Analysis of the Photovoltaic Waste-Recycling Process in Polish Conditions—A Short Review

Abstract

:1. Introduction

2. Materials for Photovoltaics Cell Technology

- (a)

- Monocrystalline;

- (b)

- Polycrystalline;

- (c)

- Ribbon sheets.

- (a)

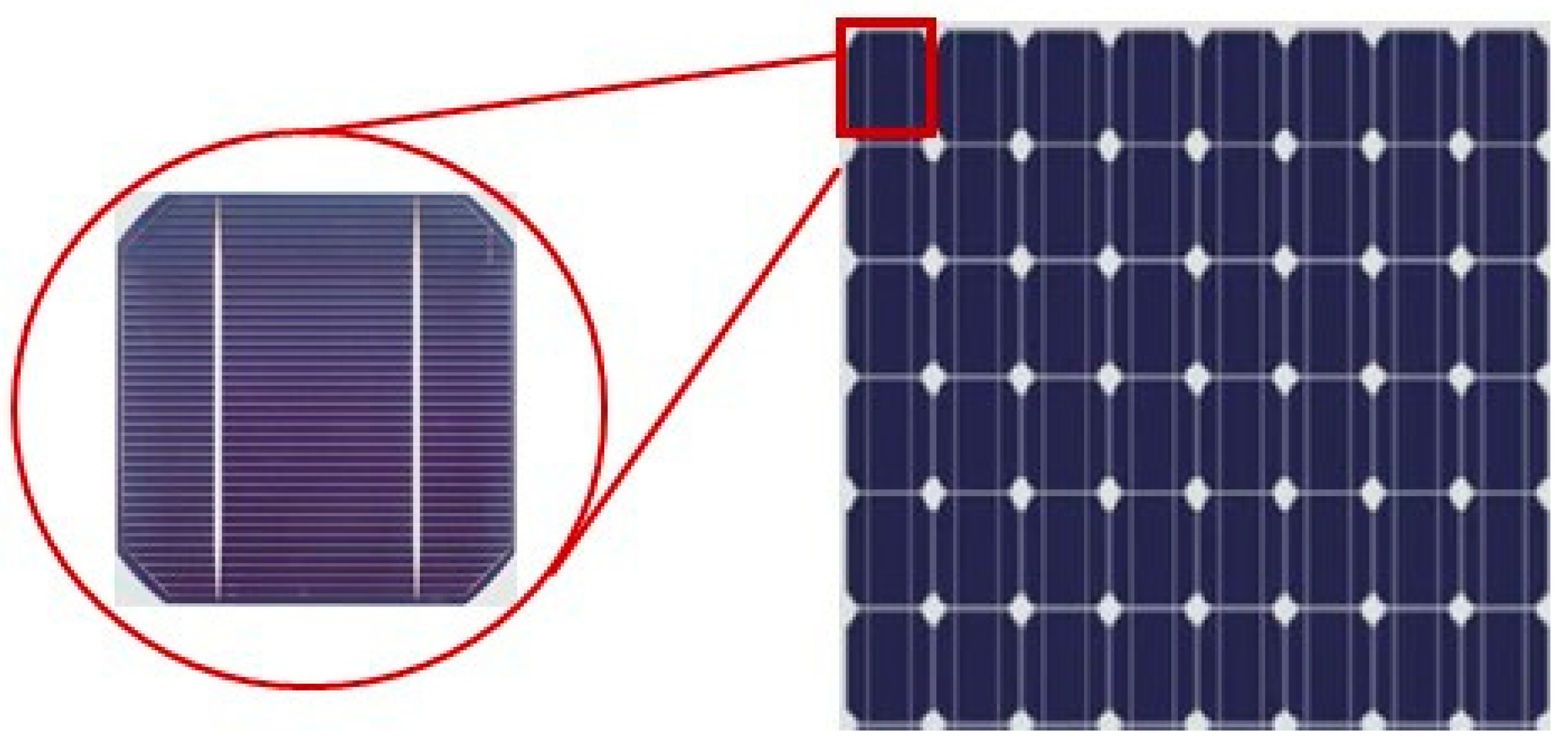

- Monocrystalline cells are made of a single crystal of silicon having an ordered structure, which can be obtained from the crystallization process from each of the solid, liquid, or gas phases [19]. A single silicon crystal, after the production of a monocrystalline cell, acquires a dark blue color, with cut or rounded corners (Figure 1). Monocrystalline cells are characterized by high efficiency (usually about 18–22%) and durability, which entails high production costs. Photovoltaic panels made of monocrystalline cells have a moderate indicator of power decrease with increasing temperature as well as an increase in power with decreasing temperature in which the solar installation operates. Monocrystalline panels work best in conditions of strong sunlight or low ambient temperatures; any drops in insolation and an increase in ambient temperature significantly reduce the efficiency of cells made of monocrystalline silicon [20].

