Analyzing Health, Safety, and Environmental Risks of Construction Projects Using the Fuzzy Analytic Hierarchy Process: A Field Study Based on a Project Management Body of Knowledge

Abstract

:1. Introduction

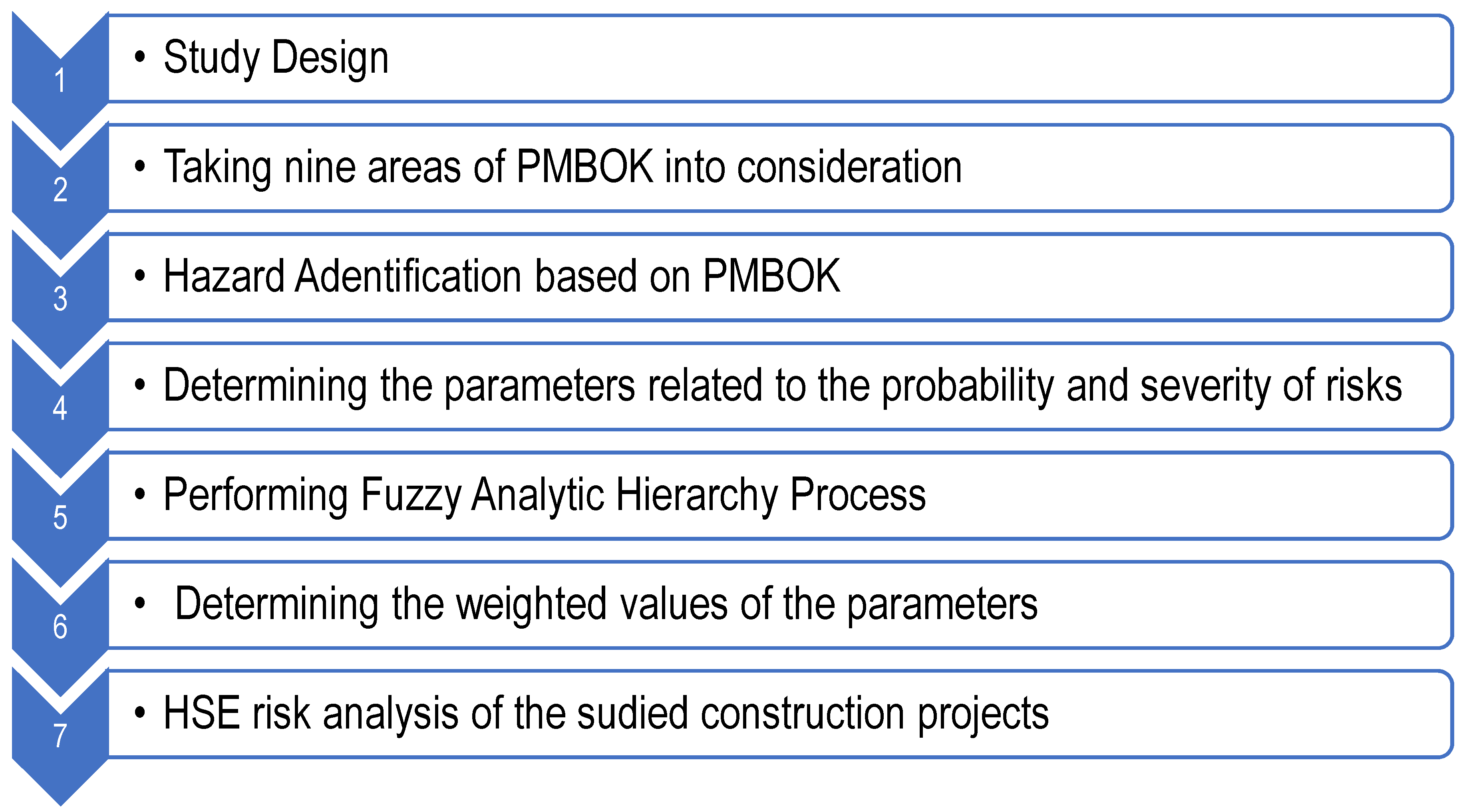

2. Materials and Methods

2.1. Study Design

Project Management Body of Knowledge

- Integration;

- Scope;

- Time;

- Cost;

- Quality;

- Human Resources;

- Communications;

- Risk;

- Procurement.

