Ecological Transition in the Field of Brake Pad Manufacturing: An Overview of the Potential Green Constituents

Abstract

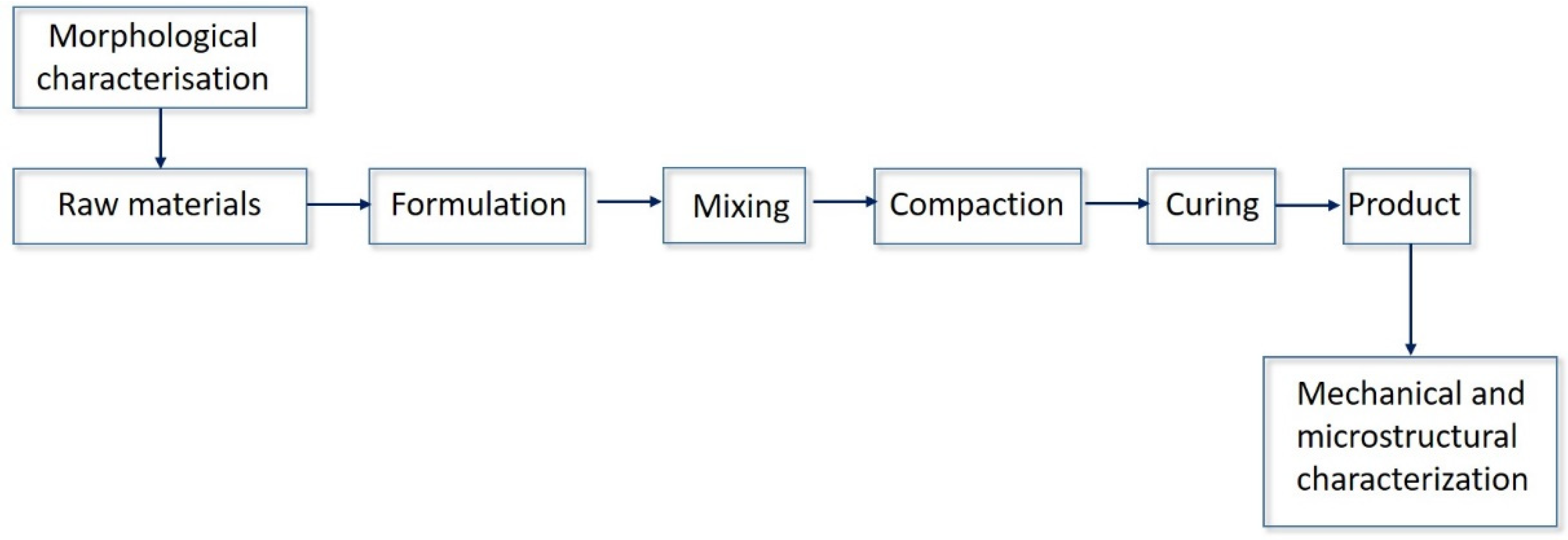

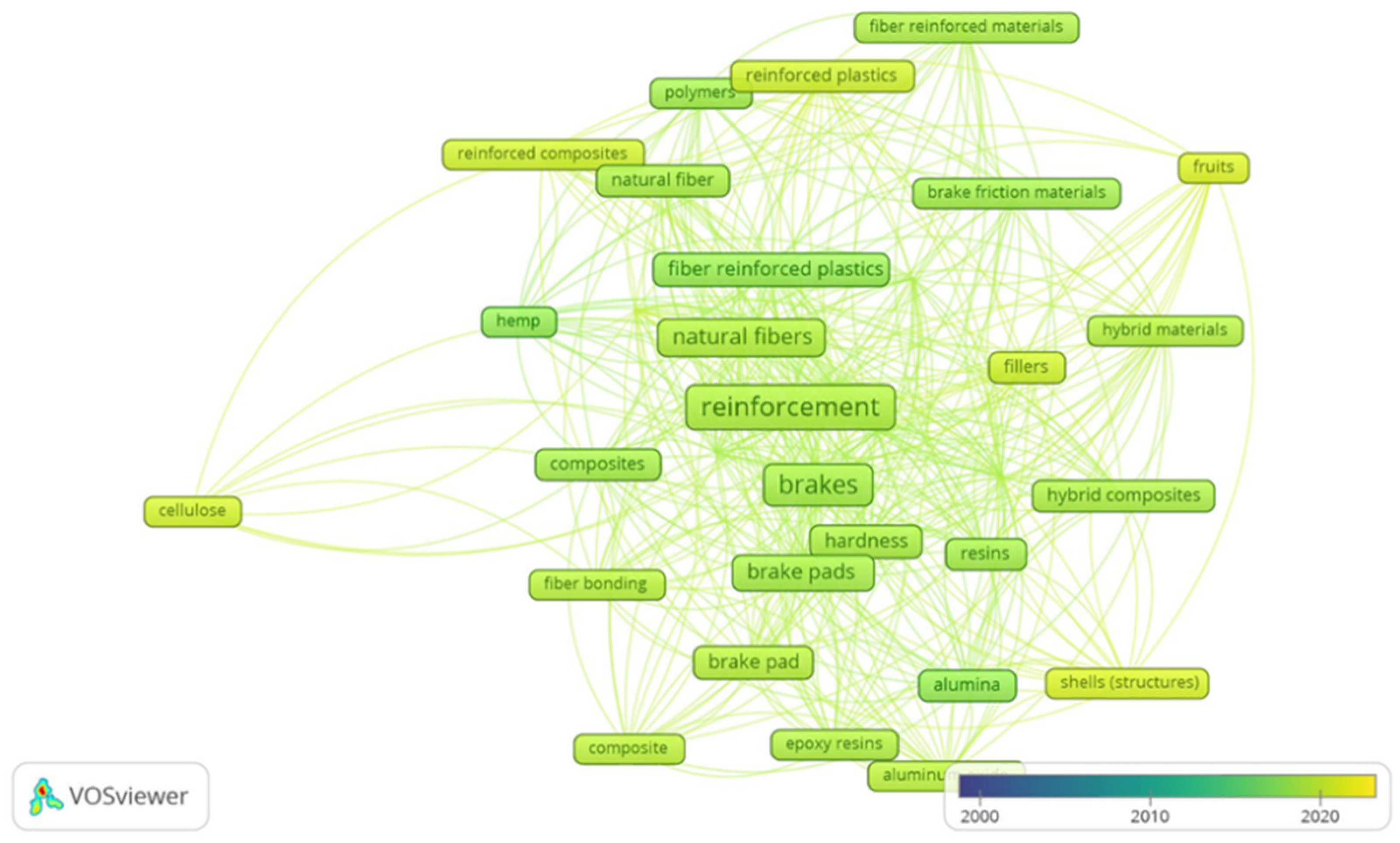

:1. Introduction

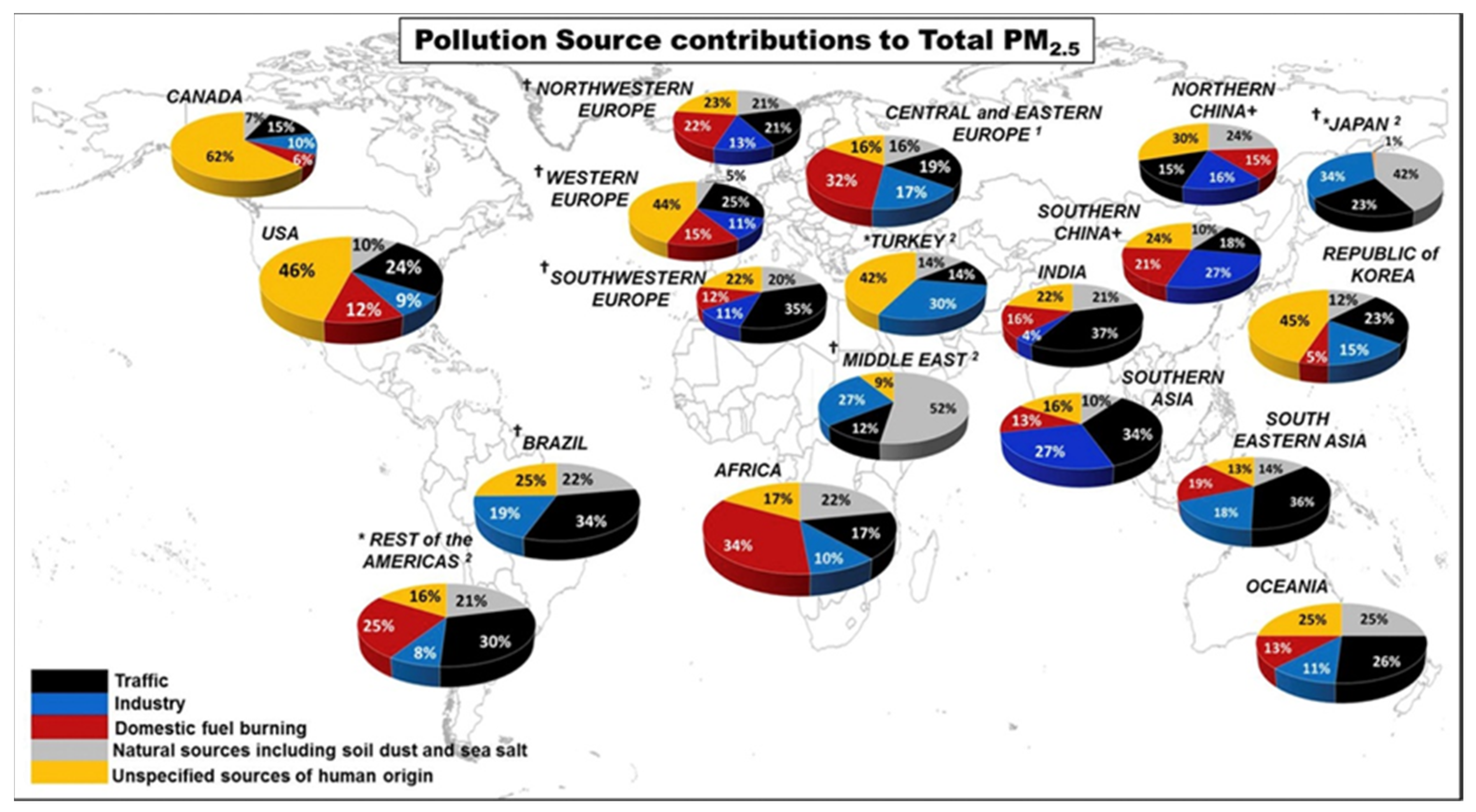

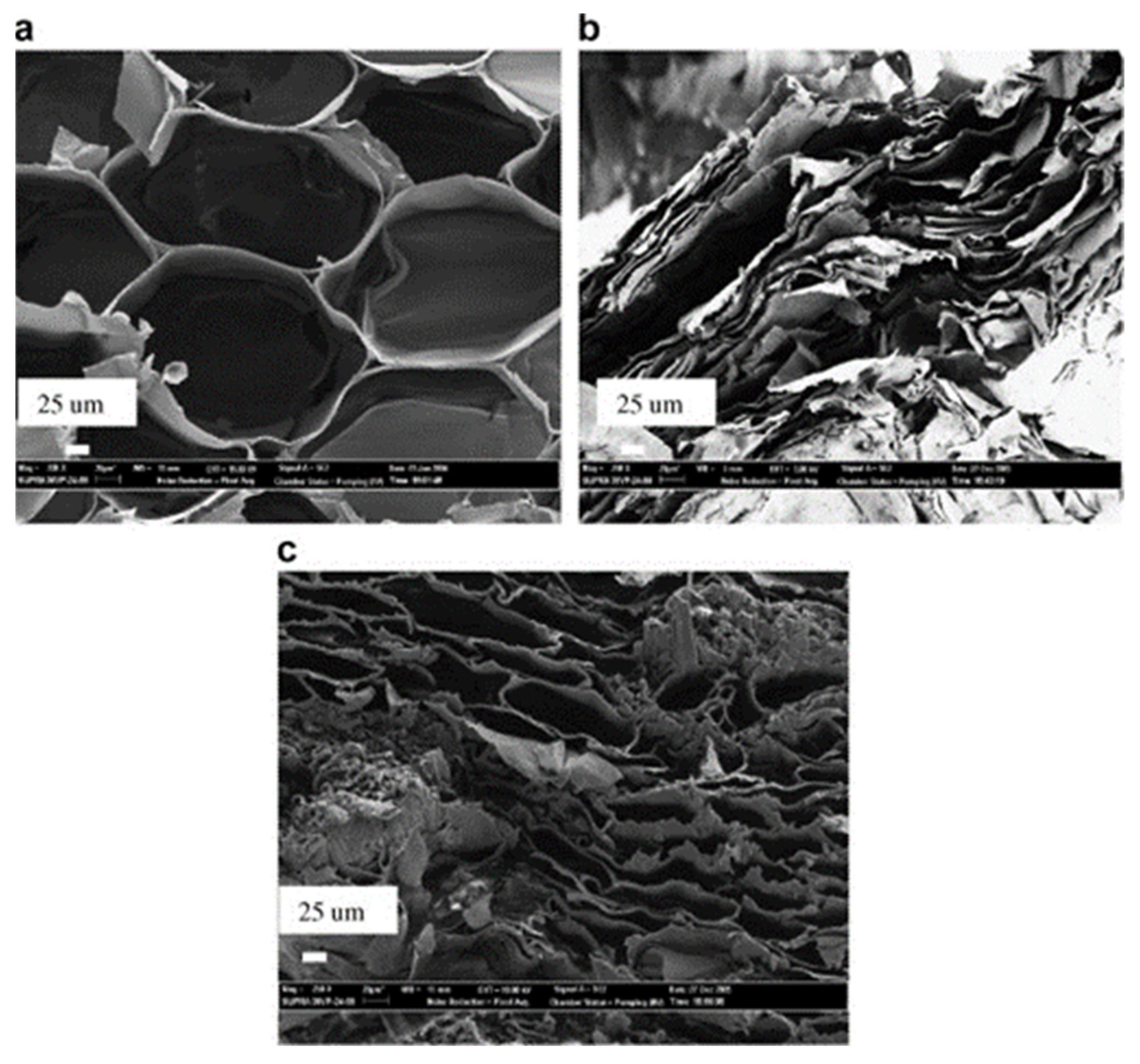

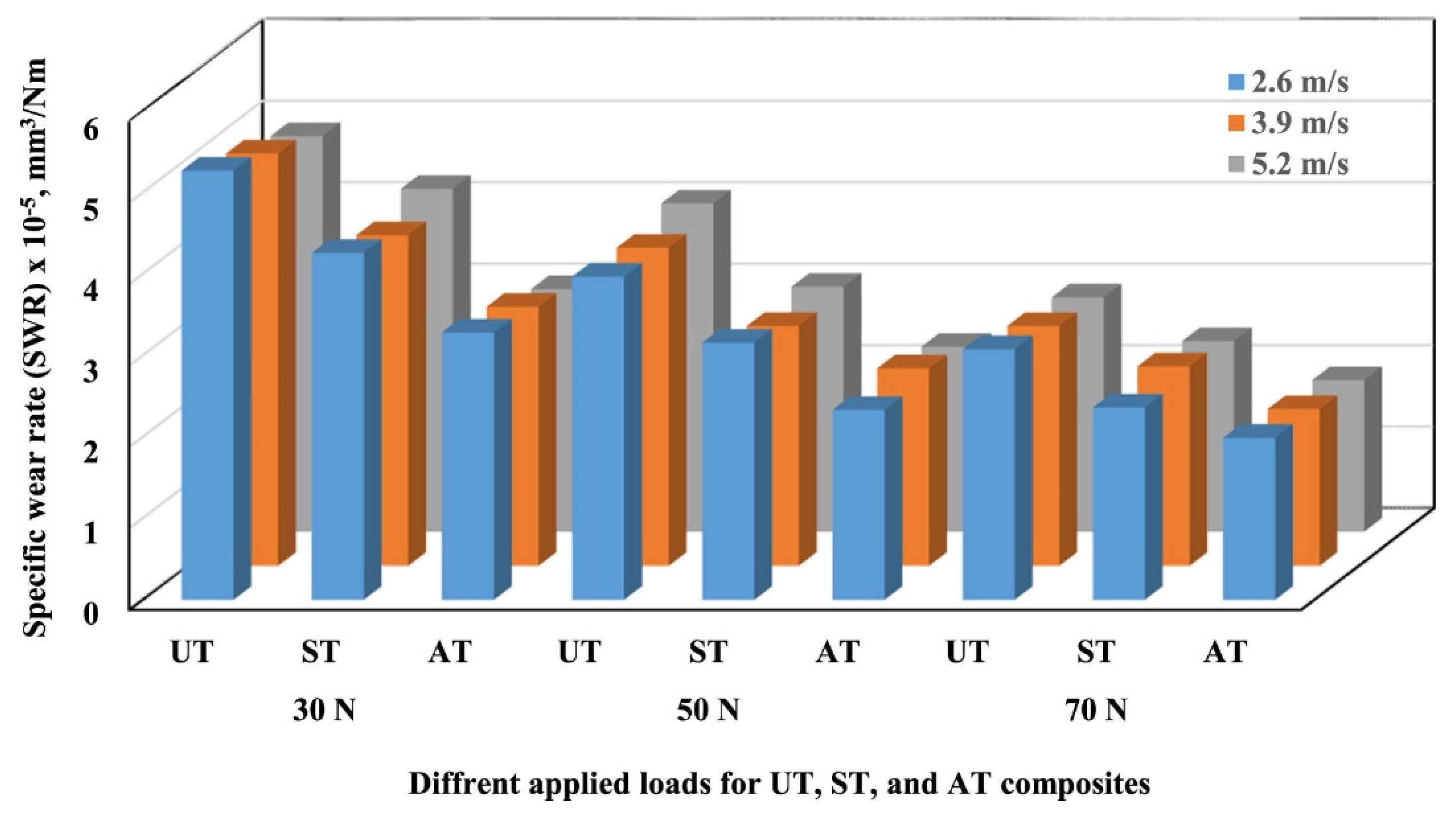

1.1. Particulate Matter

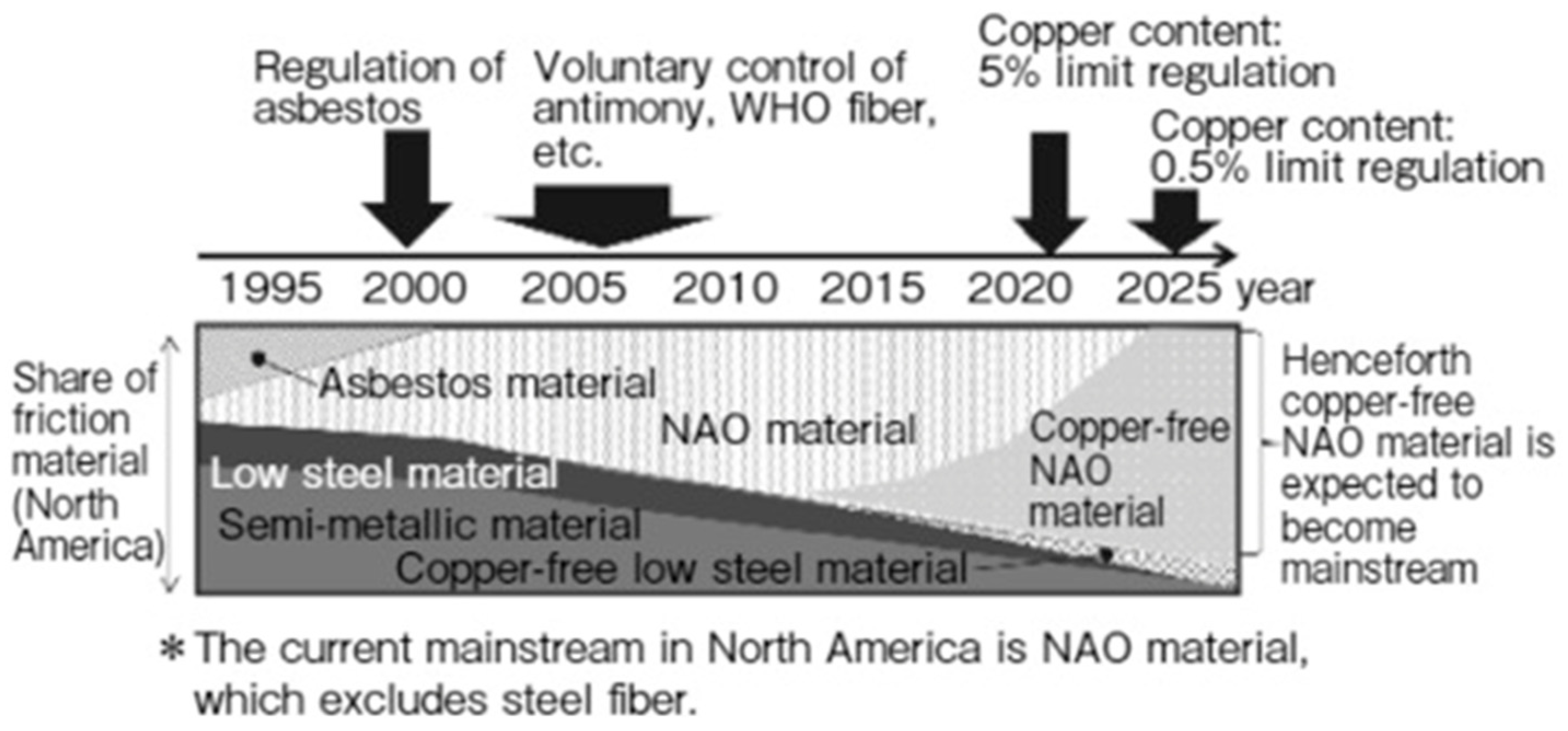

1.2. Pollution from Brake Systems

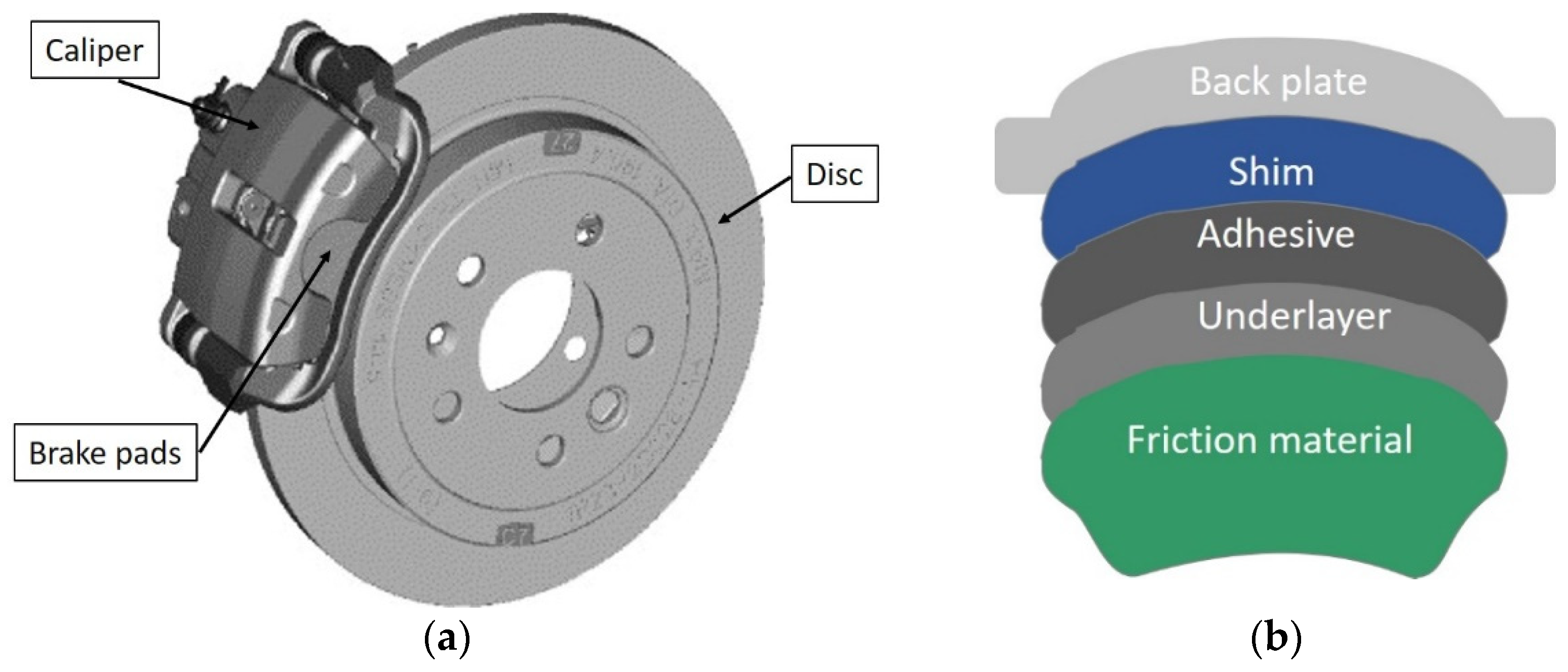

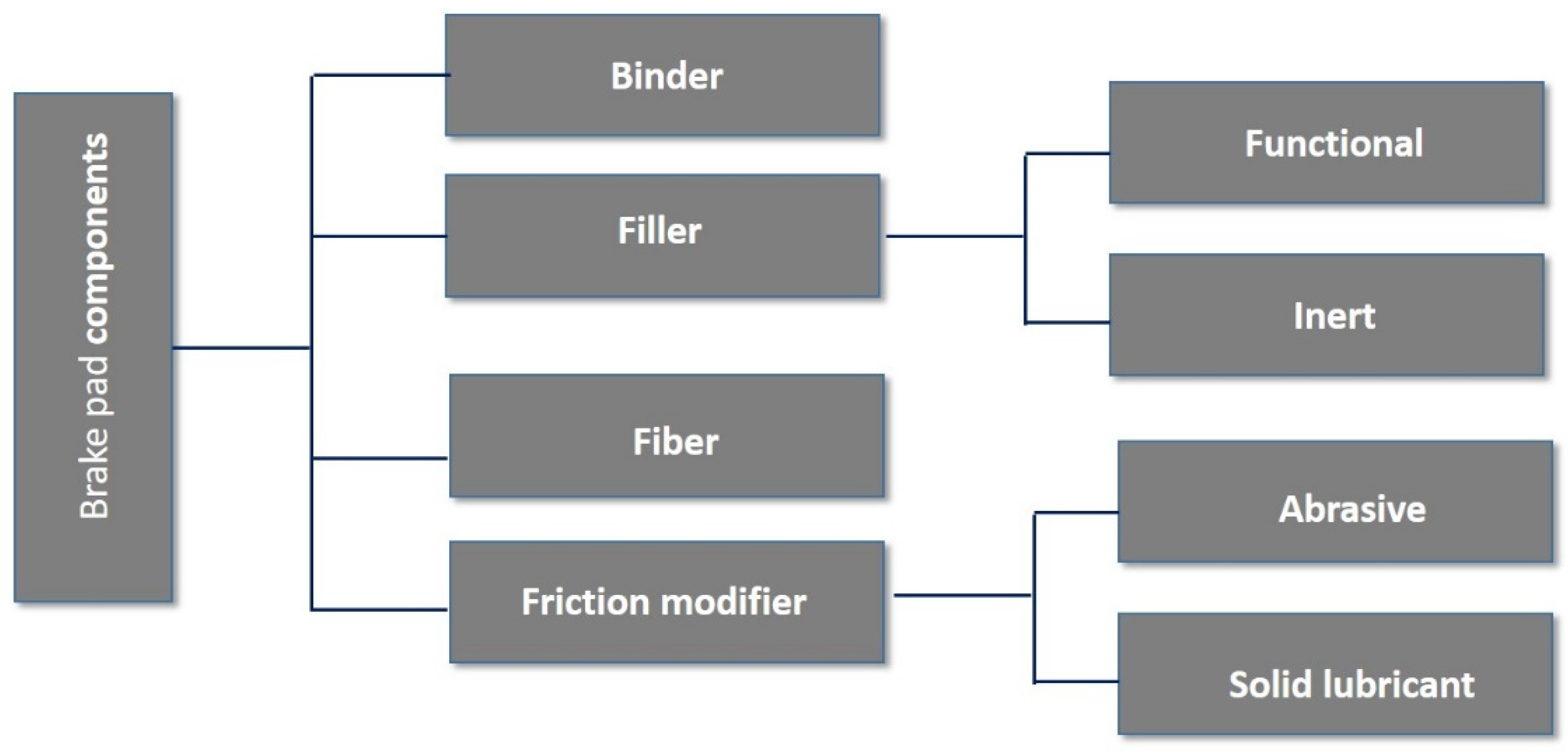

2. Friction Materials Overview

2.1. Binder

2.2. Fiber

2.3. Friction Modifiers

2.4. Filler

2.4.1. Inorganic Filler

2.4.2. Organic Filler

3. Green Constituents as Alternatives for Friction Materials

3.1. Green Binders

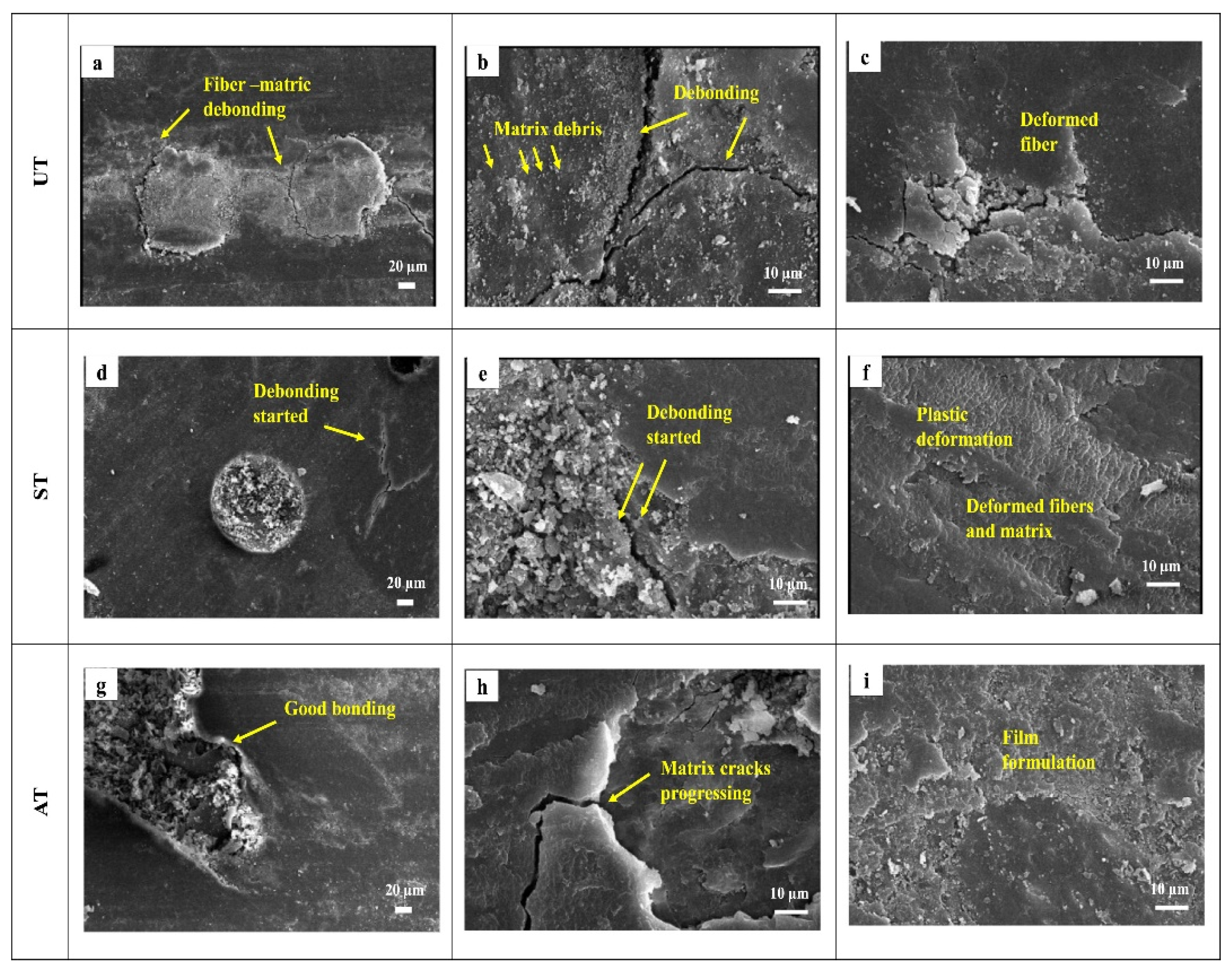

3.2. Fibers

3.3. Friction Modifier

3.4. Fillers

4. Friction Materials from Industrial Waste

5. Conclusions

5.1. A: Binder

5.2. B: Fibers

5.3. C: Friction Modifier

5.4. D: Filler

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviation

| PM | Particulate matter |

| WHO | World Health Organization |

| IT | Interim targets |

| EPA | Environmental Protection Agency |

| USAEPA | National Ambient Air Quality Standards (NAAQS) |

| BPWD | Brake pad wear debris |

| US EPA | United States Environmental Protection Agency |

| IARC | International Agency for Research on Cancer |

| LM | Low Metallic |

| SM | Semimetallic |

| NAO | Nonasbestos organic |

| PF | Phenolic resin |

| CVD | Cardiovascular diseases |

| BFM | Brake friction materials |

