Drivers of Artificial Intelligence and Their Effects on Supply Chain Resilience and Performance: An Empirical Analysis on an Emerging Market

Abstract

:1. Introduction

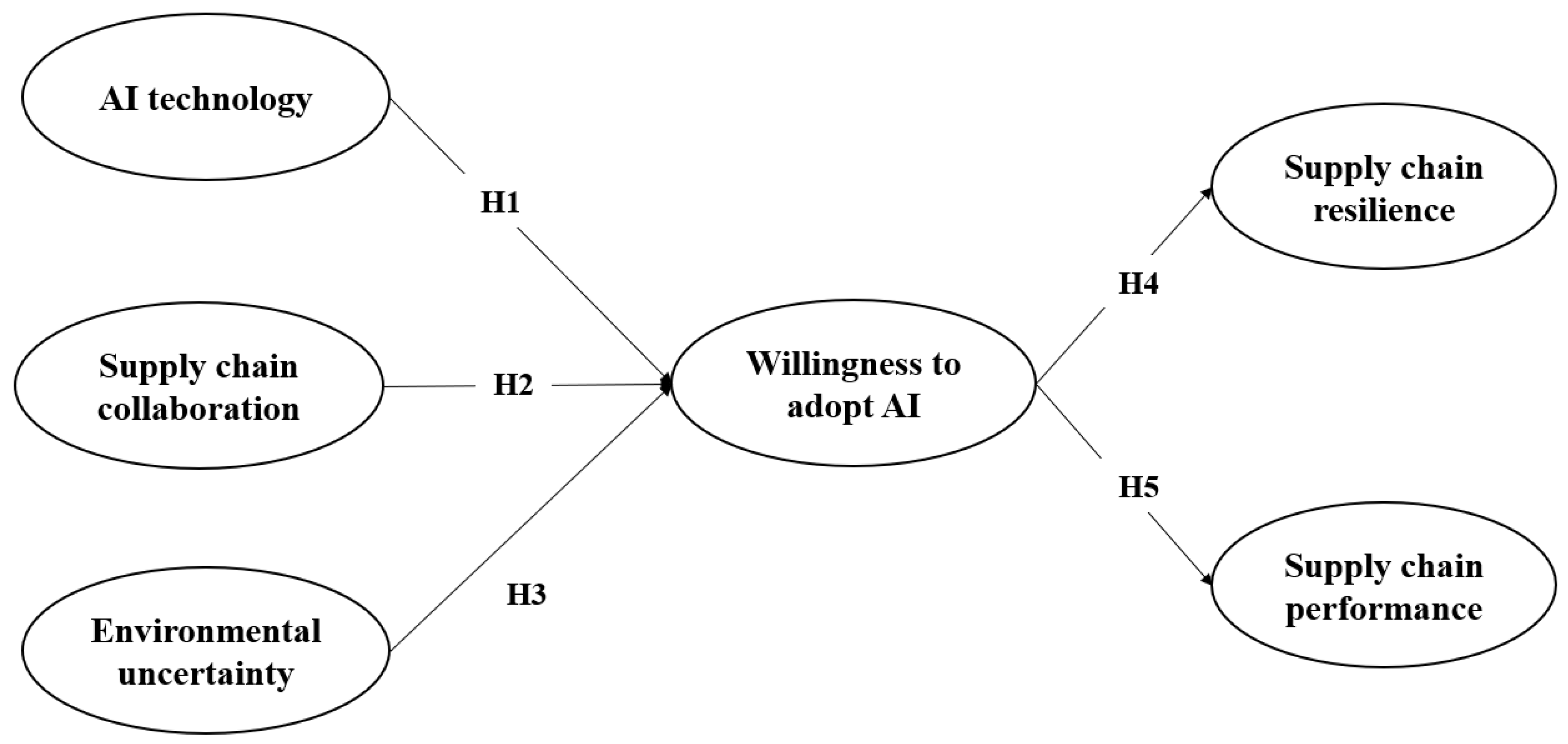

2. Literature Review and Hypothesis Development

2.1. Artificial Intelligence Technology Compatibility and Adoption Willingness

2.2. Supply Chain Collaboration and Willingness to Adopt

2.3. Environmental Uncertainty and Willingness to Adopt

2.4. Willingness to Adopt and Supply Chain Resilience

2.5. Willingness to Adopt and Supply Chain Performance

3. Methodology

3.1. Sampling and Data Collection

3.2. Bias Testing

3.3. Variables and Measurement

4. Analyses and Results

4.1. Measurement Reliability and Validity

4.2. Hypothesis Testing

5. Discussion and Conclusions

5.1. Theoretical and Practical Implications

5.2. Limitations and Future Research Avenues

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| AI | artificial intelligence |

| SCM | supply chain management |

References

- Spieske, A.; Birkel, H. Improving Supply Chain Resilience through Industry 4.0: A Systematic Literature Review under the Impressions of the COVID-19 Pandemic. Comput. Ind. Eng. 2021, 158, 107452. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.-K.; Huang, T.-Y. The Multi-Level Hierarchical Structure of the Enablers for Supply Chain Resilience Using Cloud Model-DEMATEL–ISM Method. Sustainability 2022, 14, 12116. [Google Scholar] [CrossRef]

- Grzybowska, K.; Tubis, A.A. Supply Chain Resilience in Reality VUCA—An International Delphi Study. Sustainability 2022, 14, 10711. [Google Scholar] [CrossRef]