2.2. Identification of HSE-Related Risks

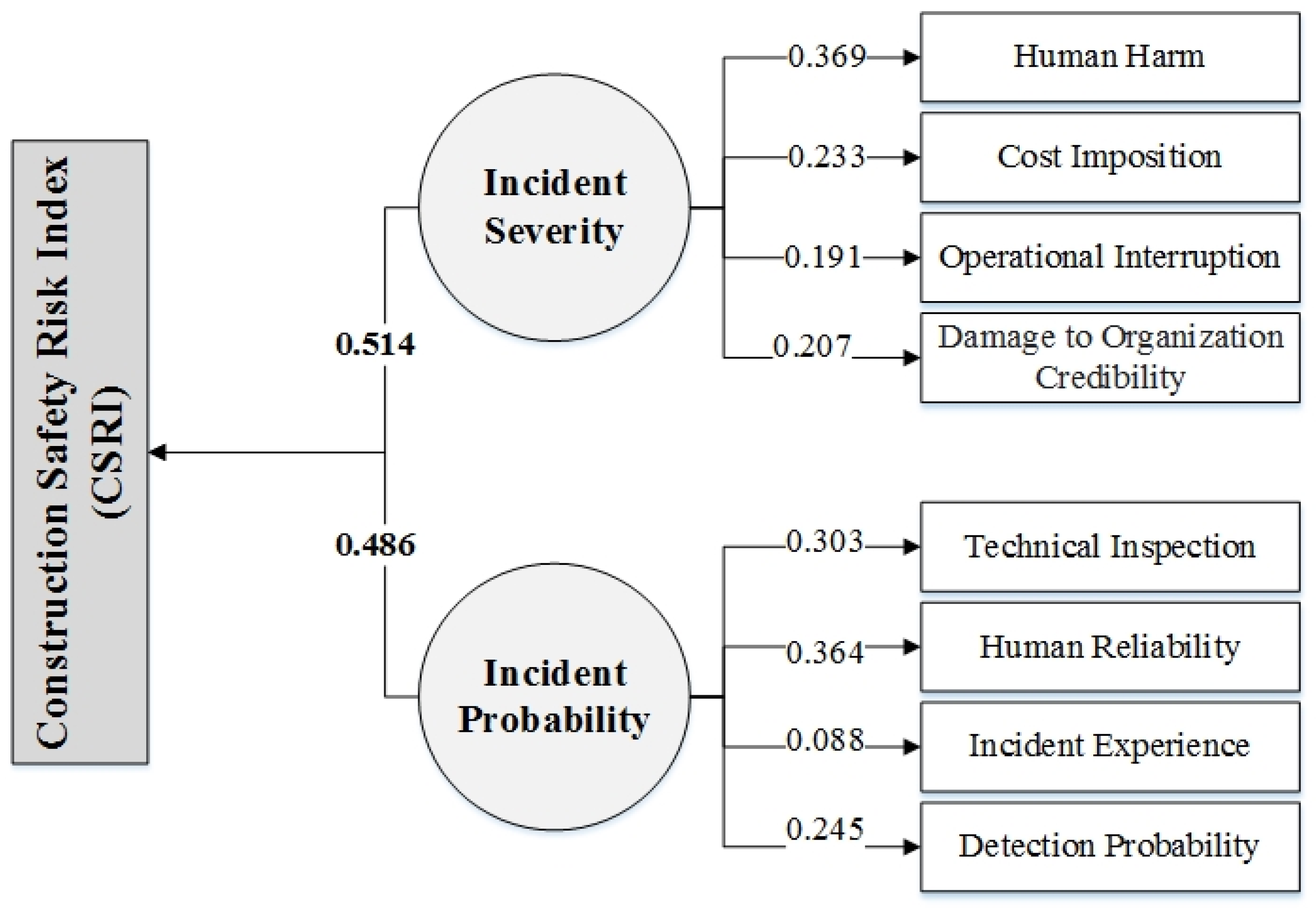

2.3. Measurement of Sub-Parameters of Risk Dimensions

2.3.1. Probability of Occurrence

- Detection probability;

- Human reliability;

- Technical inspection;

- Accident experience;

- Severity of occurrence.

2.3.2. Severity of Occurrence

- human injury;

- financial loss;

- operational interruption;

- reputational damage.

