Using Computer Vision for Monitoring the Quality of 3D-Printed Concrete Structures

Abstract

1. Introduction

2. Materials and Methods

2.1. Previous Studies

2.2. Objective

- Identifying appropriate texture-extraction algorithms.

- Defining metrics for inferring the textural feature quality of the concrete 3DP element.

- Defining thresholds or ranges of values of the metrics for decision-making related to rectification actions.

2.3. Image Textural Analysis Methods

2.4. Inferring Texture Feature Quality—A Measure of Variability

2.5. Materials Used

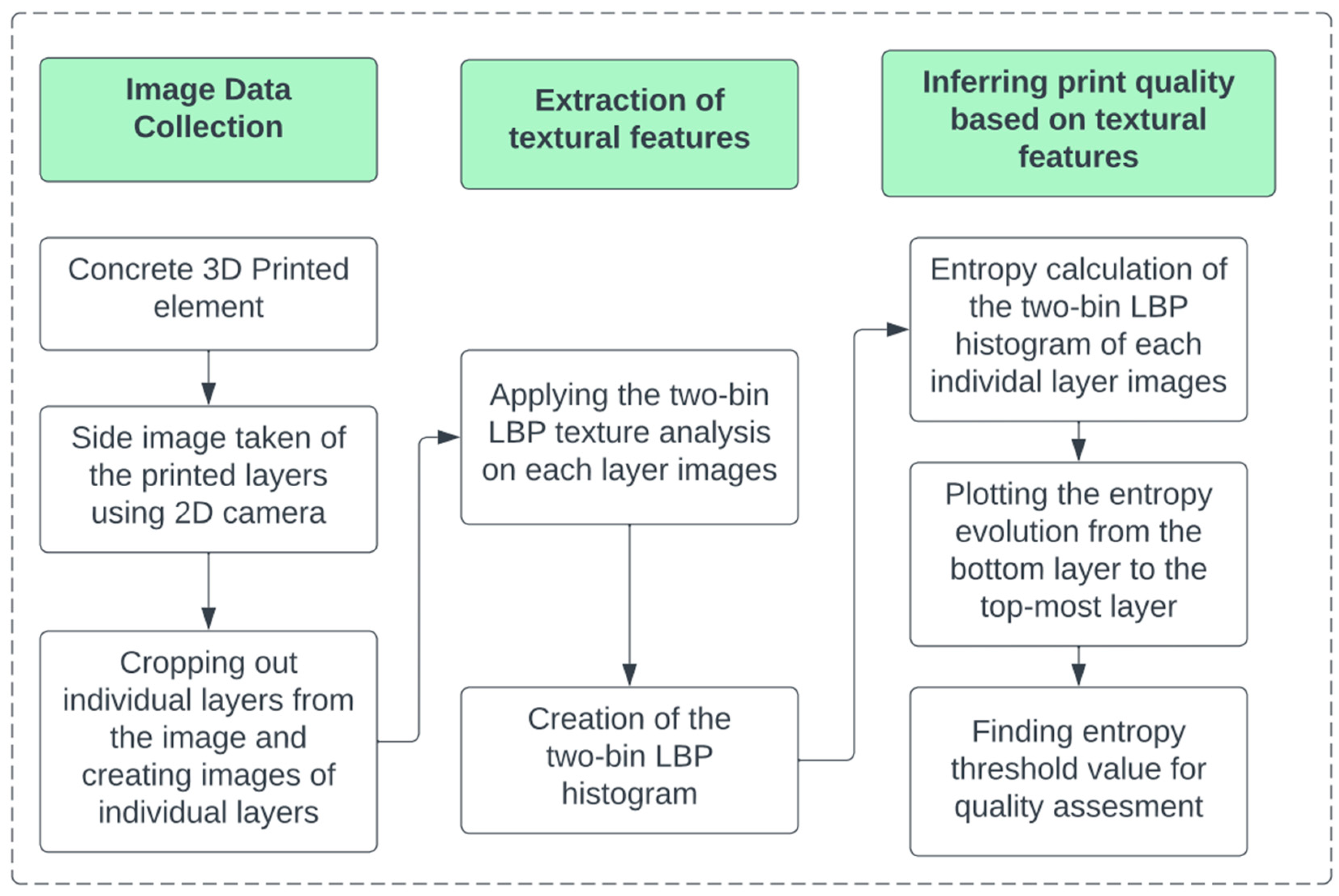

2.6. Methodology

- (1)

- Image Data Collection

- (2)

- Extraction of textural features using the two-bin LBP analysis

- (3)