| BPW | Brake pads waste |

| CNSL | Cashew nut shell liquid |

| NBR | Nitrile butadiene |

| EPO | European Patent Office |

References

- El-Fadel, M.; Massoud, M. Particulate matter in urban areas: Health-based economic assessment. Sci. Total Environ. 2000, 257, 133–146. [Google Scholar] [CrossRef]

- Cambra-López, M.; Aarnink, A.J.A.; Zhao, Y.; Calvet, S.; Torres, A.G. Airborne particulate matter from livestock production systems: A review of an air pollution problem. Environ. Pollut. 2010, 158, 1–17. [Google Scholar] [CrossRef]

- Kastury, F.; Smith, E.; Juhasz, A.L. A critical review of approaches and limitations of inhalation bioavailability and bioaccessibility of metal(loid)s from ambient particulate matter or dust. Sci. Total Environ. 2017, 574, 1054–1074. [Google Scholar] [CrossRef] [PubMed]

- Martinelli, N.; Olivieri, O.; Girelli, D. Air particulate matter and cardiovascular disease: A narrative review. Eur. J. Intern. Med. 2013, 24, 295–302. [Google Scholar] [CrossRef]

- Kelly, F.J.; Fussell, J.C. Size, source and chemical composition as determinants of toxicity attributable to ambient particulate matter. Atmos. Environ. 2012, 60, 504–526. [Google Scholar] [CrossRef]

- Perrone, M.G.; Gualtieri, M.; Consonni, V.; Ferrero, L.; Sangiorgi, G.; Longhin, E.; Ballabio, D.; Bolzacchini, E.; Camatini, M. Particle size, chemical composition, seasons of the year and urban, rural or remote site origins as determinants of biological effects of particulate matter on pulmonary cells. Environ. Pollut. 2013, 176, 215–227. [Google Scholar] [CrossRef] [PubMed]