- Soni, N.; Sharma, E.K.; Singh, N.; Kapoor, A. Artificial Intelligence in Business: From Research and Innovation to Market Deployment. Procedia Comput. Sci. 2020, 167, 2200–2210. [Google Scholar] [CrossRef]

- Chien, Y.-H.; Yao, C.-K. Development of an AI Userbot for Engineering Design Education Using an Intent and Flow Combined Framework. Appl. Sci. 2020, 10, 7970. [Google Scholar] [CrossRef]

- Tong, S.; Jia, N.; Luo, X.; Fang, Z. The Janus face of artificial intelligence feedback: Deployment versus disclosure effects on employee performance. Strateg. Manag. J. 2021, 42, 1600–1631. [Google Scholar] [CrossRef]

- Agrawal, R.; Wankhede, V.A.; Kumar, A.; Luthra, S.; Majumdar, A.; Kazancoglu, Y. An Exploratory State-of-the-Art Review of Artificial Intelligence Applications in Circular Economy using Structural Topic Modeling. Oper. Manag. Res. 2022, 15, 609–626. [Google Scholar] [CrossRef]

- Min, H. Artificial Intelligence in Supply Chain Management: Theory and Applications. Int. J. Logist. Res. Appl. 2010, 13, 13–39. [Google Scholar] [CrossRef]

- Toorajipour, R.; Sohrabpour, V.; Nazarpour, A.; Oghazi, P.; Fischl, M. Artificial intelligence in supply chain management: A systematic literature review. J. Bus. Res. 2021, 122, 502–517. [Google Scholar] [CrossRef]

- Dubey, R.; Bryde, D.J.; Blome, C.; Roubaud, D.; Giannakis, M. Facilitating Artificial Intelligence Powered Supply Chain Analytics through Alliance Management during the Pandemic Crises in the B2B Context. Ind. Mark. Manag. 2021, 96, 135–146. [Google Scholar] [CrossRef]

- Kaplan, A.; Haenlein, M. Siri, Siri, in My Hand: Who’s the Fairest in the Land? On the Interpretations, Illustrations, and Implications of Artificial Intelligence. Bus. Horiz. 2019, 62, 15–25. [Google Scholar] [CrossRef]