- Inferring print quality based on textural features—calculation of entropy

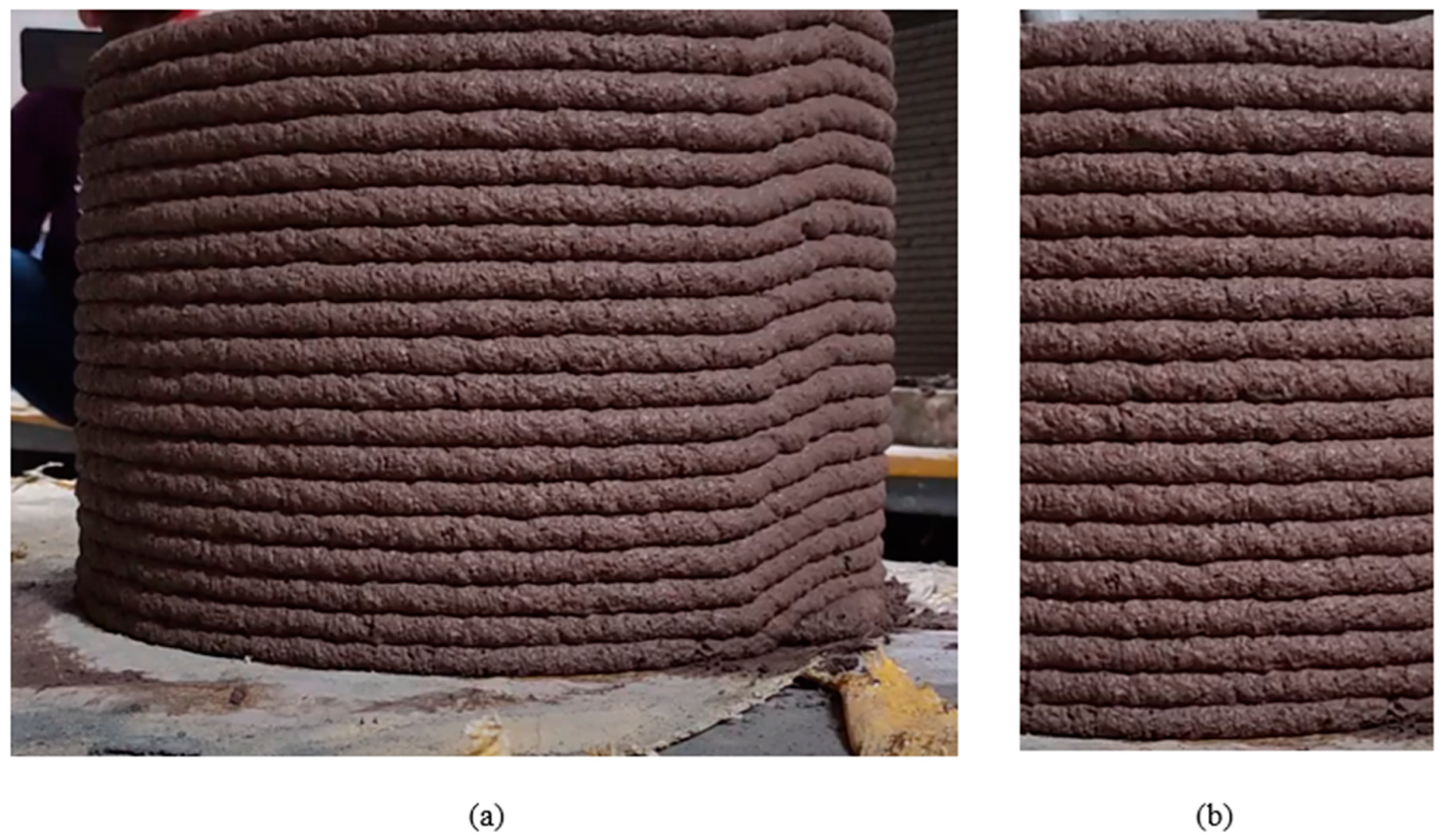

2.6.1. Image Data Collection

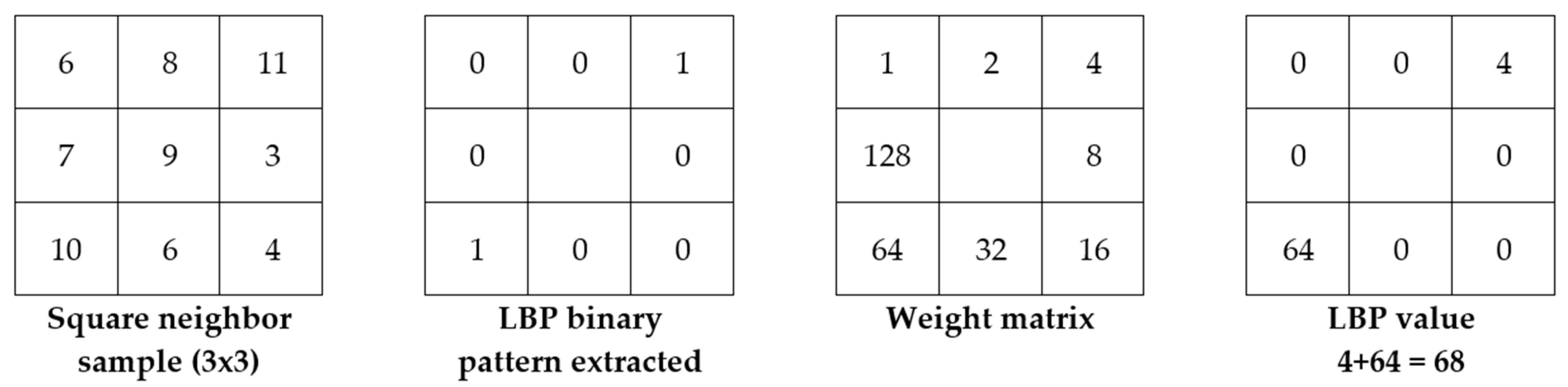

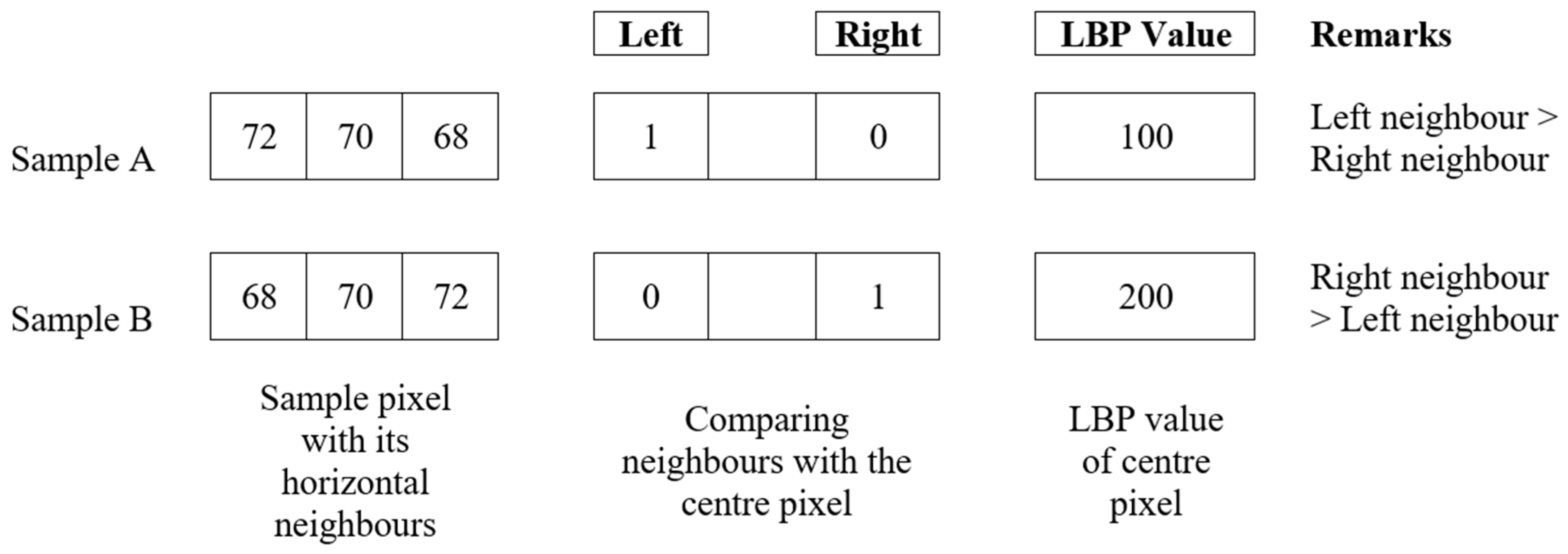

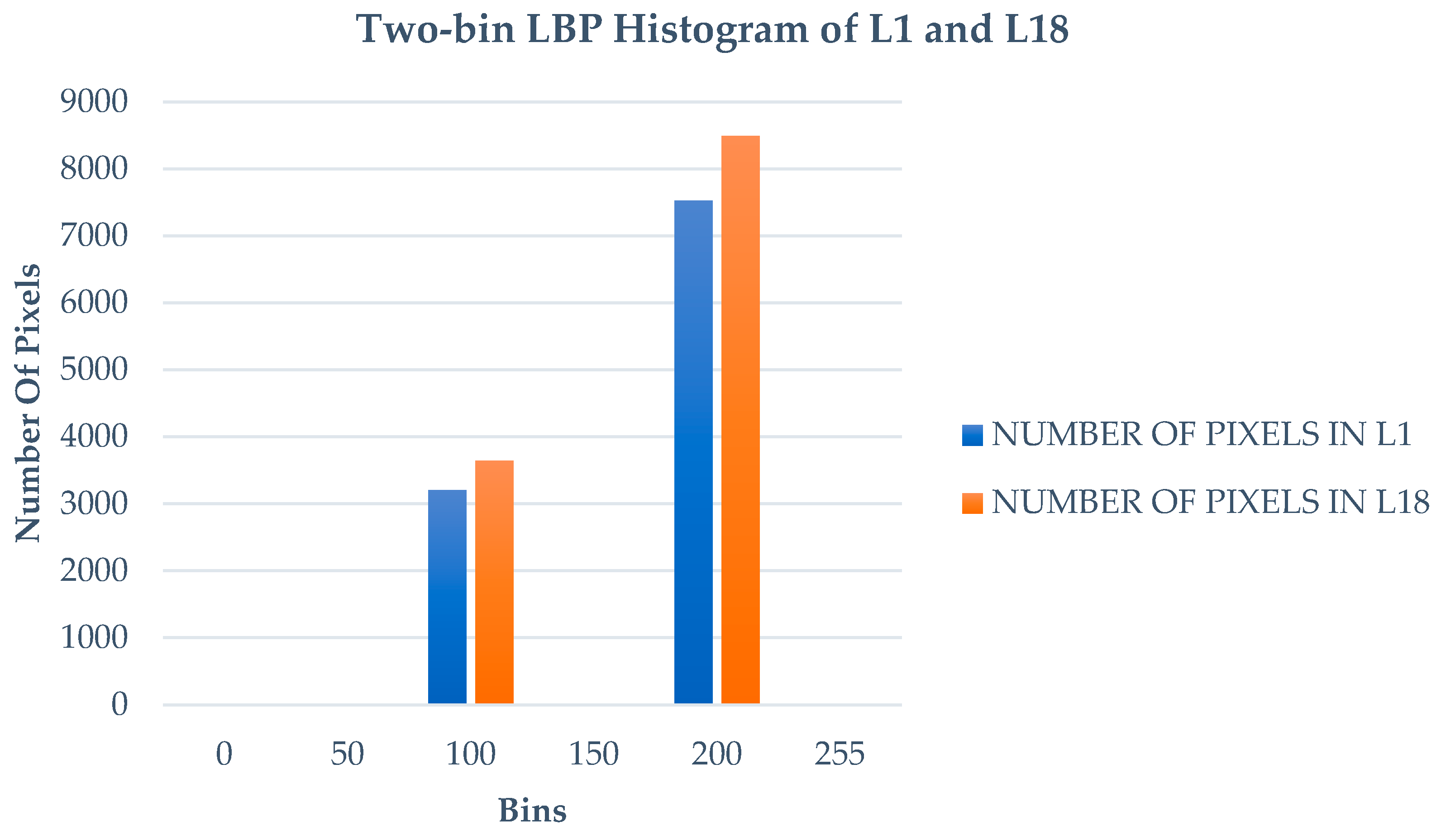

2.6.2. Extraction of Texture Feature Using Two-Bin LBP Analysis

2.6.3. Post-Processing of Two-Bin LBP Histogram to Calculate the Entropy

3. Results

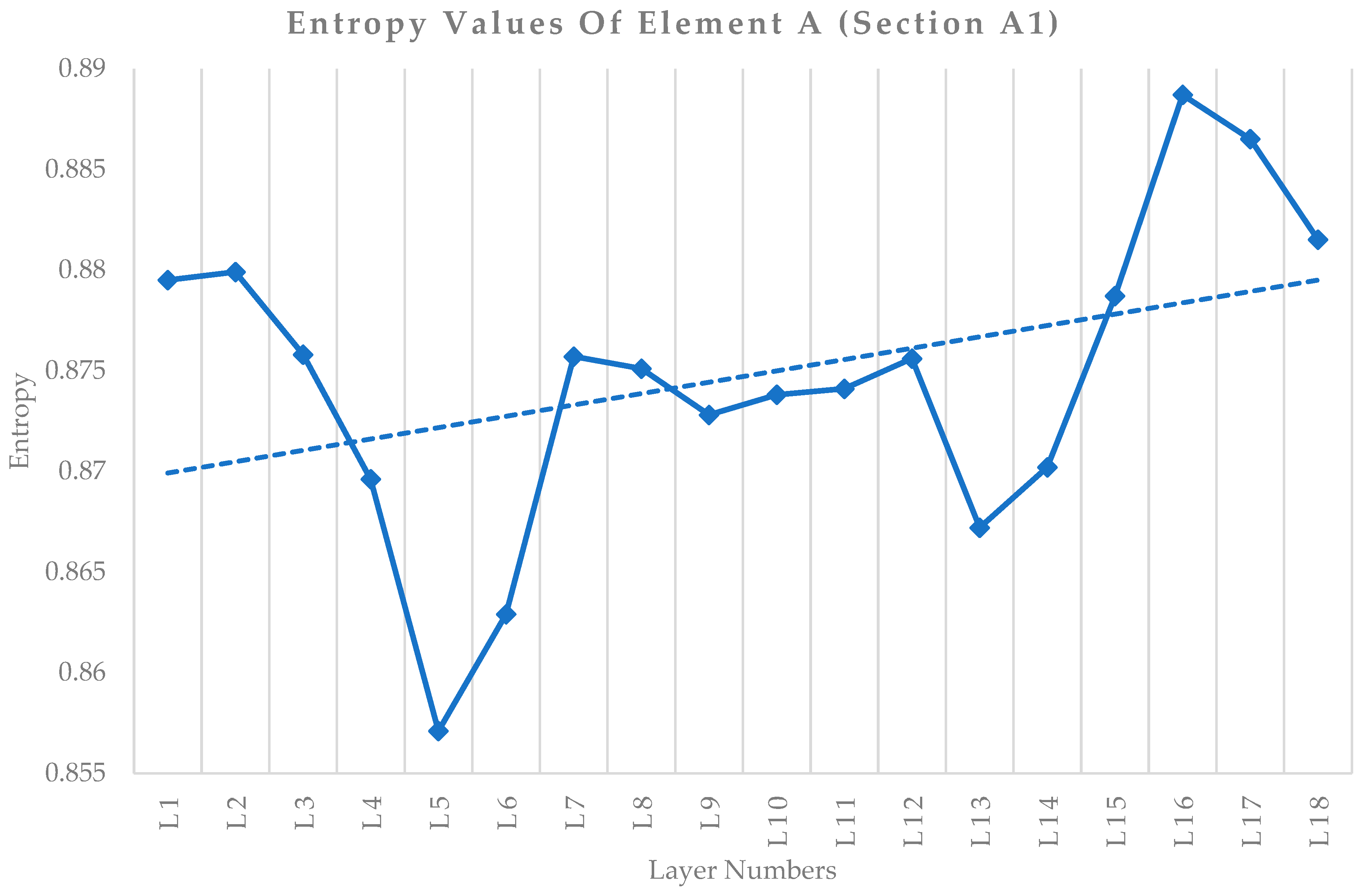

3.1. Entropy Variations in Element A

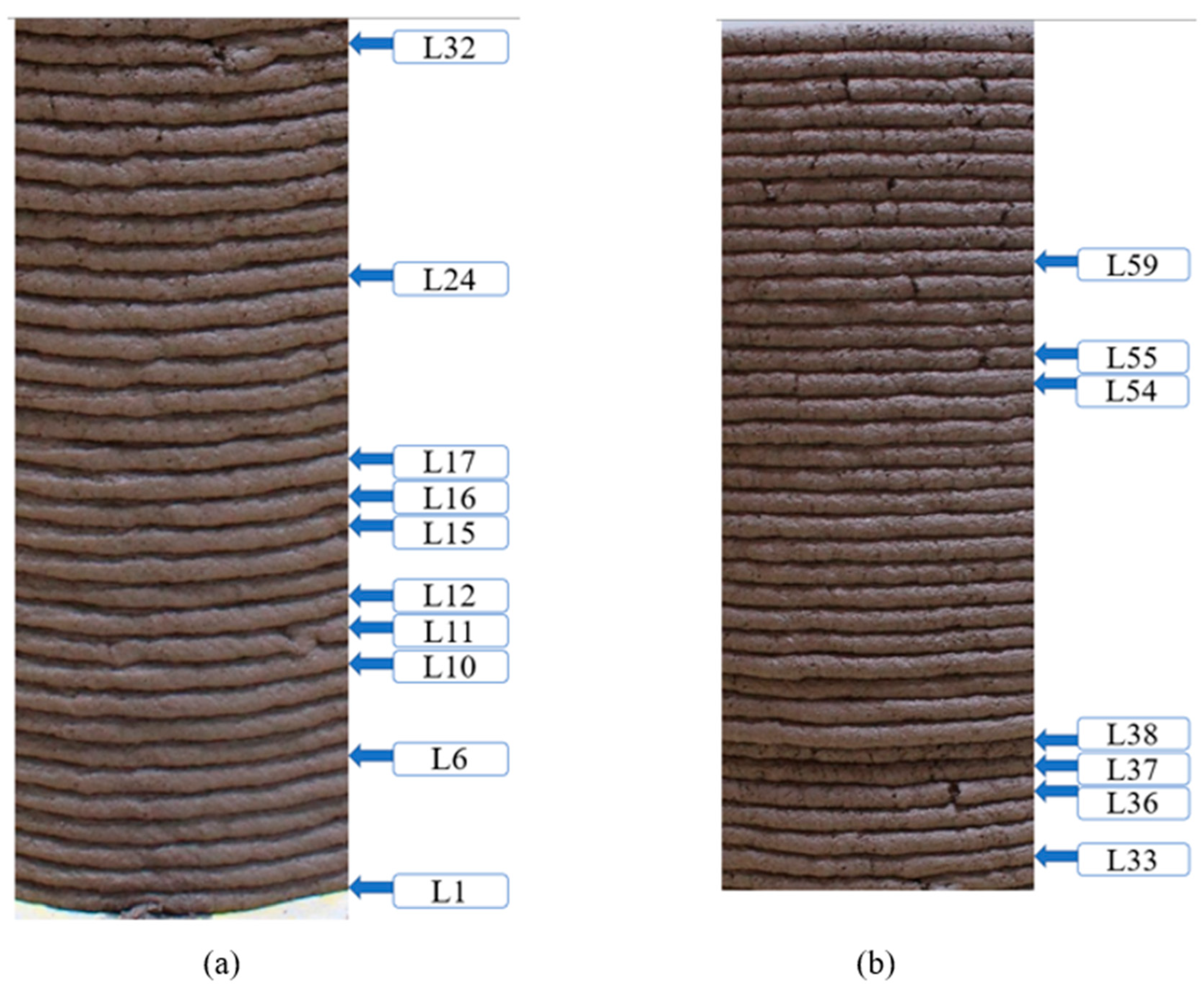

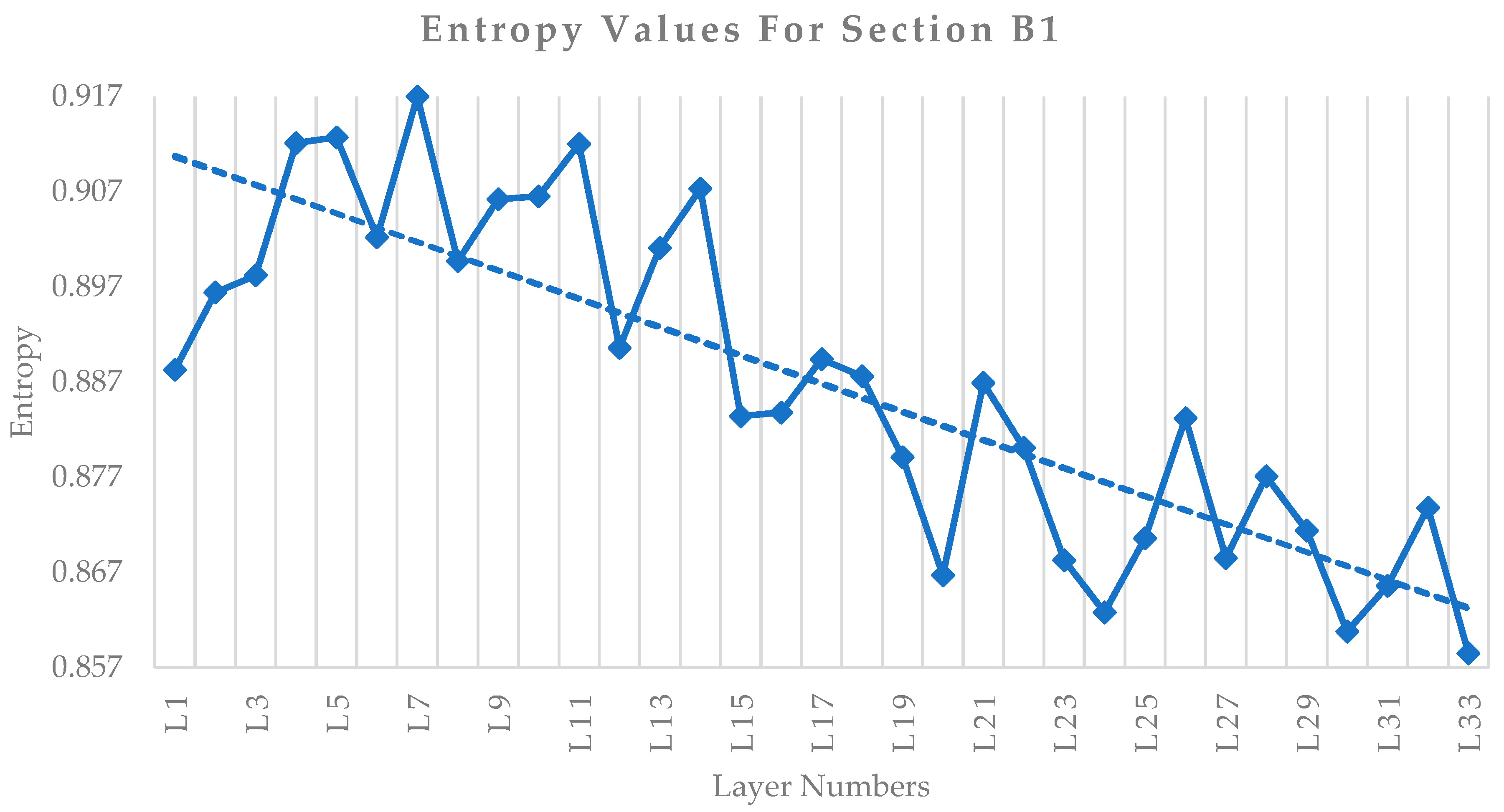

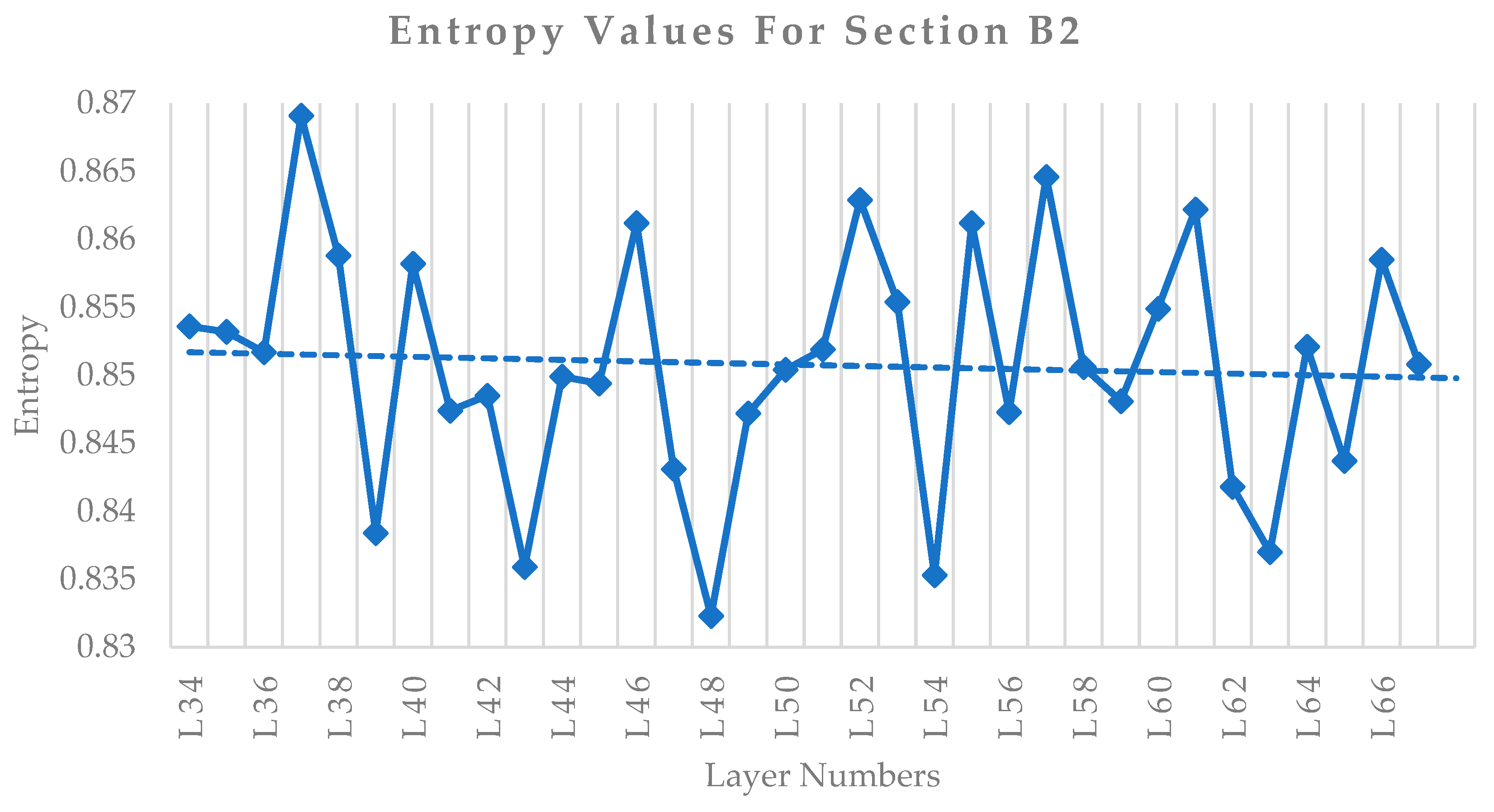

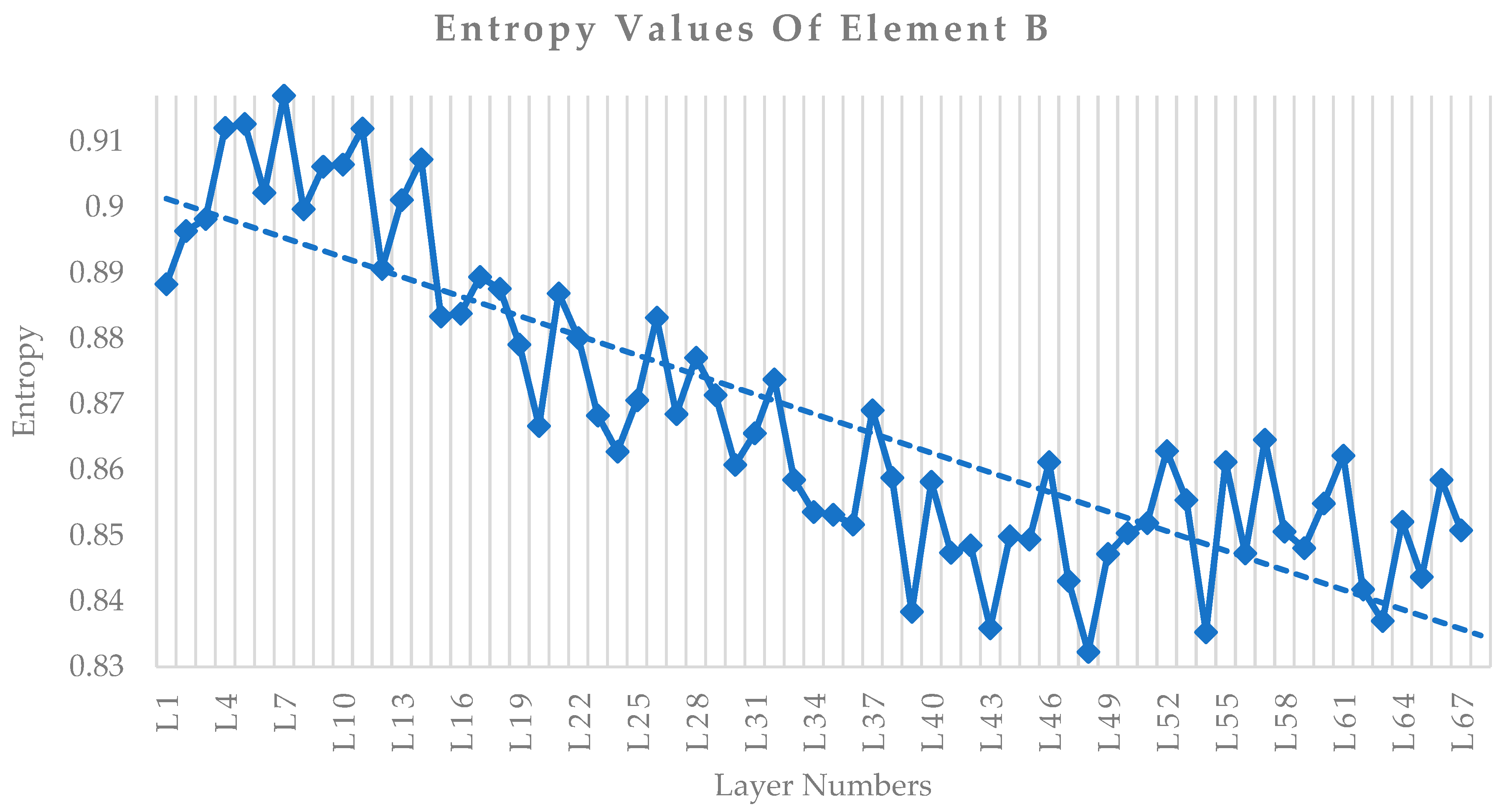

3.2. Entropy Variations in Element B

