Design of Sustainable Asphalt Mixtures for Bike Lanes Using RAP and Ceramic Waste as Substitutes for Natural Aggregates

Abstract

:1. Introduction

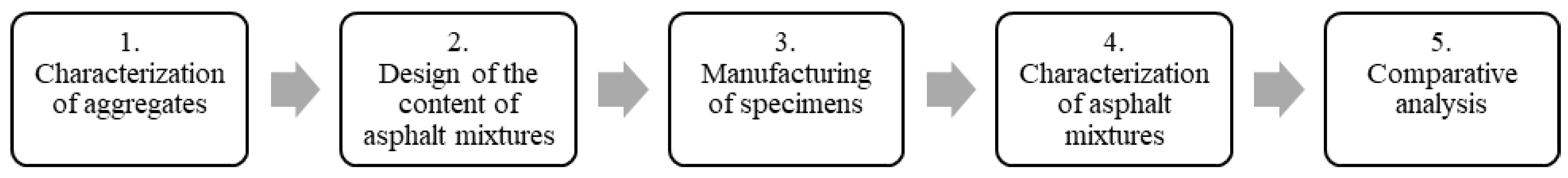

2. Materials and Methods

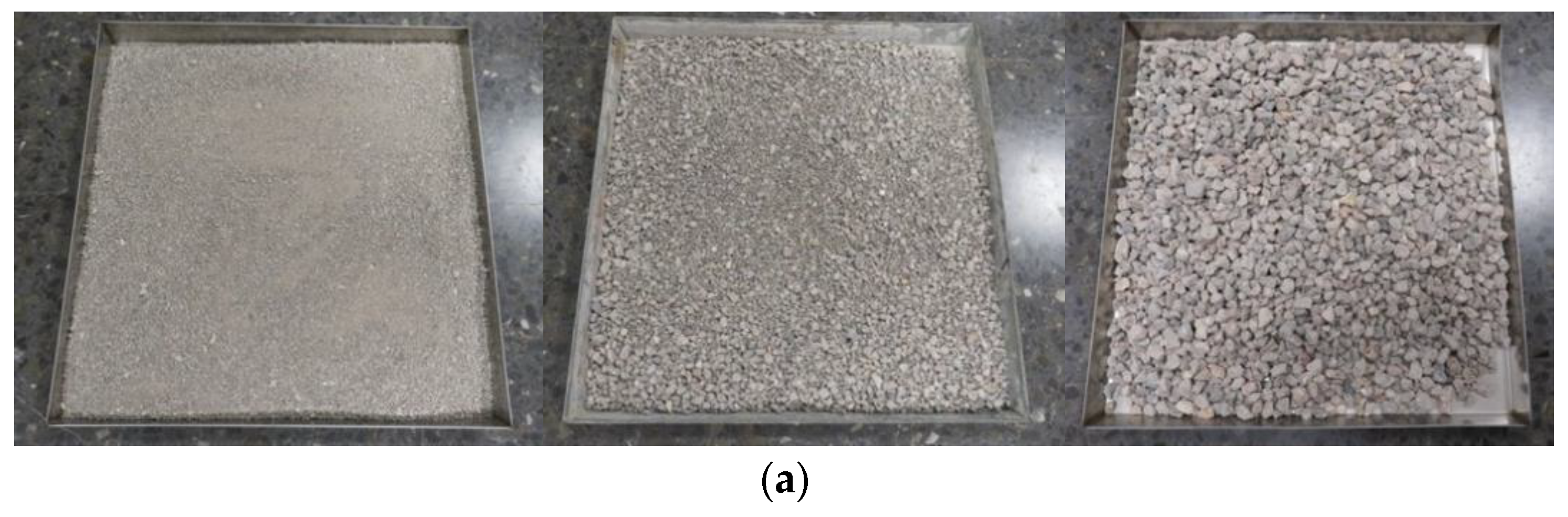

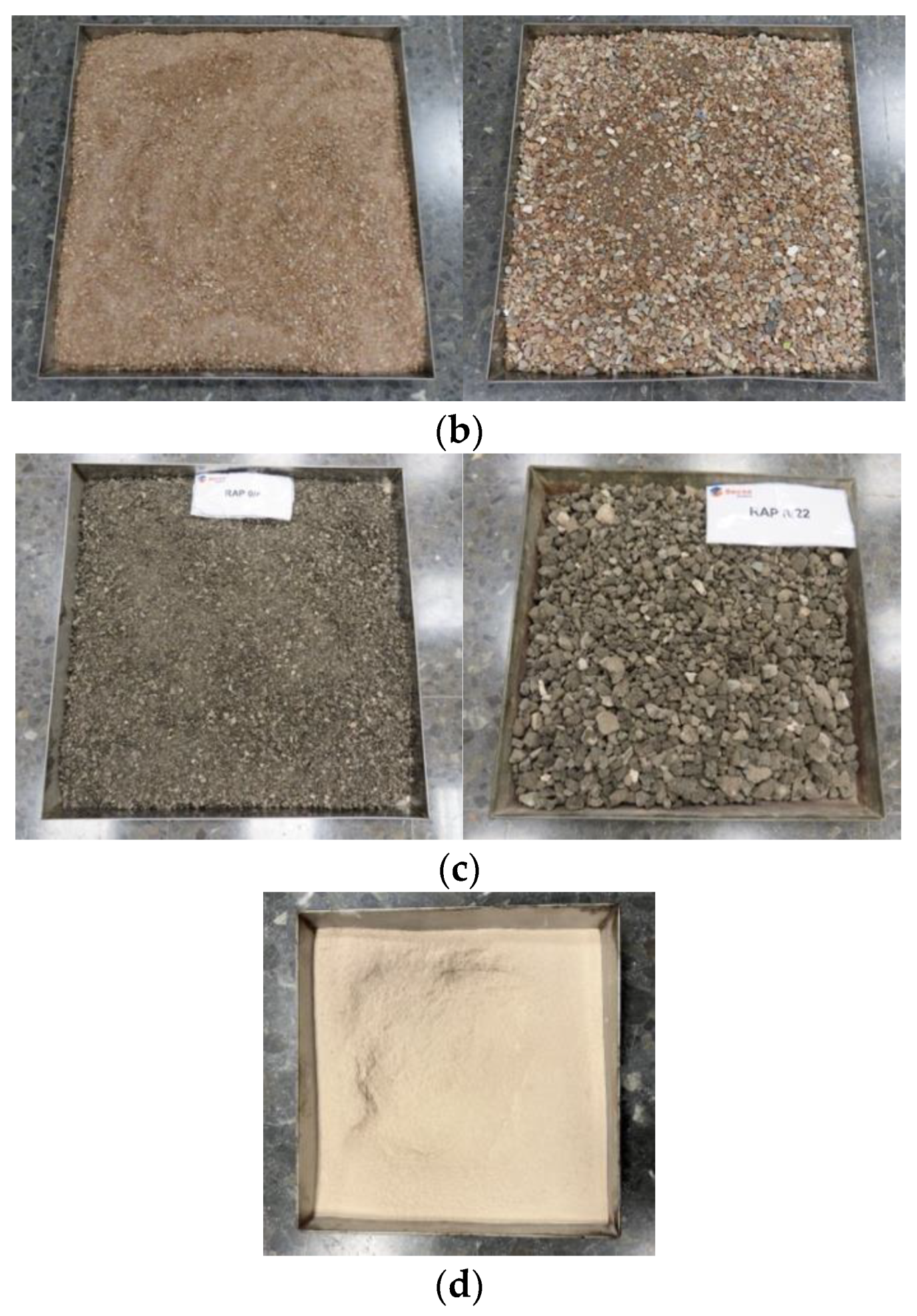

2.1. Materials

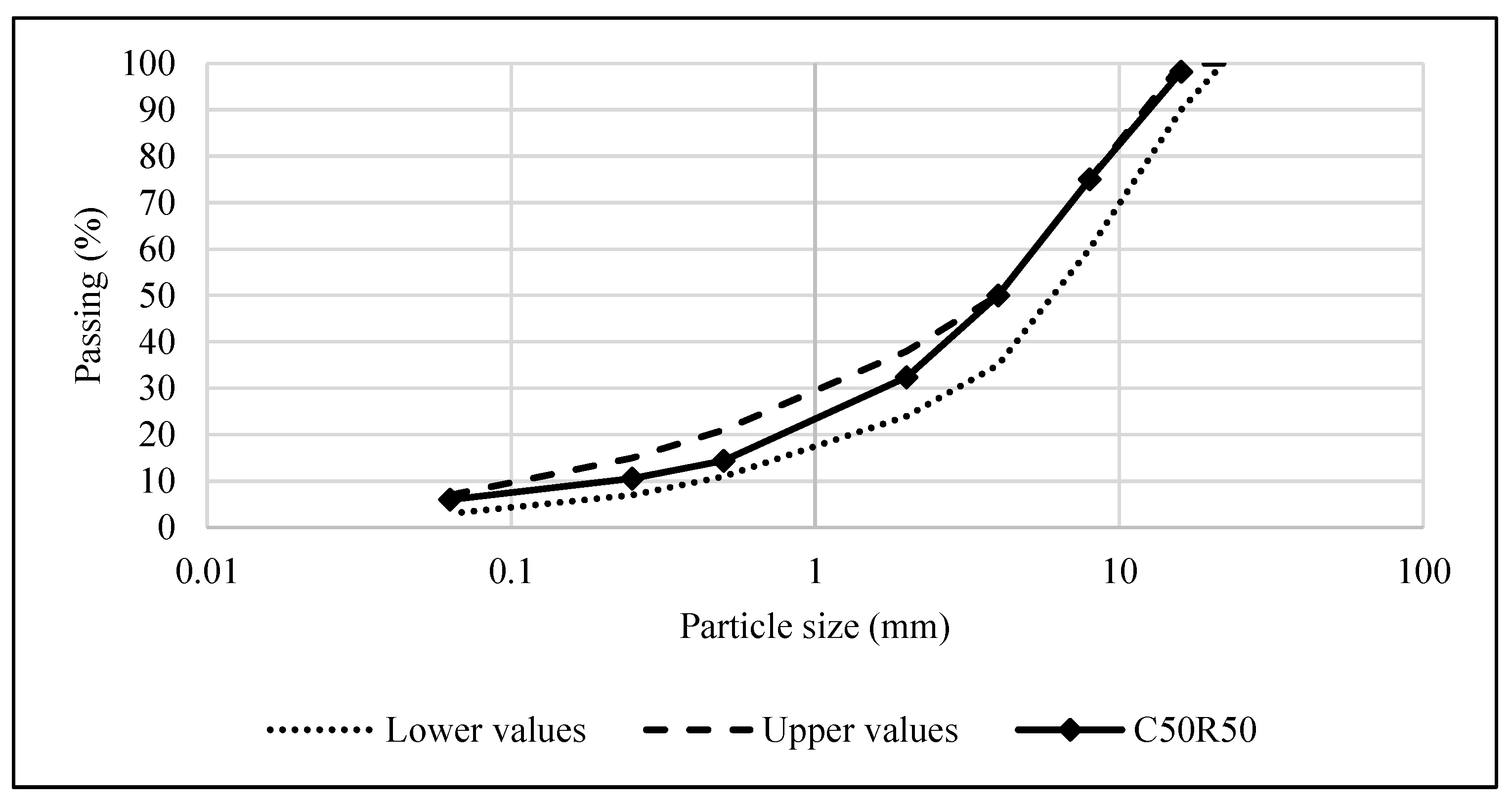

2.2. Design of Asphalt Mixtures

2.3. Manufacturing of Asphalt Mixture Specimens

3. Results

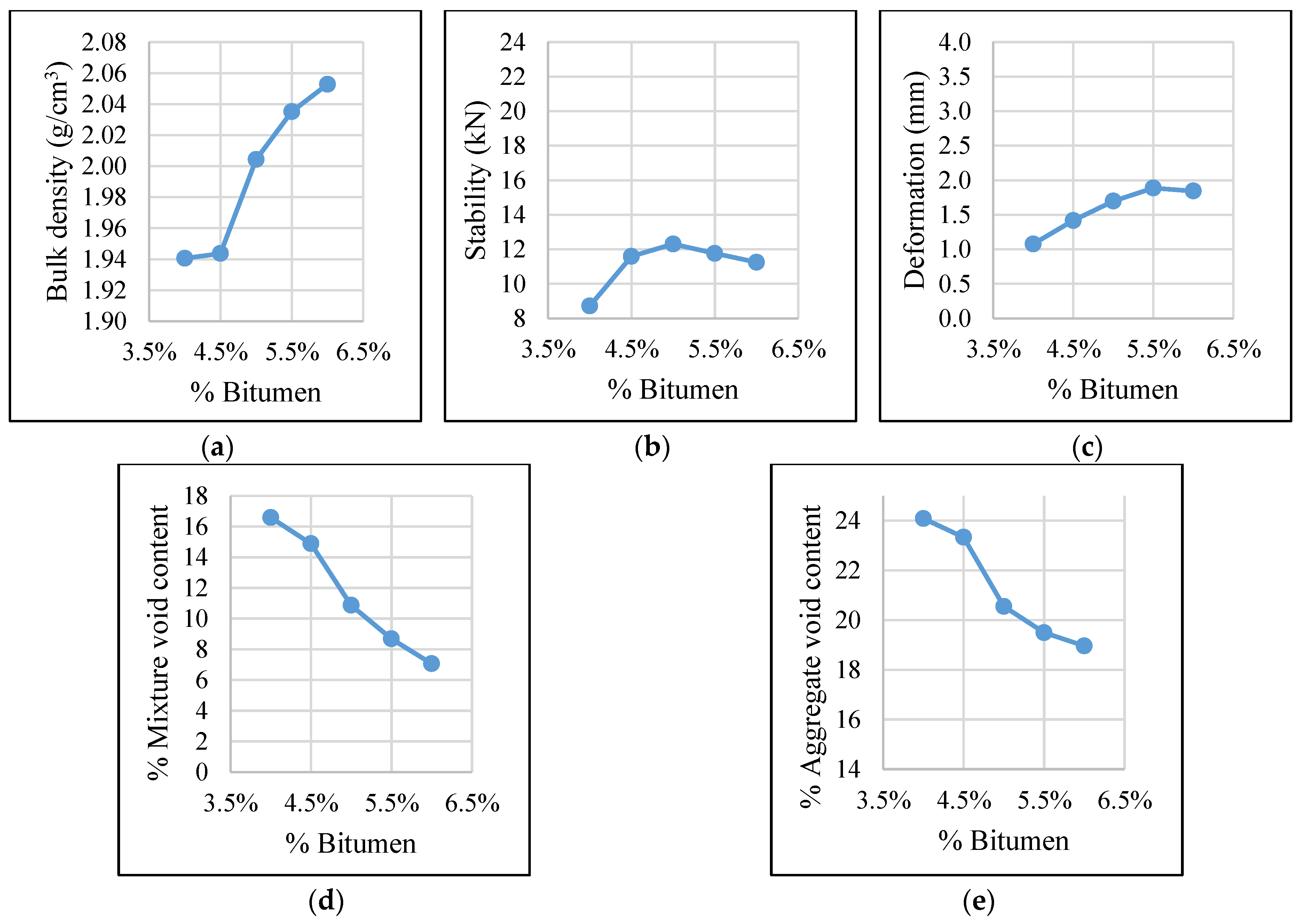

3.1. Asphalt Mixture C100

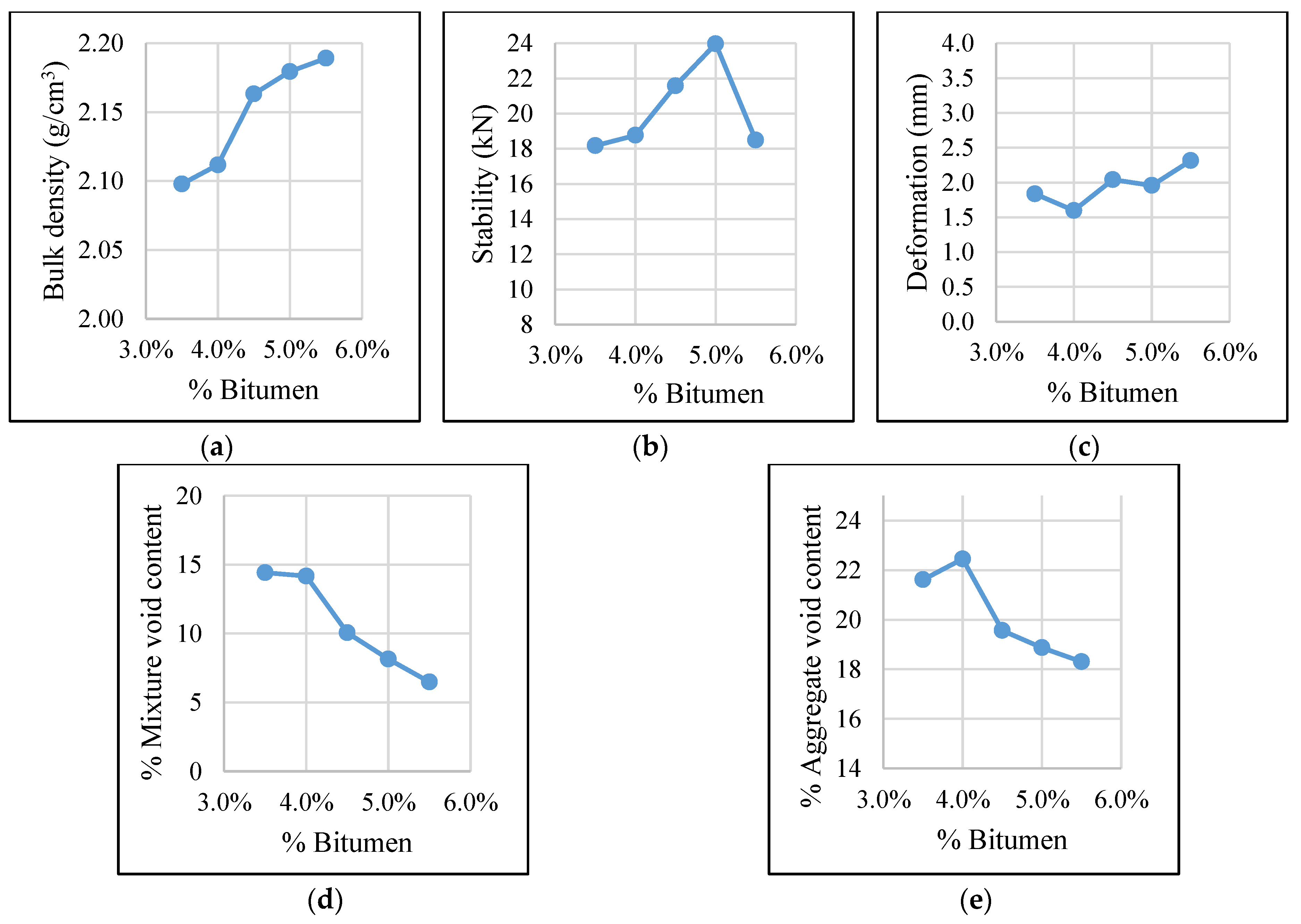

3.2. Asphalt Mixture C50R50

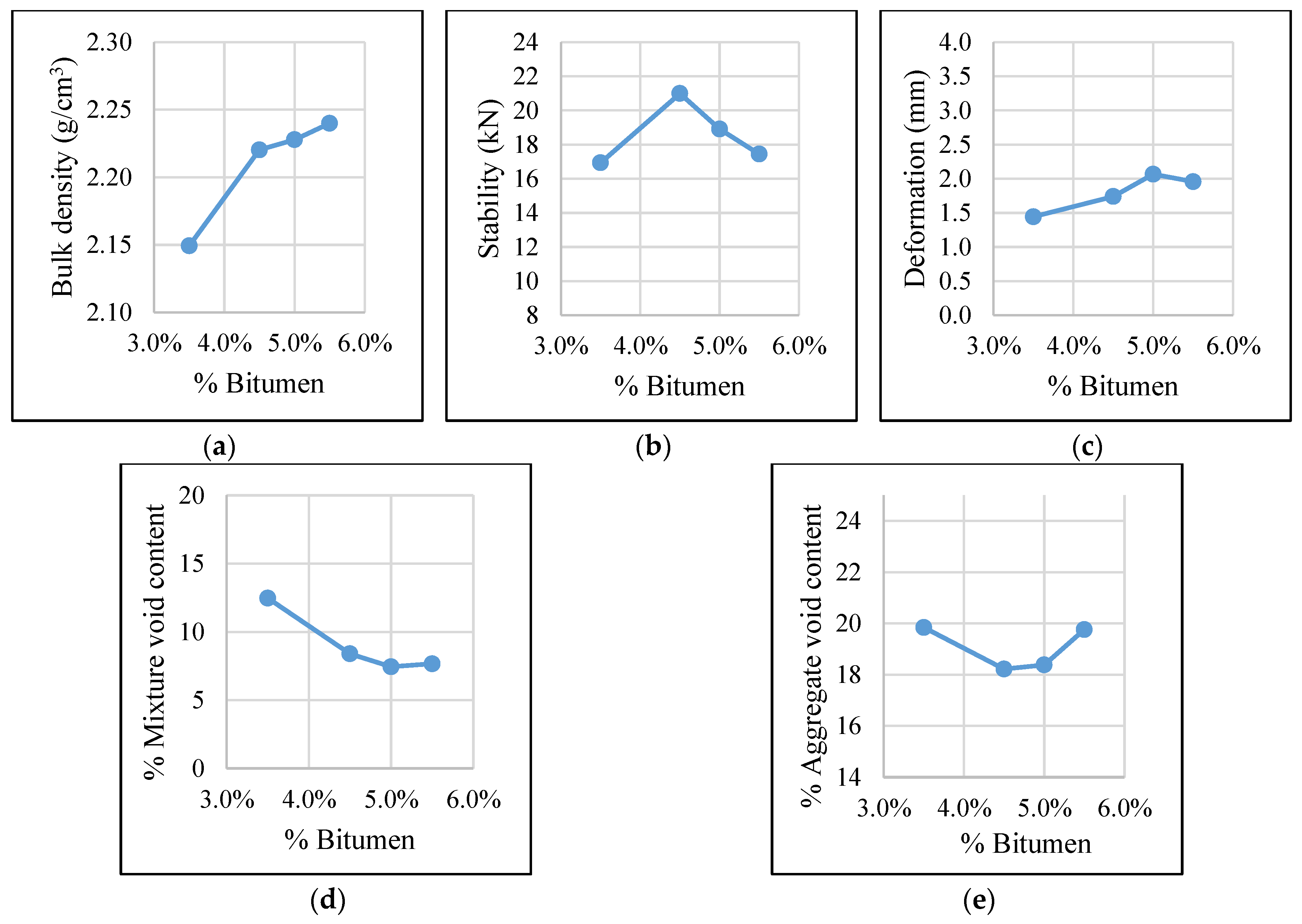

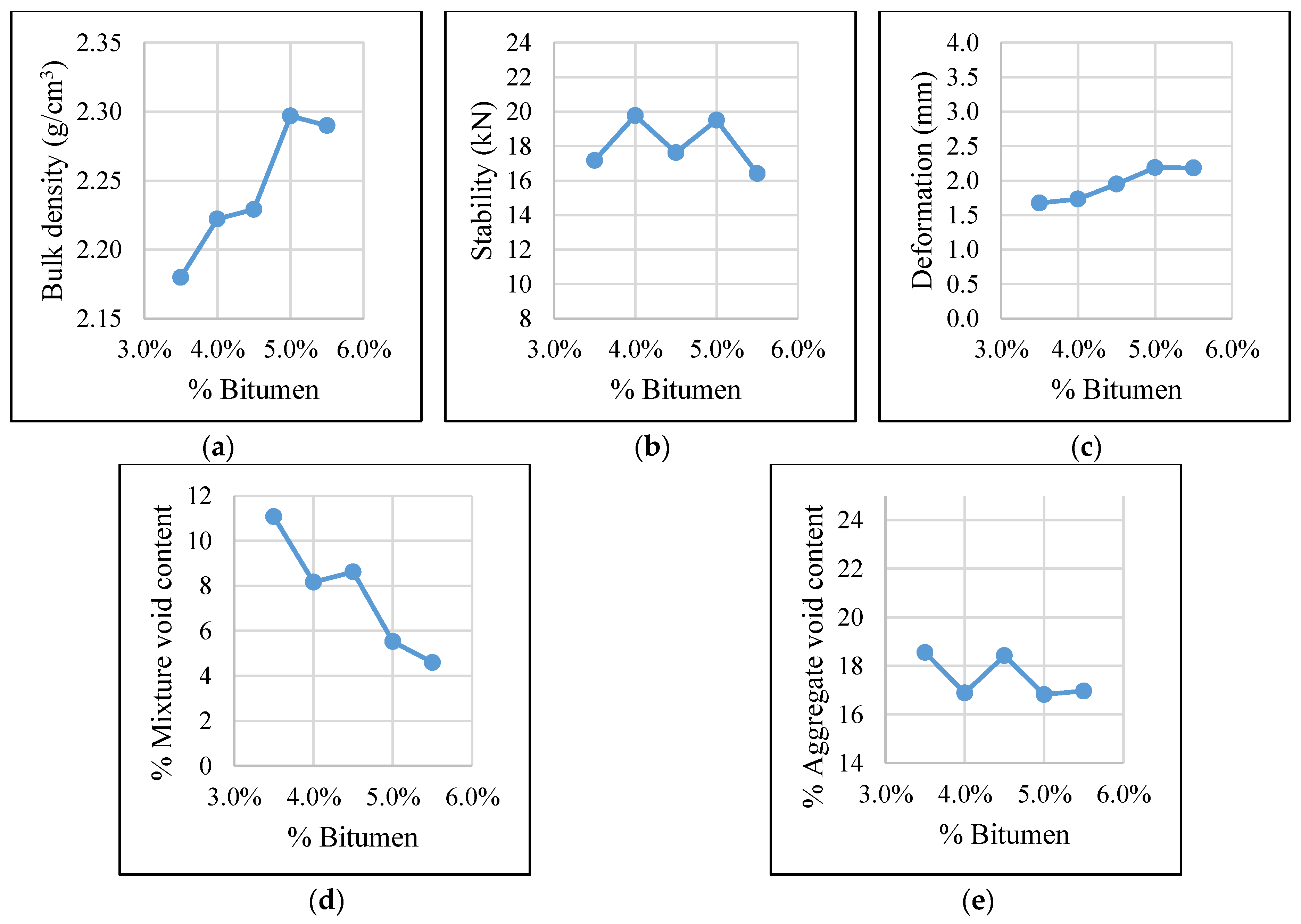

3.3. Asphalt Mixture C35R50A15

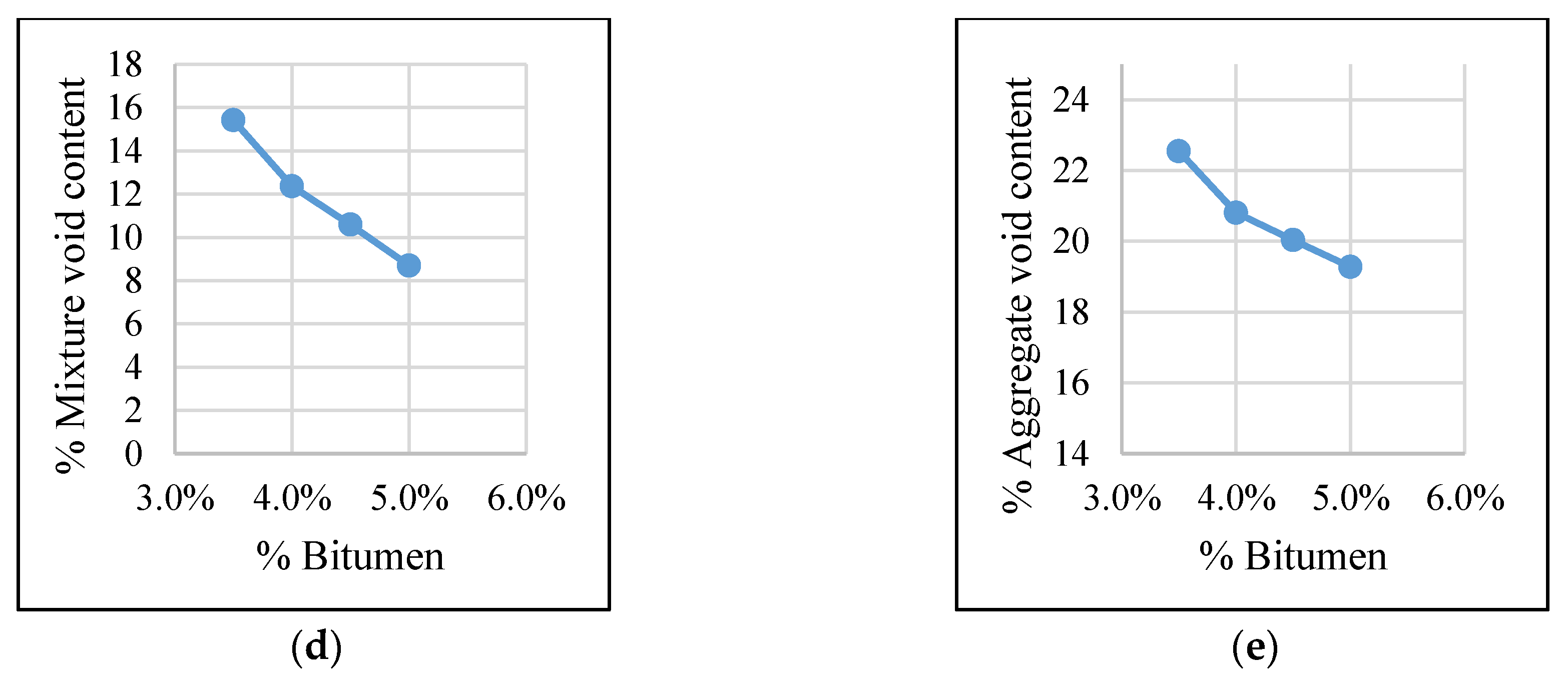

3.4. Asphalt Mixture C50R25A25

3.5. Asphalt Mixture C35R25A40

