Design of a Disinfection and Epidemic Prevention Robot Based on Fuzzy QFD and the ARIZ Algorithm

Abstract

:1. Introduction

2. Related Work

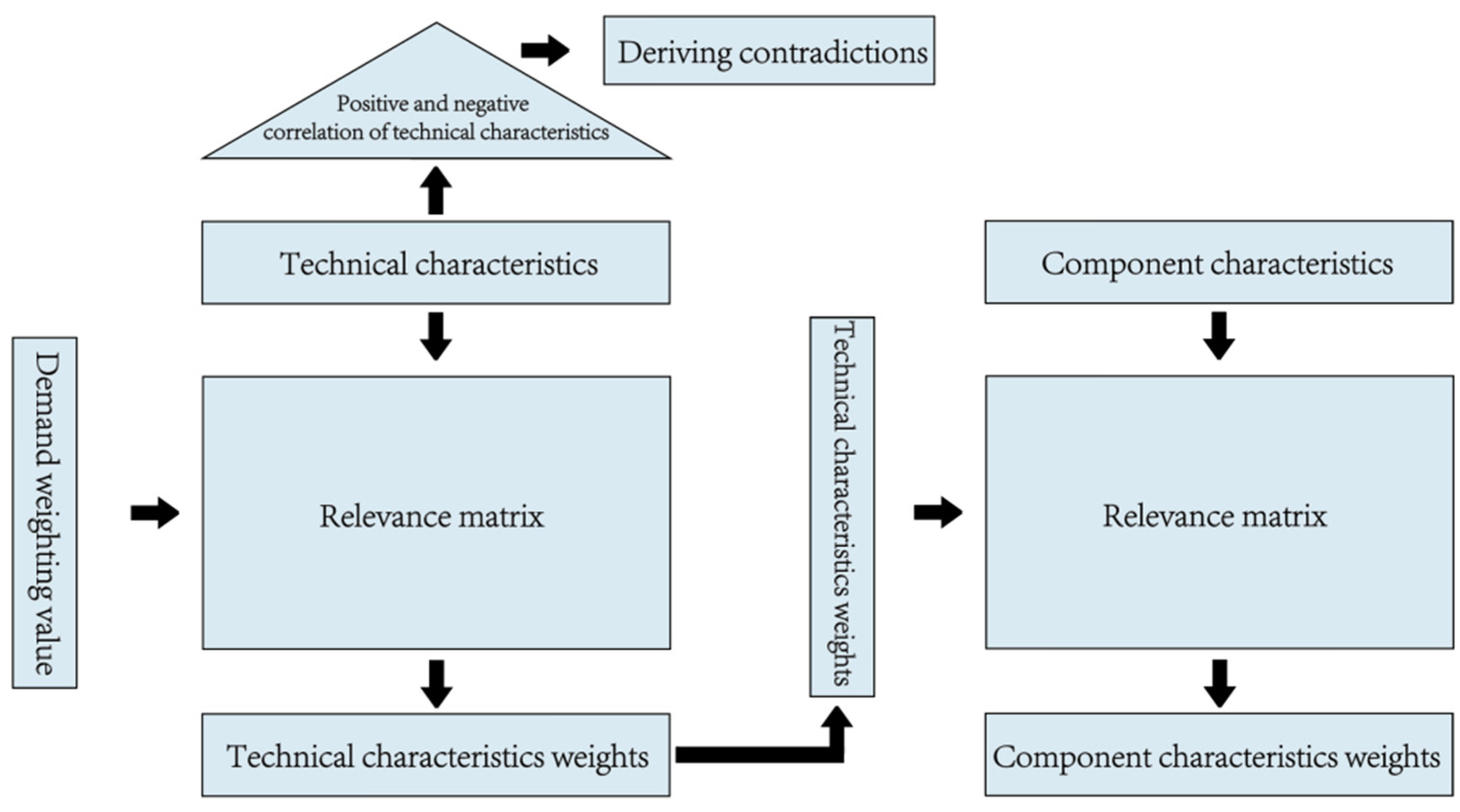

3. Research Framework

3.1. Design Process

3.2. Analysis of Infection and Epidemic Prevention Robot’s Requirements