- (b)

- Polycrystalline cells are made of polycrystalline silicon plates of an irregular shape. Polycrystalline silicon is produced from crushed silicon crystals that are melted and then cast in the form of a cuboid, cooling and cutting into plates of appropriate thickness [19]. Due to the technology of producing polycrystalline cells, they usually have a blue color and clearly defined crystal edges (Figure 2). Polycrystalline cells are characterized by quite high efficiency, ranging from 14–18%. Photovoltaic panels made of polycrystalline cells are characterized by an efficiency lower than that of a monocrystalline module and a high rate of power drop with increasing temperature, usually lower than a mono module. Photovoltaic modules made of polycrystalline cells can withstand weather fluctuations and drops in sunlight much better than cells made of single crystal. Taking into account the price of photovoltaic panels made of polycrystalline cells, which are cheaper than monocrystalline ones per watt of installed power by about 8–15%, and the fact that polycrystalline cells perform much better in average weather conditions, they are much more popular than monocrystalline photovoltaic panels. The low price of these modules is influenced by the low production costs of polycrystals [20]. An alternative to silicon wafers are crystalline silicon ribbons, the production of which is based on wafers from ingots. Ribbon technologies are characterized by the fact that the wafers are crystallized directly from the molten material to the desired thickness, and there are no losses in the gaps. Consequently, they offer a high potential to significantly reduce the cost of PV energy compared to ingot wafer technology [21].

- (a)

- Amorphous silicon (a-Si);

- (b)

- Cadmium telluride (CdTe);

- (c)

- Multi-junction cells (a-Si-μc Si);

- (d)

- Copper indium gallium (di)selenide (CIGS), copper indium (di)selenide (CIS).

- (a)

- Amorphous silicon cells (a-Si) consist of a very thin layer of non-crystallized silicon in a shapeless form, which is deposited on a substrate made of another material, such as glass, ceramics, plastic, or stainless steel (Figure 3a). The production technology of amorphous silicon cells is simple and allows to save a large amount of electricity and materials and also makes it possible to obtain cells with a large surface without having to cut them into plates. Amorphous silicon cells are characterized by low efficiency even for thin-film cells (efficiency in the range of 6–10%), low price, slight burgundy color, and complete absence of visible silicon crystals. Photovoltaic panels made of amorphous silicon cells do not lose their efficiency even on cloudy days. The advantage of amorphous modules is a very low power drop with increasing temperature; for this reason, hybrid modules are often used instead of them and based on combined amorphous and microcrystalline silicon cells [26,27].

- (b)

- Cadmium telluride (CdTe) cells are thin-film cells made of cadmium telluride, which is a semiconductor, deposited on a glass substrate (Figure 3b). Their characteristic feature is the fact that the cadmium compound used in the production of cells allows the creation of an entire photovoltaic panel using a single cell. Cadmium telluride cells have a fairly high efficiency for thin-film cells (oscillating between 10–14%) and are characterized by a black color. These cells are often used in the production of flexible photovoltaic panels that can be easily adapted to the building facade [28].

- (c)

- Multi-junction cells (a-Si-μc Si) are tandem solar cells that consist of amorphous and microcrystalline silicon junctions. The latest research concerns the study of new joint patterns as a two-dimensional photonic crystal. Such innovative solutions increase the efficiency of light conversion by more than 20% compared to conventional planar configurations [29].

- (d)

- Cells made of indium-copper (di)selenide (CIS) and gallium (CIGS) are made of a semiconductor material consisting of a mixture of copper-indium (di)selenide, for CIS (chemical formula CuIn1-xSe2), or of copper-indium-gallium (di)selenium (chemical formula Cu(In1-xGax)Se2 (Figure 3c)). The possibility of using four types of elements allows to increase the efficiency of the cells by increasing the scope of absorption of solar radiation. The efficiency of CIS/CIGS cells is slightly higher than that of CdTe cells (they range between 12–16%). As in the case of CdTe cells, the technology used to produce CIS/CIGS cells allows for the creation of an entire photovoltaic panel with a single cell [30].Figure 3. View of materials used in the production of second-generation photovoltaic cells: (a) amorphous silicon; (b) cadmium telluride (CdTe); and (c) CIGS (copper indium gallium diselenide) Adapted from [31].Figure 3. View of materials used in the production of second-generation photovoltaic cells: (a) amorphous silicon; (b) cadmium telluride (CdTe); and (c) CIGS (copper indium gallium diselenide) Adapted from [31].

- (a)

- Dye-sensitized solar cells;

- (b)

- Organic solar cells;

- (c)

- Perovskite cells;

- (d)

- Quantum dot cells;

- (e)

- PERC (passivated emitter and rear cell) and PERL (passivated emitter and rear locally diffused).

- (a)

