Understanding Sustainability of Construction Products: Answers from Investors, Contractors, and Sellers of Building Materials

Abstract

:1. Introduction

- reducing energy use in new and existing buildings;

- optimizing the use of renewable energy sources;

- decarbonizing all energy supplies to buildings;

- minimizing embodied GHG emissions in construction materials and construction works (construction, renovation, and demolition) both in the construction of new and renovated existing buildings;

- reducing GHG emissions from building operations.

2. Materials and Methods

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- European Commission. The European Green Deal; European Commission: Brussels, Belgium, 2019. [Google Scholar]

- European Commission. A European Green Deal. Striving to be the First Climate-Neutral Continent. Available online: https://ec.europa.eu/info/strategy/priorities-2019-2024/european-green-deal_en (accessed on 15 December 2021).

- European Commission. Delivering European Green Deal. Brussels, Belgium. 2021. Available online: https://ec.europa.eu/info/strategy/priorities-2019-2024/european-green-deal/delivering-european-green-deal_en (accessed on 15 December 2021).

- Global Alliance for Buildings and Construction, International Energy Agency and the United Nations Environment Programme. 2019 Global Status Report for Buildings and Construction: Towards a Zero-Emission, Efficient and Resilient Buildings and Construction Sector. Available online: https://www.worldgbc.org/news-media/2019-global-status-report-buildings-andconstruction (accessed on 15 December 2021).

- European Environment Agency. Trends and Projections in Europe 2021. Copenhagen, Denmark. 2021. Available online: https://www.eea.europa.eu/publications/trends-and-projections-in-europe-2021 (accessed on 15 December 2021).

- European Academies Science Advisory Council. Decarbonisation of Buildings: For Climate, Health and Jobs. Halle, Germany, 2021. Available online: https://easac.eu/publications/details/decarbonisation-of-buildings-for-climate-health-and-jobs/ (accessed on 15 December 2021).

- European Environmental Agency, Progress on Energy Efficiency in Europe. Copenhagen, Denmark. 2021. Available online: https://www.eea.europa.eu/data-and-maps/indicators/progress-on-energy-efficiency-in-europe-3/assessment (accessed on 15 December 2021).

- Directive 2002/91/EC of the European Parliament and the Council. Available online: https://eur-lex.europa.eu/legal-content/EN/ALL/?uri=CELEX:32002L0091 (accessed on 19 December 2021).

- Directive 2010/31/EU of the European Parliament and the Council. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:32010L0031 (accessed on 19 December 2021).

- Directive 2018/844/EU of the European Parliament and the Council. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:32018L0844 (accessed on 19 December 2021).

- Kubečková, D.; Vrbová, M. Historical Development of Thermal Protection of Prefab Residential Housing and Its Future, an Example of the Czech Republic. Energies 2021, 14, 2623. [Google Scholar] [CrossRef]

- Pasker, R. The European ETICS Market at a Glance: Facts, Figures, Latest Trends. In Proceedings of the 5th European ETICS Forum, Prague, Czech Republic, 16 September 2021; European Association for External Thermal Insulation Composite Systems (EAE): Berlin, Germany, 2021. [Google Scholar]

- Künzel, H.; Künzel, H.M.; Sedlbauer, K. Long-term performance of external thermal insulation systems (ETICS). Acta Archit. 2006, 5, 11–24. [Google Scholar]

- Barreira, E.; de Freitas, V.P. Experimental study of the hygrothermal behaviour of External Thermal Insulation Composite Systems (ETICS). Build. Environ. 2013, 63, 31–39. [Google Scholar] [CrossRef]

- Amaro, B.; Saraiva, D.; de Brito, J.; Flores-Colen, I. Statistical survey of the pathology, diagnosis and rehabilitation of ETICS in walls. J. Civ. Eng. Manag. 2014, 20, 511–526. [Google Scholar] [CrossRef] [Green Version]