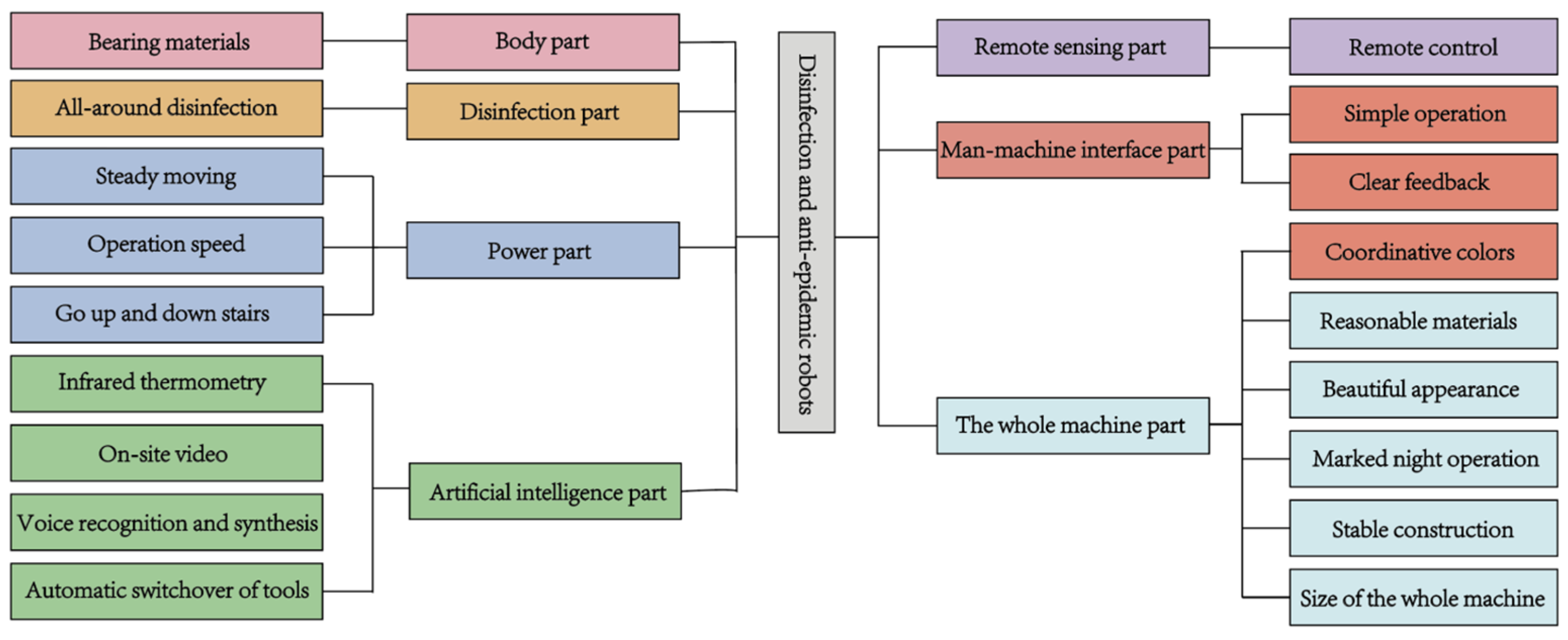

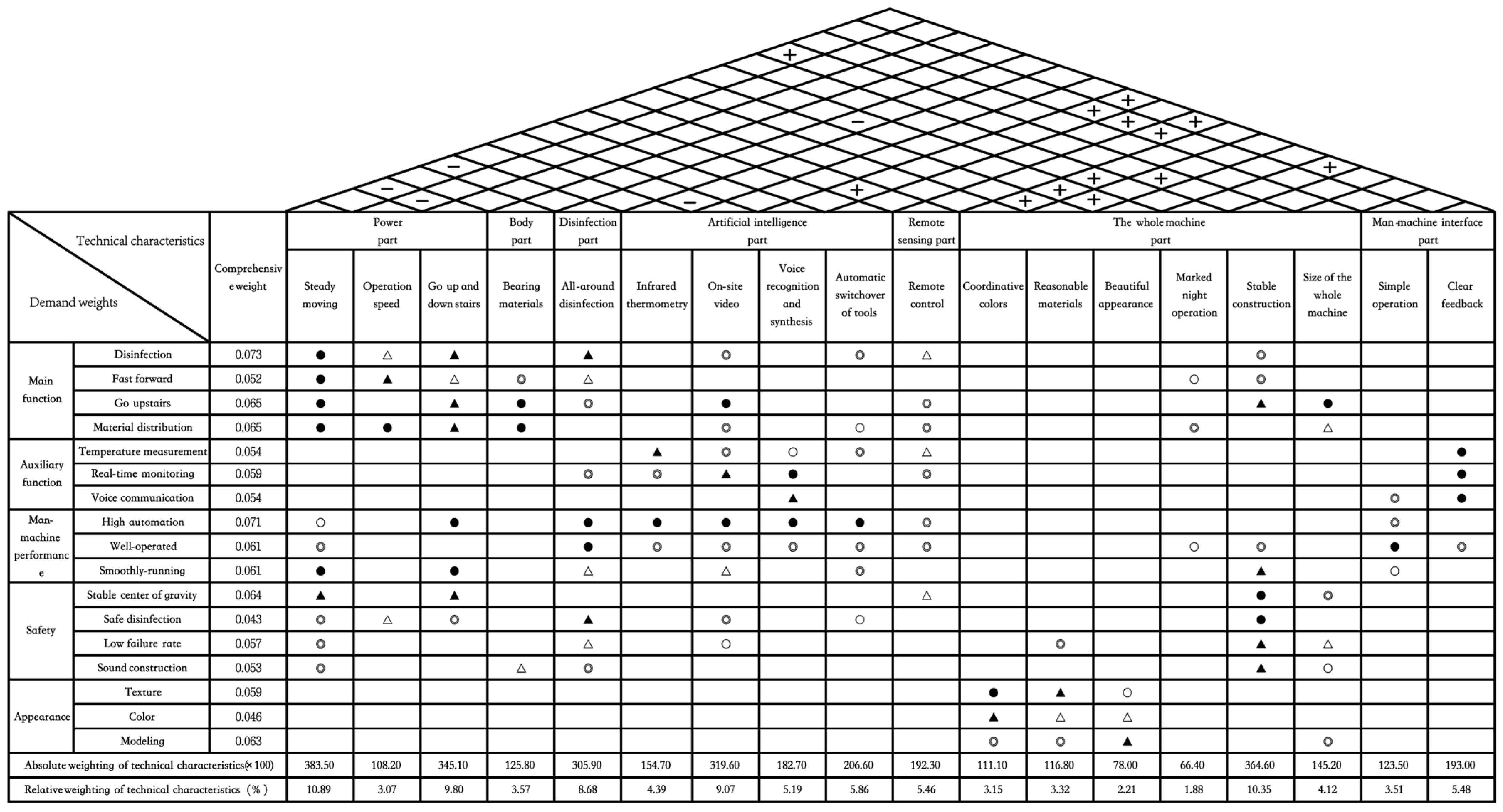

3.3. Demand Transformation of the Disinfection and Epidemic Prevention Robot

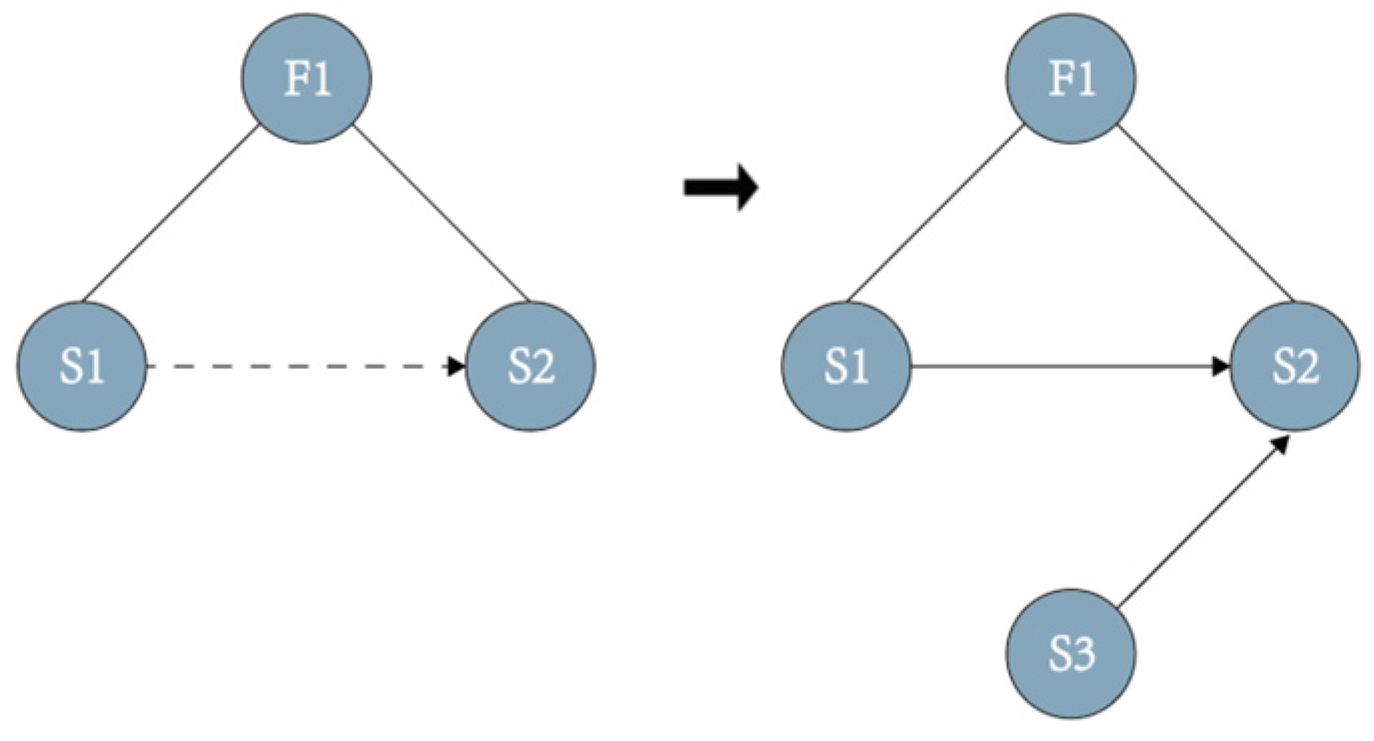

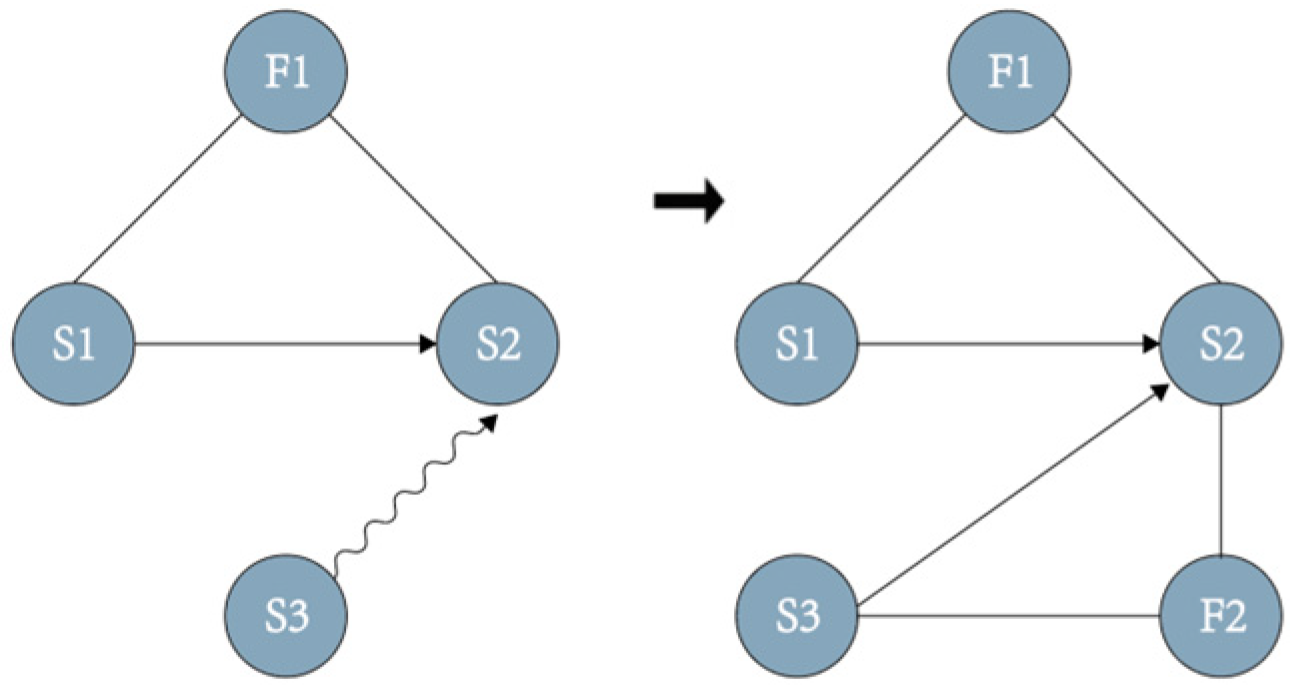