- Dye solar cell/dye-sensitized solar cell (DSC/DSSC) has a relatively simple structure. The cell consists of an anode and a cathode with an electrolyte between them. The anode is a glass plate covered with a transparent conductive oxide (TCO) layer. Indium tin oxide (ITO) or fluorine-doped tin oxide are most commonly used. A thin layer of titanium dioxide (TiO2) is applied to the foil. The anode is soaked in a dye solution that binds to TiO2. The DSC cathode is a glass plate with a thin layer of Pt as catalyst. The electrolyte is an iodide/triiodide solution. Both electrodes are pressed against each other and sealed so that the cell does not leak. An external load may be energized as light strikes the anode of a dye solar cell. These cells can be printed on transparent surfaces, such as windows, transparent walls, or skylights, and then work on both sides in conditions where other types of photovoltaic cells would be useless. Dye cells can be divided into organic and inorganic ones, and they use photosynthesis to convert energy from solar radiation to electricity. Dye cells have quite a good price/performance ratio (efficiency in laboratory conditions is up to 13%) [34,35,36]. To improve the electrical conductivity and light capture in the back layers, the conductive crystal is most often indium-doped tin oxide (ITO) and zinc oxide doped with fluoride (FTO). The semiconductor electrode is usually a thin layer (~5–30 m) layer of nanocrystalline titanium dioxide (TiO2), the porous structure of which facilitates the deposition of the dye on the surface. DSSCs operate in low-light conditions. This type of cells is ideal for low-density applications, such as rooftop solar collectors, where the mechanical strength and light weight of the glassless collector is a great advantage because the thin, conductive material allows for quick heat dissipation. The disadvantage is the need to use a liquid electrolyte, which may freeze at low temperatures. An additional disadvantage is that the electrolyte solution contains organic compounds that are toxic to human health and the environment. Recently, progress has been made in the field of materials and the use of materials such as ruthenium compounds, quantum dots, natural dyes, and organic compounds excluding metals [37].

- (b)

- Organic cells’ structure is based on organic materials that include, among others, polymers (or macromolecules) and small molecules. Organic photovoltaic cells is a rapidly developing photovoltaic technology that improves cell efficiency up to 18.2%, with a long service life of over 10 years without encapsulation [31]. Despite their drawbacks, these cells are cheap, flexible, and lightweight [38,39].

- (c)

- A perovskite solar cell is a type of solar cell containing a perovskite structural compound, most commonly a hybrid organic–inorganic lead or tin halide-based material, as the active light-collecting layer. Perovskite materials such as methylammonium lead halides are cheap and relatively simple to manufacture. Perovskite cells are printed on PET film, thanks to which they are thin, light, flexible, and efficient; they can be used in places that do not have perfect lighting and in the interiors of buildings with artificial lighting. A compound with a perovskite structure is used as an active layer that is sandwiched between an electron transporting layer (usually mesoporous) and a hole transport layer. Perovskite cells are easy to manufacture, and their high water absorption coefficient allows them to absorb the entire visible solar spectrum with ultra-thin layers (~500 nm) [40]. These cells are unstable in the environment of moisture and oxygen; they are brittle and not very resistant to heat. The absorbing material dissolves in water, which leads to the degradation of the cells. To counter this, it is necessary to encapsulate the perovskite absorber, for example, in a composite of carbon nanotubes [41]. The highest efficiency of perovskite cells (21.1–21.6%) was obtained by mixing various cations to create perovskite structure: rubidium, cesium, lead, tin, germanium, and anions that can optimize the solar spectra, namely chloride, bromide, and rhodium anions [42,43]

- (d)

- Quantum dot cells (QDs) are nanoscale semiconductor materials belonging to groups II–VI, III–V, or IV–VI of the periodic table of the elements, which have a discrete spectrum of quantized energy because motion electrons and holes are limited. Due to the nanoscale dimensions, usually in the range of 2–10 nm [44,45], they show properties intermediate between mass semiconductors and discrete atoms or particles. In the QD structure, we can distinguish a core in which there are layers of various compounds. It is also possible to embed the QD in a die made of a different material. The QD concentration affects the yield of the material, and the addition of nanoparticles can even improve the yield up to 40% depending on the concentration of nanodots. The advantages of CPV based on QDs include a favorable power-to-weight ratio, savings in weight and space, low energy consumption, and versatile use. Some of the QDs can be toxic (CdSe) and require a protective coating and are difficult to size controlling.

- (e)

- As regards PERC (passivated emitter and rear cell) and PERL (passivated emitter and rear locally diffused), the first high-performance PERC cells were produced in 1988, with the efficiency of 21.8% confirmed in Sandia in October 1988 (20.9% according to the applicable standards) [46]. As can be seen from the general data of patent H01L31/02168 [46], the invention discloses a method of preparing a PERC solar cell: a passivated film is placed locally on the back of a silicon chip by screen printing to form a back passivation layer with specific patterns. The material performance is influenced by the method of fiber preparation, the process of back-polishing and etching, and then decontamination of the glass. For the production of PERC, the method of local screen printing of alumina foil or silicon oxide foil on the back of the silicon chip is used, thermal treatment is carried out, and then, the anti-reflective silicon oxide face is deposited.

3. Production and Market of Individual Photovoltaic Panels

4. Recycling Process of Photovoltaic Panels

- After delamination, the recovery of Ag, In, and Si and high-purity glass from a thin photovoltaic film withdrawn from use and photovoltaic modules based on Si;

- The use of solid waste from the production of PV panels containing a mixture of broken silicon wafers and cells;

- Dry powder or filings formed during cutting and containing mainly Si as waste from the production of PV panels This approach can ensure high-value and high-efficiency recycling of photovoltaic modules (thin film and silicon) and allows for the economic recovery of all materials for reuse.

5. The Recycling Process of Solar Panels in Poland in Terms of Legal and Environmental Conditions

- − Inert waste;

- − Non-hazardous waste;

- − Hazardous waste.

- R3: Recycling or regeneration of organic substances that are not used as solvents;

- R4: Recycling or recovery of metals and metal compounds;

- R5: Recycling or recovery of other inorganic materials.

6. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Available online: www.globeenergia.pl (accessed on 15 April 2021).

- Parida, B.; Iniyan, S.; Gois, R. A review of solar photovoltaic technologies. Renew. Sustain. Energy Rev. 2011, 15, 1625–1636. [Google Scholar] [CrossRef]

- Paiano, A. Photovoltaic waste assessment in Italy. Renew. Sustain. Energy Rev. 2015, 41, 99–112. [Google Scholar] [CrossRef]

- KPEiK, 2019, Krajowy Plan na Rzecz Energii i Klimatu na Lata 2021–2030, Założenia i Cele Oraz Polityki i Działania, Ministerstwo Aktywów Państwowych. 18 December 2019. Available online: https://www.gov.pl/ (accessed on 15 September 2021). (In Polish)

- SET Plan. In The Strategic Energy Technology; European Union: Maastricht, The Netherlands, 2018.

- PEP. Polityka Energetyczna Polski do 2040; Ministerstwo Klimatu i Środowiska: Warsaw, Poland, 2021. (In Polish) [Google Scholar]

- SROR. Strategia na Rzecz Odpowiedzialnego Rozwoju do Roku 2020 (z Perspektywą do 2030r); Uchwała Rady Ministrów: Warszawa, Poland, 2017. (In Polish) [Google Scholar]

- KRIE. Kierunki Rozwoju Innowacji Energetycznej; Ministerstwo Energii: Warsaw, Poland, 2017. (In Polish) [Google Scholar]

- PSE. Plan Rozwoju w Zakresie Zaspokojenia Obecnego i Przyszłego Zapotrzebowania na Energie Elektryczną na Lata 2021–2030; Polskie Sieci Elektroenergetyczne: Konstancin-Jeziorna, Poland, 2020. (In Polish) [Google Scholar]

- A Union that aims higher. Political Guidelines for the Next Term of the European Commission (2019–2024); A Union That Aims Higher: Brussels, Belgium, 2020. [Google Scholar]

- WEEE. Directive 2012/19EU of the European Parliament and of the Council; European Parliament and the Council of the European Union: Brussels, Belgium, 2012. [Google Scholar]

- Chowdhury, M.S.; Rahman, K.S.; Chowdhury, T.; Nuthammachot, N.; Techato, K.; Akhtaruzzaman, M.; Tiong, S.K.; Sopian, K.; Amin, N. An overview of solar photovoltaic panels ’end-of-life material recycling. Energy Strategy Rev. 2020, 27, 100431. [Google Scholar] [CrossRef]

- Ahmadi, M.H.; Baghban, A.; Sadeghzadeh, M.; Zamen, M.; Mosavi, A.; Shamshirband, S.; Kumar, R.; Mohammadi-Khanaposhtani, M. Evaluation of electrical efficiency of photovoltaic thermal solar collector. Eng. Appl. Comput. Fluid Mech. 2020, 14, 545–565. [Google Scholar] [CrossRef] [Green Version]

- Xu, Y.P.; Ouyang, P.; Xing, S.M.; Qi, L.Y.; Jafari, H. Optimal structure design of a PV/FC HRES using amended Water Strider Algorithm. Energy Rep. 2021, 7, 2057–2067. [Google Scholar] [CrossRef]

- Adewole, B.Z.; Malomo, B.O.; Olatunji, O.P.; Ikobayo, A.O. Simulation and Experimental Verification of Electrical Power Output of a Microcontroller Based Solar Tracking Photovoltaic Module. Int. J. Sustain. Energy Environ. Res. 2020, 9, 34–45. [Google Scholar] [CrossRef]

- Flizikowski, J.; Mroziński, A. Inżynieria Instalacji Fotowoltaicznych; Wydawnictwo Współfinansowane ze Środków Funduszy Norweskich oraz Środków Krajowych: Bydgoszcz, Poland, 2016. (In Polish) [Google Scholar]

- Kibria, M.A.; Saidur, R.; Al-Sulaiman, F.A.; Aziz, M.M.A. Development of a thermal model for a hybrid photovoltaic module and phase change materials storage integrated in buildings. Sol. Energy 2016, 124, 114–123. [Google Scholar] [CrossRef]

- Huang, B.; Zhao, J.; Chai, J.; Xue, B.; Zhao, F.; Wang, X. Environmental influence assessment of China’s multi-crystalline silicon (multi-Si) photovoltaic modules considering recycling process. Sol. Energy 2017, 143, 132–141. [Google Scholar] [CrossRef]

- Preet, S.; Bhushan, B.; Mahajan, T. Experimental investigation of water based photovoltaic/thermal (PV/T) system with and without phase change material (PCM). Sol. Energy 2017, 155, 1104–1120. [Google Scholar] [CrossRef]

- Jastrzębska, G. Ogniwa Słoneczne Budowa, Technologia i Zastosowanie; Wydawnictwo Komunikacji i Łączności: Warszawa, Poland, 2014. (In Polish) [Google Scholar]

- Hahn, G.; Schönecker, A. New crystalline silicon ribbon materials for photovoltaics. J. Phys. Condens. Matter 2004, 16, R161. [Google Scholar] [CrossRef] [Green Version]

- Jung, B.; Park, J.; Seo, D.; Park, N. Sustainable system for raw-metal recovery from crystalline silicon solar panels: From noble-metal extraction to lead removal. ACS Sustain. Chem. Eng. 2016, 4, 4079–4083. [Google Scholar] [CrossRef]

- Available online: www.instsani.pl (accessed on 10 September 2021).

