1. Introduction

Solid biofuels (SBF) are defined as solid fuels produced directly or indirectly from biomass; their raw material is firewood, residues from forests (FR), from agriculture (AR), and from agro-industries (AIR) mainly. SBF are maintained in a solid state until a combustion reaction occurs to satisfy an end-use [

1]. In general, SBF production follows one of two process types: thermochemical (pyrolysis, carbonization, and torrefaction) or densification (briquetting, pelleting, or chipping) [

2]. The contribution of SBF to the world’s consumption of primary energy reached 42.2 EJ in 2017, corresponding to 63% of the total participation of renewable energies and 11.4% of the total energy consumed during that year in the world (370 EJ). The traditional use of SBF as firewood still represents 65% (27.4 EJ) of the total amount, mainly in the residential sector for cooking and space heating. Modern technologies consume the remaining 35% (14.8 EJ), 4% (1.6 EJ) for electricity generation and 31% (13.2 EJ) for industrial heat [

3]. According to [

4], by 2040, SBF’s electricity generation will increase at an average annual growing rate (AAGR) of 5.1%, and SBF’s heat generation will have a 2.7% AAGR, this last mainly due to process heat in industry and space conditioning in the residential sector [

5].

Some authors expect that the traditional use of firewood and charcoal will continue mainly in developing countries but globally will decrease at an average annual rate of −0.5% by 2040 [

4]. This prediction is based on two assumptions: (1) according to calculations made by [

6], between 2015 and 2050, the world’s rural population will decrease at an annual rate of −0.3%, and (2) there will be a substitution of firewood by fossil fuels in urban areas [

7]. Additionally, traditional firewood use is associated with unsustainable exploitation of the forest, which translates into 5% of annual deforestation [

8] and 34% of yearly forest degradation [

9].

In Mexico, in 2017, the final energy consumption was 5363 PJ, where SBF contributed 367 PJ, corresponding to 5.6% of the final energy consumption (4.7% firewood and 0.9% sugarcane bagasse), also corresponding to 50.2% of the total share of renewable energies [

10] of the final consumption. Traditional use of SBF represent 68% (250 PJ), firewood 206 PJ and charcoal 44 PJ as primary cooking fuels, adopting shares from [

11]. Modern technologies currently burn the remaining 32% (117 PJ).

The modern use of SBF comes from biomass originally from residues from forests, agriculture, and agro-industries. The use of SBF derived from residues avoids negative impacts of plantations such as conflicts over changes in land use and loss of biodiversity [

12,

13] or those associated with land competition and land for energy crop plantations vs. land for food crops [

14]. AIR give rise to other impacts that are not usually adequately evaluated because they are mitigated when they are valued for their nutritional, mechanical, or energy properties [

15].

The energy potential from available Mexican AIR amounts to 127.8 PJ/year, according to the recent assessment of [

16], where sugarcane bagasse represents 56.4%, maize cob 38.3%, coffee pulp and hull 2.3%, agave bagasse 2.0%, and barley husk, groundnut shells, and rice husk 1.1%. Consequently, sugarcane bagasse currently is the most consumed AIR in the country.

The current AR and AIR management in Mexico generates numerous impacts; among them is the traditional practice of slash-and-burn, which causes at least 44% of forest fires [

17]. Additionally, in many cases, the AR that remain in the field after harvesting are burnt. Both activities emit particulate material, 30% of PM is black carbon [

18], a greenhouse effect compound [

14]. In addition, AIR are left in open air dumps all over the country, providing an appropriate environment for pathogen incubation, sheltering harmful fauna, and affecting local biodiversity [

19]. The bacterial decomposition of AIR generates biogas emissions rich in methane (an important GHG) [

20]; it may also produce toxic leachate flows contaminating water sources [

21]. In summary, this final disposal practice of AIR affects the ecosystem and human health and represents an economical expense [

22].

On the other hand, if AIR are transformed into SBF employing appropriate technologies, these SBF can also provide a local source of energy at a low cost and generate security in the energy supply, employment, and a lower environmental impact [

23]. Additionally, it can reduce emissions of GHGs and water pollutants, as well as health and biodiversity impacts [

24].