- Dirican, C. The Impacts of Robotics, Artificial Intelligence on Business and Economics. Procedia Soc. Behav. Sci. 2015, 195, 564–573. [Google Scholar] [CrossRef] [Green Version]

- Tornatzky, L.G.; Fleischer, M.; Chakrabarti, A.K. Processes of Technological Innovation; Lexington Books: Blue Ridge Summit, PA, USA, 1990. [Google Scholar]

- Lin, H.-F. Understanding the Determinants of Electronic Supply Chain Management System Adoption: Using the Technology–Organization–Environment Framework. Technol. Forecast. Soc. Chang. 2014, 86, 80–92. [Google Scholar] [CrossRef]

- Gutierrez, A.; Boukrami, E.; Lumsden, R. Technological, Organisational and Environmental Factors Influencing Managers’ Decision to Adopt Cloud Computing in the UK. J. Enterp. Inf. Manag. 2015, 28, 788–807. [Google Scholar] [CrossRef]

- Ghaleb, E.A.A.; Dominic, P.D.D.; Fati, S.M.; Muneer, A.; Ali, R.F. The Assessment of Big Data Adoption Readiness with a Technology–Organization–Environment Framework: A Perspective towards Healthcare Employees. Sustainability 2021, 13, 8379. [Google Scholar] [CrossRef]

- Wernerfelt, B. A Resource-Based View of the Firm. Strat. Mgmt. J. 1984, 5, 171–180. [Google Scholar] [CrossRef]

- Barney, J. Firm Resources and Sustained Competitive Advantage. J. Manag. 1991, 17, 99–120. [Google Scholar] [CrossRef]

- Grant, R.M. The Resource-Based Theory of Competitive Advantage: Implications for Strategy Formulation. Calif. Manag. Rev. 1991, 33, 114–135. [Google Scholar] [CrossRef] [Green Version]

- Hart, S.L.; Dowell, G. Invited Editorial: A Natural-Resource-Based View of the Firm: Fifteen Years After. J. Manag. 2011, 37, 1464–1479. [Google Scholar] [CrossRef]

- Helfat, C.E.; Peteraf, M.A. The Dynamic Resource-Based View: Capability Lifecycles. Strat. Mgmt. J. 2003, 24, 997–1010. [Google Scholar] [CrossRef]

- Halldorsson, A.; Kotzab, H.; Mikkola, J.H.; Skjøtt-Larsen, T. Complementary Theories to Supply Chain Management. Supply Chain Manag. 2007, 12, 284–296. [Google Scholar] [CrossRef]

- Baum, S.; Barrett, A.; Yampolskiy, R.V. Modeling and Interpreting Expert Disagreement About Artificial Superintelligence; Social Science Research Network: Rochester, NY, USA, 2017. [Google Scholar]

- Baker, J. The Technology–Organization–Environment Framework. Inf. Syst. Theory 2012, 28, 231–245. [Google Scholar] [CrossRef]

- Soosay, C.A.; Hyland, P. A Decade of Supply Chain Collaboration and Directions for Future Research. Supply Chain Manag. 2015, 20, 613–630. [Google Scholar] [CrossRef]

- Baryannis, G.; Validi, S.; Dani, S.; Antoniou, G. Supply Chain Risk Management and Artificial Intelligence: State of the Art and Future Research Directions. Int. J. Prod. Res. 2019, 57, 2179–2202. [Google Scholar] [CrossRef]

- Pan, M.J.; Jang, W.Y. Determinants of the Adoption of Enterprise Resource Planning within the Technology-Organization-Environment Framework: Taiwan’s Communications Industry. J. Comput. Inf. Syst. 2008, 48, 94–102. [Google Scholar] [CrossRef]

- Singeh, F.W.; Abrizah, A.; Kiran, K. Bringing the Digital Library Success Factors into the Realm of the Technology-Organization-Environment Framework. Electron. Libr. 2020, 38, 659–675. [Google Scholar] [CrossRef]