3.4. Conflict Resolution of the Disinfection and Epidemic Prevention Robot

| Conflict | Solution Principle | Solution Plan |

|---|---|---|

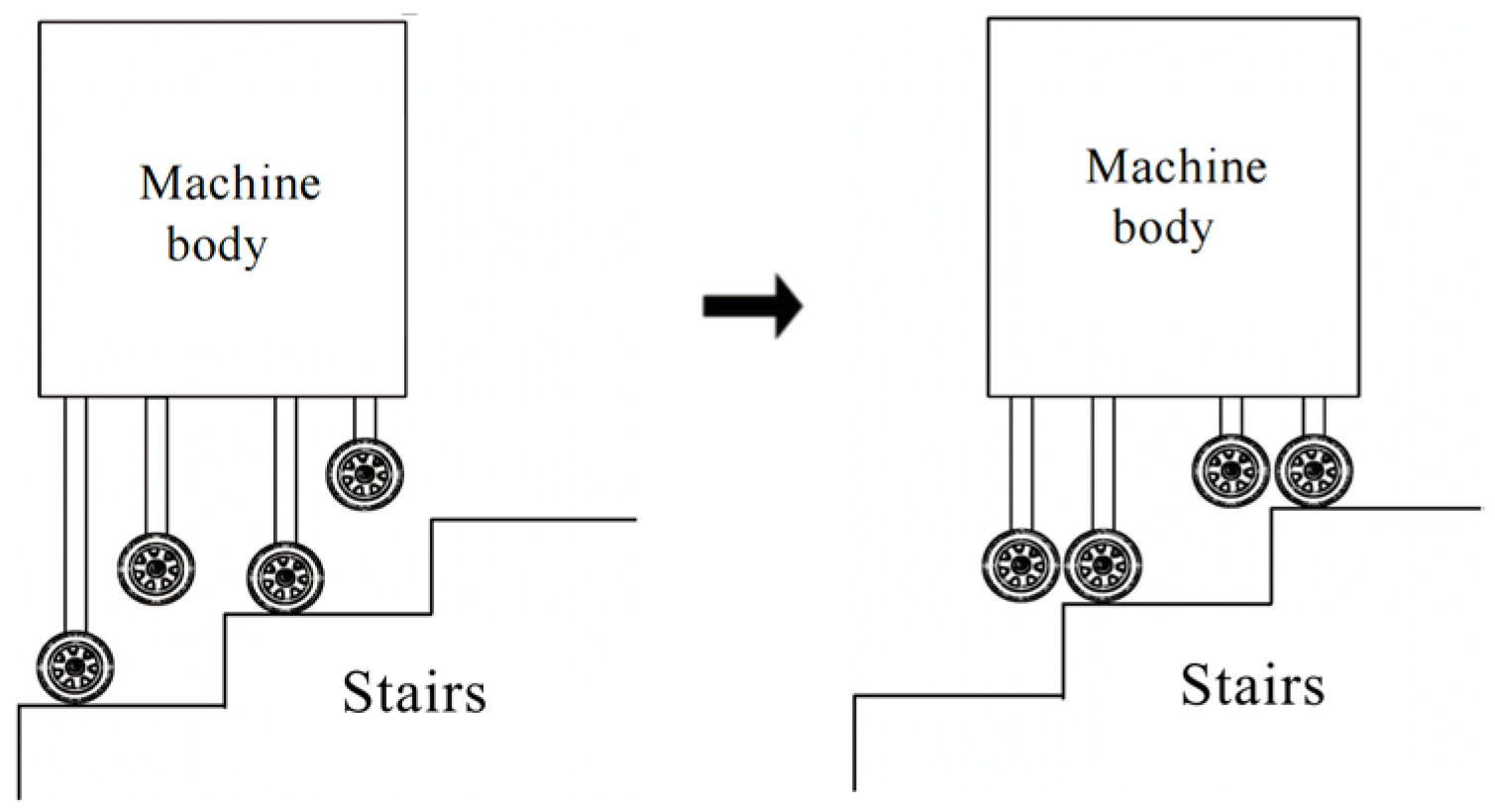

| Steady movement—movement up and down the stairs | No. 17 multidimensional operation principle | See Figure 7 |