3.6. Asphalt Mixture C50A50

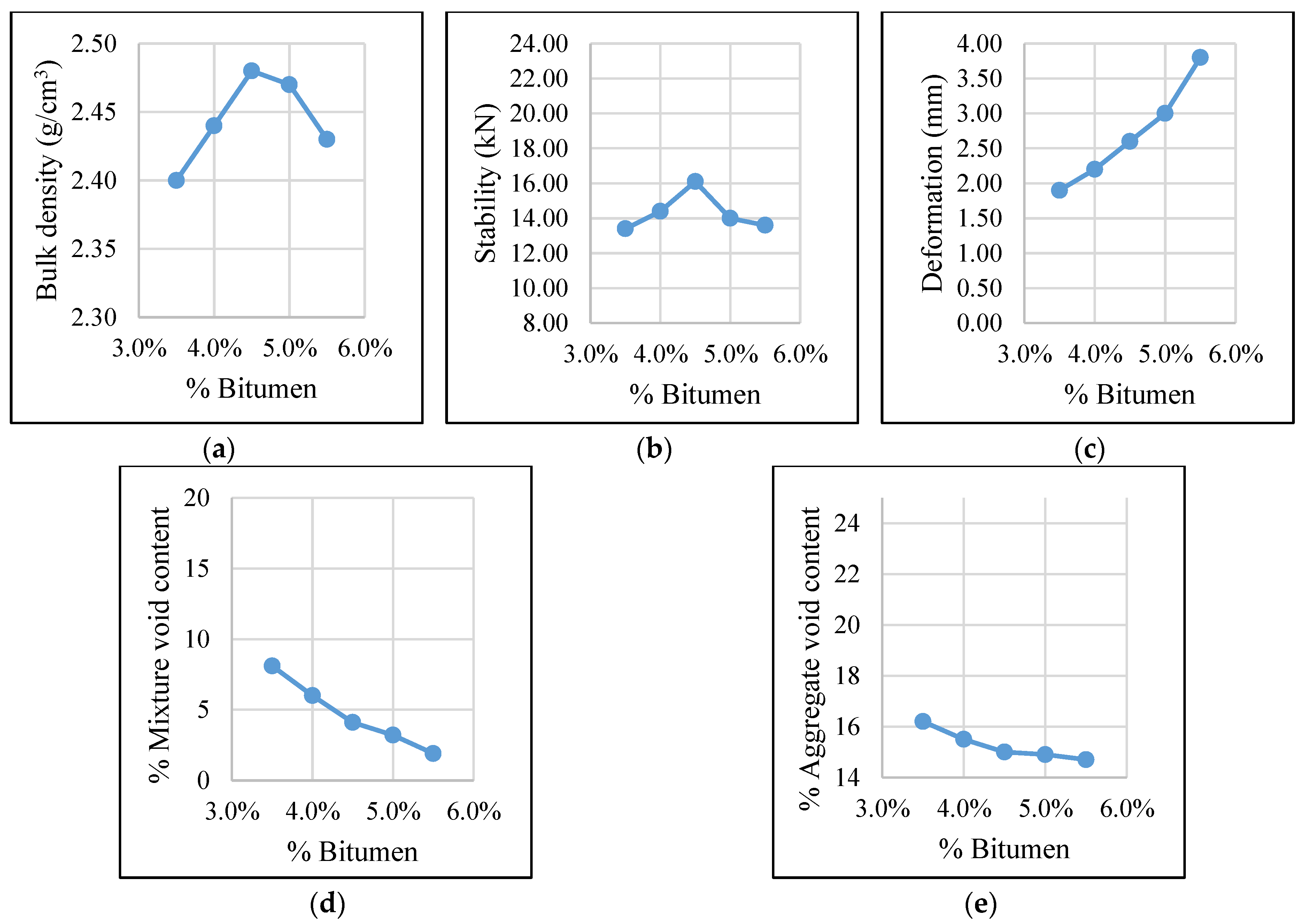

3.7. Asphalt Mixture A100

4. Discussion

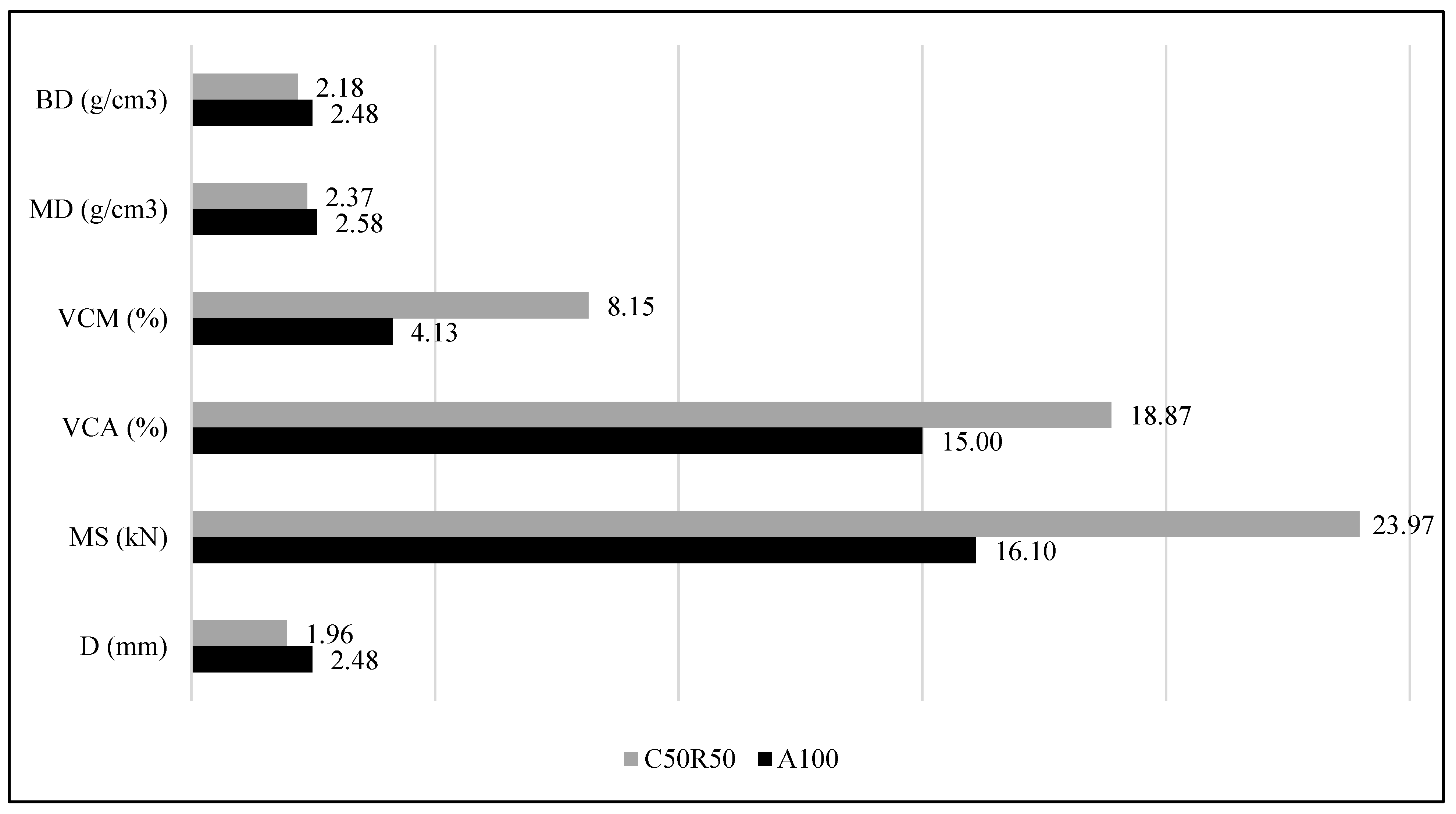

4.1. Comparative Analysis of Asphalt Mixtures

4.2. Proposal of Sustainable Asphalt Mixture

4.3. Limitations of Use

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- IPCC. Climate Change 2014: Mitigation of Climate Change. Contribution of Working Group III to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; Intergovernmental Panel on Climate Change 2014; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2014. [Google Scholar]

- Chester, M.V.; Horvath, A. Environmental assessment of passenger transportation should include infrastructure and supply chains. Environ. Res. Lett. 2009, 4, 024008. [Google Scholar] [CrossRef]