- de Freitas, S.S.; de Freitas, V.P. Cracks on ETICS along thermal insulation joints: Case study and a pathology catalogue. Struct. Surv. 2016, 34, 57–72. [Google Scholar] [CrossRef]

- Sulakatko, V.; Liisma, E.; Soekov, E. Increasing construction quality of external thermal insulation composite system (ETICS) by revealing on-site degradation factors. Procedia Environ. Sci. 2017, 38, 765–772. [Google Scholar] [CrossRef]

- Orlik-Kożdoń, B.; Nowoświat, A.; Krause, P.; Ponikiewski, T. A numerical and experimental investigation of temperature field in place of anchors in ETICS system. Constr. Build. Mater. 2018, 167, 553–565. [Google Scholar]

- Norvaišienė, R.; Buhagiar, V.; Burlingis, A.; Miškinis, K. Investigation of mechanical resistance of external thermal insulation composite systems (ETICS). J. Build. Eng. 2020, 32, 101682. [Google Scholar] [CrossRef]

- Ślusarek, J.; Orlik-Kożdoń, B.; Bochen, J.; Muzyczuk, T. Impact of the imperfection of thermal insulation on structural changes of thin-layer facade claddings in ETICS. J. Build. Eng. 2020, 32, 101487. [Google Scholar] [CrossRef]

- Parracha, J.L.; Borsoi, G.; Flores-Colen, I.; Veiga, R.; Nunes, L.; Dionísio, A.; Faria, P. Performance parameters of ETICS: Correlating water resistance, bio-susceptibility and surface properties. Constr. Build. Mater. 2021, 272, 121956. [Google Scholar] [CrossRef]

- Parracha, J.L.; Borsoi, G.; Veiga, R.; Flores-Colen, I.; Nunes, L.; Garcia, A.R.; Ilharco, L.M.; Dionísio, A.; Faria, P. Effects of hygrothermal, UV and SO2 accelerated ageing on the durability of ETICS in urban environments. Build. Environ. 2021, 204, 108151. [Google Scholar] [CrossRef]

- Regulation (EU), No. 305/2011 of the European Parliament and of the Council. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:32011R0305 (accessed on 20 August 2021).

- European Organization for Technical Assessment (EOTA). ETAG 004: Guideline for European Technical Approval of External Thermal Insulation Composite Systems (ETICS) with Rendering; European Organization for Technical Assessment (EOTA): Brussels, Belgium, 2013. [Google Scholar]

- European Organization for Technical Assessment (EOTA). European Assessment Document EAD 040083-00-04040 External Thermal Insulation Composite Systems (ETICS) with Renderings; European Organization for Technical Assessment (EOTA): Brussels, Belgium, 2020. [Google Scholar]

- Michalak, J. External Thermal Insulation Composite Systems (ETICS) from Industry and Academia Perspective. Sustainability 2021, 13, 13705. [Google Scholar] [CrossRef]

- Röck, M.; Saade, M.R.M.; Balouktsi, M.; Rasmussen, F.N.; Birgisdottir, H.; Frischknecht, R.; Habert, G.; Lützkendorf, T.; Passer, A. Embodied GHG emissions of buildings–The hidden challenge for effective climate change mitigation. Appl. Energy 2020, 258, 114107. [Google Scholar] [CrossRef]

- Wall, S. CE Marking of Construction Products—Evolution of the European Approach to Harmonisation of Construction Products in the Light of Environmental Sustainability Aspects. Sustainability 2021, 13, 6396. [Google Scholar] [CrossRef]

- European Commission. M/350 EN Standardisation Mandate to CEN. In Development of Horizontal Standardized Methods for Assessment of the Integrated Environmental Performance of Buildings; European Commission: Brussels, Belgium, 2004. [Google Scholar]

- EN 15804:2012; Sustainability of Construction Works-Environmental Product Declarations-Core Rules for the Product Category of Construction Product. European Committee for Standardization (CEN): Brussels, Belgium, 2012.

