Network Analysis of Industrial Symbiosis in Chemical Industrial Parks: A Case Study of Nanjing Jiangbei New Materials High-Tech Park

Abstract

:1. Introduction

1.1. Background

1.2. Literature Review

1.3. Aims and Questions

2. Materials and Methods

2.1. Study Area

2.2. Methods

2.2.1. Characteristics Analysis

2.2.2. Power Quantification Analysis

2.2.3. Structure Analysis

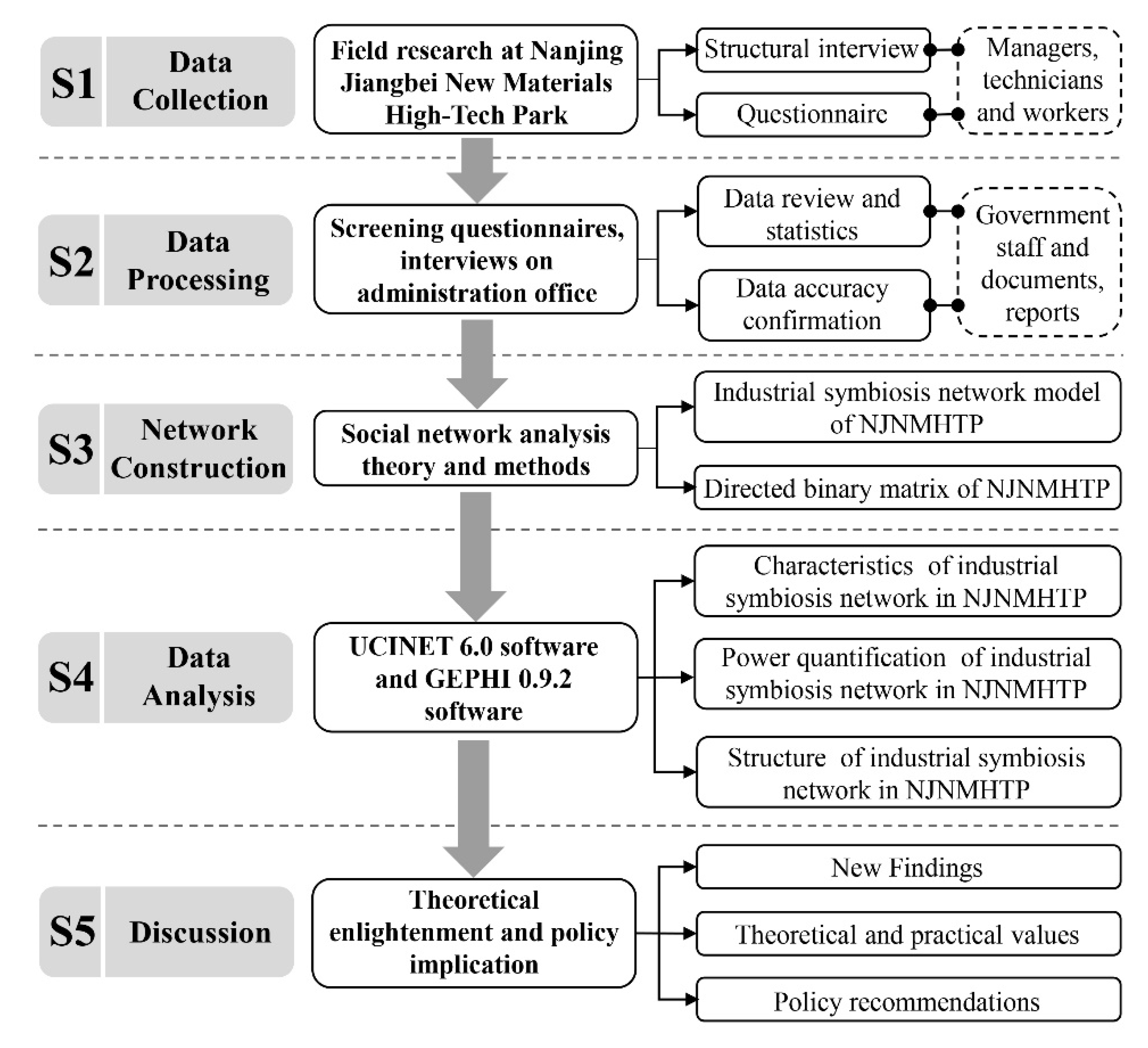

2.3. Research Steps and Data Resources

3. Results

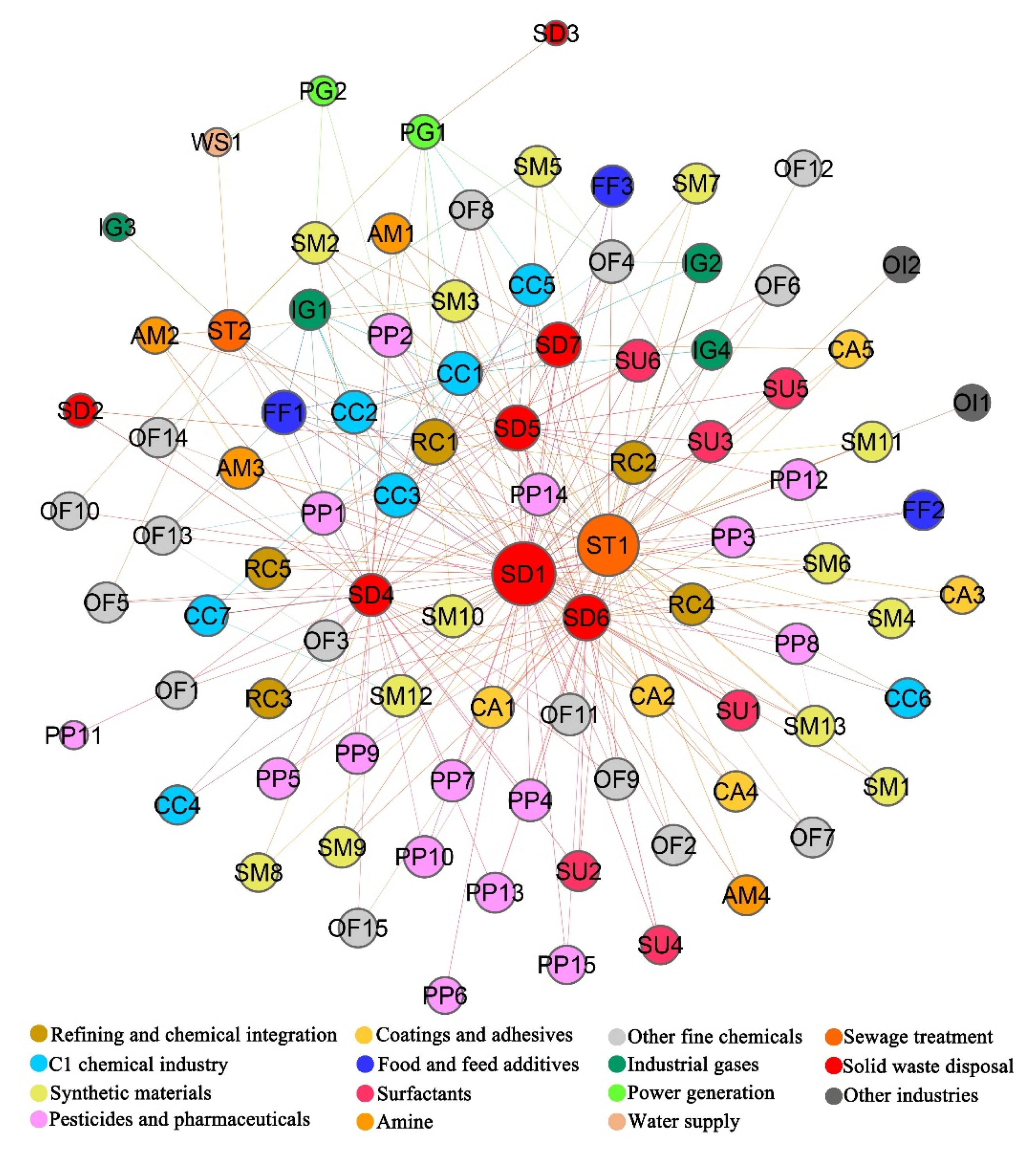

3.1. Characteristics of the Industrial Symbiosis Network in NJNMHTP

3.2. Power Quantification of Industrial Symbiosis Network in NJNMHTP

3.2.1. Degree

3.2.2. Centrality

3.3. Structure of the Industrial Symbiosis Network in NJNMHTP

3.3.1. Core-Periphery Structure

3.3.2. Block Model

4. Discussion

4.1. Structural Characteristics of the Industrial Symbiosis Network

4.2. Scale and Agglomeration Characteristics of the Industrial Symbiosis Network

4.3. Enterprise Connection Characteristics of the Industrial Symbiosis Network

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

Appendix B

| No. | Category | Enterprises and Nodes |

|---|---|---|

