Evaluating the Environmental and Economic Performance of Municipal Solid Waste Disposal by All-Component Resource Recovery

Abstract

:1. Introduction

2. Materials and Methods

2.1. Methodology

2.2. Goal and Scope Definition

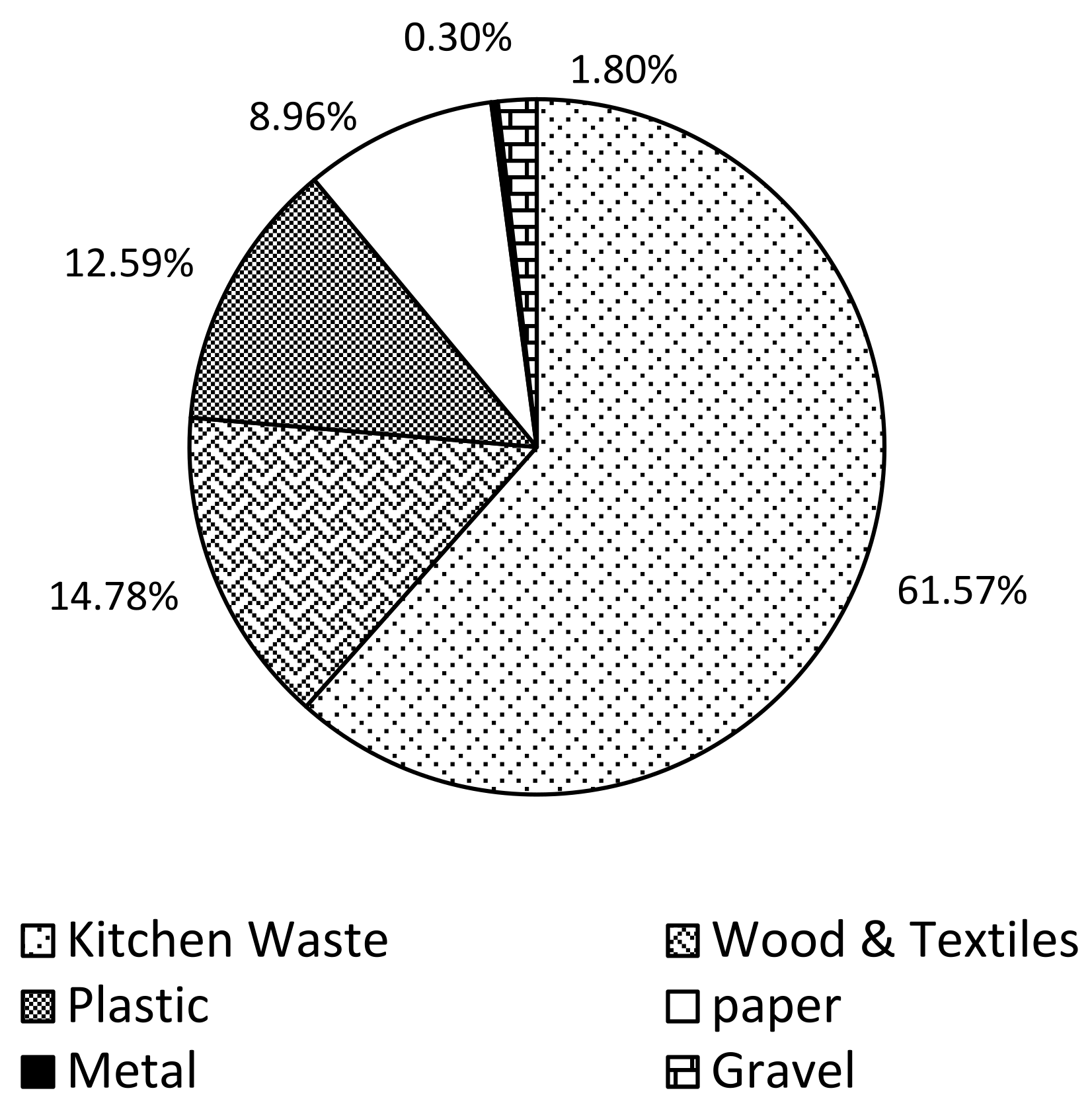

2.2.1. Selected Study Site and Function Unit

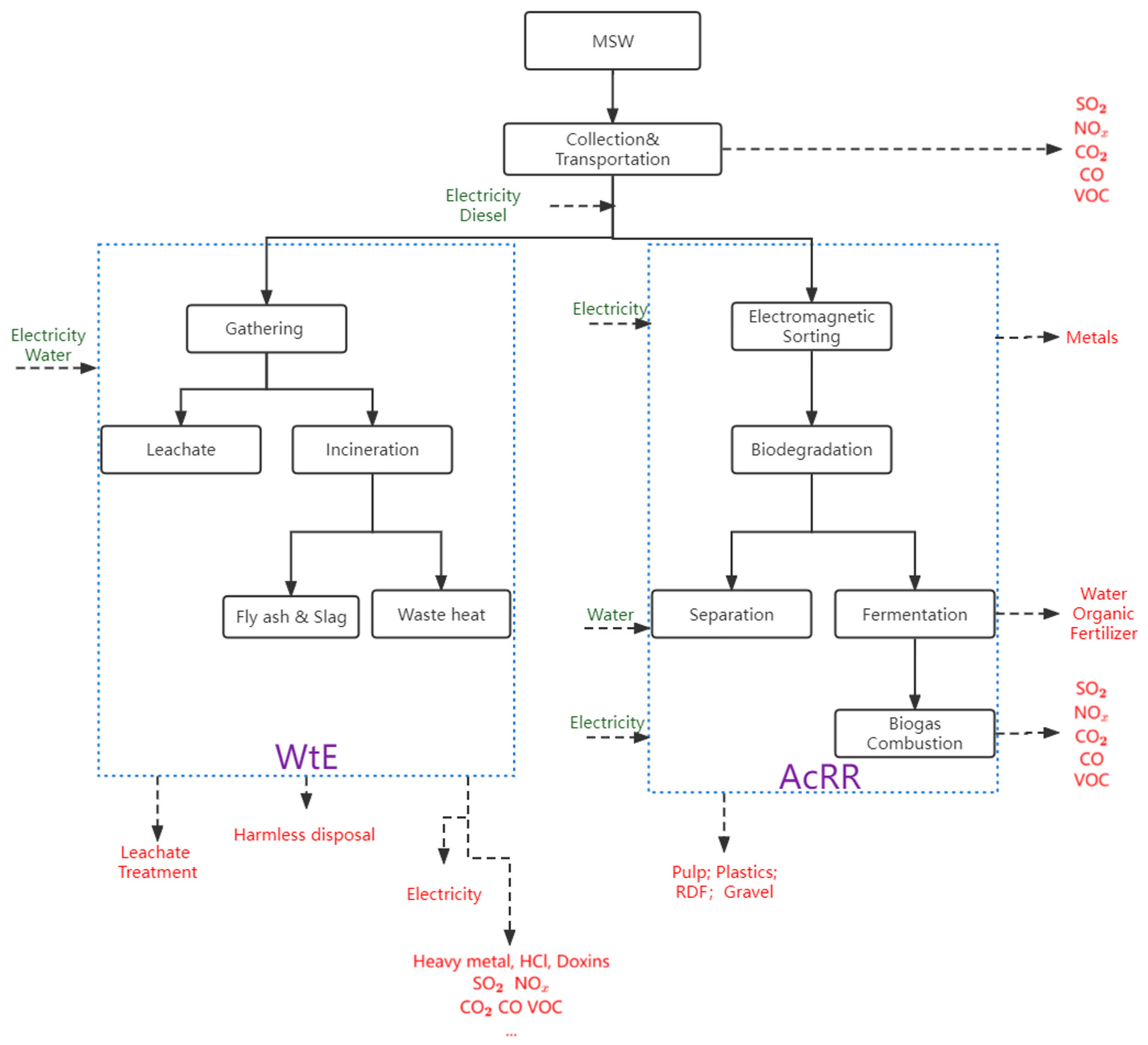

