Acoustic Retrofit Approach of an Apartment Living Room Using Multi-Perforated Gypsum Boards in Terms of Heavy-Weight Impact Sounds

Abstract

:1. Introduction

2. Materials and Methods

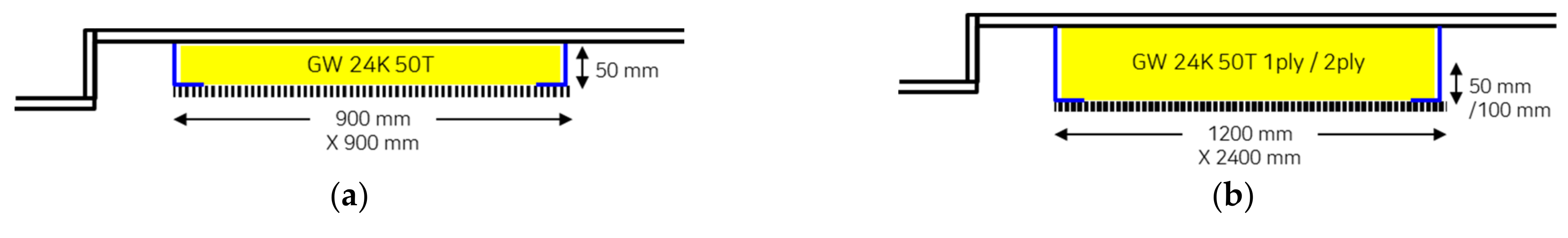

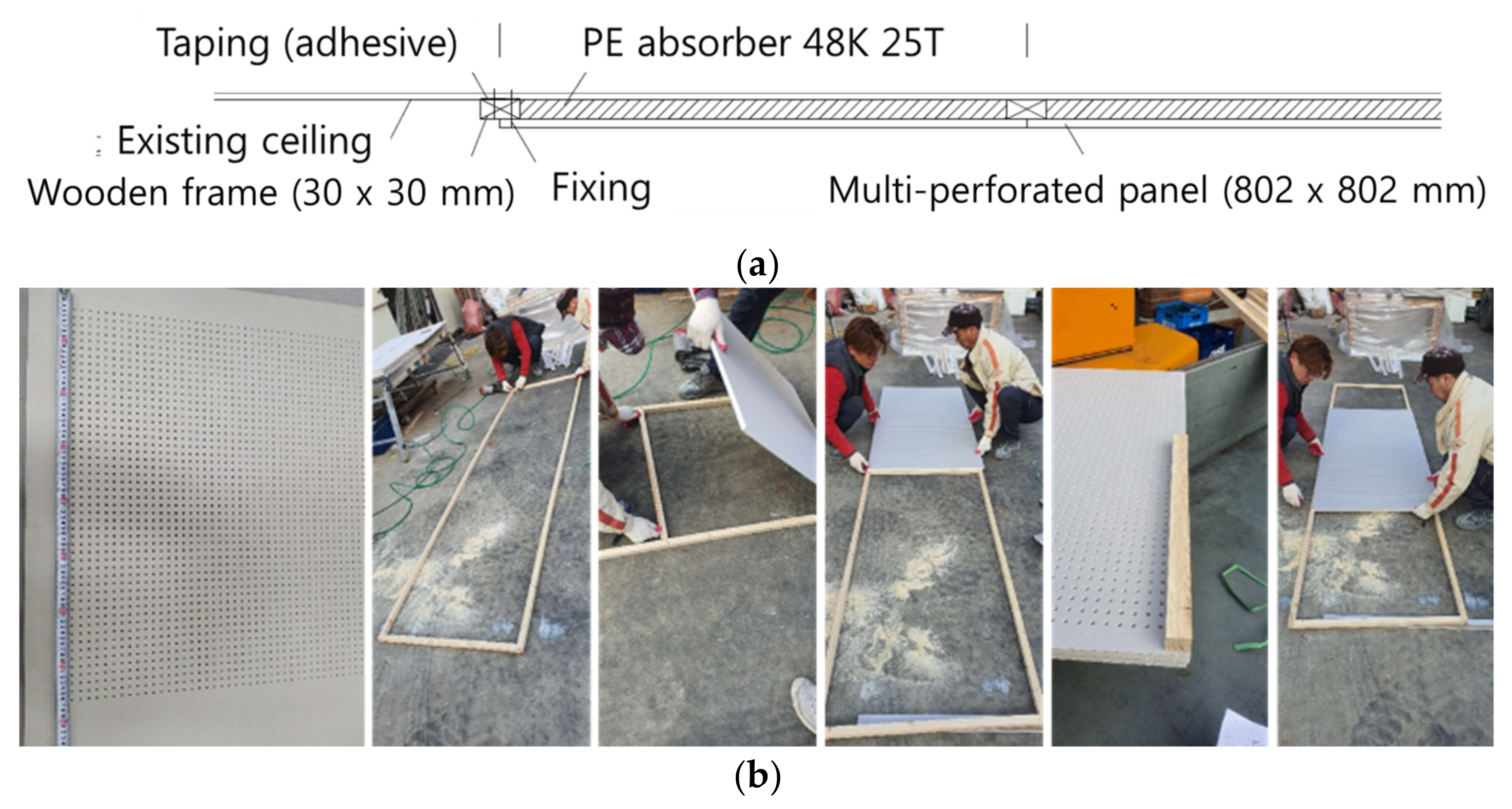