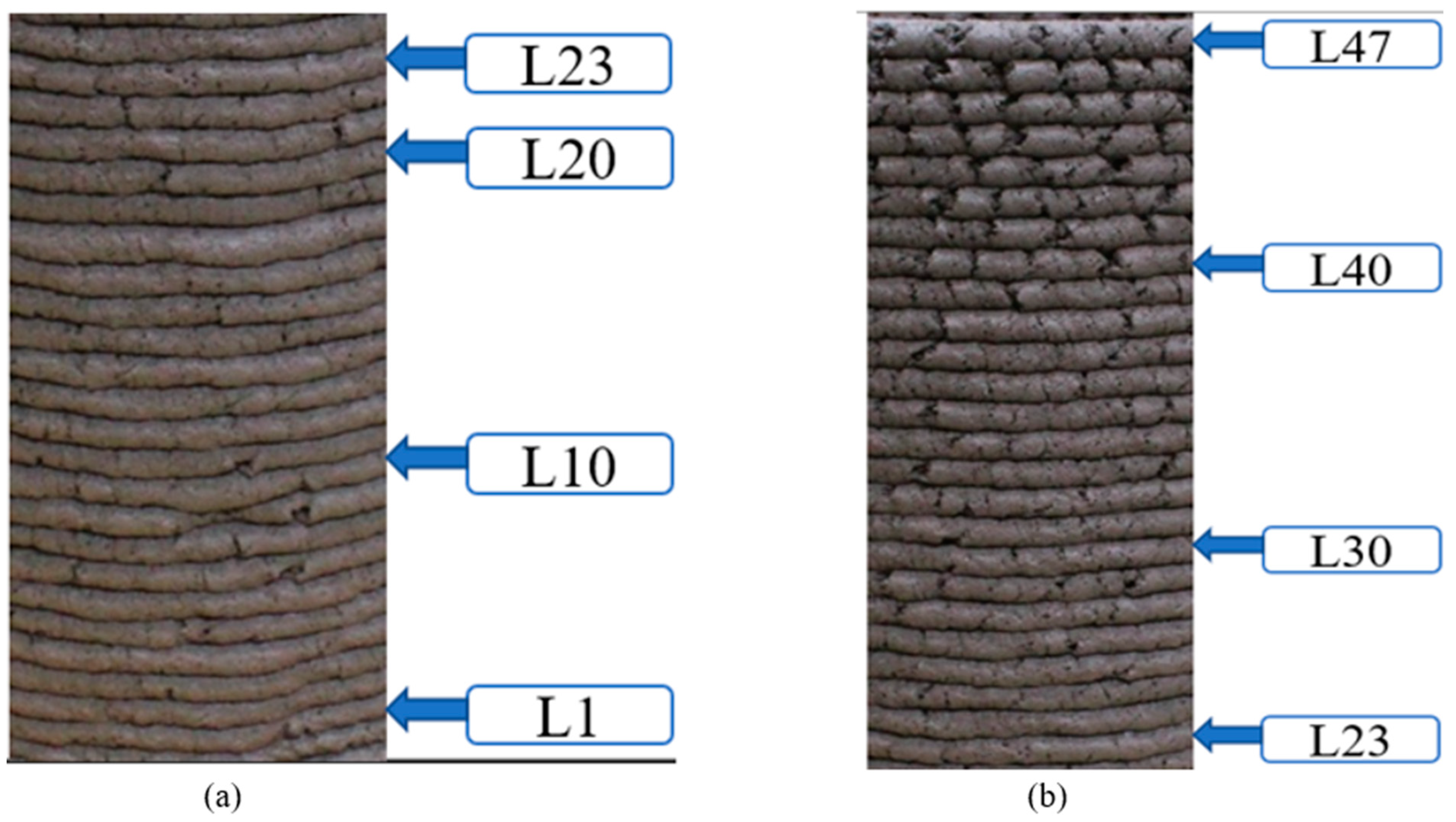

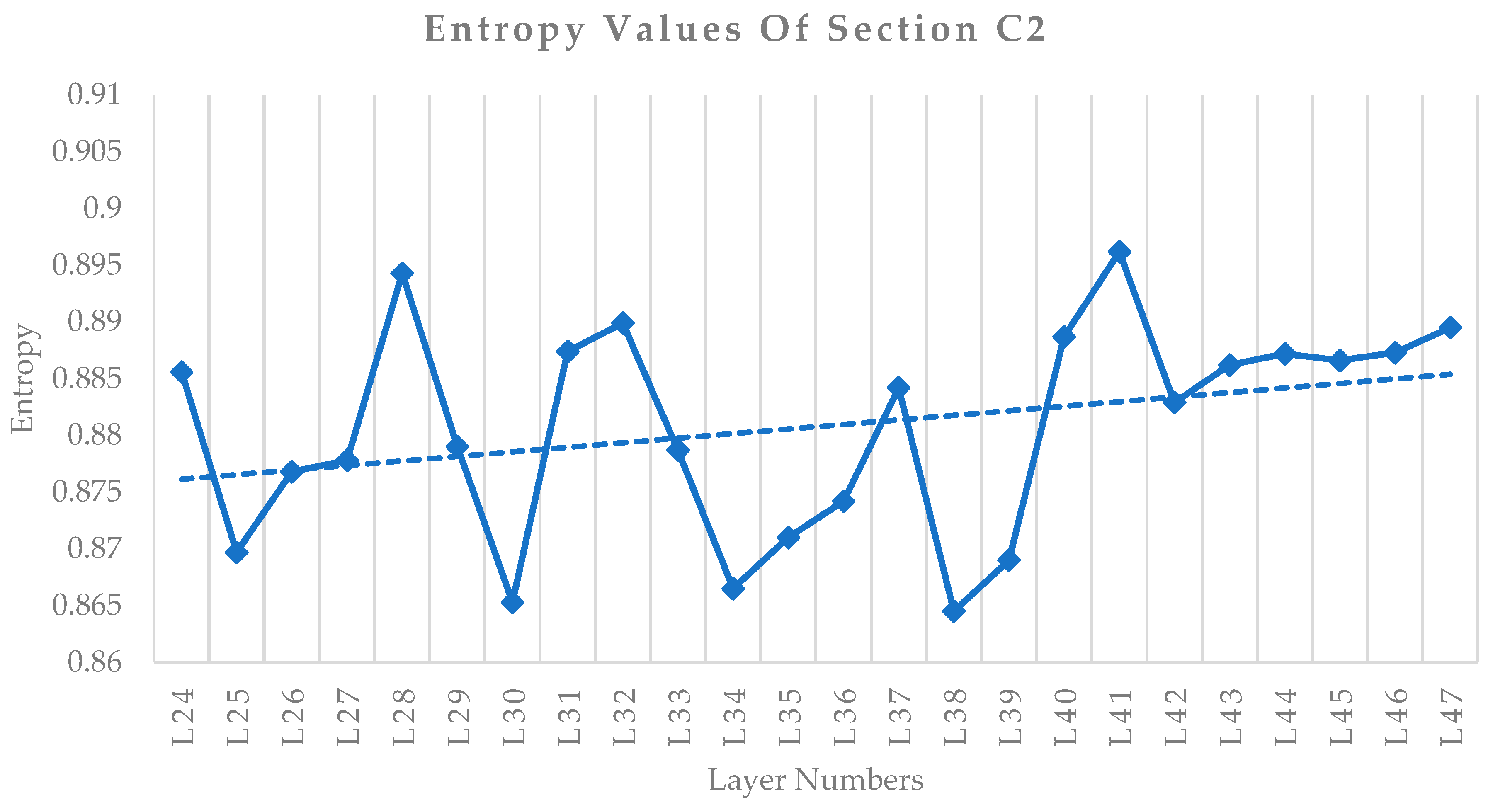

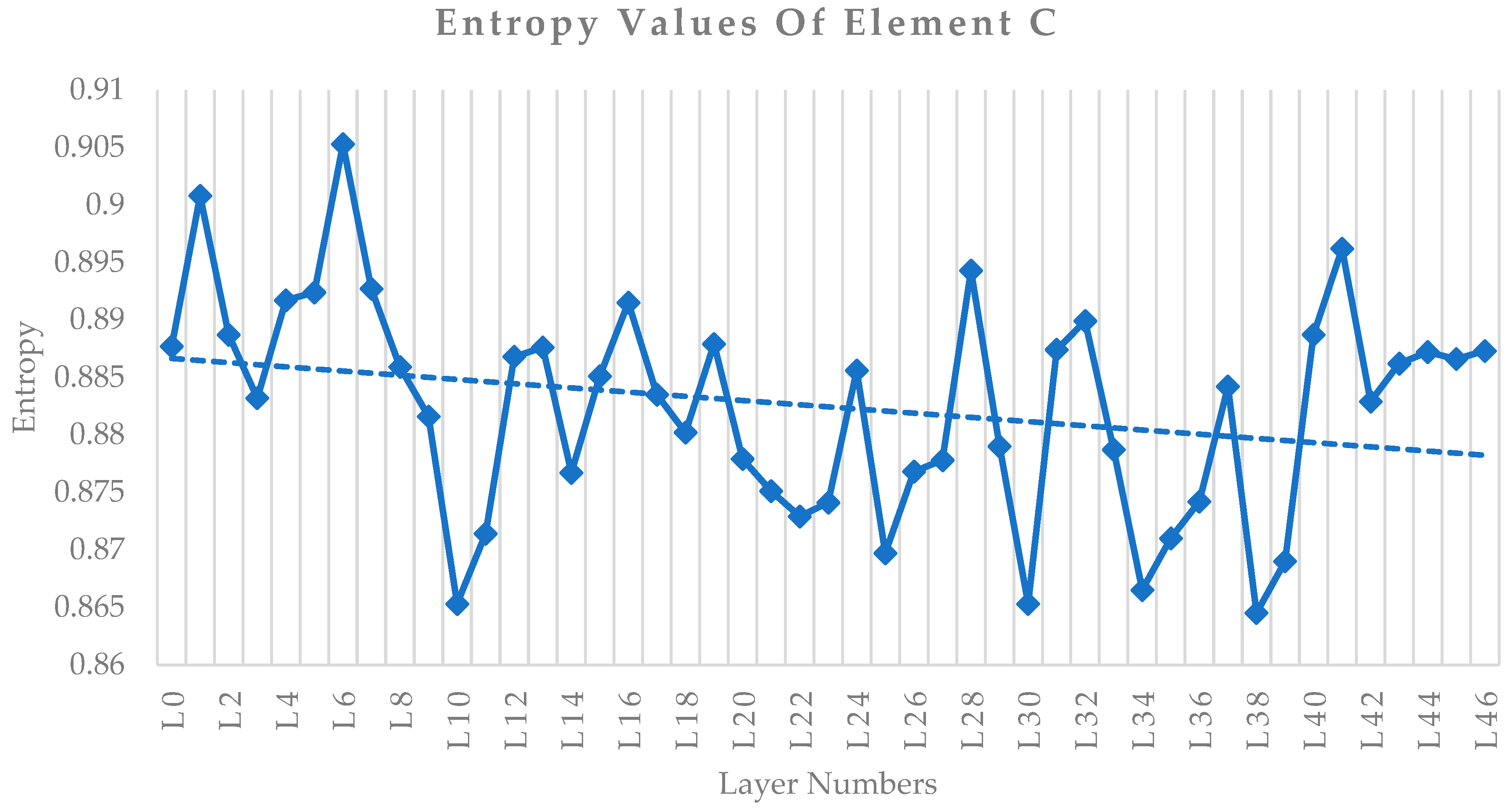

3.3. Entropy Variations in Element C

4. Discussion

4.1. Entropy Value Evolution Study

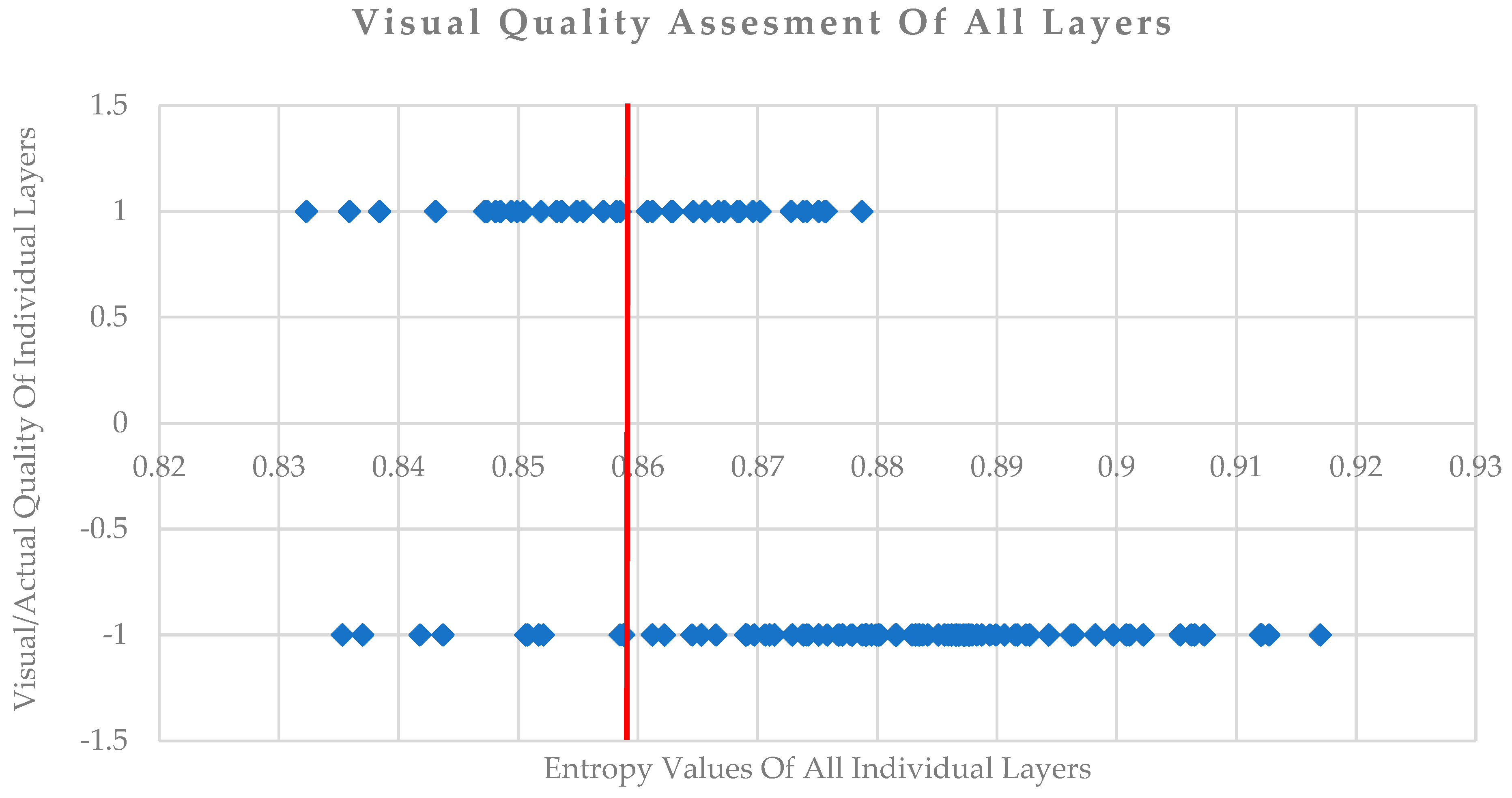

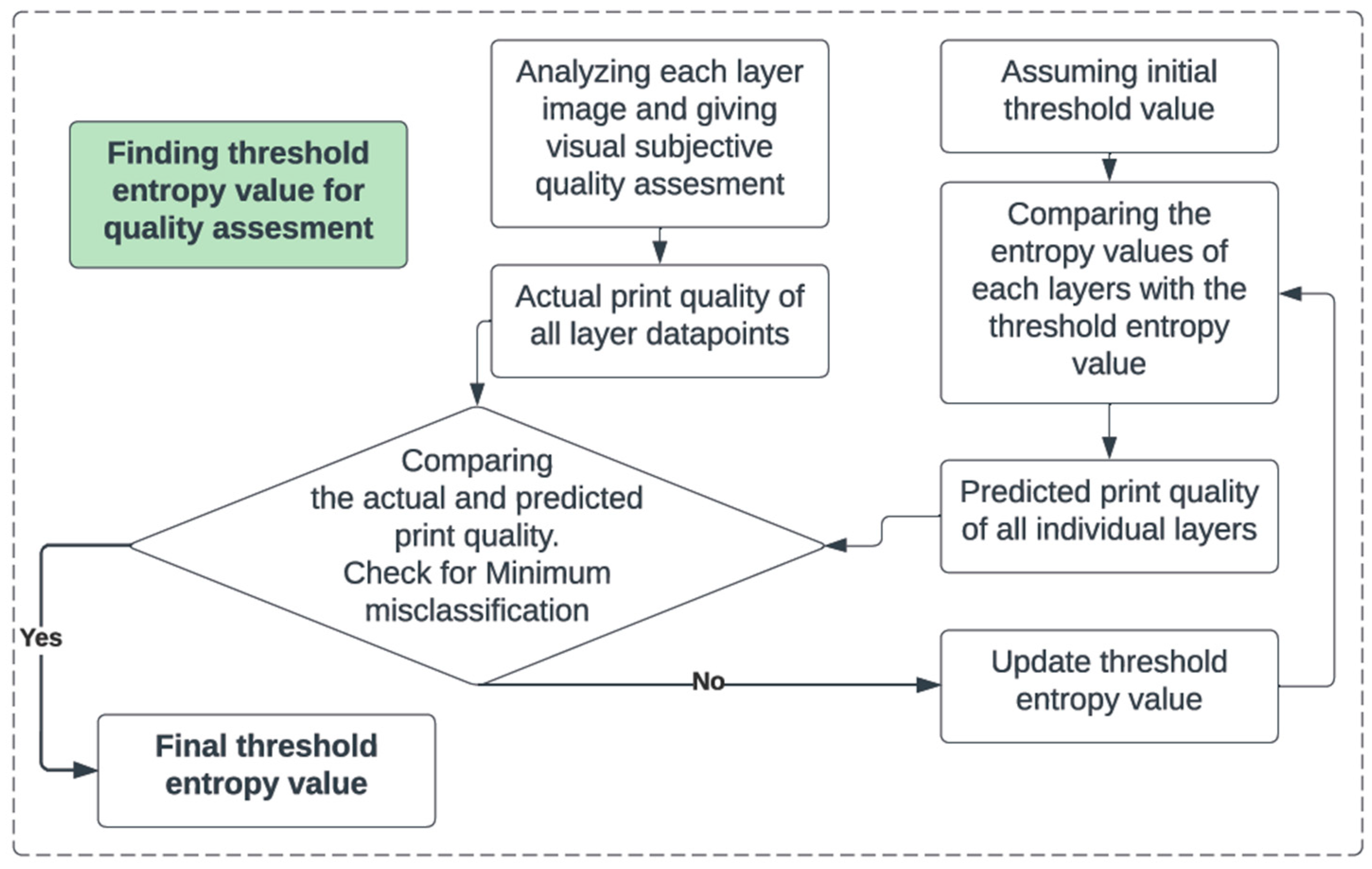

4.2. Threshold Value Calculation

5. Conclusions

- A continuous, non-intrusive measurement of buildability changes over time is achieved in this study. Workability reduction over time is indirectly quantified using vision-based techniques. The characterization of the mix is not within the scope of this study.

- LBP texture-extraction methods chosen in this study are immune to brightness or illumination changes in image pixels. Hence, this methodology can be applied to any environmental conditions without significant changes.

