Screening of Cooling Technologies in Europe: Alternatives to Vapour Compression and Possible Market Developments

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

- While in the report of Fischer et al. (1991), technologies, such as Stirling cycle refrigeration, Malone cycle refrigeration, evaporative cooling and thermo-elastic heat pumps were discussed and assessed, Brown et al. (2014) excluded further study investigation, stating that these technologies would not be competitive with the traditional VC market. In contrast, in this paper, discussing the technologies mentioned above has been resumed to update potential developments that were not promising in 2014 [24,26].

- The Brown et al. (2014) study focused on selecting six technologies, resulting in sorption cooling, magnetic cooling, thermo-acoustic cooling, desiccant cooling, thermoelectric cooling and transcritical CO2 cycle technologies. Their physical principles are presented by advancements, the state of technology and the overall assessment. Moreover, Brown et al. (2014) assessed other cooling technologies based on efficiency criteria, such as the Ranque–Hilsh tube or vortex tube, and various gas cycles, e.g., Brayton cycle or Eric(c)son cycle, pulse tube refrigerator, Einstein absorption cycle, and the ejector cycle refrigeration, stating that, for the foreseeable future, they were not able to compete with the VC technology [24].

- In 2014, Goetzler et al. reported in detail the assessment of the Bernoulli heat pump, critical-flow refrigeration cycle, and electrocaloric technologies by identifying them as in the early stage of research and development (R&D). Besides, the absorption heat pump, adsorption heat pump, Brayton heat pump, duplex Stirling cycle, ejector heat pump, evaporative cooling, evaporative liquid desiccant A/C, ground-coupled solid desiccant A/C, magnetocaloric, membrane heat pump (HP), stand-alone liquid desiccant A/C, stand-alone solid desiccant A/C, thermo-acoustic, thermo-elastic, thermoelectric, thermotunneling, and Vuilleumier heat pump were assumed as the remaining viable technology options and further investigated. Lastly, the pulse-tube refrigeration and the vortex-tube cooling were excluded from the research [36]. Previous studies stated that they were not suitable for space conditioning applications [39].

- ARMINES et al. (2016) screened multiple cooling technologies still under development by describing their working principles, recent research and TRL level. The screened technologies are Insulation Improved Thermal Resistance: gas-filled panels and aerogel panels, Lorenz–Meutzner cycle refrigeration, ejector cycle refrigeration for combined refrigerator/freezer, Stirling cycle refrigeration, thermo-acoustic refrigeration, thermo-elastic refrigeration, and magnetic refrigeration. Remarkably, these are appointed as promising non-available cooling technologies [38].

- In 2017, Goetzler et al. identified eighteen technologies and divided them into four groups. The first group is named Technology Enhancements for Current Systems. It involves HVAC sensors, panels, filtration and coatings beyond the study’s scope. The second group is called the Alternative Gas-Fired Heat Pumps Technologies, and includes the Vuilleumier heat pump, ejector heat pump, and fuel cell combined cooling, heating and power system. This technology group mainly uses natural gas and a thermally activated heat pump cycle to provide heating and cool more efficiently. The third group, named Alternative Electrically Driven Heat Pump Technologies, involves membrane cooling system, metastable critical-flow cycle, thermo-elastic cooling system, Sanderson-Rocker Arm Mechanism (S-RAM), turbo-compressor-condenser-expander heat pump, electrocaloric cooling system, electrochemical heat pump and magnetocaloric cooling system. This group aims to provide a more efficient heating and cooling deployment using advanced VC or NVC technologies, with electricity as the primary energy source. The last group of technologies is named Alternative System Architecture, which involves robotic devices, dynamic clothing technologies and wearable devices for personal comfort, aiming to reduce HVAC systems’ operating requirements by providing comfort to buildings. It is beyond the study’s scope [29].

- Goetzler et al. (2019) analyzed different technologies in HVAC, appliances, refrigeration and water heating and assembled them into five different groups. The first group included HVAC systems, such as thermostats, control devices for space cooling and dehumidification, and hardware and software solutions for HVAC equipment. The second group, named Water Heating, focused on water heaters with smart-connected controls. The third group, named Appliances, Refrigeration, and Relevant Miscellaneous Electric Loads (MELs), focused on general appliances. The fourth group, called Related Natural Gas Technologies, included combined heat and power (CHP) systems for buildings, smart thermostats, water heaters and innovative clothes dryers. The fifth group, which included the most relevant material for the present study, is called Cross-Cutting, and groups thermal energy storage, modulating capacity vapor compression, and non-vapor compression (NVC) material and systems. Significantly, regarding the NVC technologies, Goetzler et al. (2019) stated that researchers estimate energy savings of 20% and are more significant compared to the traditional VC technologies, which may have a high potential in buildings application. Moreover, it mentioned that NVC technologies might offer energy storage that can shift grid-tied energy usage to an off-peak period and offer separate sensible and latent cooling, allowing buildings to operate at a lower energy consumption [37].