- Malik, S.; Chadhar, M.; Vatanasakdakul, S.; Chetty, M. Factors Affecting the Organizational Adoption of Blockchain Technology: Extending the Technology–Organization–Environment (TOE) Framework in the Australian Context. Sustainability 2021, 13, 9404. [Google Scholar] [CrossRef]

- Wong, C.Y.; Boon-itt, S.; Wong, C.W.Y. The Contingency Effects of Environmental Uncertainty on the Relationship between Supply Chain Integration and Operational Performance. J. Oper. Manag. 2011, 29, 604–615. [Google Scholar] [CrossRef]

- Durach, C.F.; Wieland, A.; Machuca, J.A.D. Antecedents and Dimensions of Supply Chain Robustness: A Systematic Literature Review. Int. J. Phys. Distrib. Logist. Manag. 2015, 45, 118–137. [Google Scholar] [CrossRef] [Green Version]

- Ponomarov, S.Y.; Holcomb, M.C. Understanding the Concept of Supply Chain Resilience. Int. J. Logist. Manag. 2009, 20, 124–143. [Google Scholar] [CrossRef]

- Belhadi, A.; Mani, V.; Kamble, S.S.; Khan, S.A.R.; Verma, S. Artificial Intelligence-Driven Innovation for Enhancing Supply Chain Resilience and Performance under the Effect of Supply Chain Dynamism: An Empirical Investigation. Ann. Oper. Res. 2021, 1–26. [Google Scholar] [CrossRef] [PubMed]

- Yin, W.; Ran, W. Supply Chain Diversification, Digital Transformation, and Supply Chain Resilience: Configuration Analysis Based on fsQCA. Sustainability 2022, 14, 7690. [Google Scholar] [CrossRef]

- Frederico, G.F.; Kumar, V.; Garza-Reyes, J.A.; Kumar, A.; Agrawal, R. Impact of I4.0 technologies and their interoperability on performance: Future pathways for supply chain resilience post-COVID-19. Int. J. Logist. Manag. 2021; ahead-of-print. [Google Scholar] [CrossRef]

- Grover, P.; Kar, A.K.; Dwivedi, Y.K. Understanding Artificial Intelligence Adoption in Operations Management: Insights from the Review of Academic Literature and Social Media Discussions. Ann. Oper. Res. 2022, 308, 177–213. [Google Scholar] [CrossRef]

- Dubey, R.; Gunasekaran, A.; Childe, S.J.; Bryde, D.J.; Giannakis, M.; Foropon, C.; Roubaud, D.; Hazen, B.T. Big Data Analytics and Artificial Intelligence Pathway to Operational Performance under the Effects of Entrepreneurial Orientation and Environmental Dynamism: A Study of Manufacturing Organisations. Int. J. Prod. Econ. 2020, 226, 107599. [Google Scholar] [CrossRef]

- Bottani, E.; Centobelli, P.; Gallo, M.; Kaviani, M.A.; Jain, V.; Murino, T. Modelling Wholesale Distribution Operations: An Artificial Intelligence Framework. Ind. Manag. Data Syst. 2018, 119, 698–718. [Google Scholar] [CrossRef]

- Tarafdar, M.; Qrunfleh, S. Agile Supply Chain Strategy and Supply Chain Performance: Complementary Roles of Supply Chain Practices and Information Systems Capability for Agility. Int. J. Prod. Res. 2017, 55, 925–938. [Google Scholar] [CrossRef] [Green Version]

- Shen, K.; Tong, X.; Wu, T.; Zhang, F. The Next Frontier for AI in China Could Add $600 Billion to Its Economy. McKinsey. 2022. Available online: https://www.mckinsey.com/capabilities/quantumblack/our-insights/the-next-frontier-for-ai-in-china-could-add-600-billion-to-its-economy (accessed on 2 September 2022).