- Maté, T.; Guaita, R.; Pichiule, M.; Linares, C.; Díaz, J. Short-term effect of fine particulate matter (PM2.5) on daily mortality due to diseases of the circulatory system in Madrid (Spain). Sci. Total Environ. 2010, 408, 5750–5757. [Google Scholar] [CrossRef]

- Atkinson, R.W.; Kang, S.; Anderson, H.R.; Mills, I.C.; Walton, H.A. Epidemiological time series studies of PM2.5 and daily mortality and hospital admissions: A systematic review and meta-analysis. Thorax 2014, 69, 660–665. [Google Scholar] [CrossRef] [Green Version]

- Wu, C.F.; Woodward, A.; Li, Y.R.; Kan, H.; Balasubramanian, R.; Latif, M.T.; Sahani, M.; Cheng, T.J.; Chio, C.P.; Taneepanichskul, N.; et al. Regulation of fine particulate matter (PM2.5) in the Pacific Rim: Perspectives from the APRU Global Health Program. Air Qual. Atmos. Health 2017, 10, 1039–1049. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, F.; Li, W.; Yin, L.; Wang, Y.; Yan, R.; Lao, X.Q.; Kan, H.; Tse, L.A. Does utilizing WHO’s interim targets further reduce the risk—Meta-analysis on ambient particulate matter pollution and mortality of cardiovascular diseases? Environ. Pollut. 2018, 242, 1299–1307. [Google Scholar] [CrossRef]

- Implications of Changing PM10 Air Quality Standards on Pacific Northwest Communities Affected by Windblown dust|Elsevier Enhanced Reader. Available online: https://reader.elsevier.com/reader/sd/pii/S1352231011005760?token=E4D49EC40B202078158567371242358AD1F2C26F483B91FFD3740BBB3FC3123DBEFC7DC417A8170BC7FEBB8232640699&originRegion=eu-west-1&originCreation=20210511124012 (accessed on 11 May 2021).