- Klugmann-Radziemska, E. Fotowoltaika w Teorii i Praktyce; Wydawnictwo BTC: Legionowo, Poland, 2010. (In Polish) [Google Scholar]

- Huang, W.H.; Shin, W.J.; Wang, L.; Sun, W.C.; Tao, M. Strategy and technology to recycle wafer-silicon solar modules. Sol. Energy 2017, 144, 22–31. [Google Scholar] [CrossRef] [Green Version]

- Fiandra, V.; Sanino, L.; Andreozzi, C.; Corcelli, F.; Graditi, G. Silicon photovoltaic modules at end-of-life: Removal of polymers layers and separation of materials. Waste Manag. 2019, 87, 97–107. [Google Scholar] [CrossRef]

- Tao, J.; Yu, S. Review on feasible recycling pathways and technologies of solar photovoltaic modules. Sol. Energy Mater. Sol. Cells 2015, 141, 108–124. [Google Scholar] [CrossRef]

- Goris, M.J.A.A.; Rosca, V.; Geerligs, L.J.; deGier, B. Production of Recyclable Crystalline Si PV Modules. In Proceedings of the 31st European Photovoltaic Solar Energy Conference and Exhibition, Hamburg, Germany, 14–18 September 2015; pp. 1925–1929. [Google Scholar] [CrossRef]

- Zhang, C.; Li, X.; Shang, A.; Zhan, Y.; Yang, Z.; Wu, S. Performance-improved thin-film a-Si:H/µc-Si:H tandem solar cells by two dimensionally nanopaterning photoactive layer. Nanoscale Res. Lett. 2014, 9, 73. [Google Scholar] [CrossRef] [Green Version]

- De Castro, C.; Mediavilla, M.; Miguel, L.J.; Frechoso, F. Global solar electric potential: A review of their technical and sustainable limits. Renew. Sustain. Energy Rev. 2013, 28, 824–835. [Google Scholar] [CrossRef]

- Fthenakis, V. Sustainability of photovoltaics: The case for thin-film solar cells. Renew. Sustain. Energy Rev. 2009, 13, 2746–2750. [Google Scholar] [CrossRef] [Green Version]

- Kushiya, K. Key near–term R&D issues for continuous improvement in CIS- based thin-film PV modules. Sol. Energy Mater. Sol. Cells 2009, 93, 1037–1041. [Google Scholar]

- Available online: www.solartime.pl (accessed on 10 September 2021).

- Available online: www.hcdesign.pl (accessed on 10 September 2021).

- Ma, T.; Li, Z.; Zhao, J. Photovoltaic panel integrated with phase change materials (PV-PCM): Technology overview and materials selection. Renew. Sustain. Energy Rev. 2019, 116, 109–406. [Google Scholar] [CrossRef]

- Polman, A.; Knight, M.; Garnete, E.C.; Ehrler, B.; Sinke, W.C. Photovoltaic materials: Present efficiencies and future challenges. Science 2016, 352, aad4424. [Google Scholar] [CrossRef] [Green Version]

- Shalini, S.; Balasundaraprabhu, R.; Kumar, T.S.; Prabavathy, N.; Senthilarasu, S.; Prasanna, S. Status and outlook of sensitizers/dyes used in dye sensitized solar cells (DSSC): A review. Int. J. Energy Res. 2016, 40, 1303–1320. [Google Scholar] [CrossRef]

- Fuentes, M.; Vivar, M.; de la Casa, J.; Aguilera, J. An experimental comparison between commercial hybrid PV-T and simple PV systems intended for PIPV. Renew. Sustain. Energy Rev. 2018, 93, 110–120. [Google Scholar] [CrossRef]

- Available online: https://www.nrel.gov/ (accessed on 10 September 2021).

- Yin, W.; Shi, T.; Yan, Y. Unique Properties of Halide Perovskites as Possible Origins of the Superior Solar Cell Performance. Adv. Mater. 2014, 26, 4653–4658. [Google Scholar] [CrossRef] [PubMed]

- Habisreutinger, S.N.; Leijtens, T.; Eperon, G.E.; Stranks, S.D.; Nicholas, R.J.; Snaith, H.J. Carbon nanotube/polymer composites as a highly stable hole collection layer in perovskite solar cells. Nano Lett. 2014, 14, 5561–5568. [Google Scholar] [CrossRef] [PubMed]

- Saliba, M.; Matsui, T.; Seo, J.; Domanski, K.; Correa-Baena, J.; Nazeeruddin, M.K.; Zakeeruddin, S.M.; Tress, W.; Abate, A.; Hagfeldt, A.; et al. Cesium-containing triple cation perovskite solar cells: Improvedstability, reproducibility and high efficiency. Energy Environ. Sci. 2016, 9, 1989–1997. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Saliba, M.; Matsui, T.; Domanski, K.; Seo, J.-Y.; Ummadisingu, A.; Zakeeruddin, S.M.; Correa-Baena, J.-P.; Tress, W.R.; Abate, A.; Hagfeldt, A.; et al. Incorporation of rubidium cations into perovskite solar cells improves photovoltaic performance. Science 2016, 354, 206–209. [Google Scholar] [CrossRef]