| 1 | Refining and chemical integration | BASF-YPC Co., Ltd. (RC1), Nanjing Yuangang Fine Chemicals Co., Ltd. (RC2), Nanjing Yangzi Eastman Chemical Ltd. (RC3), Nanjing Qidong Chemical Co., Ltd. (RC4), Jiangsu Lianxing New Material Co., Ltd. (RC5) |

| 2 | C1 chemical industry | Nanjing Chengzhi Clean Energy Co., Ltd. (CC1), Nanjing Chengzhi Yongqing Energy Science and Technology Co., Ltd. (CC2), Celanese (Nanjing) Chemical Co., Ltd. (CC3), BP YPC Acetyls Company (Nanjing) Limited (CC4), Wacker Chemicals (Nanjing) Co., Ltd. (CC5), Nanjing Nalcohol New Material Co., Ltd. (CC6), Nanjing Rongxin Chemical Co., Ltd. (CC7) |

| 3 | Synthetic materials | Nanjing Jinling Plastic and Petrochemical Co., Ltd. (SM1), Nanjing Jinling Huntsman New Material Co., Ltd. (SM2), Nanjing Hongbaoli Polyurethane Co., Ltd. (SM3), Nanjing Stepan Jinling Chemical Co., Ltd. (SM4), KPX Chemical (Nanjing) Co., Ltd. (SM5), Nanjing Jinqi Chemical Group Co., Ltd. (SM6), GPRO Group Jiangsu Zhongshan Chemical Co., Ltd. (SM7), Nanjing Hicol Polymer Material Co., Ltd. (SM8), H.b. Fuller (Nanjing) Chemical Co., Ltd. (SM9), INSA GPRO (Nanjing) Synthetic Rubber Co., Ltd. (SM10), Jinling Aliancys Resins Co., Ltd. (SM11), SI Group (Nanjing) Co., Ltd. (SM12), Dynea (Nanjing) Co., Ltd. (SM13) |