- Ma, S. China Emerging as Global AI Pioneer. China Daily. 2022. Available online: https://global.chinadaily.com.cn/a/202207/29/WS62e32108a310fd2b29e6f050.html (accessed on 3 September 2022).

- Daueconsulting. The AI Ecosystem in China. 2020. Available online: https://daxueconsulting.com/wp-content/uploads/2020/03/AI-in-China-2020-White-Paper-by-daxue-consulting-1.pdf (accessed on 1 September 2022).

- Hult, G.T.M.; Ketchen, D.J.; Griffith, D.A.; Finnegan, C.A.; Gonzalez-Padron, T.; Harmancioglu, N.; Huang, Y.; Talay, M.B.; Cavusgil, S.T. Data Equivalence in Cross-Cultural International Business Research: Assessment and Guidelines. J. Int. Bus. Stud. 2008, 39, 1027–1044. [Google Scholar] [CrossRef]

- Hoskisson, R.E.; Eden, L.; Lau, C.M.; Wright, M. Strategy in Emerging Economies. Acad. Manag. J. 2000, 43, 249–267. [Google Scholar] [CrossRef]

- Armstrong, J.S.; Overton, T.S. Estimating Nonresponse Bias in Mail Surveys. J. Mark. Res. 1977, 14, 396–402. [Google Scholar] [CrossRef]

- Chang, S.-J.; van Witteloostuijn, A.; Eden, L. From the Editors: Common Method Variance in International Business Research. J. Int. Bus. Stud. 2010, 41, 178–184. [Google Scholar] [CrossRef]

- Johnson, R.E.; Rosen, C.C.; Djurdjevic, E. Assessing the Impact of Common Method Variance on Higher Order Multidimensional Constructs. J. Appl. Psychol. 2011, 96, 744–761. [Google Scholar] [CrossRef] [PubMed]

- Podsakoff, P.M.; MacKenzie, S.B.; Lee, J.-Y.; Podsakoff, N.P. Common Method Biases in Behavioral Research: A Critical Review of the Literature and Recommended Remedies. J. Appl. Psychol. 2003, 88, 879–903. [Google Scholar] [CrossRef] [PubMed]

- Chowdhury, M.M.H.; Quaddus, M. Supply Chain Resilience: Conceptualization and Scale Development Using Dynamic Capability Theory. Int. J. Prod. Econ. 2017, 188, 185–204. [Google Scholar] [CrossRef]

- Dubey, R.; Gunasekaran, A.; Childe, S.J.; Fosso Wamba, S.; Roubaud, D.; Foropon, C. Empirical Investigation of Data Analytics Capability and Organizational Flexibility as Complements to Supply Chain Resilience. Int. J. Prod. Res. 2021, 59, 110–128. [Google Scholar] [CrossRef]

- Alshamaila, Y.; Papagiannidis, S.; Li, F. Cloud Computing Adoption by SMEs in the North East of England: A Multi-perspective Framework. J. Enterp. Inf. Manag. 2013, 26, 250–275. [Google Scholar] [CrossRef] [Green Version]

- Rogers, E.M. Diffusion of Innovations, 5th ed.; Free Press: New York, NY, USA, 2003. [Google Scholar]

- Agarwal, R.; Prasad, J. The Role of Innovation Characteristics and Perceived Voluntariness in the Acceptance of Information Technologies. Decis. Sci. 1997, 28, 557–582. [Google Scholar] [CrossRef]

- Kurnia, S.; Choudrie, J.; Mahbubur, R.M.; Alzougool, B. E-Commerce Technology Adoption: A Malaysian Grocery SME Retail Sector Study. J. Bus. Res. 2015, 68, 1906–1918. [Google Scholar] [CrossRef] [Green Version]

- Papastathopoulou, P.; Avlonitis, G.J.; Panagopoulos, N.G. Intraorganizational Information and Communication Technology Diffusion: Implications for Industrial Sellers and Buyers. Ind. Mark. Manag. 2007, 36, 322–336. [Google Scholar] [CrossRef]