2.4. HSE Risk Analysis of Construction Projects

- CRI: Construction risk index;

- Probability: Incident probability;

- Severity: Incident severity;

- Pi: Numerical index of sub-parameters of incident probability (Table 1);

- PWi: Normalized weight of each of sub-parameters of incident probability (Figure 2);

- Si: Numerical index of sub-parameters of incident severity (Table 2);

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhou, X.-H.; Shen, S.-L.; Xu, Y.-S.; Zhou, A.-N. Analysis of Production Safety in the Construction Industry of China in 2018. Sustainability 2019, 11, 4537. [Google Scholar] [CrossRef] [Green Version]

- Othman, I.; Shafiq, N.; Nuruddin, M. Effective safety management in construction project. In Proceedings of the International Conference on Architecture and Civil Engineering (ICACE 2017), Petaling Jaya, Malaysia, 8–9 May 2017. [Google Scholar]

- Mahdinia, M.; Yarandi, M.S.; Jafarinia, E.; Soltanzadeh, A. Development of a New Technique for Safety Risk Assessment in Construction Projects Based on Fuzzy Analytic Hierarchy Process. Eng. Struct. 2021, 7, 04021037. [Google Scholar] [CrossRef]

- Kang, Y.; Siddiqui, S.; Suk, S.J.; Chi, S.; Kim, C. Trends of Fall Accidents in the U.S. Construction Industry. J. Constr. Eng. Manag. 2017, 143, 04017043. [Google Scholar] [CrossRef]

- Soltanzadeh, A.; Mohammadfam, I.; Moghimbeigi, A.; Ghiasvand, R. Key factors contributing to accident severity rate in construction industry in Iran: A regression modelling approach/Primjena regresijskog modela u analizi ključnih čimbenika koji pridonose težini nesreća u građevinskoj industriji u Iranu. Arch. Ind. Hyg. Toxicol. 2016, 67, 47–53. [Google Scholar] [CrossRef] [Green Version]

- Shafique, M.; Rafiq, M. An Overview of Construction Occupational Accidents in Hong Kong: A Recent Trend and Future Perspectives. Appl. Sci. 2019, 9, 2069. [Google Scholar] [CrossRef] [Green Version]

- Zhou, Z.; Li, C.; Mi, C.; Qian, L. Exploring the Potential Use of Near-Miss Information to Improve Construction Safety Performance. Sustainability 2019, 11, 1264. [Google Scholar] [CrossRef] [Green Version]

- Winge, S.; Albrechtsen, E.; Mostue, B.A. Causal factors and connections in construction accidents. Saf. Sci. 2018, 112, 130–141. [Google Scholar] [CrossRef]

- Mohandes, S.R.; Sadeghi, H.; Mahdiyar, A.; Durdyev, S.; Banaitis, A.; Yahya, K.; Ismail, S. Assessing Construction Labours’ Safety Level: A Fuzzy MCDM Approach. J. Civ. Eng. Manag. 2020, 26, 175–188. [Google Scholar] [CrossRef] [Green Version]

- Choi, S.D.; Guo, L.; Kim, J.; Xiong, S. Comparison of fatal occupational injuries in construction industry in the United States, South Korea, and China. Int. J. Ind. Ergon. 2019, 71, 64–74. [Google Scholar] [CrossRef]

- Mohammadi, A.; Tavakolan, M.; Khosravi, Y. Factors influencing safety performance on construction projects: A review. Saf. Sci. 2018, 109, 382–397. [Google Scholar] [CrossRef]

- Project Management Institute. Guide to the Project Management Body of Knowledge; Project Management Institute: Newtown Square, PA, USA, 2018. [Google Scholar]

- Majumder, D.; Debnath, J.; Biswas, A. Risk Analysis in Construction Sites Using Fuzzy Reasoning and Fuzzy Analytic Hierarchy Process. Procedia Technol. 2013, 10, 604–614. [Google Scholar] [CrossRef] [Green Version]

- Zarei, E.; Khan, F.; Abbassi, R. An advanced approach to the system safety in sociotechnical systems. Saf. Sci. 2023, 158, 105961. [Google Scholar] [CrossRef]

- Liu, B.; Lu, Q. Creating a Sustainable Workplace Environment: Influence of Workplace Safety Climate on Chinese Healthcare Employees’ Presenteeism from the Perspective of Affect and Cognition. Sustainability 2020, 12, 2414. [Google Scholar] [CrossRef] [Green Version]