- The layer thickness reduction due to the weight of the top layers was captured indirectly through the entropy of the surface texture.

- The methodology is also able to detect other deformations, such as undulations of concrete layers, happening due to errors in robotic gantry movements.

- Using the error-minimization method, a threshold entropy value beyond which most printed layers have defects/deformities is identified. Higher entropy values beyond the threshold can be used to trigger corrective actions in the 3D-printing process to avoid defects or deformities.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, J.; Wang, J.; Dong, S.; Yu, X.; Han, B. A review of the current progress and application of 3D printed concrete. Compos. Part A Appl. Sci. Manuf. 2019, 125, 105533. [Google Scholar] [CrossRef]

- Tobi, A.L.M.; Omar, S.A.; Yehia, Z.; Al-Ojaili, S.; Hashim, A.; Orhan, O. Cost viability of 3D printed house in UK. IOP Conf. Ser. Mater. Sci. Eng. 2018, 319, 012061. [Google Scholar] [CrossRef]

- Vantyghem, G.; de Corte, W.; Shakour, E.; Amir, O. 3D printing of a post-tensioned concrete girder designed by topology optimization. Autom. Constr. 2020, 112, 103084. [Google Scholar] [CrossRef]

- Martens, P.; Mathot, M.; Bos, F.; Coenders, J. Optimising 3D printed concrete structures using topology optimisation, in: High Tech Concrete: Where Technology and Engineering Meet. In Proceedings of the 2017 Fib Symposium, Maastricht, The Netherlands, 12–16 June 2017; pp. 301–309. [Google Scholar] [CrossRef]

- Villacres, J.; Guaman, R.; Menendez, O. Auat Cheein, 3D Printing Deformation Estimation Using Artificial Vision Strategies for Smart-Construction. In Proceedings of the IECON (Industrial Electronics Conference), Online Conference, 13–16 October 2021. [Google Scholar] [CrossRef]

- Kazemian, A.; Yuan, X.; Davtalab, O.; Khoshnevis, B. Automation in Construction Computer vision for real-time extrusion quality monitoring and control in robotic construction. Autom. Constr. 2019, 101, 92–98. [Google Scholar] [CrossRef]