- Zaridis, A.; Vlachos, I.; Bourlakis, M. SMEs Strategy and Scale Constraints Impact on Agri-Food Supply Chain Collaboration and Firm Performance. Prod. Plan. Control 2021, 32, 1165–1178. [Google Scholar] [CrossRef]

- Sreedevi, R.; Saranga, H. Uncertainty and Supply Chain Risk: The Moderating Role of Supply Chain Flexibility in Risk Mitigation. Int. J. Prod. Econ. 2017, 193, 332–342. [Google Scholar] [CrossRef]

- Wong, W.Y.C.; Lai, K.-H.; Shang, K.-C.; Lu, C.-S. Uncovering the Value of Green Advertising for Environmental Management Practices: Green Advertising and Environmental Management. Bus. Strat. Environ. 2014, 23, 117–130. [Google Scholar] [CrossRef]

- Richter, N.F.; Sinkovics, R.R.; Ringle, C.M.; Schlägel, C. A Critical Look at the Use of SEM in International Business Research. Int. Market. Rev. 2016, 33, 376–404. [Google Scholar] [CrossRef] [Green Version]

- Cepeda-Carrion, G.; Cegarra-Navarro, J.-G.; Cillo, V. Tips to use partial least squares structural equation modelling (PLS-SEM) in knowledge management. J. Knowl. Manag. 2019, 23, 67–89. [Google Scholar] [CrossRef]

- Fornell, C.; Larcker, D.F. Evaluating Structural Equation Models with Unobservable Variables and Measurement Error. J. Mark. Res. 1981, 18, 39–50. [Google Scholar] [CrossRef]

- Nunnally, J.C. Psychometric Theory; McGraw-Hill: New York, NY, USA, 1978. [Google Scholar]

- Chin, W.W.; Marcoulides, G. The Partial Least Squares Approach to Structural Equation Modeling. Organ. Res. Methods 1998, 295, 295–336. [Google Scholar]

- Hulland, J. Use of Partial Least Squares (PLS) in Strategic Management Research: A Review of Four Recent Studies. Strat. Mgmt. J. 1999, 20, 195–204. [Google Scholar] [CrossRef]

- Henseler, J.; Ringle, C.M.; Sarstedt, M. A New Criterion for Assessing Discriminant Validity in Variance-Based Structural Equation Modeling. J. Acad. Mark. Sci. 2015, 43, 115–135. [Google Scholar] [CrossRef] [Green Version]

- Geisser, S. The Predictive Sample Reuse Method with Applications. J. Am. Stat. Assoc. 1975, 70, 320–328. [Google Scholar] [CrossRef]

- Stone, M. Cross-Validatory Choice and Assessment of Statistical Predictions. J. R. Stat. Society Ser. B Methodol. 1974, 36, 111–133. [Google Scholar] [CrossRef]

- Henseler, J.; Ringle, C.M.; Sinkovics, R.R. The Use of Partial Least Squares Path Modeling in International Marketing. In New Challenges to International Marketing (Advances in International Marketing, 20); Sinkovics, R.R., Ghauri, P.N., Eds.; Emerald Group Publishing Limited: Bingley, UK, 2009; pp. 277–319. [Google Scholar]

- Zhao, X.; Lynch, J.G.; Chen, Q. Reconsidering Baron and Kenny: Myths and Truths about Mediation Analysis. J. Consum. Res. 2010, 37, 197–206. [Google Scholar] [CrossRef]

| Construct and Indicators | Mean | STD | SFL |

|---|---|---|---|

| AI technology advantage (PT: AVE = 0.597, alpha = 0.866, CR = 0.899) | |||

| The use of artificial intelligence technology can improve enterprise risk control capabilities. | 5.868 | 0.782 | 0.782 |

| The use of artificial intelligence technology will reduce the operating costs of the entire enterprise. | 5.909 | 0.821 | 0.768 |

