Modelling and Analysis of Power-Regenerating Potential for High-Speed Train Suspensions

Abstract

:1. Introduction

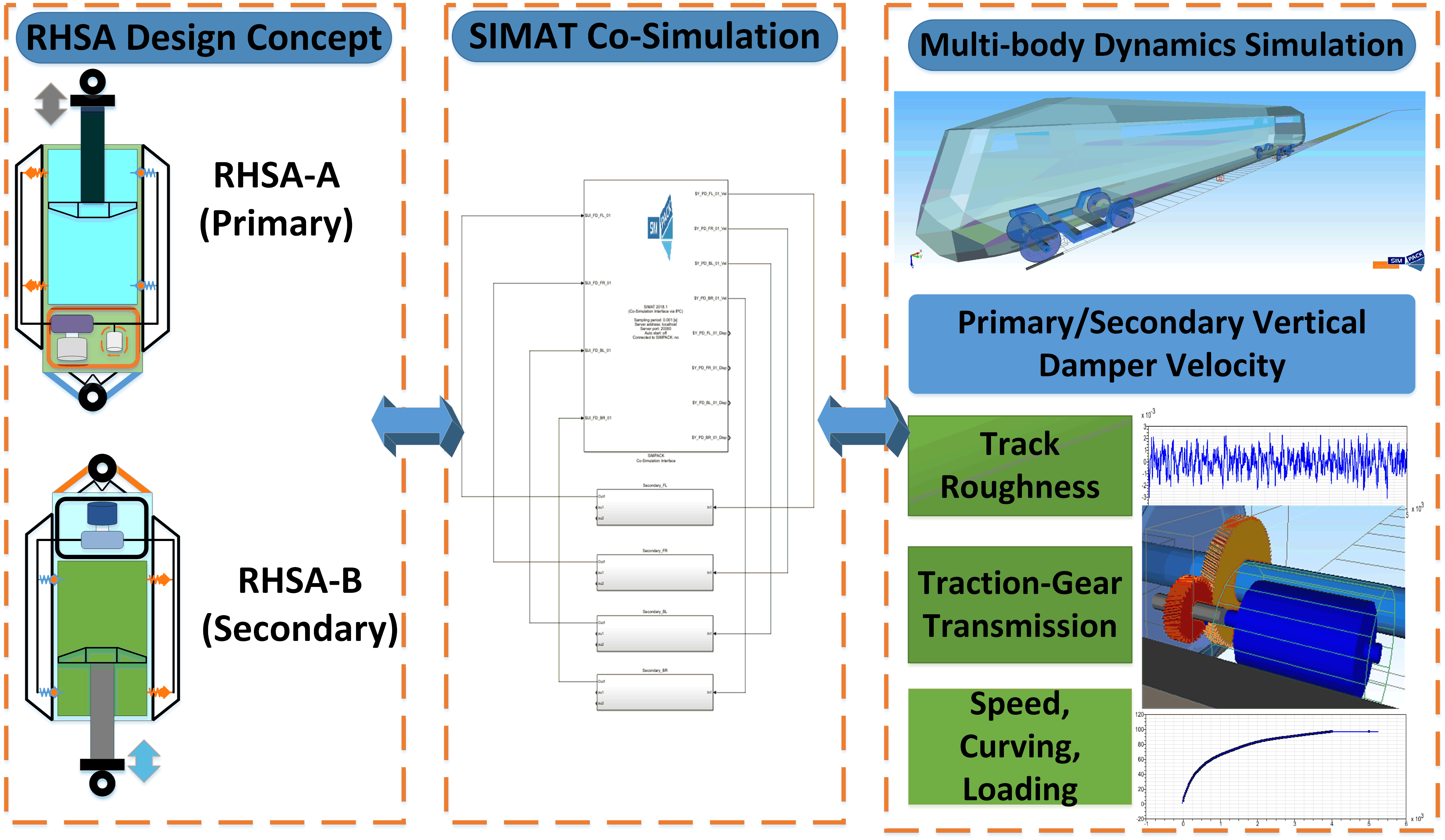

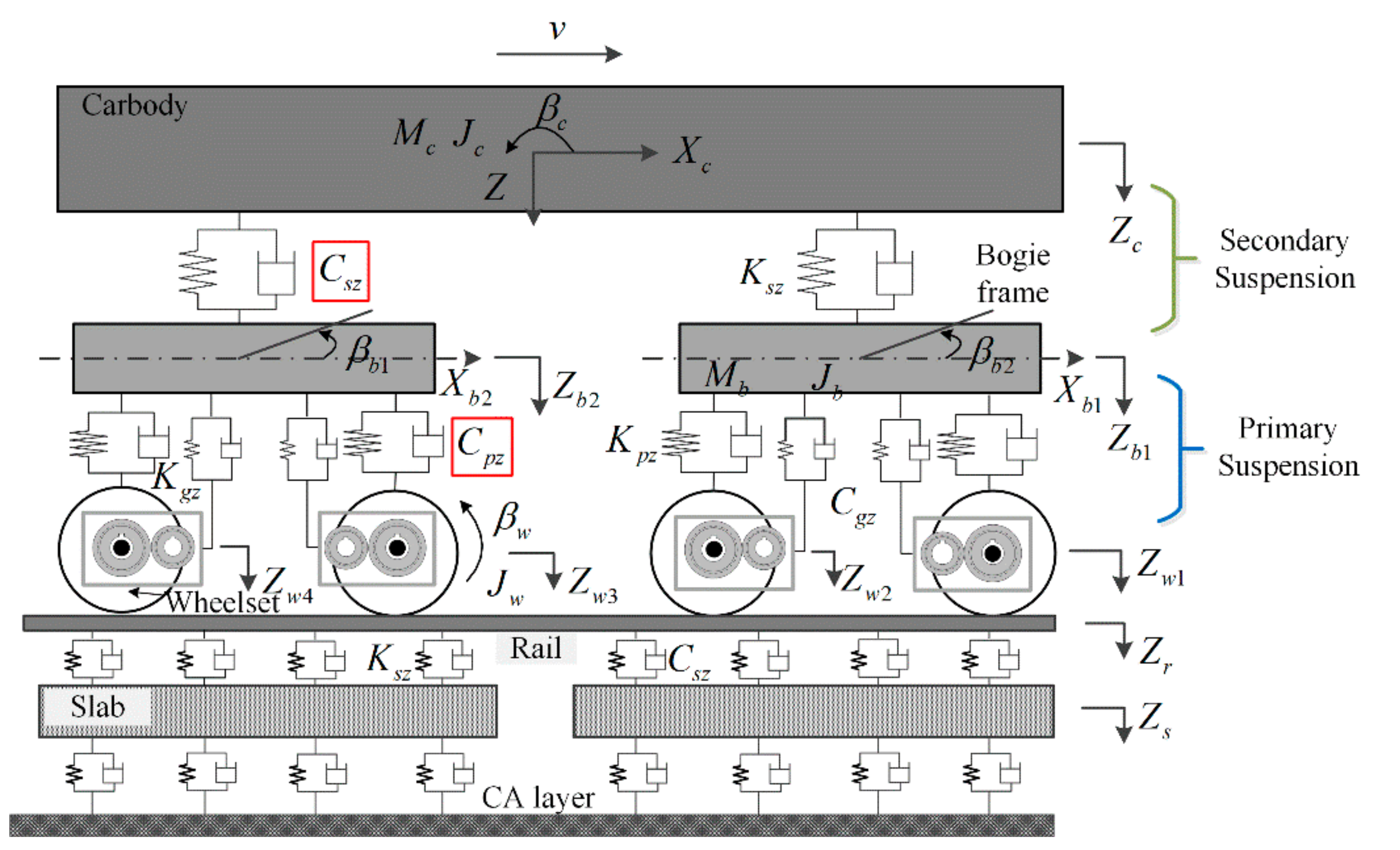

2. Modelling and Dynamics

2.1. Vehicle Suspension Dynamics

2.2. Modelling of the HERDs

2.2.1. Hydraulic Motor, Accumulator, and Generator

- (a)

- The size of the piston-rod cylinder (rebound and compression chambers) was assumed to be equivalent to the railway suspension tube, ignoring the heat exchange between the piston and inner cylinder surface under rapid cycling conditions.

- (b)

- The external electrical load was assumed to be identical to the generator’s internal load resistance to maximise the power-regeneration capability whilst providing the required consistency in damping force for the suspension system.

- (c)

- Mechanical frictions, thermal losses, and leakage were not considered in the hydraulic circuits and hydraulic motor model flow. In a real application, when the fluid flows under variable pressure, the thermal losses caused by variation in the gas temperature will inevitably influence the gas behaviour.

- (d)

- The pressures in the fluid chamber instead of those in the gas chamber were used to calculate the flow rate, which was reasonable due to the transient pressure balance inside the accumulator.