| Conflict | Resolution Principle | Resolution Plan |

|---|---|---|

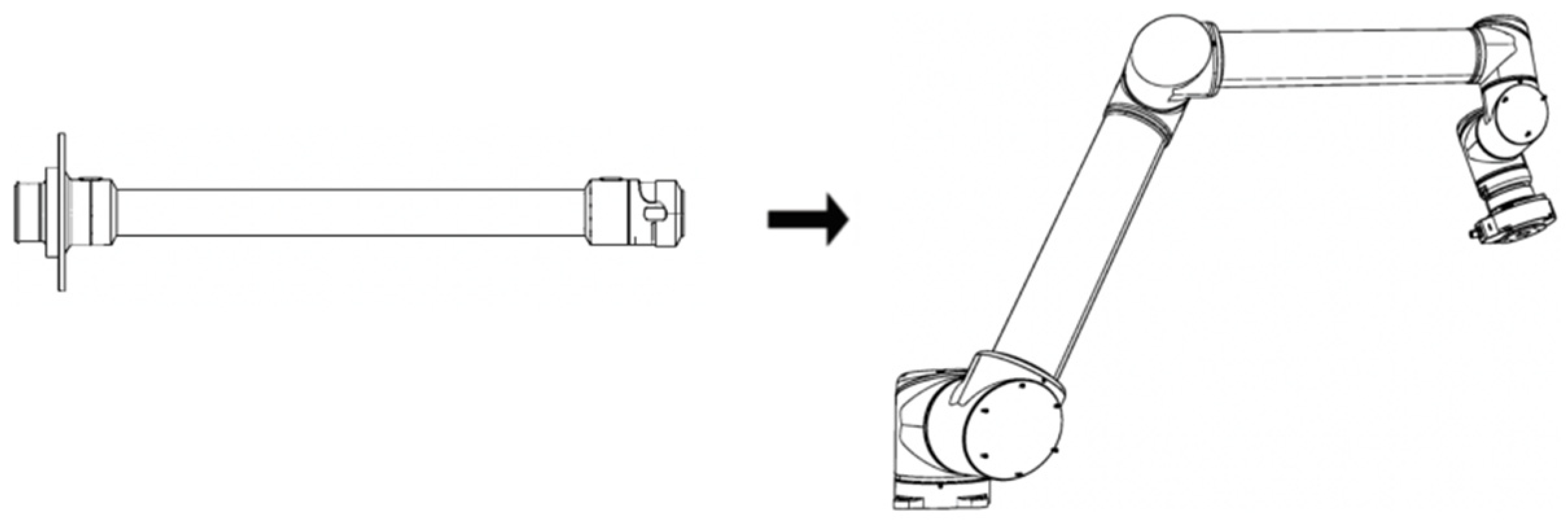

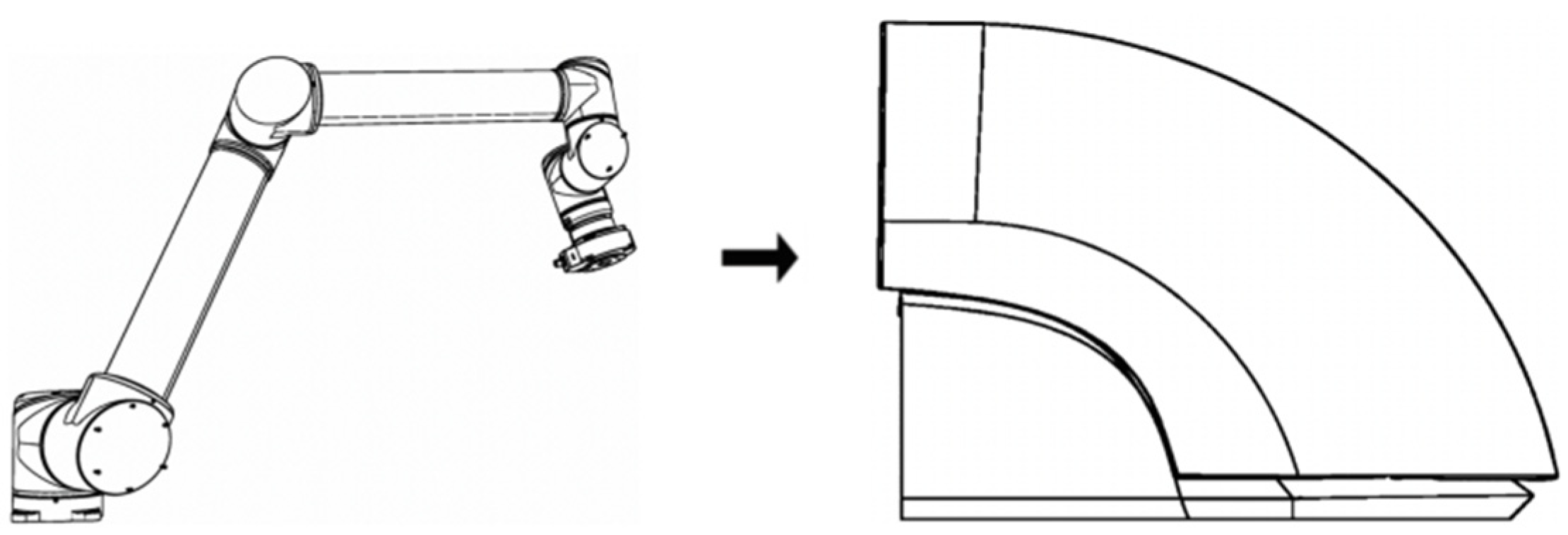

| Running speed—movement up and down stairs | Standard solution1.2.1 Standard solution 2.1.1 | See Figure 8, Figure 9 and Figure 10 |

| Conflict | Recommended Invention Principle | Resolution |

|---|---|---|

| Steady movement—all-around disinfection | No. 35 performance conversion principle | See Figure 11 |