- Noland, R.B.; Hanson, C.S. Life-cycle greenhouse gas emissions associated with a highway reconstruction: A New Jersey case study. J. Clean. Prod. 2015, 107, 731–740. [Google Scholar] [CrossRef]

- Statistical Office of the European Communities. EUROSTAT: Waste Statistics; Eurostat: Luxembourg, 2018; Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Waste_statistics#Total_waste_generation (accessed on 30 September 2021).

- European Commission. Directive 2008/98/Ec of The European Parliament and of The Council of 19 November 2008 on Waste and Repealing Certain Directives. Off. J. Eur. Union 2008, 34, 99–126. [Google Scholar]

- INE. Estadísticas Sobre Generación de Residuos; Instituto Nacional de Estadística: Madrid, Spain, 2022; Available online: https://www.ine.es/dyngs/INEbase/es/categoria.htm?c=Estadistica_P&cid=1254735976612 (accessed on 17 September 2022).

- Williams, B.A.; Willis, J.R.; Shacat, J. Asphalt Pavement Industry Survey on Recycled Materials and Warm-Mix Asphalt Usage: 2019; NAPA: Greenbelt, MD, USA, 2020. [Google Scholar]

- Hajj, E.Y.; Sebaaly, P.E.; Kandiah, P. Use of Reclaimed Asphalt Pavements (RAP) in Airfields HMA Pavements; AAPTP Project 05–06; Department of Civil and Environmental Engineering College of Engineering, University of Nevada Reno: Reno, NV, USA, 2008; pp. 1–136. [Google Scholar]

- Jamshidi, A.; White, G. Evaluation of performance and challenges of use of waste materials in pavement construction: A critical review. Appl. Sci. 2019, 10, 226. [Google Scholar] [CrossRef] [Green Version]

- Zhu, J.; Ma, T.; Fang, Z. Characterization of agglomeration of reclaimed asphalt pavement for cold recycling. Constr. Build. Mater. 2020, 240, 117912. [Google Scholar] [CrossRef]