Moreover, sustainable management of AR and AIR can generate economic income by converting them into SBF [

25], especially when substituting fossil fuels, reducing their consumption and GHG emissions, and developing a bio-economy strategy [

26]. The production and service chains of Mexican agribusiness generate many wastes, presumably of non-commercial quality; however, some AIR can be valued as renewable energy in the form of SBF to cover heat energy needs and adequate final waste disposal [

27]. AIR can also incorporate significant economic co-benefits such as the zero or low cost of raw material and cost reductions in biomass logistics, in addition to competing favorably against other renewable energies and fossil fuels.

To develop the untapped energy potential of AIR as SBF sustainably and improve the sustainability of the current energy use of AIR in Mexico, a literature review on sustainability assessment methods of solid biofuels derived from agroindustrial residues was undertaken. We found out that a vast number of authors apply LCA to determine only the environmental impacts of SBF energy systems [

20,

21,

22,

23,

27,

28,

29,

30,

31,

32]. However, fewer authors incorporate elements of the economic dimension along with environmental impacts through technical–economic assessments (TEA) of the use of AIR for heat generation [

19,

25,

33,

34]; this last article presents the TEA of current use of orange peels and the potential use of sugarcane straw to generate heat from a fruit-processing facility in Mexico. Moreover, few articles analyze three sustainability dimensions: the social, economic, and environmental dimensions of energy systems that use SBF–AIR were found. Among the few is [

35,

36,

37] that present a sustainability assessment methodology based on a set of sustainability indicators, each one evaluated independently without aggregation and using LCA. Manara and Zabaniotou [

35] apply their methodology to a case study to evaluate an AIR use energy system for heat and electricity generation on a micro-scale. They perform a sensitivity analysis on each indicator’s preliminary results. They manage to identify the critical factors for this kind of energy system’s social adoption and economic feasibility. Finally, they also identify an increase or decrease in these factors as signals towards greater or lesser sustainability.

Myllyviita [

38] assessed the sustainability of pellets produced from wood industry co-products using indicators belonging to a recognized sustainability indicator set. These authors applied a Multi-criteria analysis method (MCA) called the analytical hierarchical process (AHP) to convert the stakeholders’ value judgments or preferences (experts and users) on each indicator’s weight. Once the indicators have a value and a specific weight factor, they were added to form an integrated index comprising the social, economic, and environmental dimensions for each alternative.

When searching for methods for sustainability assessment of energy projects, we found out that a large number of studies apply multicriteria analysis methods (MCA) to aggregate sustainability indicators in a single sustainability index [

38,

39,

40,

41,

42]. This broad application of MCA arises from the multi-dimensional nature of sustainability assessments, which has to make use of indicators of very diverse nature in order to reflect the complexity of the biophysical and socio-economic systems that come into play; condensing into a single value helps to achieve a rational outcome [

39], even when stakeholder preferences diverge.

MCA methods may be classified into continuous or discrete types. We observe that in general, sustainability assessments are discrete choice problems because, in contrast to continuous type MCAs, which present a theoretically infinite number of alternatives defined by an objective function [

43], sustainability assessments present a reduced number of alternatives [

39], which are evaluated by indicators that can be quantitative or qualitative. It is necessary to point out that, in order to include qualitative indicators in an MCA, they must be previously subjectively qualified with a value judgment expressed on a numerical scale. Thanks to this numerical expression of qualitative variables, it is possible to carry out an inclusive formal assessment of sustainability-related aspects to society, such as the level of well-being [

38].

Discrete MCA types include the AHP mentioned above [

44], the multi-attribute analysis theory (MAUT) [

42], preference ranking organization method for enrichment evaluations (PROMETHEE) [

45,

46] and the elimination and choice translating reality (ELECTRE) Method [

47]. The last two are named overclassifying methods because they reduce the size of the alternatives set by comparing indicators between alternatives [

38], dividing the set of alternatives into two subsets depending on the indicators’ magnitude differences: more favorable and less favorable alternatives. This overclassification leads to a domination degree of one alternative over the other, facilitating its hierarchical order. An overclassifying method’s advantage is that it can use information with incomplete values. This characteristic is advantageous in evaluating SBF–AIR because intermittence is frequent when collecting measured data in the agro-industry. Another advantage of overclassifying methods is to avoid extreme assumptions concerning the validity of the main actors’ preferences [