| 4 | Pesticides and pharmaceuticals | Jiangsu Flag Chemical Industry Co., Ltd. (PP1), Nanjing Red Sun Biochemistry Co., Ltd. (PP2), Jiangsu Chengyang Crop Science Co., Ltd. (PP3), Vision Fluorochem(Nanjing) Ltd. (PP4), Jiangsu Pesticide Research Institute Co., Ltd. (PP5), Trust Crop Protection Technology Co., Ltd. (PP6), Nanjing Teva-Chem. Co., Ltd. (PP7), Nanjing Goodagro Co., Ltd. (PP8), Nanjing NAU Pesticide Technology Co., Ltd. (PP9), Jiangsu State Farms Biochemistry Co., Ltd. (PP10), Nanjing White Whale Pharmaceutical Co., Ltd. (PP11), Nanjing Well Pharmaceutical Co., Ltd. (PP12), Nanjing Huicheng Pharmaceutical Co., Ltd. (PP13), Nanjing Hairun Pharmaceutical Co., Ltd. (PP14), Nanjing Pharmaceutical Factory Co., Ltd. (PP15) |

| 5 | Coatings and adhesives | Nanjing Changjiang Paint Co., Ltd. (CA1), NBC (Nanjing) Co., Ltd. (CA2), Nanjing Titanium Dioxide Chemical Co., Ltd. (CA3), Soken High-Tech Material (Nanjing) Co., Ltd. (CA4), Nanjing Night Sight Li Fine Chemical Co., Ltd. (CA5) |

| 6 | Food and feed additives | Bluestar Adisseo Nanjing Co., Ltd. (FF1), Golden Time Chemical (Jiangsu) Co., Ltd. (FF2), Jiangsu Maida New Materials Co., Ltd. (FF3) |

| 7 | Surfactants | Nanjing Yangzi Oxiranchem Co., Ltd. (SU1), Nanjing Regal Polymer Co., Ltd. (SU2), Nanjing Bote New Materials Co., Ltd. (SU3), Nanjing Huashi New Material Co., Ltd. (SU4), Nanjing Maysta New Materials Co., Ltd. (SU5), Jiangsu Jintung Surfactant Co., Ltd. (SU6) |

| 8 | Amine | Basf Speciality Chemicals (Nanjing) Ltd. (AM1), Eastman Chemical (Nanjing) Co., Ltd. (AM2), Evonik Specialty Chemicals (Nanjing) Co., Ltd. (AM3), Nanjing HBL Alkyol Amines Co., Ltd. (AM4) |

| 9 | Other fine chemicals | Nanjing Shuguang Fine Chemical Co., Ltd. (OF1), Nanjing Jinling Chemical Plant Co., Ltd. (OF2), Nalco Industrial Services (Nanjing) Co., Ltd. (OF3), Jiangsu Dynamic Chemical Co., Ltd. (OF4), Ashland Chemicals(Nanjing) Co., Ltd. (OF5), Kemira Chemicals (Nanjing) Co., Ltd. (OF6), Smit (Nanjing) Leather Chemicals Co., Ltd. (OF7), OQ Advanced Derivatives Nanjing Ltd. (OF8), Sino-High(China) Co., Ltd. (OF9), Sinopec Catalyst Nanjing Company (OF10), GPRO New Materials Co., Ltd. (OF11), Superchem Nanjing Limited. (OF12), Heraeus Precious Metal Technology (China) Co., Ltd. (OF13), DyStar Nanjing Colours Co., Ltd. (OF14), Nanjing TOP Chemical Technology Co., Ltd. (OF15) |

| 10 | Industrial gases | Air Products and Chemicals (Nanjing) Co., Ltd. (IG1), Linde Nanjing Gases Chemical Industrial Park Co., Ltd. (IG2), Nanjing Prax Nanlian Industrial Gas Co., Ltd. (IG3), Messer Gas Products (Nanjing) Co., Ltd. (IG4) |

| 11 | Power generation | Nanjing Chemical Industry Park Thermoelectricity Co., Ltd. (PG1), Huaneng Nanjing Thermal Power Co., Ltd. (PG2) |

| 12 | Water supply | Sembcorp NCIP Water Co. (WS1) |

| 13 | Sewage treatment | Sembcorp Nanjing SUIWU Co. (ST1), Puritek Company Ltd. (ST2) |

| 14 | Solid waste disposal | Nanjing Chemical Industrial Park Tianyu Solid Waste Disposal Co., Ltd. (SD1), Nanjing Huihe Environmental Engineering Technology Co., Ltd. (SD2), Nanjing CEC Environmental Protection Bioenergy Co., Ltd. (SD3), Nanjing Veolia Tongjun Environmental Service Co., Ltd. (SD4), Nanjing ENN Environmental Protection Technology Co., Ltd. (SD5), Nanjing Fuchang Environmental Co., Ltd. (SD6), Nanjing Changjiang Jiangyu Environmental Technology Co., Ltd. (SD7) |

| 15 | Other industries | Nanjing Fanshun Packaging Co., Ltd. (OI1), Jiangsu Sunpower Heat Exchanger and Pressure Vessel Co., Ltd. (OI2) |

References

- Intergovernmental Panel on Climate Change. Global Warming of 1.5 °C. An IPCC Special Report on the Impacts of Global Warming of 1.5 °C above Pre-Industrial Levels and Related Global Greenhouse Gas Emission Pathways, in the Context of Strengthening the Global Response to the Threat of Climate Change, Sustainable Development, and Efforts to Eradicate Poverty. Available online: https://www.ipcc.ch/site/assets/uploads/sites/2/2019/06/SR15_Full_Report_High_Res.pdf (accessed on 25 September 2021).