- Cardoso, R.; Silva, R.V.; de Brito, J.; Dhir, R. Use of recycled aggregates from construction and demolition waste in geotechnical applications: A literature review. Waste Manag. 2016, 49, 131–145. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, Z.; Guo, D.; Xu, C.; Zhang, K. Study on cooling effect and pavement performance of thermal-resistant asphalt mixture. Adv. Mater. Sci. Eng. 2018, 2018, 6107656. [Google Scholar] [CrossRef] [Green Version]

- Che, T.; Pan, B.; Ouyang, J. The laboratory evaluation of incorporating ceramsite into HMA as fine aggregates. Constr. Build. Mater. 2018, 186, 1239–1246. [Google Scholar] [CrossRef]

- Silvestre, R.; Medel, E.; García, A.; Navas, J. Utilizing recycled ceramic aggregates obtained from tile industry in the design of open graded wearing course on both laboratory and in situ basis. Mater. Des. 2013, 50, 471–478. [Google Scholar] [CrossRef]

- Silvestre, R.; Medel, E.; García, A.; Navas, J. Using ceramic wastes from tile industry as a partial substitute of natural aggregates in hot mix asphalt binder courses. Constr. Build. Mater. 2013, 45, 115–122. [Google Scholar] [CrossRef] [Green Version]

- Feng, D.; Yi, J.; Wang, D. Performance and thermal evaluation of incorporating waste ceramic aggregates in wearing layer of asphalt pavement. J. Mater. Civ. Eng. 2013, 25, 857–863. [Google Scholar] [CrossRef]

- Tavira, J.; Jiménez, J.R.; Ayuso, J.; López-Uceda, A.; Ledesma, E.F. Recycling screening waste and recycled mixed aggregates from construction and demolition waste in paved bike lanes. J. Clean. Prod. 2018, 190, 211–220. [Google Scholar] [CrossRef]