- Patel, P.; Aggarwal, S.G.; Tsai, C.J.; Okuda, T. Theoretical and field evaluation of a PM2.5 high-volume impactor inlet design. Atmos. Environ. 2021, 244, 17811. [Google Scholar] [CrossRef]

- Naing, N.N.; Lee, H.K. Microextraction and analysis of contaminants adsorbed on atmospheric fine particulate matter: A review. J. Chromatogr. A 2020, 1627, 461433. [Google Scholar] [CrossRef] [PubMed]

- Kim, K.H.; Kabir, E.; Kabir, S. A review on the human health impact of airborne particulate matter. Environ. Int. 2015, 74, 136–143. [Google Scholar] [CrossRef] [PubMed]

- Harrison, R.M.; Yin, J. Particulate matter in the atmosphere: Which particle properties are important for its effects on health? Sci. Total Environ. 2000, 249, 85–101. [Google Scholar] [CrossRef]

- Klimenko, A. Aggregated toxicity of road vehicles as basis for future regulation in the field of atmospheric air protection. SN Appl. Sci. 2020, 2, 2050. [Google Scholar] [CrossRef]

- Han, X.; Naeher, L.P. A review of traffic-related air pollution exposure assessment studies in the developing world. Environ. Int. 2006, 32, 106–120. [Google Scholar] [CrossRef]

- Beji, A.; Deboudt, K.; Khardi, S.; Muresan, B.; Flament, P.; Fourmentin, M.; Lumière, L. Non-exhaust particle emissions under various driving conditions: Implications for sustainable mobility. Transp. Res. Part D Transp. Environ. 2020, 81, 102290. [Google Scholar] [CrossRef]

- Grigoratos, T.; Martini, G. Brake wear particle emissions: A review. Environ. Sci. Pollut. Res. 2015, 22, 2491–2504. [Google Scholar] [CrossRef] [Green Version]

- Karagulian, F.; Belis, C.A.; Dora, C.F.C.; Prüss-Ustün, A.M.; Bonjour, S.; Adair-Rohani, H.; Amann, M. Contributions to cities’ ambient particulate matter (PM): A systematic review of local source contributions at global level. Atmos. Environ. 2015, 120, 475–483. [Google Scholar] [CrossRef]

- Maiorana, S.; Teoldi, F.; Silvani, S.; Mancini, A.; Sanguineti, A.; Mariani, F.; Cella, C.; Lopez, A.; Potenza, M.A.C.; Lodi, M.; et al. Phytotoxicity of wear debris from traditional and innovative brake pads. Environ. Int. 2019, 123, 156–163. [Google Scholar] [CrossRef]

- Dodd, M.D.; Ebbs, S.D.; Gibson, D.J.; Filip, P. Alteration of root growth by lettuce, wheat, and soybean in response to wear debris from automotive brake pads. Arch. Environ. Contam. Toxicol. 2014, 67, 557–564. [Google Scholar] [CrossRef] [PubMed]

- Volta, A.; Sforzini, S.; Camurati, C.; Teoldi, F.; Maiorana, S.; Croce, A.; Benfenati, E.; Perricone, G.; Lodi, M.; Viarengo, A. Ecotoxicological effects of atmospheric particulate produced by braking systems on aquatic and edaphic organisms. Environ. Int. 2020, 137, 105564. [Google Scholar] [CrossRef] [PubMed]

- Gasser, M.; Riediker, M.; Mueller, L.; Perrenoud, A.; Blank, F.; Gehr, P.; Rothen-Rutishauser, B. Toxic effects of brake wear particles on epithelial lung cells in vitro. Part. Fibre Toxicol. 2009, 6, 30. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kakooei, H.; Marioryad, H. Evaluation of exposure to the airborne asbestos in an automobile brake and clutch manufacturing industry in Iran. Regul. Toxicol. Pharmacol. 2010, 56, 143–147. [Google Scholar] [CrossRef]

- Paustenbach, D.J.; Finley, B.L.; Lu, E.T.; Brorby, G.P.; Sheehan, P.J. Environmental and occupational health hazards associated with the presence of asbestos in brake linings and pads (1900 to present): A “state-of-the-art” review. J. Toxicol. Environ. Health Part B Crit. Rev. 2004, 7, 25–80. [Google Scholar] [CrossRef]

- Takahashi, K.; Landrigan, P.J. The Global Health Dimensions of Asbestos and Asbestos-Related Diseases. Ann. Glob. Health 2016, 82, 209–213. [Google Scholar] [CrossRef]

- Poland, C.A.; Duffin, R. Critical Reviews in Toxicology The toxicology of chrysotile-containing brake debris: Implications for mesothelioma. Crit. Rev. Toxicol. 2019, 49, 11–35. [Google Scholar] [CrossRef]

- Mahale, V.; Bijwe, J.; Sinha, S. Influence of nano-potassium titanate particles on the performance of NAO brake-pads. Wear 2017, 376–377, 727–737. [Google Scholar] [CrossRef]

- Cho, K.H.; Cho, M.H.; Kim, S.J.; Jang, H. Tribological properties of potassium titanate in the brake friction material; morphological effects. Tribol. Lett. 2008, 32, 59–66. [Google Scholar] [CrossRef]

- Jadhav, S.P.; Sawant, S.H. A review paper: Development of novel friction material for vehicle brake pad application to minimize environmental and health issues. Mater. Today Proc. 2019, 19, 209–212. [Google Scholar] [CrossRef]

- Straffelini, G.; Ciudin, R.; Ciotti, A.; Gialanella, S. Present knowledge and perspectives on the role of copper in brake materials and related environmental issues: A critical assessment. Environ. Pollut. 2015, 207, 211–219. [Google Scholar] [CrossRef] [PubMed]

- Figliuzzi, M.; Tironi, M.; Longaretti, L.; Mancini, A.; Teoldi, F.; Sangalli, F.; Remuzzi, A. Copper-dependent biological effects of particulate matter produced by brake systems on lung alveolar cells. Arch. Toxicol. 2020, 94, 2965–2979. [Google Scholar] [CrossRef] [PubMed]

- Zhang, M.; Guo, X.; Tian, B.; Wang, J.; Qi, S.; Yang, Y.; Xin, B. Improved bioleaching of copper and zinc from brake pad waste by low-temperature thermal pretreatment and its mechanisms. Waste Manag. 2019, 87, 629–635. [Google Scholar] [CrossRef] [PubMed]

- Grigoratos, T. Regulation on Brake/Tire Composition; Elsevier: Amsterdam, The Netherlands, 2018; ISBN 9780128117705. [Google Scholar]

- Fujiwara, F.; Rebagliati, R.J.; Marrero, J.; Gómez, D.; Smichowski, P. Antimony as a traffic-related element in size-fractionated road dust samples collected in Buenos Aires. Microchem. J. 2011, 97, 62–67. [Google Scholar] [CrossRef]

- Li, J.; Zheng, B.H.; He, Y.; Zhou, Y.; Chen, X.; Ruan, S.; Yang, Y.; Dai, C.; Tang, L. Antimony contamination, consequences and removal techniques: A review. Ecotoxicol. Environ. Saf. 2018, 156, 125–134. [Google Scholar] [CrossRef]

- Iijima, A.; Sato, K.; Yano, K.; Tago, H.; Kato, M.; Kimura, H.; Furuta, N. Particle size and composition distribution analysis of automotive brake abrasion dusts for the evaluation of antimony sources of airborne particulate matter. Atmos. Environ. 2007, 41, 4908–4919. [Google Scholar] [CrossRef]

- Halada, K. Progress of ecomaterials toward a sustainable society. Curr. Opin. Solid State Mater. Sci. 2003, 7, 209–216. [Google Scholar] [CrossRef]

- Papinniemi, A.; Lai, J.C.S.; Zhao, J.; Loader, L. Brake squeal: A literature review. Appl. Acoust. 2002, 63, 391–400. [Google Scholar] [CrossRef]

- Kchaou, M.; Sellami, A.; Elleuch, R.; Singh, H. Friction characteristics of a brake friction material under different braking conditions. Mater. Des. 2013, 52, 533–540. [Google Scholar] [CrossRef]

- Aranke, O.; Algenaid, W.; Awe, S.; Joshi, S. Coatings for automotive gray cast iron brake discs: A review. Coatings 2019, 9, 552. [Google Scholar] [CrossRef] [Green Version]

- Blau, P.J.; Jolly, B.C.; Qu, J.; Peter, W.H.; Blue, C.A. Tribological investigation of titanium-based materials for brakes. Wear 2007, 263, 1202–1211. [Google Scholar] [CrossRef]

- Chan, D.; Stachowiak, G.W. Review of automotive brake friction materials. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2004, 218, 953–966. [Google Scholar] [CrossRef]

- EL-Tayeb, N.S.M.; Liew, K.W. On the dry and wet sliding performance of potentially new frictional brake pad materials for automotive industry. Wear 2009, 266, 275–287. [Google Scholar] [CrossRef]

- Saindane, U.V.; Soni, S.; Menghani, J.V. Recent research status on synthesis and characterization of natural fibers reinforced polymer composites and modern friction materials—An overview. Mater. Today Proc. 2020, 26, 1616–1620. [Google Scholar] [CrossRef]

- Nosko, O.; Olofsson, U. Effective density of airborne wear particles from car brake materials. J. Aerosol Sci. 2017, 107, 94–106. [Google Scholar] [CrossRef]

- Faga, M.G.; Casamassa, E.; Iodice, V.; Sin, A.; Gautier, G. Morphological and structural features affecting the friction properties of carbon materials for brake pads. Tribol. Int. 2019, 140, 105889. [Google Scholar] [CrossRef]

- Baklouti, M.; Cristol, A.L.; Desplanques, Y.; Elleuch, R. Impact of the glass fibers addition on tribological behavior and braking performances of organic matrix composites for brake lining. Wear 2015, 330, 507–514. [Google Scholar] [CrossRef]

- Kumar, V.V.; Kumaran, S.S. Friction material composite: Types of brake friction material formulations and effects of various ingredients on brake performance-a review. Mater. Res. Express 2019, 6, 082005. [Google Scholar] [CrossRef]

- Wei, L.; Choy, Y.S.; Cheung, C.S. A study of brake contact pairs under different friction conditions with respect to characteristics of brake pad surfaces. Tribol. Int. 2019, 138, 99–110. [Google Scholar] [CrossRef]

- Sinha, A.; Ischia, G.; Menapace, C.; Gialanella, S. Experimental characterization protocols for wear products from disc brake materials. Atmosphere 2020, 11, 1102. [Google Scholar] [CrossRef]

- Aleksendrić, D.; Carlone, P. Soft Computing in the Design and Manufacturing of Composite Materials; Elesevier: Amsterdam, The Netherlands, 2015; ISBN 9781782421801. [Google Scholar]

- Venkatesh, S.; Murugapoopathiraja, K. Scoping review of brake friction material for automotive. Mater. Today Proc. 2019, 16, 927–933. [Google Scholar] [CrossRef]

- Kukutschová, J.; Filip, P. Review of Brake Wear Emissions: A Review of Brake Emission Measurement Studies: Identification of Gaps and Future Needs; Elesevier: Amsterdam, The Netherlands, 2018; ISBN 9780128117705. [Google Scholar]

- Cai, P.; Wang, Y.; Wang, T.; Wang, Q. Effect of resins on thermal, mechanical and tribological properties of friction materials. Tribol. Int. 2015, 87, 1–10. [Google Scholar] [CrossRef]

- Binda, F.F.; De Alvarenga Oliveira, V.; Fortulan, C.A.; Palhares, L.B.; Dos Santos, C.G. Friction elements based on phenolic resin and slate powder. J. Mater. Res. Technol. 2020, 9, 3378–3383. [Google Scholar] [CrossRef]

- Gurunath, P.V.; Bijwe, J. Friction and wear studies on brake-pad materials based on newly developed resin. Wear 2007, 263, 1212–1219. [Google Scholar] [CrossRef]