2.2. Methods

- TRL 1—Basic principles observed;

- TRL 2—Technology concept formulated;

- TRL 3—Experimental proof of concept;

- TRL 4—Technology validated in lab;

- TRL 5—Technology validated in a relevant environment (industrially relevant environment in the case of key enabling technologies);

- TRL 6—Technology demonstrated in a relevant environment (industrially relevant environment in the case of critical enabling technologies);

- TRL 7—System prototype demonstration in an operational environment;

- TRL 8—System complete qualified;

- TRL 9—Actual system is proven in operation environment (competitive manufacturing in the case of key enabling technologies; or space).

- Analyze different sources with desk research;

- Identify the most relevant and recent references for the study;

- Comprehensively assess the data and pieces of information of the selected sources;

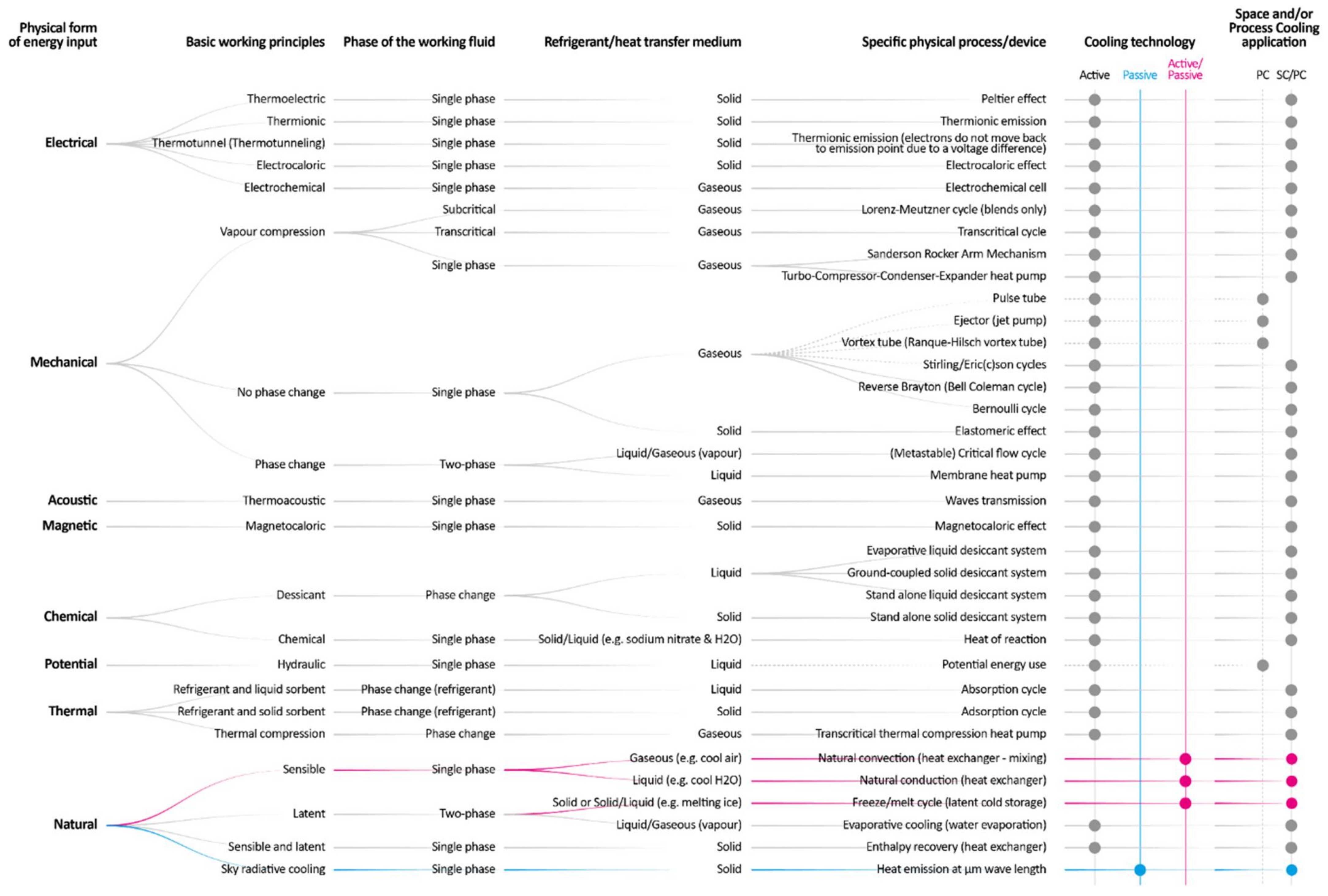

- List and classify into categorizes the cooling technologies;

- Deepen the investigation of the technical, economic and viability aspects of the cooling technologies;

- Produce an exhaustive TRL classification for each cooling technology regarding their current advancement, viability status, applicability sector, efficiency and costs if available;

- Select the most suitable alternative cooling technology based on the criteria;

- Detail the selected alternative cooling technologies;

- Discuss the most promising among the selected technologies.