2.2.2. System Boundary

2.3. Environmental Assessment with LCA

2.3.1. Key Assumptions

2.3.2. Data Issues

2.4. Financial Assessment

3. Results and Discussion

3.1. Resource Input and Output

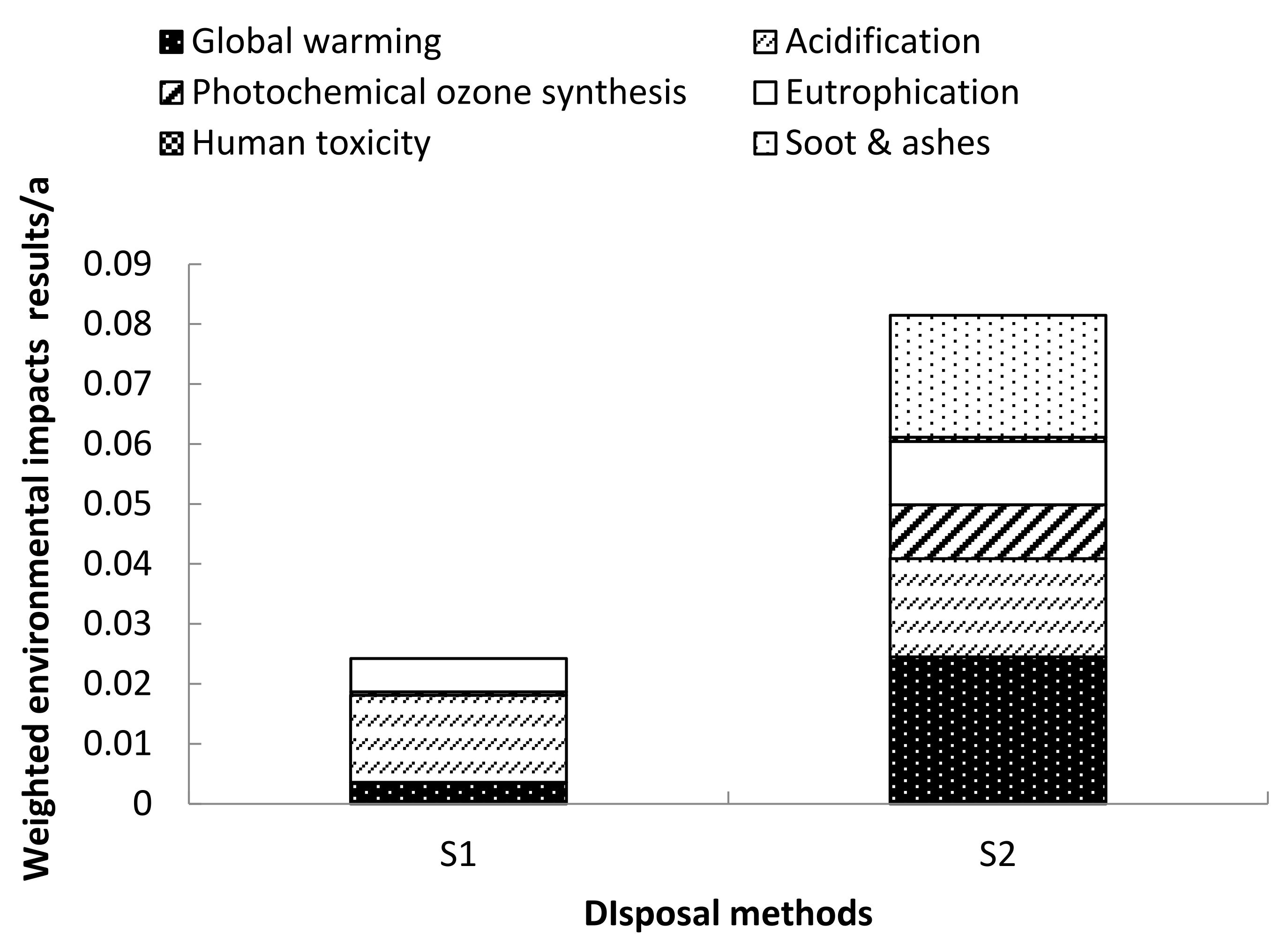

3.2. Environmental Emissions and Environmental Impacts

3.3. Financial Performance

4. Conclusions and Suggestions

- (1)

- Strengthen policy support. The state should increase assistance to other resource treatment methods while supporting waste incineration, improving the law and issuing relevant documents to promote China’s resource level, and strengthen the development of a recycling economy to further realize China’s ecological and environmental protection.