- Bijwe, J.; Nidhi; Majumdar, N.; Satapathy, B.K. Influence of modified phenolic resins on the fade and recovery behavior of friction materials. Wear 2005, 259, 1068–1078. [Google Scholar] [CrossRef]

- Kim, S.J.; Jang, H. Friction and wear of friction materials containing two different phenolic resins reinforced with aramid pulp. Tribol. Int. 2000, 33, 477–484. [Google Scholar] [CrossRef]

- Wu, Y.; Zeng, M.; Xu, Q.; Hou, S.; Jin, H.; Fan, L. Effects of glass-to-rubber transition of thermosetting resin matrix on the friction and wear properties of friction materials. Tribol. Int. 2012, 54, 51–57. [Google Scholar] [CrossRef]

- Ghosh, P.; Banerjee, S.S.; Khastgir, D. Performance assessment of hybrid fibrous fillers on the tribological and thermo-mechanical behaviors of elastomer modified phenolic resin friction composite. SN Appl. Sci. 2020, 2, 788. [Google Scholar] [CrossRef] [Green Version]

- Kim, S.J.; Cho, M.H.; Lim, D.S.; Jang, H. Synergistic effects of aramid pulp and potassium titanate whiskers in the automotive friction material. Wear 2001, 251, 1484–1491. [Google Scholar] [CrossRef]

- ÖZtüRk, B.; Arslan, F.; Öztürk, S. Effects of different kinds of fibers on mechanical and tribological properties of brake friction materials. Tribol. Trans. 2013, 56, 536–545. [Google Scholar] [CrossRef]

- Singh, T.; Patnaik, A.; Chauhan, R.; Chauhan, P. Selection of brake friction materials using hybrid analytical hierarchy process and vise Kriterijumska Optimizacija Kompromisno Resenje approach. Polym. Compos. 2018, 39, 1655–1662. [Google Scholar] [CrossRef]

- Qu, X.; Zhang, L.; Ding, H.; Liu, G. The Effect of Steel Fiber Orientation on Frictional Properties of Asbestos-Free Friction Materials. Polym. Compos. 2004, 25, 94–101. [Google Scholar] [CrossRef]

- Öztürk, B.; Öztürk, S. Effects of resin type and fiber length on the mechanical and tribological properties of brake friction materials. Tribol. Lett. 2011, 42, 339–350. [Google Scholar] [CrossRef]

- Öztürk, B.; Arslan, F.; Öztürk, S. Hot wear properties of ceramic and basalt fiber reinforced hybrid friction materials. Tribol. Int. 2007, 40, 37–48. [Google Scholar] [CrossRef]

- Casamassa, E.; Gautier, G.; Sin, A.; Kukutschova, J.; Faga, M.G. Granular and platelet titanate as promising brake pads ingredients. Open Ceram. 2021, 6, 100128. [Google Scholar] [CrossRef]

- Kumar, M.; Satapathy, B.K.; Patnaik, A.; Kolluri, D.K.; Tomar, B.S. Evaluation of fade-recovery performance of hybrid friction composites based on ternary combination of ceramic-fibers, ceramic-whiskers, and aramid-fibers. J. Appl. Polym. Sci. 2012, 124, 3650–3661. [Google Scholar] [CrossRef]

- Singh, T.; Tiwari, A.; Patnaik, A.; Chauhan, R.; Ali, S. Influence of wollastonite shape and amount on tribo-performance of non-asbestos organic brake friction composites. Wear 2017, 386, 157–164. [Google Scholar] [CrossRef]

- Aranganathan, N.; Bijwe, J. Special grade of graphite in NAO friction materials for possible replacement of copper. Wear 2015, 330, 515–523. [Google Scholar] [CrossRef]

- Jang, H.; Ko, K.; Kim, S.J.; Basch, R.H.; Fash, J.W. The effect of metal fibers on the friction performance of automotive brake friction materials. Wear 2004, 256, 406–414. [Google Scholar] [CrossRef]

- Sterle, W.; Prietzel, C.; Kloß, H.; Dmitriev, A.I. On the role of copper in brake friction materials. Tribol. Int. 2010, 43, 2317–2326. [Google Scholar] [CrossRef]

- Sundarkrishnaa, K.L. Friction Material Composites; Springer International Publishing: Berlin/Heidelberg, Germany, 2015. [Google Scholar]

- Singh, T.; Patnaik, A.; Chauhan, R.; Rishiraj, A. Assessment of braking performance of lapinus–wollastonite fibre reinforced friction composite materials. J. King Saud Univ.-Eng. Sci. 2017, 29, 183–190. [Google Scholar] [CrossRef] [Green Version]

- Tátrai, E.; Kováčiková, Z.; Broózik, M.; Six, É. Pulmonary toxicity of wollastonite in vivo and in vitro. J. Appl. Toxicol. 2004, 24, 147–154. [Google Scholar] [CrossRef] [PubMed]

- Xin, X.; Xu, C.G.; Qing, L.F. Friction properties of sisal fibre reinforced resin brake composites. Wear 2007, 262, 736–741. [Google Scholar] [CrossRef]

- Fei, J.; Wang, H.K.; Huang, J.F.; Zeng, X.R.; Luo, W. Effects of carbon fiber length on the tribological properties of paper-based friction materials. Tribol. Int. 2014, 72, 179–186. [Google Scholar] [CrossRef]

- Bagheri Kazem Abadi, S.; Khavandi, A.; Kharazi, Y. Effects of mixing the steel and carbon fibers on the friction and wear properties of a PMC friction material. Appl. Compos. Mater. 2010, 17, 151–158. [Google Scholar] [CrossRef]

- Manoharan, S.; Sai Krishnan, G.; Ganesh Babu, L.; Vijay, R.; Lenin Singaravelu, D. Synergistic effect of red mud-iron sulfide particles on fade-recovery characteristics of non-asbestos organic brake friction composites. Mater. Res. Express 2019, 6, 105311. [Google Scholar] [CrossRef]

- Shin, M.W.; Kim, Y.H.; Jang, H. Effect of the Abrasive Size on the Friction Effectiveness and Instability of Brake Friction Materials: A Case Study with Zircon. Tribol. Lett. 2014, 55, 371–379. [Google Scholar] [CrossRef]

- Jang, H.; Kim, S.J. The effects of antimony trisulfide (Sb2S3) and zirconium silicate (ZrSiO4) in the automotive brake friction material on friction characteristics. Wear 2000, 239, 229–236. [Google Scholar] [CrossRef]

- Jeganmohan, S.; Sugozu, B.; Kumar, M.; Selvam, D.R. Experimental Investigation on the Friction and Wear Characteristics of Palm Seed Powder Reinforced Brake Pad Friction Composites. J. Inst. Eng. Ser. D 2020, 101, 61–69. [Google Scholar] [CrossRef]

- Matějka, V.; Lu, Y.; Fan, Y.; Kratošová, G.; Lešková, J. Effects of silicon carbide in semi-metallic brake materials on friction performance and friction layer formation. Wear 2008, 265, 1121–1128. [Google Scholar] [CrossRef]

- Cho, M.H.; Ju, J.; Kim, S.J.; Jang, H. Tribological properties of solid lubricants (graphite, Sb2S3, MoS2) for automotive brake friction materials. Wear 2006, 260, 855–860. [Google Scholar] [CrossRef]

- Kim, S.J.; Hyung Cho, M.; Hyung Cho, K.; Jang, H. Complementary effects of solid lubricants in the automotive brake lining. Tribol. Int. 2007, 40, 15–20. [Google Scholar] [CrossRef]

- Kim, S.S.; Hwang, H.J.; Shin, M.W.; Jang, H. Friction and vibration of automotive brake pads containing different abrasive particles. Wear 2011, 271, 1194–1202. [Google Scholar] [CrossRef]

- Dufresne, A.; Bégin, R.; Dion, C.; Jagirdar, J.; Rom, W.N.; Loosereewanich, P.; Muir, D.C.F.; Ritchie, A.C.; Perrault, G. Angular and fibrous particles in lung in relation to silica-induced diseases. Int. Arch. Occup. Environ. Health 1998, 71, 263–269. [Google Scholar] [CrossRef] [PubMed]

- Rödelsperger, K.; Brückel, B. The carcinogenicity of WHO fibers of silicon carbide: SiC whiskers compared to cleavage fragments of granular SiC. Inhal. Toxicol. 2006, 18, 623–631. [Google Scholar] [CrossRef] [PubMed]

- Manoharan, S.; Vijay, R.; Lenin Singaravelu, D.; Kchaou, M. Experimental Investigation on the Tribo-Thermal Properties of Brake Friction Materials Containing Various Forms of Graphite: A Comparative Study. Arab. J. Sci. Eng. 2019, 44, 1459–1473. [Google Scholar] [CrossRef]

- Balaji, S.; Mohamed Aslam Noorani, A.B. Tribological performance of graphene/graphite filled phenolic composites—A comparative study. Compos. Commun. 2019, 15, 34–39. [Google Scholar] [CrossRef]

- Österle, W.; Dmitriev, A.I. The role of solid lubricants for brake friction materials. Lubricants 2016, 4, 5. [Google Scholar] [CrossRef] [Green Version]

- Suvorov, S.A.; Skurikhin, V.V. Vermiculite-a promising material for high-temperature heat insulators. Refract. Ind. Ceram. 2003, 44, 186–193. [Google Scholar] [CrossRef]

- Xu, X.L.; Lu, X.; Yang, D.L.; Zhang, E. Effects of vermiculite on the tribological behavior of PI-matrix friction materials. IOP Conf. Ser. Mater. Sci. Eng. 2015, 87, 012024. [Google Scholar] [CrossRef]

- Chamnipan, R.; Chutima, S.; Uthaisangsuk, V. Processing and characterization of nano filler containing friction material. Mater. Today Proc. 2018, 5, 9467–9475. [Google Scholar] [CrossRef]

- Dante, R.C. Abrasives, Ceramic, and Inorganic Materials; Elsevier: Amsterdam, The Netherlands, 2016. [Google Scholar]

- Egeonu, D.; Oluah, C.; Okolo, P.N. Production of Eco-Friendly Brake Pad Using Raw Materials Sourced Locally In Nsukka. Int. J. Energy Technol. Policy 2015, 5, 47–54. [Google Scholar]

- Kosbe, P.; Patil, P.; Manickam, M.; Ramamurthy, G. Effect of hexagonal boron nitride (h-BN) inclusion on thermal characteristics of disc brake friction composites. Diam. Relat. Mater. 2020, 107, 107895. [Google Scholar] [CrossRef]

- Jang, H.; Lee, J.S.; Fash, J.W. Compositional effects of the brake friction material on creep groan phenomena. Wear 2001, 250, 1477–1483. [Google Scholar] [CrossRef]

- Almaslow, A.; Ghazali, M.J.; Talib, R.J.; Ratnam, C.T.; Azhari, C.H. Effects of epoxidized natural rubber-alumina nanoparticles (ENRAN) composites in semi-metallic brake friction materials. Wear 2013, 302, 1392–1396. [Google Scholar] [CrossRef]

- Nakason, C.; Wannavilai, P.; Kaesaman, A. Effect of vulcanization system on properties of thermoplastic vulcanizates based on epoxidized natural rubber/polypropylene blends. Polym. Test. 2006, 25, 34–41. [Google Scholar] [CrossRef]

- Thiyagarajan, V.; Kalaichelvan, K.; Vijay, R.; Lenin Singaravelu, D. Influence of thermal conductivity and thermal stability on the fade and recovery characteristics of non-asbestos semi-metallic disc brake pad. J. Braz. Soc. Mech. Sci. Eng. 2016, 38, 1207–1219. [Google Scholar] [CrossRef]

- Satapathy, B.K.; Patnaik, A.; Dadkar, N.; Kolluri, D.K.; Tomar, B.S. Influence of vermiculite on performance of flyash-based fibre-reinforced hybrid composites as friction materials. Mater. Des. 2011, 32, 4354–4361. [Google Scholar] [CrossRef]

- Sudhan Raj, J.; Christy, T.V.; Darius Gnanaraj, S.; Sugozu, B. Influence of calcium sulfate whiskers on the tribological characteristics of automotive brake friction materials. Eng. Sci. Technol. Int. J. 2020, 23, 445–451. [Google Scholar] [CrossRef]

- Arsada, R.; Surojo, E.; Ariawan, D.; Muhayat, N.; Raharjo, W.W. Effect of NBR (Nitrile Butadiene Rubber) on flexural strength of composite friction brake. IOP Conf. Ser. Mater. Sci. Eng. 2018, 420, 012057. [Google Scholar] [CrossRef] [Green Version]

- Basfar, A.A.; Abdel-Aziz, M.M.; Mofti, S. Influence of different curing systems on the physico-mechanical properties and stability of SBR and NR rubbers. Radiat. Phys. Chem. 2002, 63, 81–87. [Google Scholar] [CrossRef]

- Singaravelu, D.L.; Vijay, R.; Filip, P. Influence of various cashew friction dusts on the fade and recovery characteristics of non-asbestos copper free brake friction composites. Wear 2019, 426–427, 1129–1141. [Google Scholar] [CrossRef]

- Lagel, M.C.; Hai, L.; Pizzi, A.; Basso, M.C.; Delmotte, L.; Abdalla, S.; Zahed, A.; Al-Marzouki, F.M. Automotive brake pads made with a bioresin matrix. Ind. Crops Prod. 2016, 85, 372–381. [Google Scholar] [CrossRef]

- Agrawal, A.; Kaushik, N.; Biswas, S. Derivatives and Applications of Lignin–An Insight. SciTech J. 2014, 1, 30–36. [Google Scholar]

- Nehez, N.J. Lignin-based friction material. Can. Pat. 1997, 2, 242–554. [Google Scholar]

- US9534650B2-Friction Material-Google Patents. Available online: https://patents.google.com/patent/US9534650B2/en?q=brake+pad%2C+lignin&oq=brake+pad%2C+lignin (accessed on 18 June 2021).