- Bera, D.; Qian, L.; Tseng, T.-K.; Holloway, P.-H. Quantum Dots and Their Multimodal Applications: A Review. Materials 2010, 3, 2260–2345. [Google Scholar] [CrossRef] [Green Version]

- Tian, J.; Cao, G. Semiconductor quantum dot-sensitized solar cells. Nano Rev. 2013, 4, 22578. [Google Scholar] [CrossRef]

- Green, M.A. The Passivated Emitter and Rear Cell (PERC):From conception to mass production. Sol. Energy Mater. Sol. Cells 2015, 143, 190–197. [Google Scholar] [CrossRef]

- Coatings for -Devices Characterised by at Least One Potential Jump Barrier or Surface Barrier for Solar Cells the Coatings Being Antireflective or Having Enhancing Optical Properties for the Solar. Cells. Patent H01L31/02168, 8 September 2006.

- Kenisarin, M.M. Thermophysical properties of some organic phase change materials for latent heat storage: A review. Sol. Energy 2014, 107, 553–575. [Google Scholar] [CrossRef]

- Umair, M.M.; Zhang, Y.; Iqbal, K.; Zhang, S.; Tang, B. Novel strategies and supporting materials applied to shape-stabilize organic phase change materials for thermal energy storage: A review. Appl. Energy 2019, 235, 846–873. [Google Scholar] [CrossRef]

- Nazir, H.; Batool, M.; Osorio, F.J.B.; Isaza-Ruiz, M.; Xu, X.; Vignarooban, K.; Phelan, P.; Kannan, A.M. Recent developments in phase change materials for energy storage applications: A review. Int. J. Heat. Mass Transf. 2019, 129, 491–523. [Google Scholar] [CrossRef]

- Pandey, A.K.; Hossain, M.S.; Tyagi, V.V.; Abd Rahim, N.; Jeyraj, A.; Selvaraj, L.; Sari, A. Novel approaches and recent developments on potential applications of phase change materials in solar energy. Renew Sustain. Energy Rev. 2018, 82, 281–323. [Google Scholar] [CrossRef]

- Sultan, S.M.; Ervina Efzan, M.N. Review on recent Photovoltaic/Thermal (PV/T) technology advances and applications. Sol. Energy 2018, 173, 939–954. [Google Scholar] [CrossRef]

- Azeumo, M.F.; Germana, C.; Ippolito, N.M.; Franco, M.; Luigi, P.; Settimio, S. Photovoltaic module recycling, a physical and a chemical recovery process. Sol. Energy Mater. Sol. Cells 2019, 193, 314–319. [Google Scholar] [CrossRef]

- Kreiger, M.A.; Shonnard, D.R.; Pearce, J.M. Life cycle analysis of silane recycling in amorphous silicon-based solar photovoltaic manufacturing. Resour. Conserv. Recycl. 2013, 70, 44–49. [Google Scholar] [CrossRef] [Green Version]

- Savvilotidou, V.; Antoniou, A.; Gidarakos, E. Toxicity assessment and feasible recycling process for amorphous silicon and CIS waste photovoltaic panels. Waste Manag. 2017, 59, 394–402. [Google Scholar] [CrossRef]

- Curtis, T.L.; Buchanan, H.; Smith, L.; Heath, G. Drivers, Barriers, Enablers, and U.S. Policy Considerations; National Renewable Energy Laboratory. Available online: https://www.nrel.gov/docs/fy21osti/74550.pdf (accessed on 18 August 2021).

- Xu, Y.; Li, J.; Tan, Q.; Peters, A.L.; Yang, C. Global Status of Recycling Waste Solar Panels: A Review. Waste Manag. 2018, 75, 450–458. [Google Scholar] [CrossRef]

- Strupeit, L.; Bocken, N. Towards a Circular Photovoltaic Economy: The Role of Servicebased Business Models. In Proceedings of the 3rd PLATE 2019 Conference, Berlin, Germany, 18–20 September 2019. [Google Scholar]

- Ranjan, S.; Balaji, S.; Panella, R.A.; Ydstie, B.E. Silicon solar cell production. Comput. Chem. Eng. 2011, 35, 1438–1453. [Google Scholar] [CrossRef]

- Choi, J.-K.; Fthenakis, V. Economic feasibility of recycling photovoltaic modules. J. Ind. Ecol. 2010, 14, 947–964. [Google Scholar] [CrossRef]

- Choi, J.-K.; Fthenakis, V. Design and optimization of photovoltaics recycling infrastructure. Environ.Sci. Technol. 2010, 44, 8678–8683. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.M.; Fthenakis, V. Kinetics study on separation of cadmium from tellurium in acidic solution media using ion-exchange resins. J. Hazard. Mater. 2005, 125, 80–88. [Google Scholar] [CrossRef] [PubMed]

- Fthenakis, V.M.; Wang, W. Extraction and separation of Cd and Te from cadmium telluride photovoltaic manufacturing scrap. Prog. Photovolt. Res. Appl. 2006, 14, 363–371. [Google Scholar] [CrossRef]

