Classification of Corrosion Severity in Concrete Structures Using Ultrasonic Imaging and Linear Discriminant Analysis

Abstract

1. Introduction

2. Research Methodology

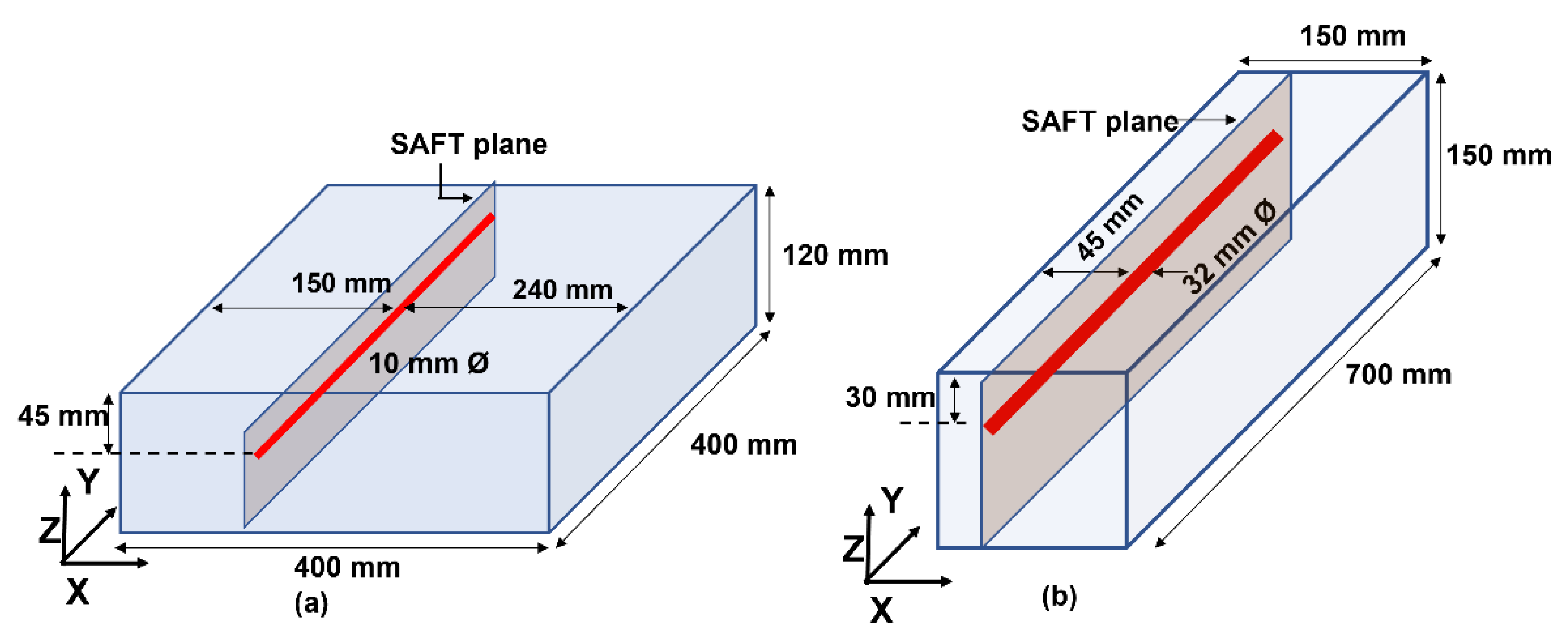

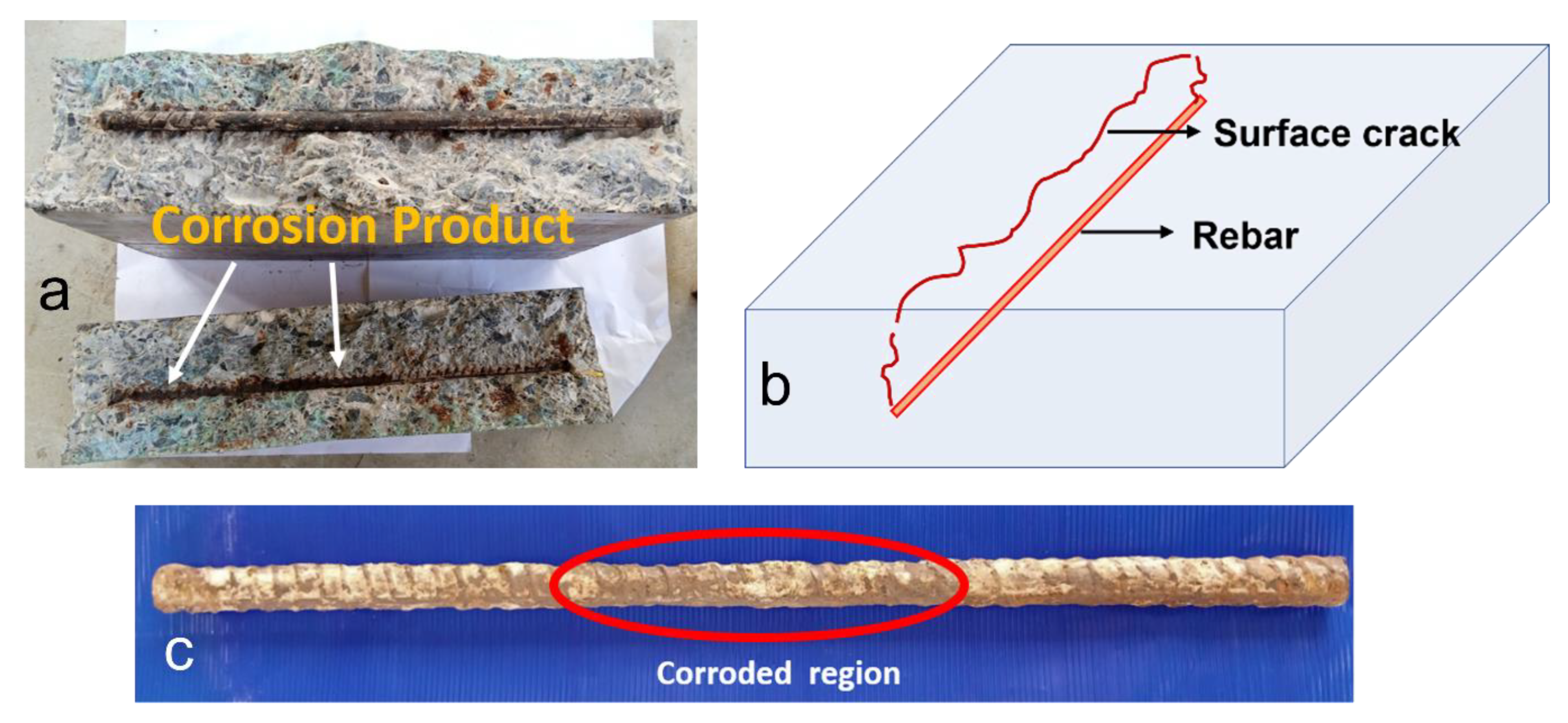

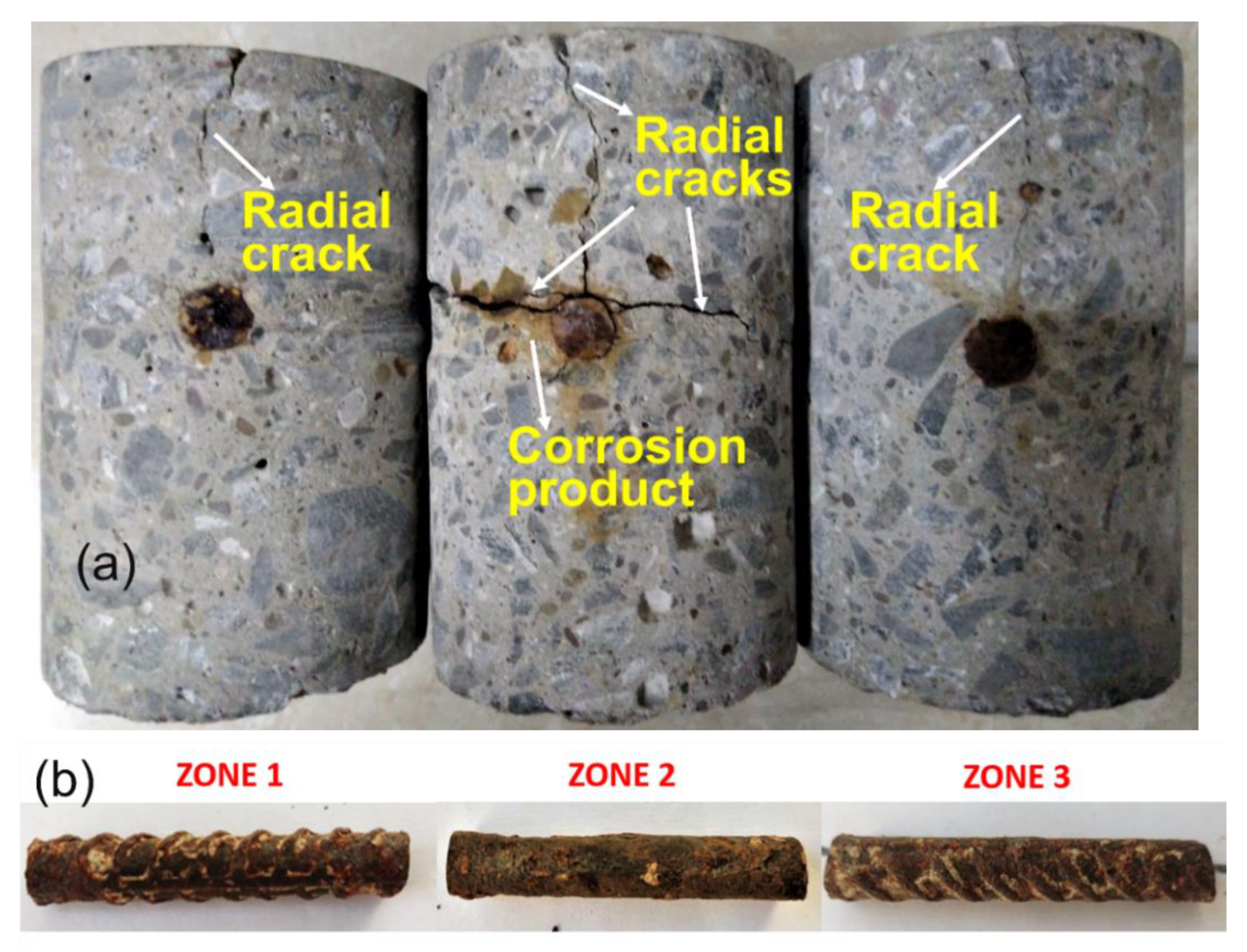

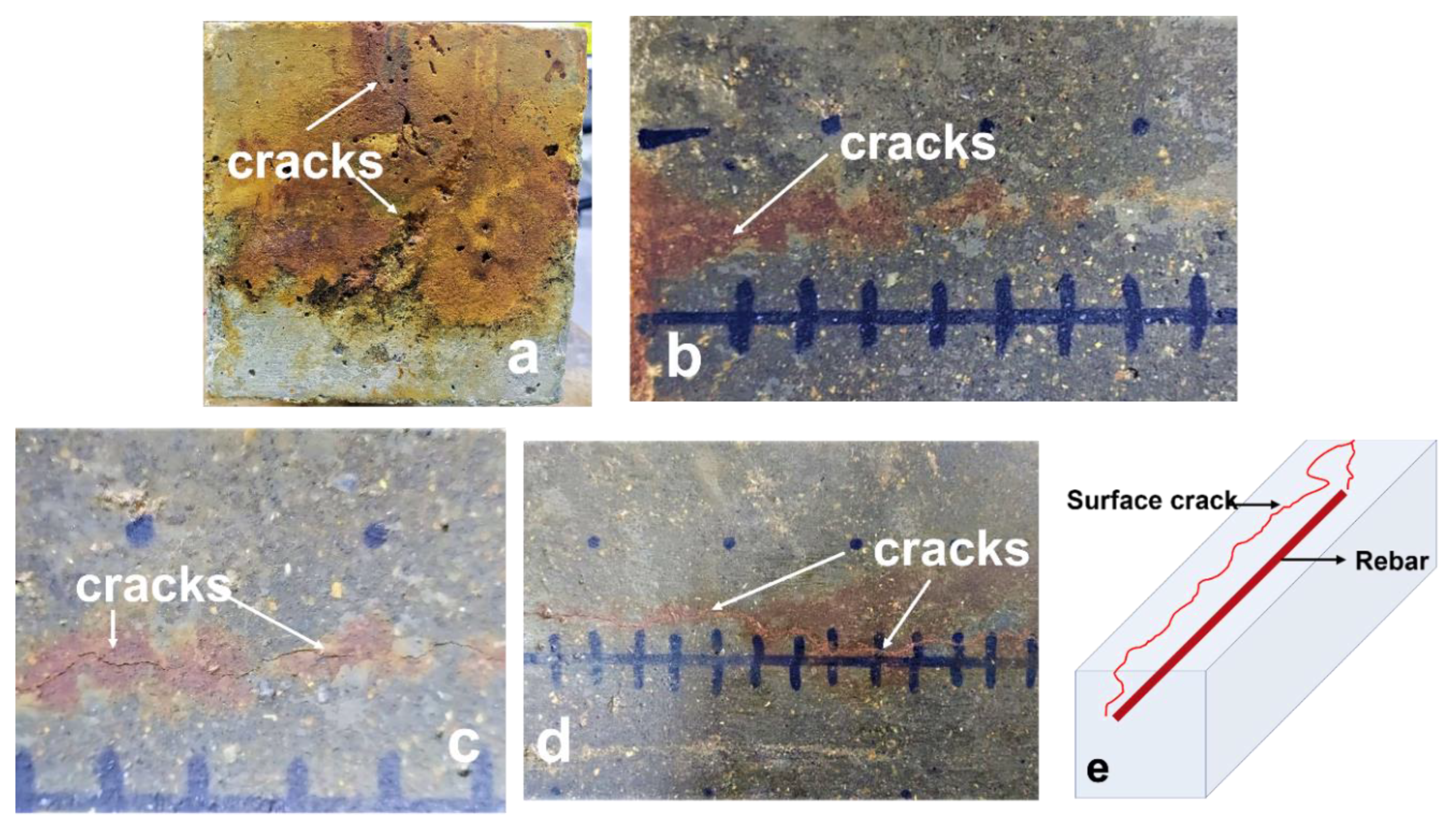

2.1. Specimen Details

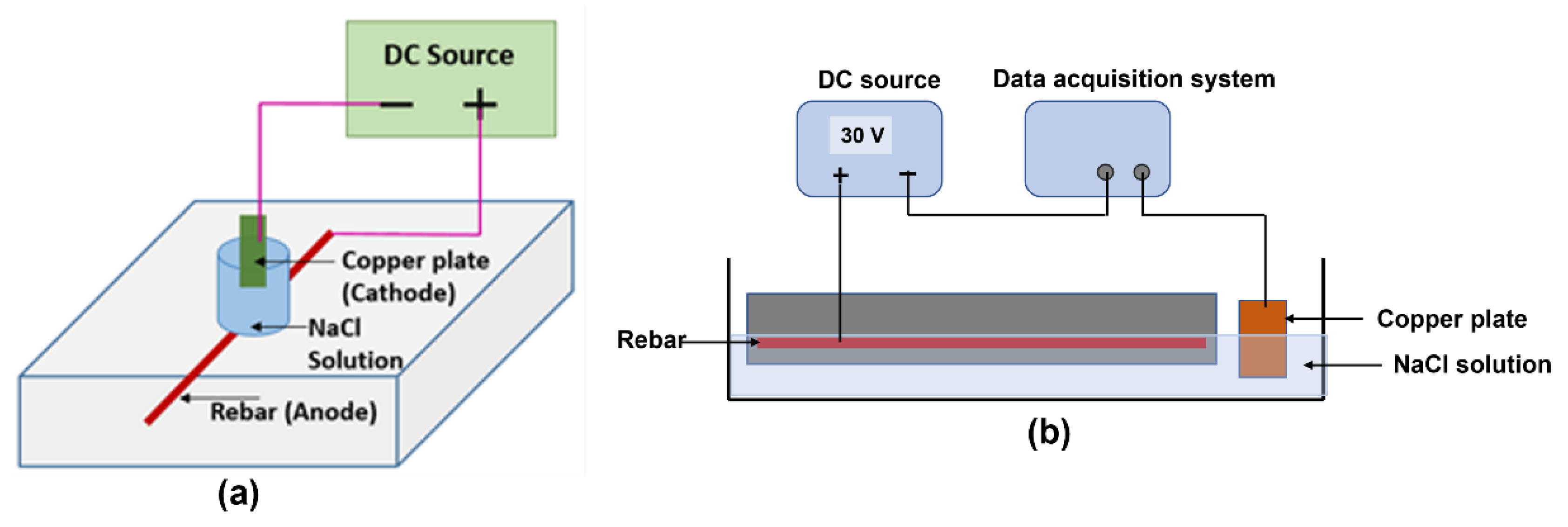

2.2. Accelerated Corrosion Setup

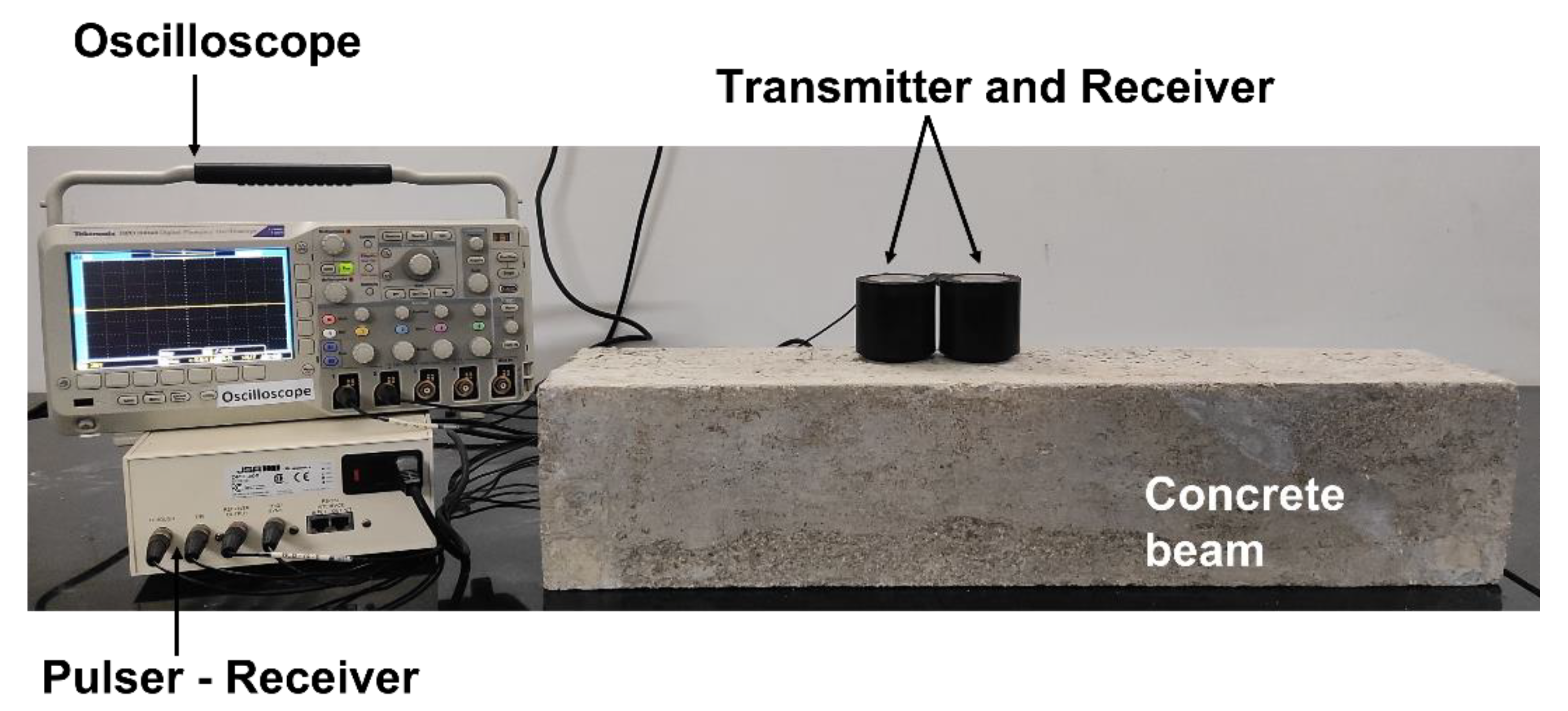

2.3. Methodology of Ultrasonic Scanning