- Bovea, M.D.; Ibáñez-Forés, V.; Agustí-Juan, I. Environmental product declaration (EPD) labeling of construction and building materials. In Eco-Efficient Construction and Building Materials: Life Cycle Assessment (LCA), Eco-Labelling and Case Studies; Woodhead Publishing: New York, NY, USA, 2014; pp. 125–150. ISBN 9780857097675. [Google Scholar]

- Brinkmann, T.; Metzger, L. Ecological assessment based on environmental product declarations. In Progress in Life Cycle Assessment; Springer: Cham, Switzerland, 2018; pp. 21–31. [Google Scholar]

- European Commission. Single Market for Green Products Initiative. Available online: https://ec.europa.eu/environment/eussd/smgp/index.htm (accessed on 22 December 2021).

- Durão, V.; Silvestre, J.D.; Mateus, R.; de Brito, J. Assessment and communication of the environmental performance of construction products in Europe: Comparison between PEF and EN 15804 compliant EPD schemes. Resour. Conserv. Recycl. 2020, 156, 104703. [Google Scholar] [CrossRef] [Green Version]

- Passer, A.; Lasvaux, S.; Allacker, K.; De Lathauwer, D.; Spirinckx, C.; Wittstock, B.; Kellenberger, D.; Gschösser, F.; Wall, J.; Wallbaum, H. Environmental product declarations entering the building sector: Critical reflections based on 5 to 10 years’ experience in different European countries. Int. J. Life Cycle Assess. 2015, 20, 1199–1212. [Google Scholar] [CrossRef] [Green Version]

- Anderson, J.; Moncaster, A. Embodied carbon of concrete in buildings, Part 1: Analysis of published EPD. Build. Cities 2020, 1, 198–217. [Google Scholar] [CrossRef]

- Lasvaux, S.; Achim, F.; Garat, P.; Peuportier, B.; Chevalier, J.; Habert, G. Correlations in Life Cycle Impact Assessment methods (LCIA) and indicators for construction materials: What matters? Ecol. Indic. 2016, 67, 174–182. [Google Scholar] [CrossRef]

- Ströbele, B.; Lützkendorf, T. Communicating environmental information: Rethinking options for construction products. Build. Res. Inf. 2019, 47, 681–696. [Google Scholar] [CrossRef]

- Rosario, P.D.; Palumbo, E.; Traverso, M. Environmental Product Declarations as Data Source for the Environmental Assessment of Buildings in the Context of Level (s) and DGNB: How Feasible Is Their Adoption? Sustainability 2021, 13, 6143. [Google Scholar] [CrossRef]

- Michałowski, B.; Michalak, J. Sustainability-oriented assessment of external thermal insulation composite systems: A case study from Poland. Cogent Eng. 2021, 8, 1943152. [Google Scholar] [CrossRef]

- Adibi, N.; Mousavi, M.; Escobar, R.M.; Glachant, M.; Adibi, A. Mainstream Use of EPDs in Buildings: Lessons Learned from Europe. In Proceedings of the ISBS 2019 4th International Sustainable Buildings Symposium, Dallas, TX, USA, 18–20 July 2019; Gültekin, A.B., Ed.; IntechOpen: Ankara, Turkey, 2019. [Google Scholar]

- Kunič, R. Carbon footprint of thermal insulation materials in building envelopes. Energy Effic. 2017, 10, 1511–1528. [Google Scholar] [CrossRef]

- Grazieschi, G.; Asdrubali, F.; Thomas, G. Embodied energy and carbon of building insulating materials: A critical review. Clean. Environ. Syst. 2021, 2, 100032. [Google Scholar] [CrossRef]

- Pargana, N.; Pinheiro, M.D.; Silvestre, J.D.; de Brito, J. Comparative environmental life cycle assessment of thermal insulation materials of buildings. Energy Build. 2014, 82, 466–481. [Google Scholar]

- Dovjak, M.; Košir, M.; Pajek, L.; Iglič, N.; Božiček, D.; Kunič, R. Environmental impact of thermal insulations: How do natural insulation products differ from synthetic ones? Earth Environ. Sci. 2017, 92, 012009. [Google Scholar] [CrossRef]