- (2)

- Pre-analysis of MSW’s components. AcRR is designed for MSW without waste sorting, so when the composition of the waste is less reproducible, its economic benefits will be affected. Therefore, it is necessary to scientifically analyze the components of local municipal solid waste before selecting this treatment method and formulate a reasonable construction plan based on the analysis results.

- (3)

- Enrich the industrial system of secondary resources. The various secondary resources obtained after AcRR treatment need to be matched with the corresponding secondary resources industrial system, so that the secondary resources can be further transformed into products and enter the market, adding a powerful driving force for the recycling economy.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Scheinberg, A.; Wilson, D.C.; Rodic, L. Solid Waste Management in the World’s Cities; EarthScan: Newcastle, UK, 2010. [Google Scholar]

- Karak, T.; Bhagat, R.M.; Bhattacharyya, P. Municipal solid waste generation, composition, and management: The world scenario critical review. Crit. Rev. Environ. Sci. Technol. 2012, 42, 1509–1630. [Google Scholar] [CrossRef]

- Laurent, A.; Bakas, I.; Clavreul, J.; Bernstad, A.; Niero, M.; Gentil, E.; Hauschild, M.Z.; Christensen, T.H. Review of LCA studies of solid waste management systems—Part I: Lessons learned and perspectives. Waste Manag. 2014, 34, 573–588. [Google Scholar] [CrossRef] [PubMed]

- World Bank. What a Waste: A global Review of Solid Waste Management; Urban Development Series Knowledge Papers; World Bank: Washington, DC, USA, 2012; Available online: https://go.exlibris.link/zz1yj96M (accessed on 7 August 2018).

- Astrup, T.F.; Tonini, D.; Turconi, R.; Boldrin, A. Life cycle assessment of thermal Waste-to-Energy technologies: Review and recommendations. Waste Manag. 2014, 37, 104–115. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kumar, A.; Samadder, S.R. A review on technological options of waste to energy for effective management of municipal solid waste. Waste Manag. 2017, 69, 407–422. [Google Scholar] [CrossRef]

- Arafat, H.A.; Jijakli, K.; Ahsan, A. Environmental performance and energy recovery potential of five processes for municipal solid waste treatment. J. Clean. Prod. 2015, 105, 233–240. [Google Scholar] [CrossRef]

- Fernandez-Gonzalez, J.M.; Grindlay, A.L.; Serrano-Bernardo, F.; Rodriguez-Rojas, M.I.; Zamorano, M. Economic and environmental review of Waste-to-Energy systems for municipal solid waste management in medium and small municipalities. Waste Manag. 2017, 67, 360–374. [Google Scholar] [CrossRef]

- Lombardi, L.; Carnevale, E.; Corti, A. A review of technologies and performances of thermal treatment systems for energy recovery from waste. Waste Manag. 2015, 37, 26–44. [Google Scholar] [CrossRef]

- Shen, C. Resource Utilization of Kitchen Waste in Guangzhou; South China University of Technology: Guangzhou, China, 2013. [Google Scholar]

- Zhou, R.C. Analysis Method and Characteristics of the Standardization of Reference Values of Climate Change in China in Life Cycle Assessment; Beijing University: Beijing, China, 2003. [Google Scholar]

- Yang, J.X.; Wang, R.S.; Liu, J.R. Methodology of life cycle impact assessment for Chinese products. Acta Sci. Circumst. 2001, 21, 234–238. [Google Scholar] [CrossRef]

- Commission of the European Communities. Directive on Industrial Emissions of 24 November 2010 on Industrial Emissions (Integrated Pollution Pevention and Control); Commission of the European Communities: Brussels, Belgium, 2010. [Google Scholar]

- Pei, C.; Xiao, X.; Mei, J. Characteristic accumulation of PCDD/Fs in pine needles near an MSWI and emission levels of the MSWI in Pearl River Delta: A case study. Chemosphere 2017, 181, 360–367. [Google Scholar]

