1. Introduction

The regeneration of abandoned industrial buildings (RAIBs), rather than their demolition or rebuilding, has received extensive attention in urban renewal efforts to achieve urban sustainable development goals [

1,

2,

3]. The sustainable development goals (SDGs) are seventeen global development goals proposed by the United Nations, which continue to guide global development efforts from 2015 to 2030 after the expiry of the millennium development goals (MDGs) from 2000 to 2015 [

4]. The eleventh goal is directly related to cities and urban sustainable development [

5]. The regeneration of abandoned industrial buildings is the refurbishment and reuse of abandoned industrial buildings to meet the needs of new functions on the premise that the original buildings are not completely dismantled [

6]. RAIBs not only extend the physical life of buildings, reduce the creation of demolition waste, preserve the historical and cultural context, but also contribute to significant social, economic, cultural, and environmental benefits to sustainable urbanization [

7,

8,

9,

10,

11]. However, the rapid growth of RAIB projects, resulting in the safety performance of refurbishment, is a major challenge. The refurbishment of the RAIB project needs to comply with the preservation laws of abandoned industrial buildings (AIBs) and current occupational health and safety (OHS) standards, and also involve partial structural demolition, structural renovation, facade retentions, modern plumbing, electrical, heating, ventilation and air conditioning (HVAC) and communications systems’ retrofit and building pollutants treatments [

12]. Compared with new buildings, the refurbishment of RAIB projects have more complexity, uncertainty and are potentially dangerous [

13]. Neglecting the refurbishment safety of RAIB projects can lead to accidents and injury. For example, On 19 March 2016, two workers fell from a height while removing the roof of a steel structure factory at a machinery factory in Liuzhou city, Guangxi Province, China, causing the death of one and injury of the other. In May 2019, a tractor factory under renovation collapsed during partial demolition located in No.148 Zhaohua Road, Changning District, Shanghai, China, causing 10 deaths, 15 injuries and direct economic losses of 34.3 million yuan. Accidents will lead to cost increases, schedule delays and other adverse effects [

14,

15]. Accordingly, in order to improve the safety performance of RAIB projects and realize sustainable urbanization, the safety problem of the RAIBs must be considered.

A safety program as a proactive approach is considered to be one of the most effective tools to reduce accidents and injury on construction projects [

16,

17]. A reasonable safety program can not only prevent personal injury, but also minimize the loss of machinery and equipment [

18]. In order to develop an effective safety program, factors affecting safety program implementation need to be identified. Especially with limited resources, identifying critical success factors (CSFs) is essential to improve safety performance. CSFs affecting the implementation of safety programs have been extensively studied in new buildings. Management support, personal safety awareness, communication, and the establishment of safety committees have been identified as CSFs for safety program implementation in new buildings [

19,

20,

21,

22]. However, no research has been done in the RAIB projects, which is increasingly vital not only in China, but also in other developing countries.

RAIB projects have different characteristics from new construction projects and general refurbishment projects. For example, The AIBs were built earlier and the data preservation technology was backward, so the complete basic design information could not be provided. Therefore, designers and construction personnel cannot obtain comprehensive structural information of AIBs. Moreover, the RAIB projects need to operate on the original building structure and space, resulting in a limited workspace. Besides, the transformation technology of RAIB projects is more complex under the background of the preservation of building features, green regeneration, and low carbon concept. More importantly, for the AIBs with pollution in the process of original function use, industrial buildings, equipment pipe networks, and the surrounding environment are polluted to varying degrees due to the erosion of various hazard sources such as acid, alkali, heavy metal, organic matter, and even microorganism. During the RAIBs construction, a large number of toxic and harmful industrial residues will enter the human body through breathing, skin, and even mouth with construction dust, threatening human health. Therefore, the previous related studies on new construction projects may not be applicable to RAIB projects. The CSFs for safety program implementation of RAIB projects require further investigation.

The main aim of this study is to determine the CSFs for safety program implementation of RAIB projects based on the fuzzy-DEMATEL method to ensure the effective implementation of the safety program, improve the safety performance of RAIB projects, and achieve sustainable RAIB projects. Firstly, combining background information of RAIBs with literature reviews and experts’ opinions, the factors affecting safety program implementation of RAIB projects are identified. Then fuzzy and decision-making trial and evaluation laboratory (DEMATEL) approach is used to examine the importance of the influencing factors and the causal relationship between them. Finally, according to the causal diagram of these influencing factors obtained from the study, the CSFs for safety program implementation of RAIB projects can be determined. This study fills the research gap of limited safety program research of RAIB projects. It would be useful for managers and stakeholders to prioritize CSFs for the safety program of RAIB projects and make an effective safety program for RAIB projects.