- Tůmová, E.; Drochytka, R.; Černý, V.; Čada, P. Development of organic and biodegradable insulating material for ETICS. Procedia Eng. 2017, 195, 81–87. [Google Scholar]

- Hill, C.; Norton, A.; Dibdiakova, J. A comparison of the environmental impacts of different categories of insulation materials. Energy Build. 2018, 162, 12–20. [Google Scholar] [CrossRef]

- Palumbo, M.; Lacasta, A.M.; Giraldo, M.P.; Haurie, L.; Correal, E. Bio-based insulation materials and their hygrothermal performance in a building envelope system (ETICS). Energy Build. 2018, 174, 147–155. [Google Scholar]

- Streimikiene, D.; Skulskis, V.; Balezentis, T.; Agnusdei, G.P. Uncertain multi-criteria sustainability assessment of green building insulation materials. Energy Build. 2020, 219, 110021. [Google Scholar] [CrossRef]

- Kumar, D.; Zou, P.X.; Memon, R.A.; Alam, M.M.; Sanjayan, J.G.; Kumar, S. Life-cycle cost analysis of building wall and insulation materials. J. Build. Phys. 2020, 43, 428–455. [Google Scholar] [CrossRef]

- Famielec, J.; Famielec, S. Integracja nauk ekonomicznych, technicznych i chemicznych na rzecz rozwoju zrównoważonego. Ekon. I Sr. 2016, 58, 47–61. [Google Scholar]

- Stamatopoulos, C. A holistic view of finite populations for determining an appropriate sample size. Appl. Sci. Innov. Res. 2019, 3, 219–244. [Google Scholar] [CrossRef]

- Cochran, W.G. Sampling Techniques, 3rd ed.; John Wiley & Sons: New York, NY, USA, 1977. [Google Scholar]

- Łukasik, M.; Michałowski, B.; Michalak, J. Assessment of the Constancy of Performance of Cementitious Adhesives for Ceramic Tiles: Analysis of the Test Results Commissioned by Polish Market Surveillance Authorities. Appl. Sci. 2020, 10, 6561. [Google Scholar] [CrossRef]

- Kulesza, M.; Łukasik, M.; Michalowski, B.; Michalak, J. Risk related to the assessment and verification of the constancy of performance of construction products. Analysis of the results of the tests of cementitious adhesives for ceramic tiles commissioned by Polish construction supervision authorities in 2016–2020. Cem. Wapno Beton 2020, 25, 444–456. [Google Scholar]

- Ustawa o Wyrobach Budowalnych. Available online: http://isap.sejm.gov.pl/isap.nsf/DocDetails.xsp?id=WDU20040920881 (accessed on 10 January 2022).

- Potrč, T.; Rebec, K.M.; Knez, F.; Kunič, R.; Legat, A. Environmental footprint of external thermal insulation composite systems with different insulation types. Energy Procedia 2016, 96, 312–322. [Google Scholar] [CrossRef] [Green Version]

- Michalak, J.; Czernik, S.; Marcinek, M.; Michałowski, B. Environmental burdens of external thermal insulation systems. expanded polystyrene vs. mineral wool: Case study from Poland. Sustainability 2020, 12, 4532. [Google Scholar] [CrossRef]

- Czernik, S.; Marcinek, M.; Michałowski, B.; Piasecki, M.; Tomaszewska, J.; Michalak, J. Environmental Footprint of Cementitious Adhesives—Components of ETICS. Sustainability 2020, 12, 8998. [Google Scholar] [CrossRef]

- Michałowski, B.; Marcinek, M.; Tomaszewska, J.; Czernik, S.; Piasecki, M.; Geryło, R.; Michalak, J. Influence of rendering type on the environmental characteristics of expanded polystyrene-based external thermal insulation composite system. Buildings 2020, 10, 47. [Google Scholar] [CrossRef] [Green Version]