- Javier, G.; Pablo, F.; Navarro, A.C.; Rebeca, R.; Elena, B.; Gonzalo, L. Cancer mortality in towns in the vicinity of incinerators and installations for the recovery or disposal of hazardous waste. Environ. Int. 2013, 51, 31–44. [Google Scholar]

- Assamoi, B.; Lawryshyn, Y. The environmental comparison of landfilling vs. incineration of MSW accounting for waste diversion. Waste Manag. 2012, 32, 1019–1030. [Google Scholar] [CrossRef] [PubMed]

- Liang, Z.J.; Yuan, J.G.; Zhang, W.; Lin, X.X.; Che, T.T.; Yang, Z.Y. Environmental Impact Analysis of Two Kinds of Municipal Solid Waste Disposal Technologies: Based on Life Cycle Assessment Method. Environ. Sanit. Eng. 2019, 27, 8–14. [Google Scholar]

- Arena, U.; Mastellone, M.L.; Perugini, F. The environmental performance of alternative solid waste management options: A life cycle assessment study. Chem. Eng. J. 2003, 96, 207–222. [Google Scholar] [CrossRef]

- ISO14040:2006; Environmental Management-Life Cycle Assessment—Principles and Framework. International Organization for Standardization: Geneva, Switzerland, 2006.

- Zhou, D.X.; Ma, X.Q.; Liang, Z.Q. Life cycle analysis of high-temperature aerobic static composting of municipal solid waste in Guangzhou. Environ. Pollut. Control. 2012, 5, 83–87. [Google Scholar]

- National Development and Reform Commission of the People’s Republic of China for Climate Change. China Regional Power Grid Carbon Dioxide Baseline Emission Factor BM [EB/OL]; National Development and Reform Commission of the People’s Republic of China for Climate Change: Beijing, China, 2016. [Google Scholar]

- Dong, J.; Ma, X. Life cycle assessment on biodiesel production. Mod. Chem. Ind. 2007, 9, 59–63. [Google Scholar]

- Yang, F. Reduction Technologies of Typical Pollutional Gaseous Emissions during Kitchen Waste Composting and Life Cycle Assessment of Management; China Agricultural University: Beijing, China, 2014. [Google Scholar]

- GB 18485-2014; Municipal Solid Waste Incineration Pollution Control Standard. Environmental Science Press: Beijing, China, 2014.

- GB 14554-93; Odor Emission Standards. Standard Press: Beijing, China, 1993.

- Zhao, W.; Sun, Y.Z.; Zhang, W.Y.; Liang, S. Eco-efficiency analysis of municipal solid waste recycling systems by using life cycle approaches. Acta Ecol. Sin. 2016, 22, 7216–7218. [Google Scholar]

- Li, J.; Zhang, Y.; Sun, T. The health risk levels of different age groups of residents living in the vicinity of municipal solid waste incinerator posed by PCDD/Fs in atmosphere and soil. Sci. Total Environ. 2018, 631, 81–91. [Google Scholar] [CrossRef]

- CML-IE, Leiden University. CML-IA Characterisation Factors. 2016. Available online: http://cml.leiden.edu/software/data-cmlia.html (accessed on 7 August 2018).

- Abduli, M.A.; Naghib, A.; Yonesi, M.; Akbari, A. Life cycle assessment (LCA) of solid waste management strategies in Tehran: Landfill and composting plus landfill. Environ. Monit. Assess. 2011, 178, 487–498. [Google Scholar] [CrossRef]

- Jensen, M.B.; Møller, J.; Scheutz, C. Comparison of the organic waste management systems in the Danish–German border region using life cycle assessment (LCA). Waste Manag. 2016, 49, 491–504. [Google Scholar] [CrossRef]

- National Energy Administration. National Development and Reform Commission on the Adjustment of the Sales of Electricity tariff Classification Structure of the Relevant Issues. Available online: http://www.nea.gov.cn/2014-06/06/c_133388608.htm (accessed on 7 August 2018).

- National Development and Reform Commission of the People’s Republic of China. Notice of the National Development and Reform Commission on Perfecting the Policy of Garbage Incineration Price. Available online: http://www.gov.cn/zwgk/2012-04/10/content_2109921.htm (accessed on 7 August 2018).