2.2.2. Power Conversion and Damping Force

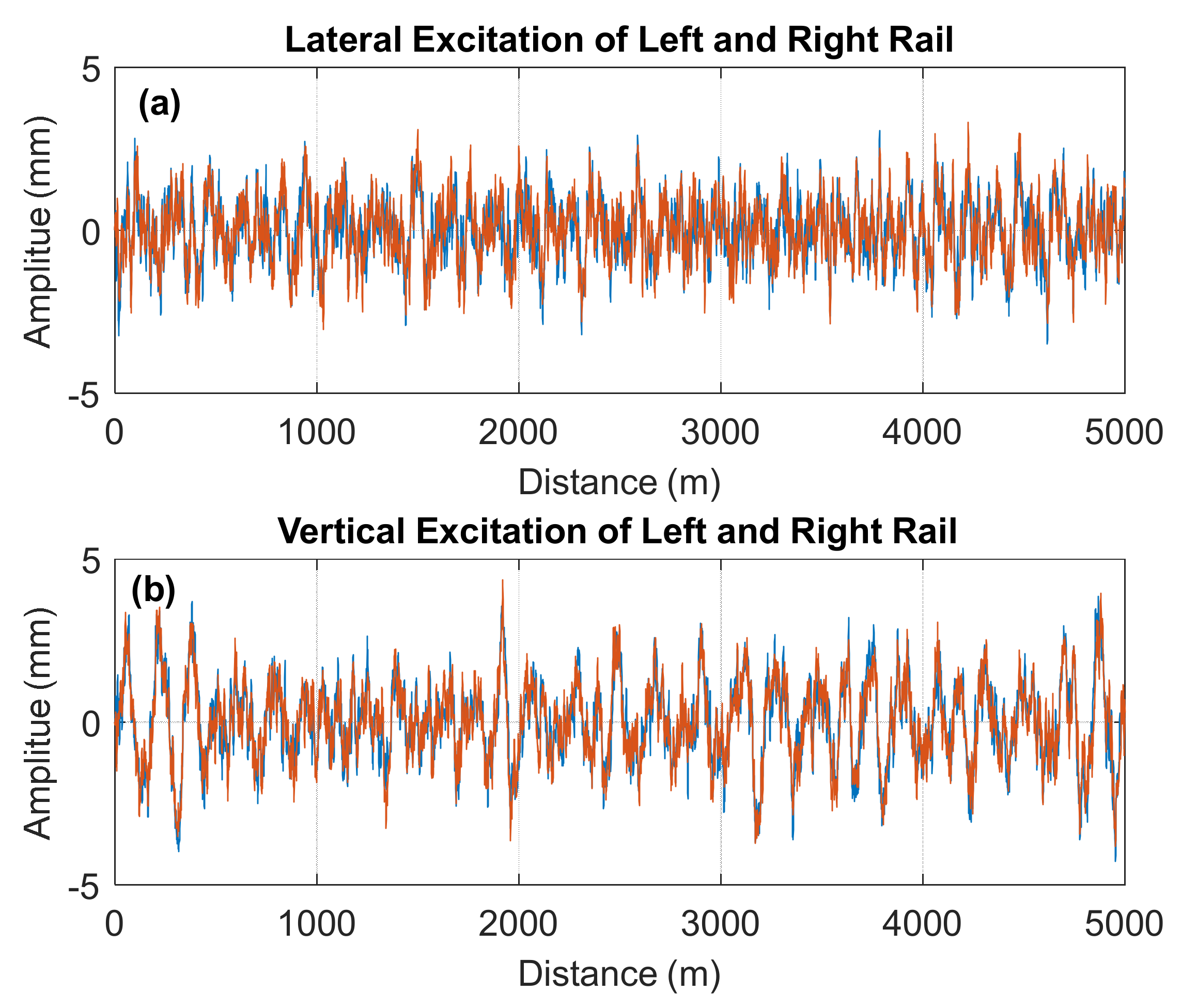

2.3. Track Design and Irregularity

3. Simulation and Analysis

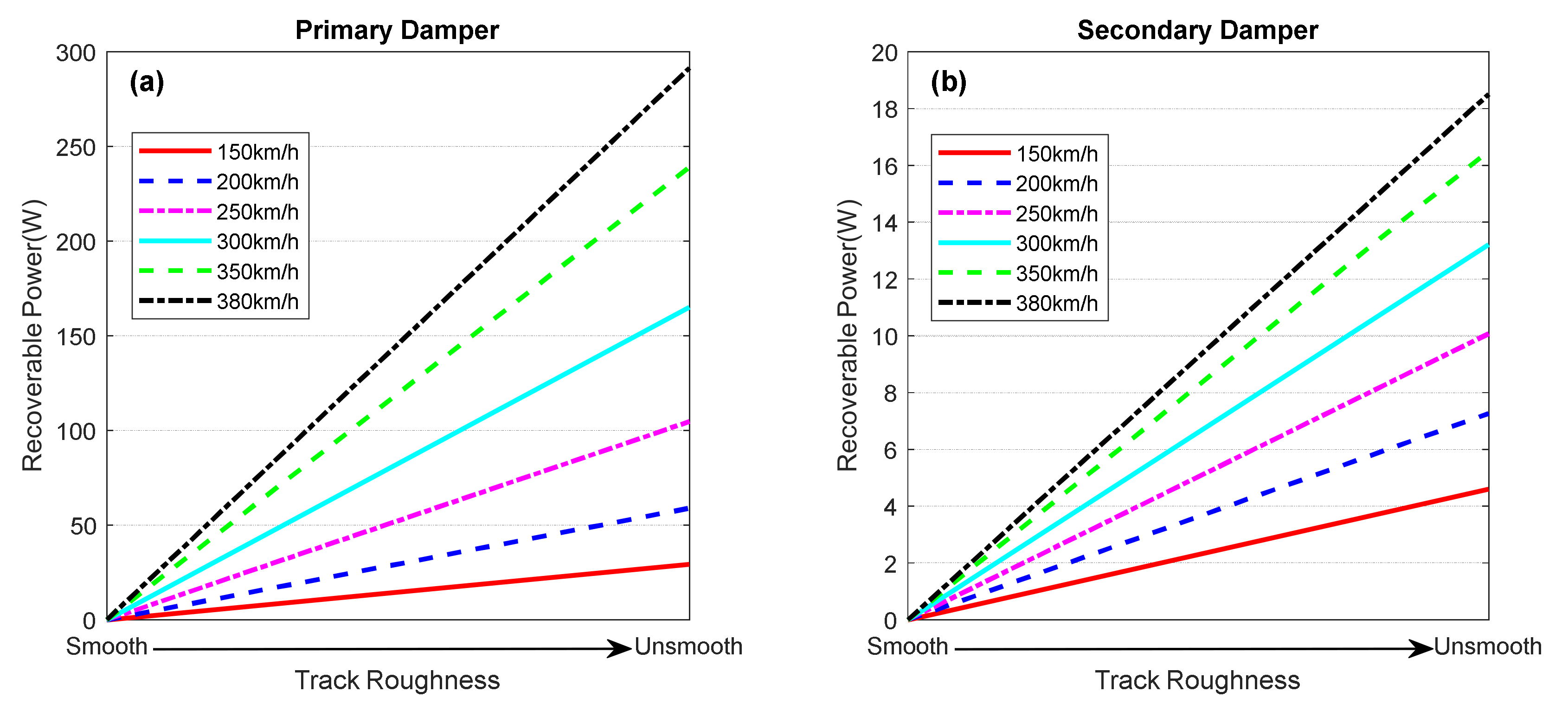

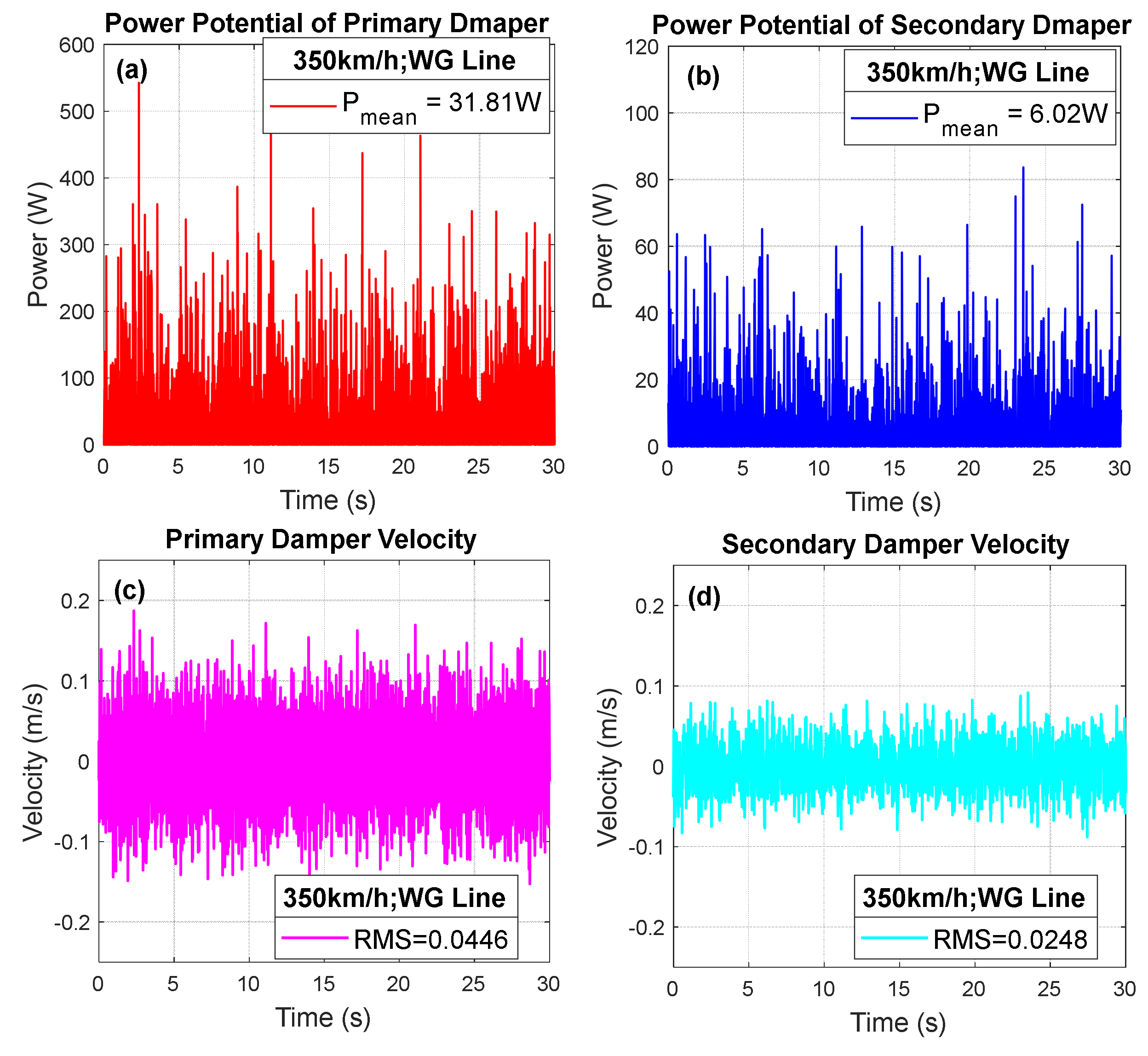

3.1. Power-Regeneration Potential

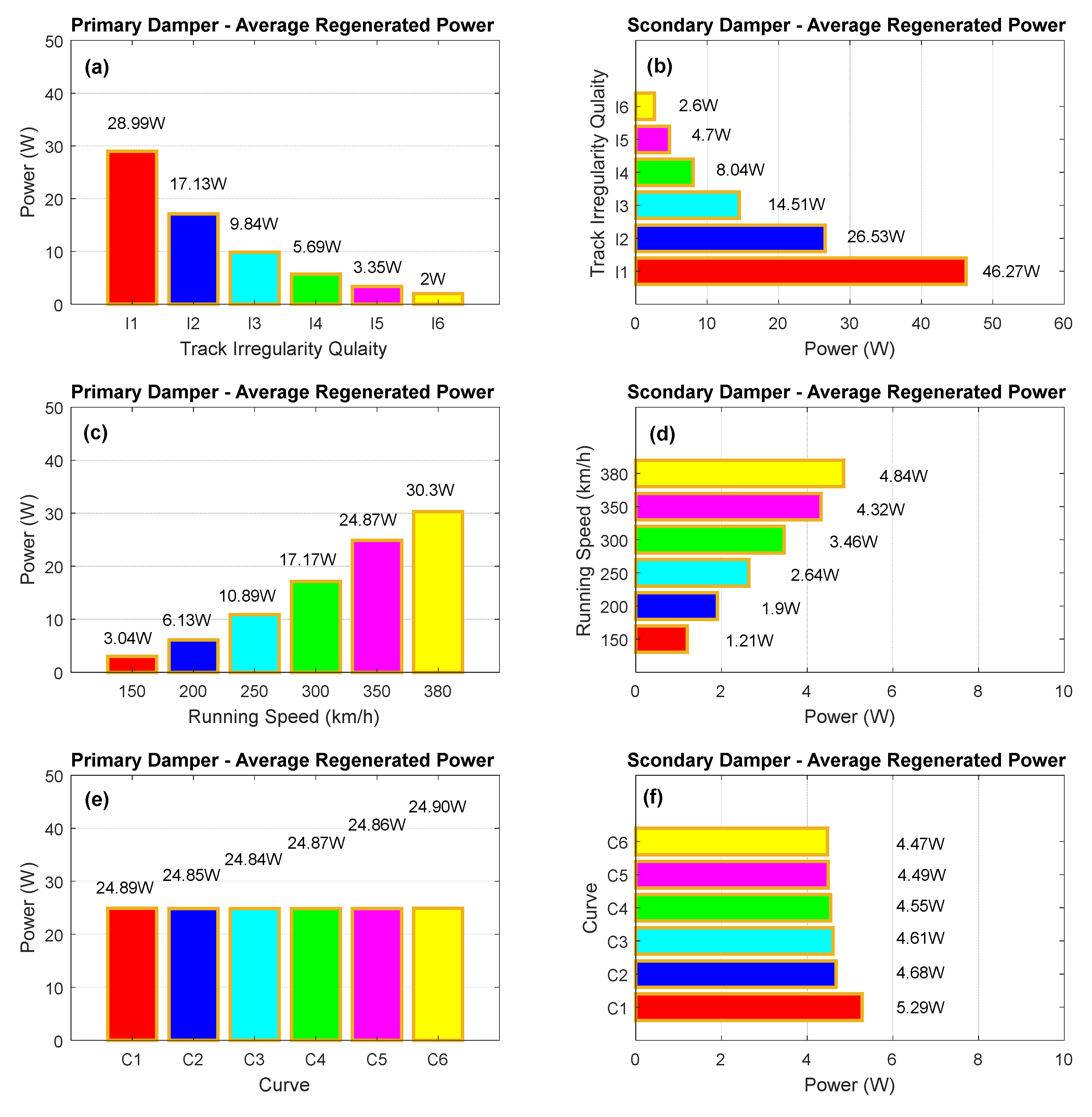

3.2. Track Irregularity, Running Speed, and Curving Analysis

3.3. Speed Profile and Instantaneous Power Analysis

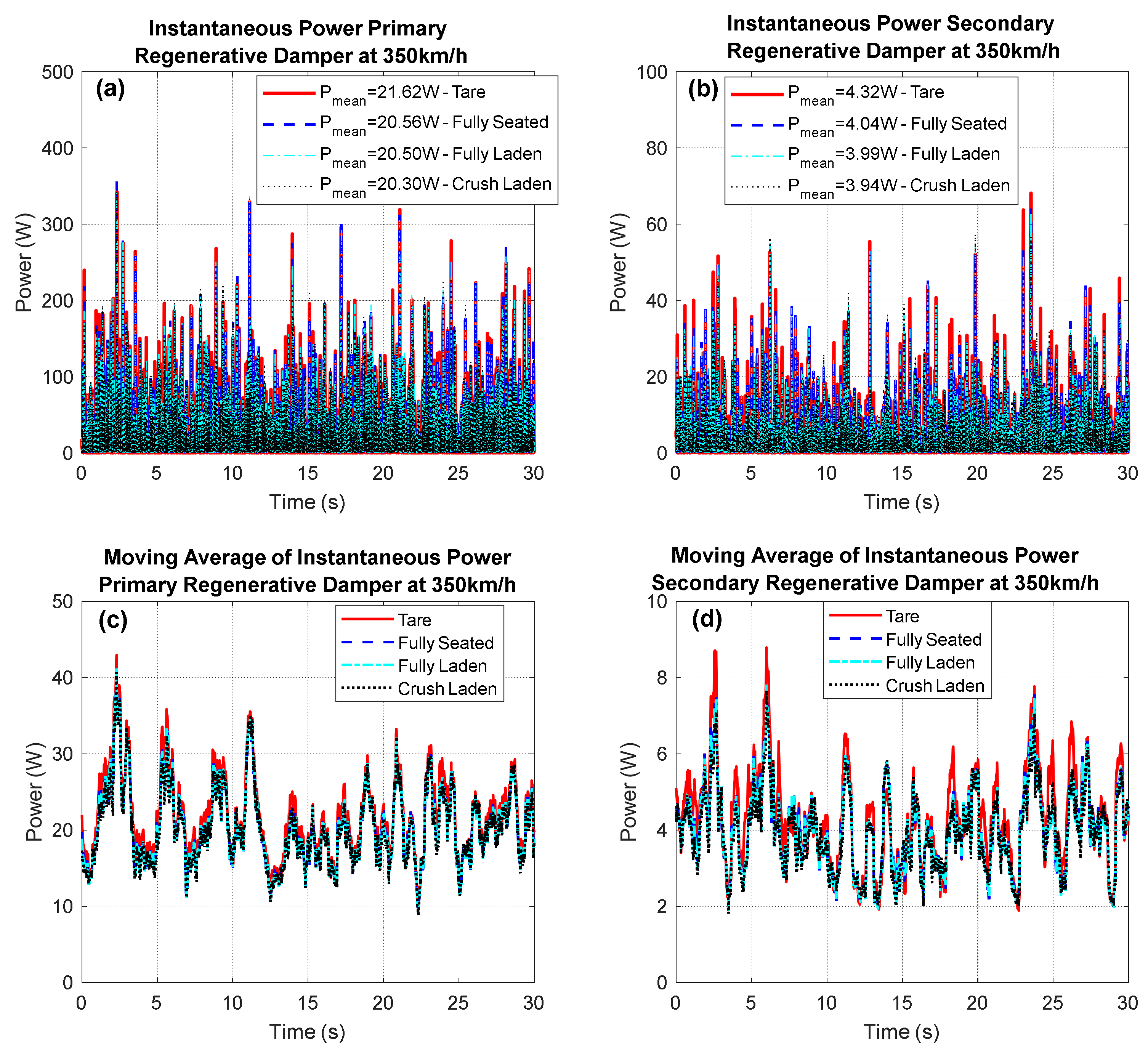

3.4. Loading Comparisons

4. Conclusions

- (1)

- The simulation results indicated that the proposed power-regenerative damper showed considerable potential and recoverable power in the vertical motion direction per damper when applied in both the primary and secondary vertical dampers. The analysis