Res. Lett. 2011, 6, 014014. [Google Scholar] [CrossRef]

- United Nations. Population. Available online: https://www.un.org/en/global-issues/population (accessed on 30 October 2022).

- World Wildlife Fund. Cotton|Industries|WWF. Available online: https://www.worldwildlife.org/industries/cotton (accessed on 21 October 2022).

- Nyakatawa, E.; Lemunyon, J.L. Predicting Soil Erosion in Conservation Tillage Cotton Production Systems Using the Revised Universal Soil Loss Equation (RUSLE). Soil Tillage Res. 2001, 57, 213–224. [Google Scholar] [CrossRef]

- Nachimuthu, G.; Webb, A. On-Farm Soil Conservation Measures in Cotton Farming Systems of Australia: A Sustainability Analysis. J. Soil Water Conserv. 2016, 71, 75A–80A. [Google Scholar] [CrossRef]

- Food and Agriculture Organization of the United Nations. Water for Sustainable Food and Agriculture: A Report Produced for the G20 Presidency of Germany. Food & Agriculture Org.: Rome, Italy, 2017; ISBN 978-92-5-109977-3. [Google Scholar]

- Sustainable Fashion. The Water Consumption Attributable to Cotton Production. Available online: https://sustainfashion.info/the-water-consumption-attributable-to-cotton-production/ (accessed on 21 October 2022).

- Averink, J. Global Water Footprint of Industrial Hemp Textile. Available online: https://essay.utwente.nl/68219/1/Averink,%20J.%200198501%20openbaar.pdf (accessed on 5 November 2022).

- Shen, L.; Patel, M. Life Cycle Assessment of Man-Made Cellulose Fibres. Lenzing. Ber. 2010, 88, 1–59. [Google Scholar]

- Changing Markets. Dirty Fashion: How Pollution in the Global Textiles Supply Chain Is Making Viscose Toxic. Available online: http://changingmarkets.org/wp-content/uploads/2017/06/CHANGING_MARKETS_DIRTY_FASHION_REPORT_SPREAD_WEB.pdf (accessed on 20 October 2022).

- Common Objective. Fibre Briefing: Viscose. Available online: http://www.commonobjective.co/article/fibre-briefing-viscose (accessed on 31 October 2022).

- Sengupta, A.K. Rayon Fibres. In Manufactured Fibre Technology; Gupta, V.B., Kothari, V.K., Eds.; Springer: Dordrecht, The Netherlands, 1997; pp. 480–513. ISBN 978-94-011-5854-1. [Google Scholar]

- Textile Exchange. Preferred Manmade Cellulosics—About Preferred Manmade Cellulosics. Available online: https://hub.textileexchange.org/textileexchange/learning-center/mmcellulosics (accessed on 14 September 2022).

- Iroegbu, A.O.C.; Ray, S.S. Bamboos: From Bioresource to Sustainable Materials and Chemicals. Sustainability 2021, 13, 12200. [Google Scholar] [CrossRef]

- Nayak, L.; Mishra, S.P. Prospect of Bamboo as a Renewable Textile Fiber, Historical Overview, Labeling, Controversies and Regulation. Fash. Text. 2016, 3, 2. [Google Scholar] [CrossRef] [Green Version]

- Ferreira, E.; Kalliola, R.; Ruokolainen, K. Bamboo, Climate Change and Forest Use: A Critical Combination for Southwestern Amazonian Forests? Ambio 2020, 49, 1353–1363. [Google Scholar] [CrossRef] [Green Version]

- Yiping, L.; Yanxia, L.; Buckingham, K.; Henley, G.; Guomo, Z. Bamboo and Climate Change Mitigation: A Comparative Analysis of Carbon Sequestration. Int. Netw. Bamboo Ratt. 2010, 30. Available online: https://www.inbar.int/wp-content/uploads/2020/05/1489457789.pdf (accessed on 6 November 2022).