2.3. Limits of the Study

3. Results

3.1. Taxonomy of the Cooling Technologies and Main Features

3.2. Selection of Alternative Cooling Technologies

- TRL: a mark from 5 to 9 is set as the most promising baseline for the cooling technologies to reach the market in the upcoming future. Consequently, only the technologies presented in Table A1 that have reached these certain levels are selected.

- Energy Efficiency: the technologies’ energy efficiency is indicated in Table A1 with VC efficiency as a baseline. Only the technologies with equal or higher efficiencies are considered.

- Costs: the technology costs are presented in Table A1, with the VC costs as a baseline. Consequently, only the technologies with equal or lower costs are considered being competitive with VC.

- Transcritical cycle;

- Pulse tube;

- Reverse Brayton (Bell Coleman cycle);

- Membrane HP;

- Evaporative cooling (water evaporation);

- Absorption and adsorption.

3.3. Presentation of Alternative Cooling Technologies

3.3.1. Transcritical Cycle

3.3.2. Pulse Tube

3.3.3. Reverse Brayton (Bell Coleman Cycle)

3.3.4. Membrane HP

3.3.5. Evaporative Cooling (Water Evaporation)

3.3.6. Absorption and Adsorption

4. Discussion

- Membrane HP;

- Transcritical cycle;

- Reverse Brayton (Bell Coleman cycle);

- Absorption cooling.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Technology | TRL (Year) | Sector | Efficiency | Costs |

|---|---|---|---|---|

| Thermoelectric | 4 (2016) | SC/PC | Lower [36] | Equal (Assumption) [34] |

| Thermionic | 2 (2014) | SC/PC | Higher (Assumption) [36] | Equal (Assumption) [36] |

| Thermotunnel | 2 (2019) | SC/PC | Higher (Assumption) [36] | Equal (Assumption) [47] |

| Electrocaloric | 2 (2019) | SC/PC | Higher (Assumption) [36] | Unknown |

| Electrochemical | 3–4 (2017) | SC/PC | Higher (Assumption) [34] | Unknown |

| Vapour Compression: RACs and CACs | Up to 9 (2019) | SC/PC | - | - |

| Lorenz-Meutzner Cycle (blend only) | 4 (2019) | SC/PC | Higher (Assumption) [47] | Not identified |

| Transcritical Cycle | Up to 9 (2016) | SC/PC | Unknown | Higher [36] |

| Sanderson Rocker Arm Mechanism | 3–4 (2017) | SC/PC | Unknown | Unknown |

| Turbo-Compressor-Condenser-Expander HPs | 3–4 (2017) | SC/PC | Higher (Assumption) [36] | Unknown |

| Pulse Tube | 6 (2014) | PC | Lower [36] | Not Identified |

| Ejector (Jet Pump) | 3 (2014) | PC | Lower [36] | Lower (Assumption) [47] |

| Vortex Tube (Raque–Hilsch Vortex Tube) | 4 (2014) | PC | Lower [36] | Lower [36] |

| Stirling/Eric(c)son Cycles: Reverse Stirling | 4 (2017) | SC/PC | Lower [36] | Unknown |

| Duplex Stirling | 3–4 (2017) | SC/PC | Lower [47] | Unknown |

| Transcritical Cycle HP | 3–4 (2017) | SC/PC | Lower [36] | Lower (Assumption) [36] |

| Reverse Eric(c)son Cycles | 4 (2019) | SC/PC | Lower [47] | Not identified |

| Reverse Brayton (Bell Coleman Cycle) | 5–9 (2011) | SC/PC | Lower [36] | Not identified |

| Bernoulli Cycle | 3–4 (2017) | SC/PC | Lower [47] | Equal (Assumption) [47] |

| Elastomeric Effect | 2 (2016) | SC/PC | Higher (Assumption) [47] | Not Identified |

| (Metastable) Critical Flow Cycle | 3–4 (2017) | SC/PC | Lower [47] | Unknown |

| Membrane HP | 5–6 (2017) | SC/PC | Higher (Assumption) [36] | Equal (Assumption) [47] |