| The use of artificial intelligence technology will improve the IT technical service capabilities of enterprises. | 5.921 | 0.763 | 0.778 |

| The use of artificial intelligence technology will improve the input-output ratio of enterprises to IT. | 5.799 | 0.721 | 0.756 |

| The company has a comparative advantage in leveraging artificial intelligence technology. | 5.846 | 0.838 | 0.776 |

| Adopting AI technology can give companies a competitive advantage. | 5.903 | 0.793 | 0.777 |

| Supply chain collaboration (SCC: AVE = 0.605, alpha = 0.837, CR = 0.885) | |||

| The company has access to the information systems of other companies in the supply chain. | 5.572 | 0.984 | 0.771 |

| Collaboration between supply chain companies to improve production processes. | 5.755 | 0.863 | 0.786 |

| Cooperation between supply chain enterprises to obtain supply in an economical way. | 5.780 | 0.840 | 0.788 |

| Cooperation between supply chain enterprises to improve competitiveness. | 5.849 | 0.953 | 0.779 |

| Co-pricing products between supply chain companies. | 5.626 | 0.905 | 0.767 |

| Environmental uncertainty (EU: AVE = 0.590, alpha = 0.884, CR = 0.910) | |||

| The global business environment is full of challenges. | 6.091 | 0.884 | 0.82 |

| The changing global business environment. | 5.836 | 0.951 | 0.765 |

| The global business environment offers many opportunities for change. | 5.903 | 0.897 | 0.783 |

| Customer demand fluctuates wildly over and over again. | 5.761 | 0.812 | 0.759 |

| The product mix produced by the company changes dramatically over and over again. | 5.814 | 0.862 | 0.752 |

| Supply requirements change every week. | 5.887 | 0.858 | 0.765 |

| The company’s products need a lot of technical transformation. | 5.881 | 0.804 | 0.729 |

| Willingness to adopt AI (WTA: AVE = 0.645, alpha = 0.871, CR = 0.879) | |||

| The company is willing to experiment with artificial intelligence technology. | 6.116 | 0.895 | 0.827 |

| The company plans to adopt artificial intelligence technology soon. | 5.78 | 0.922 | 0.793 |

| The company has adopted artificial intelligence technology. | 5.827 | 0.816 | 0.788 |

| The company is expected to adopt artificial intelligence technology in the future. | 5.906 | 0.923 | 0.804 |

| Supply chain resilience (SCR: AVE = 0.554, alpha = 0.911, CR = 0.925) | |||

| The company has the ability to quickly restore the flow of materials. | 5.695 | 1.008 | 0.749 |

| The company has the ability to quickly resume operations. | 5.796 | 0.974 | 0.756 |

| Enterprise supply chains are recovering quickly. | 5.682 | 0.998 | 0.75 |

| Enterprise supply chains can quickly return to normal. | 5.748 | 0.914 | 0.73 |

| The company can flexibly deal with interference problems. | 5.758 | 0.919 | 0.742 |

| The Company Can Respond Quickly to Disruptions. | 5.591 | 0.943 | 0.735 |

| The company can take adequate measures to deal with the crisis. | 5.824 | 0.915 | 0.77 |

| The company has a response team to alleviate the crisis. | 5.934 | 0.928 | 0.732 |

| The company can reduce the impact of losses through our ability to deal with the crisis. | 5.789 | 0.909 | 0.734 |

| The company can recover from the crisis at a lower cost. | 5.528 | 0.977 | 0.744 |

| Supply chain performance (SCP: AVE = 0.590, alpha = 0.913, CR = 0.928) | |||

| Suppliers deliver materials, components, products on time. | 5.821 | 0.814 | 0.788 |

| Suppliers provide safe and reliable materials, components, and products. | 5.959 | 0.848 | 0.749 |

| Suppliers provide materials, components, products at the lowest cost. | 5.918 | 0.854 | 0.763 |