- Kauffman, G.B.; Karbassi, M. A Demonstration of the Cuprammonium Rayon Process. J. Chem. Educ. 1985, 62, 878. [Google Scholar] [CrossRef]

- Hong, Y.-K.; Chung, K.-H.; Lee, W.-S. Structure of Regenerated Cellulose Fibers from DMAc/LiCl Solution. Text. Res. J. 1998, 68, 65–69. [Google Scholar] [CrossRef]

- Moriam, K.; Sawada, D.; Nieminen, K.; Hummel, M.; Ma, Y.; Rissanen, M.; Sixta, H. Towards Regenerated Cellulose Fibers with High Toughness. Cellulose 2021, 28, 9547–9566. [Google Scholar] [CrossRef]

- White, P. 4—Lyocell: The Production Process and Market Development. In Regenerated Cellulose Fibres; Woodings, C., Ed.; Woodhead Publishing Series in Textiles; Woodhead Publishing: Sawston, UK, 2001; pp. 62–87. ISBN 978-1-85573-459-3. [Google Scholar]

- Shen, L.; Worrell, E.; Patel, M.K. Environmental Impact Assessment of Man-Made Cellulose Fibres. Resour. Conserv. Recycl. 2010, 55, 260–274. [Google Scholar] [CrossRef]

- Ouyang, Y.; Leininger, T.D.; SRS Center for Bottomland Hardwoods Research. How Sustainable Are Eucalyptus Plantations? Available online: https://www.srs.fs.usda.gov/compass/2016/05/05/how-sustainable-are-eucalyptus-plantations/ (accessed on 21 October 2022).

- Ouyang, Y.; Xu, D.; Leininger, T.D.; Zhang, N. A System Dynamic Model to Estimate Hydrological Processes and Water Use in a Eucalypt Plantation. Ecol. Eng. 2016, 86, 290–299. [Google Scholar] [CrossRef]

- Williams, D. What Is Coppicing? (And Why It’s Amazing). Available online: https://www.growingwithnature.org/what-is-coppicing/ (accessed on 31 October 2022).

- Costa, S.A.; Cerón, A.A.; Petreca, B.B.; Costa, S.M. Fibers of Cellulose Sugarcane Bagasse with Bromelain Enzyme Immobilized to Application in Dressing. SN Appl. Sci. 2020, 2, 285. [Google Scholar] [CrossRef] [Green Version]

- Sirlene, M.; Costa, S.; Costa, S.; Pahl, R.; Mazzola, P. Textile Fiber Produced from Sugarcane Bagasse Cellulose: An Agro-Industrial Residue. Int. J. Text. Fash. Technol. (IJTFT) 2013, 3, 15–28. [Google Scholar]

- Dever, M.; Collier, B.J.; Petrovan, S.; Collier, J.R. Lyocell Solutions from Alternative Cellulose Sources. Cloth. Text. Res. J. 2003, 21, 167–173. [Google Scholar] [CrossRef]

- Gericke, A.; Van der Pol, J. A Comparative Study of Regenerated Bamboo, Cotton and Viscose Rayon Fabrics. Part 2: Antimicrobial Properties. J. Consum. Sci. 2011, 39. [Google Scholar] [CrossRef] [Green Version]

- Millati, R.; Wikandari, R.; Ariyanto, T.; Putri, R.U.; Taherzadeh, M.J. Pretreatment Technologies for Anaerobic Digestion of Lignocelluloses and Toxic Feedstocks. Bioresour. Technol. 2020, 304, 122998. [Google Scholar] [CrossRef]

- World Wildlife Fund. Sugarcane Farming’s Toll on the Environment|Magazine Articles|WWF. Available online: https://www.worldwildlife.org/magazine/issues/summer-2015/articles/sugarcane-farming-s-toll-on-the-environment (accessed on 31 October 2022).

- Zhao, X.; Wei, X.; Guo, Y.; Qiu, C.; Long, S.; Wang, Y.; Qiu, H. Industrial Hemp—An Old but Versatile Bast Fiber Crop. J. Nat. Fibers 2021, 19, 1–14. [Google Scholar] [CrossRef]

- Zhang, S.; Chen, C.; Duan, C.; Hu, H.; Li, H.; Li, J.; Liu, Y.; Ma, X.; Stavik, J.; Ni, Y. Regenerated Cellulose by the Lyocell Process, a Brief Review of the Process and Properties. BioRes 2018, 13, 4577–4592. [Google Scholar] [CrossRef]

- Periyasamy, A.P.; Khanum, R.; Effect of Fibrillation on Pilling Tendency of Lyocell Fiber. Bangladesh Text. Today 2012. Available online: https://www.textiletoday.com.bd/effect-of-fibrillation-on-pilling-tendency-of-lyocell-fiber/ (accessed on 31 October 2022).