- Galindro, B.M.; Welling, S.; Bey, N.; Olsen, S.I.; Soares, S.R.; Ryding, S.O. Making use of life cycle assessment and environmental product declarations: A survey with practitioners. J. Ind. Ecol. 2020, 24, 965–975. [Google Scholar] [CrossRef]

- Michalak, J.; Michałowski, B. Understanding of Construction Product Assessment Issues and Sustainability among Investors, Architects, Contractors, and Sellers of Construction Products in Poland. Energies 2021, 14, 1941. [Google Scholar] [CrossRef]

- Balouktsi, M.; Lützkendorf, T.; Röck, M.; Passer, A.; Reisinger, T.; Frischknecht, R. Survey results on acceptance and use of Life Cycle Assessment among designers in world regions: IEA EBC Annex 72. IOP Conf. Ser. Earth Environ. Sci. 2020, 588, 032023. [Google Scholar] [CrossRef]

- Yamane, T.; Kaneko, S. The Sustainable Development Goals as new business norms: A survey experiment on stakeholder preferences. Ecol. Econ. 2022, 191, 107236. [Google Scholar] [CrossRef]

- Yamane, T.; Kaneko, S. Is the younger generation a driving force toward achieving the sustainable development goals? Survey experiments. J. Clean. Prod. 2021, 292, 125932. [Google Scholar] [CrossRef]

- Yamane, T.; Kaneko, S. Impact of raising awareness of Sustainable Development Goals: A survey experiment eliciting stakeholder preferences for corporate behavior. J. Clean. Prod. 2021, 285, 125291. [Google Scholar] [CrossRef]

- Mansell, P.; Philbin, S.P.; Konstantinou, E. Redefining the use of sustainable development goals at the organisation and project levels—A survey of engineers. Adm. Sci. 2020, 10, 55. [Google Scholar] [CrossRef]

- Šebestová, J.; Sroka, W. Sustainable development goals and SMEs decisions: Czech Republic vs. Poland. J. East. Eur. Cent. Asian Res. 2020, 7, 39–50. [Google Scholar] [CrossRef]

- Raszkowski, A.; Bartniczak, B. On the road to sustainability: Implementation of the 2030 Agenda sustainable development goals (SDG) in Poland. Sustainability 2019, 11, 366. [Google Scholar] [CrossRef] [Green Version]

- Tomaszewska, J. Polish transition towards circular economy: Materials management and implications for the construction sector. Materials 2020, 13, 5228. [Google Scholar] [CrossRef]

| Professional Group | Population Size, N | Sample Size Equation (1), n0 | Sample Size Equation (2), n | Real Sample Size |

|---|---|---|---|---|

| Investors | 479 | 213 | 147 | 181 |

| Constructors | 9369 | 369 | 355 | 522 |

| Sellers | 280 | 162 | 102 | 116 |

| Total | 819 | |||

| Professional Group | Sample Size Equation (2), n | Real Sample Size | Non-Respondent Rate, % |

