Effect of Using ECC Layer on the Flexural Performance of RC Beams Previously Strengthened with EB CFRP Laminates

Abstract

:1. Introduction

2. Experimental Work

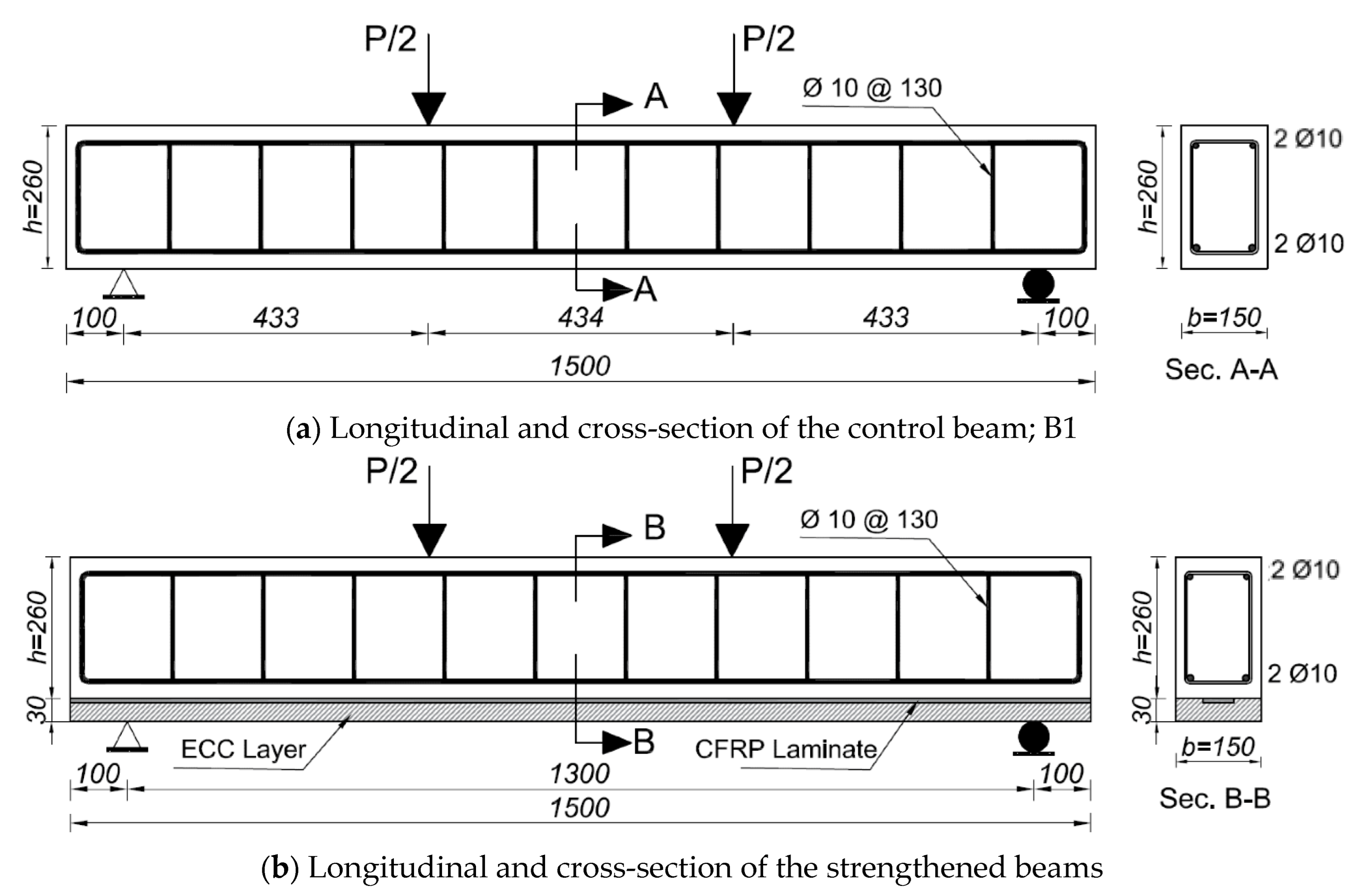

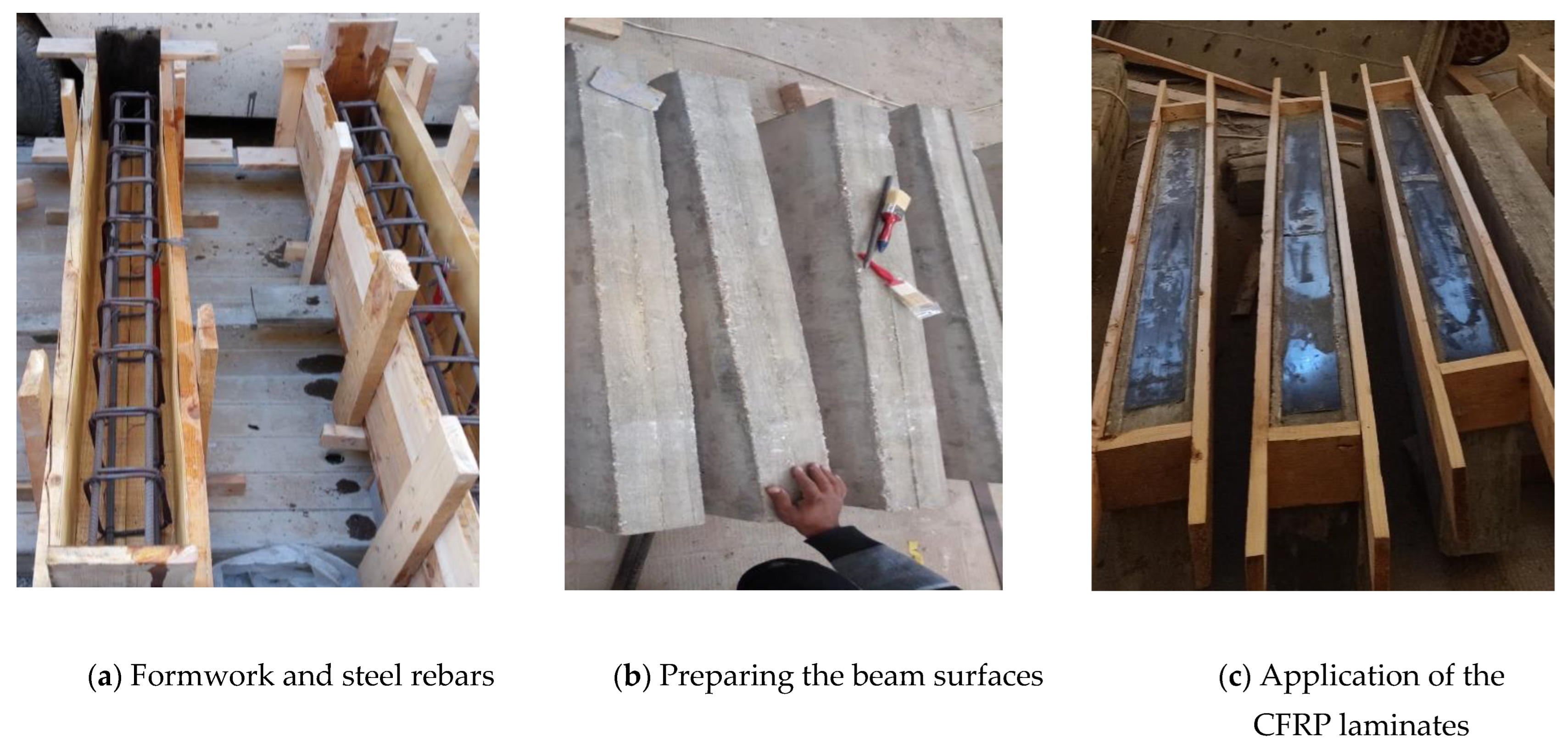

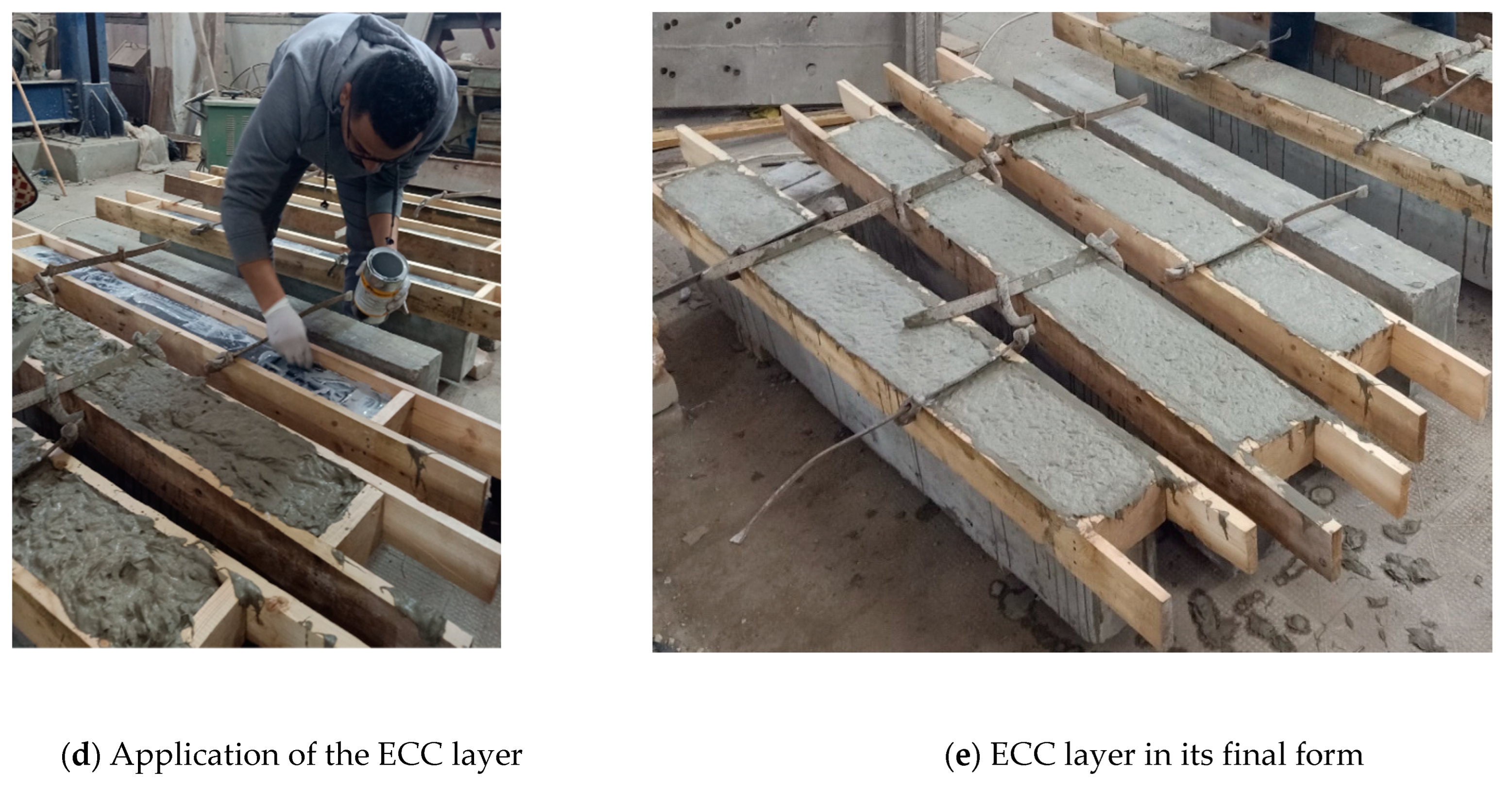

2.1. Details of Specimens and Test Matrix

2.2. Materials Properties, Mix Proportions, and Specimen Preparation

2.3. Test Setup and Instrumentations