- TITK. Cellulose Research: Lyohemp®—Latest Generation Sustainable Fiber. Available online: https://www.titk.de/en/innovations/lyocell-/-lyohemp/ (accessed on 5 November 2022).

- Zhou, Y.; Zhang, X.; Zhang, J.; Cheng, Y.; Wu, J.; Yu, J.; Zhang, J. Molecular Weight Characterization of Cellulose Using Ionic Liquids. Polym. Test. 2021, 93, 106985. [Google Scholar] [CrossRef]

- Nogueira, C.; Silva, M.E.C. Sensory Analysis of Textiles Products. Presented at the Semana de Engenharia 2010, Guimarães, Dubrovik, Croatia, 3 October 2010. [Google Scholar]

- Thomsen, A.B.; Rasmussen, S.; Bohn, V.; Nielsen, K.V.; Thygesen, A. Hemp Raw Materials: The Effect of Cultivar, Growth Conditions and Pretreatment on the Chemical Composition of the Fibres; Risø DTU-National Laboratory for Sustainable Energy: Roskilde, Denmark, 2005; p. 31. [Google Scholar]

- Chen, X.; Zhang, K.; Xiao, L.-P.; Sun, R.-C.; Song, G. Total Utilization of Lignin and Carbohydrates in Eucalyptus Grandis: An Integrated Biorefinery Strategy towards Phenolics, Levulinic Acid, and Furfural. Biotechnol. Biofuels 2020, 13, 2. [Google Scholar] [CrossRef] [PubMed]

- Tonoli, G.H.D.; Teixeira, E.M.; Corrêa, A.C.; Marconcini, J.M.; Caixeta, L.A.; Pereira-da-Silva, M.A.; Mattoso, L.H.C. Cellulose Micro/Nanofibres from Eucalyptus Kraft Pulp: Preparation and Properties. Carbohydr. Polym. 2012, 89, 80–88. [Google Scholar] [CrossRef]

- Moradbak, A.; Tahir, P.M.; Mohamed, A.Z.; Halis, R. Alkaline Sulfite Anthraquinone and Methanol Pulping of Bamboo (Gigantochloa Scortechinii). Bioresources 2016, 11, 235–248. [Google Scholar] [CrossRef] [Green Version]

- Chen, H.; Wang, Y.; Qiu, J.; Song, J.; Wang, J.; Liu, M.; Wo, Q.; Jiang, L.; Yang, T. Properties and Application of Kraft Pulp Prepared from Waste Bamboo Powder. BioRes 2022, 17, 6262–6276. [Google Scholar] [CrossRef]

- Blade, S.; Gaudiel, R.; Kerr, N. Low-THC Hemp Research in the Black and Brown Soil Zones of Alberta, Canada. In Perspectives on New Crops and New Uses; ASHS Press: Alexandria, VA, USA, 1999; pp. 306–310. [Google Scholar]

- Wimalasiri, E.M.; Jahanshiri, E.; Chimonyo, V.G.P.; Kuruppuarachchi, N.; Suhairi, T.A.S.T.M.; Azam-Ali, S.N.; Gregory, P.J. A Framework for the Development of Hemp (Cannabis sativa L.) as a Crop for the Future in Tropical Environments. Ind. Crops Prod. 2021, 172, 113999. [Google Scholar] [CrossRef]

- De Prato, L.; Ansari, O.; Hardy, G.E.S.J.; Howieson, J.; O’Hara, G.; Ruthrof, K.X. The Cannabinoid Profile and Growth of Hemp (Cannabis sativa L.) Is Influenced by Tropical Daylengths and Temperatures, Genotype and Nitrogen Nutrition. Ind. Crops Prod. 2022, 178, 114605. [Google Scholar] [CrossRef]

- Wimalasiri, E.M.; Jahanshiri, E.; Syaherah, T.A.; Kuruppuarachchi, N.; Chimonyo, V.G.P.; Azam-Ali, S.N.; Gregory, P.J. Datasets for the Development of Hemp (Cannabis sativa L.) as a Crop for the Future in Tropical Environments (Malaysia). Data Brief 2022, 40, 107807. [Google Scholar] [CrossRef]

- Cannabis Business Plan. Global Hemp Market. Available online: https://cannabusinessplans.com/global-hemp-market/ (accessed on 6 November 2022).