| The quantity required is supplied on order. | 5.947 | 0.789 | 0.763 |

| Enterprise Supply Chain Improves Efficiency. | 5.915 | 0.881 | 0.755 |

| Enterprise supply chains become more stable. | 5.874 | 0.906 | 0.757 |

| Over the past three years, enterprise supply chains have been optimized. | 5.947 | 0.858 | 0.768 |

| Corporate supply chains improve customer satisfaction. | 6.028 | 0.837 | 0.775 |

| The delivery speed and time of the enterprise supply chain is shortened. | 5.884 | 0.855 | 0.792 |

| Constructs | 1 | 2 | 3 | 4 | 5 | 6 |

|---|---|---|---|---|---|---|

| 1. AI technology advantage | 0.773 | |||||

| 2. Supply chain collaboration | 0.333 | 0.778 | ||||

| 3. Environment Uncertainty | 0.323 | 0.277 | 0.768 | |||

| 4. Willingness to adopt AI | 0.335 | 0.396 | 0.33 | 0.803 | ||

| 5. Supply chain Resilience | 0.363 | 0.505 | 0.433 | 0.462 | 0.744 | |

| 6. Supply chain performance | 0.279 | 0.437 | 0.364 | 0.457 | 0.564 | 0.768 |

| Indirect Effect | Estimate | p-Values |

|---|---|---|

| Direct effects | ||

| AI technology advantages → Willingness to adopt AI | 0.178 | ** |

| Supply chain collaboration → Willingness to adopt AI | 0.283 | *** |

| Environmental uncertainty → Willingness to adopt AI | 0.195 | ** |

| AI technology advantages → Supply chain resilience | 0.107 | * |

| Supply chain collaboration → Supply chain resilience | 0.315 | *** |

| Environmental uncertainty → Supply chain resilience | 0.238 | ** |

| AI technology advantages → Supply chain performance | 0.044 | n.s. |

| Supply chain collaboration → Supply chain performance | 0.248 | *** |

| Environmental uncertainty → Supply chain performance | 0.187 | * |

| Willingness to adopt AI → Supply chain resilience | 0.223 | ** |

| Willingness to adopt AI → Supply chain performance | 0.272 | *** |

| Indirect effects | ||

| AI technology advantages → Willingness to adopt AI → Supply chain resilience | 0.040 | * |

| Supply chain collaboration → Willingness to adopt AI → Supply chain resilience | 0.063 | ** |

| Environmental uncertainty → Willingness to adopt AI → Supply chain resilience | 0.043 | * |

| AI technology advantages → Willingness to adopt AI → Supply chain performance | 0.048 | * |

| Supply chain collaboration → Willingness to adopt AI → Supply chain performance | 0.077 | ** |

| Environmental uncertainty → Willingness to adopt AI → Supply chain performance | 0.053 | ** |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, M.; Pan, X. Drivers of Artificial Intelligence and Their Effects on Supply Chain Resilience and Performance: An Empirical Analysis on an Emerging Market. Sustainability 2022, 14, 16836. https://doi.org/10.3390/su142416836

Wang M, Pan X. Drivers of Artificial Intelligence and Their Effects on Supply Chain Resilience and Performance: An Empirical Analysis on an Emerging Market. Sustainability. 2022; 14(24):16836. https://doi.org/10.3390/su142416836

Chicago/Turabian StyleWang, Mengmeng, and Xiaoming Pan. 2022. "Drivers of Artificial Intelligence and Their Effects on Supply Chain Resilience and Performance: An Empirical Analysis on an Emerging Market" Sustainability 14, no. 24: 16836. https://doi.org/10.3390/su142416836

APA StyleWang, M., & Pan, X. (2022). Drivers of Artificial Intelligence and Their Effects on Supply Chain Resilience and Performance: An Empirical Analysis on an Emerging Market. Sustainability, 14(24), 16836. https://doi.org/10.3390/su142416836