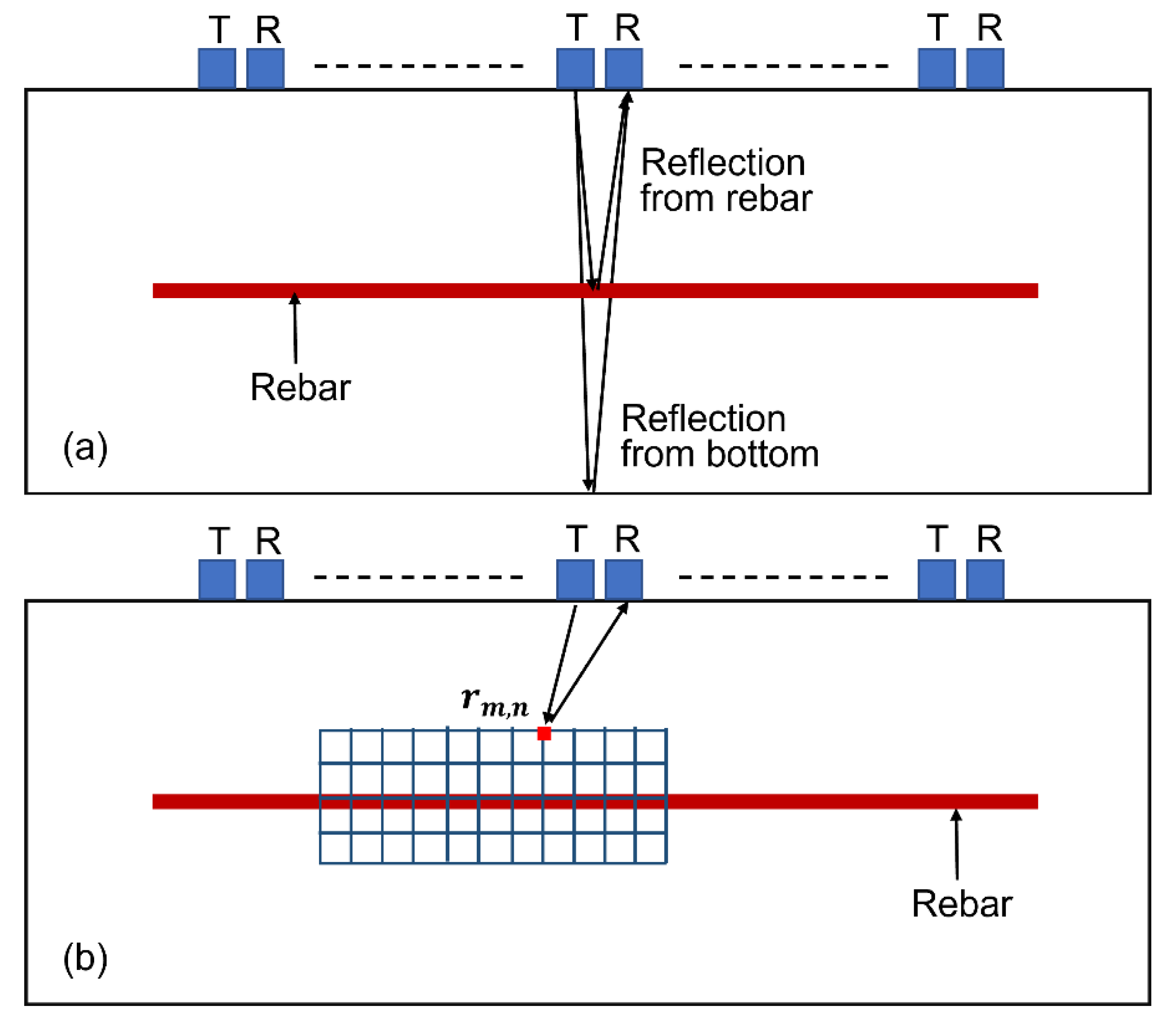

2.4. Imaging Methodology

2.4.1. Image Reconstruction Using the Synthetic Aperture Focusing Technique

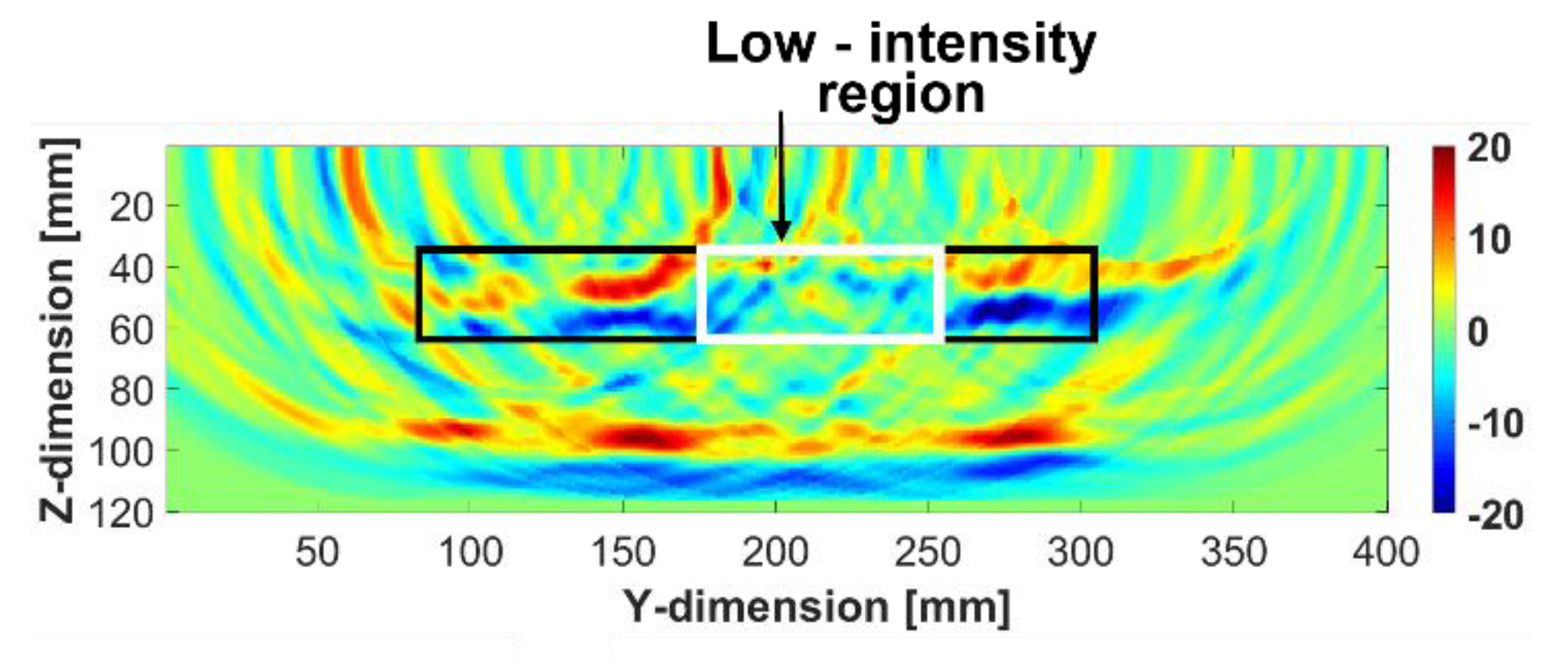

2.4.2. Vertical SAFT Images in the y–z Plane—Slabs

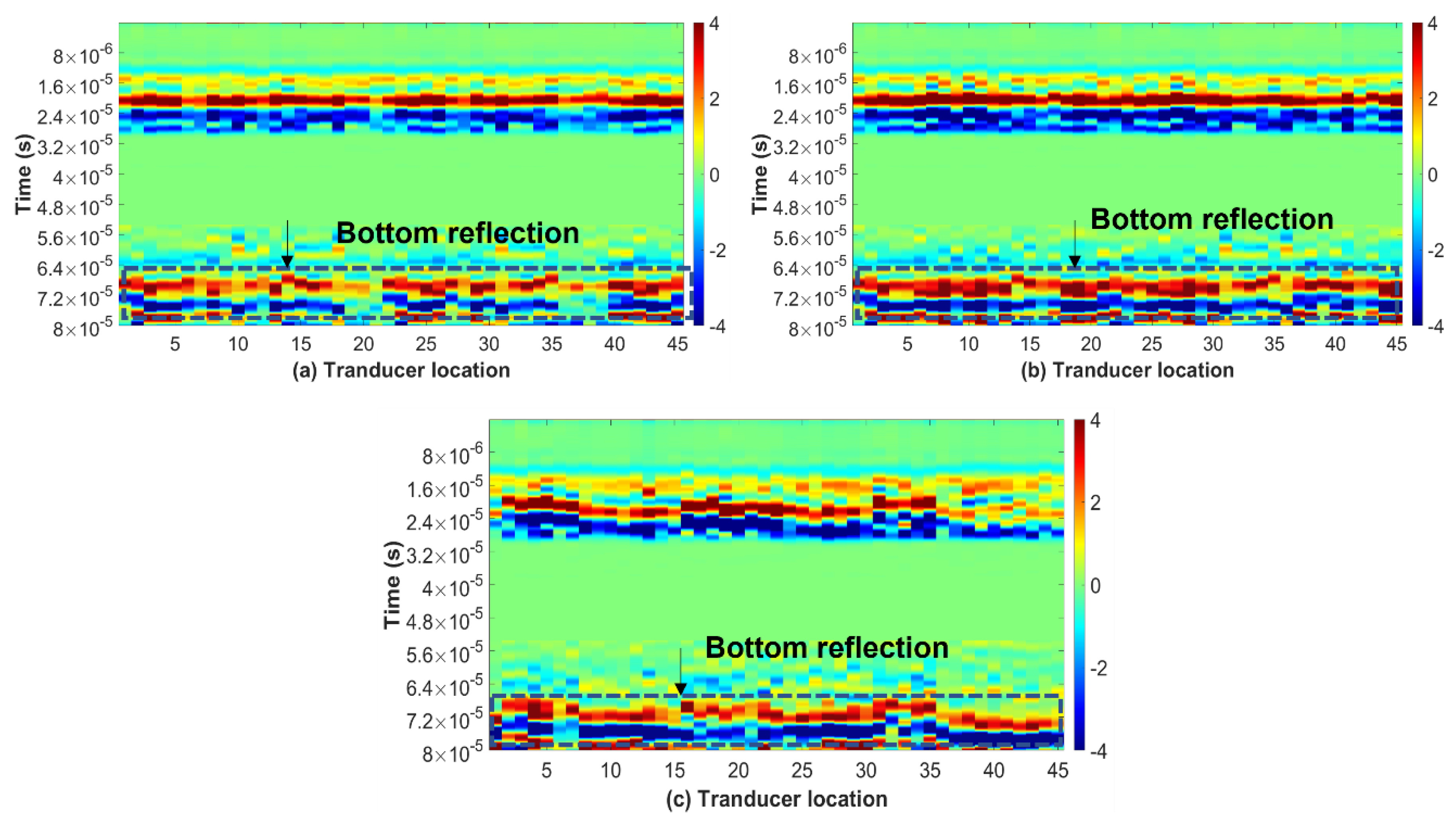

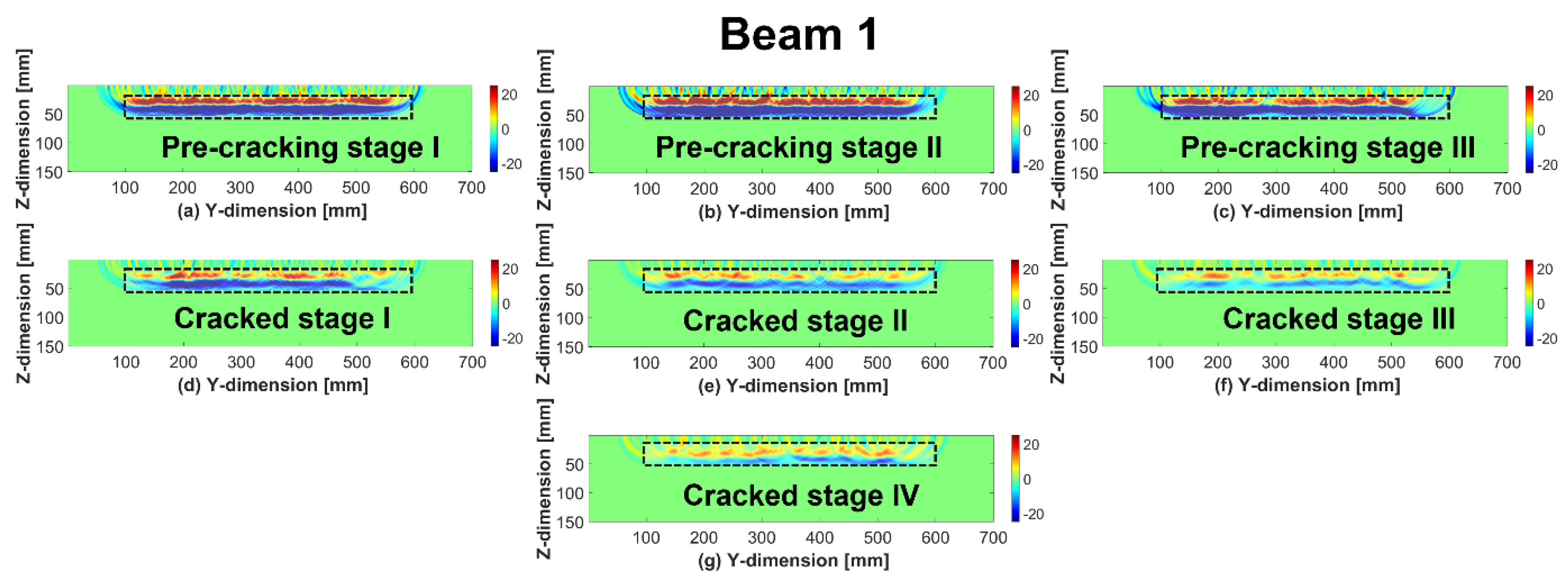

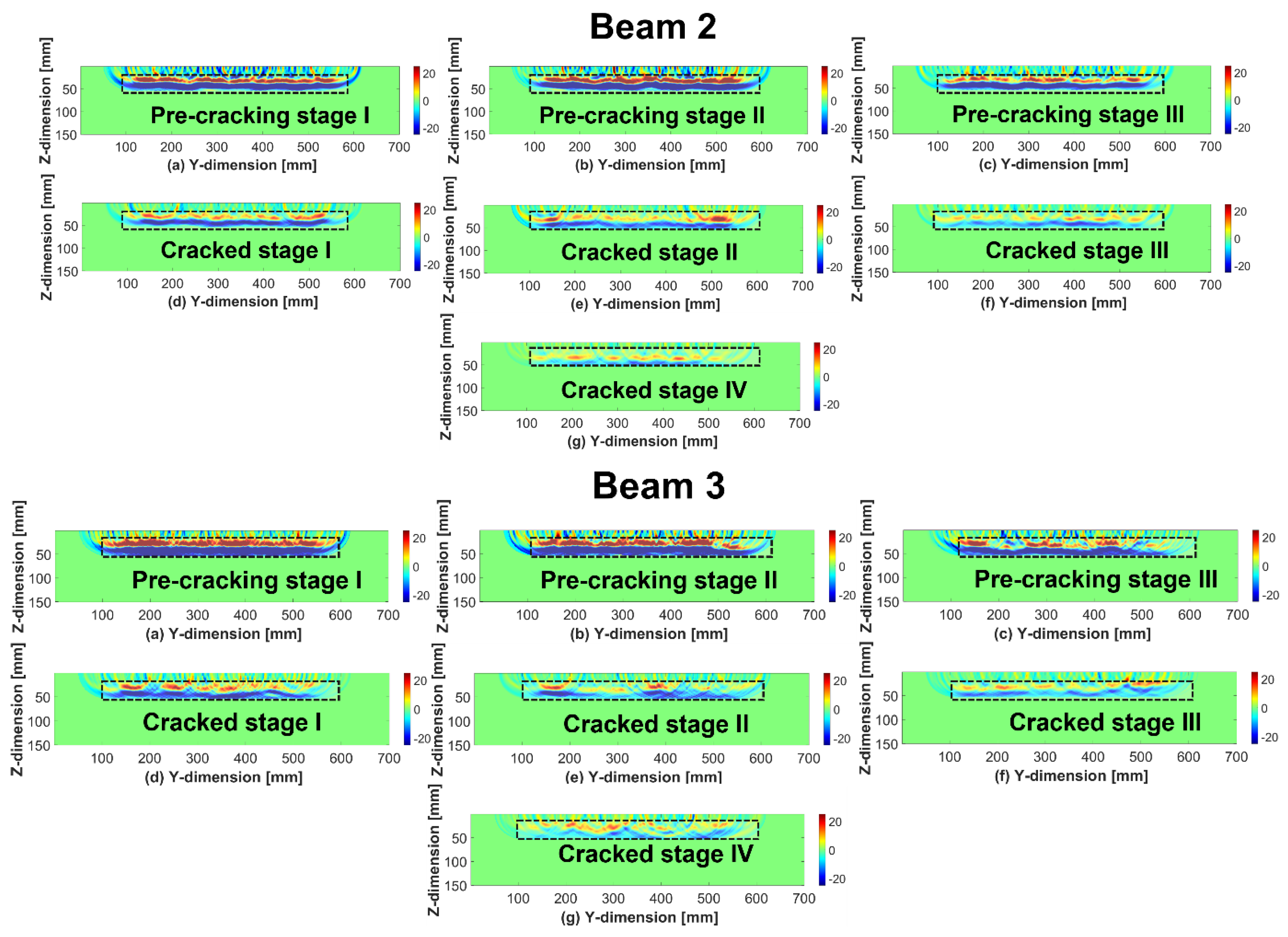

2.4.3. Vertical SAFT Images in the y–z Plane—Beams

3. Statistical Classification

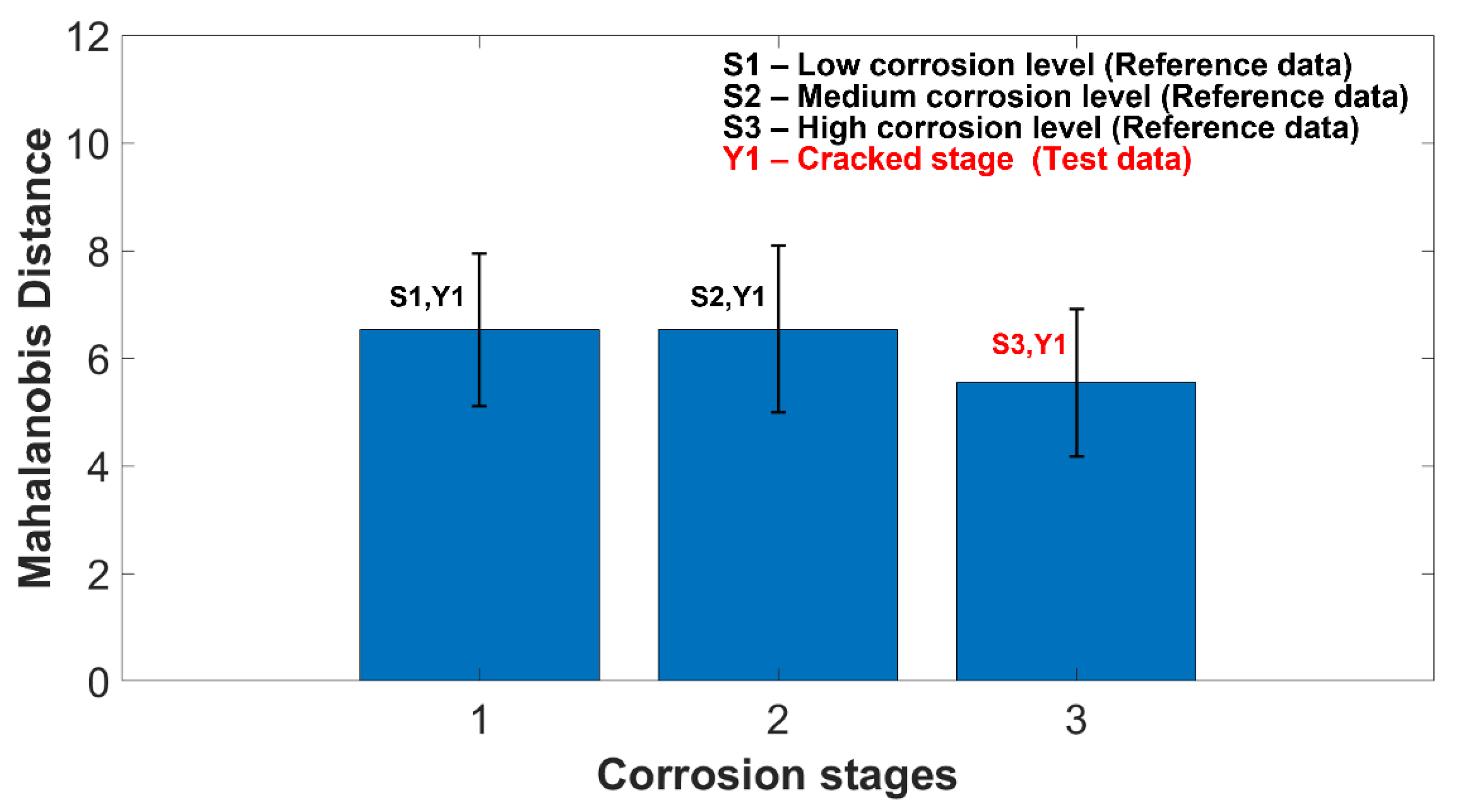

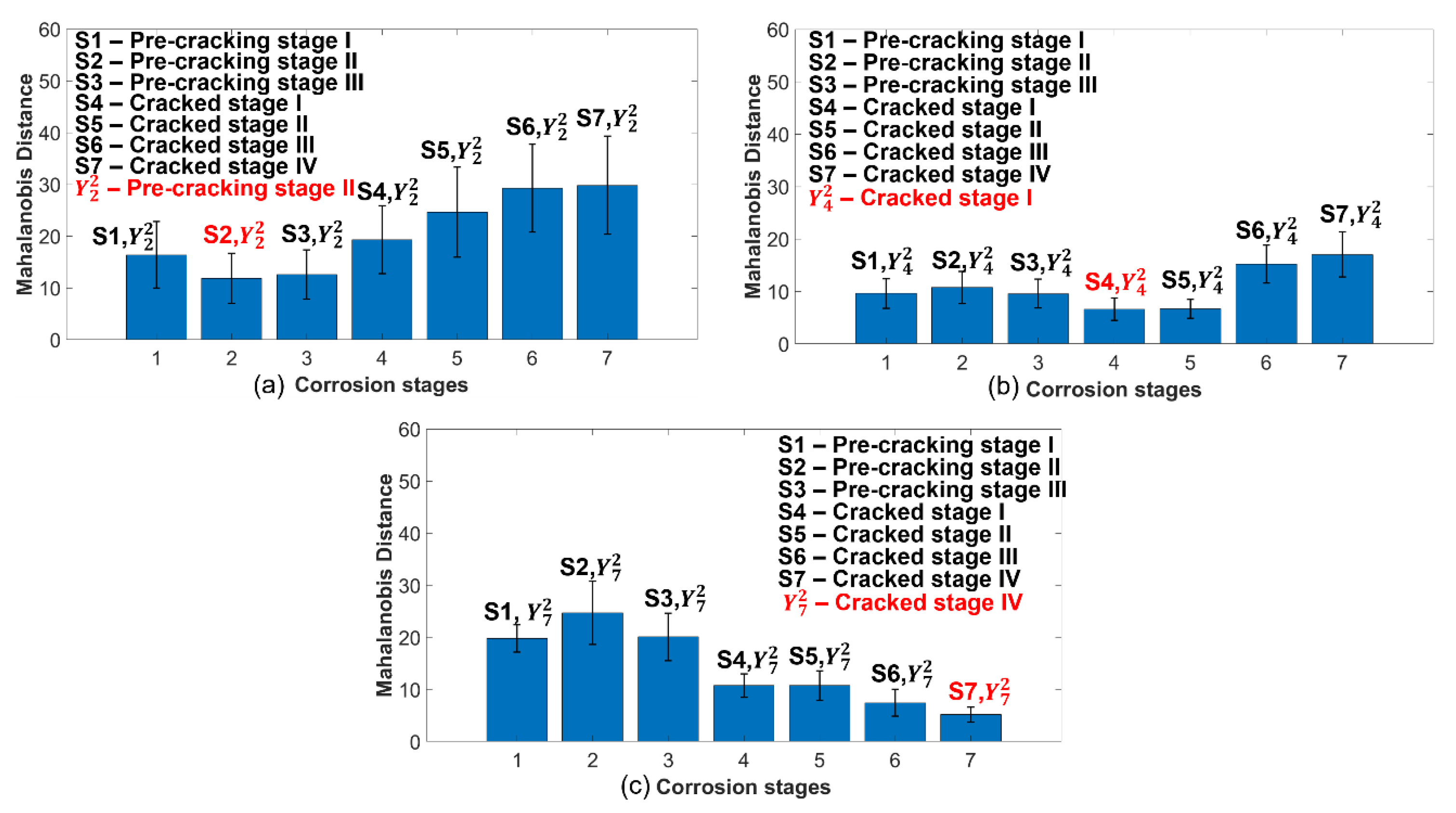