The remainder of the paper is structured as follows.

Section 2 introduces the background information of RAIBs in China;

Section 3 reviews the literature related to CSFs, occupational safety and health of RAIB projects, safety program implementation.

Section 4 describes the research method of triangular fuzzy number and DEMATEL in detail, as well as the data collection;

Section 5 reports the corresponding results; Discussion for this paper is shown in

Section 6;

Section 7 states the theoretical and managerial implications of this study.

Section 8 describes the conclusion and limitation of this paper.

2. Background Information

The regeneration mode refers to the new function of AIBs after being regenerated [

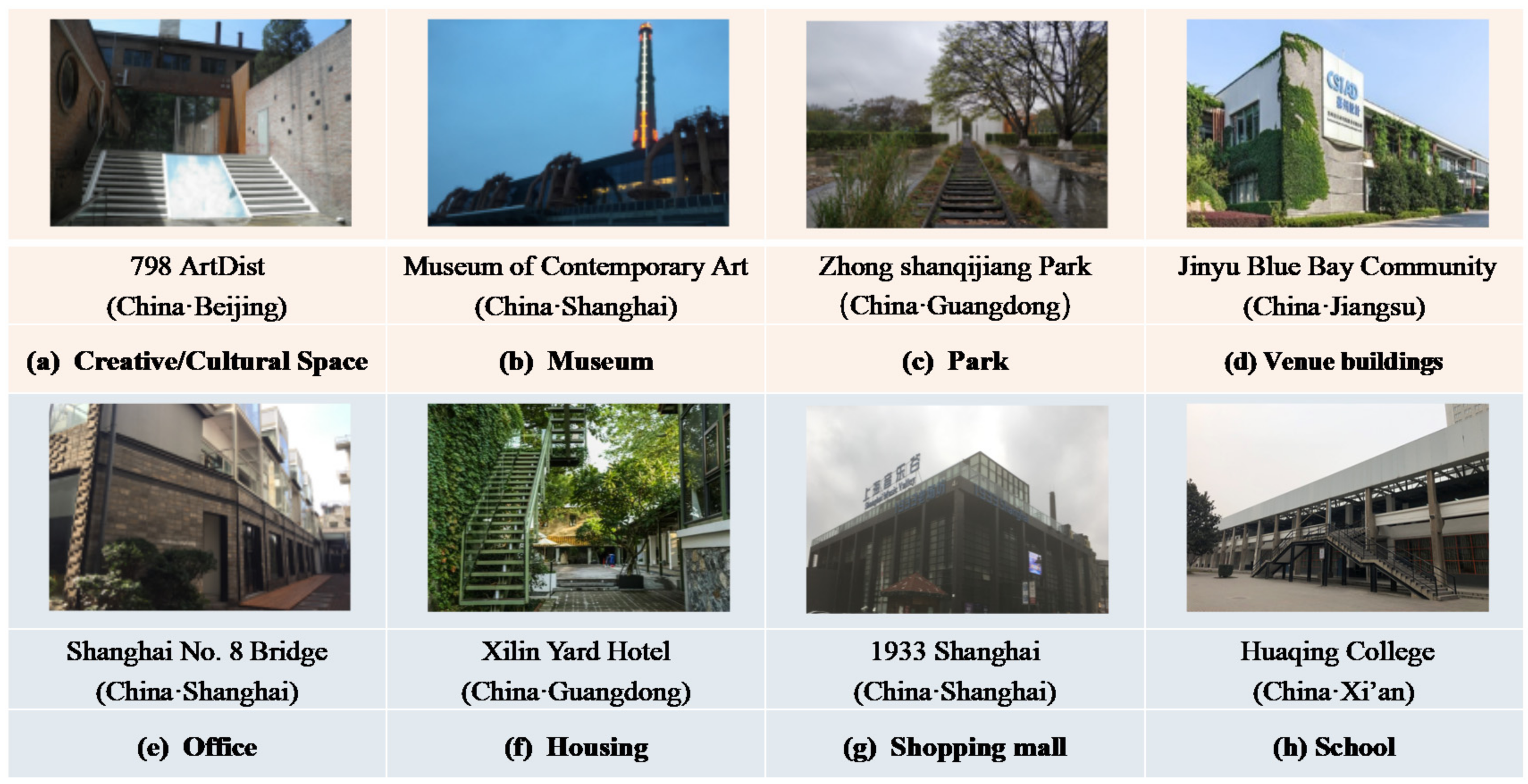

23]. The research team conducted an in-depth investigation on 148 completed RAIB projects in China’s 30 cities during 2015–2018. We found eight regeneration modes for AIBs, including (i) creative/cultural spaces, (ii) museums, (iii) parks, (iv) venue buildings, (v) offices, (vi) housing, (vii) shopping malls, and (viii) schools (several representative RAIB projects are shown in

Figure 1.

It is necessary to refurbish the AIBs in order to meet the requirements of new functions. According to Li et al. (2018), the main refurbishment aspects of RAIB projects involve demolition work, ground and foundation, main structure, envelope structure, mechanical and electrical installation, and green retrofit [

24]. The main contents of each aspect are shown in

Figure 2. In general, these contents can be briefly explained as the following six aspects. (1) In order to meet the needs of new functions and take economic factors into consideration, the buildings (part of main structure and envelope structure) and mechanical and electrical systems (such as water supply, drainage, HVAC, electrical, fire protection, etc.) that are seriously damaged and have no great historical value will be demolished or partially demolished. In addition, the original working equipment in the AIBs that is no longer in use needs to be removed to make room for the interior. (2) For retained AIBs, especially those with high story height and large column spacing, designers often divide the space vertically into two floors to meet the needs of new functions, which will require the addition of indoor stairs and floors, and will also be divided into multiple spaces horizontally. Because these additions will lead to load changes, existing structures generally need to be strengthened to ensure that the bearing capacity meets the requirements. Similarly, the change of ground load will also lead to the insufficient bearing capacity of the base and foundation, so it is necessary to reinforce the base and foundation. (3) In order to retain the historical