|---|---|---|---|

| Investors | 147 | 181 | 4.42 |

| Constructors | 355 | 522 | 7.48 |

| Sellers | 102 | 116 | 3.45 |

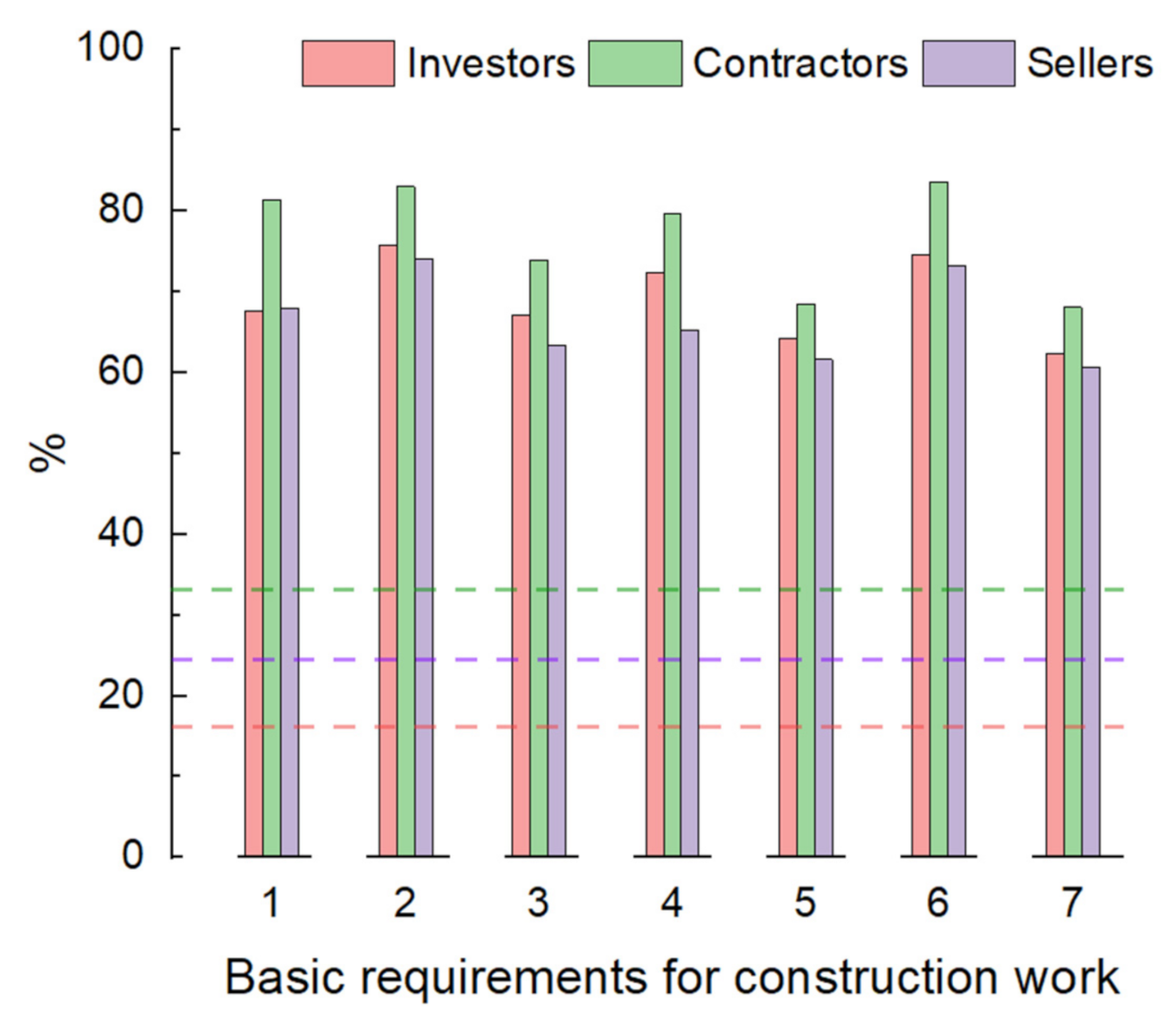

| No. | Question | Investors (173) | Contractors (483) | Sellers (112) |

|---|---|---|---|---|

| 1. | From the following requirements, highlight those that are basic requirements for construction works under Regulation (EU) No 305/2011 of the European Parliament and of the Council (CPR): | |||