3.1. Mahalanobis Distance

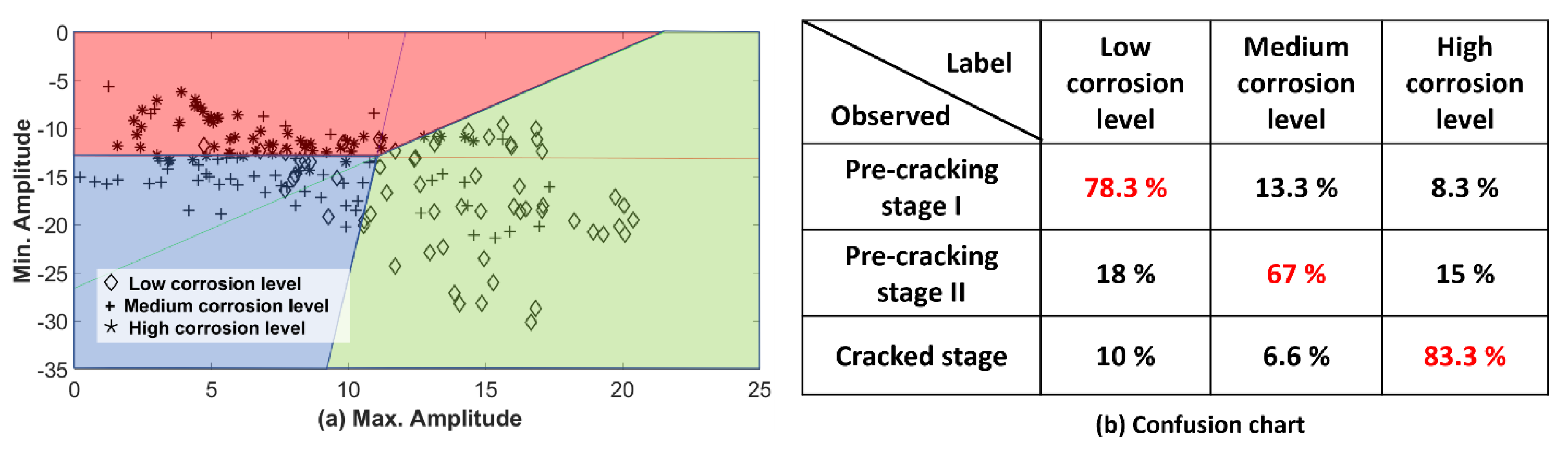

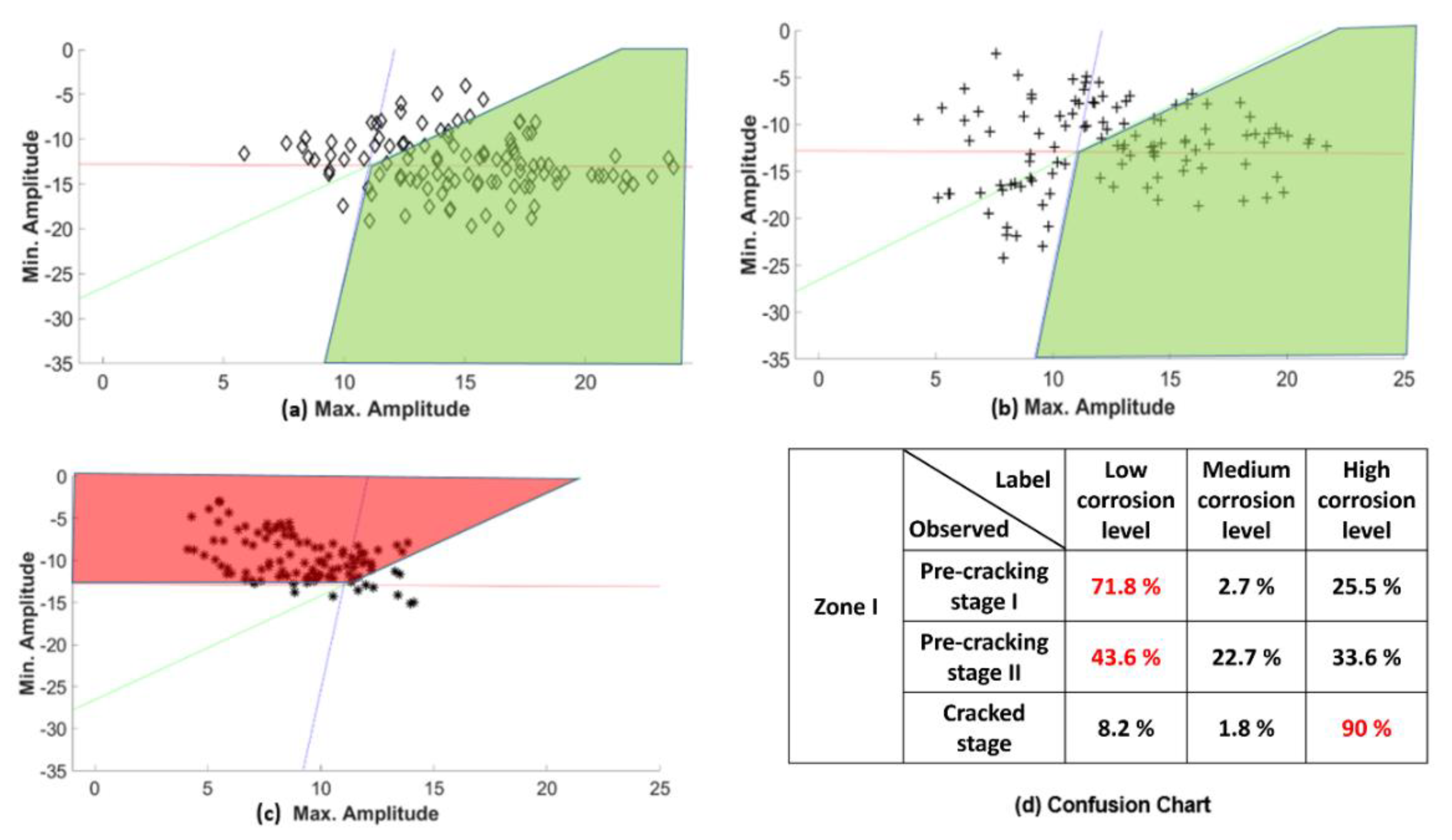

3.2. Linear Discriminant Analysis

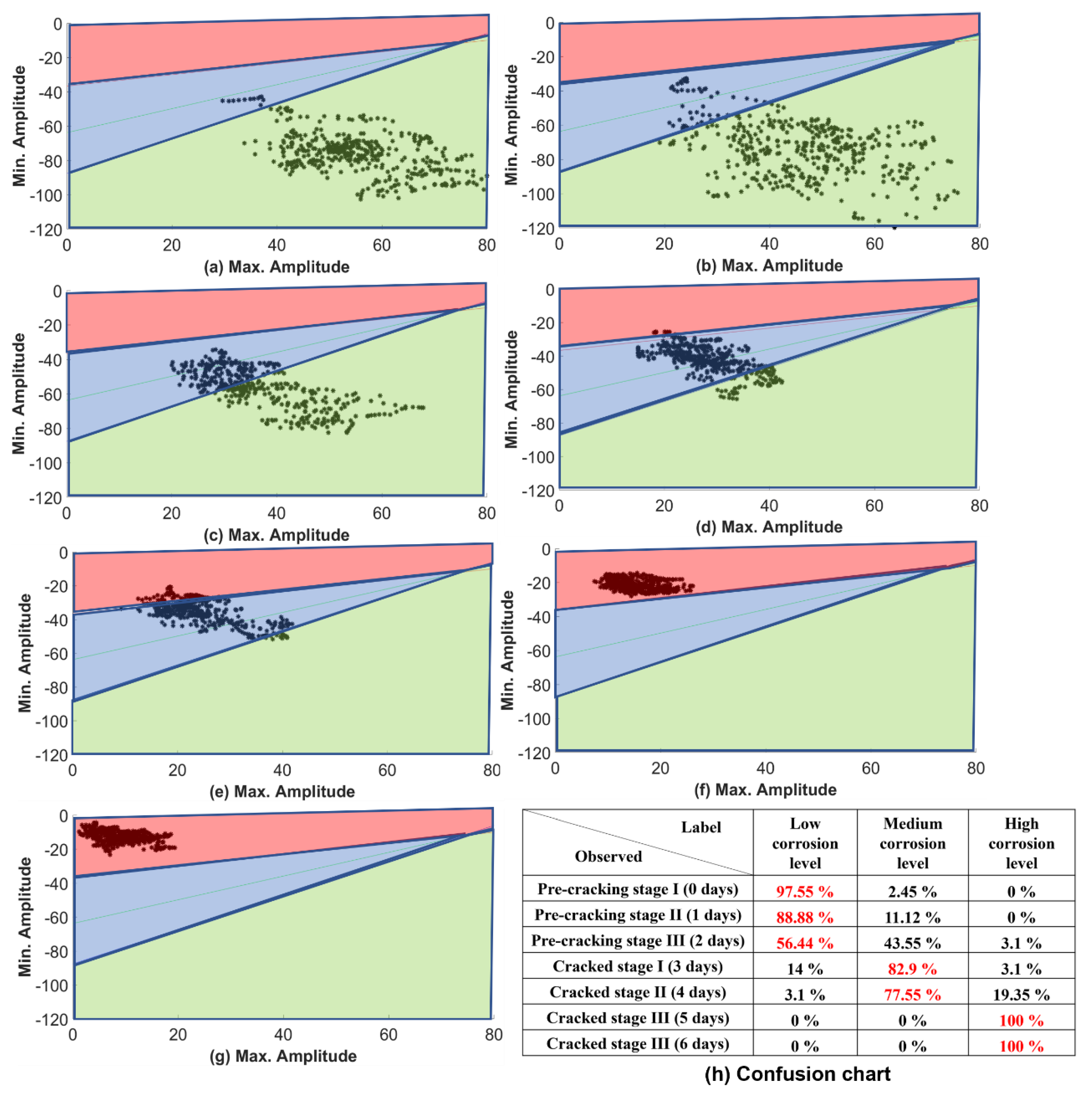

3.3. Image-Based Corrosion Classification

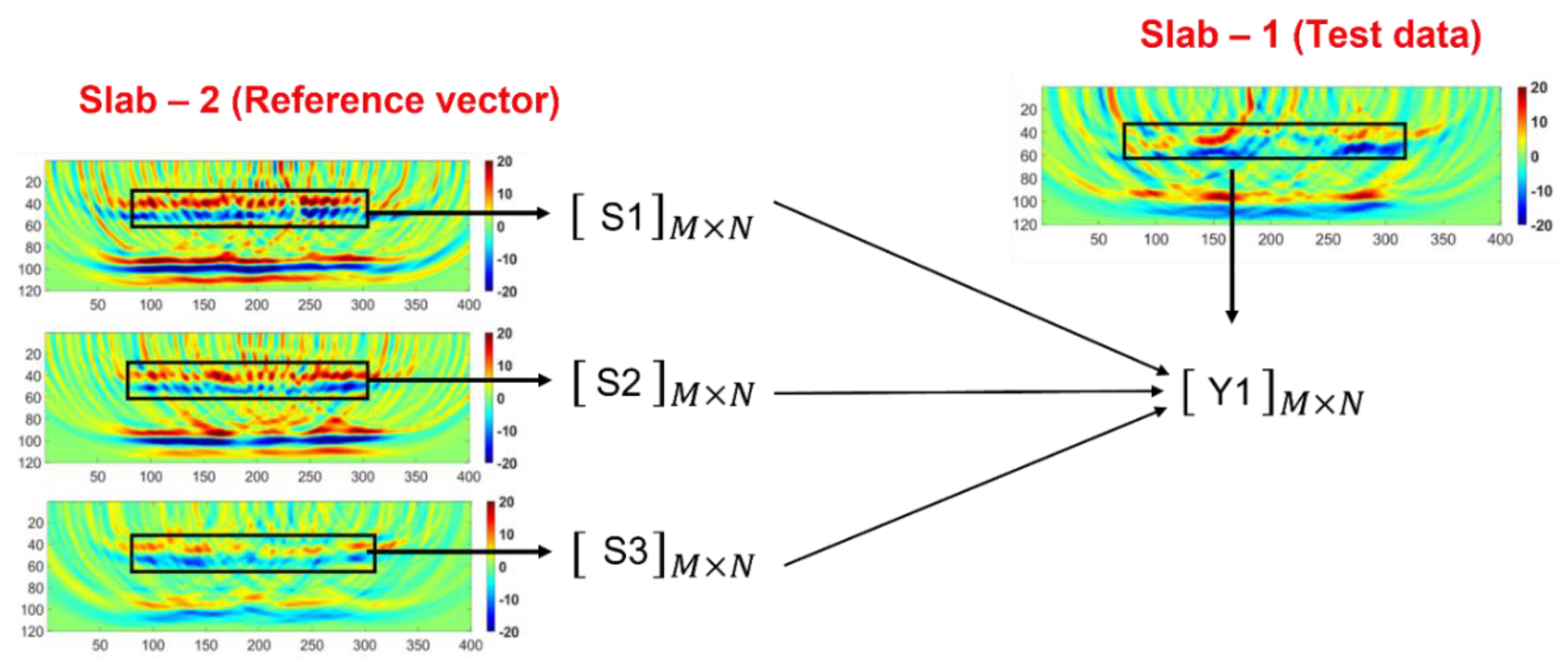

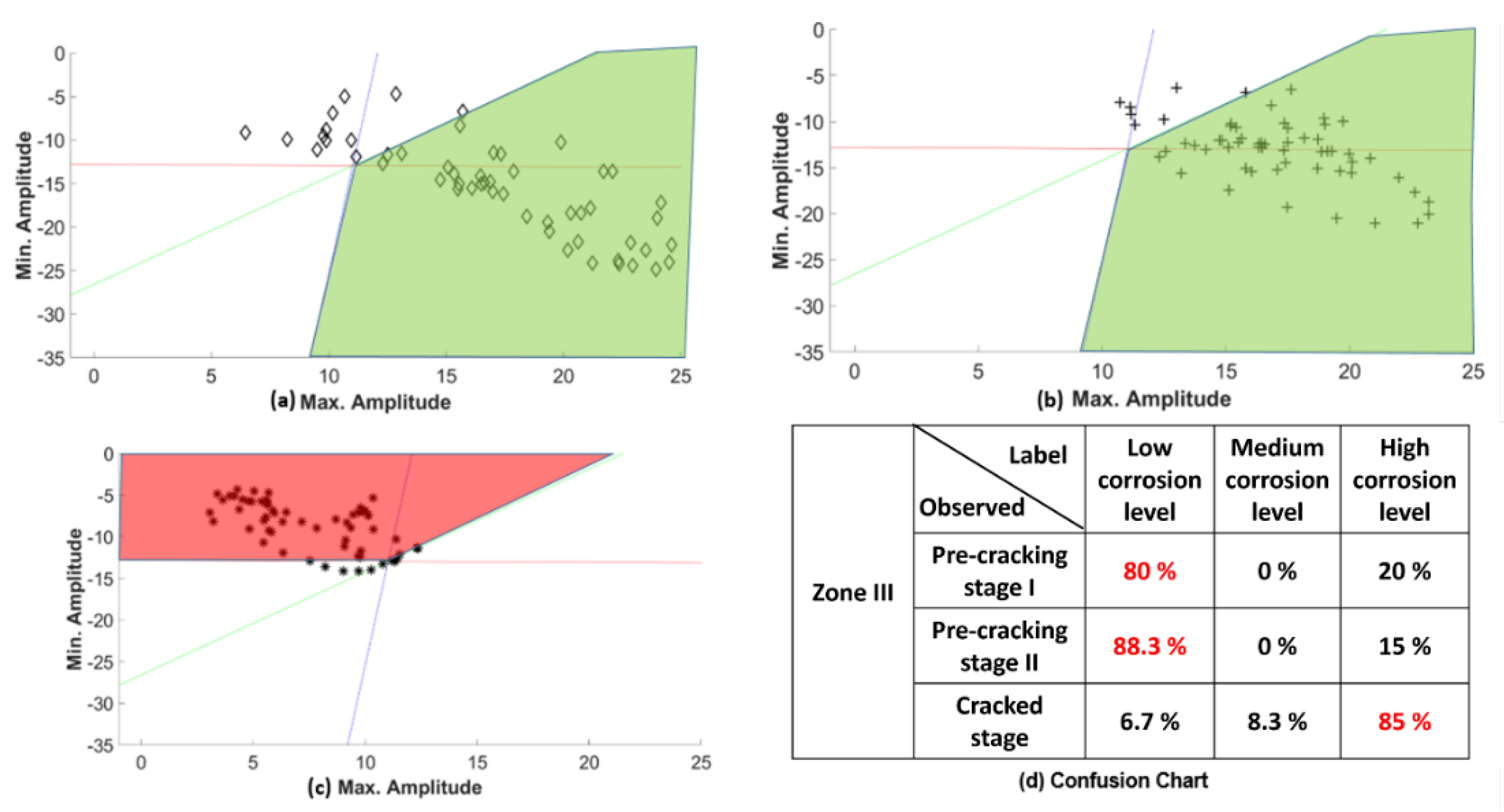

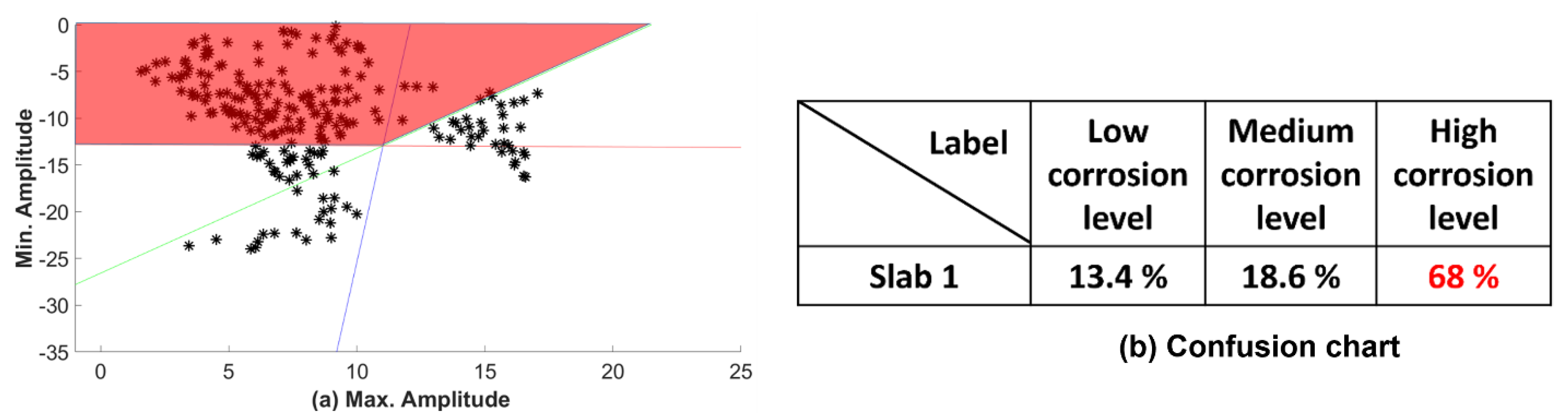

3.3.1. Corrosion Severity Classification—Slabs

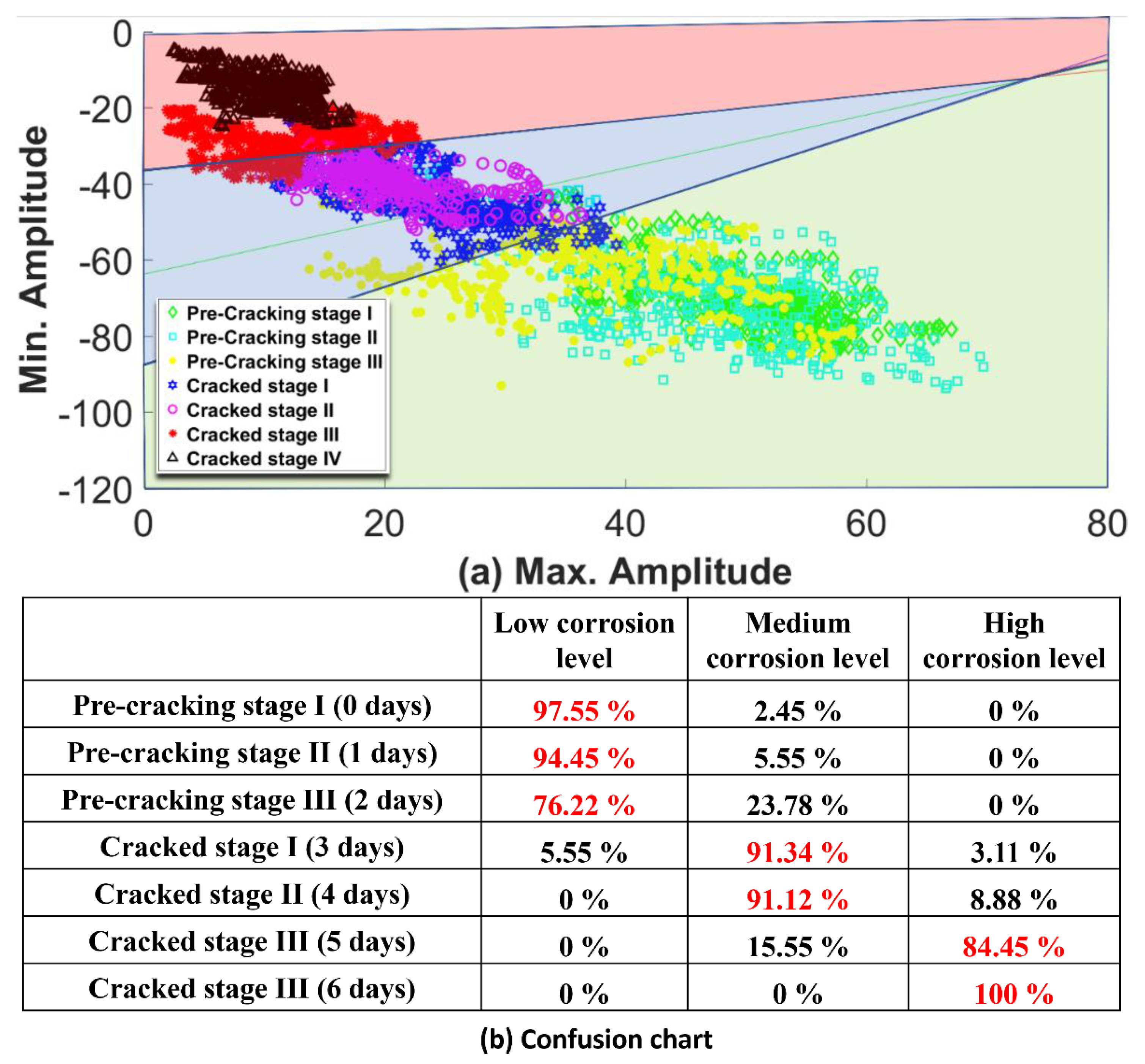

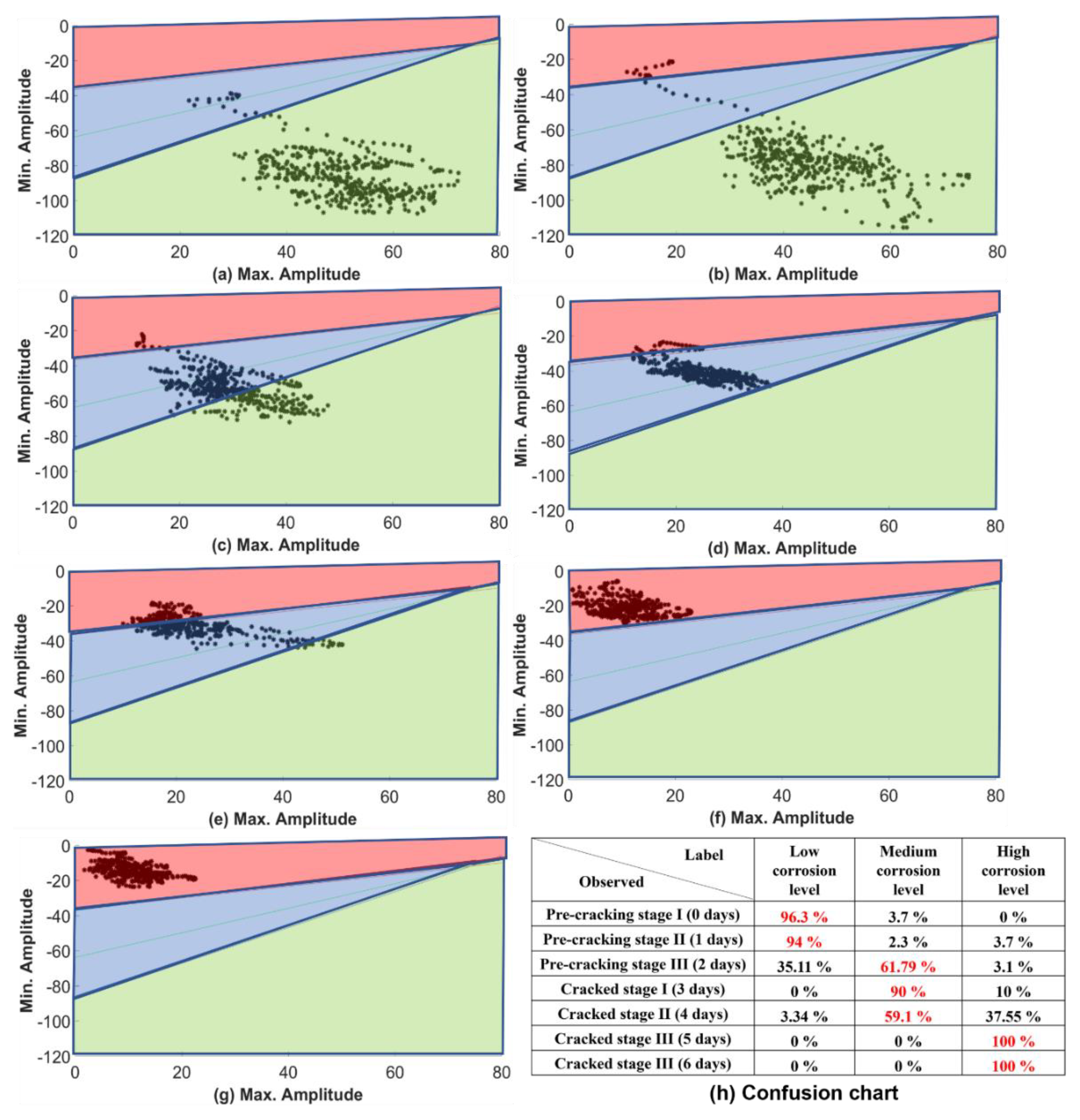

3.3.2. Corrosion Severity Classification—Beams