- Boileau, P.-E. Sustainability and prevention in occupational health and safety. Ind. Health 2016, 54, 293–295. [Google Scholar] [CrossRef] [Green Version]

- Zarei, E.; Khan, F.; Abbassi, R. A dynamic human-factor risk model to analyze safety in sociotechnical systems. Process Saf. Environ. Prot. 2022, 164, 479–498. [Google Scholar] [CrossRef]

- Zarei, E.; Karimi, A.; Habibi, E.; Barkhordari, A.; Reniers, G. Dynamic occupational accidents modeling using dynamic hybrid Bayesian confirmatory factor analysis: An in-depth psychometrics study. Saf. Sci. 2021, 136, 105146. [Google Scholar] [CrossRef]

- Nawaz, W.; Linke, P.; Koҫ, M. Safety and sustainability nexus: A review and appraisal. J. Clean. Prod. 2019, 216, 74–87. [Google Scholar] [CrossRef]

- Alkaissy, M.; Arashpour, M.; Ashuri, B.; Bai, Y.; Hosseini, R. Safety management in construction: 20 years of risk modeling. Saf. Sci. 2020, 129, 104805. [Google Scholar] [CrossRef]

- Mohammadfam, I.; Soltanzadeh, A.; Moghimbeigi, A.; Akbarzadeh, M. Modeling of Individual and Organizational Factors Affecting Traumatic Occupational Injuries Based on the Structural Equation Modeling: A Case Study in Large Construction Industries. Arch. Trauma Res. 2016, 5, e33595. [Google Scholar] [CrossRef] [Green Version]

- Kramar, U.; Dragan, D.; Topolšek, D. The Holistic Approach to Urban Mobility Planning with a Modified Focus Group, SWOT, and Fuzzy Analytical Hierarchical Process. Sustainability 2019, 11, 6599. [Google Scholar] [CrossRef]

- Hatefi, S.M.; Tamošaitienė, J. Construction projects assessment based on the sustainable development criteria by an integrated fuzzy AHP and improved GRA model. Sustainability 2018, 10, 991. [Google Scholar]

- Nesticò, A.; He, S.; De Mare, G.; Benintendi, R.; Maselli, G. The ALARP Principle in the Cost-Benefit Analysis for the Acceptability of Investment Risk. Sustainability 2018, 10, 4668. [Google Scholar] [CrossRef] [Green Version]

- Mohammadfam, I.; Soltanzadeh, A.; Moghimbeigi, A.; Akbarzadeh, M. Confirmatory Factor Analysis of Occupational Injuries: Presenting an Analytical Tool. Trauma Mon. 2016, 22. [Google Scholar] [CrossRef]

- Jo, B.W.; Lee, Y.S.; Kim, J.H.; Khan, R.M.A. Trend Analysis of Construction Industrial Accidents in Korea from 2011 to 2015. Sustainability 2017, 9, 1297. [Google Scholar] [CrossRef] [Green Version]

- Seker, S.; Zavadskas, E.K. Application of Fuzzy DEMATEL Method for Analyzing Occupational Risks on Construction Sites. Sustainability 2017, 9, 2083. [Google Scholar] [CrossRef] [Green Version]

- Yang, Y.; Tang, W.; Shen, W.; Wang, T. Enhancing Risk Management by Partnering in International EPC Projects: Perspective from Evolutionary Game in Chinese Construction Companies. Sustainability 2019, 11, 5332. [Google Scholar] [CrossRef] [Green Version]

- Kim, J.Y.; Lee, D.S.; Kim, J.D.; Kim, G.H. Priority of Accident Cause Based on Tower Crane Type for the Realization of Sustainable Management at Korean Construction Sites. Sustainability 2021, 13, 242. [Google Scholar] [CrossRef]

- Soltanzadeh, A.; Mahdinia, M. Path analysis of occupational injuries based on the structural equation modeling approach: A retrospective study in the construction industry. Iran Occup. Health 2019, 16, 47–57. [Google Scholar]

- Woolley, M.J.; Goode, N.; Read, G.J.M.; Salmon, P.M. Have we reached the organisational ceiling? A review of applied accident causation models, methods and contributing factors in construction. Theor. Issues Ergon. Sci. 2019, 20, 533–555. [Google Scholar] [CrossRef]