- Liu, Z.; Adams, M.; Cote, R.P.; Chen, Q.; Wu, R.; Wen, Z.; Liu, W.; Dong, L. How does circular economy respond to greenhouse gas emissions reduction: An analysis of Chinese plastic recycling industries? Renew. Sust. Energ. Rev. 2018, 91, 1162–1169. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, Y. Circular economy is game-changing municipal wastewater treatment technology towards energy and carbon neutrality. Chem. Eng. J. 2022, 429, 132114. [Google Scholar] [CrossRef]

- Chertow, M.R. Industrial symbiosis: Literature and taxonomy. Annu. Rev. Energy Environ. 2000, 25, 313–337. [Google Scholar] [CrossRef] [Green Version]

- Chertow, M.R. “Uncovering” industrial symbiosis. J. Ind. Ecol. 2007, 11, 11–30. [Google Scholar] [CrossRef]

- Levi, P.G.; Cullen, J.M. Mapping global flows of chemicals: From fossil fuel feedstocks to chemical products. Environ. Sci. Technol. 2018, 52, 1725–1734. [Google Scholar] [CrossRef]

- Zhu, B.; Zhou, W.; Hu, S.; Li, Q.; Griffy-Brown, C.; Jin, Y. CO2 emissions and reduction potential in China’s chemical industry. Energy 2010, 35, 4663–4670. [Google Scholar] [CrossRef]

- Chen, C.; Reniers, G. Chemical industry in China: The current status, safety problems, and pathways for future sustainable development. Saf. Sci. 2020, 128, 104741. [Google Scholar] [CrossRef]

- China Petroleum and Chemical Industry Federation. China Chemical Industry Yearbook 2017/18; China National Chemical Information Center: Beijing, China, 2019; pp. 12–20. [Google Scholar]

- National Bureau of Statistics of China. China Energy Statistical Yearbook 2018; China Statistics Press: Beijing, China, 2019; pp. 58–93.

- Ministry of Ecology and Environment; National Bureau of Statistics of China. China Statistical Yearbook on Environment 2019; China Statistics Press: Beijing, China, 2020; pp. 9–96.

- Zhang, Y.; Song, Y.; Zou, H. Transformation of pollution control and green development: Evidence from China’s chemical industry. J. Environ. Manag. 2020, 275, 111246. [Google Scholar] [CrossRef]

- He, G.; Chen, C.; Zhang, L.; Lu, Y. Public perception and attitude towards chemical industry park in Dalian, Bohai Rim. Environ. Pollut. 2018, 235, 825–835. [Google Scholar] [CrossRef]

- Fan, Y.; Qiao, Q.; Fang, L.; Yao, Y. Emergy analysis on industrial symbiosis of an industrial park—A case study of Hefei economic and technological development area. J. Clean Prod. 2017, 141, 791–798. [Google Scholar] [CrossRef]

- Park, J.Y.; Park, H.S. Securing a competitive advantage through industrial symbiosis development. J. Ind. Ecol. 2014, 18, 677–683. [Google Scholar] [CrossRef]

- Geng, Y.; Liu, Z.; Xue, B.; Dong, H.; Fujita, T.; Chiu, A. Emergy-based assessment on industrial symbiosis: A case of Shenyang economic and technological development zone. Environ. Sci. Pollut. Res. 2014, 21, 13572–13587. [Google Scholar] [CrossRef]

- Zhe, L.; Yong, G.; Hung-Suck, P.; Huijuan, D.; Liang, D.; Tsuyoshi, F. An emergy-based hybrid method for assessing industrial symbiosis of an industrial park. J. Clean Prod. 2016, 114, 132–140. [Google Scholar] [CrossRef]

- Guo, B.; Geng, Y.; Sterr, T.; Dong, L.; Liu, Y. Evaluation of promoting industrial symbiosis in a chemical industrial park: A case of Midong. J. Clean Prod. 2016, 135, 995–1008. [Google Scholar] [CrossRef]

- Zhang, Y.; Duan, S.; Li, J.; Shao, S.; Wang, W.; Zhang, S. Life cycle assessment of industrial symbiosis in Songmudao chemical industrial park, Dalian, China. J. Clean Prod. 2017, 158, 192–199. [Google Scholar] [CrossRef]

- Wang, S.; Lu, C.; Gao, Y.; Wang, K.; Zhang, R. Life cycle assessment of reduction of environmental impacts via industrial symbiosis in an energy-intensive industrial park in China. J. Clean Prod. 2019, 241, 118358. [Google Scholar] [CrossRef]

- Taddeo, R.; Simboli, A.; Morgante, A. Implementing eco-industrial parks in existing clusters. Findings from a historical Italian chemical site. J. Clean Prod. 2012, 33, 22–29. [Google Scholar] [CrossRef]