3. Test Results and Discussions

3.1. Ultimate Flexural Capacities and Deformations

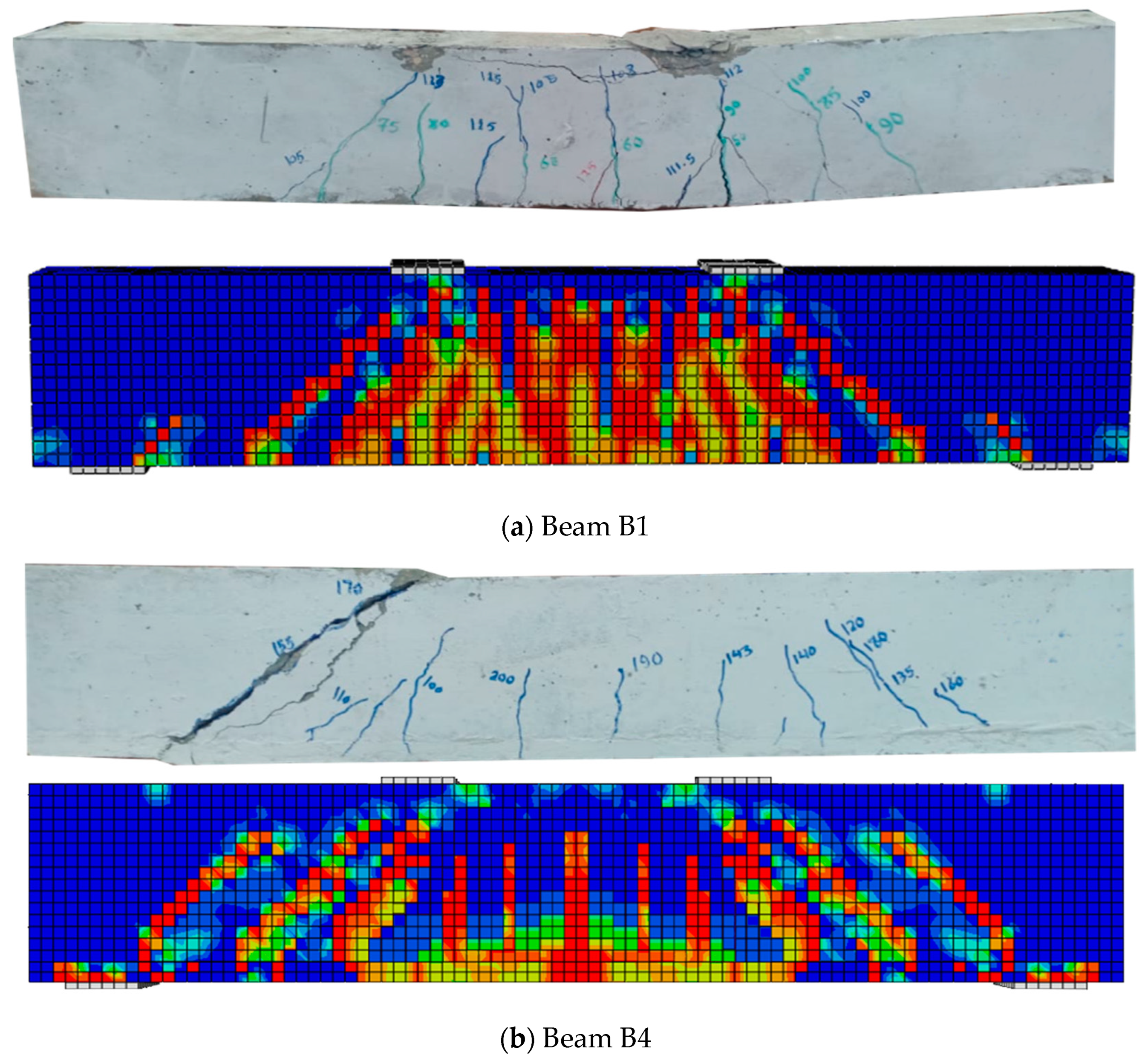

3.2. Modes of Failure and Cracking Patterns

3.3. Stiffness of the Tested Beams

4. Finite Element Modeling

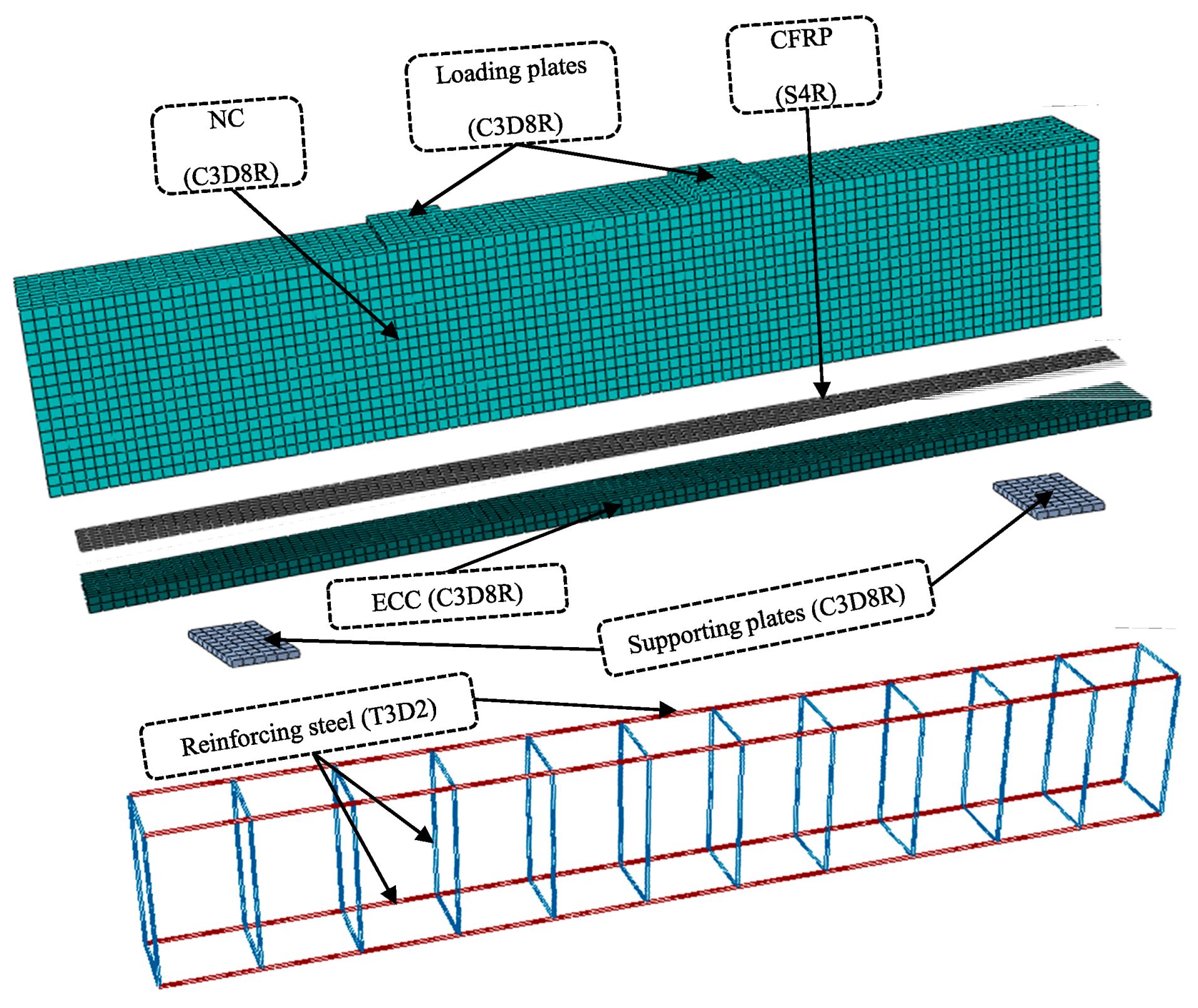

4.1. Model Built-Up and Interaction Properties

4.2. Material Constitutive Models

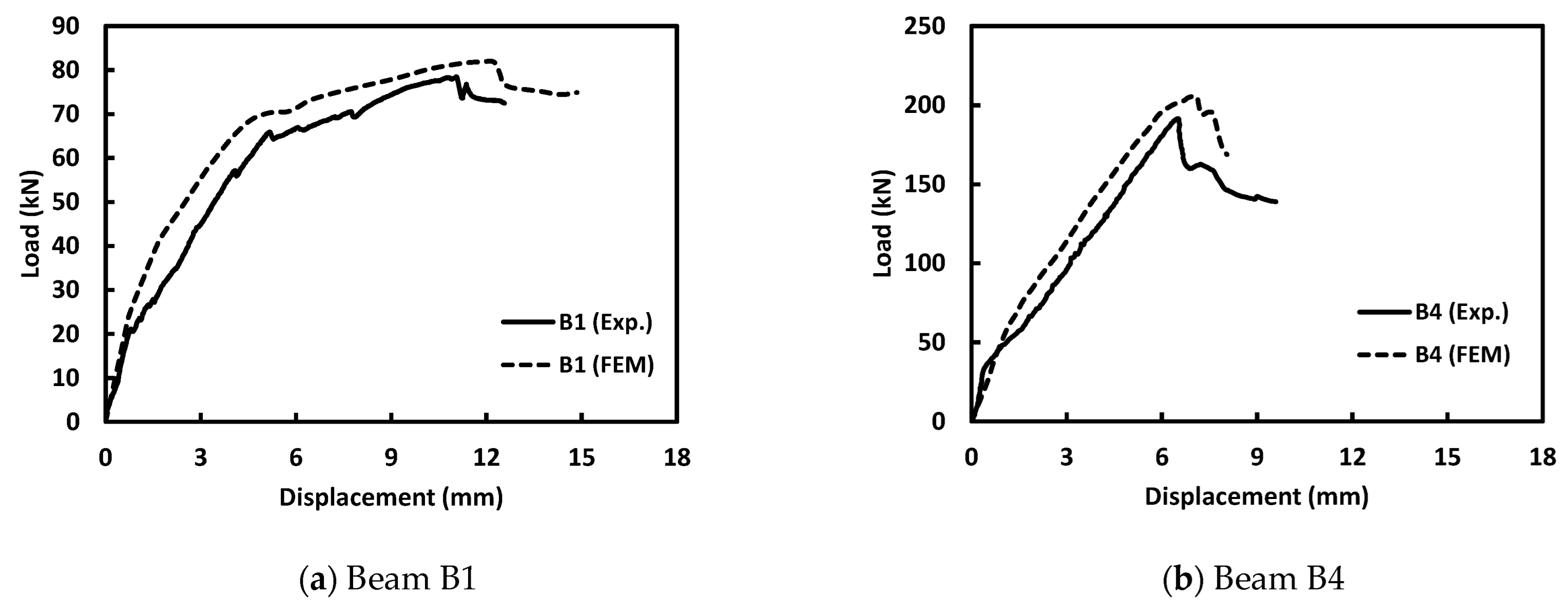

4.3. Validation of the FEMs