revealed that, in the case of a high-speed rail journey, higher levels of track irregularities, higher curve cases, and lower carbody weights were beneficial for power regeneration.

- (2)

- The HERDs could operate effectively in power regeneration whilst negotiating track of different qualities. Using different track irregularities as inputs, the estimations of the regenerated power content were in the range of 2–28.99 W and 2.6–46.27 W, respectively. These referred to the power per HERD unit of the primary and secondary dampers at a speed of 350 km/h. A higher vehicle speed was the main influencing factor in maximising power regeneration.

- (3)

- At constant speed, the power potential (total potential power) and regenerative power (HERDs can recover power) on the measured high-speed WG line by the HERDs was not significantly influenced by the curve radius (a range of curve radii and cant deficiencies were studied). Vehicle loading also did not have a great influence, whereas the track quality and vehicle speed were dominant factors. The power capability of the regenerative damper highly depended on the scheduled train operational speed.

- (4)

- According to the design of the power-regenerating damper, the external load resistance was set to be identical to the generator’s internal resistance, which could maximise the regenerated power level and efficiency. In the case of a high-speed train profile (25 to 350 km/h) over a distance of 5 km, the HERDs could maintain a stable regenerative efficiency of around 45.62% and 47.89%, respectively. It also was revealed that the average and instantaneous regenerated power of the secondary was significantly smaller than in the primary.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Goswami, A.; Sen, P. Nanomaterials for Green Energy; Micro and Nano Technologies; Elsevier: Amsterdam, The Netherlands, 2018; ISBN 978-0-12-813731-4. [Google Scholar]

- Dang, N.; Bozorgzadeh, E.; Venkatasubramanian, N. Advances in Computers; Elsevier: Amsterdam, The Netherlands, 2012; Volume 87. [Google Scholar]

- Beeby, S.P.; Cao, Z.; Almussallam, A. Multidisciplinary Know-How for Smart-Textiles Developers; Woodhead Publishing Series in Textiles; Woodhead Publishing: Sawston, UK, 2013; ISBN 978-0-85709-342-4. [Google Scholar]

