1. Introduction

Over the last several decades, a drastic increase in world energy consumption and the associated environmental deterioration and global warming have aroused wide and profound public concern [

1]. To address these energy and environmental problems, various solutions from deepening the penetration of renewable energy (i.e., supply-side) to improving the energy efficiency of energy-using systems (i.e., user-side) have been developed and applied [

2,

3]. As an essential connection bridging these solutions between the supply and user sides, energy management has been attracting increasing attention for the rationalisation of energy utilisation [

4,

5], for whose fulfillment, efficient energy storage and transportation are indispensable [

6,

7].

In terms of energy management involving thermal energy, phase change materials (PCMs) have been widely recognised as efficient and effective media to fulfill thermal energy storage and transportation [

8,

9]. Ice, with the features of high heat of fusion and easy availability, has been applied in thermal energy storage of various sectors such as cold chain and air conditioning. In addition to its role in thermal energy storage media, an ice–water (or aqueous solution) mixture slurry can serve as a heat transfer fluid for thermal energy transportation. Compared to other PCM slurries (e.g., phase change emulsions), ice slurry was the first being industrialised and widely deployed thanks to its advantages of low cost, high efficiency, large thermal capacity, and good pumpability [

10,

11,

12]. Recent research on ice slurry mainly focuses on its properties and performance characterisation (including heat transfer and flow), ice slurry generation, and practical applications. Among them, the generation of ice slurry is one of the primary key topics in any ice slurry systems. It is a hotspot in research regarding ice slurry, as the cost of current ice slurry generators accounts for a major proportion, which impedes the deeper application of this promising technology [

13]. Currently, there are various technologies for ice slurry generation, such as supercooled water technology, scraped surface technology, vacuum technology, and refrigerant direct contact technology [

14,

15]. Scraped surface technology is one of the most popular methods, usually relying on the rotation of scraper blades within heat exchanger tubes to break the ice layer grown on the inner surface for ice slurry generation. This feature enables the easy control of the ice fraction in ice slurry; however, it tends to require custom evaporator design and lead to additional mechanical consumption, which typically causes additional energy consumption by around 10–20% compared to that of the supercooled method [

13,

16]. The supercooled water method utilises the supercooling feature of water, which can be cooled by a few degrees below the normal freezing point without crystallizing; then, by agitating the supercooled water to release the supercooled degree, ice crystals can be generated [

17]. Compared to other technologies, supercooled water technology boasts of simplicity, low energy cost, and wide adaptability, and is suitable for large-scale air conditioning systems. More details about different ice slurry generation technologies can be found in Satio [

10], Kauffeld et al. [

13], and Kauffeld and Gund [

18].

Recent research regarding supercooled water ice slurry generation technology usually focuses on avoiding ice blockage, development of control mechanisms, investigation of supercooling degree-releasing methods, and optimal system design. Ice blockage is likely to occur in the supercooling heat exchanger, which can lead to discontinuous ice slurry generation and a drop in system efficiency [

19]. The occurrence of ice blockages is tightly associated with nucleation and thus affected by many factors, including but not limited to supercooling degree, water flow velocity, insoluble particles, and wall roughness. It has been reported that the supercooling degree is the most important factor, the increase of which contributes to system capacity and controllability while improving the probability of crystallization and decreasing the risk of blockage [

20]. Tanino and Kozawa [

21] experimentally studied the acceptable range of supercooling degree while considering the system efficiency. They summarised the optimal supercooling range from 1 to 2 °C, which can simultaneously avoid ice blockage and maintain decent system efficiency. As the maximum acceptable supercooling degree can be increased with a low wall roughness, surface modifications have been studied and utilised. For instance, Wang et al. [

22] studied the water contact angle of stainless steel and nanocomposite fluorocarbon coatings. It was found that the water contact angle increased from 84 to 163° and the maximum supercooling degree in the coated supercooling heat exchanger reached around 1.7 °C compared to that of 0.9 °C in the uncoated supercooling heat exchanger. Furthermore, insoluble particles in water influenced the supercooling degree. Okawa [

23] used the silver iodide as the foreign particles to study the nucleation characteristics under different foreign particle concentrations, and found that the crystallisation temperature depends on the total surface area of particles. In particular, the existence of tiny ice crystal seeds in the source water is one of the most common reasons for ice blockage in a supercooled water ice slurry generation system. In practice, preheating (usually by 0.5 °C) is of great necessity to remove ice crystals before beginning another supercooling cycle [

14]; however, this preheating no doubt is a source of energy loss.