- Duque Schumacher, A.G.; Pequito, S.; Pazour, J. Industrial Hemp Fiber: A Sustainable and Economical Alternative to Cotton. J. Clean. Prod. 2020, 268, 122180. [Google Scholar] [CrossRef]

- Grand View Research. Industrial Hemp Market Worth $16.75 Billion By 2030. Available online: https://www.grandviewresearch.com/press-release/global-industrial-hemp-market (accessed on 7 November 2022).

- Alary, B. How Alberta Is Poised to Become a Hub of the Hemp Industry. Available online: https://www.techlifetoday.ca/articles/2019/alberta-poised-to-become-a-hemp-hub (accessed on 25 October 2022).

- Health Canada. List of Approved Cultivars for the 2022 Growing Season: Industrial Hemp Varieties Approved for Commercial Production. Available online: https://www.canada.ca/en/health-canada/services/drugs-medication/cannabis/producing-selling-hemp/commercial-licence/list-approved-cultivars-cannabis-sativa.html (accessed on 25 October 2022).

- Government of Alberta—Agriculture and Forestry. Growing Hemp in Alberta—Growing Hemp in Alberta—Open Government. Available online: https://open.alberta.ca/dataset/growing-hemp-in-alberta/resource/9babce43-b6f6-422c-85cd-283ea1a56147 (accessed on 14 September 2022).

- Musio, S.; Müssig, J.; Amaducci, S. Optimizing Hemp Fiber Production for High Performance Composite Applications. Front. Plant Sci. 2018, 9, 1702. [Google Scholar] [CrossRef] [PubMed]

- Horne, M.R.L. 5B—Bast Fibres: Hemp Cultivation and Production. In Handbook of Natural Fibres, 2nd ed.; Kozłowski, R.M., Mackiewicz-Talarczyk, M., Eds.; Woodhead Publishing Series in Textiles; Woodhead Publishing: Sawston, UK, 2020; pp. 163–196. ISBN 978-0-12-818398-4. [Google Scholar]

- Manian, A.P.; Cordin, M.; Pham, T. Extraction of Cellulose Fibers from Flax and Hemp: A Review. Cellulose 2021, 28, 8275–8294. [Google Scholar] [CrossRef]

- Zimniewska, M. Hemp Fibre Properties and Processing Target Textile: A Review. Materials 2022, 15, 1901. [Google Scholar] [CrossRef] [PubMed]

- Żuk-Gołaszewska, K.; Gołaszewski, J. Cannabis sativa L.—Cultivation and Quality of Raw Material. J. Elem. 2018, 23, 971–984. [Google Scholar] [CrossRef]

- Ahmed, A.T.M.F.; Islam, M.Z.; Mahmud, M.S.; Sarker, M.E.; Islam, M.R. Hemp as a Potential Raw Material toward a Sustainable World: A Review. Heliyon 2022, 8, e08753. [Google Scholar] [CrossRef] [PubMed]

- Meister, F.; Sigmund, I.; Paulitz, J.; Kosan, B.; Kreig, M.; Mooz, M. Novel Dissolving Pulps Based on Annual Plants for the Application in the Lyocell Process. Presented at the 56th Dornbirn MFC, Dornbirn, Austria, 13–15 September 2017. [Google Scholar]

- Han, J.S. Properties of Nonwood Fibers; The Korean Society of Science and Technology: Seoul, Korea, 1998; pp. 3–12. [Google Scholar]

- Krotov, V.S. Use of AAS Pulping for Flax and Hemp Shives. J. Int. Hemp Assoc. 1995, 3, 16–18. [Google Scholar]

- Gümüşkaya, E.; Usta, M.; Balaban, M. Carbohydrate Components and Crystalline Structure of Organosolv Hemp (Cannabis sativa L.) Bast Fibers Pulp. Bioresour. Technol. 2007, 98, 491–497. [Google Scholar] [CrossRef]