characteristics of AIBs, the envelope structure generally needs to be retained. However, due to its poor thermal insulation effect and high energy consumption, it does not meet the current requirements. As a result, energy-saving renovation of envelope structure (especially the original doors and windows, external walls, and roofs) need to be carried out and the use of new energy technology is recommended. (4) As for the reserved existing resources (such as original building materials and equipment), many of them will be recycled into works of art or landscape pieces for exhibition to reflect the historical and cultural sense of AIBs. (5) Some of the retained electromechanical systems may need to be repaired, and new electromechanical systems (such as air conditioning systems, fire protection systems) may also be required. (6) For the AIBs that are polluted during the use of their original functions, the soil, buildings, equipment pipe network and the surrounding environment need to be polluted.

4. Methods

There have been lots of techniques to explore the critical factors of a project by researchers, such as the Analytic Hierarchy Process (AHP) approach [

33,

74], the Technique for Order Preference by Similarity to an Ideal Solution (TOPSIS) approach [

75], and the structural equation model (SEM) [

35]. However, AHP and TOPSIS approaches could not examine the interrelationship between factors, and the structural equation model requires a certain number of samples. To avoid these disadvantages, the Decision-making Trial and Evaluation Laboratory (DEMATEL) technique is considered as the best technique to identify critical factors. The DEMATEL approach was proposed in the Geneva Research Center of the Battelle Memorial Institute in 1972 by Gabus and Fontela [

76]. It is a system analysis method that uses graph theory and matrix tools to explain complicated problems. It obtains the mutual influence and causality among factors in complex problems based on the experience and knowledge of experts, and then reveals the driving factors through comprehensive analysis. To solve the fuzziness caused by experts’ subjective judgment, the triangle fuzzy number method is introduced to process the initial direct relation matrix to improve the accuracy of the DEMATEL method by Wu and Lee [

77]. The Fuzzy DEMATEL technique also can be used with a small sample size [

78]. At present, fuzzy DEMATEL method has been widely used in the research of CSFs in the field of supply chain management [

79,

80,

81] and the construction industry [

82,

83,

84,

85]. Therefore, the fuzzy DEMATEL method (

Figure 3) was used to identify the CSFs for safety program implementation of RAIB projects in this study. The flow diagram of the fuzzy DEMATEL approach is shown in

Figure 3.