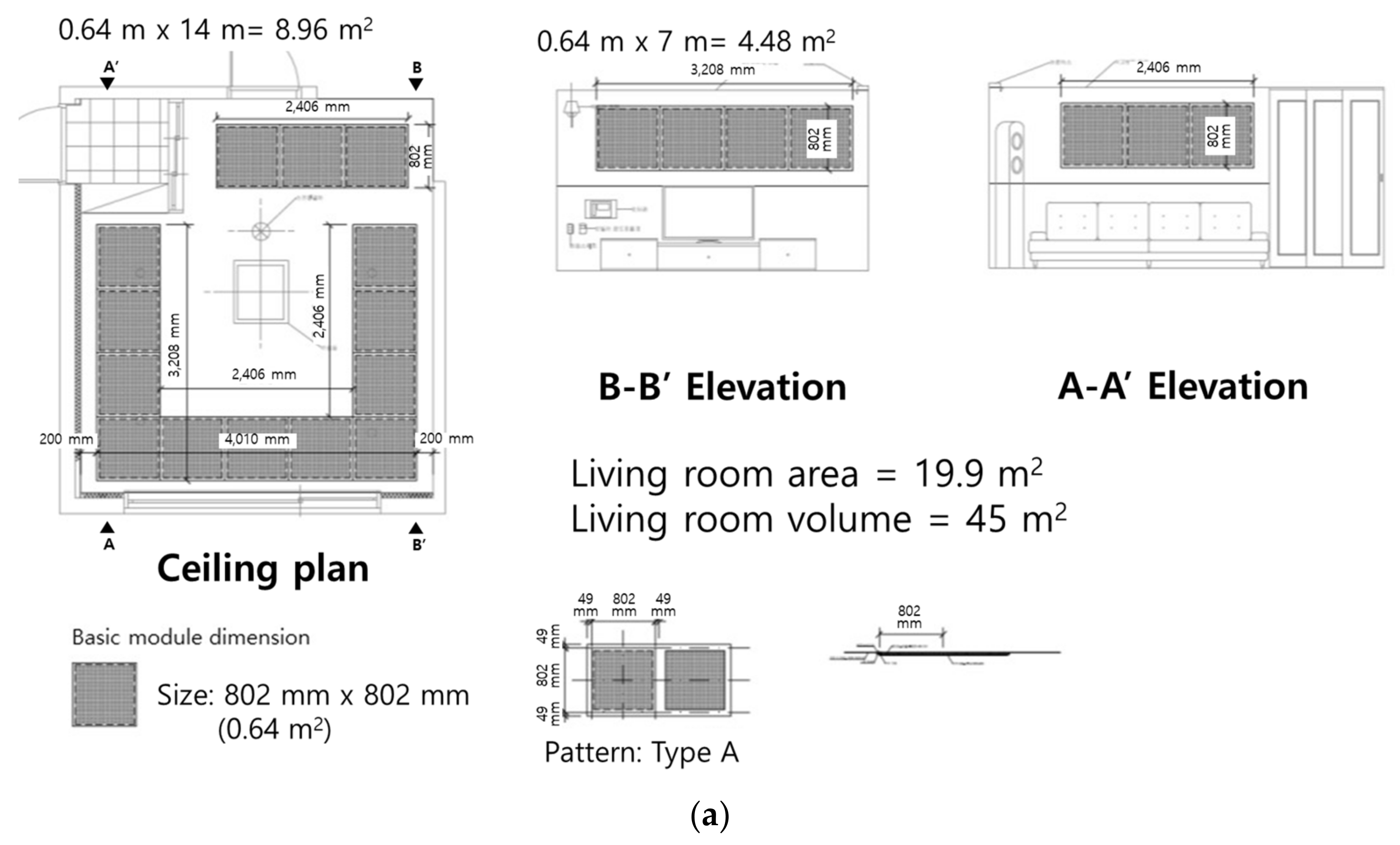

2.1. The Specimen Profile using Multi-Perforated Gypsum Boards

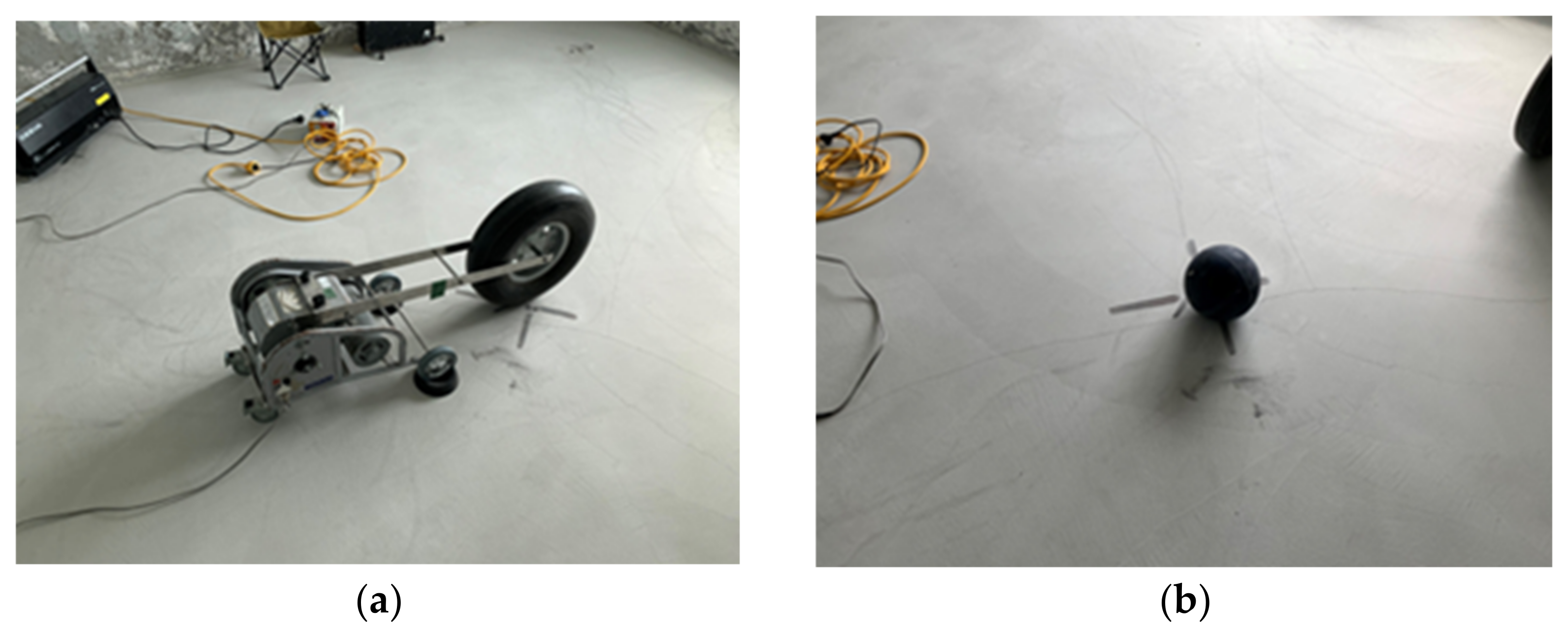

2.2. Experiment I