Releasing the supercooling degree is a necessary process for ice slurry generation when using supercooled water technology, and has also been extensively investigated. Collison and stirring are among the main traditional methods for releasing the supercooling degree [

17,

22]. An alternative method is ultrasonic vibration; many studies have confirmed its advantages, including good uniformity and rapid response of crystallisation. For instance, Inada et al. [

24] studied the performance of supercooling degree releasing using ultrasonic vibrations under 28 kHz, and found that the ice crystals could be generated under a lower supercooling degree compared to the other traditional methods. Zhang et al. [

25] investigated and confirmed the relationship between cavitation bubbles induced by ultrasonic waves and the effect of supercooled state release. Hozumi et al. [

26] experimentally compared ice slurry generation under the same frequency with different ultrasonic vibration powers, and the results showed that higher power contributed to the effect of supercooling degree release.

Due to the importance of establishment and releasing of supercooling degree in the ice slurry generation process using supercooled water technology, much effort has been assigned from the system aspect to stabilise the supercooling status while improving its efficiency. The indirect ice slurry generation system was first studied to enhance the stability of the cold source for ice slurry generation, and various indirect ice slurry generation systems have been developed and applied in practical air conditioning systems and cooling systems for different purposes [

13,

27,

28]. To simplify the system and reduce the overall heat transfer temperature difference, direct ice slurry generation systems have been developed in recent years, and a number of solutions at the system level have been proposed to ensure its stability. For instance, Tanino and Kozawa [

21] developed a direct ice slurry generation system with an ice concentrator that could produce ice slurry with a concentration of 5–10%, which enabled the enrichment of ice concentration based on ice slurry flow with low ice concentration, thereby avoiding ice blockage. Wang developed a direct ice slurry generation system with double supercooling heat exchangers for continuous ice slurry generation; these two supercooling heat exchangers can be switched when an ice blockage happened in one of them. However, these solutions introduce extra costs and may compensate for the benefits of direct ice slurry generation systems. Therefore, an in-depth comparison between direct and indirect ice slurry generation systems along with a comparison to other conventional ice slurry generation systems is of value.

From the above discussions, it can be seen that many questions remain to be addressed in supercooled water ice slurry generation, such as energy-saving in preheating process, quantitative performance assessment between direct and indirect ice slurry generation systems, and economic benefit enhancement compared to conventional ice slurry generation systems (e.g., scraped surface ice slurry generators). In this study, a regeneration cycle was proposed to effectively reduce the energy loss during the preheating of supercooled water ice slurry generation. Ice slurry generation systems with heat regeneration enhancement were developed, and their performance and life-cycle cost were experimentally investigated and assessed in comparison with a conventional scraped surface ice slurry generator. It is an innovative idea to apply heat regeneration for preheating the return water in ice slurry generation systems, thereby improving the system performance and economic benefits. The following parts of this paper are organised as follows:

Section 2 details the research methodology in this study; specifically,

Section 2.1 and

Section 2.2 introduce the principle of the heat regeneration enhancement and the experimental system, respectively.

Section 2.3 states the experiment plan and procedure, while

Section 2.4 presents the development of the key performance indicators. The setup of the economic analysis is detailed in

Section 2.5.

Section 3 presents and discusses the performance results of ice slurry generation systems with and without heat regeneration enhancement (

Section 3.1 and

Section 3.2, respectively) and the results of the economic analysis. Finally, useful conclusions of this research are summarised in

Section 4.

4. Conclusions

Efficient ice slurry generation plays a primary role in energy savings and the cost-effective application of ice slurry for thermal energy storage and transportation. In this study, a heat regeneration approach was proposed to enhance the efficiency of supercooled water ice slurry generation; this was integrated into a direct and an indirect supercooled water ice slurry generation systems, and the corresponding system performances were experimentally investigated under different working conditions through a series of comparative studies. Based on our performance evaluation, the life-cycle costs of the enhanced ice slurry generation systems were further assessed via reference to a conventional scraped surface ice slurry generation system used as benchmark.