- Masoumian, M.; Kopacek, P. End-of-Life Management of Photovoltaics Modules. IFAC-PapersOnLine 2015, 48, 162–167. [Google Scholar] [CrossRef]

- Dubey, S.; Jadhav, N.Y.; Zakirova, B. Socio-economic and environmental impacts of silicon based photovoltaic (PV) technologies. Energy Procedia 2013, 33, 322–334. [Google Scholar] [CrossRef] [Green Version]

- Hahne, A.; Hirn, G. Recycling photovoltaic modules. In BINE (Information Service Energy Expertise); FizKarlsrue: Eggenstein-Leopoldshafen, Germany, 2010. [Google Scholar]

- Kim, Y.; Lee, J. Dissolution of ethylene vinyl acetate in crystalline silicon on PV modules using ultrasonic irradiation and organic solvent. Sol. Energy Mater. Sol. Cells 2012, 98, 317–322. [Google Scholar] [CrossRef]

- Raugei, M.; Bargigli, S.; Ulgiati, S. Life cycle assessment and energy pay-back time of advanced photovoltaic modules: CdTeand CIS compared to poly-Si. Energy 2007, 32, 1310–1318. [Google Scholar] [CrossRef]

- Sinha, P. Life cycle materials and water management for CdTe photovoltaics. Sol. Energy Mater. Sol. Cells 2013, 119, 271–275. [Google Scholar] [CrossRef]

- Goodrich, A.; Hacke, P. A wafer-based monocrystalline silicon photovoltaics roadmap: Utilizing known technology improvement opportunities for further reductions in manufacturing costs. Sol. Energy Mater. Sol. Cells 2013, 114, 110–135. [Google Scholar] [CrossRef]

- Sasala, R.A.; Bohland, J.; Smigielskic, K. Physical and Chemical Pathways for Economic Recycling of Cadmium Telluride Thin-Film Photovoltaic Modules; Solar Cells Inc.: Toledo, OH, USA, 1996. [Google Scholar]

- Fernàndez, L.J.; Ferrer, R.; Aponte, D.F.; Fernàndez, P. Recycling silicon solar cell waste in cement-based systems. Sol. Energy Mater. Sol. Cells 2011, 95, 1701–1706. [Google Scholar] [CrossRef]

- Granata, G.; Pagnanelli, F.; Moscardini, E.; Havlik, T.; Toro, L. Recycling of photovoltaic panels by physics operations. Sol. Energy Mater. Sol. Cells 2014, 123, 239–248. [Google Scholar] [CrossRef]

- Pagnanelli, F.; Moscardini, E.; Granata, G.; Atia, T.A.; Altimari, P.; Havlik, T.; Toro, L. Physical and chemical treatment of end of life panels: An integrated automatic approach viable for different photovoltaic technologies. Waste Manag. 2017, 59, 422–431. [Google Scholar] [CrossRef] [PubMed]

- Kand, S.; Yoo, S.; Lee, J.; Boo, B.; Ryu, H. Experimental investigations for recycling of silicon and glass from waste photovoltaic modules. Renew. Energy 2012, 47, 152–159. [Google Scholar]

- Chen, W.-S.; Chen, Y.-J.; Yueh, K.-C.; Cheng, C.-P.; Chang, T.-C. Recovery of valuable metal from Photovoltaic solar cells through extraction. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2020; Volume 720, p. 012007. [Google Scholar] [CrossRef]

- Yi, Y.K.; Kim, H.S.; Tran, T.; Hong, S.K.; Kim, M.J. Recovering valuable metals from recycled photovoltaic modules. J. Air Waste Manag. Assoc. 2014, 64, 797–807. [Google Scholar] [CrossRef]

- D’Adamo, I.; Miliacca, M.; Rosa, P. Economic Feasibility for Recycling of Waste Crystalline Silicon Photovoltaic Modules. Int. J. Photoenergy 2017, 2017, 4184676. [Google Scholar] [CrossRef]

- Marwede, M.; Berger, W.; Schlummer, M.; Mäurer, A.; Reller, A. Recycling paths for thin-film chalcogenide photovoltaic waste–Current feasible processes, Renew. Energy 2013, 55, 220–229. [Google Scholar]

- Chen, W.-S.; Chen, Y.-J.; Lee, C.-H.; Cheng, Y.-J.; Chen, Y.-A.; Liu, F.-W.; Wang, Y.-C.; Chueh, Y.-L. Recovery of Valuable Materials from the Waste Crystalline-Silicon Photovoltaic Cell and Ribbon. Processes 2021, 9, 712. [Google Scholar] [CrossRef]

- Cerchier, P.; Brunelli, K.; Pezzato, L.; Audoin, C.; Rakotoniaina, J.P.; Sessa, T.; Tammaro, M.; Sabia, G.; Attanasio, A.; Forte, C.; et al. Innovative recycling of end of life silicon PV panels: Resielp. Detritus 2021, 16, 41–47. [Google Scholar] [CrossRef]

- Selvi, A.; Rajasekar, A.; Theerthagiri, J.; Ananthaselvam, A.; Sathishkumar, K.; Madhavan, J.; Rahman, P.K. Rahman6Integrated Remediation Processes Toward Heavy Metal Removal/Recovery From Various Environments: A Review. Front. Environ. Sci. 2019, 7, 66. [Google Scholar] [CrossRef] [Green Version]