- Ahmad, R.; Tehsin, Z.; Malik, S.T.; Asad, S.A.; Shahzad, M.; Bilal, M.; Shah, M.M.; Khan, S.A. Phytoremediation Potential of Hemp (Cannabis sativa L.): Identification and Characterization of Heavy Metals Responsive Genes. CLEAN—Soil Air Water 2016, 44, 195–201. [Google Scholar] [CrossRef]

- Griga, M.; Bjelková, M. Flax (Linum usitatissimum L.) and Hemp (Cannabis sativa L.) as Fibre Crops for Phytoextraction of Heavy Metals: Biological, Agro-Technological and Economical Point of View. In Plant-Based Remediation Processes; Gupta, D.K., Ed.; Soil Biology; Springer: Berlin/Heidelberg, Germany, 2013; pp. 199–237. ISBN 978-3-642-35564-6. [Google Scholar]

- Linger, P.; Ostwald, A.; Haensler, J. Cannabis sativa L. Growing on Heavy Metal Contaminated Soil: Growth, Cadmium Uptake and Photosynthesis. Biol. Plant. 2005, 49, 567–576. [Google Scholar] [CrossRef]

- Shi, G.; Liu, C.; Cui, M.; Ma, Y.; Cai, Q. Cadmium Tolerance and Bioaccumulation of 18 Hemp Accessions. Appl. Biochem. Biotechnol. 2012, 168, 163–173. [Google Scholar] [CrossRef]

- Paulitz, J.; Sigmund, I.; Kosan, B.; Meister, F. Lyocell Fibers for Textile Processing Derived from Organically Grown Hemp. Procedia Eng. 2017, 200, 260–268. [Google Scholar] [CrossRef]

- Rosenau, T.; Potthast, A.; Adorjan, I.; Hofinger, A.; Sixta, H.; Firgo, H.; Kosma, P. Cellulose Solutions in N-Methylmorpholine-N-Oxide (NMMO)—Degradation Processes and Stabilizers. Cellulose 2002, 9, 283–291. [Google Scholar] [CrossRef]

- Rosenau, T.; Potthast, A.; Kosma, P.; Chen; Gratzl, J.S. Autocatalytic Decomposition of N-Methylmorpholine N-Oxide Induced by Mannich Intermediates. J. Org. Chem. 1999, 64, 2166–2167. [Google Scholar] [CrossRef]

- Kosan, B.; Michels, C.; Meister, F. Dissolution and Forming of Cellulose with Ionic Liquids. Cellulose 2008, 15, 59–66. [Google Scholar] [CrossRef]

- Fang, Z.; Li, B.; Liu, Y.; Zhu, J.; Li, G.; Hou, G.; Zhou, J.; Qiu, X. Critical Role of Degree of Polymerization of Cellulose in Super-Strong Nanocellulose Films. Matter 2020, 2, 1000–1014. [Google Scholar] [CrossRef]

- Krässig, H.; Kitchen, W. Factors Influencing Tensile Properties of Cellulose Fibers. J. Polym. Sci. 1961, 51, 123–172. [Google Scholar] [CrossRef]

- Mechanical Properties of Polymer Nanocomposites. In Fundamentals, Properties, and Applications of Polymer Nanocomposites; Koo, J.H. (Ed.) Cambridge University Press: Cambridge, UK, 2016; pp. 273–331. ISBN 978-1-139-34276-6. [Google Scholar]

- Gwon, J.-G.; Lee, D.-B.; Cho, H.-J.; Lee, S.-Y. Preparation and Characteristics of Cellulose Acetate Based Nanocomposites Reinforced with Cellulose Nanocrystals (CNCs). J. Korean Wood Sci. Technol. 2018, 46, 565–576. [Google Scholar] [CrossRef]

- Bajwa, D.S.; Rehovsky, C.; Shojaeiarani, J.; Stark, N.; Bajwa, S.; Dietenberger, M.A. Functionalized Cellulose Nanocrystals: A Potential Fire Retardant for Polymer Composites. Polymers 2019, 11, 1361. [Google Scholar] [CrossRef] [Green Version]

- Khan, B.A.; Warner, P.; Wang, H. Antibacterial Properties of Hemp and Other Natural Fibre Plants: A Review. BioResources 2014, 9, 3642–3659. [Google Scholar] [CrossRef]