| Conflict | Recommended Invention Principle | Resolution |

|---|---|---|

| All-around disinfection—beautiful shape | No. 2 embedded principle | See Figure 12 |

| Conflict | Recommended Invention Principle | Resolution |

|---|---|---|

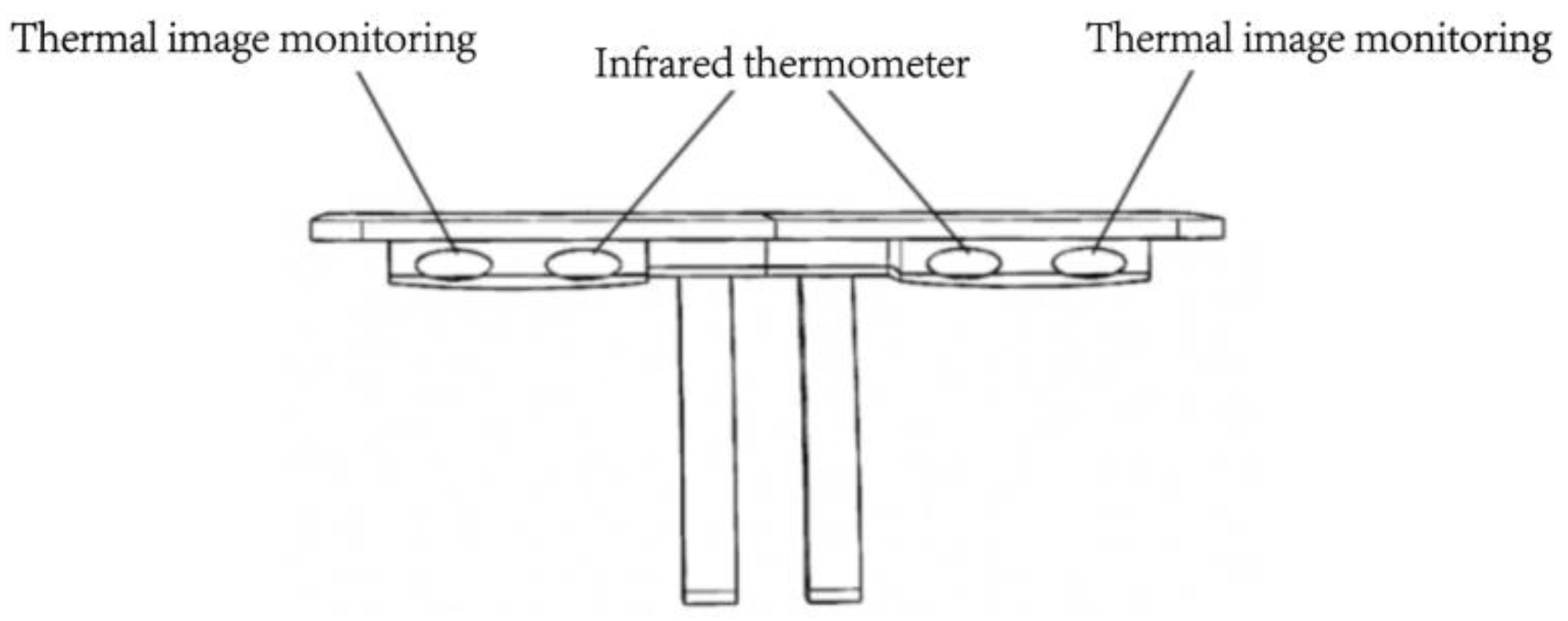

| Infrared thermometry—on-site video monitoring | No. 6 versatility principle | See Figure 13 |