- Zhao, W.; Yu, H.; Liang, S.; Zhang, W.; Yang, Z. Resource impacts of municipal solid waste treatment systems in Chinese cities based on hybrid life cycle assessment. Resour. Conserv. Recycl. 2018, 130, 215–225. [Google Scholar] [CrossRef]

- Liu, B.Y. An analysis of energy consumption for paper industry both abroad and domestic. China Pulp Pap. Ind. 2010, 31, 14–21. [Google Scholar]

- Zhang, X.; Cai, Z.S.; Li, H. Energy consumption analysis of fertilizer production in China. Mod. Chem. Ind. 2014, 34, 12–15. [Google Scholar] [CrossRef]

- Liang, J.L.; Dai, J.F.; Feng, W.J.; Xu, J.C. Life cycle assessment of metallic copper produced by the pyrometallurgical and hydrometallurgical processes. J. Lanzhou Univ. Technol. 2006, 32, 19–21. [Google Scholar] [CrossRef]

- Ministry of Industry and Information Technology of People’s Republic of China. Technical Report on Comprehensive Utilization of Renewable Resources; 2014. Available online: https://globaledge.msu.edu/global-resources/resource/10663 (accessed on 23 November 2022).

- Fan, W.G.; Xu, M.; Dong, X.B.; Wei, H.J. Considerable environmental impact of the rapid development of China’s express delivery industry. Resour. Conserv. Recycl. 2017, 126, 174–176. [Google Scholar] [CrossRef]

- Dai, W.H.; Huang, Y.; Wu, L.; Yu, J. Relationships between soil organic matter content (SOM) and pH in topsoil of zonal soil in China. Acta Pedol. Sin. 2009, 46, 851–860. [Google Scholar]

- Alvarenga, P.; Mourinha, C.; Farto, M.; Santos, T.; Palma, P.; Sengo, J.; Morais, M.C.; Cunha-Queda, C. Sewage sludge, compost and other representative organic wastes as agricultural soil amendments: Benefits versus limiting factors. Waste Manag. 2015, 40, 44–52. [Google Scholar] [CrossRef]

- Talaiekhozani, A.; Bagheri, M.; Goli, A.; Talaei Khoozani, M.R. An overview of principles of odor production, emission, and control methods in wastewater collection and treatment systems. J. Environ. Manag. 2016, 170, 186–206. [Google Scholar] [CrossRef] [PubMed]

- Qian, P.; Ma, C.H. Spatio-Temporal Dynamics of Carbon Emission of Energy Consumption in China. J. Southwest Univ. (Nat. Sci. Ed.) 2019, 41, 93–100. [Google Scholar] [CrossRef]

- Li, M.; Wang, C.; Ni, M. Hazardous impact of PCDD/Fs emissions from the MWI on soil during 2007–2014. Acta Sci. Circumst. 2016, 10, 3804–3809. [Google Scholar]

- Shen, H.T.; Guan, R.F.; Ding, G.Q.; Chen, Q.; Lou, X.M. Polychlorinated dibenzop-dioxins/furans (PCDD/Fs) and polychlorinated biphenyls (PCBs) in Zhejiang foods (2006–2015): Market basket and polluted areas. Sci. Total Environ. 2017, 574, 120–127. [Google Scholar] [CrossRef]

- Zheng, J.; Ou, J.; Mo, Z.; Yin, S. Mercury emission inventory and its spatial characteristics in the Pearl River Delta region, China. Sci. Total Environ. 2011, 412, 214–222. [Google Scholar] [CrossRef] [PubMed]

- He, Y.F.; Xi, B.D.; Wang, Q.; Zhang, X.X.; Li, X.J. Health Risk Assessment and Exemption Management of MSWI Fly Ash’s Melting Residues. Res. Environ. Sci. 2005, 18. [Google Scholar] [CrossRef]

- Li, S.; Williams, G.; Guo, Y. Health benefits from improved outdoor air quality and intervention in China. Environ. Pollut. 2016, 214, 17–25. [Google Scholar] [CrossRef] [PubMed]

- Gao, J.C.; Jiang, Q.Z.; Nie, Z.C.; Cai, Z.J.; Cao, Y. Business Accounting and Prediction of the Total Cost of Domestic Garbage Treatment in Shenzhen. Math. Model. Its Appl. 2018, 7, 59–68. [Google Scholar]