| Thermoacoustic | 4 (2016) | SC/PC | Lower [36] | Equal (Assumption) [47] |

| Magnetocaloric | 3–4 (2016) | SC/PC | Higher (Assumption) [47] | Unknown |

| Desiccant: Evaporative Liquid Dessiccant System | 3–4 (2019) | SC/PC | Higher (Assumption) [36] | Equal (Assumption) [36] |

| Ground-Coupled Solid Desiccant System | 3–4 (2017) | SC/PC | Higher [47] | Higher (Assumption) [36] |

| Stand-Alone Liquid Desiccant System | 3–4 (2017) | SC/PC | Lower [36] | Higher (Assumption) [36] |

| Stand-Alone Solid Desiccant System | 3–4 (2017) | SC/PC | Lower [47] | Higher [36] |

| Heat of Reaction | 2 (2019) | PC | Unknown | Not identified |

| Potential Energy Use | 6–9 (2019) | SC/PC | Not identified | Not identified |

| Absorption and Adsorption | 3–9 (2014) | SC/PC | Lower [47] | Higher [47] |

| Transcritical Thermal Compression HP | 4 (2019) | SC/PC | Lower [36] | Higher [47] |

| Natural Convection (Heat Exchanger–Mixing) | Up to 9 (2019) | SC/PC | Not identified | Not identified |

| Natural Conduction (Heat Exchanger) | Up to 9 (2019) | SC/PC | Not identified | Not identified |

| Freeze/Melt Cycle (Latent Cold Storage) | Up to 9 (2019) | SC/PC | Not identified | Not identified |

| Evaporative Cooling (Water Evaporation) | Up to 9 (2019) | SC/PC | Not identified | Equal (When used as independent system) [36] |

| Enthalpy Recovery (Heat Exchanger) | 7–8 (2017) | SC/PC | Not identified | Not identified |

| Sky Radiative Cooling | 3–4 (2019) | SC/PC | Not identified | Unknown |

References

- European Commission. 2020 Climate & Energy Package. Available online: https://ec.europa.eu/clima/policies/strategies/2020_en (accessed on 8 February 2022).

- European Commission. EU Emissions Trading System (EU ETS). Available online: https://ec.europa.eu/clima/policies/ets_en (accessed on 8 February 2022).

- Progress Made in Cutting Emissions. Available online: https://ec.europa.eu/clima/policies/strategies/progress_en (accessed on 12 October 2020).

- European Union. Directive (EU) 2018/2001 of the European Parliament and of the Council on the Promotion of the Use of Energy from Renewable Sources. Off. J. Eur. Union 2018, 2018, 82–209. [Google Scholar]

- European Commission. Energy Efficiency Targets–The EU Has Set Ambitious Energy Efficiency Targets for 2020 and 2030 to Reduce Primary and Final Energy Consumption. Available online: https://energy.ec.europa.eu/topics/energy-efficiency/energy-efficiency-targets-directive-and-rules/energy-efficiency-targets_en (accessed on 8 February 2022).

- European Commission. Going Climate-Neutral by 2050; Publication Office of the European Union: Luxembourg, 2019. [CrossRef]

- European Commission. L 328. Off. J. Eur. Union 2018, 61, 1–230. [Google Scholar]

- Energy Savings Statistics. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php/Energy_saving_statistics#Final_energy_consumption_and_distance_to_2020_and_2030_targets (accessed on 13 October 2020).

- Eurostat. Table on EU Policy-Europe 2020 Indicators-Headline Indicators-Climate Change and Energy-Primary Energy Consumption. Available online: https://ec.europa.eu/eurostat/databrowser/view/t2020_33/default/table?lang=en (accessed on 8 February 2022).

- Fleiter, T.; Steinbach, J.; Ragwitz, M.; Arens, M.; Aydemir, A.; Elsland, R.; Frassine, C.; Herbst, A.; Hirzel, S. Mapping and Analyses of the Current and Future (2020–2030) Heating/Cooling Fuel Deployment (Fossil/Renewables); European Commission: Brussels, Belgium, 2016. [Google Scholar] [CrossRef]

- Pezzutto, S.; Fazeli, R.; De Felice, M.; Sparber, W. Future Development of the Air-Conditioning Market in Europe: An Outlook until 2020. WIREs Energy Environ. 2016, 5, 649–669. [Google Scholar] [CrossRef]

- Pezzutto, S.; Toleikyte, A.; De Felice, M. Assessment of the Space Heating and Cooling Market in the EU28: A Comparison between EU15 and EU13 Member States. Int. J. Contemp. Energy 2015, 1, 39–52. [Google Scholar] [CrossRef]

- Pezzutto, S.; Croce, S.; Zambotti, S.; Kranzl, L.; Novelli, A.; Zambelli, P. Assessment of the Space Heating and Domestic Hot Water Market in Europe—Open Data and Results. Energies 2019, 12, 1760. [Google Scholar] [CrossRef]

- Heating and Cooling. Available online: https://ec.europa.eu/easme/en/section/horizon-2020-energy-efficiency/heating-and-cooling#:~:text=Heating and cooling constitutes around,is generated from renewable energy (accessed on 13 October 2020).