4. Conclusions and Future Work

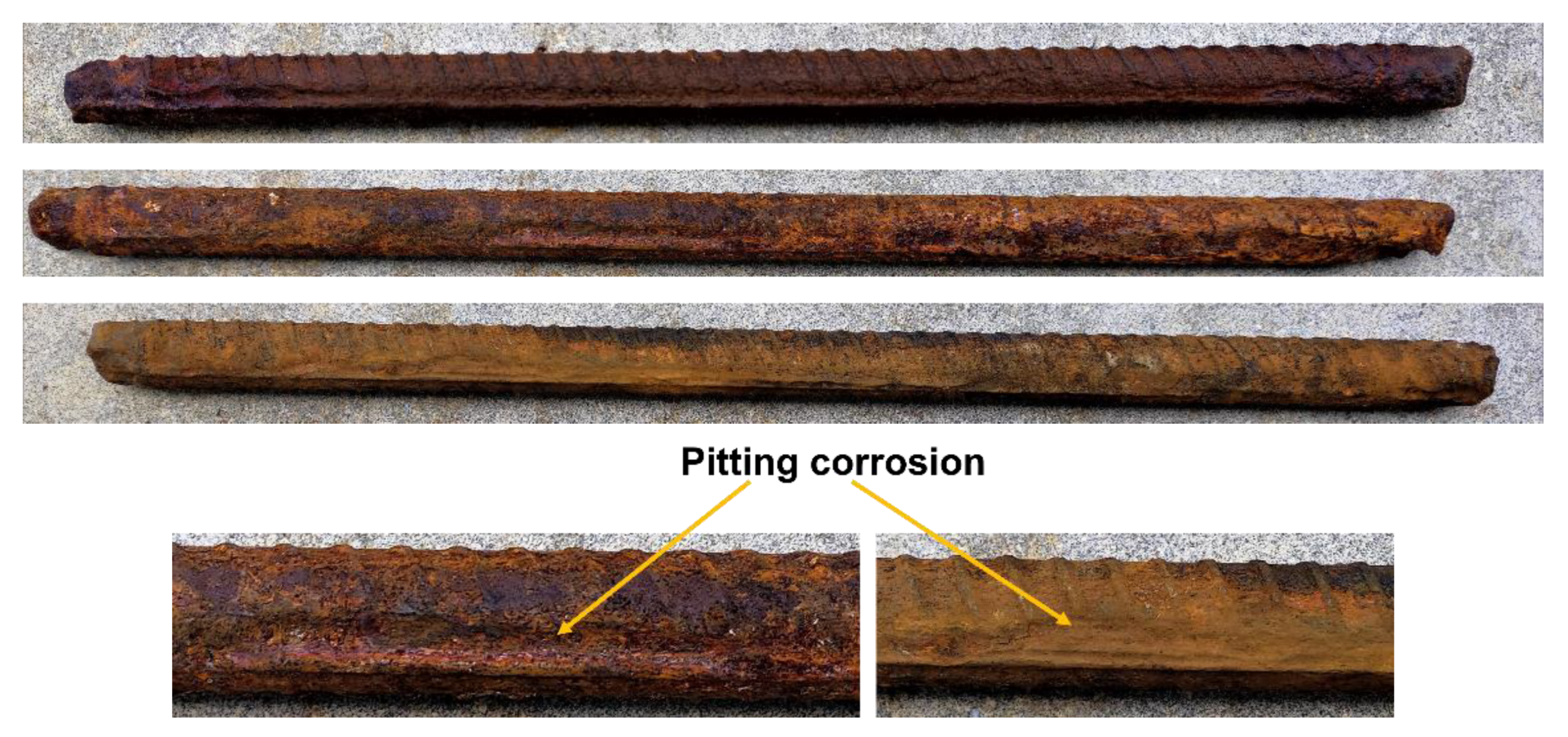

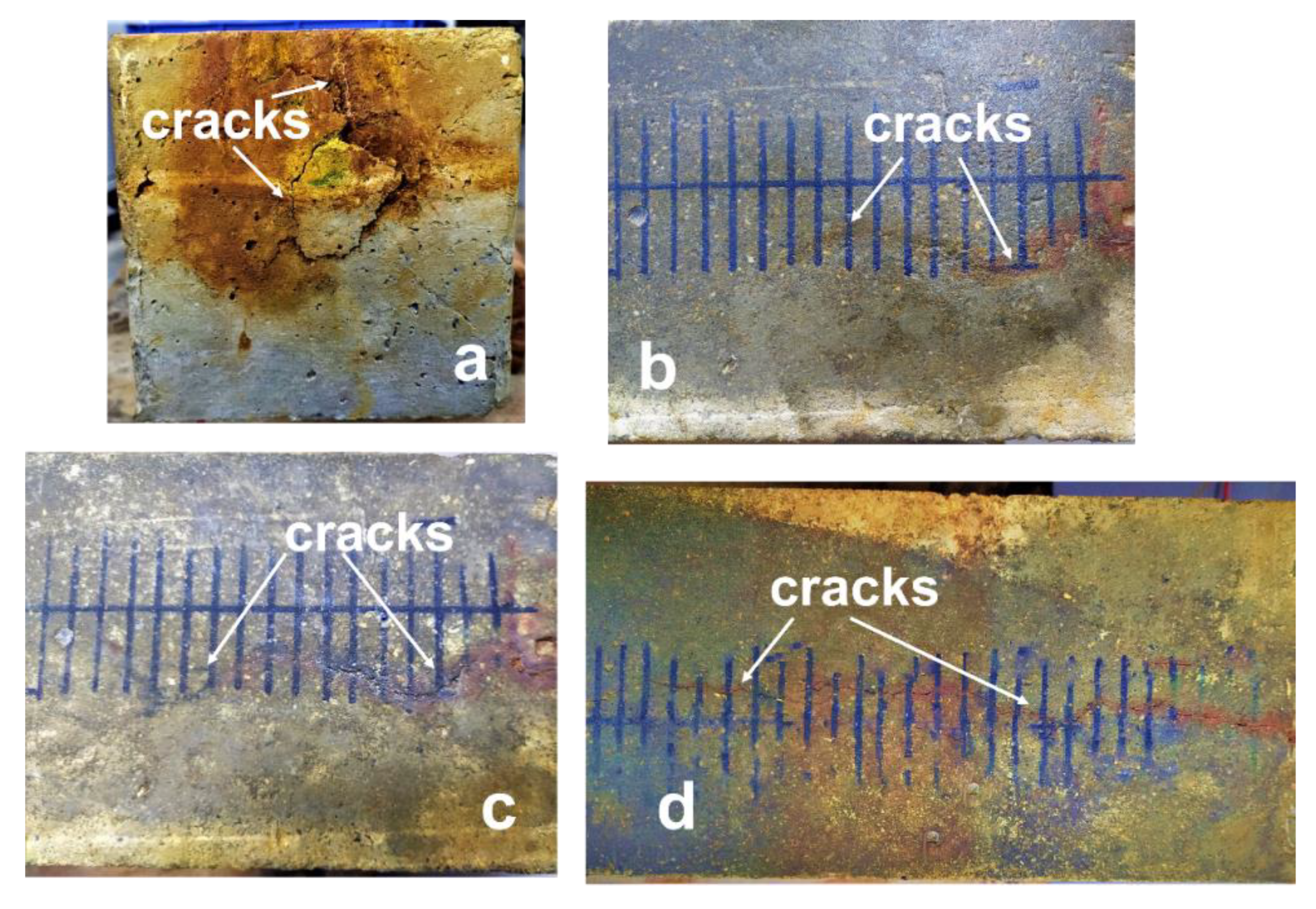

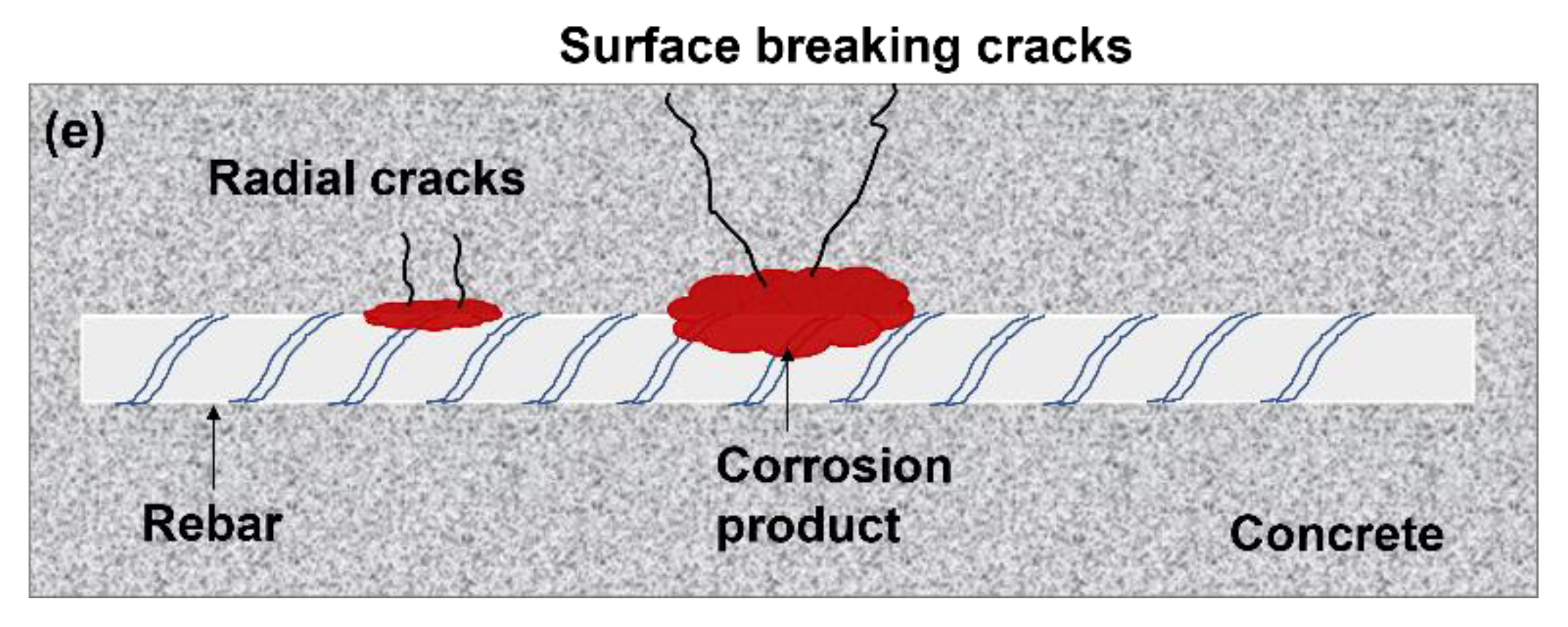

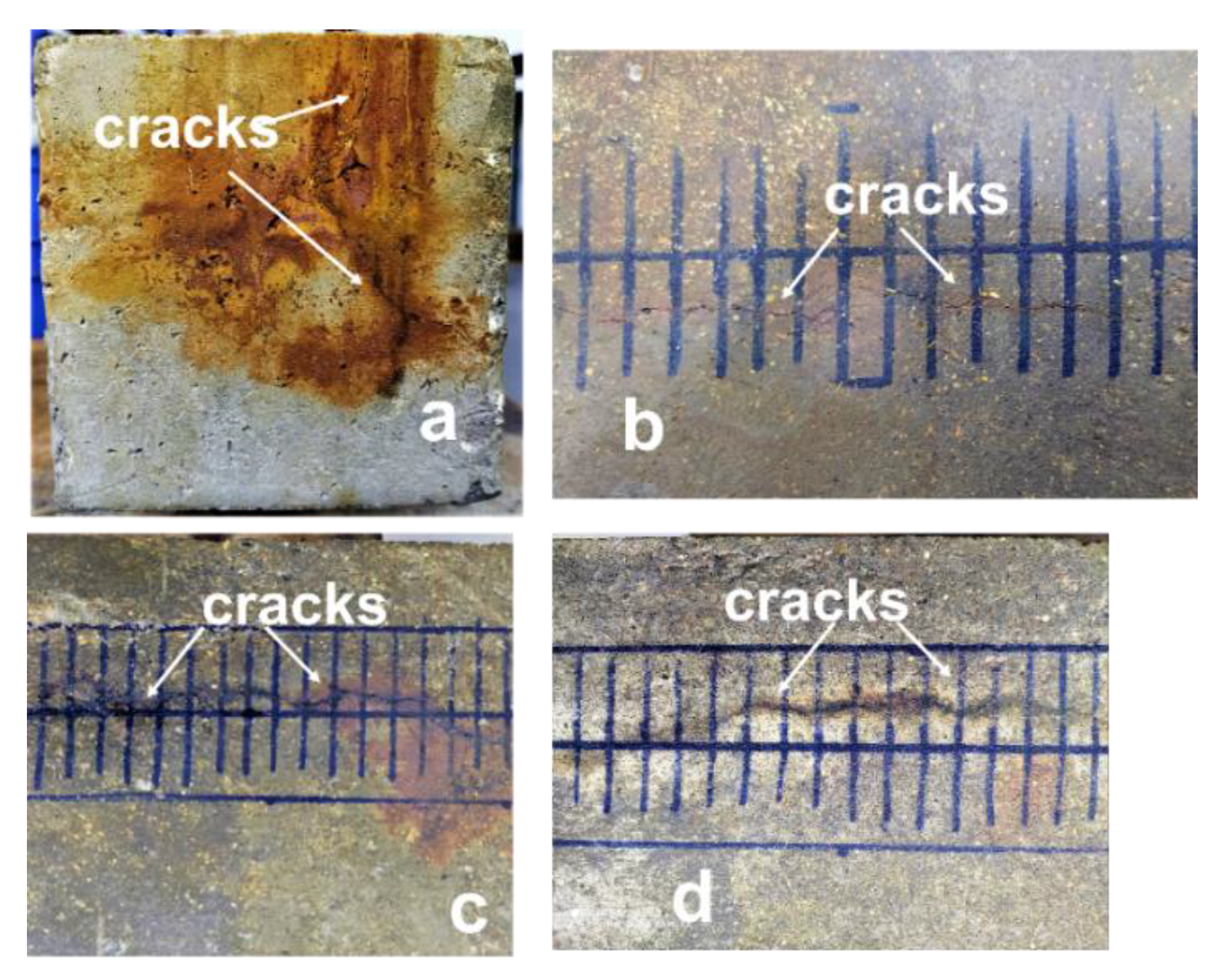

- The SAFT images, generated at various levels of progressing corrosion, depict a gradually depleting rebar image. This can be treated as the primary evidence of corrosion activity.

- Two methods were examined for assessing the severity of damage due to corrosion—Mahalanobis distance and linear discriminant