- Kiziroglou, M.E.; Yeatman, E.M. Functional Materials for Sustainable Energy Applications; Woodhead Publishing Series in Energy; Woodhead Publishing: Sawston, UK, 2012; ISBN 978-0-85709-059-1. [Google Scholar]

- Pei, J.; Zhou, B.; Lyu, L. E-Road: The Largest Energy Supply of the Future. Appl. Energy 2019, 241, 174–183. [Google Scholar] [CrossRef]

- Zou, H.-X.; Zhao, L.-C.; Gao, Q.-H.; Zuo, L.; Liu, F.-R.; Tan, T.; Wei, K.-X.; Zhang, W.-M. Mechanical Modulations for Enhancing Energy Harvesting: Principles, Methods and Applications. Appl. Energy 2019, 255, 113871. [Google Scholar] [CrossRef]

- Abdelkareem, M.A.A.; Xu, L.; Ali, M.K.A.; Elagouz, A.; Mi, J.; Guo, S.; Liu, Y.; Zuo, L. Vibration Energy Harvesting in Automotive Suspension System: A Detailed Review. Appl. Energy 2018, 229, 672–699. [Google Scholar] [CrossRef]

- Abdelkareem, M.A.A.; Xu, L.; Ali, M.K.A.; El-Daly, A.-R.B.M.; Hassan, M.A.; Elagouz, A.; Bo, Y. Analysis of the Prospective Vibrational Energy Harvesting of Heavy-Duty Truck Suspensions: A Simulation Approach. Energy 2019, 173, 332–351. [Google Scholar] [CrossRef]

- Gholikhani, M.; Roshani, H.; Dessouky, S.; Papagiannakis, A.T. A Critical Review of Roadway Energy Harvesting Technologies. Appl. Energy 2020, 261, 114388. [Google Scholar] [CrossRef]

- Li, C.; Luo, S.; Cole, C.; Spiryagin, M. An Overview: Modern Techniques for Railway Vehicle on-Board Health Monitoring Systems. Veh. Syst. Dyn. 2017, 55, 1045–1070. [Google Scholar] [CrossRef]

- Sun, W.; Lu, G.; Ye, C.; Chen, S.; Hou, Y.; Wang, D.; Wang, L.; Oeser, M. The State of the Art: Application of Green Technology in Sustainable Pavement. Adv. Mater. Sci. Eng. 2018, 2018, 9760464. [Google Scholar] [CrossRef] [Green Version]

- Song, Y.; Liu, Z.; Rønnquist, A.; Nåvik, P.; Liu, Z. Contact Wire Irregularity Stochastics and Effect on High-Speed Railway Pantograph–Catenary Interactions. IEEE Trans. Instrum. Meas. 2020, 69, 8196–8206. [Google Scholar] [CrossRef]

- Song, Y.; Zhang, M.; Øiseth, O.; Rønnquist, A. Wind Deflection Analysis of Railway Catenary under Crosswind Based on Nonlinear Finite Element Model and Wind Tunnel Test. Mech. Mach. Theory 2022, 168, 104608. [Google Scholar] [CrossRef]

- Gholikhani, M.; Tahami, S.A.; Khalili, M.; Dessouky, S. Electromagnetic Energy Harvesting Technology: Key to Sustainability in Transportation Systems. Sustainability 2019, 11, 4906. [Google Scholar] [CrossRef] [Green Version]

- Buhaug, H.; Urdal, H. An Urbanization Bomb—Population Growth and Social Disorder in Cities. Glob. Environ. Chang. 2013, 23, 1–10. [Google Scholar] [CrossRef]

- Bernal, E.; Spiryagin, M.; Cole, C. Onboard Condition Monitoring Sensors, Systems and Techniques for Freight Railway Vehicles: A Review. IEEE Sens. J. 2019, 19, 4–24. [Google Scholar] [CrossRef]

- Baptista, M.; de Medeiros, I.P.; Malere, J.P.; Prendinger, H.; Nascimento, C.L.; Henriques, E.M.P. Improved Time-Based Maintenance in Aeronautics with Regressive Support Vector Machines. In Proceedings of the Annual Conference of the Prognostics and Health Monitoring Society, Denver, CO, USA, 3 October 2016; Volume 7, p. 10. [Google Scholar]

- Pasquale, G.D.; Somà, A.; Fraccarollo, F. Piezoelectric Energy Harvesting for Autonomous Sensors Network on Safety-Improved Railway Vehicles. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2012, 226, 1107–1117. [Google Scholar] [CrossRef]

- Cho, J.Y.; Jeong, S.; Jabbar, H.; Song, Y.; Ahn, J.H.; Kim, J.H.; Jung, H.J.; Yoo, H.H.; Sung, T.H. Piezoelectric Energy Harvesting System with Magnetic Pendulum Movement for Self-Powered Safety Sensor of Trains. Sens. Actuators A Phys. 2016, 250, 210–218. [Google Scholar] [CrossRef]

- Wang, J.; Shi, Z.; Xiang, H.; Song, G. Modeling on Energy Harvesting from a Railway System Using Piezoelectric Transducers. Smart Mater. Struct. 2015, 24, 105017. [Google Scholar] [CrossRef]

- Nagode, C.; Ahmadian, M.; Taheri, S. Motion-Based Energy Harvesting Devices for Railroad Applications. In Proceedings of the Rail Equipment Engineering, Urbana, IL, USA, 28 October 2010; American Society of Mechanical Engineers Digital Collection. Volume 2, pp. 267–271. [Google Scholar]

- Hou, W.; Li, Y.; Guo, W.; Li, J.; Chen, Y.; Duan, X. Railway Vehicle Induced Vibration Energy Harvesting and Saving of Rail Transit Segmental Prefabricated and Assembling Bridges. J. Clean. Prod. 2018, 182, 946–959. [Google Scholar] [CrossRef]

- Gao, M.; Wang, P.; Wang, Y.; Yao, L. Self-Powered ZigBee Wireless Sensor Nodes for Railway Condition Monitoring. IEEE Trans. Intell. Transp. Syst. 2018, 19, 900–909. [Google Scholar] [CrossRef]

- Siang, J.; Lim, M.H.; Leong, M.S. Review of Vibration-Based Energy Harvesting Technology: Mechanism and Architectural Approach. Int. J. Energy Res. 2018, 42, 1866–1893. [Google Scholar] [CrossRef]