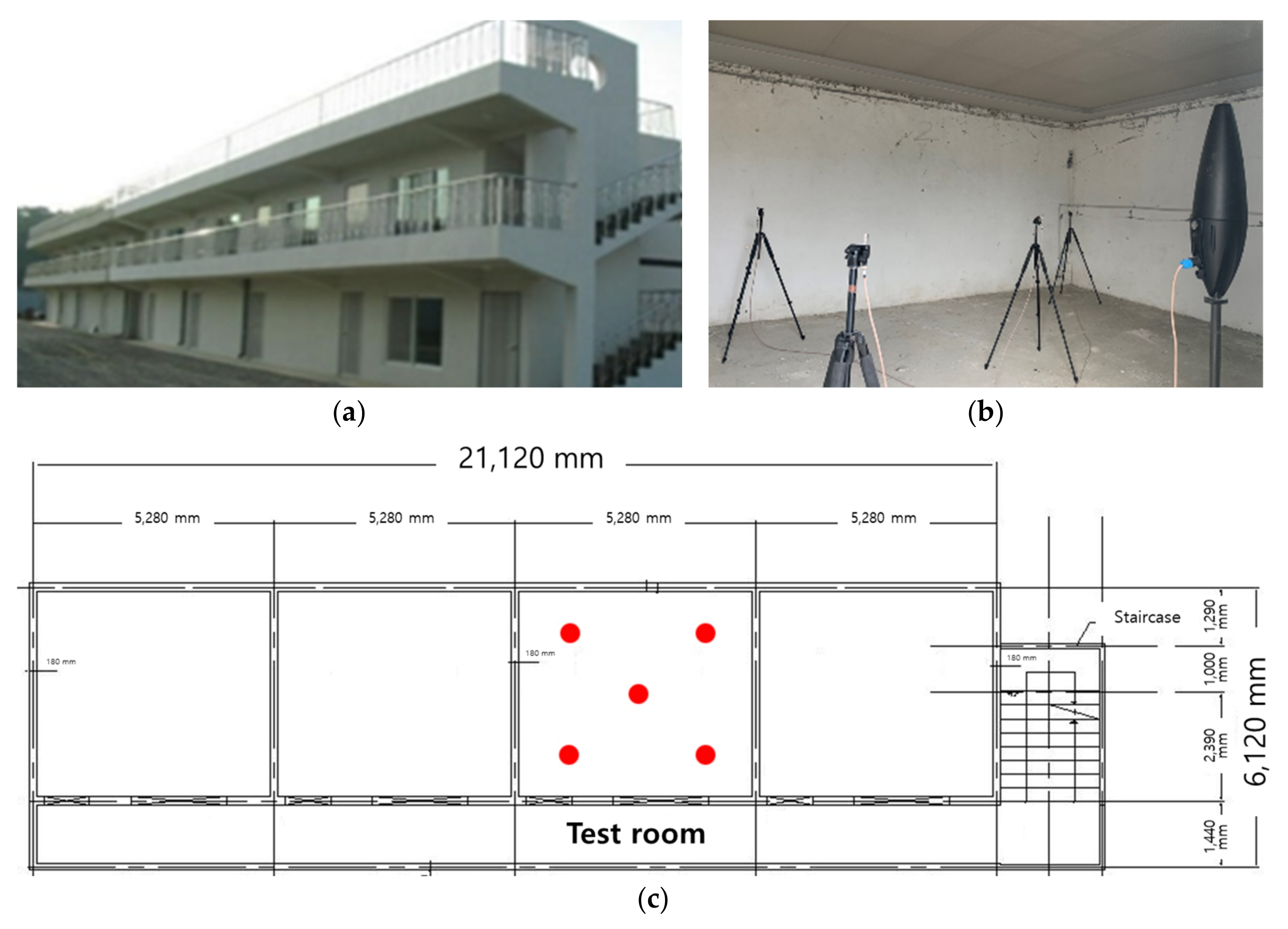

2.2.1. The Box-Type Test Building

2.2.2. Experimental Configurations

2.3. Experiment II