- Ahmed, I. Use of Waste Materials in Highway Construction (FHWA/IN/JHRP-91/3); Department of Civil Engineering, Purdue University: West Lafayette, IN, USA, 1991; p. 299. [Google Scholar]

- Wu, S.; Xue, Y.; Ye, Q.; Chen, Y. Utilization of steel slag as aggregates for stone mastic asphalt (SMA) mixtures. Build. Environ. 2007, 42, 2580–2585. [Google Scholar] [CrossRef]

- Chen, J.S.; Wei, S.H. Engineering properties and performance of asphalt mixtures incorporating steel slag. Constr. Build. Mater. 2016, 128, 148–153. [Google Scholar] [CrossRef]

- Amelian, S.; Manian, M.; Abtahi, S.M.; Goli, A. Moisture sensitivity and mechanical performance assessment of warm mix asphalt containing by-product steel slag. J. Clean. Prod. 2018, 176, 329–337. [Google Scholar] [CrossRef]

- Pattanaik, M.L.; Choudhary, R.; Kumar, B.; Kumar, A. Mechanical properties of open graded friction course mixtures with different contents of electric arc furnace steel slag as an alternative aggregate from steel industries. Road Mater. Pavement Des. 2021, 22, 268–292. [Google Scholar] [CrossRef]

- Pattanaik, M.L.; Choudhary, R.; Kumar, B. Moisture susceptibility of open-graded friction course mixes with EAF steel slag and modified binders. Adv. Civ. Eng. Mater. 2019, 8, 248–266. [Google Scholar] [CrossRef]

- Lastra-González, P.; Calzada-Pérez, M.A.; Castro-Fresno, D.; Vega-Zamanillo, Á.; Indacoechea-Vega, I. Comparative analysis of the performance of asphalt concretes modified by dry way with polymeric waste. Constr. Build. Mater. 2016, 112, 1133–1140. [Google Scholar] [CrossRef] [Green Version]

- Jamshidi, A.; Kurumisawa, K.; Nawa, T.; Igarashi, T. Performance of pavements incorporating waste glass: The current state of the art. Renew. Sustain. Energy Rev. 2016, 64, 211–236. [Google Scholar] [CrossRef]

- Movilla-Quesada, D.; Raposeiras, A.C.; Muñoz, O.; Castro-Fresno, D. Reduction in the use of mineral aggregate by recycling cellulose ashes to decrease the aging of hot asphalt mixtures. Constr. Build. Mater. 2017, 143, 547–557. [Google Scholar] [CrossRef] [Green Version]

- Movilla-Quesada, D.; Raposeiras, A.C.; Lagos-Varas, M.; Muñoz-Cáceres, O.; Andrés-Valeri, V.C.; Troncoso, L. Study of the Optimal Dosage of Celullose Ash as a Contribution Filler in Asphalt Mixtures Based on Its Adhesiveness under Moisture Conditions. Sustainability 2021, 13, 854. [Google Scholar] [CrossRef]

- UNE-EN 12697-8; Bituminous Mixtures—Test Methods—Part 8: Determination of Void Characteristics of Bituminous Specimens. Asociación Española de Normalización: Madrid, Spain, 2020.

- UNE-EN 12697-6; Bituminous Mixtures—Test Methods for Hot Mix Asphalt—Part 6: Determination of Bulk Density of Bituminous Specimens. Asociación Española de Normalización: Madrid, Spain, 2012.

- UNE-EN 12697-5; Bituminous Mixtures—Test Methods—Part 5: Determination of the Maximum Density. Asociación Española de Normalización: Madrid, Spain, 2020.

- UNE-EN 12697-34; Bituminous Mixtures—Test Methods—Part 34: Marshall Test. Asociación Española de Normalización: Madrid, Spain, 2022.

- UNE-EN 933-2; Tests for Geometrical Properties of Aggregates—Part 2: Determination of Particle Size Distribution—Test Sieves, Nominal Size of Apertures. Asociación Española de Normalización: Madrid, Spain, 2022.

- Spanish Ministry of Public Works. Pliego de Prescripciones Técnicas Generales Para Obras de Carreteras Y Puentes de la Dirección General de Carreteras (PG-3); Ministerio de Fomento, Dirección General de Carreteras: Madrid, Spain, 2008. [Google Scholar]

- UNE-EN 12697-35; Bituminous Mixtures—Test Methods—Part 35: Laboratory Mixing. Asociación Española de Normalización: Madrid, Spain, 2017.

- UNE-EN 12697-30; Bituminous Mixtures—Test Methods—Part 30: Specimen Preparation by Impact Compactor. Asociación Española de Normalización: Madrid, Spain, 2019.

| Material | Fraction | Test Sieves for Aggregates UNE-EN 933-2 [32] (mm) | D * | WA * | B * | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 22 | 16 | 8 | 4 | 2 | 0.5 | 0.25 | 0.063 | |||||

| Filler | - | 100 | 100 | 100 | 100 | 100 | 99.93 | 99.43 | 78.86 | - | - | - |

| NA | 0/4 | 100 | 100 | 99.64 | 97.37 | 64.33 | 24.81 | 17.16 | 3.02 | 2.767 | 0.68 | - |

| 4/10 | 100 | 100 | 74.69 | 18.63 | 2.79 | 1.50 | 0.51 | 0.48 | 2.783 | 1.49 | - | |

| 10/20 | 99.80 | 75.53 | 1.35 | 0.28 | 0.14 | 0.14 | 0.12 | 0.11 | 2.731 | 1.33 | - | |

| CWA | 0/4 | 100 | 100 | 99.60 | 77.06 | 45.05 | 13.80 | 8.64 | 4.80 | 2.595 | 5.91 | - |

| 4/10 | 100 | 100 | 69.39 | 27.75 | 16.73 | 6.68 | 4.33 | 1.22 | 2.519 | 6.31 | - | |

| RAP | 0/8 | 100 | 100 | 97.66 | 73.90 | 50.18 | 24.29 | 18.11 | 10.44 | - | - | 4.42 |

| 8/22 | 99.82 | 92.94 | 36.01 | 23.42 | 17.45 | 10.46 | 8.34 | 4.80 | - | - | 2.51 | |

| AC16 surf S ** | 100 | 90–100 | 64–79 | 44–59 | 31–46 | 16–27 | 11–20 | 4–8 | - | |||