3.5. Transformation of Technological Characteristics of the Disinfection and Epidemic Prevention Robot

4. Design Practice and Discussion

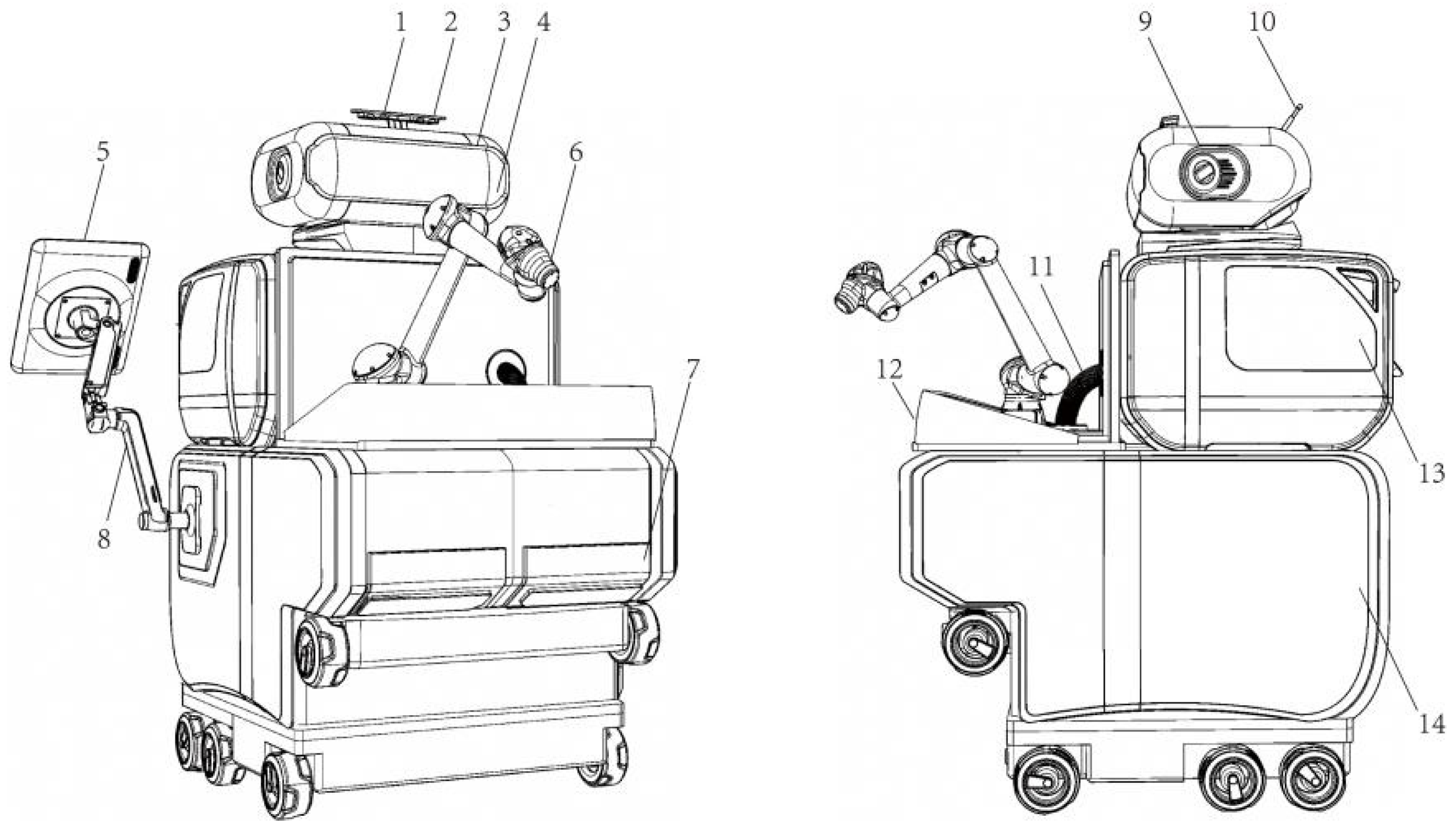

4.1. Design Practice

4.2. Discussion

5. Conclusions

- (1)

- To reduce the bias and subjectivity in decision making, this paper combines AHP and QFD theories with fuzzy mathematics as a means to improve the objectivity of the design strategy.

- (2)

- A multi-level transformation of the fuzzy QFD tool was performed to ensure that the social demand for disinfection robots, the technical characteristics of disinfection robots, and the component characteristics of disinfection robots remain highly consistent.

- (3)

- The designed disinfection and epidemic prevention robot can replace people in all aspects and fields to complete the disinfection and epidemic prevention work.

- (1)

- In the context of the globalization of epidemics, it is very important and necessary to design a robot that can completely replace humans in epidemic prevention tasks.

- (2)

- The research methods in this paper can also provide research ideas and references that can be used so solve other related industrial product design problems.

- (3)

- Combining statistical science, decision science, mathematical derivation, and other disciplines into design is a future research field that is very important.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhao, D.; Chen, W. Design and Research of Smart Neck Helmets Based on the KANO-QFD Model and TRIZ Theory. Secur. Commun. Netw. 2021, 2021, 4693719. [Google Scholar] [CrossRef]

- Kowalska, M.; Pazdzior, M.; Krzton-Maziopa, A. Implementation of QFD method in quality analysis of confectionery products. J. Intell. Manuf. 2018, 29, 439–447. [Google Scholar] [CrossRef]

- Sireli, Y.; Kauffmann, P.; Ozan, E. Integration of Kano’s model into QFD for multiple product design. IEEE Trans. Eng. Manag. 2007, 54, 380–390. [Google Scholar] [CrossRef]

- Chen, M.S.; Lin, C.C.; Tai, Y.Y.; Lin, M.C. A grey relation approach to the integrated process of QFD and QE. Concurr. Eng. 2011, 19, 35–53. [Google Scholar] [CrossRef]

- Hartono, M. Incorporating service quality tools into Kansei Engineering in services: A case study of Indonesian tourists. Procedia Econ. Financ. 2012, 4, 201–212. [Google Scholar] [CrossRef] [Green Version]

- Wudhikarn, R.; Pongpatcharatorntep, D. An Improved Intellectual Capital Management Method for Selecting and Prioritizing Intangible-Related Aspects: A Case Study of Small Enterprise in Thailand. Mathematics 2022, 10, 626. [Google Scholar] [CrossRef]