- Arafa Badr, A. Anti-Microbial and Durability Characteristics of Socks Made of Cotton and Regenerated Cellulosic Fibers. Alex. Eng. J. 2018, 57, 3367–3373. [Google Scholar] [CrossRef]

- Khan, B.A.; Wang, J.; Warner, P.; Wang, H. Antibacterial Properties of Hemp Hurd Powder against E. Coli. J. Appl. Polym. Sci. 2015, 132. [Google Scholar] [CrossRef]

- O’Connell, K. Hemp vs Paper|Hemp Paper Benefits. Available online: https://ministryofhemp.com/blog/hemp-paper/ (accessed on 13 September 2022).

- Brown, R. The Environmental Crisis Caused by Textile Waste. Available online: https://www.roadrunnerwm.com/blog/textile-waste-environmental-crisis (accessed on 13 September 2022).

- Ecotextiles (and Two Sisters Ecotextiles). Estimating the Carbon Footprint of a Fabric. Available online: https://embed.tumblr.com/widgets/share/button?canonicalUrl=https%3A%2F%2Foecotextiles.blog%2F2011%2F01%2F19%2Festimating-the-carbon-footprint-of-a-fabric%2F&postcontent%5Btitle%5D=Estimating%20the%20carbon%20footprint%20of%20a%20fabric&postcontent%5Bcontent%5D=https%3A%2F%2Foecotextiles.blog%2F2011%2F01%2F19%2Festimating-the-carbon-footprint-of-a-fabric%2F (accessed on 25 October 2022).

- Future Market Insights Cellulose Fiber Market: Cellulose Fiber Market by Application, Process of Manufacturing & Region—Forecast 2022—2032. Available online: https://www.futuremarketinsights.com/reports/cellulose-fiber-market (accessed on 6 November 2022).

- Research and Markets ltd. Lyocell Fiber Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2022–2027. Available online: https://www.researchandmarkets.com/reports/5530547/lyocell-fiber-market-global-industry-trends (accessed on 13 September 2022).

- IMARC. North America Lyocell Fiber Market Report: Industry Trends and Forecast 2022–2027. Available online: https://www.imarcgroup.com/north-america-lyocell-fiber-market (accessed on 24 October 2022).

- Proficient Market Insights. Viscose Staple Fiber Market Projected to Surpass 16924.39 Million USD and Grow at a 4.43% CAGR During the 2022–2027 Forecast Timeframe. Available online: https://www.globenewswire.com/news-release/2022/10/20/2538221/0/en/Viscose-Staple-Fiber-Market-Projected-to-Surpass-16924-39-million-USD-and-Grow-at-a-4-43-CAGR-During-the-2022-2027-Forecast-Timeframe-104-Pages-Report.html (accessed on 7 November 2022).

- VynZ Research USA. Global Personal Protective Equipment (PPE) Market Was Valued at USD 52.7 Billion in 2019 and Is Expected to Reach USD 92.5 Billion by 2025, Observing a CAGR of 8.7% during 2020–2025. Available online: https://www.globenewswire.com/news-release/2020/04/14/2015737/0/en/Global-Personal-Protective-Equipment-PPE-Market-was-Valued-at-USD-52-7-billion-in-2019-and-is-Expected-to-Reach-USD-92-5-billion-by-2025-Observing-a-CAGR-of-8-7-during-2020-2025-Vy.html (accessed on 13 September 2022).

- Fortune Business Insights. Personal Protective Equipment [PPE] Market Size|Trends, 2029. Available online: https://www.fortunebusinessinsights.com/personal-protective-equipment-ppe-market-102015 (accessed on 11 October 2022).

- Available online: https://www.alliedmarketresearch.com/north-america-protective-clothing-market-A06968 (accessed on 11 October 2022).

- Growman Research and Consulting Pvt Ltd. Medical Nonwoven Disposables Market Size to Surpass US$ 27.70 Billion by 2030—Growth Plus Reports. Available online: https://www.globenewswire.com/news-release/2022/09/26/2522543/0/en/Medical-Nonwoven-Disposables-Market-Size-to-Surpass-US-27-70-Billion-by-2030-Growth-Plus-Reports.html (accessed on 11 October 2022).