- Pezzutto, S.; De Felice, M.; Fazeli, R.; Kranzl, L.; Zambotti, S. Status Quo of the Air-Conditioning Market in Europe: Assessment of the Building Stock. Energies 2017, 10, 1253. [Google Scholar] [CrossRef]

- European Commission. JRC-IDEES 2015. Available online: https://data.jrc.ec.europa.eu/dataset/jrc-10110-10001 (accessed on 7 February 2022).

- Arora, C.P. Refrigeration and Air Conditioning; Tata McGraw-Hill Publishing: New Delhi, India, 2000. [Google Scholar]

- GitLab. Hotmaps/Building Stock Analysis. Available online: https://gitlab.com/hotmaps/building-stock/-/tree/master/data (accessed on 5 October 2020).

- MTA. Process Cooling Solutions for Plastics–MTA. Available online: https://www.mta-it.com/eng/applications/process-cooling-solutions/plastics.php (accessed on 5 February 2022).

- Pezzutto, A.S.; Sparber, W.; Fedrizzi, R. Analysis of the Space Heating and Cooling Market in Europe. Methods 2014, 12, 14. Available online: https://d1wqtxts1xzle7.cloudfront.net/36872580/Paper_for_the_3rd_International_PhD-Day_Linz_Simon_Pezzutto_final_version_to_publish-libre.pdf?1425594995=&response-content-disposition=inline%3B+filename%3DAnalysis_of_the_space_heating_and_coolin.pdf&Expires=1646226498&Signature=GGwBwu7cmG3GuEWlhst-X8WSXg-3D2b-tNTo2VxYGm7NOI6pk6G2DyeatZh02Nx0kJsCVNzb-m5IdKGogXRjM6~6N0W81cEHcbCLJr4UpdMBDyVPNsD4GaOafKkHKaGXrLZSVj8uWrza~xZD0qynYAPhjeXPFw680jmJyHNAQMhTgPRlCCMUSBLRyS2n12Ubyk7AYIIkh-Hce9lruFddQI5arlMiM8TB7lBYWwKMBXKflf2F6iA-M5~r9yiczhp622cX5kSiPIqNZ~TGdhvDHHVDoqY3So~0vBPFxz4tIwsdjyPa7KvpCUIGUSE5xNhhhkQ2RdypfGta5d57oewKag__&Key-Pair-Id=APKAJLOHF5GGSLRBV4ZA (accessed on 12 November 2020).

- Pezzutto, A.S.; Sparber, W.; Fedrizzi, R. Analysis of the Space Heating and Cooling Market in Europe. 2012. Available online: https://www.semanticscholar.org/paper/Analysis-of-the-Space-Heating-and-Cooling-Market-in-Pezzutto-Sparber/52bfb64cf13cbe4c6bac4d1491ddfd85d9a9d3a0 (accessed on 12 November 2020).

- European Partnership for Energy and the Environment (EPEE). The Rising Need for Cooling. Available online: http://countoncooling.eu/index.php/the-rising-need-for-cooling/ (accessed on 8 February 2022).

- Braungardt, D.S.; Bürger, D.V.; Zieger, J.; Kenkmann, T. Contribution of Renewable Cooling to the Renewable Energy Target of the EU. ETDEWEB 2018, 16–24. [Google Scholar]

- Brown, J.S.; Domanski, P.A. Review of Alternative Cooling Technologies. Appl. Therm. Eng. 2014, 64, 252–262. [Google Scholar] [CrossRef]

- EUROVENT Market Intelligence. Available online: https://www.eurovent-marketintelligence.eu/ (accessed on 15 October 2020).