- Puente, M.R.; Arozamena, E.R.; Evans, S. Industrial symbiosis opportunities for small and medium sized enterprises: Preliminary study in the Besaya region (Cantabria, Northern Spain). J. Clean Prod. 2015, 87, 357–374. [Google Scholar] [CrossRef]

- ElMassah, S. Industrial symbiosis within eco-industrial parks: Sustainable development for Borg El-Arab in Egypt. Bus. Strategy Environ. 2018, 27, 884–892. [Google Scholar] [CrossRef]

- Liu, C.; Côté, R.P.; Zhang, K. Implementing a three-level approach in industrial symbiosis. J. Clean Prod. 2015, 87, 318–327. [Google Scholar] [CrossRef]

- Cervo, H.; Ogé, S.; Maqbool, A.S.; Mendez Alva, F.; Lessard, L.; Bredimas, A.; Ferrasse, J.H.; Van Eetvelde, G. A case study of industrial symbiosis in the Humber region using the EPOS methodology. Sustainability 2019, 11, 6940. [Google Scholar] [CrossRef] [Green Version]

- Gang, W.; Xiao, F.; Hoong, C.K. Symbiosis analysis on industrial ecological system. Chin. J. Chem. Eng. 2014, 22, 690–698. [Google Scholar]

- Cui, H.; Liu, C.; Côté, R.; Liu, W. Understanding the evolution of industrial symbiosis with a system dynamics model: A case study of Hai Hua industrial symbiosis, China. Sustainability 2018, 10, 3873. [Google Scholar] [CrossRef] [Green Version]

- Ren, J.; Liang, H.; Dong, L.; Sun, L.; Gao, Z. Design for sustainability of industrial symbiosis based on emergy and multi objective particle swarm optimization. Sci. Total Environ. 2016, 562, 789–801. [Google Scholar] [CrossRef]

- Yu, F.; Han, F.; Cui, Z. Evolution of industrial symbiosis in an eco-industrial park in China. J. Clean Prod. 2015, 87, 339–347. [Google Scholar] [CrossRef]

- Ji, Y.; Liu, Z.; Wu, J.; He, Y.; Xu, H. Which factors promote or inhibit enterprises’ participation in industrial symbiosis? An analytical approach and a case study in China. J. Clean Prod. 2020, 244, 118600. [Google Scholar] [CrossRef]

- Chopra, S.S.; Khanna, V. Understanding resilience in industrial symbiosis networks: Insights from network analysis. J. Environ. Manag. 2014, 141, 86–94. [Google Scholar] [CrossRef]

- Zhang, Y.; Zheng, H.; Fath, B.D. Ecological network analysis of an industrial symbiosis system: A case study of the Shandong Lubei eco-industrial park. Ecol. Model. 2015, 306, 174–184. [Google Scholar] [CrossRef]

- Li, Y.; Shi, L. The resilience of interdependent industrial symbiosis networks: A case of Yixing economic and technological development zone. J. Ind. Ecol. 2015, 19, 264–273. [Google Scholar] [CrossRef]

- Zhang, X.; Chai, L. Structural features and evolutionary mechanisms of industrial symbiosis networks: Comparable analyses of two different cases. J. Clean Prod. 2019, 213, 528–539. [Google Scholar] [CrossRef]

- Festel, G.; Geng, Y. Chemical industry parks in China. In The Chemical and Pharmaceutical Industry in China: Opportunities and Threats for Foreign Companies; Springer: Berlin, Germany, 2005; pp. 53–62. [Google Scholar]

- Hu, X.; Zhang, N.; Liu, Y. In vitro ingestion and inhalation bioaccessibility of soilborne lead, cadmium, arsenic and chromium near a chemical industrial park for health risk assessment. Environ. Pollut. Bioavailab. 2019, 31, 316–322. [Google Scholar] [CrossRef] [Green Version]

- People’s Daily Online. Nanjing Jiangbei New Materials High-Tech Park Ranked Second in the List of China’s Top 30 Chemical Industrial Parks in 2021. Available online: http://js.people.com.cn/n2/2021/0604/c360301-34761655.html (accessed on 13 July 2021).

- China Association of Circular Economy. Nanjing Chemical Industrial Park Passed the Acceptance Inspection of China’s National Standardized Experimental Project for a Circular Economy. Available online: https://www.chinacace.org/news/view?id=2952 (accessed on 13 July 2021).

- Scott, J. Social network analysis. Sociology 1988, 22, 109–127. [Google Scholar] [CrossRef]

- Freeman, L. The Development of Social Network Analysis: A Study in the Sociology of Science; Empirical Press: Vancouver, BC, Canada, 2004; pp. 1–43. [Google Scholar]

- Butts, C.T. Social network analysis: A methodological introduction. Asian J. Soc. Psychol. 2008, 11, 13–41. [Google Scholar] [CrossRef] [Green Version]

- Newman, M.E. The structure and function of complex networks. SIAM Rev. 2003, 45, 167–256. [Google Scholar] [CrossRef] [Green Version]

- Otte, E.; Rousseau, R. Social network analysis: A powerful strategy, also for the information sciences. J. Inf. Sci. 2002, 28, 441–453. [Google Scholar] [CrossRef]