| Characteristic | Method | Unit | Limits | |

|---|---|---|---|---|

| Min. | Max. | |||

| Penetration (25 °C; 100 g; 5 s) | EN 1426 | 0.1 mm | 35 | 50 |

| Softening point | EN 1427 | °C | 50 | 58 |

| Penetration index | EN 12591 | - | −1.5 | +0.7 |

| Fraass breaking point | EN 12593 | °C | - | −5 |

| Solubility | EN 12592 | % | 99.0 | - |

| Flash point | EN 2592 | °C | 240 | - |

| Asphalt Mixture * | Material Content | Replacement Rate ** | ||

|---|---|---|---|---|

| Ceramic Waste Aggregates (CWA) | RAP | Natural Aggregates (NA) | ||

| C100 | 100% | - | - | 100% |

| C50R50 | 50% | 50% | - | 100% |

| C35R50A15 | 35% | 50% | 15% | 85% |

| C50R25A25 | 50% | 25% | 25% | 75% |

| C35R25A40 | 35% | 25% | 40% | 60% |

| C50A50 | 50% | - | 50% | 50% |

| A100 | - | - | 100% | 0% |

| Asphalt Mixture | Bitumen in Mixture (%) | Filler | NA | CWA | RAP | ||||

|---|---|---|---|---|---|---|---|---|---|

| 0/4 | 4/10 | 10/20 | 0/4 | 4/10 | 0/8 | 8/22 | |||

| C100 | 6.0 | 6.91% | - | - | - | 11.56% | 81.52% | - | - |

| 5.5 | 6.37% | - | - | - | 12.12% | 81.51% | - | - | |

| 5.0 | 5.56% | - | - | - | 12.94% | 81.51% | - | - | |

| 4.5 | 4.75% | - | - | - | 13.76% | 81.49% | - | - | |

| 4.0 | 3.94% | - | - | - | 14.58% | 81.48% | - | - | |

| C50R50 | 5.5 | 1.67% | - | - | - | 21.24% | 25.17% | 22.49% | 23.92% |

| 5.0 | 0.87% | - | - | - | 22.54% | 24.53% | 22.65% | 24.41% | |

| 4.5 | 0.60% | - | - | - | 23.84% | 23.88% | 22.82% | 24.90% | |

| 4.0 | 0.00% | - | - | - | 18.24% | 29.79% | 16.69% | 31.31% | |

| 3.5 | 0.00% | - | - | - | 8.96% | 40.87% | 13.31% | 33.36% | |

| C35R50A15 | 5.5 | 2.29% | 3.17% | 3.45% | 5.26% | 11.88% | 21.20% | 19.57% | 27.68% |

| 5.0 | 1.57% | 3.97% | 3.23% | 5.48% | 11.07% | 22.18% | 20.07% | 27.43% | |

| 4.5 | 0.85% | 4.70% | 3.21% | 5.57% | 10.32% | 23.10% | 20.28% | 27.47% | |

| 4.0 | 0.23% | 5.46% | 3.21% | 5.51% | 9.05% | 24.55% | 19.32% | 28.68% | |

| 3.5 | 0.03% | 8.09% | 2.58% | 3.78% | 6.18% | 27.60% | 12.00% | 36.25% | |

| C50R25A25 | 5.5 | 4.02% | 5.63% | 4.44% | 9.53% | 16.61% | 30.64% | 8.87% | 14.75% |

| 5.0 | 3.31% | 6.88% | 3.99% | 9.56% | 15.69% | 31.81% | 9.07% | 14.68% | |

| 4.5 | 2.59% | 8.24% | 3.46% | 9.58% | 14.50% | 33.25% | 9.46% | 14.41% | |

| 4.0 | 1.85% | 9.32% | 3.30% | 9.53% | 12.97% | 35.03% | 10.41% | 13.59% | |

| 3.5 | 1.11% | 10.70% | 3.05% | 9.26% | 10.75% | 37.50% | 11.43% | 12.70% | |

| C35R25A40 | 5.5 | 4.12% | 10.10% | 10.46% | 13.12% | 12.83% | 20.24% | 10.03% | 13.59% |

| 5.0 | 3.42% | 11.63% | 9.97% | 12.98% | 11.81% | 21.44% | 10.02% | 13.73% | |

| 4.5 | 2.71% | 13.22% | 9.40% | 12.86% | 10.71% | 22.71% | 10.05% | 13.83% | |

| 4.0 | 1.98% | 14.64% | 8.81% | 12.98% | 9.68% | 23.92% | 10.43% | 13.57% | |

| 3.5 | 1.23% | 15.97% | 8.13% | 13.27% | 8.51% | 25.26% | 11.05% | 13.07% | |

| C50A50 | 5.5 | 6.14% | 13.43% | 10.92% | 19.51% | 18.67% | 31.33% | - | - |

| 5.0 | 5.39% | 15.20% | 10.12% | 19.29% | 17.18% | 32.82% | - | - | |

| 4.5 | 4.63% | 17.10% | 9.32% | 18.94% | 15.51% | 34.50% | - | - | |

| 4.0 | 3.89% | 19.18% | 8.49% | 18.46% | 13.60% | 36.39% | - | - | |

| 3.5 | 3.14% | 21.49% | 7.60% | 17.77% | 11.40% | 38.60% | - | - | |

| A100 | 5.5 | 6.90% | 31.56% | 36.62% | 24.92% | - | - | - | - |

| 5.0 | 6.09% | 32.95% | 35.89% | 25.06% | - | - | - | - | |

| 4.5 | 5.29% | 34.28% | 35.18% | 25.25% | - | - | - | - | |

| 4.0 | 4.48% | 35.63% | 34.43% | 25.47% | - | - | - | - | |

| 3.5 | 3.67% | 36.95% | 33.58% | 25.80% | - | - | - | - | |

| Asphalt Mixture | BIN (%) | F/B | BD (g/cm3) | MD (g/cm3) | VCM (%) | VCA (%) | MS (kN) | D (mm) |

|---|---|---|---|---|---|---|---|---|

| C100 | 6.0 | 1.17 | 2.053 | 2.210 | 7.059 | 18.959 | 11.76 | 1.84 |

| C50R50 | 5.0 | 1.20 | 2.179 | 2.374 | 8.152 | 18.871 | 23.97 | 1.96 |

| C35R50A15 | 4.5 | 1.20 | 2.220 | 2.425 | 8.393 | 18.218 | 20.99 | 1.74 |

| C50R25A25 | 5.0 | 1.20 | 2.190 | 2.420 | 8.699 | 19.277 | 19.12 | 1.75 |

| C35R25A40 | 5.0 | 1.20 | 2.297 | 2.433 | 5.526 | 16.822 | 19.51 | 2.19 |

| C50A50 | 5.0 | 1.20 | 2.218 | 2.358 | 5.879 | 16.592 | 16.78 | 1.92 |

| A100 | 4.5 | 1.20 | 2.480 | 2.580 | 4.125 | 15.000 | 16.10 | 2.48 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Llopis-Castelló, D.; Alonso-Troyano, C.; Álvarez-Troncoso, P.; Marzá-Beltrán, A.; García, A. Design of Sustainable Asphalt Mixtures for Bike Lanes Using RAP and Ceramic Waste as Substitutes for Natural Aggregates. Sustainability 2022, 14, 15777. https://doi.org/10.3390/su142315777

Llopis-Castelló D, Alonso-Troyano C, Álvarez-Troncoso P, Marzá-Beltrán A, García A. Design of Sustainable Asphalt Mixtures for Bike Lanes Using RAP and Ceramic Waste as Substitutes for Natural Aggregates. Sustainability. 2022; 14(23):15777. https://doi.org/10.3390/su142315777

Chicago/Turabian StyleLlopis-Castelló, David, Carlos Alonso-Troyano, Pablo Álvarez-Troncoso, Aida Marzá-Beltrán, and Alfredo García. 2022. "Design of Sustainable Asphalt Mixtures for Bike Lanes Using RAP and Ceramic Waste as Substitutes for Natural Aggregates" Sustainability 14, no. 23: 15777. https://doi.org/10.3390/su142315777