- Fischer, S.K.; Hughes, P.J.; Fairchild, P.D.; Kusik, C.L.; Dieckmann, J.T.; McMahon, E.M.; Hobday, N. Energy and Global Warming Impacts of CFC Alternative Technologies; Bpi Information Services: Washington, DC, USA, 1991. [Google Scholar]

- Gauger, D.C.; Shapiro, H.N.; Pate, M.B. Alternative Technologies for Refrigeration and Air-Conditioning Application; Research and Development: Washington, DC, USA, 1995. [Google Scholar]

- Commission Decision C(2017)7124. G. Technology Readiness Levels (TRL); Horizon 2020—Work Programme 2014-2015 General Annexes; 2020. [Google Scholar]

- Goetzler, W.; Shandross, R.; Young, J.; Petritchenko, O.; Ringo, D.; McClive, S. Energy Savings Potential and RD&D Opportunities for Commercial Building HVAC Systems; Technical Report for U.S. Department of Energy, Office of Energy Efficiency and Renewable Energy, Building Technologies Office: Burlington, MA, USA, 2018. [Google Scholar]

- Deng, J.; Wang, R.Z.; Han, G.Y. A Review of Thermally Activated Cooling Technologies for Combined Cooling, Heating and Power Systems. Prog. Energy Combust. Sci. 2011, 37, 172–203. [Google Scholar] [CrossRef]

- Osterman, E.; Tyagi, V.V.; Butala, V.; Rahim, N.A.; Stritih, U. Review of PCM Based Cooling Technologies for Buildings. Energy Build. 2012, 49, 37–49. [Google Scholar] [CrossRef]

- Montagnino, F.M. Solar Cooling Technologies. Design, Application and Performance of Existing Projects. Sol. Energy 2017, 154, 144–157. [Google Scholar] [CrossRef]

- de Negri, J.F.; Pezzutto, S.; Gantioler, S.; Moser, D.; Sparber, W. A Comprehensive Analysis of Public and Private Funding for Photovoltaics Research and Development in the European Union, Norway, and Turkey. Energies 2020, 13, 2743. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, L.; Gong, G.; Li, H.; Tang, G. Review of Solar Thermoelectric Cooling Technologies for Use in Zero Energy Buildings. Energy Build. 2015, 102, 207–216. [Google Scholar] [CrossRef]

- Oró, E.; Depoorter, V.; Pflugradt, N.; Salom, J. Overview of Direct Air Free Cooling and Thermal Energy Storage Potential Energy Savings in Data Centres. Appl. Therm. Eng. 2015, 85, 100–110. [Google Scholar] [CrossRef]

- Goetzler, W.; Shandross, R.; Young, J.; Petritchenko, O.; Ringo, D.; McClive, S. Energy Savings Potential and RD&D Opportunities for Commercial Building HVAC Systems; Technical Report for U.S. Department of Energy, Office of Energy Efficiency and Renewable Energy, Building Technologies Office: Burlington, MA, USA, 2017. [Google Scholar]

- Goetzler, B.; Guernsey, M.; Kassuga, T.; Young, J.; Savidge, T.; Bouza, A.; Neukomm, M.; Sawyer, K. Grid-Interactive Efficient Buildings Technical Report Series: Lighting and Electronics; Technical Report for U.S. Department of Energy, Office of Energy Efficiency and Renewable Energy, Building Technologies Office: Burlington, MA, USA, 2019. [Google Scholar]

- European Commission. Technology Roadmap in Preparatory/Review Study on Commission Regulation (EC) No. 643/2009 with Regard to Ecodesign Requirements for Household Refrigeration Appliances and Commission Delegated Regulation (EU) No. 1060/2010 with Regard to Energy Labelling; European Commission: Brussels, Belgium, 2016. [Google Scholar]

- Mitchell, M.P.; Fabris, D.; Tomlinson, B.J. Double Vortex Tube as Heat Exchanger and Flow Impedance for a Pulse Tube Refrigerator. In Cryocoolers 10; Ross, R.G., Ed.; Springer: Boston, MA, USA, 2002; pp. 257–264. [Google Scholar] [CrossRef]

- Young, M.K.; Shin, D.K.K.; Lee, J.H.H. A New Ericsson Cycle Comprising a Scroll Expander and a Scroll Compressor for Power and Refrigeration Applications. In Proceedings of the 2004 International Refrigeration and Air Conditioning Conference at Purdue, Purdue, IN, USA, 12–15 July 2004. [Google Scholar]

- Gupta, K. Reusable Instant Cooler Based on Endothermic Chemical Reactions. Int. J. Innov. Res. Sci. Eng. Technol. 2016, 5, 9. [Google Scholar] [CrossRef]

- Coulter, J.O. Case for Cooling an Electronic Device via an Endothermic Reaction. U.S. Patent 9,608,686 B1, 28 March 2017. [Google Scholar]

- Lechner, N. Heating, Cooling, Lighting: Sustainable Design Methods for Architects; John Wiley and Sons: Hoboken, NJ, USA, 2014. [Google Scholar]

- Holzer, P.; Psomas, T. Ventilative Cooling Sourcebook: Energy in Buildings and Communities Programme. March 2018; Department of Civil Engineering, Aalborg University: Aalborg, Denmark, 2018. [Google Scholar]