- Genc, O.; van Capelleveen, G.; Erdis, E.; Yildiz, O.; Yazan, D.M. A socio-ecological approach to improve industrial zones towards eco-industrial parks. J. Environ. Manag. 2019, 250, 109507. [Google Scholar] [CrossRef] [Green Version]

- Borgatti, S.P.; Everett, M.G. Models of core/periphery structures. Soc. Netw. 2000, 21, 375–395. [Google Scholar] [CrossRef]

- Rombach, M.P.; Porter, M.A.; Fowler, J.H.; Mucha, P.J. Core-periphery structure in networks. SIAM J. Appl. Math. 2014, 74, 167–190. [Google Scholar] [CrossRef] [Green Version]

- Li, X.; Xiao, R. Analyzing network topological characteristics of eco-industrial parks from the perspective of resilience: A case study. Ecol. Indic. 2017, 74, 403–413. [Google Scholar] [CrossRef]

- Song, X.; Geng, Y.; Dong, H.; Chen, W. Social network analysis on industrial symbiosis: A case of Gujiao eco-industrial park. J. Clean Prod. 2018, 193, 414–423. [Google Scholar] [CrossRef]

- Domenech, T.; Davies, M. Structure and morphology of industrial symbiosis networks: The case of Kalundborg. Procedia Soc. Behav. Sci. 2011, 10, 79–89. [Google Scholar] [CrossRef] [Green Version]

- Doménech, T.; Davies, M. The role of embeddedness in industrial symbiosis networks: Phases in the evolution of industrial symbiosis networks. Bus. Strategy Environ. 2011, 20, 281–296. [Google Scholar] [CrossRef]

- Zhang, Y.; Zheng, H.; Chen, B.; Yang, N. Social network analysis and network connectedness analysis for industrial symbiotic systems: Model development and case study. Front. Earth Sci. 2013, 7, 169–181. [Google Scholar] [CrossRef]

- Zhu, J.; Ruth, M. Exploring the resilience of industrial ecosystems. J. Environ. Manag. 2013, 122, 65–75. [Google Scholar] [CrossRef] [PubMed]

- Li, B.; Xiang, P.; Hu, M.; Zhang, C.; Dong, L. The vulnerability of industrial symbiosis: A case study of Qijiang Industrial Park, China. J. Clean Prod. 2017, 157, 267–277. [Google Scholar] [CrossRef]

| No. | Nodes | DNin | DNout | DN | DCN | BCN | CCN | No. | Nodes | DNin | DNout | DN | DCN | BCN | CCN |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | RC1 | 2 | 16 | 18 | 20 | 3.531 | 53.571 | 47 | FF2 | 0 | 2 | 2 | 2.222 | 0 | 47.368 |