- Song, G.; Sun, Y.Y.; Zhao, C. Social cost accounting for municipal solid waste incineration in Beijing. China Popul. Resour. Environ. 2017, 8, 17–27. [Google Scholar]

| MSW Disposal | Resource Consumption | Major Pollutants | Data Sources | |

|---|---|---|---|---|

| S1 a | MSW transportation | Diesel | CO2, NOx, SO2, CO, VOC | Zhou et al., 2012 [20] |

| Resource separating | Electricity | CO2, NOx, SO2 | 2016 China Regional Power Grid Carbon dioxide baseline emission factor BM [21] | |

| Dong et al., 2007 [22] | ||||

| The combustion of biogas | CO2, NOx, SO2, N2O, NH3 | Yang et al., 2014 [23] | ||

| S2 b | Diesel and Electricity | CO2, NOx, SO2, CO, VOC | GB 18485-2014 Pollution Control Standard for Incineration of Municipal Solid Waste [24] | |

| GB 2414554-93 for Emission Standard for Odor Pollutants [25] | ||||

| Zhao et al., 2016 [26] | ||||

| Environmental Impact | Pollutants | Equivalent Factor | Normalization Coefficient | Weight Coefficient |

|---|---|---|---|---|

| Global warming | CO2 | 1 | 8700 kg CO2 eq/(person·a) | 0.83 |

| N2O | 296 | |||

| CO | 2 | |||

| Acidification | SO2 | 1 | 36 kg SO2 eq/(person·a) | 0.73 |

| NOx | 0.7 | |||

| Photochemical ozone synthesis | VOC | 0.6 | 0.65 kg C2H4 eq/(person·a) | 0.53 |

| CO | 0.03 | |||

| Eutrophication | NOx | 1.35 | 62 kg NO3 eq/(person·a) | 0.73 |

| Human toxicity | 2,3,7,8-TCDD | 1,933,982,792 | 8760 kg 1,4-DCB eq/(person·a) | 1.99 |

| Cd2 | 289 | |||

| Hg3 | 6008 | |||

| Pb2 | 467 | |||

| Soot and Ashes | PM10 | 1 | 1.8 kg eq/(person·a) | 0.61 |

| One Ton of MSW Disposal | S1 | S2 | |||

|---|---|---|---|---|---|

| Energy/material input | Diesel/L | 0.94 | 0.94 | ||

| Electricity/kW·h | 50 | 61.6 | |||

| Water/m3 | 0.6 | 2.3 | |||

| Energy/material recovery | Metal/kg | 3.5 | Electricity/kW·h | 342 | |

| Pulp/kg | 158 | ||||

| Plastics/kg | 122 | ||||

| Organic fertilizers /kg | 168 | ||||

| RDF/kg | 160 | ||||

| Inorganics/kg | 65.4 | ||||

| Greenhouse gases emission/kg | CO2 | 37.57 | 256.21 | ||

| N2O | 0.0005 | - | |||

| Other gas pollutant emissions/kg | CO | 0.006 | 0.345 | ||

| SO2 | 0.47 | 0.285 | |||

| NOx | 0.35 | 0.75 | |||

| NH3 | 0.01 | 0.012 (Ⅲ Standard) | |||

| VOC | 0.0009 | 0.18 × 10−4 | |||

| H2S | 0.15 | 1.08 × 10−4 | |||

| HCl | - | 7.36 × 10−4 | |||

| Hg | - | 1.50 × 10−4 | |||

| Cd+Tl | - | 3.00 × 10−4 | |||

| Sb + As + Pb + Cr + | - | 3.00 × 10−3 | |||

| Co + Cu + Mn + Ni | |||||

| PCDD/DFs (kg TEQ) | - | 3.00 × 10−10 | |||

| Solid pollutant emissions/kg | Fly ash | - | 37.76 | ||

| Bottom ash | - | 134.25 | |||

| Environmental Impact | Pollutants | Equivalent Factor | Normalization Coefficient | Weight Coefficient | Total Emission/kg | Emission Equivalent/kg | ||