- Buswell, R.; Kinnell, P.; Xu, J.; Hack, N.; Kloft, H.; Maboudi, M.; Gerke, M.; Massin, P.; Grasser, G.; Wolfs, R.; et al. Inspection Methods for 3D Concrete Printing. In RILEM Bookseries; Springer: Berlin/Heidelberg, Germany, 2020; Volume 28, pp. 790–803. [Google Scholar] [CrossRef]

- Lim, S.; Buswell, R.A.; Valentine, P.J.; Piker, D.; Austin, S.A.; de Kestelier, X. Modelling curved-layered printing paths for fabricating large-scale construction components. Addit. Manuf. 2016, 12, 216–230. [Google Scholar] [CrossRef]

- Panda, B.; Lim, J.H.; Tan, M.J. Mechanical properties and deformation behaviour of early age concrete in the context of digital construction. Compos. B Eng. 2019, 165, 563–571. [Google Scholar] [CrossRef]

- Le, T.T.; Austin, S.A.; Lim, S.; Buswell, R.A.; Gibb, A.G.F.; Thorpe, T. Mix design and fresh properties for high-performance printing concrete. Mater. Struct. Mater. Constr. 2012, 45, 1221–1232. [Google Scholar] [CrossRef]

- Panda, B.; Lim, J.H.; Mohamed, N.A.N.; Paul, S.C.; Tay, Y.W.D.; Tan, M.J. Automation of robotic concrete printing using feedback control system. In Proceedings of the ISARC 2017—Proceedings of the 34th International Symposium on Automation and Robotics in Construction, Taipei, Taiwan, 28 June–1 July 2017; pp. 276–280. [Google Scholar] [CrossRef]

- Goh, G.D.; Sing, S.L.; Yeong, W.Y. A Review on Machine Learning in 3D Printing: Applications, Potential, and Challenges; Springer: Dordrecht, The Netherlands, 2021. [Google Scholar] [CrossRef]

- Nair, A.; Aditya, S.D.; Adarsh, R.N.; Nandan, M.; Dharek, M.S.; Sreedhara, B.M.; Prashant, S.C.; Sreekeshava, K.S. Additive Manufacturing of Concrete: Challenges and opportunities. IOP Conf. Ser. Mater. Sci. Eng. 2020, 814, 012022. [Google Scholar] [CrossRef]

- Jolin, M.; Burns, D.; Bissonnette, B.; Gagnon, F.; Bolduc, L.-S. Understanding the pumpability of concrete. In Proceedings of the Shotcrete for Underground Support XI Engineering Conferences International, Davos, Switzerland, 7–10 June 2009; pp. 193–207. [Google Scholar]

- Tay, Y.W.D.; Qian, Y.; Tan, M.J. Printability region for 3D concrete printing using slump and slump flow test. Compos. B Eng. 2019, 174, 106968. [Google Scholar] [CrossRef]

- Bos, F.; Wolfs, R.; Ahmed, Z.; Salet, T. Additive manufacturing of concrete in construction: Potentials and challenges of 3D concrete printing. Virtual Phys. Prototyp. 2016, 11, 209–225. [Google Scholar] [CrossRef]

- Reiter, L.; Wangler, T.; Roussel, N.; Flatt, R.J. The role of early age structural build-up in digital fabrication with concrete. Cem. Concr. Res. 2018, 112, 86–95. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, Y.; She, W.; Yang, L.; Liu, G.; Yang, Y. Rheological and harden properties of the high-thixotropy 3D printing concrete. Constr. Build Mater. 2019, 201, 278–285. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, Y.; Liu, G.; Yang, Y.; Wu, M.; Pang, B. Fresh properties of a novel 3D printing concrete ink. Constr. Build. Mater. 2018, 174, 263–271. [Google Scholar] [CrossRef]

- Roussel, N. Rheological requirements for printable concretes. Cem. Concr. Res. 2018, 112, 76–85. [Google Scholar] [CrossRef]

- Rahul, A.V.; Santhanam, M.; Meena, H.; Ghani, Z. 3D printable concrete: Mixture design and test methods. Cem. Concr. Compos. 2019, 97, 13–23. [Google Scholar] [CrossRef]

- Jayathilakage, R.; Sanjayan, J.; Rajeev, P. Direct shear test for the assessment of rheological parameters of concrete for 3D printing applications. Mater. Struct. /Mater. Constr. 2019, 52, 1–13. [Google Scholar] [CrossRef]

- Malaeb, Z.; Hachem, H.; Tourbah, A.; Maalouf, T.; el Zarwi, N.; Hamzeh, F. 3D Concrete Printing: Machine and Mix Design. Int. J. Civ. Eng. Technol. 2015, 6, 14–22. [Google Scholar]

- Ma, G.; Li, Z.; Wang, L. Printable properties of cementitious material containing copper tailings for extrusion based 3D printing. Constr. Build Mater. 2018, 162, 613–627. [Google Scholar] [CrossRef]

- Moeini, M.A.; Hosseinpoor, M.; Yahia, A. Effectiveness of the rheometric methods to evaluate the build-up of cementitious mortars used for 3D printing. Constr. Build Mater. 2020, 257, 119551. [Google Scholar] [CrossRef]

- Mazhoud, B.; Perrot, A.; Picandet, V.; Rangeard, D.; Courteille, E. Underwater 3D printing of cement-based mortar. Constr. Build Mater. 2019, 214, 458–467. [Google Scholar] [CrossRef]

- Ahmed, S.; Yehia, S. Evaluation of Workability and Structuration Rate of Locally Developed 3D Printing Concrete Using Conventional Methods. Materials 2022, 15, 1243. [Google Scholar] [CrossRef]

- Izadgoshasb, H.; Kandiri, A.; Shakor, P.; Laghi, V.; Gasparini, G. Predicting compressive strength of 3D printed mortar in structural members using machine learning. Appl. Sci. 2021, 11, 10826. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, P.; Gao, R.X. Deep learning-based tensile strength prediction in fused deposition modeling. Comput. Ind. 2019, 107, 11–21. [Google Scholar] [CrossRef]

- Lao, W.; Li, M.; Tjahjowidodo, T. Variable-geometry nozzle for surface quality enhancement in 3D concrete printing. Addit. Manuf. 2021, 37, 101638. [Google Scholar] [CrossRef]

- Ashrafi, N.; Duarte, J.P.; Nazarian, S.; Meisel, N.A. Evaluating the relationship between deposition and layer quality in large-scale additive manufacturing of concrete. Virtual Phys. Prototyp. 2019, 14, 135–140. [Google Scholar] [CrossRef]

- Davtalab, O.; Kazemian, A.; Yuan, X. Khoshnevis, Automated inspection in robotic additive manufacturing using deep learning for layer deformation detection. J. Intell. Manuf. 2020, 33, 771–784. [Google Scholar] [CrossRef]

- Jin, Z.; Zhang, Z.; Gu, G.X. Autonomous in-situ correction of fused deposition modeling printers using computer vision and deep learning. Manuf. Lett. 2019, 22, 11–15. [Google Scholar] [CrossRef]

- Bisheh, M.N.; Chang, S.I.; Lei, S. A layer-by-layer quality monitoring framework for 3D printing. Comput. Ind. Eng. 2021, 157, 107314. [Google Scholar] [CrossRef]

- Wu, D.; Wei, Y.; Terpenny, J. Predictive modelling of surface roughness in fused deposition modelling using data fusion. Int. J. Prod. Res. 2019, 57, 3992–4006. [Google Scholar] [CrossRef]

- Zhang, Z.; Fidan, I. Failure detection of fused filament fabrication via deep learning. In Proceedings of the Solid Freeform Fabrication 2019: Proceedings of the 30th Annual International Solid Freeform Fabrication Symposium—An Additive Manufacturing Conference, SFF, Austin, TX, USA, 12–14 August 2019; pp. 2156–2164. [Google Scholar]

- Nasiri, S.; Khosravani, M.R. Machine learning in predicting mechanical behavior of additively manufactured parts. J. Mater. Res. Technol. 2021, 14, 1137–1153. [Google Scholar] [CrossRef]

- Oleff, A.; Küster, B.; Stonis, M.; Overmeyer, L. Process monitoring for material extrusion additive manufacturing: A state-of-the-art review. Prog. Addit. Manuf. 2021, 6, 705–730. [Google Scholar] [CrossRef]

- Armi, L.; Fekri-Ershad, S. Texture image analysis and texture classification methods—A review. Texture Image Anal. 2019, 2, 1–29. [Google Scholar]

- Tuceryan, M.; Jain, A.K. Chapter 2.1 texture analysis. In Handbook of Pattern Recognition and Computer Vision; World Scientific: Singapore, 1993; pp. 235–276. [Google Scholar]

- Huang, D.; Shan, C.; Ardabilian, M.; Wang, Y.; Chen, L. Local binary patterns and its application to facial image analysis: A survey, IEEE Transactions on Systems. Man. Cybern. Part C Appl. Rev. 2011, 41, 765–781. [Google Scholar] [CrossRef]

- Arsho, Local Binary Patterns implementation using Python 3. 2017. Available online: https://github.com/arsho/local_binary_patterns (accessed on 13 October 2022).