48]. For this reason, they are considered very suitable for the evaluation of renewable energy projects [

49,

50] and have also been used successfully in evaluations of energy systems sustainability [

51]. However, while ELECTRE ignores the magnitude of differences between indicators of alternatives and only pays attention to preferences to determine a hierarchical order, PROMETHEE measures the difference between indicators by pairs of alternatives and uses preference functions to identify unmistakably the preferred alternative instead, which results in the alternatives hierarchization [

52]. According to [

36], PROMETHEE performs better than other overclassifying methods due to its ability to measure the differences between alternatives.

However, any problem involving alternatives evaluation through specific criteria or indicators requires the determination of the relative importance or specific impact of those indicators that are usually characterized by the weight assigned to it in an evaluation and have a decisive influence on evaluating the alternatives.

Among the methods to determine the weight factors (

) of the indicators are the hierarchical weighting methods and the equal weights method [

39,

53,

54]. There are three types of hierarchical weighting methods distinguished by the use of quantitative or qualitative information on the relative importance of the indicators: subjective weighting methods, objective weighting methods, and combined weighting methods. In the equal weighting method, as its name implies, the weight assigned to each indicator is the same; a decision-maker uses it when there is not enough knowledge to decide the importance of an indicator. A serious disadvantage of this method is its ignorance of each indicator’s relative importance [

39].

In the case of subjective weighting, the experts who evaluate can explain their evaluation clearly; however, this judgment depends above all on the existence of professionals who have the knowledge and information necessary to form a preference and issue an assessment of the relative importance of an indicator [

39]. Combined or integrated methods are those that combine a subjective weighting with an objective weighting for the same indicator, in order to reduce, on the one hand, the possible lack of experience or knowledge of the evaluating expert and, on the other hand, obtain weightings opposed to common sense [

55]. When these weight factors are combined, they form a hybrid weighting factor.

Objective methods use mathematical methods to process measured quantitative data and consequently obtain a degree of difference between indicators, which signifies their importance. Among the most used objective weighting methods according to [

39] are the following three: (1) the horizontal and vertical optimal weighting method, (2) the technique for order preference by similarity to ideal solution (TOPSIS), and (3) the entropic method. The first two methods reflect the differences in the behavior of the entire system to be evaluated. Because our problem involves field measurements of indicators of a very diverse nature, economic, social, and environmental, we consider that it is convenient to use the entropic method because it reflects the relative importance between indicators based on the differences between alternatives of an indicator for the same criterion. While TOPSIS and the horizontal and vertical methods evaluate the data of already integrated indicators, the entropic method performs its evaluation based on the differences of the indicators by criterion [

39].

To perform a sustainability assessment of an energy production system with SBF from AIR, we consider it necessary to use sustainability indicators that explicitly display impacts on the environment, economy, or society. For example, we need indicators where the quantitative difference between the impact value of this SBF system and an energy system fueled with fossil fuels could be precisely calculated.

Among the characteristics of these chosen indicators are that they must be measurable and applicable at the local or project level, they must reflect the preferences of all related actors, and also, according to [

56,

57], an indicator that seeks to measure sustainability must be related to known threshold values, minimum or maximum limits, or both. However, there are indicators for which limit values cannot be defined, and yet they can represent sustainability conditions [

58,

59].

To evaluate the positive and negative effects of taking advantage of AIR to transform them into SBF and use them in combustion energy systems or devices, it is necessary to measure the variables that reflect the maximum changes concerning a situation in the absence of the proposed energy production system. When regarding the economic dimension, it is necessary to introduce sustainability indicators that show its advantages as the null or low cost of the residues as raw material and the avoided costs of logistics and final disposal that produces their utilization [

60]. It is also necessary to introduce social indicators that reflect the creation of jobs involved in logistics and transforming the AIR to SBF and use them in final energy technologies. Other examples are the salary level and health benefits by avoiding infection sources due to open-air dumps [

60]. We also need to assess the environmental benefits of avoiding air pollution due to the emission of criteria pollutants and greenhouse gases throughout their life cycle and accounting normally as avoided emissions by the fossil fuels substitution [

35].