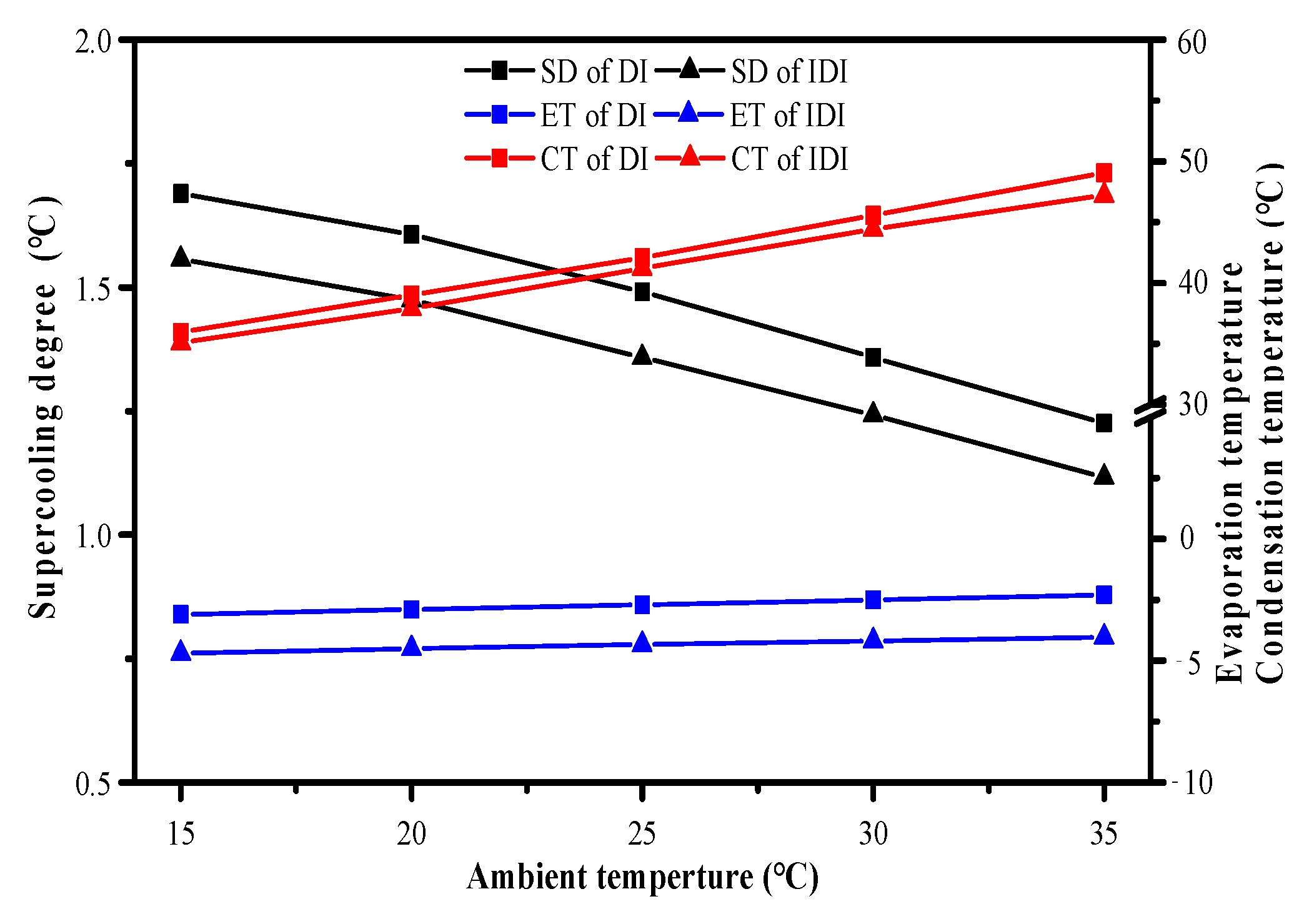

The experimental results showed that the supercooling degree of the enhanced systems was effectively increased, which improved the effective utilisation rate of cold energy from 76.5% to 88.0% in maximum for direct ice slurry generation. For both direct and indirect systems, the unit ice mass power consumption can be reduced by about 12–20%. When varying the ambient temperature from 15 °C to 35 °C, the COP of the direct and indirect ice slurry generation systems ranged from 2.80 to 1.90 and 2.26 to 1.57, respectively. Due to the existence of a secondary coolant loop, the efficiency of direct ice slurry generation system outperformed the indirect one, and its supercooling degree was 10% higher. As a result, the operational cost of the enhanced indirect ice slurry generation system reached USD 4605 compared USD 3775 for the enhanced direct ice slurry generation system, which were much lower than the scraped surface ice slurry generator (USD 7627). The total life-cycle costs of the direct and indirect ice slurry generation systems were USD 7650 and USD 9217, respectively only 62.0% and 74.7% that of the scraped surface ice slurry generator.