- Lim, X. The Super-Cool Materials That Send Heat to Space. Nature 2020, 577, 18–20. [Google Scholar] [CrossRef]

- Rony, R.U.; Yang, H.; Krishnan, S.; Song, J. Recent Advances in Transcritical CO2 (R744) Heat Pump System: A Review. Energies 2019, 12, 457. [Google Scholar] [CrossRef]

- Goetzler, W.; Zogg, R.; Young, J.; Johnson, C. Alternatives to Vapor-Compression HVAC Technology. ASHRAE J. 2014, 56, 12–23. [Google Scholar]

- Astolfi, M. 3-Technical options for Organic Rankine Cycle systems. In Technologies and Applications; Woodhead Publishing: Cambridge, UK, 2017; pp. 67–89. [Google Scholar] [CrossRef]

- Hrnjak, P.S. Editorial: Carbon Dioxide Systems. HVAC R Res. 2006, 12, 1–2. [Google Scholar] [CrossRef]

- Kim, M.-H.; Pettersen, J.; Bullard, C.W. Fundamental Process and System Design Issues in CO2 Vapor Compression Systems. Prog. Energy Combust. Sci. 2004, 30, 119–174. [Google Scholar] [CrossRef]

- Groll, E.A.; Kim, J.-H. Review Article: Review of Recent Advances toward Transcritical CO2 Cycle Technology. HVAC R Res. 2007, 13, 499–520. [Google Scholar] [CrossRef]

- Arpagaus, C.; Bless, F.; Schiffmann, J.; Bertsch, S.S. Multi-Temperature Heat Pumps: A Literature Review. Int. J. Refrig. 2016, 69, 437–465. [Google Scholar] [CrossRef]

- Karampour, M.; Sawalha, S. State-of-the-Art Integrated CO2 Refrigeration System for Supermarkets: A Comparative Analysis. Int. J. Refrig. 2018, 86, 239–257. [Google Scholar] [CrossRef]

- Karampour, M.; Sawalha, S. Energy Efficiency Evaluation of Integrated CO2 Trans-Critical System in Supermarkets: A Field Measurements and Modelling Analysis. Int. J. Refrig. 2017, 82, 470–486. [Google Scholar] [CrossRef]

- Gullo, P.; Hafner, A.; Banasiak, K. Transcritical R744 Refrigeration Systems for Supermarket Applications: Current Status and Future Perspectives. Int. J. Refrig. 2018, 93, 269–310. [Google Scholar] [CrossRef]

- Song, Y.; Cui, C.; Li, M.; Cao, F. Investigation on the Effects of the Optimal Medium-Temperature on the System Performance in a Transcritical CO2 System with a Dedicated Transcritical CO2 Subcooler. Appl. Therm. Eng. 2020, 168, 114846. [Google Scholar] [CrossRef]

- Bert, J. Pulse Tube Cryocoolers: A Cryogen-Free Path To 2K; Department of Physics, Stanford University: Stanford, CA, USA, 2007; pp. 3–9. [Google Scholar]

- Lienerth, C.; Thummes, G.; Heiden, C. Progress in Low Noise Cooling Performance of a Pulse-Tube Cooler for HT-SQUID Operation. IEEE Trans. Appl. Supercond. 2001, 11, 812–815. [Google Scholar] [CrossRef]

- D’Addabbo, A.; Bucci, C.; Canonica, L.; Di Domizio, S.; Gorla, P.; Marini, L.; Nucciotti, A.; Nutini, I.; Rusconi, C.; Welliver, B. An Active Noise Cancellation Technique for the CUORE Pulse Tube Cryocoolers. Cryogenics 2018, 93, 56–65. [Google Scholar] [CrossRef]

- Nast, T.C.; Roth, E.; Olson, J.; Champagne, P.; Frank, D. Qualification of Lockheed Martin Micro Pulse Tube Cryocooler to TRL6. Cryocoolers 2014, 18, 42–47. [Google Scholar]

- Sridhar, K.R.; Nanjundan, A.; Gottmann, M.; Swanson, T.D.; Didion, J. Evaluation of a Reverse Brayton Cycle Heat Pump for Lunar Base Cooling. SAE Trans. 1994, 103, 568–574. [Google Scholar]

- Woods, J.; Pellegrino, J.; Kozubal, E.; Slayzak, S.; Burch, J. Modeling of a Membrane-Based Absorption Heat Pump. J. Memb. Sci. 2009, 337, 113–124. [Google Scholar] [CrossRef]

- Bukshaisha, A.A.; Fronk, B.M. Simulation of Seasonal Performance of a Membrane Heat Pump System in Different Climate Regions. In Proceedings of the 17th International Refrigeration and Air Conditioning Conference at Purdue 2018, West Lafayette, IN, USA, 9–12 July 2018. [Google Scholar]

- CLEAR Comfortable Low Energy Architecture. Available online: https://www.new-learn.info/packages/clear/thermal/buildings/passive_system/evaporating_cooling.html (accessed on 12 November 2020).