- Park, J.; Hwang, H.; Kim, J.Y.; Choi, J.W. Applicability of lignin polymers for automobile brake pads as binder and filler materials and their performance characteristics. Environ. Technol. 2020, 41, 488–497. [Google Scholar] [CrossRef]

- Lee, P.W.; Filip, P. Friction and wear of Cu-free and Sb-free environmental friendly automotive brake materials. Wear 2013, 302, 1404–1413. [Google Scholar] [CrossRef]

- Xicola, A.S.; Angeleri, A.; Lupone, F.; Caldarola, D.; Conte, A.; Colombo, P. Friction Material, in Particular for the Manufacturing of a Brake Pad, and Associated Preparation Methods. 2015. Available online: https://patents.google.com/patent/US20170016500 (accessed on 20 January 2022).

- Thyavihalli Girijappa, Y.G.; Mavinkere Rangappa, S.; Parameswaranpillai, J.; Siengchin, S. Natural Fibers as Sustainable and Renewable Resource for Development of Eco-Friendly Composites: A Comprehensive Review. Front. Mater. 2019, 6, 226. [Google Scholar] [CrossRef]

- Riccieri, J.E.; De Carvalho, L.H.; Vázquez, A. Interfacial properties and initial step of the water sorption in unidirectional unsaturated polyester/vegetable fiber composites. Polym. Compos. 1999, 20, 29–37. [Google Scholar] [CrossRef]

- Srinivasa, C.V.; Bharath, K.N. Impact and hardness properties of areca fiber-epoxy reinforced composites. J. Mater. Environ. Sci. 2011, 2, 351–356. [Google Scholar]

- Li, X.; Tabil, L.G.; Panigrahi, S. Chemical treatments of natural fiber for use in natural fiber-reinforced composites: A review. J. Polym. Environ. 2007, 15, 25–33. [Google Scholar] [CrossRef]

- Vilay, V.; Mariatti, M.; Mat Taib, R.; Todo, M. Effect of fiber surface treatment and fiber loading on the properties of bagasse fiber-reinforced unsaturated polyester composites. Compos. Sci. Technol. 2008, 68, 631–638. [Google Scholar] [CrossRef]

- Methacanon, P.; Weerawatsophon, U.; Sumransin, N.; Prahsarn, C.; Bergado, D.T. Properties and potential application of the selected natural fibers as limited life geotextiles. Carbohydr. Polym. 2010, 82, 1090–1096. [Google Scholar] [CrossRef]

- Lee, S.H.; Wang, S. Biodegradable polymers/bamboo fiber biocomposite with bio-based coupling agent. Compos. Part A Appl. Sci. Manuf. 2006, 37, 80–91. [Google Scholar] [CrossRef]

- Aziz, S.H.; Ansell, M.P. The effect of alkalization and fibre alignment on the mechanical and thermal properties of kenaf and hemp bast fibre composites: Part 1—Polyester resin matrix. Compos. Sci. Technol. 2004, 64, 1219–1230. [Google Scholar] [CrossRef]

- Rashid, B.; Leman, Z.; Jawaid, M.; Ghazali, M.J.; Ishak, M.R.; Abdelgnei, M.A. Dry sliding wear behavior of untreated and treated sugar palm fiber filled phenolic composites using factorial technique. Wear 2017, 380–381, 26–35. [Google Scholar] [CrossRef]

- Ikpambese, K.K.; Gundu, D.T.; Tuleun, L.T. Evaluation of palm kernel fibers (PKFs) for production of asbestos-free automotive brake pads. J. King Saud Univ.-Eng. Sci. 2016, 28, 110–118. [Google Scholar] [CrossRef] [Green Version]

- Srinivasa, C.V.; Arifulla, A.; Goutham, N.; Santhosh, T.; Jaeethendra, H.J.; Ravikumar, R.B.; Anil, S.G.; Santhosh Kumar, D.G.; Ashish, J. Static bending and impact behaviour of areca fibers composites. Mater. Des. 2011, 32, 2469–2475. [Google Scholar] [CrossRef]

- Dinakaran, K.; Ramesh, H.; Joseph, A.D.; Murugan, R.; Jothi, S. Development and characterization of areca fiber reinforced polymer composite. Mater. Today Proc. 2019, 18, 934–940. [Google Scholar] [CrossRef]

- Bashir, M.; Qayoum, A.; Saleem, S.S. Influence of lignocellulosic banana fiber on the thermal stability of brake pad material. Mater. Res. Express 2019, 6, 115551. [Google Scholar] [CrossRef]

- Zhen-Yu, W.; Jie, W.; Feng-Hong, C.; Yun-Hai, M.; Singh, T.; Fekete, G. Influence of banana fiber on physicomechanical and tribological properties of phenolic based friction composites. Mater. Res. Express 2019, 6, 075103. [Google Scholar] [CrossRef]

- Nabi Saheb, D.; Jog, J.P. Natural fiber polymer composites: A review. Adv. Polym. Technol. 1999, 18, 351–363. [Google Scholar] [CrossRef]

- Gurunathan, T.; Mohanty, S.; Nayak, S.K. A review of the recent developments in biocomposites based on natural fibres and their application perspectives. Compos. Part A Appl. Sci. Manuf. 2015, 77, 1–25. [Google Scholar] [CrossRef]

- Hemnath, A.; Anbuchezhiyan, G.; NanthaKumar, P.; Senthilkumar, N. Tensile and flexural behaviour of rice husk and sugarcane bagasse reinforced polyester composites. Mater. Today Proc. 2021, 46, 3451–3454. [Google Scholar] [CrossRef]

- Binoj, J.S.; Raj, R.E.; Sreenivasan, V.S.; Thusnavis, G.R. Morphological, Physical, Mechanical, Chemical and Thermal Characterization of Sustainable Indian Areca Fruit Husk Fibers (Areca Catechu L.) as Potential Alternate for Hazardous Synthetic Fibers. J. Bionic Eng. 2016, 13, 156–165. [Google Scholar] [CrossRef]

- Ma, Y.; Wu, S.; Zhuang, J.; Tong, J.; Xiao, Y.; Qi, H. The evaluation of physio-mechanical and tribological characterization of friction composites reinforced by waste corn stalk. Materials 2018, 11, 901. [Google Scholar] [CrossRef] [Green Version]

- Lawal, S.S.; Ademoh, N.A.; Bala, K.C.; Abdulrahman, A.S. Reviews in Automobile Brake Pads Production and Prospects of Agro Base Composites of Cashew Nut Shells and Nigerian Gum Arabic Binder. Covenant J. Eng. Technol. 2019, 3, 2682–5317. Available online: https://journals.covenantuniversity.edu.ng/index.php/cjet/article/view/1797 (accessed on 20 January 2022).

- Ahmad, F.; Choi, H.S.; Park, M.K. A Review: Natural Fiber Composites Selection in View of Mechanical, Light Weight, and Economic Properties; Wiley-VCH Verlag: Weinheim, Germany, 2015; Volume 300, pp. 10–24. [Google Scholar]

- Ma, Y.; Liu, Y.; Ma, S.; Wang, H.; Gao, Z.; Sun, J.; Tong, J.; Guo, L. Friction and wear properties of dumbbell-shaped jute fiber-reinforced friction materials. J. Appl. Polym. Sci. 2014, 131. [Google Scholar] [CrossRef]

- Fiore, V.; Di Bella, G.; Valenza, A. The effect of alkaline treatment on mechanical properties of kenaf fibers and their epoxy composites. Compos. Part B Eng. 2015, 68, 14–21. [Google Scholar] [CrossRef]

- Dittenber, D.B.; Gangarao, H.V.S. Critical review of recent publications on use of natural composites in infrastructure. Compos. Part A Appl. Sci. Manuf. 2012, 43, 1419–1429. [Google Scholar] [CrossRef]

- Liu, Y.; Ma, Y.; Che, J.; Duanmu, L.; Zhuang, J.; Tong, J. Natural fibre reinforced non-asbestos organic non-metallic friction composites: Effect of abaca fibre on mechanical and tribological behaviour. Mater. Res. Express 2018, 5, 055101. [Google Scholar] [CrossRef]

- Bongarde, U.S.; Shinde, V. Review on natural fiber reinforcement polymer composites. Int. J. Eng. Sci. Innov. Technol. 2014, 3, 431–436. [Google Scholar]

- Fu, Z.; Suo, B.; Yun, R.; Lu, Y.; Wang, H.; Qi, S.; Jiang, S.; Lu, Y.; Matejka, V. Development of eco-friendly brake friction composites containing flax fibers. J. Reinf. Plast. Compos. 2012, 31, 681–689. [Google Scholar] [CrossRef] [Green Version]

- Singh, T.; Pruncu, C.I.; Gangil, B.; Singh, V.; Fekete, G. Comparative performance assessment of pineapple and Kevlar fibers based friction composites. J. Mater. Res. Technol. 2020, 9, 1491–1499. [Google Scholar] [CrossRef]

- Biocomposites Reinforced with Natural Fibers: 2000–2010|Elsevier Enhanced Reader. Available online: https://reader.elsevier.com/reader/sd/pii/S0079670012000391?token=E40D95EC33905B639F8E3841ED0467C85229DD51EF890FEE718C193480543DB0E70530DA42F4C1428D0A91B1DD0478DF (accessed on 29 March 2021).