|---|---|---|---|---|---|---|---|---|

| S1 | S2 | S1 | S2 | |||||

| Global warming | CO2 | 1 | 8700 kg CO2 eq/(person·a) | 0.83 | 37.57 | 256.21 | 37.734 | 256.9 |

| N2O | 296 | 0.0005 | _ | |||||

| CO | 2 | 0.006 | 0.345 | |||||

| Acidification | SO2 | 1 | 36 kg SO2 eq/(person·a) | 0.73 | 0.47 | 0.285 | 0.715 | 0.81 |

| NOx | 0.7 | 0.35 | 0.75 | |||||

| Photochemical ozone synthesis | VOC | 0.6 | 0.65 kg C2H4 eq/(person·a) | 0.53 | 0.0009 | 0.001 | 0.00072 | 0.01095 |

| CO | 0.03 | 0.006 | 0.345 | |||||

| Eutrophication | NOx | 1.35 | 62 kg NO3 eq/(person·a) | 0.73 | 0.35 | 0.75 | 0.473 | 1.0125 |

| Human toxicity | 2,3,7,8-TCDD | 1933982792 | 8760 kg 1,4-DCB eq/(person·a) | 1.99 | - | 3E-10 | - | 2.968 |

| Cd2 | 289 | - | 0.0003 | |||||

| Hg3 | 6008 | - | 0.00015 | |||||

| Pb2 | 467 | - | 0.003 | |||||

| Soot and Ashes | PM10 | 1 | 1.8 kg eq/(person·a) | 0.61 | - | 0.06 | - | 0.06 |

| Project | S1 | S2 | ||||||

|---|---|---|---|---|---|---|---|---|

| Consumption/ Output | Unit Price/ ¥ | Consumption/Output | Unit Price/ ¥ | |||||

| Expenditure | Input | Diesel/L | 0.216 | 6.4 | Input | Diesel/L | 0.276 | 6.4 |

| Electricity/kW·h | 50 | 0.6642 | Electricity/kW·h | 61.6 | 0.6642 | |||

| Water/m3 | 0.6 | 4.86 | Water/m3 | 2.3 | 4.86 | |||

| Management costs | 220 | Management costs | 220 | |||||

| Depreciation | 8.22 | Depreciation | 12.33 | |||||

| Operating costs | 265.73 | 286.29 | ||||||

| Income | Output/kg | Plastics | 122 | 2 | Output/kW·h | Electricity | 280 | 0.65 |

| Pulp | 158 | 1.2 | 62 | 0.4505 | ||||

| Organic fertilizers | 168 | 0.7 | ||||||

| Metal | 3.5 | 0.5 | ||||||

| RDF | 160 | 0 | ||||||

| Inorganics | 65.4 | 0 | ||||||

| Product revenue | 552.95 | 209.931 | ||||||

| Net income per tonne/¥ | 287.22 | −76.359 | ||||||

| Annual total MSW/ton | 36,500 | |||||||

| Annual net income/¥ | 104,835,000,000 | −278,710,000,000 | ||||||

| Total investment/¥ | 30,000,000 | 45,000,000 | ||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liang, Z.; Luo, Z.; Yuan, J.; Li, M.; Xia, Y.; Che, T.; Huang, L.; Liu, J. Evaluating the Environmental and Economic Performance of Municipal Solid Waste Disposal by All-Component Resource Recovery. Sustainability 2022, 14, 16898. https://doi.org/10.3390/su142416898

Liang Z, Luo Z, Yuan J, Li M, Xia Y, Che T, Huang L, Liu J. Evaluating the Environmental and Economic Performance of Municipal Solid Waste Disposal by All-Component Resource Recovery. Sustainability. 2022; 14(24):16898. https://doi.org/10.3390/su142416898

Chicago/Turabian StyleLiang, Zhenjiang, Ziling Luo, Jiangang Yuan, Meiyun Li, Yongyan Xia, Tingting Che, Lingyue Huang, and Jianyi Liu. 2022. "Evaluating the Environmental and Economic Performance of Municipal Solid Waste Disposal by All-Component Resource Recovery" Sustainability 14, no. 24: 16898. https://doi.org/10.3390/su142416898