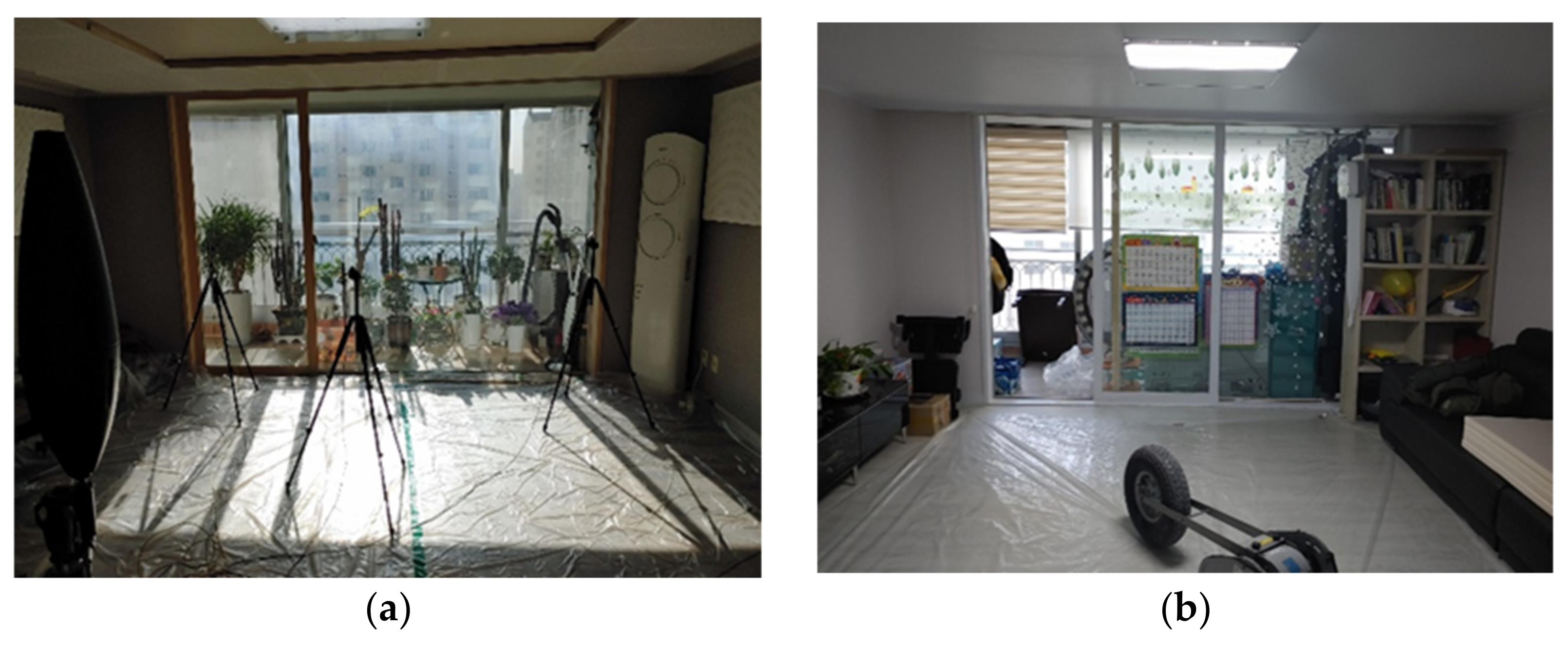

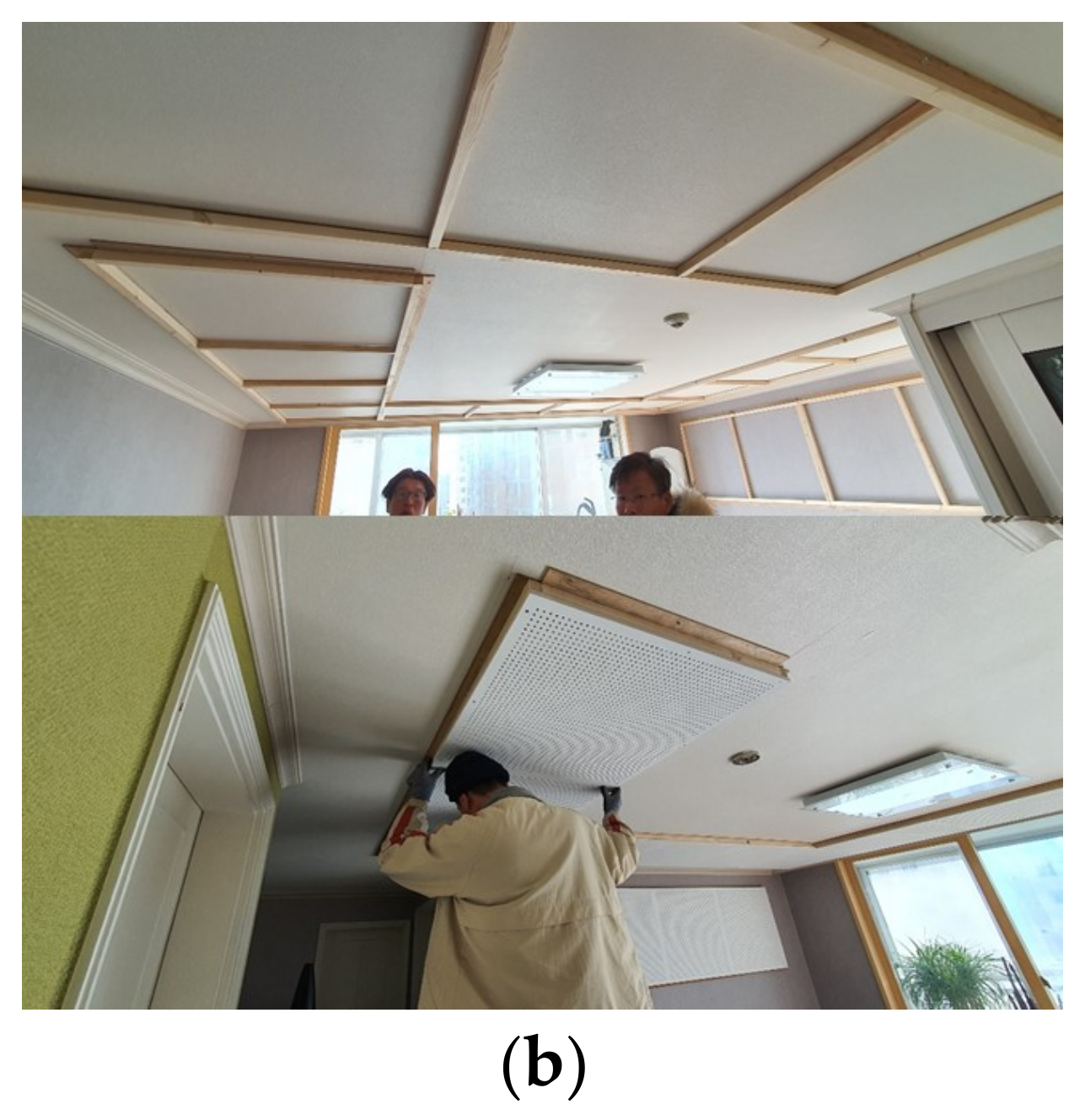

2.3.1. The Actual Apartment Building

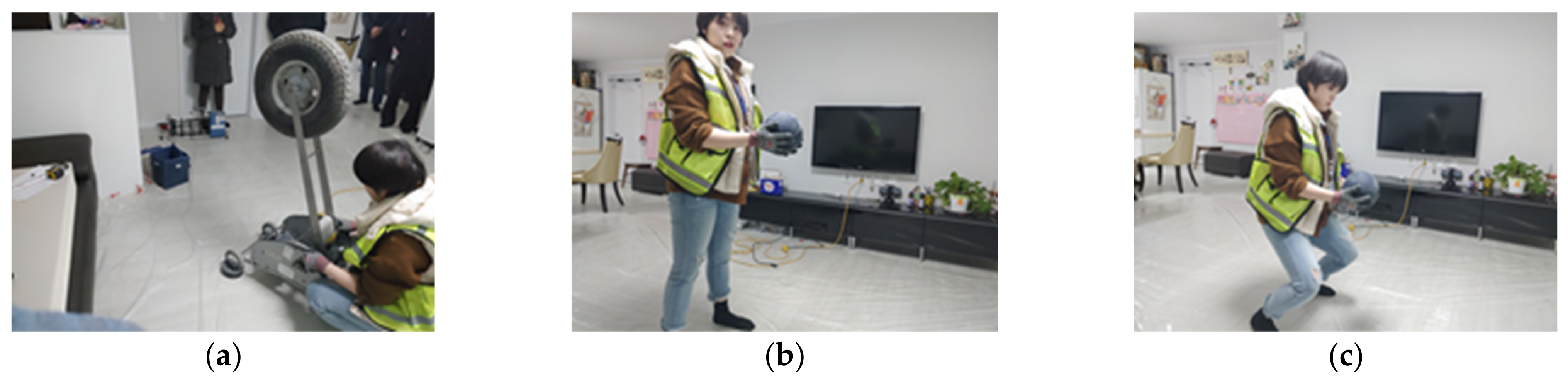