- Bernard, S.S.; Jayakumari, L.S. Pressure and temperature sensitivity analysis of palm fiber as a biobased reinforcement material in brake pad. J. Braz. Soc. Mech. Sci. Eng. 2018, 40, 1–12. [Google Scholar] [CrossRef]

- Sai Krishnan, G.; Ganesh Babu, L.; Pradhan, R.; Kumar, S. Study on tribological properties of palm kernel fiber for brake pad applications. Mater. Res. Express 2019, 7, 015102. [Google Scholar] [CrossRef]

- Ravikumar, K.; Pridhar, T. Evaluation on properties and characterization of asbestos free palm kernel shell fibre (PKSF)/polymer composites for brake pads. Mater. Res. Express 2019, 6, 1165d2. [Google Scholar] [CrossRef]

- Sai Krishnan, G.; Jayakumari, L.S.; Ganesh Babu, L.; Suresh, G. Investigation on the physical, mechanical and tribological properties of areca sheath fibers for brake pad applications. Mater. Res. Express 2019, 6, 085109. [Google Scholar] [CrossRef]

- Mustafa, A.; Abdollah, M.F.B.; Shuhimi, F.F.; Ismail, N.; Amiruddin, H.; Umehara, N. Selection and verification of kenaf fibres as an alternative friction material using Weighted Decision Matrix method. Mater. Des. 2015, 67, 577–582. [Google Scholar] [CrossRef]

- Ramesh, P.; Krishnan, G.S.; Ragu, R.; Suresh, G.; Srinivasan, S. Investigation on the Physical/Mechanical Properties of NAO brake friction Composites by using Kenaf fiber. IOP Conf. Ser. Mater. Sci. Eng. 2020, 961, 012016. [Google Scholar] [CrossRef]

- Paramasivam, K.; Jayaraj, J.J.; Ramar, K.; Subramani, Y.; Ajithkumar, K.; Kabilan, N. Evaluation of natural fibers for the production of automotive brake pads replacement for asbestos brake pad. AIP Conf. Proc. 2020, 2311, 040005. [Google Scholar]

- Idris, U.D.; Aigbodion, V.S.; Abubakar, I.J.; Nwoye, C.I. Eco-friendly asbestos free brake-pad: Using banana peels. J. King Saud Univ.-Eng. Sci. 2015, 27, 185–192. [Google Scholar] [CrossRef] [Green Version]

- Sai Krishnan, G.; Shanmugasundar, G.; Vanitha, M.; Sivashanmugam, N. Mechanical Properties of Chemically Treated Banana and Ramie Fibre Reinforced Polypropylene Composites. IOP Conf. Ser. Mater. Sci. Eng. 2020, 961, 012013. [Google Scholar] [CrossRef]

- Juan, R.S.; Kurniawan, C.; Marbun, J.; Simamora, P. Mechanical properties of brake pad composite made from candlenut shell and coconut shell. J. Phys. Conf. Ser. 2020, 1428, 012018. [Google Scholar] [CrossRef] [Green Version]

- Agunsoye, J.O.; Aigbodion, V.S. Bagasse filled recycled polyethylene bio-composites: Morphological and mechanical properties study. Results Phys. 2013, 3, 187–194. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y.; Wang, L.; Liu, D.; Ma, Y.; Tian, Y.; Tong, J.; Senthamaraikannan, P.; Saravanakumar, S. Evaluation of wear resistance of corn stalk fiber reinforced brake friction materials prepared by wet granulation. Wear 2019, 432–433, 102918. [Google Scholar] [CrossRef]

- Satapathy, B.K.; Bijwe, J. Performance of friction materials based on variation in nature of organic fibres Part I. Fade and recovery behaviour. Wear 2004, 257, 573–584. [Google Scholar] [CrossRef]

- Mishra, V.; Biswas, S. Three-body abrasive wear behavior of short jute fiber reinforced epoxy composites. Polym. Compos. 2016, 37, 270–278. [Google Scholar] [CrossRef]

- Sun, C.; Liu, A.; Du, G. Plasma treatment of bamboo fibers on the tribological property of polyimide composite filled with graphite. Surf. Interface Anal. 2018, 50, 234–239. [Google Scholar] [CrossRef]

- Marewad, D.S.; Singh, G.P.; Adivarekar, R.V. Asbestos free brake pad using Micro cellulose fibre for automotive industry. Int. J. Adv. Res. Ideas Innov. Technol. 2018, 4, 685–690. [Google Scholar]

- Tavangar, R.; Moghadam, H.A.; Khavandi, A.; Banaeifar, S. Comparison of dry sliding behavior and wear mechanism of low metallic and copper-free brake pads. Tribol. Int. 2020, 151, 106416. [Google Scholar] [CrossRef]

- Sai Krishnan, G.; Pravin Kumar, J.; Shanmugasundar, G.; Vanitha, M.; Sivashanmugam, N. Investigation on the alkali treatment of Demostachya Bipinnata fibers for automobile applications-A green composite. Mater. Today Proc. 2020, 43, 828–831. [Google Scholar] [CrossRef]

- Ganesh Babu, L. Influence of benzoyl chloride treatment on the tribological characteristics of Cyperus pangorei fibers based non-asbestos brake friction composites. Mater. Res. Express 2020, 7, 015303. [Google Scholar] [CrossRef]

- Bajpai, P.K.; Singh, I.; Madaan, J. Tribological behavior of natural fiber reinforced PLA composites. Wear 2013, 297, 829–840. [Google Scholar] [CrossRef]

- Mylsamy, B.; Chinnasamy, V.; Palaniappan, S.K.; Subramani, S.P.; Gopalsamy, C. Effect of surface treatment on the tribological properties of Coccinia Indica cellulosic fiber reinforced polymer composites. J. Mater. Res. Technol. 2020, 9, 16423–16434. [Google Scholar] [CrossRef]

- Akıncıoğlu, G.; Öktem, H.; Uygur, I.; Akıncıoğlu, S. Determination of Friction-Wear Performance and Properties of Eco-Friendly Brake Pads Reinforced with Hazelnut Shell and Boron Dusts. Arab. J. Sci. Eng. 2018, 43, 4727–4737. [Google Scholar] [CrossRef]

- Sim, J.; Park, C.; Moon, D.Y. Characteristics of basalt fiber as a strengthening material for concrete structures. Compos. Part B Eng. 2005, 36, 504–512. [Google Scholar] [CrossRef]

- Jacob Moses, A.; Suresh Babu, A.; Ananda Kumar, S. Analysis of physical properties and wear behavior of phenol formaldehyde—Basalt fiber reinforced brake pad. Mater. Today Proc. 2020, 33, 1128–1132. [Google Scholar] [CrossRef]

- Zhao, X.; Ouyang, J.; Yang, H.; Tan, Q. Effect of basalt fibers for reinforcing resin-based brake composites. Minerals 2020, 10, 490. [Google Scholar] [CrossRef]

- Ilanko, A.K.; Vijayaraghavan, S. Wear behavior of asbestos-free eco-friendly composites for automobile brake materials. Friction 2016, 4, 144–152. [Google Scholar] [CrossRef] [Green Version]

- Atmika, I.K.A.; Subagia, I.D.G.A.; Surata, I.W.; Sutantra, I.N. Hardness and wear rate of basalt/alumina/shellfish powder reinforced phenolic resin matrix hybrid composite brake lining pads. IOP Conf. Ser. Mater. Sci. Eng. 2019, 539, 012012. [Google Scholar] [CrossRef]

- Abutu, J.; Lawal, S.A.; Ndaliman, M.B.; Lafia-Araga, R.A.; Adedipe, O.; Choudhury, I.A. Effects of process parameters on the properties of brake pad developed from seashell as reinforcement material using grey relational analysis. Eng. Sci. Technol. Int. J. 2018, 21, 787–797. [Google Scholar] [CrossRef]

- Maleque, M.A.; Atiqah, A.; Atiqah, A. Development and Characterization of Coir Fibre Reinforced Composite Brake Friction Materials. Arab. J. Sci. Eng. 2013, 38, 3191–3199. [Google Scholar] [CrossRef]

- Li, M. Palm Fiber-Reinforced Environment-Friendly Type Brake Pad and Preparation Method Thereof. 2013. Available online: https://worldwide.espacenet.com/patent/search/family/049689956/publication/CN103436236A?q=Palm%20fiber-reinforced%20environment-friendly%20type%20brake%20pad%20and%20preparation%20method%20thereof (accessed on 20 January 2022).

- Li, M. Brake Pad for Flax Fiber Reinforced Environmental-Friendly Car and Preparation Method Thereof. 2013. Available online: https://patents.google.com/patent/CN103361031B/en (accessed on 20 January 2022).

- Huang, X. Environment-Friendly Brake Pad. 2015. Available online: https://worldwide.espacenet.com/patent/search/family/054273075/publication/CN104976258A?q=pn%3DCN104976258A (accessed on 20 January 2022).

- Li, M. Automobile Brake Pad Mixing with Bamboo Fibers. 2013. Available online: https://worldwide.espacenet.com/patent/search/family/049648539/publication/CN103423345A?q=pn%3DCN103423345A (accessed on 20 January 2022).

- Jiang, Y. Hibiscus Manihot Fiber Reinforced Environment-Friendly Brake Pad and Preparation Method Thereof. 2016. Available online: https://worldwide.espacenet.com/patent/search/family/057090887/publication/CN106015400A?q=Hibiscus%20manihot%20fiber%20reinforced%20environment-friendly%20brake%20pad%20AND%20preparation%20method%20thereof%202016 (accessed on 20 January 2022).

- Li, X. Method for Preparing Brake Pad from Basalt Fiber. 2016. Available online: https://worldwide.espacenet.com/patent/search/family/058837619/publication/CN106641049A?q=pn%3DCN106641049A (accessed on 20 January 2022).

- Bakirdere, S.; Orenay, S.; Korkmaz, M. Effect of Boron on Human Health. Open Miner. Process. J. 2014, 3, 54–59. [Google Scholar] [CrossRef] [Green Version]

- Turkez, H.; Geyikoglu, F.; Tatar, A.; Keles, M.S.; Kaplan, I. The effects of some boron compounds against heavy metal toxicity in human blood. Exp. Toxicol. Pathol. 2012, 64, 93–101. [Google Scholar] [CrossRef]

- Jeganmohan, S.; Sugozu, B. Usage of powder pinus brutia cone and colemanite combination in brake friction composites as friction modifier. Mater. Today Proc. 2019, 27, 2072–2075. [Google Scholar] [CrossRef]

- Sugozu, I.; Mutlu, I.; Sugozu, K.B. The effect of ulexite to the tribological properties of brake lining materials. Polym. Compos. 2018, 39, 55–62. [Google Scholar] [CrossRef]

- Jajuha, U.; Ahlawat, V. Investigation of three-body abrasive wear characteristics of white ark shell powder. Mater. Today Proc. 2020, 44, 4315–4323. [Google Scholar] [CrossRef]

- Pinca Bretotean, C.; Lemle, D.; Szabo, A.; Bretotean, C.P.; Lemle, L.D.; Szabo, A. Ecological composites materials for brake pads using shells as filler material. Mater. Plast. 2019, 56, 588. [Google Scholar] [CrossRef]

- Akıncıoğlu, G.; Akıncıoğlu, S.; Öktem, H.; Uygur, İ. Wear response of non-asbestos brake pad composites reinforced with walnut shell dust. J. Aust. Ceram. Soc. 2020, 56, 1061–1072. [Google Scholar] [CrossRef]

- Obot, M.U.; Yawas, D.S.; Aku, S.Y. Development of an abrasive material using periwinkle shells. J. King Saud Univ.-Eng. Sci. 2017, 29, 284–288. [Google Scholar] [CrossRef] [Green Version]

- Yawas, D.S.; Aku, S.Y.; Amaren, S.G. Morphology and properties of periwinkle shell asbestos-free brake pad. J. King Saud Univ.-Eng. Sci. 2016, 28, 103–109. [Google Scholar] [CrossRef] [Green Version]

- Solomon, W.C.; Lilly, M.T.; Sodiki, J.I. Production of Asbestos-free Brake Pad Using Groundnut Shell as Filler Material. Int. J. Sci. Eng. Invent. 2018, 4, 21-to. [Google Scholar] [CrossRef]

- Keskin, A. Investigation of using natural zeolite in brake pad. Sci. Res. Essays 2011, 6, 4893–4904. [Google Scholar] [CrossRef]

- Chandradass, J.; Surabhi, M.A.; Sethupathi, P.B.; Jawahar, P. Development of low cost brake pad material using asbestos free sugarcane bagasse ash hybrid composites. Mater. Today Proc. 2021, 45, 7050–7057. [Google Scholar] [CrossRef]

- Primaningtyas, W.E.; Sakura, R.R.; Suheni; Syafi’I, I.; Adhyaksa, A.A.G.A.D. Asbestos-free Brake Pad Using Composite Polymer Strengthened with Rice Husk Powder. IOP Conf. Ser. Mater. Sci. Eng. 2019, 462, 012015. [Google Scholar] [CrossRef]

- Bahari, S.A.; Isa, K.H.; Kassim, M.A.; Mohamed, Z.; Othman, E.A. Investigation on hardness and impact resistance of automotive brake pad composed with rice husk dust. AIP Conf. Proc. 2012, 1455, 155–161. [Google Scholar]

- Singh, T.; Patnaik, A.; Gangil, B.; Chauhan, R. Optimization of tribo-performance of brake friction materials: Effect of nano filler. Wear 2015, 324–325, 10–16. [Google Scholar] [CrossRef]

- Singh, T.; Rathi, M.K.; Patnaik, A.; Chauhan, R.; Ali, S.; Fekete, G. Application of waste tire rubber particles in non-asbestos organic brake friction composite materials. Mater. Res. Express 2019, 6, 035703. [Google Scholar] [CrossRef]

- Manoharan, S.; Shihab, A.I.; Alemdar, A.S.A.; Babu, L.G.; Vijay, R.; Lenin Singaravelu, D. Influence of recycled basalt-aramid fibres integration on the mechanical and thermal properties of brake friction composites. Mater. Res. Express 2019, 6, 115310. [Google Scholar] [CrossRef]