- Murali, S.; Pugazhendhi, S. An integrated model to identify and rank the after sales service strategies of firms engaged in household appliances business. Int. J. Serv. Oper. Manag. 2016, 24, 99–124. [Google Scholar] [CrossRef]

- Liu, A.; Hu, H.; Zhang, X.; Lei, D. Novel two-phase approach for process optimization of customer collaborative design based on fuzzy-QFD and DSM. IEEE Trans. Eng. Manag. 2017, 64, 193–207. [Google Scholar] [CrossRef]

- Ma, H.; Chu, X.; Xue, D.; Chen, D. A systematic decision making approach for product conceptual design based on fuzzy morphological matrix. Expert Syst. Appl. 2017, 81, 444–456. [Google Scholar] [CrossRef]

- Kang, X.; Zhu, Q. Integrated fuzzy linguistic preference relations approach and fuzzy Quality Function Deployment to the sustainable design of hybrid electric vehicles. Concurr. Eng. 2022, 30, 1063293X221117291. [Google Scholar] [CrossRef]

- Vinodh, S.; Manjunatheshwara, K.J.; Karthik Sundaram, S.; Kirthivasan, V. Application of fuzzy quality function deployment for sustainable design of consumer electronics products: A case study. Clean Technol. Environ. Policy 2017, 19, 1021–1030. [Google Scholar] [CrossRef]

- Kang, X.; Yang, M.; Wu, Y.; Ni, B. Integrating evaluation grid method and fuzzy quality function deployment to new product development. Math. Probl. Eng. 2018, 2018, 2451470. [Google Scholar] [CrossRef]

- Li, S.; Tang, D.; Wang, Q. Rating engineering characteristics in open design using a probabilistic language method based on fuzzy QFD. Comput. Ind. Eng. 2019, 135, 348–358. [Google Scholar] [CrossRef]

- Gündoğdu, F.K.; Kahraman, C. A novel spherical fuzzy QFD method and its application to the linear delta robot technology development. Eng. Appl. Artif. Intell. 2020, 87, 103348. [Google Scholar] [CrossRef]

- Wang, H.; Fang, Z.; Wang, D.; Liu, S. An integrated fuzzy QFD and grey decision-making approach for supply chain collaborative quality design of large complex products. Comput. Ind. Eng. 2020, 140, 106212. [Google Scholar] [CrossRef]

- Lin, Y.; Cheng, H.P.; Tseng, M.L.; Tsai, J.C. Using QFD and ANP to analyze the environmental production requirements in linguistic preferences. Expert Syst. Appl. 2010, 37, 2186–2196. [Google Scholar] [CrossRef]

- Fey, V.R.; Rivin, E.I.; Vertkin, I.M. Application of the theory of inventive problem solving to design and manufacturing systems. CIRP Ann. 1994, 43, 107–110. [Google Scholar] [CrossRef]

- Krasnoslobodtsev, V.; Langevin, R. TRIZ application in development of climbing robots. In First TRIZ Symposium; Technical Innovation Center Inc.: Worcester, MA, USA, 2005. [Google Scholar]

- Zhang, F.; Yang, M.; Liu, W. Using integrated quality function deployment and theory of innovation problem solving approach for ergonomic product design. Comput. Ind. Eng. 2014, 76, 60–74. [Google Scholar] [CrossRef]

- Maruanaya, G.J.T.; Maruanaya, R.F.; Hariyanto, D. Web-Based Recruitment Selection Application Development with Analytical Hierarchy Process (AHP) Method. J. Phys. Conf. Ser. 2021, 2111, 012045. [Google Scholar] [CrossRef]

- Wu, Y.; Cheng, J. Continuous fuzzy kano model and fuzzy AHP model for aesthetic product design: Case study of an electric scooter. Math. Probl. Eng. 2018, 2018, 4162539. [Google Scholar] [CrossRef]

- Wu, Y.; Kang, X. Establishment of an aggregation model associated with instrument interface design based on Kansei factors of electric vehicle drivers. Math. Probl. Eng. 2020, 2020, 8315641. [Google Scholar] [CrossRef]

- Yazdani, M.; Kahraman, C.; Zarate, P.; Onar, S.C. A fuzzy multi attribute decision framework with integration of QFD and grey relational analysis. Expert Syst. Appl. 2019, 115, 474–485. [Google Scholar] [CrossRef] [Green Version]

- Keshteli, R.N.; Davoodvandi, E. Using fuzzy AHP and fuzzy TOPSIS in fuzzy QFD: A case study in ceramic and tile industry of Iran. Int. J. Product. Qual. Manag. 2017, 20, 197–216. [Google Scholar] [CrossRef]

- Aktepe, A. Application of fuzzy quality function deployment model, group decision making and choquet integral to improve service quality in engineering education. Int. J. Eng. Educ. 2019, 35, 182–194. [Google Scholar]

- Yamashina, H.; Ito, T.; Kawada, H. Innovative product development process by integrating QFD and TRIZ. Int. J. Prod. Res. 2002, 40, 1031–1050. [Google Scholar] [CrossRef]

- Su, J.N.; Wei, J. Design of rosebud picking machine based on AHP/QFD/TRIZ. J. Mach. Des. 2020, 37, 121–126. [Google Scholar]

- Ozsoydan, F.; Kandemir, C.; Demirtas, E. Neural-network-based genetic algorithm for optimal kitchen faucet styles. Neural Netw. World 2015, 25, 387–404. [Google Scholar] [CrossRef] [Green Version]

- Kobayashi, M.; Kinumura, T.; Higashi, M. A method for supporting aesthetic design based on the analysis of the relationships between customer kansei and aesthetic element. Comput.-Aided Des. Appl. 2016, 13, 281–288. [Google Scholar] [CrossRef] [Green Version]

- Wang, K.C. A hybrid Kansei engineering design expert system based on grey system theory and support vector regression. Expert Syst. Appl. 2011, 38, 8738–8750. [Google Scholar] [CrossRef]

- Wang, K.C. User-oriented product form design evaluation using integrated Kansei engineering scheme. J. Converg. Inf. Technol. 2011, 6, 420–438. [Google Scholar]