| 117 | 393 | 76 | |

| 131 | 401 | 83 | |

| 116 | 357 | 71 | |

| 125 | 385 | 73 | |

| 111 | 331 | 69 | |

| 129 | 404 | 82 | |

| 108 | 329 | 68 | |

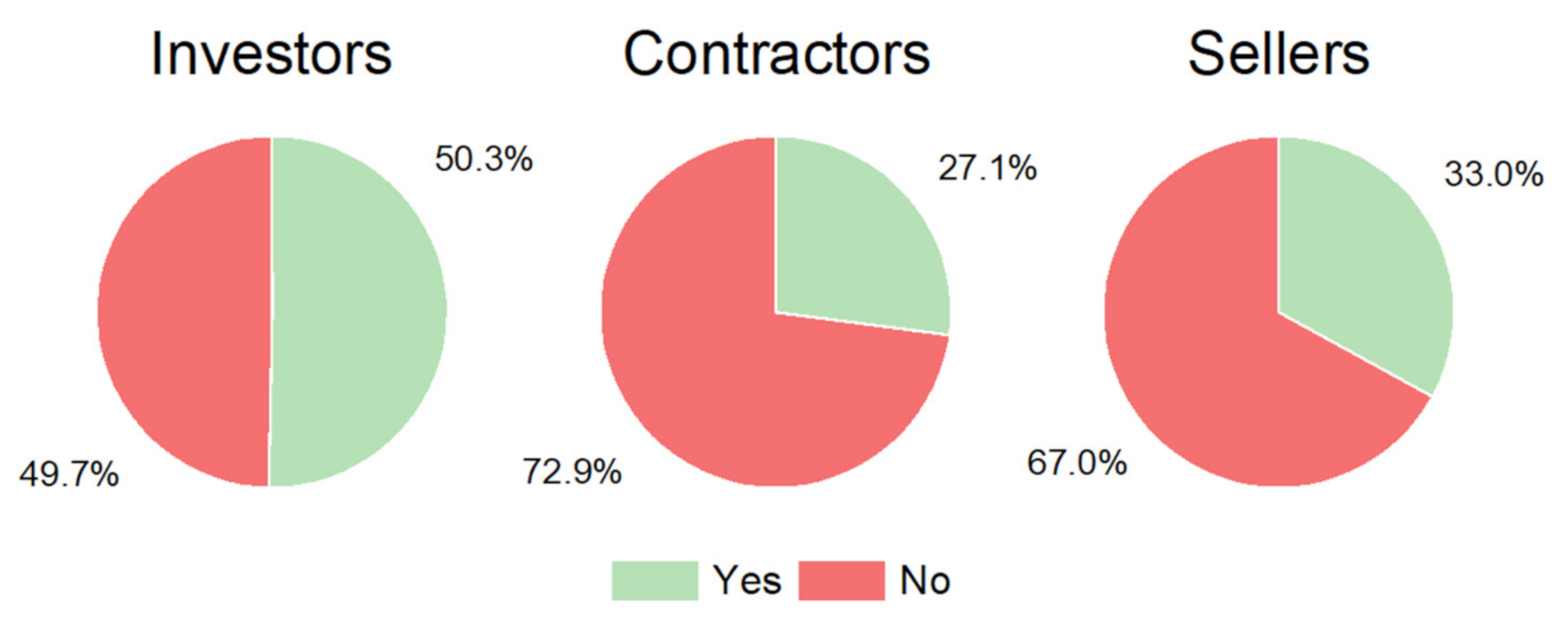

| 2. | Do you know the environmental burden of global warming potential of 1 m2 of the ETICS? | |||