- Singh, T.; Patnaik, A.; Chauhan, R. Optimization of tribological properties of cement kiln dust-filled brake pad using grey relation analysis. Mater. Des. 2016, 89, 1335–1342. [Google Scholar] [CrossRef]

- Mohanty, S.; Chugh, Y.P. Development of fly ash-based automotive brake lining. Tribol. Int. 2007, 40, 1217–1224. [Google Scholar] [CrossRef]

- Öztürk, B.; Mutlu, T. Effects of Zinc Borate and Fly Ash on the Mechanical and Tribological Characteristics of Brake Friction Materials. Tribol. Trans. 2016, 59, 622–631. [Google Scholar] [CrossRef]

- Dadkar, N.; Tomar, B.S.; Satapathy, B.K.; Patnaik, A. Performance assessment of hybrid composite friction materials based on flyash-rock fibre combination. Mater. Des. 2010, 31, 723–731. [Google Scholar] [CrossRef]

- Wang, T.M.; Hou, K.H.; Chang, Y.T.; Lee, W.C.; Ger, M. Der The preparation of slag fiber and its application in heat resistant friction composites. Mater. Des. 2010, 31, 4296–4301. [Google Scholar] [CrossRef]

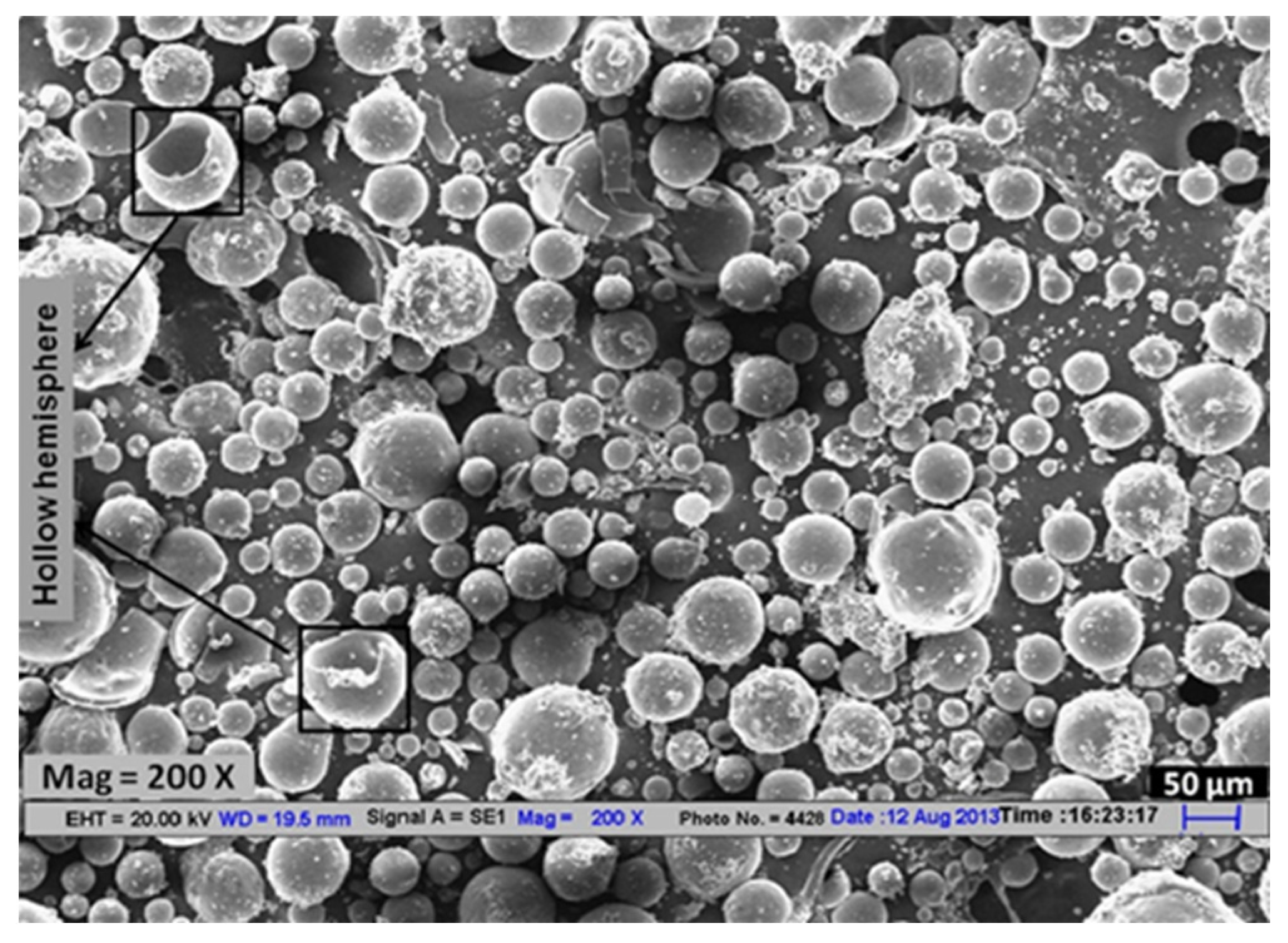

- Tiwari, A.; Jaggi, H.S.; Kachhap, R.K.; Satapathy, B.K.; Maiti, S.N.; Tomar, B.S. Comparative performance assessment of cenosphere and barium sulphate based friction composites. Wear 2014, 309, 259–268. [Google Scholar] [CrossRef]

- Tasala Gradin, K.; Åström, A.H. Evaluation of an Eco Audit tool-through an LCA of a novel car disc brake. In Proceedings of the DS 91 Proceedings of NordDesign 2018, Linköping, Sweden, 14–17 August 2018. [Google Scholar]

- Hu, X.; Wang, N.; Pan, P.; Bai, T. Performance evaluation of asphalt mixture using brake pad waste as mineral filler. Constr. Build. Mater. 2017, 138, 410–417. [Google Scholar] [CrossRef]

- Bai, T.; Song, Z.; Wang, H.; Wu, Y.; Huang, W. Performance evaluation of metakaolin geopolymer modified by different solid wastes. J. Clean. Prod. 2019, 226, 114–121. [Google Scholar] [CrossRef]

| Indicator | Averaging Period | Level | Primary/Secondary | Form | Agency |

|---|---|---|---|---|---|

| PM10 | 24 h mean | 150 μg/m3 | Primary and Secondary | Not to be exceeded on more than once per year on average over a 3-year period | NAAQS EPA 1 [13] |

| PM2.5 | Annual mean | 12 μg/m3 | Primary | Averaged over 3 years | |

| Annual mean | 15 μg/m3 | Secondary | Averaged over 3 years | ||

| 24 h | 35 μg/m3 | Primary and secondary | Annual arithmetic mean, averaged over 3 years | ||

| PM10 | Annual | 20 μg/m3 | - | - | WHO 2 [13] |

| 24 h | 50 μg/m3 | - | - | ||

| PM2.5 | Annual | 10 μg/m3 | - | - | |

| 24 h | 25 μg/m3 | - | - |

| Friction Materials Typologies | Common Content | Main Characteristics |

|---|---|---|

| Low metallic | Fe (10–50%), steel, copper and copper alloys and different abrasives |

|

| Semimetallic | More than 50% Fe and steel fiber and alloy, porous iron powder, abrasives and graphite/coke lubricants |

|

| NAO | 50% metallic components, friction dust, phenolic resin, graphite and other reinforcements |

|

| Fibrous Material | Advantage | Drawback | |

|---|---|---|---|

| Metallic | Steel |

|

|

| Copper and copper alloy |

|

| |

| Brass |

|

| |

| Organic | Kevlar |

|

|

| Inorganic | Wollastonite |

|

|

| Potassium titanate |

|

| |

| Glass |

|

| |

| Carbon fiber |

|

|

| Abrasive | Zircon, zirconium silicate, quartz, alumina, zirconia, silicon carbide, chromium oxide, silica, mullite. | [82,83,84,85] |

| Lubricant | Antimony trisulphide, graphite, molybdenum disulphide, tin sulphide, petroleum coke, lead sulphide. | [86,87] |

| Name | Role (Space/Functional) | Advantages | Drawback |

|---|---|---|---|

| INORGANIC | |||

| Vermiculite | Functional |

|

|

| Barium sulphate | Space |

|

|

| Mica | Functional |

| - |

| Molybdenum trioxide | Functional |

| - |

| Calcium carbonate | Space |

| - |

| Hexagonal boron nitride (h-BN) | Functional |

| - |

| ORGANIC | |||

| Cashew friction dust | Functional |

| - |

| Rubber | Functional |

|

|

| Plant | Elongation (%) | Density (g/cm3) | Tensile Strength (MPa) | Tensile Modulus (GPa) | Most Used Chemical Treatment | References |

|---|---|---|---|---|---|---|

| Sugar palm | 12.8 | 1.48 | 276 | 3.85 | Alkaline treatment | [124] |

| Palm kernel | - | - | - | - | Sodium hydroxide | [125] |

| Areca | 1.47–1.48 | 1.05–1.25 | 35.68 | - | Alkaline treatment | [126,127,118] |

| Banana | 10.35 | 1.35 | 529–914 | - | Alkaline | [128,129,130,131] |

| Bagasse | 1 | 1.3 | 222–290 | - | Alkaline + Acrylic acid (AA) | [120,132,133] |

| Corn stalks | 1.90–2.30 | 0.21–0.38 | 33.40–34.80 | - | Alkaline treatment | [134,135] |

| Jute | 1.5–1.8 | 1.3 | 393–773 | 10–30 | Alkaline + HCl; HCHO and C6H6 + NaOH + H2SO4 | [133,136,137] |

| Bamboo | 1.4 | 1.1 | 500 | Alkaline | [136] | |

| Kenaf | 2.5–3.5 | 1.2 | 223–930 | 40 | Alkaline | [138,139] |

| Abaca | 2.9 | 1.5 | 430–813 | NaOH + H2SO4 | [140,131] | |

| Flax | 2.7–3.2 | 1.5 | 345–1035 | NaOH + HCl | [136,141,142,131] | |

| Coconut | 15–51.4 | 1.15–1.46 | 95–230 | - | - | [133] |

| Pineapple | 14.5 | 0.8–1.6 | 400–627 | Alkaline | [143,144] | |

| Sisal | 2.0–7.0 | 1.33–1.5 | 363–700 | 9.8–38 | NaOH–Ammonia base liquor+ H2SiO3, Na2B4O7–HCHO–NaHSiO3 | [78,139] |

| Code | Title | Inventor | Reference |

|---|---|---|---|

| CN103436236A | Palm-fiber-reinforced environmentally friendly type brake pad and preparation method thereof | LI MEIFENG | [174] |

| CN103361031A | Brake pad for flax-fiber-reinforced environmentally friendly car and preparation method thereof | LI MEIFENG | [175] |

| CN104976258A | Environmentally friendly brake pad | HUANG XIAOSHUANG | [176] |

| CN103423345A | Automobile brake pad mixing with bamboo fibers | LI MEIFENG | [177] |

| CN106015400A | Hibiscus-Manihot-fiber-reinforced environmentally friendly brake pad and preparation method thereof | JIANG YIKUAN | [178] |

| CN106641049A | Method for preparing brake pad from basalt fiber | LI XIAOCHUAN | [179] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gautier di Confiengo, G.; Faga, M.G. Ecological Transition in the Field of Brake Pad Manufacturing: An Overview of the Potential Green Constituents. Sustainability 2022, 14, 2508. https://doi.org/10.3390/su14052508

Gautier di Confiengo G, Faga MG. Ecological Transition in the Field of Brake Pad Manufacturing: An Overview of the Potential Green Constituents. Sustainability. 2022; 14(5):2508. https://doi.org/10.3390/su14052508

Chicago/Turabian StyleGautier di Confiengo, Giovanna, and Maria Giulia Faga. 2022. "Ecological Transition in the Field of Brake Pad Manufacturing: An Overview of the Potential Green Constituents" Sustainability 14, no. 5: 2508. https://doi.org/10.3390/su14052508

APA StyleGautier di Confiengo, G., & Faga, M. G. (2022). Ecological Transition in the Field of Brake Pad Manufacturing: An Overview of the Potential Green Constituents. Sustainability, 14(5), 2508. https://doi.org/10.3390/su14052508