- Zadeh, L.A. Fuzzy sets. Inf. Control 1965, 8, 338–353. [Google Scholar] [CrossRef]

| Scale | Implication |

|---|---|

| 0.5 | By comparison, the two elements are equally important. |

| 0.6 | By comparison, one element is slightly more important than the other. |

| 0.7 | By comparison, one element is obviously more important than the other. |

| 0.8 | By comparison, one element is strongly more important than the other. |

| 0.9 | By comparison, one element is extremely more important than the other. |

| 0.1, 0.2, 0.3, 0.4 (complementary) | If the element is obtained by comparing the element with the element , the element is obtained by comparing the element with element . |

| Objective Level | Criterion Level | Weight | Index Level | Weight (w1–w5) | Comprehensive Weight | Order | |

|---|---|---|---|---|---|---|---|

| Disinfection and anti-epidemic robot | Main function (A1) | 0.255 | Disinfection | A11 | 0.287 | 0.073 | 1 |

| Fast forward movement | A12 | 0.204 | 0.052 | 15 | |||

| Upstairs movement | A13 | 0.254 | 0.065 | 3 | |||

| Material distribution | A14 | 0.254 | 0.065 | 4 | |||

| Auxiliary function (A2) | 0.167 | Temperature measurement | A21 | 0.325 | 0.054 | 12 | |

| Real-time monitoring | A22 | 0.350 | 0.059 | 9 | |||

| Voice communication | A23 | 0.325 | 0.054 | 13 | |||

| Man–machine performance (A3) | 0.192 | High automation | A31 | 0.367 | 0.071 | 2 | |

| Good operation | A32 | 0.317 | 0.061 | 7 | |||

| Smooth running | A33 | 0.317 | 0.061 | 8 | |||

| Safety (A4) | 0.217 | Stable center of gravity | A41 | 0.296 | 0.064 | 5 | |

| Safe disinfection | A42 | 0.196 | 0.043 | 17 | |||

| Low failure rate | A43 | 0.263 | 0.057 | 11 | |||

| Sound construction | A44 | 0.246 | 0.053 | 14 | |||

| Appearance (A5) | 0.167 | Texture | A51 | 0.350 | 0.059 | 10 | |

| Color | A52 | 0.275 | 0.046 | 16 | |||

| Modeling | A53 | 0.375 | 0.063 | 6 | |||

| First-Grade Demand | Second-Grade Demand | Corresponding Technical Specifications | First-Grade Demand | Second-Grade Demand | Corresponding Technical Specifications |

|---|---|---|---|---|---|

| Main function | Disinfection | Disinfection device | Man–machine performance | High automation | Remote control |

| Automatic switchover of tools | Automatic switchover of tools | ||||

| Movement up and down stairs | Good operation | Simple operation | |||

| Clear feedback | |||||

| Fast forward movement | Steady moving | Smooth running | Simple operation | ||

| Stable construction | |||||

| Operation speed | Safety | Stable center of gravity | Stable construction | ||

| Steady moving | |||||

| Upstairs movement | Steady moving | Safe disinfection | Disinfection device | ||

| Steady moving | |||||

| Stable construction | Low failure rate | Stable construction | |||

| Movement up and down stairs | Sound construction | Stable construction | |||

| Auxiliary function | Temperature measurement | Automatic switchover of tools | Appearance | Textural quality | Reasonable materials |

| Infrared thermometry | Color | Coordinative colors | |||

| Marked night operation | |||||

| Real-time monitoring | Automatic switchover of tools | Beautiful appearance | Size of the whole machine | ||

| Beautiful appearance |

| Relevant Symbol | Express Meaning | Fuzzy Number After Conversion |

|---|---|---|

| Blank | No correlation | (0, 0, 0) |

| △ | Weak correlation | (1, 1, 3) |

| ○ | Relatively weak correlation | (1, 3, 5) |

| ◎ | Medium correlation | (3, 5, 7) |

| ● | Relatively strong correlation | (5, 7, 9) |

| ▲ | Strong correlation | (7, 9, 9) |

| Conflict | Conflict Type | Improvement Parameters | Worsening Parameters | Recommended Invention Principle |

|---|---|---|---|---|

| ① Steady movement—movement up and down stairs | Physical conflict | Principle of conditional separation | 3, 17, 19, 31, 32, 40 | |

| ② Running speed—movement up and down stairs | Complex invention problem | Construct Su-Field models | 76 standard solutions | |

| ③ Steady moving—all-around disinfection | Technical conflict | Stability of power device | Adaptability and versatility of disinfection devices | 35, 30, 34, 2 |

| ④ All-around disinfection—beautiful shape | Physical conflict | Principle of spatial isolation | 1, 2, 3, 7, 4, 17 | |

| ⑤ Infrared thermometry—on-site video monitoring | Technical conflict | Adaptability and versatility of sensing devices | Operating efficiency of sensing devices | 35, 28, 6, 37 |

| Category of Components | Index of Components |

|---|---|

| Power part | Chassis and motor construction |

| Tire | |

| Obstacle recognizer | |

| Body part | Machine casing |

| Bearing compartment | |

| Protective cover for disinfection | |

| Disinfection part | Mechanical arm for disinfection |

| Storage tank for disinfectant | |

| Artificial intelligence part | Infrared thermometer |

| Thermal detector | |

| Voice recognition and player device | |

| Feedback screen | |

| Remote sensing part | Receiver and transmitter |

| Whole machine | Size of the whole machine |

| Floodlight | |

| Decorative lamp | |

| Man–machine interface | Display screen |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, N.; Shi, C.; Kang, X. Design of a Disinfection and Epidemic Prevention Robot Based on Fuzzy QFD and the ARIZ Algorithm. Sustainability 2022, 14, 16341. https://doi.org/10.3390/su142416341

Wang N, Shi C, Kang X. Design of a Disinfection and Epidemic Prevention Robot Based on Fuzzy QFD and the ARIZ Algorithm. Sustainability. 2022; 14(24):16341. https://doi.org/10.3390/su142416341

Chicago/Turabian StyleWang, Nanyi, Chang Shi, and Xinhui Kang. 2022. "Design of a Disinfection and Epidemic Prevention Robot Based on Fuzzy QFD and the ARIZ Algorithm" Sustainability 14, no. 24: 16341. https://doi.org/10.3390/su142416341