- Satarug, S.; Baker, J.R.; Urbenjapol, S.; Haswell-Elkins, M.; Reilly, P.E.B.; Williams, D.J.; Moore, M.R. A global perspective on cadmium pollution and toxicity in non-occupationally exposed population. Toxicol. Lett. 2003, 137, 65–83. [Google Scholar] [CrossRef]

- Moon, G.; Yoo, K. Separation of Cu, Sn, Pb from photovoltaic ribbon by hydrochloric acid leaching with stannic ion followed by solvent extraction. Hydrometallurgy 2017, 171, 123–127. [Google Scholar] [CrossRef]

- Raport, Rynek fotowoltaiki w Polsce, EC BREC. In Instytut Energetyki Odnawialnej, Edycja VIII; Institution for Renewable Energy: Warsaw, Poland, 2020; Available online: https://projekty.ieo.pl/pl/raport-pv-2021 (accessed on 18 August 2021). (In Polish)

- Directive 2009/28/EC of the European Parliament and of the Council of 23 April 2009 on the Promotion of the Use of Energy from Renewable Sources and Amending and Subsequently Repealing Directives 2001/77/EC and 2003/30/EC (Text with EEA Relevance) Text with EEA Relevance—Publications Office of the EU (europa.eu). Available online: https://op.europa.eu/en/publication-detail/-/publication/72b7d0cd-0667-11ec-b5d3-01aa75ed71a1/language-en (accessed on 23 October 2021).

- Projekty Fotowoltaiczne w Polsce, Sklep Internetowy (Sklepieo.pl). Available online: https://www.ieo.pl/en/ (accessed on 23 October 2021).

- Solar Power Europe—Leading the Energy Transition. Available online: www.solarpowereurope.org (accessed on 23 October 2021).

- Available online: www.marketresearchreports.com (accessed on 26 October 2021).

- IRENA. Report of International Renewable Energy Agency, Photovoltaic Power Systems Programme; June 2016. Available online: https://www.irena.org/-/media/Files/IRENA/Agency/Publication/2016/IRENA_IEAPVPS_End-of-Life_Solar_PV_Panels_2016.pdf (accessed on 18 August 2021).

- Available online: www.thornmann.com.pl (accessed on 18 August 2021).

| Cell Base Material | Materials | Cell Structure | Efficiency | Technology Share in the World Market |

|---|---|---|---|---|

| Silicon | Crystalline | Monocrystalline/ polycrystalline | 18–22% 14–18% | 33% 48% |

| Microcrystalline | Thin films | 6–10% | 3% | |

| Amorphous | Thin films | |||

| Monocrystalline silicon cells coated with amorphous silicon | Hybrid | <23% | ok. 6% | |

| Semiconductors compounds | Halides | Cadmium telluride (CdTe) | 10–14% | 5% |

| Indium-copper diselenide and gallium (CIS/CIGS) | 12–16% | 4% | ||

| Chalcopirytes | - | - | ||

| Compounds of group II and V elements | Gallium arsenide (GaAs) | - | 1% | |

| Others | - | |||

| Others | Dye | <13% | ||

| Organic | 18.2% | |||

| Technology/ Proportion in % | Glass | Aluminum | Copper | Silver | Tin | Zinc | Silicon | Other: Polymers (EVA) + Adhesive Materials |

|---|---|---|---|---|---|---|---|---|

| Crystal Si | 74 | 10 | 0.57 | 0.006 | 0.12 | 0.12 | 3.35 | 6.55 + 1.16 |

| Amorphous Si | 86 | 0.035 | 0.9 | - | 0.043 | - | 0.007 | 0.02 |

| CdTe | 95 | 0.35 | 1 | - | - | 0.01 | - | 3.5 |

| CIGS | 84 | 12 | 0.8 | - | - | 0.12 | - | 3 |

| Installation | 2019 | 2020, First Quarter |

|---|---|---|

| Micro-installation with a power up to 50 kW | 990 MW | 1294 MW |

| Small installations with a power from 50 kW to 500 kW | 47.58 MW | above 50 MW |

| Installations with a power above 500 kW | Approximately 75 MW | |

| Installations built under the auction support system, with a power up to 1 MW | 360 MW | 400 MW |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Włodarczyk, R. Analysis of the Photovoltaic Waste-Recycling Process in Polish Conditions—A Short Review. Sustainability 2022, 14, 4739. https://doi.org/10.3390/su14084739

Włodarczyk R. Analysis of the Photovoltaic Waste-Recycling Process in Polish Conditions—A Short Review. Sustainability. 2022; 14(8):4739. https://doi.org/10.3390/su14084739

Chicago/Turabian StyleWłodarczyk, Renata. 2022. "Analysis of the Photovoltaic Waste-Recycling Process in Polish Conditions—A Short Review" Sustainability 14, no. 8: 4739. https://doi.org/10.3390/su14084739

APA StyleWłodarczyk, R. (2022). Analysis of the Photovoltaic Waste-Recycling Process in Polish Conditions—A Short Review. Sustainability, 14(8), 4739. https://doi.org/10.3390/su14084739