- Falahati, M.; Karimi, A.; Mohammadfam, I.; Mazloumi, A.; Khanteymoori, A.R.; Yaseri, M. Multi-dimensional model for determining the leading performance indicators of safety management systems. Work 2020, 67, 959–969. [Google Scholar] [CrossRef]

- Qi, H.; Zhou, Z.; Li, N.; Zhang, C. Construction safety performance evaluation based on data envelopment analysis (DEA) from a hybrid perspective of cross-sectional and longitudinal. Saf. Sci. 2021, 146, 105532. [Google Scholar] [CrossRef]

- Lin, F.; Wu, P.; Xu, Y. Investigation of Factors Influencing the Construction Safety of High-Speed Railway Stations Based on DEMATEL and ISM. Adv. Civ. Eng. 2021, 2021, 9954018. [Google Scholar] [CrossRef]

- Johansson, J.; Berglund, L.; Johansson, M.; Nygren, M.; Rask, K.; Samuelson, B.; Stenberg, M. Occupational safety in the construction industry. Work 2019, 64, 21–32. [Google Scholar] [CrossRef] [PubMed]

- Sousa, V.; Almeida, N.M.; Dias, L.A. Risk-based management of occupational safety and health in the construction industry—Part 1: Background knowledge. Saf. Sci. 2014, 66, 75–86. [Google Scholar]

- Pereira, E.; Taghaddos, H.; Hermann, R.; Han, S.; Abourizk, S. A conceptual accident causation model based on the incident root causes. In Proceedings of the5th International/11th Construction Specialty Conference, Vancouver, British Columbia, Canada, 8–10 June 2018. [Google Scholar]

- Rowlinson, S.; Jia, Y.A. Construction accident causality: An institutional analysis of heat illness incidents on site. Saf. Sci. 2015, 78, 179–189. [Google Scholar] [CrossRef]

- Kim, J.-M.; Kim, T.; Bae, J.; Son, K.; Ahn, S. Analysis of plant construction accidents and loss estimation using insurance loss records. J. Asian Arch. Build. Eng. 2019, 18, 507–516. [Google Scholar] [CrossRef] [Green Version]

- Sanni-Anibire, M.O.; Mahmoud, A.S.; Hassanain, M.A.; Salami, B.A. A risk assessment approach for enhancing construction safety performance. Saf. Sci. 2019, 121, 15–29. [Google Scholar] [CrossRef]

- Kim, M.; Lee, I.; Jung, Y. International Project Risk Management for Nuclear Power Plant (NPP) Construction: Featuring Comparative Analysis with Fossil and Gas Power Plants. Sustainability 2017, 9, 469. [Google Scholar] [CrossRef] [Green Version]

- Yang, K.; Kim, K.; Go, S. Towards Effective Safety Cost Budgeting for Apartment Construction: A Case Study of Occupational Safety and Health Expenses in South Korea. Sustainability 2021, 13, 1335. [Google Scholar]

- Nguyen, L.H.; Watanabe, T. The Impact of Project Organizational Culture on the Performance of Construction Projects. Sustainability 2017, 9, 781. [Google Scholar] [CrossRef] [Green Version]

- Husin, H.N.; Adnan, H.; Jusoff, K. Management of Safety for Quality Construction. J. Sustain. Dev. 2008, 1, 41–47. [Google Scholar] [CrossRef] [Green Version]

- Ikpe, E.; Hammon, F.; Oloke, D. Cost-Benefit Analysis for Accident Prevention in Construction Projects. J. Constr. Eng. Manag. 2012, 138, 991–998. [Google Scholar] [CrossRef]

- Garrett, J.; Teizer, J. Human factors analysis classification system relating to human error awareness taxonomy in construction safety. J. Constr. Eng. Manag. 2009, 135, 754–763. [Google Scholar]