- Fact.MR. Medical Nonwoven Disposables Market Analysis By Product (Incontinence Hygiene Products, Sterile Nonwoven Products & Wound Dressing) By Material (Polypropylene, Polyethylene, Acetate, Rayon, Acrylic, Polyamides & Polyesters) By End-User & Region—Global Market Insights 2022 to 2032. Available online: https://www.factmr.com/report/medical-nonwoven-disposables-market (accessed on 11 October 2022).

- Kalil, B. A View of the North American Nonwovens Market and Material Consumption. Available online: https://www.fiberjournal.com/a-view-of-the-north-american-nonwovens-market-and-material-consumption/ (accessed on 11 October 2022).

- Allied Market Research. Hemp Clothing Market Size, Share And Trends|Forecast By 2031. Available online: https://www.alliedmarketresearch.com/hemp-clothing-market-A16939 (accessed on 11 October 2022).

- Business Wire. Global Lyocell Fiber Market (2021 to 2029)—Increased Product Demand in the Apparel Manufacturing Industry Is Driving Growth. Available online: https://www.businesswire.com/news/home/20210709005355/en/Global-Lyocell-Fiber-Market-2021-to-2029---Increased-Product-Demand-in-the-Apparel-Manufacturing-Industry-is-Driving-Growth---ResearchAndMarkets.com (accessed on 11 October 2022).

- TBRC Business Research PVT LTD. Sustainable Fashion Market Analysis Shows The Market Progress In Attempt To Decrease Pollution In The Global Ethicalfashion Market 2020. Available online: https://www.globenewswire.com/news-release/2020/10/28/2116073/0/en/Sustainable-Fashion-Market-Analysis-Shows-The-Market-Progress-In-Attempt-To-Decrease-Pollution-In-The-Global-Ethicalfashion-Market-2020.html (accessed on 11 October 2022).

- Available online: https://www.grandviewresearch.com/industry-analysis/dental-floss-market (accessed on 13 September 2022).

- Business Wire. Global Dental Floss Market to Grow by USD 1.03 Billion during 2019-2023|Technavio. Available online: https://www.businesswire.com/news/home/20190530005031/en/Global-Dental-Floss-Market-to-Grow-by-USD-1.03-Billion-during-2019-2023-Technavio (accessed on 31 October 2022).

| Staple Fibre | Water Footprint (L/kg) |

|---|---|

| Polyester | 84–143 |

| Cotton | 4342–6902 |

| Hemp (bast) | 3108 |

| MMCF | 351–520 |

| L-MMCF | 290 |

| Hemp L-MMCF | <290 (estimate) |

| Solvent Process | Advantages | Drawbacks | |

|---|---|---|---|

| Viscose MMCF (viscose rayon, cellulose acetate, modal, triacetate) | Derivitized | α-cellulose feedstock readily available. | Waste chemicals (e.g., carbon disulphide), leading to contamination of water, air, and soil, and health concerns. |

| L-MMCF | Direct Dissolution | Environmentally friendly (NMMO 99% recoverable). α-cellulose feedstock readily available. | More expensive to produce than viscose MMCF. Longer manufacturing process. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lawson, L.; Degenstein, L.M.; Bates, B.; Chute, W.; King, D.; Dolez, P.I. Cellulose Textiles from Hemp Biomass: Opportunities and Challenges. Sustainability 2022, 14, 15337. https://doi.org/10.3390/su142215337

Lawson L, Degenstein LM, Bates B, Chute W, King D, Dolez PI. Cellulose Textiles from Hemp Biomass: Opportunities and Challenges. Sustainability. 2022; 14(22):15337. https://doi.org/10.3390/su142215337

Chicago/Turabian StyleLawson, Lelia, Lauren M. Degenstein, Bronwyn Bates, Wade Chute, Dan King, and Patricia I. Dolez. 2022. "Cellulose Textiles from Hemp Biomass: Opportunities and Challenges" Sustainability 14, no. 22: 15337. https://doi.org/10.3390/su142215337

APA StyleLawson, L., Degenstein, L. M., Bates, B., Chute, W., King, D., & Dolez, P. I. (2022). Cellulose Textiles from Hemp Biomass: Opportunities and Challenges. Sustainability, 14(22), 15337. https://doi.org/10.3390/su142215337