4.1. Triangular Fuzzy Numbers

The language judgment of decision makers always has an ambiguous characteristic. Fuzzy numbers become more meaningful to convert a subjective judgement into a range rather than a crisp value. Two types of fuzzy numbers, namely triangular and trapezoidal fuzzy numbers, are commonly used. In this study, triangular fuzzy numbers (TFNs) are used because they have simple forms that are easy to calculate [

86]. Triangular fuzzy number is a concept of fuzzy set proposed by Zadeh in 1965 to address the problem under the situation of insufficient information [

87]. We define a fuzzy number

on R to be a triangular fuzzy number if its membership function

is equal to:

where

. And where

,

repents the degree of

attributed to

,

l,

m,

u refer to the smallest value, the most likely value, and the largest value of the support of

respectively. When

,

is an exact value.

Figure 4 shows the distribution of a triangular fuzzy number.

The membership function of triangular fuzzy numbers is shown in

Figure 5. Based on the principle proposed by Zadeh [

87], consider two different triangular fuzzy numbers,

Μ1 = (

l1,

m1,

u1) and

Μ2 = (

l2,

m2,

u2), with (

l1 and

l2 ≥ 0), then the basic operation rules of triangular fuzzy numbers are defined as Formulas (2)–(6). Therefore, fuzzy ratings and their membership function are presented in

Figure 5. The conversion method between the linguistic variable and the corresponding triangular fuzzy number is shown in

Table 2 [

80,

83,

88,

89].

4.2. Fuzzy DEMATEL Method

The steps of the fuzzy DEMATEL approach are illustrated as follows:

Step 1: Choose a group of experts in a related field.

In this step, a panel of experts who have sufficient knowledge and experience in the relevant field was invited to evaluate the interaction between the factors.

Step 2: Evaluate the interactions among factors by experts with linguistic scale.

All experts were required to assess the degree of influence among factors using a linguistic variable, which includes “No influence (N)”, “Very low influence (VL)”, “Low influence (L)”, “High influence (H)” and “Very high influence (VH)”. By doing so, initial evaluation results were obtained.

Step 3: Transfer the linguistic variable into triangular fuzzy number.

According to

Table 2, the linguistic assessment of experts can be converted into corresponding triangular fuzzy numbers. Then an initial direct relation fuzzy matrix is established. The initial direct relation fuzzy matrix

of each expert can be defined as follows:

where

and

.

represents the direct influence of factor

i on factor

j. Where

k represents the evaluation result of kth expert. When

i =

j,

.

Step 4: De-fuzzy the triangular fuzzy numbers into crisp values.

Converting the fuzzy data into crisp scores (CFCS) method proposed by Opricovic and Tzeng (2003) [

90] was used to transfer triangular fuzzy numbers into crisp values. The specific steps are shown as follows:

(1) Standardize the fuzzy numbers with the Formulas (8)–(10).

(2) Then the left and right normalized values are calculated as follows:

(3) Total normalized values are calculated as follows:

(4) Crisp value of evaluation results of the Kth expert is shown as follows:

Step 5: Calculate initial direct relation matrix as follows:

where

, Then initial direct-relation matrix

is obtained.

is a crisp value reflecting the direct influence of factor

i on factor

j.

Step 6: Normalize the direct-relation matrix

The normalized direct-relation matrix

A is calculated as follows:

where

.

Step 7: Calculate the total relation matrix.

The total relation matrix

T is defined as

. When n is large enough, the matrix

T can be calculated as follows:

where

I denote identity matrix. Where

T represent the matrix

.

is not only include the direct interactions of factor

i on factor

j. but also include the indirect interactions of factor

i on factor

j.

Step 8: Calculate the degree of influential impact Ri and influenced impact Ci.

According to the total relation matrix

T, the sum of rows and the sum of columns is the degree of influential impact

Ri and influenced impact

Ci, respectively.

Ri and

Ci are calculated as follows:

Step 9: Calculate the degree of importance (Ri + Ci) and the causal degree (Ri − Ci).

(Ri + Ci) represents the importance of factors and the influence degree of factors. The greater the (Ri + Ci) is, the more significant the degree of influence of the factor is. When (Ri − Ci) > 0, it means that other factors are easily affected by these factors, which can be grouped into the cause factor. Conversely, when (Ri − Ci) < 0, it indicates that other factors can easily influence this factor, which can be grouped into the effect factor.

Step 10: Draw the casual relationship diagram.

The casual relationship diagram is drawn by (Ri + Ci) for the horizontal axis and (Ri − Ci) for the vertical axis.