In an updated literature review, we have found that some authors, refs. [

61,

62] particularly, use an integrated assessment approach that applies the integration of a multicriteria analysis method called PROMETHEE to rank alternatives and the entropic method to calculate criteria weighting coefficients.

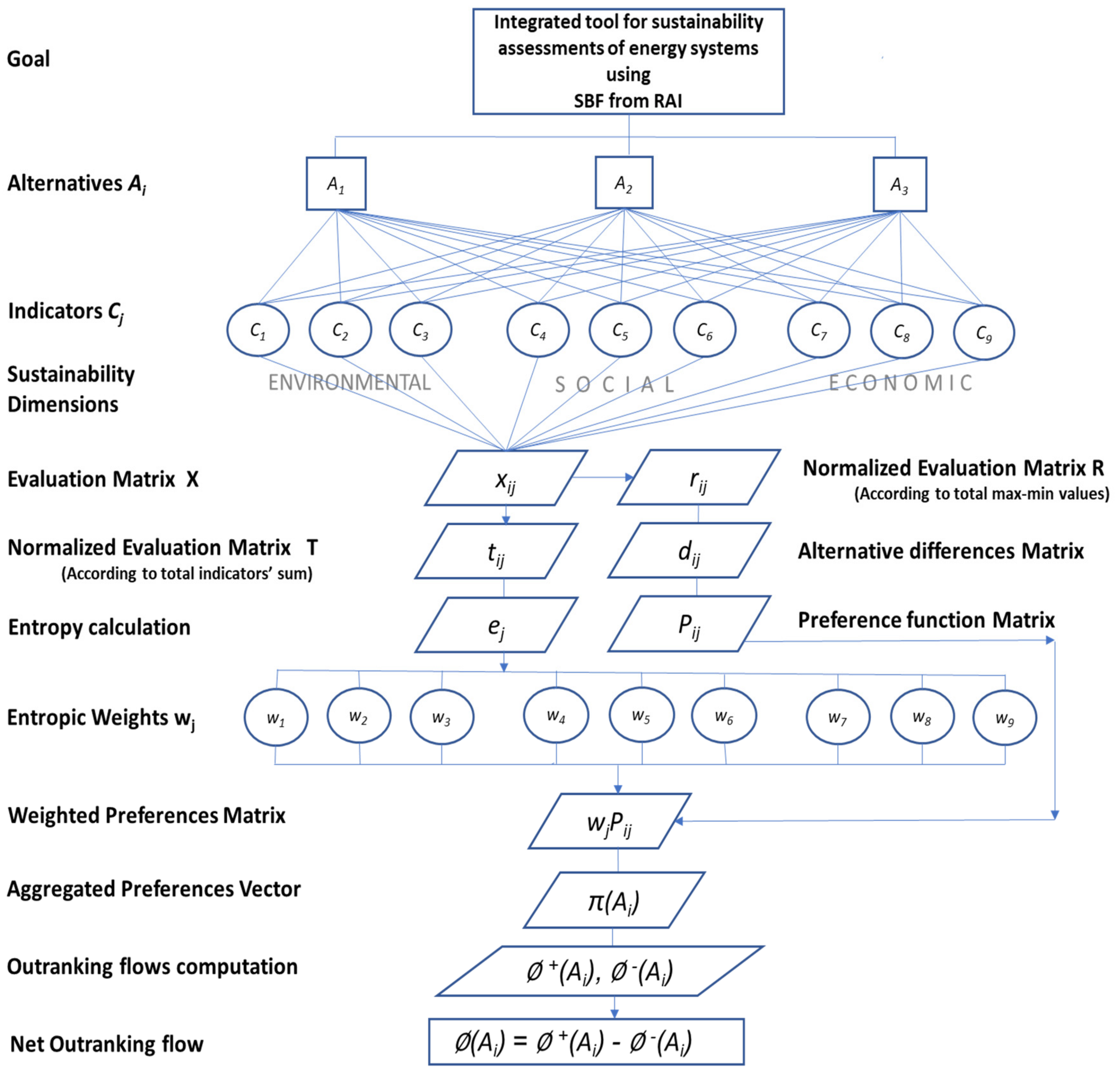

This article aims to make a sustainability assessment of energy systems that use solid biofuels made of agro-industrial residues for heat and power generation. Therefore, we apply a similar tool that integrates the PROMETHEE method to assess energy systems and the entropic method to calculate the weighting coefficients of the sustainability indicators (of the social, economic, and environmental sustainability dimensions) to perform an energy systems evaluation reaching a single aggregated value to rank each energy system sustainability compared to each energy system and considering all sustainability indicators avoiding single indicator calculation bias.

The novelty of this article is to show that the application of this tool can provide adequate sustainability assessments of energy systems/technologies considering the conditions of the Mexican agro-industrial sector. Frequently, it is not very easy to gather a group of experts that can give their opinion on various technological alternatives to SBF–AIR and discuss the relative importance of the few sustainability indicators to be constructed for energy systems using SBF. This indicator’s scarcity is mainly due to a lack of available information for assessing the socio-economic–environmental effects caused by the usage of SBF derived from forestry, agricultural, and agro-industry residues.

2. Theoretical Framework

Among all the MCA methods presented in the previous section, we chose the PROMETHEE method to perform the SBF–AIR systems’ sustainability assessment and ranking. This method is a technical–scientific tool able to handle discrete indicators of quantitative and qualitative nature. Its theory is very understandable, and its calculation procedure is easily programmable [

39]. It facilitates performing evaluations clearly and consistently, especially in the renewable energy sector [

50], and in particular in the bioenergy sector [

63]. Initially, the PROMETHEE method was proposed by Brans in 1982 for multicriteria analysis problems. This method’s base compares values by pairs accounting for the differences between two alternatives for a particular indicator [

46]. The idea is that the more significant the difference between alternatives, the greater the degree of preference. Brans and others [

46,

50,

64,