- Jilcha, K.; Kitaw, D. Industrial occupational safety and health innovation for sustainable development. Eng. Sci. Technol. Int. J. 2017, 20, 372–380. [Google Scholar] [CrossRef]

| Score | Technical Inspection | Incident Experience | Detection Probability | Human Reliability (HR) |

|---|---|---|---|---|

| 1 | Weekly | Incident data are available in similar projects and root analysis has been performed on them. | The risk is detected and revealed via the existing controls. | Regarding this risk, HR is assessed, BBS is implemented, a training program is implemented, and training outcomes are evaluated. |

| 2 | Monthly | Incident data are available through employer/contractor records, and root analysis has been performed on them. | The probability (>50%) is that the risk is detected and revealed via the existing controls. | Regarding this risk, a training program is implemented and training outcomes are evaluated. |

| 3 | Once in every three months | Incident data are available through employer/contractor records. Only a descriptive analysis has been performed on them. | The probability (<50%) is that the risk is detected and revealed via the existing controls. | Regarding this risk, a training program is implemented. |

| 4 | Once in every six months | Incident data are available through the employer/contractor records. No analysis has been performed on them. | It is unlikely (<10%) that the risk is detected and revealed via the existing controls. | Regarding this risk, compulsory and official training programs have been incompletely performed. |

| 5 | At least once during the project lifetime | No incident data is available. | There is no control, and in the case of any risk being present, it is not detectable | Regarding this risk, no measure is taken for HR assessment, BBS implementation, training, or evaluation. |

| Score | Human Harm | Cost Imposition (Financial Damage, Legal Fine) | Damaging Organization Credibility | Impact on Project Time and Operational Interruption |

|---|---|---|---|---|

| 1 | Minor harm, injury, and trauma requiring first aid. | Less than USD 2500 | Imperceptible repercussions | Operational interruption of less than 2 h |

| 2 | Moderate harm, lower trauma, and injury, leading to short-term hospitalization (up to three days). | USD 2500–5000 | Repercussions among the stakeholders | Operational interruption of up to one day |

| 3 | Severe harm, and multiple traumas and injuries, leading to long-term hospitalization (more than three days). | USD 5000–10,000 | Repercussions among the stakeholders and social networks | Operational interruption ranging from one day to one week |

| 4 | Harm leading to disability, amputation, and permanent disability. | USD 10,000–25,000 | Repercussions among the stakeholders, social networks, and widely-circulated newspapers | Operational interruption ranging from one week to one month |

| 5 | Death of one person or more. | More than USD 25,000 | Repercussions among the stakeholders, social networks, and widely-circulated newspapers, both at the national and international level | Operational interruption lasting more than one month |

| Risk Source | Causes of Incidence | Incidence Probability | Incidence Severity | CRI | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Technical Inspection | Incidence Experience | Detection Probability | Human Reliability | Human Resources | Cost Imposition | Damage to Organization’s Credibility | Project Interruption | |||

| Integrated project management | ||||||||||

| Lack of policy definition in the field of HSE. | Lack of commitment from the manager and staff. | N.A † | N.A | 3 | 3 | 5 | 5 | 5 | 5 | 2.282 ‡ |

| Lack of definition concerning the HSE needs of stakeholders | Lack of detection of the HSE needs of stakeholders. | N.A | N.A | 4 | 4 | 5 | 3 | 4 | 4 | 2.517 |

| Lack of developing HSE programs during project lifetime. | Lack of an index for evaluating HSE performance. | N.A | N.A | 3 | 2 | 5 | 4 | 4 | 4 | 1.597 |

| Absence of/HSE unit and defects in organization chart. | Improper status of HSE in projects, wrong decisions, and vulnerability to incidences occurring. | N.A | N.A | 1 | 3 | 5 | 5 | 5 | 5 | 1.670 ‡ |

| Project scope management | ||||||||||

| Insufficient knowledge of organization’s managers concerning the hazards and risks of the construction industry. | Lack of obedience to managers to resolve notified discrepancies. | N.A | N.A | 4 | 1 | 5 | 4 | 5 | 5 | 1.600 |

| Lack of attention to HSE issues when developing work breakdown structure. | Lack of attention to HSE in the breakdown structure, and a violation of these guidelines in the execution phase. | N.A | N.A | 3 | 4 | 5 | 3 | 3 | 5 | 2.255 |

| Failure to comply with the prioritization of activities based on HSE requirements. | Lack of proper fire alarm and extinguisher systems, and a lack of fall prevention guard installations. | N.A | N.A | 2 | 4 | 5 | 3 | 3 | 5 | 2.003 |