- Brown, D.; Stout, T.B.; Dirks, J.; Fernandez, N. The Prospects of Alternatives to Vapor Compression Technology for Space Cooling and Food Refrigeration Applications. Energy Eng. 2012, 109, 7–20. [Google Scholar] [CrossRef]

- Aman, J.; Ting, D.; Henshaw, P. Solar Sorption Cooling for Residential Air-Conditioning Applications. Int. J. Renew. Energy Technol. 2018, 9, 136–157. [Google Scholar] [CrossRef]

- Stryi-Hipp, G.; Dias, P.; Ivancic, A.; Mugnier, D.; Weiss, W. Solar Heating and Cooling Technology Roadmap. Eur. Technol. Platf. Renew. Heat. Cool. 2014, 1–32. [Google Scholar] [CrossRef]

- Dittmann, F.; Rivière, P.; Stabat, P. Heat Roadmap Europe: Building the Knowledge, Skills, and Capacity Required to Enable New Policies and Encourage New Investments in the Heating and Cooling Sector; The Publications Office of the European Union: Brussels, Belgium, 2017.

- ICF Consulting. International Chiller Sector Energy Efficiency and CFC Phaseout. Available online: http://www.unep.fr/ozonaction/information/mmcfiles/6303-e-ICFChillerStudyFINALwb.pdf (accessed on 17 November 2020).

- Rowe, D.; White, S. Review of International Solar Cooling Incentive Schemes. Energy Procedia 2014, 57, 3160–3170. [Google Scholar] [CrossRef][Green Version]

- Jakubcionis, M.; Carlsson, J. Estimation of European Union Residential Sector Space Cooling Potential. Energy Policy 2017, 101, 225–235. [Google Scholar] [CrossRef]

| Technology | TRL (Year) | Efficiency (Compared to VC) | Costs (Compared to VC) |

|---|---|---|---|

| Transcritical Cycle | Up to 9 (2016) | Higher (depending on climate, refrigerant mixture, and energy-efficient solutions) [46] | Higher [36] |

| Pulse Tube | 6 (2014) | Lower [36] | Not identified |

| Reverse Brayton (Bell Coleman Cycle) | 5–9 (2011) | Lower [47] | Not identified |

| Potential Energy Use | 6–9 (2019) | Not identified | Not identified |

| Electrochemical | 3–4 (2017) | Higher (Assumption) [36] | Unknown |

| Natural Convection (Heat Exchanger–Mixing) | Up to 9 (2019) | Not identified | Not identified |

| Natural Conduction (Heat Exchanger) | Up to 9 (2019) | Not identified | Not identified |

| Freeze/Melt Cycle (Latent Cold Storage) | Up to 9 (2019) | Not identified | Not identified |

| Evaporative Cooling (Water Evaporation) | Up to 9 (2019) | Not identified | Equal (When used as an independent system) [36] |

| Enthalpy Recovery (Heat Exchanger) | 7–8 (2017) | Not identified | Not identified |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pezzutto, S.; Quaglini, G.; Riviere, P.; Kranzl, L.; Novelli, A.; Zambito, A.; Wilczynski, E. Screening of Cooling Technologies in Europe: Alternatives to Vapour Compression and Possible Market Developments. Sustainability 2022, 14, 2971. https://doi.org/10.3390/su14052971

Pezzutto S, Quaglini G, Riviere P, Kranzl L, Novelli A, Zambito A, Wilczynski E. Screening of Cooling Technologies in Europe: Alternatives to Vapour Compression and Possible Market Developments. Sustainability. 2022; 14(5):2971. https://doi.org/10.3390/su14052971

Chicago/Turabian StylePezzutto, Simon, Giulio Quaglini, Philippe Riviere, Lukas Kranzl, Antonio Novelli, Andrea Zambito, and Eric Wilczynski. 2022. "Screening of Cooling Technologies in Europe: Alternatives to Vapour Compression and Possible Market Developments" Sustainability 14, no. 5: 2971. https://doi.org/10.3390/su14052971

APA StylePezzutto, S., Quaglini, G., Riviere, P., Kranzl, L., Novelli, A., Zambito, A., & Wilczynski, E. (2022). Screening of Cooling Technologies in Europe: Alternatives to Vapour Compression and Possible Market Developments. Sustainability, 14(5), 2971. https://doi.org/10.3390/su14052971