65] show a detailed description for implementing PROMETHEE. In general, a sustainability assessment depends mostly on selecting the proper sustainability indicators, in this case, for SBF–AIR systems or alternatives. In particular, this study restrained the selected sustainability indicators to the general characteristics of the 24 indicators of the existing sustainability assessment framework called the Global Bioenergy Partnership (GBEP) [

58,

66,

67]. It is common to employ these GBEP indicators to evaluate sustainability policies at the national level; however, this study applies these sustainability indicators locally since that is the level at which GBEP derived them [

58].

As mentioned in the previous section, PROMETHEE requires externally introduced weight factors to determine the relative importance of each sustainability indicator. For that purpose, we will use the integration in our methodology of the entropic weighting method to determine objectively the weight factors of each indicator [

59].

The entropic weighting method is so named because it uses Shannon’s concept of information entropy, interpreted as a measure of uncertainty in information formulated in terms of probability theory [

68] cited in [

69]. It is an objective weighting method of a set of indicators that assesses the relative importance of an indicator concerning the amount of measurable useful information it represents. According to [

70], this method allows determining the contrast degree of useful information that an indicator contains when comparing several alternatives through different indicators. If the difference between the value of an indicator’s alternatives is high, the entropy will be small, which shows that the distinctive characteristics of that indicator offer more information by having a higher contrast and, therefore, it should be assigned a higher weight. Otherwise, the relative weight should be reduced [

71].

Since most energy projects involve measurable variables and indicators, it is adequate to use the entropic method, instead of subjective methods, to calculate each indicator’s weight because obtaining expert opinion evaluations in SBF–AIR’s energy use is difficult and time-consuming. Nevertheless, the precision of this mathematical weighting method will depend exclusively on data quality.

We chose the integration of the PROMETHEE and entropic weighting methods for the following reasons: (1) It has been successfully applied in numerous sustainability assessments of energy systems. (2) The PROMETHEE method shows multiple advantages over other MCDA outranking methods. (3) The objective entropic weighting method can readily satisfy the need for exogenous weighting factors in PROMETHEE due to its ability to identify the indicators with the most useful information without the need for exhaustive expert information input.