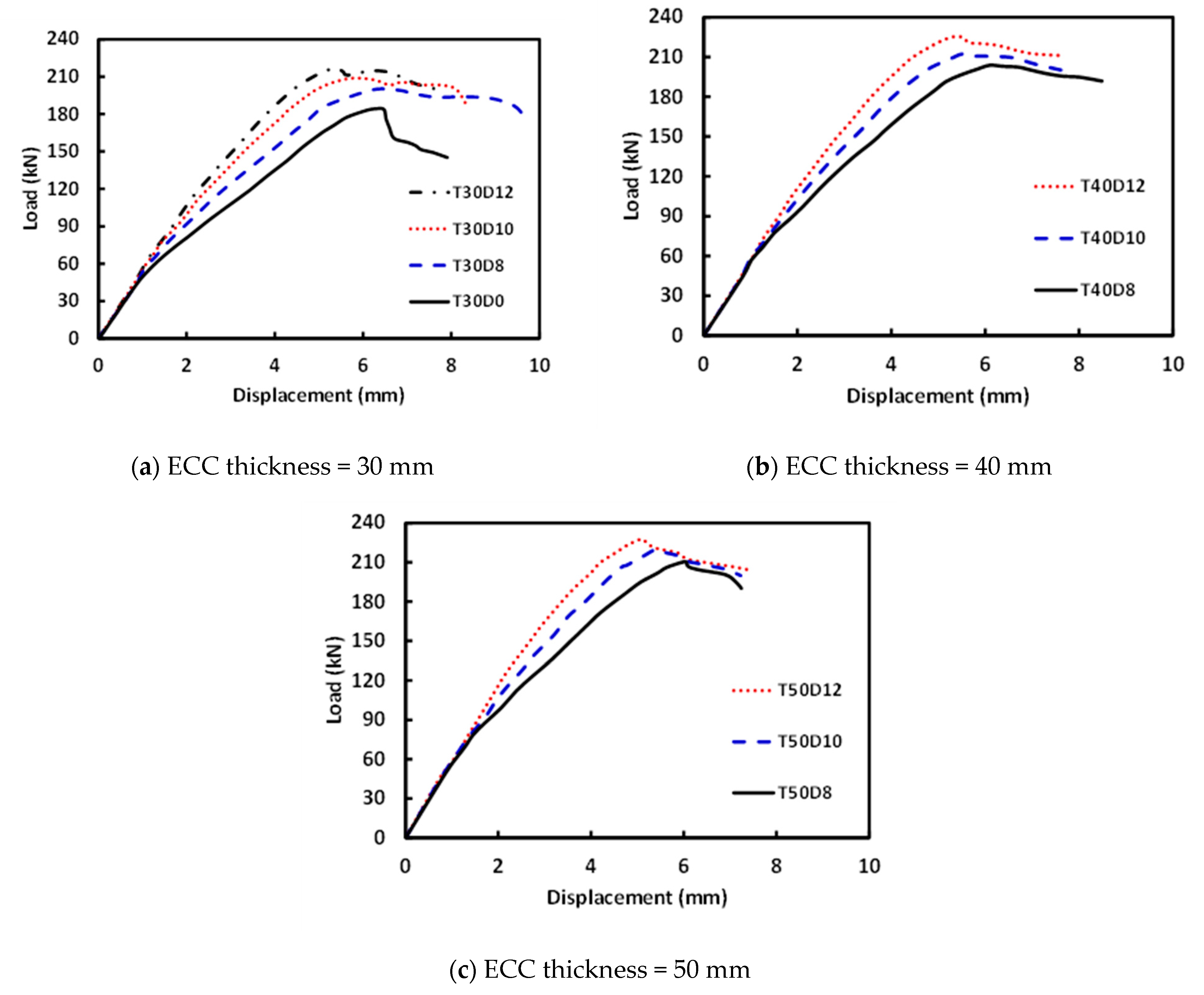

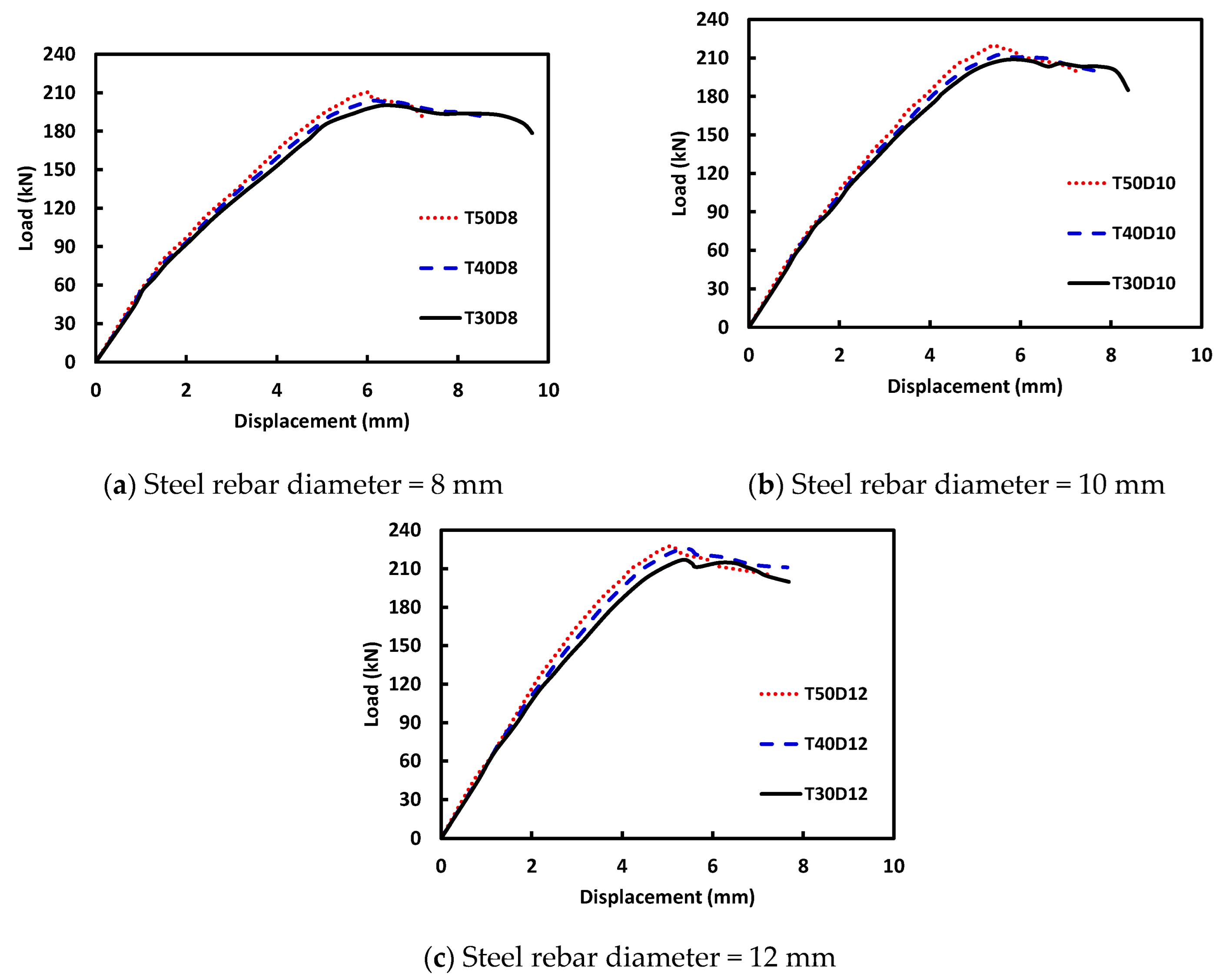

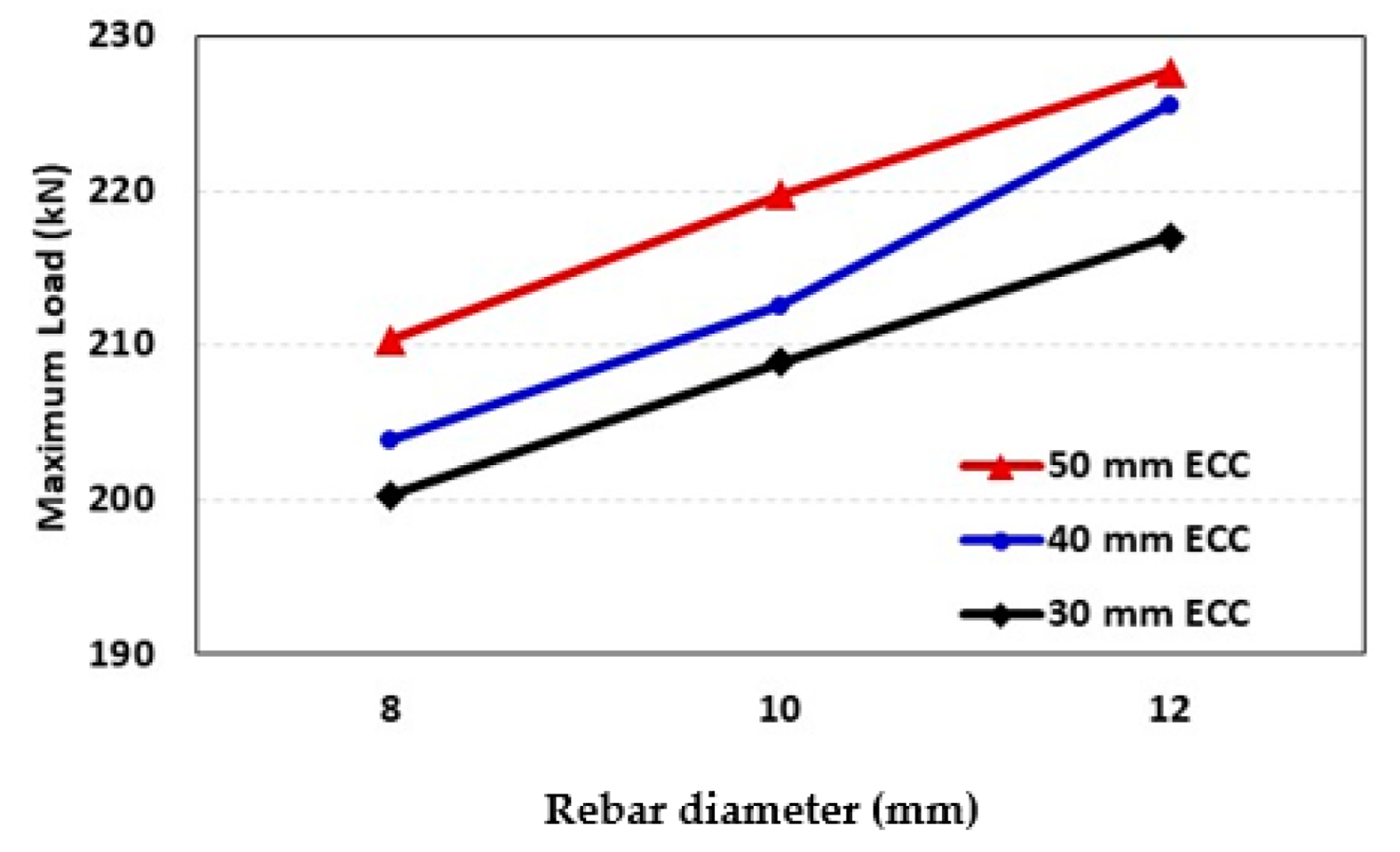

5. Parametric Study

6. Conclusions

- Strengthening RC beams with CFRP laminates enhanced both the stiffness and flexural capacity of beams. The flexural capacities were enhanced by 75% and 94% for the CFRP widths of 50 mm and 100 mm, respectively.

- Providing an ECC layer to the RC beams previously strengthened with CFRP laminates exhibited additional enhancement in the flexural capacity. The improvements in the flexural capacities were 102% and 125% for the CFRP widths of 50 mm and 100 mm, respectively, compared with the control beam.

- The employed ECC layer alongside the CFRP laminate resulted in an average increase in stiffness of about 318% when compared with the non-strengthened specimen and 149% when compared with the one strengthened with CFRP only.

- The effectiveness of the ECC thickness on the overall behavior of the strengthened beams was affected by the steel reinforcement ratio. For the beams with 8 mm and 10 mm steel rebar diameters, the peak loads increased by 1.8% and 5% when the ECC layer thickness increased from 30 mm to 40 mm and 50 mm, respectively. However, the improvements were 4% and 6.5%, respectively, in the case of the 12 mm steel rebar diameter.