| 2 | RC2 | 1 | 5 | 6 | 6.667 | 0.200 | 50.562 | 48 | FF3 | 1 | 2 | 3 | 3.333 | 0.012 | 49.180 |

| 3 | RC3 | 1 | 2 | 3 | 3.333 | 0.008 | 47.368 | 49 | SU1 | 0 | 3 | 3 | 3.333 | 0.017 | 47.872 |

| 4 | RC4 | 1 | 3 | 4 | 4.444 | 0.029 | 49.451 | 50 | SU2 | 0 | 3 | 3 | 3.333 | 0.062 | 47.368 |

| 5 | RC5 | 1 | 2 | 3 | 3.333 | 0.012 | 49.180 | 51 | SU3 | 1 | 4 | 5 | 5.556 | 0.032 | 49.180 |

| 6 | CC1 | 3 | 12 | 15 | 15.556 | 1.527 | 51.429 | 52 | SU4 | 0 | 2 | 2 | 2.222 | 0.008 | 45.685 |

| 7 | CC2 | 2 | 6 | 8 | 7.778 | 0.359 | 50.562 | 53 | SU5 | 0 | 3 | 3 | 3.333 | 0.009 | 48.128 |

| 8 | CC3 | 2 | 9 | 11 | 11.111 | 0.817 | 52.326 | 54 | SU6 | 1 | 3 | 4 | 4.444 | 0.021 | 49.724 |

| 9 | CC4 | 0 | 2 | 2 | 2.222 | 0.028 | 46.392 | 55 | AM1 | 1 | 3 | 4 | 4.444 | 0.055 | 47.368 |

| 10 | CC5 | 1 | 4 | 5 | 5.556 | 0.594 | 49.724 | 56 | AM2 | 0 | 4 | 4 | 4.444 | 0.204 | 43.269 |

| 11 | CC6 | 0 | 2 | 2 | 2.222 | 0 | 47.368 | 57 | AM3 | 2 | 3 | 5 | 5.556 | 0.494 | 49.724 |

| 12 | CC7 | 0 | 4 | 4 | 4.444 | 0.066 | 48.387 | 58 | AM4 | 0 | 2 | 2 | 2.222 | 0 | 47.368 |

| 13 | SM1 | 0 | 2 | 2 | 2.222 | 0.009 | 44.776 | 59 | OF1 | 0 | 2 | 2 | 2.222 | 0 | 44.335 |

| 14 | SM2 | 1 | 6 | 7 | 6.667 | 0.979 | 49.451 | 60 | OF2 | 0 | 3 | 3 | 3.333 | 0.017 | 47.872 |

| 15 | SM3 | 1 | 4 | 5 | 5.556 | 0.263 | 49.724 | 61 | OF3 | 0 | 5 | 5 | 5.556 | 0.223 | 48.387 |

| 16 | SM4 | 0 | 2 | 2 | 2.222 | 0 | 47.368 | 62 | OF4 | 2 | 7 | 9 | 10 | 0.850 | 50.562 |

| 17 | SM5 | 2 | 2 | 4 | 4.444 | 0.030 | 48.387 | 63 | OF5 | 0 | 3 | 3 | 3.333 | 0.089 | 47.619 |

| 18 | SM6 | 0 | 4 | 4 | 4.444 | 0.029 | 48.128 | 64 | OF6 | 0 | 3 | 3 | 3.333 | 0.009 | 48.128 |

| 19 | SM7 | 0 | 3 | 3 | 3.333 | 0 | 47.619 | 65 | OF7 | 0 | 2 | 2 | 2.222 | 0 | 47.368 |

| 20 | SM8 | 0 | 2 | 2 | 2.222 | 0.032 | 45.685 | 66 | OF8 | 0 | 3 | 3 | 3.333 | 0.054 | 46.632 |

| 21 | SM9 | 0 | 3 | 3 | 3.333 | 0.056 | 48.128 | 67 | OF9 | 0 | 4 | 4 | 4.444 | 0.097 | 49.451 |

| 22 | SM10 | 1 | 3 | 4 | 4.444 | 0.072 | 50 | 68 | OF10 | 0 | 2 | 2 | 2.222 | 0 | 44.335 |

| 23 | SM11 | 1 | 2 | 3 | 3.333 | 0 | 48.128 | 69 | OF11 | 0 | 4 | 4 | 4.444 | 0.097 | 49.451 |

| 24 | SM12 | 1 | 4 | 5 | 5.556 | 0.170 | 49.724 | 70 | OF12 | 0 | 1 | 1 | 1.111 | 0 | 42.254 |

| 25 | SM13 | 1 | 3 | 4 | 4.444 | 0.017 | 48.128 | 71 | OF13 | 4 | 1 | 5 | 5.556 | 0.076 | 45.455 |

| 26 | PP1 | 3 | 5 | 8 | 8.889 | 0.522 | 50.847 | 72 | OF14 | 0 | 3 | 3 | 3.333 | 0.072 | 47.120 |

| 27 | PP2 | 2 | 4 | 6 | 6.667 | 2.142 | 51.429 | 73 | OF15 | 0 | 2 | 2 | 2.222 | 0.032 | 45.685 |

| 28 | PP3 | 0 | 4 | 4 | 4.444 | 0.025 | 48.387 | 74 | IG1 | 4 | 8 | 12 | 10 | 0.381 | 47.872 |

| 29 | PP4 | 0 | 4 | 4 | 4.444 | 0.097 | 49.451 | 75 | IG2 | 1 | 3 | 4 | 4.444 | 0.015 | 45.918 |

| 30 | PP5 | 0 | 3 | 3 | 3.333 | 0.060 | 48.913 | 76 | IG3 | 0 | 1 | 1 | 1.111 | 0 | 33.088 |

| 31 | PP6 | 0 | 1 | 1 | 1.111 | 0 | 43.062 | 77 | IG4 | 1 | 2 | 3 | 3.333 | 0.020 | 46.632 |

| 32 | PP7 | 0 | 4 | 4 | 4.444 | 0.097 | 49.451 | 78 | PG1 | 1 | 6 | 7 | 7.778 | 2.511 | 40.541 |

| 33 | PP8 | 0 | 4 | 4 | 4.444 | 0.017 | 48.128 | 79 | PG2 | 2 | 2 | 4 | 3.333 | 0.148 | 35.156 |

| 34 | PP9 | 0 | 4 | 4 | 4.444 | 0.095 | 48.387 | 80 | WS1 | 0 | 2 | 2 | 2.222 | 0.057 | 33.457 |

| 35 | PP10 | 0 | 3 | 3 | 3.333 | 0.060 | 48.913 | 81 | ST1 | 60 | 1 | 61 | 67.778 | 32.084 | 72.581 |

| 36 | PP11 | 0 | 1 | 1 | 1.111 | 0 | 33.457 | 82 | ST2 | 13 | 1 | 14 | 14.444 | 5.407 | 49.180 |

| 37 | PP12 | 1 | 3 | 4 | 4.444 | 0.021 | 48.387 | 83 | SD1 | 62 | 1 | 63 | 68.889 | 35.121 | 75 |

| 38 | PP13 | 0 | 3 | 3 | 3.333 | 0.062 | 47.368 | 84 | SD2 | 1 | 1 | 2 | 2.222 | 0 | 39.823 |