- Gao, M.; Wang, P.; Cao, Y.; Chen, R.; Cai, D. Design and Verification of a Rail-Borne Energy Harvester for Powering Wireless Sensor Networks in the Railway Industry. IEEE Trans. Intell. Transp. Syst. 2017, 18, 1596–1609. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, Z.; Pan, H.; Salman, W.; Yuan, Y.; Liu, Y. A Portable High-Efficiency Electromagnetic Energy Harvesting System Using Supercapacitors for Renewable Energy Applications in Railroads. Energy Convers. Manag. 2016, 118, 287–294. [Google Scholar] [CrossRef]

- Wang, J.J.; Penamalli, G.P.; Zuo, L. Electromagnetic Energy Harvesting from Train Induced Railway Track Vibrations. In Proceedings of the 2012 IEEE/ASME 8th IEEE/ASME International Conference on Mechatronic and Embedded Systems and Applications, Suzhou, China, 9 July 2012; pp. 29–34. [Google Scholar]

- Pourghodrat, A.; Nelson, C.A.; Hansen, S.E.; Kamarajugadda, V.; Platt, S.R. Power Harvesting Systems Design for Railroad Safety. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2014, 228, 504–521. [Google Scholar] [CrossRef]

- Li, Z.; Zuo, L.; Kuang, J.; Luhrs, G. Energy-Harvesting Shock Absorber with a Mechanical Motion Rectifier. Smart Mater. Struct. 2012, 22, 025008. [Google Scholar] [CrossRef]

- Pan, Y.; Lin, T.; Qian, F.; Liu, C.; Yu, J.; Zuo, J.; Zuo, L. Modeling and Field-Test of a Compact Electromagnetic Energy Harvester for Railroad Transportation. Appl. Energy 2019, 247, 309–321. [Google Scholar] [CrossRef]

- Nelson, C.A.; Platt, S.R.; Albrecht, D.; Kamarajugadda, V.; Fateh, M. Power Harvesting for Railroad Track Health Monitoring Using Piezoelectric and Inductive Devices. In Proceedings of the Active and Passive Smart Structures and Integrated Systems 2008, San Diego, CA, USA, 18 April 2008; Volume 6928. [Google Scholar]

- He, X.; Xiao, G.; Hu, B.; Tan, L.; Tang, H.; He, S.; He, Z. The Applications of Energy Regeneration and Conversion Technologies Based on Hydraulic Transmission Systems: A Review. Energy Convers. Manag. 2020, 205, 112413. [Google Scholar] [CrossRef]

- Wang, R. Modelling, Testing and Analysis of a Regenerative Hydraulic Shock Absorber System. Ph.D. Thesis, University of Huddersfield, Huddersfield, UK, 2016. [Google Scholar]

- Wang, R.; Crosbee, D.; Iwnicki, S.; Zhao, Y.; Bevan, A. Power Regeneration in the Primary Suspension of a Railway Vehicle. In Proceedings of the First International Conference on Rail Transportation, Chengdu, China, 11 July 2017. [Google Scholar]

- Wang, R.; Wang, Z. Evaluation of Power Regeneration in Primary Suspension for a Railway Vehicle. Front. Mech. Eng. 2020, 15, 265–278. [Google Scholar] [CrossRef]

- Nagode, C.; Ahmadian, M.; Taheri, S. Effective Energy Harvesting Devices for Railroad Applications. In Proceedings of the Active and Passive Smart Structures and Integrated Systems 2010, San Diego, CA, USA, 9 April 2010; Volume 7643, p. 76430X. [Google Scholar]

- Pan, Y.; Liu, F.; Jiang, R.; Tu, Z.; Zuo, L. Modeling and Onboard Test of an Electromagnetic Energy Harvester for Railway Cars. Appl. Energy 2019, 250, 568–581. [Google Scholar] [CrossRef]

- Guo, S.; Xu, L.; Liu, Y.; Guo, X.; Zuo, L. Modeling and Experiments of a Hydraulic Electromagnetic Energy-Harvesting Shock Absorber. IEEE/ASME Trans. Mechatron. 2017, 22, 2684–2694. [Google Scholar] [CrossRef]

- Wang, R.; Chen, Z.; Xu, H.; Schmidt, K.; Gu, F.; Ball, A.D. Modelling and Validation of a Regenerative Shock Absorber System. In Proceedings of the 2014 20th International Conference on Automation and Computing, Cranfield, UK, 13 September 2014; pp. 32–37. [Google Scholar]

- Wang, R.; Gu, F.; Cattley, R.; Ball, A.D. Modelling, Testing and Analysis of a Regenerative Hydraulic Shock Absorber System. Energies 2016, 9, 386. [Google Scholar] [CrossRef] [Green Version]

- Zheng, P.; Wang, R.; Gao, J. A Comprehensive Review on Regenerative Shock Absorber Systems. J. Vib. Eng. Technol. 2020, 8, 225–246. [Google Scholar] [CrossRef] [Green Version]

- Wang, Z.; Song, Y.; Yin, Z.; Wang, R.; Zhang, W. Random Response Analysis of Axle-Box Bearing of a High-Speed Train Excited by Crosswinds and Track Irregularities. IEEE Trans. Veh. Technol. 2019, 68, 10607–10617. [Google Scholar] [CrossRef] [Green Version]

- Wang, Z.; Allen, P.; Mei, G.; Wang, R.; Yin, Z.; Zhang, W. Influence of Wheel-Polygonal Wear on the Dynamic Forces within the Axle-Box Bearing of a High-Speed Train. Veh. Syst. Dyn. 2020, 58, 1385–1406. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, R.; Crosbee, D.; Allen, P.; Ye, Y.; Zhang, W. Wheel Wear Analysis of Motor and Unpowered Car of a High-Speed Train. Wear 2020, 444–445, 203136. [Google Scholar] [CrossRef]

- Wang, Z.; Yin, Z.; Wang, R.; Cheng, Y.; Allen, P.; Zhang, W. Coupled Dynamic Behaviour of a Transmission System with Gear Eccentricities for a High-Speed Train. Veh. Syst. Dyn. 2021, 59, 613–634. [Google Scholar] [CrossRef]