- Regardless of the ECC layer thickness, increasing the steel rebar diameter from 8 mm to 10 mm and 12 mm enhanced the peak loads by 4.3% and 9%, respectively.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- De Lorenzis, L.; Teng, J.G. Near-surface mounted FRP reinforcement: An emerging technique for strengthening structures. Compos. Part B Eng. 2007, 38, 119–143. [Google Scholar] [CrossRef]

- Giese, A.C.H.; Giese, D.N.; Dutra, V.F.P.; Da Silva Filho, L.C.P. Flexural behavior of reinforced concrete beams strengthened with textile reinforced mortar. J. Build. Eng. 2021, 33, 101873. [Google Scholar] [CrossRef]

- El-Sherif, H.E.; Wakjira, T.G.; Ebead, U. Flexural strengthening of reinforced concrete beams using hybrid near-surface embedded/externally bonded fabric-reinforced cementitious matrix. Constr. Build. Mater. 2020, 238, 117748. [Google Scholar] [CrossRef]

- Yuan, F.; Chen, M.; Pan, J. Flexural strengthening of reinforced concrete beams with high-strength steel wire and engineered cementitious composites. Constr. Build. Mater. 2020, 254, 119284. [Google Scholar] [CrossRef]

- Alharthi, Y.M.; Emara, M.; Elamary, A.S.; Sharaky, I.A. Flexural response and load capacity of reinforced concrete beams strengthened with reinforced mortar layer. Eng. Struct. 2021, 245, 112884. [Google Scholar] [CrossRef]

- Fawzy, K.; Hassan, H.; Madqour, M. Experimental and analytical investigations of reinforced concrete beams strengthened by different CFRP sheet schemes. Frat. Integrità Strutt. 2021, 15, 123–136. [Google Scholar] [CrossRef]

- Adel, B.; Noureddine, F.; Mohcene, B.; Mesbah, H.A. Modeling of CFRP strengthened RC beams using the SNSM technique, proposed as an alternative to NSM and EBR techniques. Frat. Integrità Strutt. 2020, 14, 21–35. [Google Scholar] [CrossRef]

- Maheswaran, J.; Chellapandian, M.; Arunachelam, N. Retrofitting of severely damaged reinforced concrete members using fiber reinforced polymers: A comprehensive review. Structures 2022, 38, 1257–1276. [Google Scholar] [CrossRef]

- Al-Mahmoud, F.; Castel, A.; François, R.; Tourneur, C. Strengthening of RC members with near-surface mounted CFRP rods. Compos. Struct. 2009, 91, 138–147. [Google Scholar] [CrossRef]

- Garg, N.; Shrivastava, S. Environmental and Economic Comparison of FRP Reinforcements and Steel Reinforcements in Concrete Beams Based on Design Strength Parameter; Malaviya National Institute of Technology (MNIT): Jaipur, India; India & Govt. Engineering College: Bikaner, India, 2019. [Google Scholar]

- Larrinaga, P.; Garmendia, L.; Chastre, C.; San-José, J.T. Low-grade RC beams strengthened with TRM composite based on basalt, carbon and steel textiles: Experimental and analytical study. Case Stud. Constr. Mater. 2022, 16, e00906. [Google Scholar] [CrossRef]

- Triantafillou, T.C.; Papanicolaou, C.G. Shear strengthening of reinforced concrete members with textile reinforced mortar (TRM) jackets. Mater. Struct. Constr. 2006, 39, 93–103. [Google Scholar] [CrossRef]

- Bournas, D.A.; Lontou, P.V. Papanicolaou CG, Triantafillou TC. Textile-Reinforced Mortar versus Fiber-Reinforced Polymer Confinement in Reinforced Concrete Columns. ACI Struct. J. 2007, 104, 740. [Google Scholar] [CrossRef]

- Emara, M.; Torres, L.; Baena, M.; Barris, C.; Cahís, X. Bond response of NSM CFRP strips in concrete under sustained loading and different temperature and humidity conditions. Compos. Struct. 2018, 192, 1–7. [Google Scholar] [CrossRef]

- Coelho, M.R.F.; Sena-Cruz, J.M.; Neves, L.A.C. A review on the bond behavior of FRP NSM systems in concrete. Constr. Build. Mater. 2015, 93, 1157–1169. [Google Scholar] [CrossRef] [Green Version]

- Al-Saadi, N.T.K.; Mohammed, A.; Al-Mahaidi, R.; Sanjayan, J. A state-of-the-art review: Near-surface mounted FRP composites for reinforced concrete structures. Constr. Build. Mater. 2019, 209, 748–769. [Google Scholar] [CrossRef]

- Bilotta, A.; Ceroni, F.; Nigro, E.; Pecce, M. Efficiency of CFRP NSM strips and EBR plates for flexural strengthening of RC beams and loading pattern influence. Compos. Struct. 2015, 124, 163–175. [Google Scholar] [CrossRef]

- Panahi, M.; Zareei, S.A.; Izadi, A. Flexural strengthening of reinforced concrete beams through externally bonded FRP sheets and near surface mounted FRP bars. Case Stud. Constr. Mater. 2021, 15, e00601. [Google Scholar] [CrossRef]

- Bilotta, A.; Ceroni, F.; Di Ludovico, M.; Nigro, E.; Pecce, M.; Manfredi, G. Bond Efficiency of EBR and NSM FRP Systems for Strengthening Concrete Members. J. Compos. Constr. 2011, 15, 757–772. [Google Scholar] [CrossRef]

- Raoof, M.; El-Rimawi, J.A.; Hassanen, M.A.H. Theoretical and experimental study on externally plated R.C. beams. Eng. Struct. 2000, 22, 85–101. [Google Scholar] [CrossRef]

- Barnes, R.A.; Mays, G.C. Strengthening of reinforced concrete beams in shear by the use of externally bonded steel plates: Part 1—Experimental programme. Constr. Build. Mater. 2006, 20, 396–402. [Google Scholar] [CrossRef]

- Smith, S.; Teng, J. FRP-strengthened RC beams. II: Assessment of debonding strength models. Eng. Struct. 2002, 24, 397–417. [Google Scholar] [CrossRef]

- Teng, J.G.; Yao, J. Plate end debonding in FRP-plated RC beams-II: Strength model. Eng. Struct. 2007, 29, 2472–2486. [Google Scholar] [CrossRef]

- Al-Obaidi, S.; Saeed, Y.M.; Rad, F.N. Flexural strengthening of reinforced concrete beams with NSM-CFRP bars using mechanical interlocking. J. Build. Eng. 2020, 31, 101422. [Google Scholar] [CrossRef]

- Sharaky, I.A.; Baena, M.; Barris, C.; Sallam, H.E.M.; Torres, L. Effect of axial stiffness of NSM FRP reinforcement and concrete cover confinement on flexural behaviour of strengthened RC beams: Experimental and numerical study. Eng. Struct. 2018, 173, 987–1001. [Google Scholar] [CrossRef]

- Sharaky, I.A.; Torres, L.; Comas, J.; Barris, C. Flexural response of reinforced concrete (RC) beams strengthened with near surface mounted (NSM) fibre reinforced polymer (FRP) bars. Compos. Struct. 2014, 109, 8–22. [Google Scholar] [CrossRef]

- Leung, C.K.Y. FRP debonding from a concrete substrate: Some recent findings against conventional belief. Cem. Concr. Compos. 2006, 28, 742–748. [Google Scholar] [CrossRef]

- Zhou, A.; Qin, R.; Feo, L.; Penna, R.; Lau, D. Investigation on interfacial defect criticality of FRP-bonded concrete beams. Compos. Part B Eng. 2017, 113, 80–90. [Google Scholar] [CrossRef]

- Raoof, S.M.; Koutas, L.N.; Bournas, D.A. Textile-reinforced mortar (TRM) versus fibre-reinforced polymers (FRP) in flexural strengthening of RC beams. Constr. Build. Mater. 2017, 151, 279–291. [Google Scholar] [CrossRef]