| Project scheduling | ||||||||||

| Failure to specify the time for receiving Machinery Health Certificate at WBS. | Defects in machinery and equipment. | 4 | 3 | 3 | 4 | 5 | 4 | 5 | 5 | 4.367 |

| Failure to allocate time for HSE training at WBS. | Lack of proper training and occurrence of unsafe practices. | N.A | 4 | 4 | 4 | 5 | 3 | 4 | 5 | 3.014 |

| Failure to allocate time to make the workplace safe before the start of work (installing lifeline). | Failure to make the workplace safe. | 1 | 3 | 3 | 3 | 5 | 5 | 5 | 5 | 2.990 ‡ |

| Failure to allocate time for HSE-focused meetings (incident analysis). | Few HSE problems are presented and there is a lack of commitment at the managerial level to solve problems. | N.A | N.A | 4 | 2 | 5 | 3 | 3 | 4 | 1.676 |

| Failure to determine the time of clinical and para clinical tests (high risk occupations). | Physical incompetence of the individual at time of employment and occurrence of occupational diseases and incidents. | N.A | 4 | 5 | 3 | 5 | 3 | 4 | 4 | 2.758 |

| Risk Source | Causes of Incidence | Incidence Probability | Incidence Severity | CRI | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Technical Inspection | Incidence Experience | Detection Probability | Human Reliability | Human Resources | Cost Imposition | Damage to Organization’s Credibility | Project Interruption | |||

| Project cost management | ||||||||||

| Failure to pay employees’ salaries on time, thus creating job stress and lack of focus on the assigned tasks. | Creating job stress and setting the stage for incidents to occur. | N.A † | N.A | 4 | 5 | 4 | 4 | 4 | 5 | 2.785 |

| Lack of finances to provide standard equipment and machinery. | Defects in equipment and machinery and the occurrence of incidents. | N.A | 3 | 5 | 5 | 3 | 2 | 5 | 5 | 2.306 ‡ |

| No cost allocation for hiring an HSE supervisor, expert, and officer, proportional to the project phases. | Failure to set up an integrated HSE monitoring system. | N.A | N.A | 5 | 5 | 2 | 2 | 5 | 5 | 1.521 ‡ |

| Non-allocation of civil liability insurance policies to third parties and machinery. | Failure to receive insurance with full coverage. | N.A | 4 | 5 | 1 | 2 | 3 | 5 | 5 | 1.598 |

| No funds allocated to the implementation of improvement projects (such as lifeline systems and fuse supplies). | Failure to implement improvement projects and resolve HSE inconsistencies. | 2 | 3 | 5 | 5 | 2 | 2 | 5 | 5 | 2.608 ‡ |

| Project quality | ||||||||||

| Non-compliance with QC concepts regarding concrete and structural welding. | Poor execution of the project and occurrence of incidents in the implementation phase. | 3 | 4 | 3 | 3 | 5 | 5 | 4 | 4 | 3.550 |

| Lack of quality materials being supplied. | Failure to properly implement the project. | 2 | 5 | 3 | 4 | 5 | 5 | 5 | 3 | 3.801 |

| Lack of quality personal protective equipment. | Inability to prevent incidents. | 2 | 3 | 2 | 2 | 5 | 5 | 4 | 3 | 2.301 |

| Absence of a maintenance system for the machinery. | Inability to properly repair and maintain machinery. | 3 | 4 | 4 | 3 | 5 | 5 | 4 | 4 | 3.898 |

| Supplying consumer equipment without the necessary quality. | Inability to supply quality consumer equipment. | 4 | 3 | 3 | 3 | 5 | 4 | 4 | 3 | 3.387 |

| Human resources | ||||||||||

| Lack of training at the outset of employment. | Lack of familiarity with workplace hazards. | N.A | 3 | 2 | 1 | 5 | 3 | 4 | 4 | 1.155 |

| Failure to determine the plans and responsibilities of individuals. | Lack of familiarity with HSE tasks and performing unsafe practices. | 5 | N.A | 3 | 4 | 5 | 3 | 3 | 3 | 3.461 |

| Failure to determine the qualification requirements for HSE to employ all the staff in the project. | Employing unqualified individuals and the occurrence of unsafe acts. | 5 | 5 | 3 | 4 | 5 | 4 | 5 | 4 | 4.739 |