| 87 | 131 | 37 | |

| 86 | 352 | 75 | |

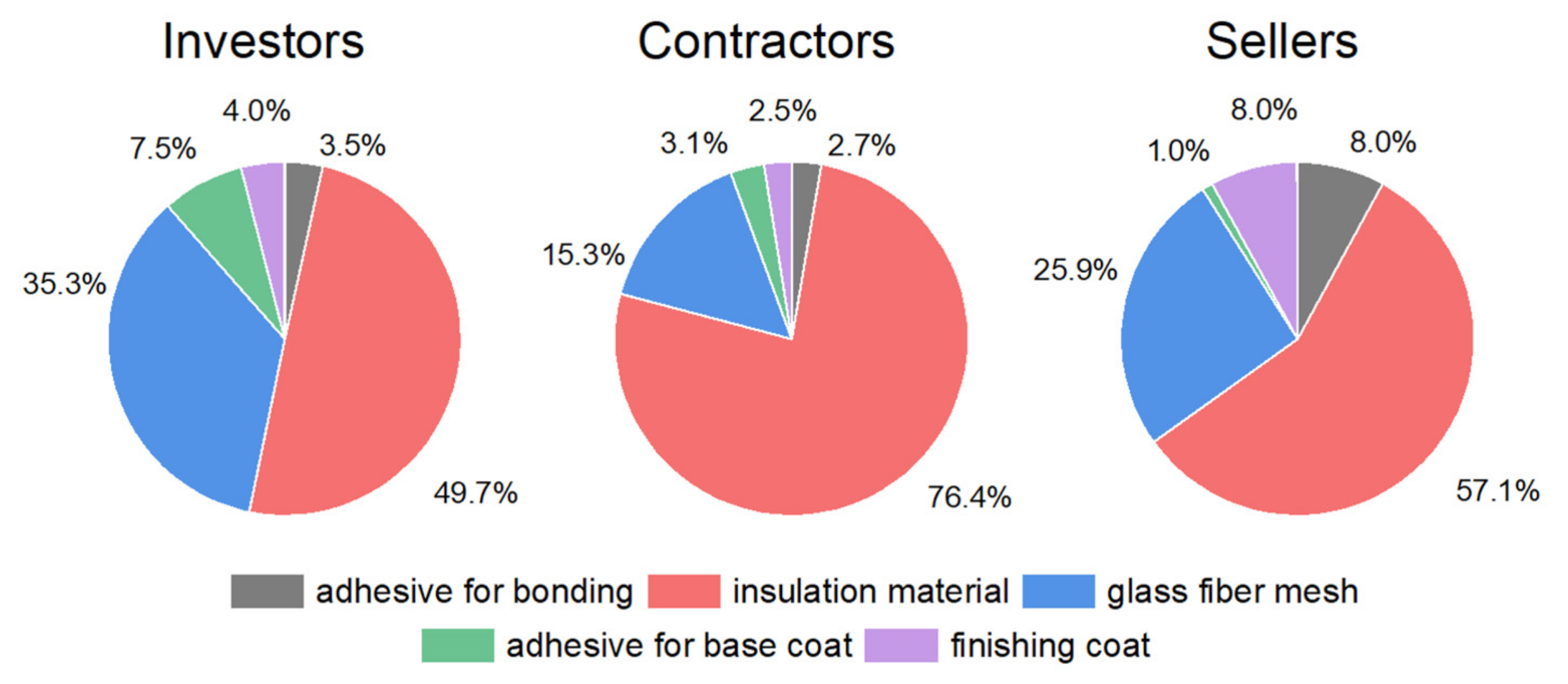

| 3. | Manufacturing which thermal insulation material has the most significant negative impact on the global warming potential: | |||

| 30 | 163 | 27 | |

| 100 | 218 | 66 | |

| 43 | 102 | 19 | |

| 4. | Production of which ETICS component has the most significant negative impact on the global warming potential: | |||

| 6 | 13 | 9 | |

| 86 | 396 | 64 | |

| 61 | 74 | 29 | |

| 13 | 15 | 1 | |

| 7 | 12 | 9 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Michalak, J.; Michałowski, B. Understanding Sustainability of Construction Products: Answers from Investors, Contractors, and Sellers of Building Materials. Sustainability 2022, 14, 3042. https://doi.org/10.3390/su14053042

Michalak J, Michałowski B. Understanding Sustainability of Construction Products: Answers from Investors, Contractors, and Sellers of Building Materials. Sustainability. 2022; 14(5):3042. https://doi.org/10.3390/su14053042

Chicago/Turabian StyleMichalak, Jacek, and Bartosz Michałowski. 2022. "Understanding Sustainability of Construction Products: Answers from Investors, Contractors, and Sellers of Building Materials" Sustainability 14, no. 5: 3042. https://doi.org/10.3390/su14053042

APA StyleMichalak, J., & Michałowski, B. (2022). Understanding Sustainability of Construction Products: Answers from Investors, Contractors, and Sellers of Building Materials. Sustainability, 14(5), 3042. https://doi.org/10.3390/su14053042