- Koutas, L.N.; Tetta, Z.; Bournas, D.A.; Triantafillou, T.C. Strengthening of Concrete Structures with Textile Reinforced Mortars: State-of-the-Art Review. J. Compos. Constr. 2019, 23, 03118001. [Google Scholar] [CrossRef]

- Vieira, A.D.A.; Triantafyllou, S.P.; Bournas, D.A. Strengthening of RC frame subassemblies against progressive collapse using TRM and NSM reinforcement. Eng. Struct. 2020, 207, 110002. [Google Scholar] [CrossRef]

- Al-Salloum, Y.; Siddiqui, N.A.; Elsanadedy, H.M.; Abadel, A.A. Textile-reinforced mortar versus FRP as strengthening material for seismically deficient RC beam-column joints. J. Compos. Constr. 2011, 15, 920–933. [Google Scholar] [CrossRef]

- Elsanadedy, H.M.; Almusallam, T.H.; Alsayed, S.H.; Al-Salloum, Y.A. Flexural strengthening of RC beams using textile reinforced mortar—Experimental and numerical study. Compos. Struct. 2013, 97, 40–55. [Google Scholar] [CrossRef]

- Zhang, D.; Ueda, T.; Furuuchi, H. Concrete cover separation failure of overlay-strengthened reinforced concrete beams. Constr. Build. Mater. 2012, 26, 735–745. [Google Scholar] [CrossRef]

- Safdar, M.; Matsumoto, T.; Kakuma, K. Flexural behavior of reinforced concrete beams repaired with ultra-high performance fiber reinforced concrete (UHPFRC). Compos. Struct. 2016, 157, 448–460. [Google Scholar] [CrossRef]

- Yin, H.; Teo, W.; Shirai, K. Experimental investigation on the behaviour of reinforced concrete slabs strengthened with ultra-high performance concrete. Constr. Build. Mater. 2017, 155, 463–474. [Google Scholar] [CrossRef]

- Prem, P.R.; Murthy, A.R. Acoustic emission and flexural behaviour of RC beams strengthened with UHPC overlay. Constr. Build. Mater. 2016, 123, 481–492. [Google Scholar] [CrossRef]

- Al-osta, M.A.; Isa, M.N.; Baluch, M.H.; Rahman, M.K. Flexural behavior of reinforced concrete beams strengthened with ultra-high performance fiber reinforced concrete. Constr. Build. Mater. 2017, 134, 279–296. [Google Scholar] [CrossRef]

- Deng, M.; Ma, F.; Ye, W.; Li, F. Flexural behavior of reinforced concrete beams strengthened by HDC and RPC. Constr. Build. Mater. 2018, 188, 995–1006. [Google Scholar] [CrossRef]

- Deng, M.; Zhang, M.; Ma, F.; Li, F.; Sun, H. Flexural strengthening of over-reinforced concrete beams with highly ductile fiber-reinforced concrete layer. Eng. Struct. 2021, 231, 111725. [Google Scholar] [CrossRef]

- Li, V.C.; Wang, S.; Wu, C. Tensile strain-hardening behavior or polyvinyl alcohol engineered cementitious composite (PVA-ECC). ACI Mater. J. 2001, 98, 483–492. [Google Scholar] [CrossRef]

- Zhang, J.; Leung, C.K.Y.; Gao, Y. Simulation of crack propagation of fiber reinforced cementitious composite under direct tension. Eng. Fract. Mech. 2011, 78, 2439–2454. [Google Scholar] [CrossRef]

- Yang, X.; Gao, W.Y.; Dai, J.G.; Lu, Z.D.; Yu, K.Q. Flexural strengthening of RC beams with CFRP grid-reinforced ECC matrix. Compos. Struct. 2018, 189, 9–26. [Google Scholar] [CrossRef]

- Hamoda, A.; Abdelazeem, F.; Emara, M. Concentric compressive behavior of hybrid concrete–Stainless Steel Double-Skin Tubular Columns incorporating High Performance Concretes. Thin-Walled Struct. 2020, 159, 107297. [Google Scholar] [CrossRef]

- Zhou, J.; Pan, J.; Leung, C.K.Y. Mechanical behavior of fiber-reinforced engineered cementitious composites in uniaxial compression. J. Mater. Civ. Eng. 2015, 27, 04014111. [Google Scholar] [CrossRef]

- Chen, Y.; Yu, J.; Leung, C.K.Y. Use of high strength Strain-Hardening Cementitious Composites for flexural repair of concrete structures with significant steel corrosion. Constr. Build. Mater. 2018, 167, 325–337. [Google Scholar] [CrossRef]

- Awad, F.; Husain, M.; Fawzy, K. Flexural behaviour of reinforced concrete beams strengthened by NSM technique using ECC. Frat. Integrità Strutt. 2022, 16, 291–309. [Google Scholar] [CrossRef]

- Zhou, Y.; Sui, L.; Huang, X.; Guo, M.; Luo, M.; Hu, B.; Cheng, C. Enhancing the EB-FRP strengthening effectiveness by incorporating a cracking-control layer of ECC with different thicknesses. Constr. Build. Mater. 2021, 286, 122975. [Google Scholar] [CrossRef]

- Hu, B.; Zhou, Y.; Xing, F.; Sui, L.; Luo, M. Experimental and theoretical investigation on the hybrid CFRP-ECC flexural strengthening of RC beams with corroded longitudinal reinforcement. Eng. Struct. 2019, 200, 109717. [Google Scholar] [CrossRef]

- Li, Z.Q.; Hou, W.; Lin, G. Flexural strengthening of RC beams with BFRP or high strength steel bar–reinforced ECC matrix. Constr. Build. Mater. 2021, 303, 124404. [Google Scholar] [CrossRef]

- ECP-203 Egyptian Code for Design and Construction of Reinforced Concrete Structures; National Housing and Building Research Center: Cairo, Egypt, 2018.

- Mahmood, E.M.; Allawi, A.A.; El-Zohairy, A. Analysis and Residual Behavior of Encased Pultruded GFRP I-Beam under Fire Loading. Sustainability 2022, 14, 13337. [Google Scholar] [CrossRef]

| Beam ID | CFRP Width (mm) | CFRP Overlap Length (mm) | ECC Layer | Remarks |

|---|---|---|---|---|

| B1 | --- | --- | --- | Control beam |

| B2 | 100 | --- | --- | 1 CFRP strip without ECC layer |

| B3 | 100 | --- | √ | 1 CFRP strip + ECC layer |

| B4 | 100 | 100 | √ | 100 mm overlapped CFRP strips + ECC layer |

| B5 | 100 | 200 | √ | 200 mm overlapped CFRP strips + ECC layer |

| B6 | 100 | 300 | √ | 300 mm overlapped CFRP strips + ECC layer |

| B7 | 100 | 200 tip-to-tip | √ | 2 CFRP layers connected tip-to-tip + ECC layer |

| B8 | 50 | --- | --- | 1 CFRP strip without ECC layer |

| B9 | 50 | --- | √ | 1 CFRP strip + ECC layer |

| B10 | 50 | 100 | √ | 100 mm overlapped CFRP strips + ECC layer |

| B11 | 50 | 100 | √ | 100 mm overlapped CFRP strips (at the third of beam span) + ECC layer |