analysis. Both methods are able to classify the corrosion severity correctly.

- The LDA-based algorithm has been implemented successfully using simple feature vectors, i.e., maximum, and minimum amplitudes of the rebar images.

- The results from the test data are consistent with the photographs of extracted rebars from the concrete specimens. The proposed techniques have a good potential of enabling decisions towards economical and timely repair of infrastructural assets.

- Future research will involve investigations with data obtained from the more complicated rebar distribution in beams with shear reinforcement and in prestressed concrete girders.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Aggelis, D.G.; Shiotani, T. Repair evaluation of concrete cracks using surface and through-transmission wave measurements. Cem. Concr. Compos. 2007, 29, 700–711. [Google Scholar] [CrossRef]

- Pidaparti, R.M.; Aghazadeh, B.S.; Whitfield, A.; Rao, A.S.; Mercier, G.P. Classification of corrosion defects in NiAl bronze through image analysis. Corros. Sci. 2010, 52, 3661–3666. [Google Scholar] [CrossRef]

- James, A.; Bazarchi, E.; Chiniforush, A.A.; Aghdam, P.P.; Hosseini, M.R.; Akbarnezhad, A.; Martek, I.; Ghodoosi, F. Rebar corrosion detection, protection, and rehabilitation of reinforced concrete structures in coastal environments: A review. Constr. Build. Mater. 2019, 224, 1026–1039. [Google Scholar] [CrossRef]

- C876-09; Standard Test Method for Corrosion Potentials of Uncoated Reinforcing Steel in Concrete. ASTM: Conshohocken, PA, USA, 2009.