- Song, Y.; Wang, Z.; Liu, Z.; Wang, R. A Spatial Coupling Model to Study Dynamic Performance of Pantograph-Catenary with Vehicle-Track Excitation. Mech. Syst. Signal Process. 2021, 151, 107336. [Google Scholar] [CrossRef]

- Wang, Z.; Yin, Z.; Allen, P.; Wang, R.; Xiong, Q.; Zhu, Y. Dynamic Analysis of Enhanced Gear Transmissions in the Vehicle-Track Coupled Dynamic System of a High-Speed Train. Veh. Syst. Dyn. 2021, 1–23. [Google Scholar] [CrossRef]

- Wang, Z.; Mei, G.; Zhang, W.; Cheng, Y.; Huang, G.; Li, F. Effects of Polygonal Wear of Wheels on the Dynamic Performance of the Gearbox Housing of a High-Speed Train. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2018, 232, 1852–1863. [Google Scholar] [CrossRef]

- Zhai, W. Vehicle—Track Coupled Dynamics; Springer: Singapore, 2020; ISBN 978-981-329-283-3. [Google Scholar]

- Connor, P. Railway Passenger Vehicle Capacity; PRC Rail Consulting Ltd.: Derby, UK, 2011; Available online: http://www.railway-technical.com/books-papers--articles/infopaper-2-railway-passeng.pdf (accessed on 15 February 2022).

- EN 15663:2017 BS EN 15663:2017+A1:2018; Railway Applications—Vehicle Reference Masses; The British Standards Institution: London, UK, 2017.

| Vehicle Component | Longitudinal | Lateral | Vertical | Roll | Yaw | Pitch |

|---|---|---|---|---|---|---|

| Carbody | ||||||

| Bogie Frame (i = 1, 2) | ||||||

| Motor (i = 1–4) | - | - | ||||

| Gearbox (i = 1–4) | - | - | ||||

| Pinion (i = 1–4) | - | |||||

| Wheelset (i = 1–4) |

| Key Component | Parameter | Symbol | Value | Units |

|---|---|---|---|---|

| Hydraulic Cylinder | Piston area (PD) | AA | 0.005 | m3 |

| Piston ring area (PD) | AB | 0.0041 | m3 | |

| Piston area (SD) | AA | 0.002 | m3 | |

| Piston ring area (SD) | AB | 0.0016 | m3 | |

| Maximum cylinder stroke | 0.15 | m | ||

| Hydraulic Motor | Motor displacement (PD) | DM | 30 | m3/rev |

| Motor displacement (SD) | DM | 18 | m3/rev | |

| Mechanical efficiency | ηM | 95 | % | |

| Volumetric efficiency | ηV | 95 | % | |

| Generator | Torque coefficient | KT | 0.93 | Nm/A |

| Electromotive voltage coefficient | KE | 0.93 | Vs/rad | |

| Shaft moment of inertia | Jt | 0.0002 | Kg m2 | |

| Internal inductance | LG | 0.03 | H | |

| Internal resistance (PD) | Rin | 20 | Ω | |

| External electrical load (PD) | RB | 20 | Ω | |

| Internal resistance (SD) | Rin | 10 | Ω | |

| External electrical load (SD) | RB | 10 | Ω | |

| Hydraulic Rectifier | Check-valve constant | DC | 2.533 × 10−6 | - |

| Accumulator port constant (PD) | Cac | 0.0038 | - | |

| Accumulator capacity (PD) | Vac | 5 × 10−4 | m3 | |

| Gas specific heat ratio of the gas-charged accumulator (PD) | kac | 1.4 | - | |

| Accumulator preload pressure (PD) | Ppc | 20 | bar |

| Curve Radius (m) | Cant Deficiency (mm) | Transition Length (m) |

|---|---|---|

| (C1) 3000 | 150 | 380 |

| (C2) 7000 | 150 | 540 |

| (C3) 8000 | 135 | 500 |

| (C4) 9000 | 125 | 490 |

| (C5) 10,000 | 115 | 430 |

| (C6) 12,000 | 100 | 370 |

| Operational Parameters and Track Characteristics | |

|---|---|

| Track Design | See Table 3; six curves (C1 to C6) |

| Track Irregularities | Six track classes [49] and measured WG line |

| Speeds | 150, 200, 300, 350, and 380 km/h and speed profiles (0–380 km/h) |

| Wheel Profile | S1002CN |

| Rail Profile | CN60 |

| Coefficient of Friction | 0.4 on tread and flange |

| Loading Conditions | Tare (33.786 tons), fully seated (39.626 tons), fully laden, (41.226 tons) and crush laden (44.994 tons) |

| Regenerative Efficiency of HERDs in Different Conditions | |||

|---|---|---|---|

| Primary Damper | Speed | Track Irregularity | Curve |

| Recoverable Efficiency | 45.06~45.89% | 44.61~45.86% | ≈45.38% |

| Secondary Damper | Speed | Track Irregularity | Curve |

| Recoverable Efficiency | 48.59~48.69%% | 48.90~49.35%% | 48.68~48.77% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, R.; Allen, P.; Song, Y.; Wang, Z. Modelling and Analysis of Power-Regenerating Potential for High-Speed Train Suspensions. Sustainability 2022, 14, 2542. https://doi.org/10.3390/su14052542

Wang R, Allen P, Song Y, Wang Z. Modelling and Analysis of Power-Regenerating Potential for High-Speed Train Suspensions. Sustainability. 2022; 14(5):2542. https://doi.org/10.3390/su14052542

Chicago/Turabian StyleWang, Ruichen, Paul Allen, Yang Song, and Zhiwei Wang. 2022. "Modelling and Analysis of Power-Regenerating Potential for High-Speed Train Suspensions" Sustainability 14, no. 5: 2542. https://doi.org/10.3390/su14052542

APA StyleWang, R., Allen, P., Song, Y., & Wang, Z. (2022). Modelling and Analysis of Power-Regenerating Potential for High-Speed Train Suspensions. Sustainability, 14(5), 2542. https://doi.org/10.3390/su14052542