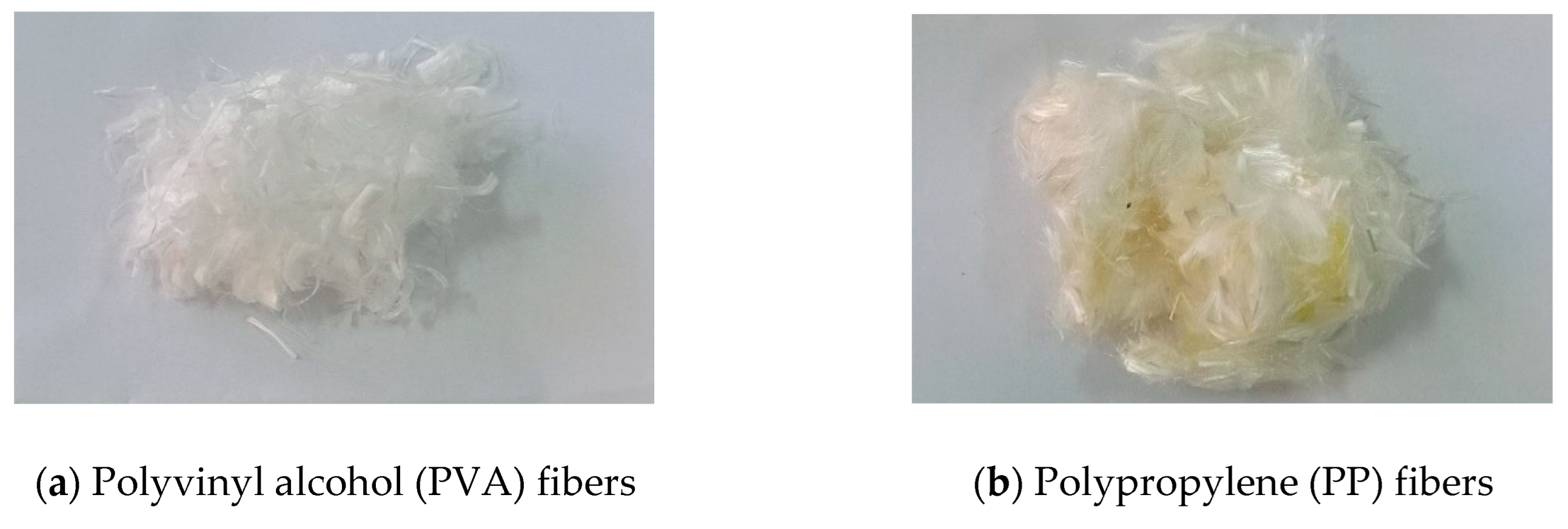

| Concrete | Cement | Fine Aggregate | Coarse Aggregate | Fly Ash | Water/Binder | PP * | PVA * | HRWR * | fc |

|---|---|---|---|---|---|---|---|---|---|

| (kg/m3) | (kg/m3) | (kg/m3) | (kg/m3) | (kg/m3) | (kg/m3) | (kg/m3) | (MPa) | ||

| NC | 350 | 700 | 1150 | --- | 0.43 | --- | --- | --- | 28 |

| ECC | 600 | 480 ** | --- | 720 | 0.25 | 19.8 | 26 | 12.5 | 49 |

| Diameter | Length | Specific Gravity | Elastic Modulus | Tensile Strength | Elongation at Breakage | |

|---|---|---|---|---|---|---|

| (μm) | (mm) | (g/cm3) | (GPa) | (MPa) | (%) | |

| PVA | 20 | 15 | 1.3 | 37 | 1300 | 7 |

| PP | 18 | 18 | 0.91 | 5.4 | 550 | 30 |

| Beam | Cracking | Yield | Ultimate | Failure Mode | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Pcr | Pcr(Bi) | ∆cr | Py | Py(Bi) | ∆y | Pu | Pu(Bi) | ∆u | K | ||

| (kN) | Pcr(B1) | (mm) | (kN) | Py(B1) | (mm) | (kN) | Pu(B1) | (mm) | (kN/mm) | ||

| B1 | 21.09 | 1.00 | 0.81 | 64.29 | 1.00 | 5.29 | 78.14 | 1.00 | 11.05 | 26.03 | F + CC |

| B2 | 26.34 | 1.19 | 0.57 | 126.80 | 1.97 | 4.96 | 151.97 | 1.94 | 6.71 | 46.21 | S + ED |

| B3 | 36.87 | 1.63 | 0.42 | 136.67 | 2.13 | 4.97 | 176.09 | 2.25 | 6.72 | 87.78 | S + EP |

| B4 | 35.19 | 1.59 | 0.39 | 169.50 | 2.64 | 5.59 | 191.41 | 2.45 | 6.51 | 90.23 | S |

| B5 | 36.08 | 1.63 | 0.26 | 172.67 | 2.67 | 4.59 | 217.05 | 2.78 | 6.30 | 138.76 | S |

| B6 | 36.25 | 1.64 | 0.18 | 181.48 | 2.82 | 4.14 | 212.29 | 2.72 | 5.62 | 201.38 | F + ICD |

| B7 | 36.58 | 1.66 | 0.38 | 194.33 | 3.02 | 6.08 | 201.18 | 2.57 | 7.22 | 96.26 | S + EP |

| B8 | 24.56 | 1.11 | 0.55 | 105.72 | 1.64 | 4.65 | 136.90 | 1.75 | 7.22 | 44.65 | S + CCS |

| B9 | 36.04 | 1.67 | 0.45 | 138.51 | 2.15 | 5.23 | 157.73 | 2.02 | 7.36 | 80.09 | S + CCS |

| B10 | 36.32 | 1.64 | 0.42 | 158.62 | 2.47 | 4.97 | 180.61 | 2.31 | 6.17 | 86.47 | S + F |

| B11 | 36.33 | 1.64 | 0.51 | 156.21 | 2.43 | 6.89 | 162.87 | 2.08 | 7.86 | 71.23 | S + F |

| Beam ID | ECC Layer Thickness (mm) | Steel Rebar Diameter (mm) | Number of Steel Rebars |

|---|---|---|---|

| T30D0 | 30 | ---- | ---- |

| T30D8 | 30 | 8 | 2 |

| T30D10 | 30 | 10 | 2 |

| T30D12 | 30 | 12 | 2 |

| T40D8 | 40 | 8 | 2 |

| T40D10 | 40 | 10 | 2 |

| T40D12 | 40 | 12 | 2 |

| T50D8 | 50 | 8 | 2 |

| T50D10 | 50 | 10 | 2 |

| T50D12 | 50 | 12 | 2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Emara, M.; El-Zohairy, A.; Fekry, M.; Husain, M. Effect of Using ECC Layer on the Flexural Performance of RC Beams Previously Strengthened with EB CFRP Laminates. Sustainability 2022, 14, 16990. https://doi.org/10.3390/su142416990

Emara M, El-Zohairy A, Fekry M, Husain M. Effect of Using ECC Layer on the Flexural Performance of RC Beams Previously Strengthened with EB CFRP Laminates. Sustainability. 2022; 14(24):16990. https://doi.org/10.3390/su142416990

Chicago/Turabian StyleEmara, Mohamed, Ayman El-Zohairy, Mahmoud Fekry, and Mohamed Husain. 2022. "Effect of Using ECC Layer on the Flexural Performance of RC Beams Previously Strengthened with EB CFRP Laminates" Sustainability 14, no. 24: 16990. https://doi.org/10.3390/su142416990