6. Discussion

Management support (C1) is the first CSF for safety program implementation of RAIB projects. Many studies also have proved that management support is the CFS for the effective implementation of safety programs [

19]. Votano and Sunindijo [

91] recommended that clients should actively participate in site-based safety programs in small and medium construction projects in Australia. The owner’s leadership during construction is the first and foremost prerequisite to improving project safety [

92,

93,

94]. In the context of RAIB projects, RAIBs practice is in the development stage, safety program of RAIB projects has not been perfected. There is a lack of guidance on safety procedures during construction, so current management support is critical to the safety performance of RAIB projects. The good safety behavior and attitude of leaders affect the safety motivation of employees and workers directly. Management support to safety also can promote the formation of a good safety culture in enterprises. Good safety culture reduces the occurrence of safety accidents [

95].

Control of subcontractor (C5) is the second CSF for safety program implementation of RAIB projects. Most RMAA contracting companies found in the construction market are subsidiaries of general building contractors or small specialty contractors of RMAA works [

42]. Small construction companies often employ workers with poor qualifications and awareness of safety hazards, which can lead to a high rate of construction accidents [

38]. Compared with the construction of new buildings, the safety technology of RAIB projects is complex and the potential risk is large. In particular, building energy-saving transformation and structural reinforcement often involve special operations, which require more qualified, capable, and safety-conscious subcontractors. Large subcontractors have full qualifications, competent management personnel, and strong safety awareness, and the less incidence of safety accidents has been confirmed by previous literature [

96].

The third CSF for safety program implementation of RAIB projects is personal attitude (C9), which is consistent with the finding of Haadir and Panuwatwanich [

21]. When the RAIB projects are in one place, the total amount of the project is small, and the working time of the local working surface is short. Under this kind of condition, workers tend to spend a short time operating unsafely leading to accidents. For example, when carrying out structural reinforcement, workers do not wear safety protective equipment due to a lack of safety awareness, which leads to skin and eyes injuries by the materials used (such as structural reinforcement glue). The workers who lack the experience of RMAA works tend to ignore the potential risks on-site [

43]. Hon et al. [

44] indicated that low safety awareness of RMAA workers is one of the root causes of accidents in RMAA works. Further, due to the relatively small number of RAIBs practices in China, operators still lack rich experience and risk identification ability in the construction process. Therefore, personal attitude must be emphasized in the implementation of the safety program for RAIB projects.

Allocation of authority and responsibility (C3) is the fourth CSF for safety program implementation of RAIB projects, which is consistent with the finding of Bavafa et al. [

61]. Due to the large number of participants in RAIB projects, the allocation of authority and responsibility of RAIB projects should also clearly specify the responsibilities of managers, employees, and workers at all levels, avoiding the potential disputes over the ownership of personnel responsibility. The clear allocation of responsibility also increases the safety motivation of personnel and improves the safety awareness of personnel to prevent the occurrence of safety accidents [

97].

Safety inspections and hazard assessment (C14) is the fifth CSF for safety program implementation of RAIBs construction, The main reason for the accidents during RAIBs construction is the incomplete understanding of the actual situation on site. The AIBs were built earlier, and the contractor was unable to obtain comprehensive original structural design information and previous maintenance and renovation design documents. Therefore, prior to construction, the contractor must carry out a comprehensive survey and assessment of the site conditions of the AIBs, which will help to take the correct action, ensure a safe working environment and avoid safety accidents. In addition, targeted safety education and training based on the information of safety inspection will make workers more capable to deal with safety problems during construction, thus greatly reducing the occurrence of accidents. Terwel and Jansen [

98] have also proposed that identifying the risk factors before construction has the greatest impact on structural safety, contributing to the overall safety of construction projects.

7. Implications

This section states the theoretical and managerial implications of this study towards the effective implementation of the safety program of RAIB projects.

7.1. Theoretical Implications

At present, safety programs are widely regarded as one of the effective strategies to improve the safety performance of RAIB projects. However, managers have limited knowledge on the implementation of safety programs of RAIB projects and the CSFs that influence their implementation. In this regard, our study will help them understand the CSFs for the effective implementation of safety programs of RAIB projects. Managers can apply the results of this study as a reference for designing effective safety programs of RAIB projects. The method proposed in this paper evaluates the relationship between the influencing factors and classifies each factor into causal group factors and effect group factors according to the experience and knowledge of experts. In fact, this approach of visualizing causality between factors through causal diagrams makes it easier to identify CSFs. As a result, with limited resources, managers are able to prioritize the application of resources to these factors. According to the interaction between the influencing factors, the performance of other factors can be improved to improve the effectiveness of the implementation of the RAIB projects.