- Chen, B.; Wang, J.; Zhao, H.; Principe, J.C. Insights into entropy as a measure of multivariate variability. Entropy 2016, 18, 196. [Google Scholar] [CrossRef]

- Gandrillon, O.; Gaillard, M.; Espinasse, T.; Garnier, N.B.; Dussiau, C.; Kosmider, O.; Sujobert, P. Entropy as a measure of variability and stemness in single-cell transcriptomics. Curr. Opin. Syst. Biol. 2021, 27, 100348. [Google Scholar] [CrossRef]

- Fastowicz, J.; Grudziński, M.; Tecław, M.; Okarma, K. Objective 3D printed surface quality assessment based on entropy of depth maps. Entropy 2019, 21, 97. [Google Scholar] [CrossRef]

- Okarma, K.; Fastowicz, J. Improved quality assessment of colour surfaces for additive manufacturing based on image entropy. Pattern Anal. Appl. 2020, 23, 1035–1047. [Google Scholar] [CrossRef]

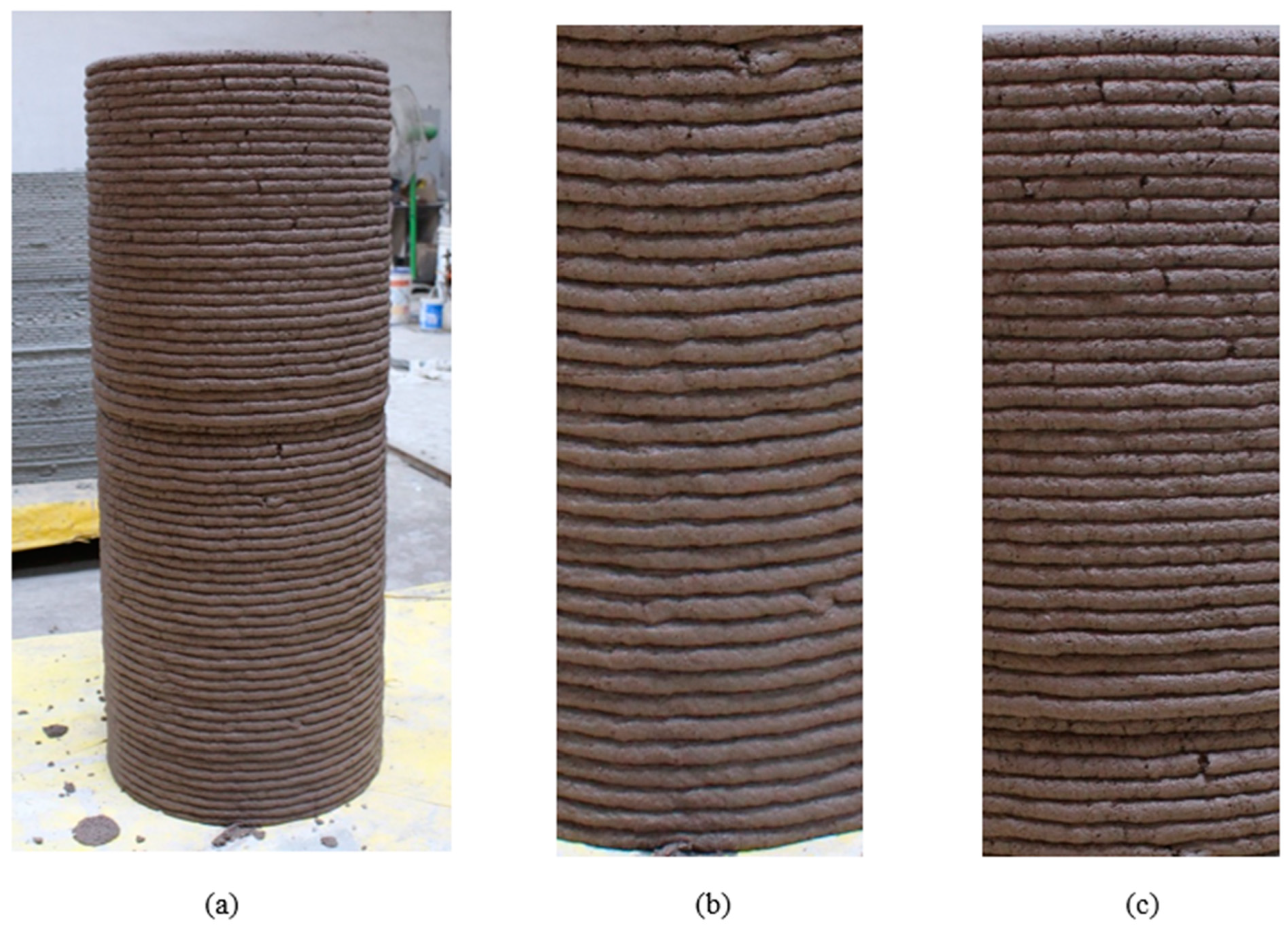

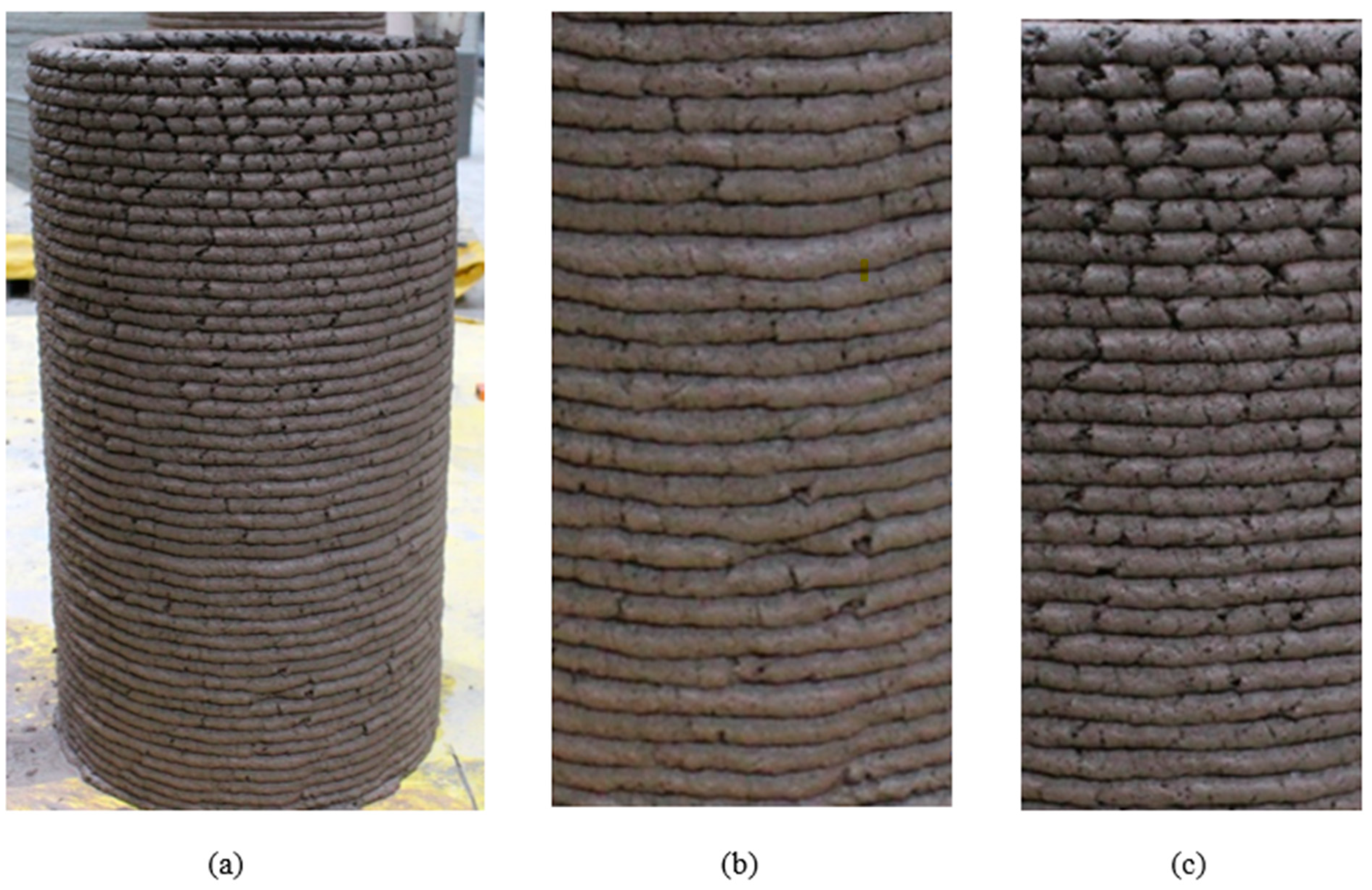

| Sl. No. | Element No. | Concrete 3D-Printed Element | Section under Analysis | Figure No. | Section No. Designation |

|---|---|---|---|---|---|

| 1 | Element A | 300 mm high circular column | Entire length | Figure 4b | Section A1 |

| 2 | Element B | 1000 mm high circular column | Top portion | Figure 5b | Section B1 |

| 3 | Element B | 1000 mm high circular column | Bottom portion | Figure 5c | Section B2 |

| 4 | Element C | 700 mm high circular column | Top portion | Figure 6b | Section C1 |

| 5 | Element C | 700 mm high circular column | Bottom portion | Figure 6c | Section C2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Senthilnathan, S.; Raphael, B. Using Computer Vision for Monitoring the Quality of 3D-Printed Concrete Structures. Sustainability 2022, 14, 15682. https://doi.org/10.3390/su142315682

Senthilnathan S, Raphael B. Using Computer Vision for Monitoring the Quality of 3D-Printed Concrete Structures. Sustainability. 2022; 14(23):15682. https://doi.org/10.3390/su142315682

Chicago/Turabian StyleSenthilnathan, Shanmugaraj, and Benny Raphael. 2022. "Using Computer Vision for Monitoring the Quality of 3D-Printed Concrete Structures" Sustainability 14, no. 23: 15682. https://doi.org/10.3390/su142315682

APA StyleSenthilnathan, S., & Raphael, B. (2022). Using Computer Vision for Monitoring the Quality of 3D-Printed Concrete Structures. Sustainability, 14(23), 15682. https://doi.org/10.3390/su142315682