| 39 | PP14 | 0 | 5 | 5 | 5.556 | 0.093 | 49.724 | 85 | SD3 | 1 | 0 | 1 | 1.111 | 0 | 28.939 |

| 40 | PP15 | 0 | 2 | 2 | 2.222 | 0.008 | 45.685 | 86 | SD4 | 36 | 0 | 36 | 40 | 10.875 | 50 |

| 41 | CA1 | 0 | 4 | 4 | 4.444 | 0.097 | 49.451 | 87 | SD5 | 19 | 2 | 21 | 23.333 | 2.894 | 53.571 |

| 42 | CA2 | 0 | 4 | 4 | 4.444 | 0.097 | 49.451 | 88 | SD6 | 38 | 0 | 38 | 42.222 | 9.456 | 54.217 |

| 43 | CA3 | 0 | 2 | 2 | 2.222 | 0.009 | 44.776 | 89 | SD7 | 10 | 3 | 13 | 14.444 | 0.920 | 52.632 |

| 44 | CA4 | 0 | 3 | 3 | 3.333 | 0.017 | 47.872 | 90 | OI1 | 0 | 1 | 1 | 1.111 | 0 | 42.254 |

| 45 | CA5 | 0 | 3 | 3 | 3.333 | 0.013 | 45.226 | 91 | OI2 | 0 | 1 | 1 | 1.111 | 0 | 42.254 |

| 46 | FF1 | 3 | 5 | 8 | 8.889 | 0.605 | 51.724 |

| Category | Nodes |

|---|---|

| Core groups | RC1, SM2, CC1, CC2, CC3, OF4, FF1, PG1, PP1, OF13, AM3, IG1, SD6, SD7, ST1, SD4, SD1, SD5, ST2 |

| Peripheral groups | SM3, SM5, SU6, AM1, OI2, CA3, CC4, CC5, PP12, CC6, SM1, SM11, AM4, RC2, PP2, SU3, FF2, SM9, PG2, SM10, AM2, OF10, PP6, CA1, SM13, SM12, OF3, OF6, OF1, RC3, OF5, OF9, PP4, SM6, OF8, PP7, SU1, CC7, SM4, OF11, FF3, PP3, SU4, PP14, IG3, SU5, PP8, PP13, RC5, IG2, PP5, PP11, CA4, PP15, OF2, PP10, SU2, SD2, WS1, OF7, OI1, OF14, CA2, SM8, PP9, IG4, OF12, OF15, CA5, SM7, SD3, RC4 |

| Max Depth of Splits 2 | Max Depth of Splits 3 | Nodes |

|---|---|---|

| I | 1 | RC1, CC2, CC3, FF1, PP1, CC4, SM9, OF5, CC7, OF14 |

| 2 | AM1, CC5, PP2, SM10, CA1, SM12, OF3, OF9, PP4, OF8, PP7, OF11, PP14, PP13, PP5, PP11, PP10, SU2, CA2, SM8, PP9, OF15 | |

| II | 3 | CC1, SM3, CA3, SM1, SU3, SM13, RC3, SM6, SU1, PP3, SU4, PP8, IG2, CA4, PP15, OF2, SD5, IG4, CA5, RC4 |

| 4 | OF4, SM5, SU6, OI2, OF13, AM3, PP12, IG1, CC6, SM11, AM4, RC2, FF2, PP6, OF6, OF1, SM4, FF3, SU5, RC5, SD7, OF7, OI1, OF12, SM7 | |

| III | 5 | SM2, AM2, OF10, IG3, WS1 |

| 6 | PG1, SD2 | |

| IV | 7 | PG2, SD4, ST2, SD3 |

| 8 | SD6, ST1, SD1 |

| Subgroup | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

|---|---|---|---|---|---|---|---|---|

| 1 | 0.044 | 0.018 | 0.050 | 0.056 | 0.000 | 0.100 | 0.375 | 0.567 |

| 2 | 0.018 | 0.000 | 0.009 | 0.005 | 0.000 | 0.045 | 0.261 | 0.697 |

| 3 | 0.050 | 0.009 | 0.026 | 0.034 | 0.020 | 0.025 | 0.013 | 0.833 |

| 4 | 0.056 | 0.005 | 0.034 | 0.020 | 0.016 | 0.020 | 0.010 | 0.573 |

| 5 | 0.000 | 0.000 | 0.020 | 0.016 | 0.000 | 0.000 | 0.450 | 0.133 |

| 6 | 0.100 | 0.045 | 0.025 | 0.020 | 0.000 | 0.000 | 0.375 | 0.000 |

| 7 | 0.375 | 0.261 | 0.013 | 0.010 | 0.450 | 0.375 | 0.000 | 0.083 |

| 8 | 0.567 | 0.697 | 0.833 | 0.573 | 0.133 | 0.000 | 0.083 | 0.333 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, K.; Wang, X.; Yan, Y. Network Analysis of Industrial Symbiosis in Chemical Industrial Parks: A Case Study of Nanjing Jiangbei New Materials High-Tech Park. Sustainability 2022, 14, 1381. https://doi.org/10.3390/su14031381

Liu K, Wang X, Yan Y. Network Analysis of Industrial Symbiosis in Chemical Industrial Parks: A Case Study of Nanjing Jiangbei New Materials High-Tech Park. Sustainability. 2022; 14(3):1381. https://doi.org/10.3390/su14031381

Chicago/Turabian StyleLiu, Kai, Xingping Wang, and Yiran Yan. 2022. "Network Analysis of Industrial Symbiosis in Chemical Industrial Parks: A Case Study of Nanjing Jiangbei New Materials High-Tech Park" Sustainability 14, no. 3: 1381. https://doi.org/10.3390/su14031381

APA StyleLiu, K., Wang, X., & Yan, Y. (2022). Network Analysis of Industrial Symbiosis in Chemical Industrial Parks: A Case Study of Nanjing Jiangbei New Materials High-Tech Park. Sustainability, 14(3), 1381. https://doi.org/10.3390/su14031381