7.2. Managerial Implications

This study will guide managers to implement effective safety programs to improve the safety performance of RAIB projects and further promote urban sustainable development goals. Management support is the most important factor affecting the effective implementation of the safety program of RAIB projects. Therefore, managers should pay much attention to the safety performance of RAIB projects. The Contractor should introduce high-quality technical personnel and management personnel with experience in the RAIB projects, and also set up a certain number of safety officers on site. The safety officer must have rich theoretical knowledge and practical experience of the RAIB projects. In addition, as the RAIB projects involve a number of contents and specialties, managers should actively organize, manage, communicate, coordinate and control effectively all professional subcontractors to ensure the safety performance of RAIB projects.

Second, managers should conscientiously implement the safety production responsibility system, clarify the responsibilities and obligations of all kinds of personnel, and conduct regular safety education and training and safety meetings, so as to form a good safety culture and safety atmosphere in the RAIB projects, and improve the safety awareness of workers. More importantly, workers should combine the protection of historical building culture and professional construction techniques with the improvement of safety awareness. Similarly, as for the selection of subcontractors, medium and large, experienced and reputable subcontractors should be selected as far as possible. Subcontractors should not only have the professional knowledge and safety awareness related to the general reconstruction of buildings, but also have a sense of responsibility for protecting the characteristics and culture of historical buildings. It has been agreed that the construction of RAIB projects should ensure that the original architectural characteristics are not damaged [

1,

2,

5].

Third, managers should also attach importance to the safety check and hazard assessment of AIBs. The AIBs are built earlier and used for a long time, so their design drawings are often not preserved completely. Therefore, managers must carry out structural detection and monitoring of the original structure of the AIBs, and structural safety assessment. When conducting structural testing, the manager must select qualified testing institutions and experienced testing personnel. In addition, it is also necessary to choose qualified environmental testing institutions to conduct safety testing on the soil and indoor environment of AIBs to prevent toxic and harmful substances from causing damage to human health. Based on the results of structural safety and environmental testing, managers conduct hazard assessments and make corresponding safety control strategies, such as formulating emergency response plans.

8. Conclusions

With increasing RAIB projects in China, safety and occupational accidents of workers tend to happen due to limited space, poor sanitary environment, complex construction technology, and uncertainty of structure in RAIB projects. Safety programs have been considered as one of the most effective ways to improve safety performance in the construction industry. In order to implement an effective safety program, to disentangle the CFSs affecting the safety program implementation of RAIB projects is critically significant. In this paper, the fuzzy DEMATEL approach has been proposed to determine the CFSs. The results show that the management support (C1), allocation of authority and responsibility (C3), control of subcontractor (C5), personal attitude (C9), and safety inspections and hazard assessment (C14) are identified as the CFSs for safety program implementation of RAIB projects. According to the interdependence among factors, other factors of the whole system will be gradually improved when these five CSFs are prioritized.

The fuzzy DEMATEL method enables us to consider the interrelation between factors and categorize the various factors into cause-and-effect groups. In fact, this method is based on graph theory and visualizes the casual relationship among factors through a cause-effect relationship diagram. Moreover, the introduction of triangle fuzzy numbers eliminates the fuzziness of experts’ evaluation. This method is applicable to explore the CSFs for safety program implementation of RAIB projects and can be applied to identify CSFs in other industries in the future.

This paper innovatively focuses on the CSFs affecting the implementation of the safety program of RAIB projects in China and examines the causal relationship among factors, which lays a theoretical foundation for the safety management of RAIB projects. Besides, the determination of CSFs focuses efforts in areas that affect the safety program implementation of RAIB projects, thereby conserving limited resources. It will provide useful guidance for managers and stakeholders to establish a reasonable and effective safety program for RAIB projects to improve the safety performance of RAIB projects. While this study has contributed to the literature, it does have some limitations. For example, this study is based on the background of the RAIB projects in China. Due to the different development stages and levels of RAIB projects in different countries, the outcomes of this study should be carefully applied to RAIB projects in other countries. A future study could be carried out using the methods proposed in this paper to compare these findings with those in the context of other countries.