- Veerachai, L.; Je-Woon, K.; Masayasu, O.; Masaru, Y. Analysis of half-cell potential measurement for corrosion of reinforced concrete. Constr. Build. Mater. 2004, 18, 155–162. [Google Scholar]

- Sadowski, L. Methodology for Assessing the Probability of Corrosion in Concrete Structures on the Basis of Half-Cell Potential and Concrete Resistivity Measurements. Sci. World J. 2013, 213, 1–8. [Google Scholar] [CrossRef]

- Senin, S.F.; Hamid, R. Ground Penetrating Radar Wave Attenuation Models for Estimation of Moisture and Chloride Content in Concrete Slab. Constr. Build. Mater. 2016, 106, 659–669. [Google Scholar] [CrossRef]

- Wiwatrojanagul, P.; Sahamitmongkol, R.; Tangtermsirikul, S.; Khamsemanan, N. A new method to determine locations of rebars and estimate cover thickness of RC structures using GPR data. Constr. Build. Mater. 2017, 140, 257–273. [Google Scholar] [CrossRef]

- Rathod, H.; Debeck, S.; Gupta, R.; Chow, B. Applicability of GPR and a rebar detector to obtain Rebar information of existing concrete structures. Case Stud. Constr. Mater. 2019, 11, e00240. [Google Scholar] [CrossRef]

- Dinh, K.; Zayed, T.; Tarussov, A. GPR image analysis for corrosion mapping in concrete slabs. In Proceedings of the Canadian Society of Civil Engineering Conference, Montreal, QC, Canada, 29 May–1 June 2013. [Google Scholar]

- Wong, P.T.W.; Lai, W.W.L.; Sham, J.F.C.; Poon, C. Hybrid non-destructive evaluation methods for characterizing chloride-induced corrosion in concrete. NDT E Int. 2019, 107, 102123. [Google Scholar] [CrossRef]

- Dinh, K.; Zayed, T.; Moufti, S.; Shami, A.; Jabri, A.; Abouhamad, M.; Dawood, T. Clustering-Based Threshold Model for Condition Assessment of Concrete Bridge Decks with Ground-Penetrating Radar. Transp. Res. Rec. 2015, 2522, 81–89. [Google Scholar] [CrossRef]

- Barnes, C.L.; Trottier, J.-F.; Forgeron, D. Improved concrete bridge deck evaluation using GPR by accounting for signal depth–amplitude effects. NDT E Int. 2008, 41, 427–433. [Google Scholar] [CrossRef]

- Tawhed, W.F.; Gassman, S.L. Damage assessment of concrete bridge decks using Impact-Echo method. ACI Mater. J. 2002, 99, 273–281. [Google Scholar]

- Schoefs, F.; Abraham, O.; Popovics, J.S. Quantitative evaluation of contactless impact echo for non-destructive assessment of void detection within tendon ducts. Constr. Build. Mater. 2012, 37, 885–892. [Google Scholar] [CrossRef]

- Krause, M.; Milmann, B.; Schickert, M.; Mayer, K. Investigation of tendon ducts by means of ultrasonic echo methods: A comparative study. In Proceedings of the 9th European Conference on Non-Destructive Testing, Berlin, Germany, 25–29 September 2006. [Google Scholar]

- Wang, Z.; Zhou, X. Impact-Echo Based Non-destructive Evaluation of Grout Condition in Post-Tensioned Bridge Ducts. Adv. Mater. Res. 2010, 168–170, 1122–1125. [Google Scholar]

- Yeh, P.-L.; Liu, P.L.; Hsu, Y.-Y. Parametric analysis of the impact-echo phase method in the differentiation of reinforcing bar and crack signals. Constr. Build. Mater. 2018, 180, 375–381. [Google Scholar] [CrossRef]

- Liang, M.; Su, P. Detection of the corrosion damage of rebar in concrete using impact-echo method. Cem. Concr. Res. 2001, 31, 1427–1436. [Google Scholar] [CrossRef]

- Alhawat, M.; Khan, A.; Ashour, A. Evaluation of Steel Corrosion in Concrete Structures Using Impact-Echo Method. Adv. Mater. Res. 2020, 1158, 147–164. [Google Scholar] [CrossRef]

- Mangual, J.; ElBatanouny, M.K.; Ziehl, P.; Matta, F. Acoustic-emission-based characterization of corrosion damage in cracked concrete with prestressing strand. ACI Mater. J. 2013, 110, 89. [Google Scholar]

- Tworzewski, P.; Teodorczyk, M.; Tworzewska, J. Tracking of Crack Formation in Concrete Using Acoustic Emission Method and Digital Image Correlation. IOP Conf. Ser. Mater. Sci. Eng. 2019, 471, 052032. [Google Scholar] [CrossRef]

- Sharma, A.; Sharma, S.; Sharma, S.; Mukherjee, A. Monitoring invisible corrosion in concrete using a combination of wave propagation techniques. Cem. Concr. Compos. 2018, 90, 89–99. [Google Scholar] [CrossRef]

- Karaiskos, G.; Deraemaeker, A.; Aggelis, D.G.; Hemelrijck, D.V. Monitoring of concrete structures using the ultrasonic pulse velocity method. Smart Mater. Struct. 2015, 24, 113001. [Google Scholar] [CrossRef]

- Shah, J.K.; Mukherjee, A. Monitoring and Imaging of Bolted Steel Plate Joints Using Ultrasonic Guided Waves. ASME J. Non-Destr. Eval. 2021, 4, 011003. [Google Scholar] [CrossRef]

- Na, W.B.; Kundu, T.; Ehsani, M. R. A Comparison of steel/concrete and glass fiber reinforced polymers/concrete interface testing by guided waves. Mater. Eval. 2003, 61, 155–161. [Google Scholar]

- Sriramadasu, R.C.; Banerjee, S.; Lu, Y.e. Sensitivity of longitudinal guided wave modes to pitting corrosion of rebars embedded in reinforced concrete. Constr. Build. Mater. 2020, 239, 117855. [Google Scholar] [CrossRef]

- Wang, X.; Chakraborty, J.; Bassil, A.; Niederleithinger, E. Detection of multiple cracks in four-point bending tests using the coda wave interferometry method. Sensors 2020, 20, 1986. [Google Scholar] [CrossRef] [PubMed]

- Niederleithinger, E.; Wang, X.; Herbrand, M.; Muller, M. Processing ultrasonic data by coda wave interferometry to monitor load tests of concrete beams. Sensors 2018, 18, 1971. [Google Scholar] [CrossRef] [PubMed]

- Beniwal, S.; Ganguli, A. Localized Condition Monitoring Around Rebars using Focused Ultrasonic Field and SAFT. Res. Non-Destr. Eval. 2016, 27, 48–67. [Google Scholar] [CrossRef]

- Beniwal, S.; Ghosh, D.; Ganguli, A. Ultrasonic imaging of concrete using scattered elastic wave modes. NDT E Int. 2016, 82, 26–35. [Google Scholar] [CrossRef]

- Ghosh, D.; Beniwal, S.; Ganguli, A.; Mukherjee, A. Reference free imaging of subsurface cracks in concrete using Rayleigh waves. Struct. Control. Health Monit. 2018, 25, e2246. [Google Scholar] [CrossRef]

- Ghosh, D.; Kumar, R.; Ganguli, A.; Mukherjee, A. Non-destructive Evaluation of Rebar Corrosion–Induced Damage in Concrete through Ultrasonic Imaging. J. Mater. Civ. Eng. 2020, 32, 04020294. [Google Scholar] [CrossRef]

- Mayakuntla, P.K.; Ghosh, D.; Ganguli, A. Non-destructive evaluation of rebar corrosion in concrete structures using ultrasonics and laser-based sensing. Non-Destr. Test. Eval. 2021, 37, 297–314. [Google Scholar] [CrossRef]

- De La Haza, A.O.; Samokrutov, A.A.; Samokrutov, P.A. Assessment of concrete structures using the Mira and Eyecon ultrasonic shear wave devices and the SAFT-C image reconstruction technique. Constr. Build. Mater. 2013, 38, 1276–1291. [Google Scholar] [CrossRef]

- Choi, P.; Kim, D.-H.; Lee, B.-H.; Won, M.C. Application of ultrasonic shear-wave tomography to identify horizontal crack or delamination in concrete pavement and bridge. Constr. Build. Mater. 2016, 121, 81–91. [Google Scholar] [CrossRef]

- Niederleithinger, E.; Wolf, J.; Mielentz, F.; Wiggenhauser, H.; Pirskawetz, S. Embedded Ultrasonic Transducers for Active and Passive Concrete Monitoring. Sensors 2015, 15, 9756–9772. [Google Scholar] [CrossRef]

- Meixedo, A.; Santos, J.; Ribeiro, D.; Calçada, R.; Todd, M. Damage detection in railway bridges using traffic-induced dynamic responses. Eng. Struct. 2021, 238, 112189. [Google Scholar] [CrossRef]

- Lai, W.C.; Chang, T.P.; Wang, J.J.; Kan, C.W.; Chen, W.W. An evaluation of Mahalanobis Distance and grey relational analysis for crack pattern in concrete structures. Comput. Mater. Sci. 2012, 65, 115–121. [Google Scholar] [CrossRef]

- Farhidzadeh, A.; Salamone, S.; Singla, P. A probabilistic approach for damage identification and crack mode classification in reinforced concrete structures. J. Intell. Mater. Syst. Struct. 2013, 24, 1722–1735. [Google Scholar] [CrossRef]

- Qiu, L.; Yuan, S.; Chang, Q.; Mei, H. On-line updating Gaussian mixture model for aircraft wing spar damage evaluation under time-varying boundary condition. Smart Mater. Struct. 2014, 23, 125001. [Google Scholar] [CrossRef]

- Vidya Sagar, R. Verification of the applicability of the Gaussian mixture modelling for damage identification in reinforced concrete structures using acoustic emission testing. J. Civ. Struct. Health Monit. 2018, 8, 395–415. [Google Scholar] [CrossRef]

- Ohno, J.K.; Ohtsu, M. Crack classification in concrete based on acoustic emission. Constr. Build. Mater. 2010, 24, 2339–2346. [Google Scholar] [CrossRef]

- Pashmforoush, F.; Khamedi, R.; Fotouhi, M.; Hajikhani, M.; Ahmadi, M. Damage Classification of Sandwich Composites Using Acoustic Emission Technique and k-means Genetic Algorithm. J. Non-Destr. Eval. 2014, 33, 481–492. [Google Scholar] [CrossRef]

- Zaki, A.; Jusman, Y.; Johari, M.A.M.; Hussin, W.M.A.W. Image Processing for Corrosion Quantification in Concrete Slabs using GPR data. J. Phys. Conf. Ser. 2020, 1471, 012049. [Google Scholar] [CrossRef]

- Majhi, S.; Mukherjee, A.; George, N.V.; Karaganov, V.; Uy, B. Corrosion monitoring in steel bars using Laser ultrasonic guided waves and advanced signal processing. Mech. Syst. Signal Process. 2021, 149, 107176. [Google Scholar] [CrossRef]

- Ramadan, S.; Gaillet, L.; Tessier, C.; Idrissi, H. Assessment of the stress corrosion cracking in a chloride medium of cables used in prestressed concrete structures by the acoustic emission technique. Meas. Sci. Technol. 2008, 19, 115702. [Google Scholar] [CrossRef]

- Xu, Y.; Wei, S.; Bao, Y.; Li, H. Automatic seismic damage identification of reinforced concrete columns from images by a region-based deep convolutional neural network. Struct. Control. Health Monit. 2019, 26, e2313. [Google Scholar] [CrossRef]

- Mata, J.; Schclar Leitao, N.; Tavares de Castro, A.; Sa da Costa, J. Construction of decision rules for early detection of a developing concrete arch dam failure scenario. A discriminant approach. Comput. Struct. 2014, 142, 45–53. [Google Scholar] [CrossRef]

- Medeiros Fatima, N.S.; Ramalho Geraldo, L.B.; Bento Mariana, P.; Medeiros Luiz, C.L. On the Evaluation of Texture and Color Features for Nondestructive Corrosion Detection. EURASIP J. Adv. Signal Process. 2010, 1, 817473. [Google Scholar] [CrossRef]

- Zaki, A.; Ibrahim, Z.; Jusman, Y. The Classification for Steel Corroded Reinforced Concrete Beams Using Linear Discriminant Analysis. In Proceedings of the 2nd Borobudur International Symposium on Humanities and Social Sciences, Magelang, Indonesia, 18 November 2020. [Google Scholar]

- IS 456-2000; Indian Standard Plain and Reinforced Concrete Code of Practice. Bureau of Indian Standards: New Delhi, India, 2020.

- IS 10262-2019; Indian Standard Concrete Mix Proportioning—Guidelines. Bureau of Indian Standards: New Delhi, India, 2019.

- Ganguli, A.; Rappaport, C.M.; Abramo, D.; Wadia-Fascetti, S. Synthetic aperture imaging for flaw detection in a concrete medium. NDT E Int. 2012, 45, 79–90. [Google Scholar] [CrossRef]

- Friedman, J.; Hastie, T.; Tibshirani, R. The Elements of Statistical Learning; Springer Series in Statistics; Springer: New York, NY, USA, 2001; Volume 1. [Google Scholar]

| Specimen | Cement | Coarse Aggregate | Sand | Water |

|---|---|---|---|---|

| Slabs 1 and 2 | 1 | 2.8 | 1.7 | 0.45 |

| Beams 1,2 and 3 | 1 | 3.0 | 2.1 | 0.45 |

| Specimen | Corrosion Stages | Corrosion Period |

|---|---|---|

| Slab 1 |

|

|

| Slab 2 |

|

|

| Beams 1, 2 and 3 |

|

|

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mayakuntla, P.K.; Ghosh, D.; Ganguli, A. Classification of Corrosion Severity in Concrete Structures Using Ultrasonic Imaging and Linear Discriminant Analysis. Sustainability 2022, 14, 15768. https://doi.org/10.3390/su142315768

Mayakuntla PK, Ghosh D, Ganguli A. Classification of Corrosion Severity in Concrete Structures Using Ultrasonic Imaging and Linear Discriminant Analysis. Sustainability. 2022; 14(23):15768. https://doi.org/10.3390/su142315768

Chicago/Turabian StyleMayakuntla, Prasanna Kumar, Debdutta Ghosh, and Abhijit Ganguli. 2022. "Classification of Corrosion Severity in Concrete Structures Using Ultrasonic Imaging and Linear Discriminant Analysis" Sustainability 14, no. 23: 15768. https://doi.org/10.3390/su142315768

APA StyleMayakuntla, P. K., Ghosh, D., & Ganguli, A. (2022). Classification of Corrosion Severity in Concrete Structures Using Ultrasonic Imaging and Linear Discriminant Analysis. Sustainability, 14(23), 15768. https://doi.org/10.3390/su142315768