| Failure to develop a special training program for all occupations. | Lack of awareness of specialized HSE information when conducting activities. | 4 | 4 | 4 | 3 | 5 | 5 | 4 | 5 | 4.353 |

| Risk Source | Causes of Incidence | Incidence Probability | Incidence Severity | CRI | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Technical Inspection | Incidence Experience | Detection Probability | Human Reliability | Human Resources | Cost Imposition | Damage to Organization’s Credibility | Project Interruption | |||

| Project risk management | ||||||||||

| Lack of proper risk management planning (identifying stakeholders, legal requirements and risk assessment). | Lack of readiness to use the full capacity of risk management techniques to enter the identification stage. | N.A † | N.A | 3 | 4 | 5 | 3 | 4 | 2 | 2.055 |

| Inability to identify HSE risks. | Lack of incident data collection, and lack of risk identification meetings. | N.A | N.A | 2 | 3 | 5 | 4 | 4 | 3 | 1.651 |

| Lack of proper assessments to identify risks. | Failure to prioritize eliminating the identified risks. | N.A | N.A | 2 | 3 | 5 | 4 | 4 | 3 | 1.651 |

| Failure to formulate the necessary controls based on the risk control pyramid and failure to follow up on the implementation of control measures. | Lack of development of all, or parts of, the control methods, and a lack of readiness of the organization to deal with risk. | N.A | N.A | 3 | 3 | 5 | 5 | 5 | 5 | 2.306 ‡ |

| Project communication | ||||||||||

| Lack of using experienced HSE advisors. | Lack of specialized inspections of equipment and lack of determination of improvement methods. | N.A | N.A | 4 | 4 | 5 | 4 | 3 | 3 | 2.416 |

| Lack of executive methods and operation controls. | Failure to determine the risks associated with each executive operation. | N.A | N.A | 3 | 2 | 5 | 5 | 5 | 5 | 1.827 ‡ |

| Underuse of the HSE experiences of other projects. | Failure to register HSE records and use them in future projects. | N.A | 3 | 2 | 3 | 5 | 5 | 5 | 5 | 2.306 ‡ |

| Project procurement management | ||||||||||

| Failure to explicitly state HSE provisions in contracts. | Defects in contracts and lack of calculation of HSE provisions in the contract by the contractor, and lack of obligation to fulfill the requirements during execution. | N.A | N.A | 3 | 2 | 5 | 5 | 5 | 5 | 1.827 ‡ |

| Failure to announce and continuously monitor HSE executive regulations. | Lack of HSE disciplinary criteria for dealing with contractors. | N.A | N.A | 2 | 3 | 5 | 4 | 4 | 5 | 1.802 |

| Failure to timely supply personal protective equipment and other items related to HSE. | Inability of the project to reduce the risk of incidents. | N.A | 2 | 2 | 2 | 5 | 5 | 5 | 5 | 1.741 |

| Lack of contractor evaluations. | Lack of managing contractors. | N.A | N.A | 4 | 4 | 5 | 4 | 5 | 5 | 2.901 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Soltanzadeh, A.; Mahdinia, M.; Omidi Oskouei, A.; Jafarinia, E.; Zarei, E.; Sadeghi-Yarandi, M. Analyzing Health, Safety, and Environmental Risks of Construction Projects Using the Fuzzy Analytic Hierarchy Process: A Field Study Based on a Project Management Body of Knowledge. Sustainability 2022, 14, 16555. https://doi.org/10.3390/su142416555

Soltanzadeh A, Mahdinia M, Omidi Oskouei A, Jafarinia E, Zarei E, Sadeghi-Yarandi M. Analyzing Health, Safety, and Environmental Risks of Construction Projects Using the Fuzzy Analytic Hierarchy Process: A Field Study Based on a Project Management Body of Knowledge. Sustainability. 2022; 14(24):16555. https://doi.org/10.3390/su142416555

Chicago/Turabian StyleSoltanzadeh, Ahmad, Mohsen Mahdinia, Alireza Omidi Oskouei, Ehsan Jafarinia, Esmaeil Zarei, and Mohsen Sadeghi-Yarandi. 2022. "Analyzing Health, Safety, and Environmental Risks of Construction Projects Using the Fuzzy Analytic Hierarchy Process: A Field Study Based on a Project Management Body of Knowledge" Sustainability 14, no. 24: 16555. https://doi.org/10.3390/su142416555