2.3.2. Experimental Configurations

2.4. Measurement and Evaluation Methods

2.4.1. Measurement Method

2.4.2. Evaluation Method

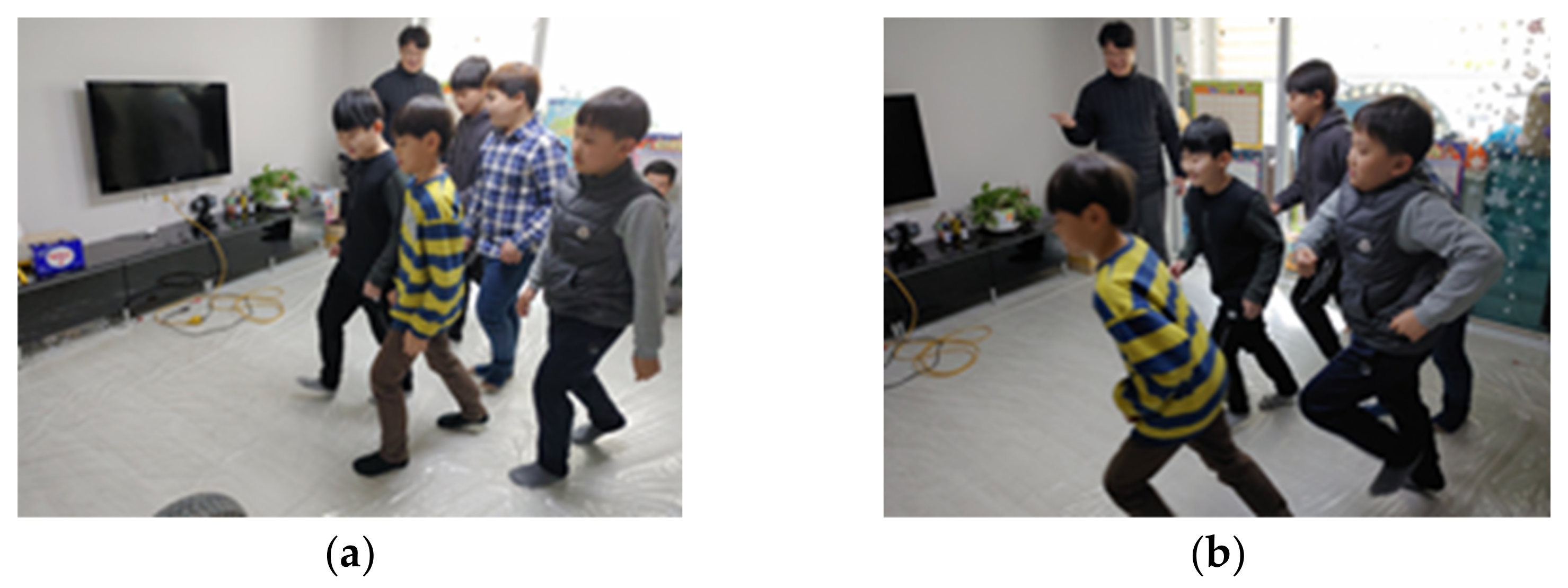

2.5. Field Questionnaire Survey

3. Results

3.1. Experiment I in the Box-Type Test Building

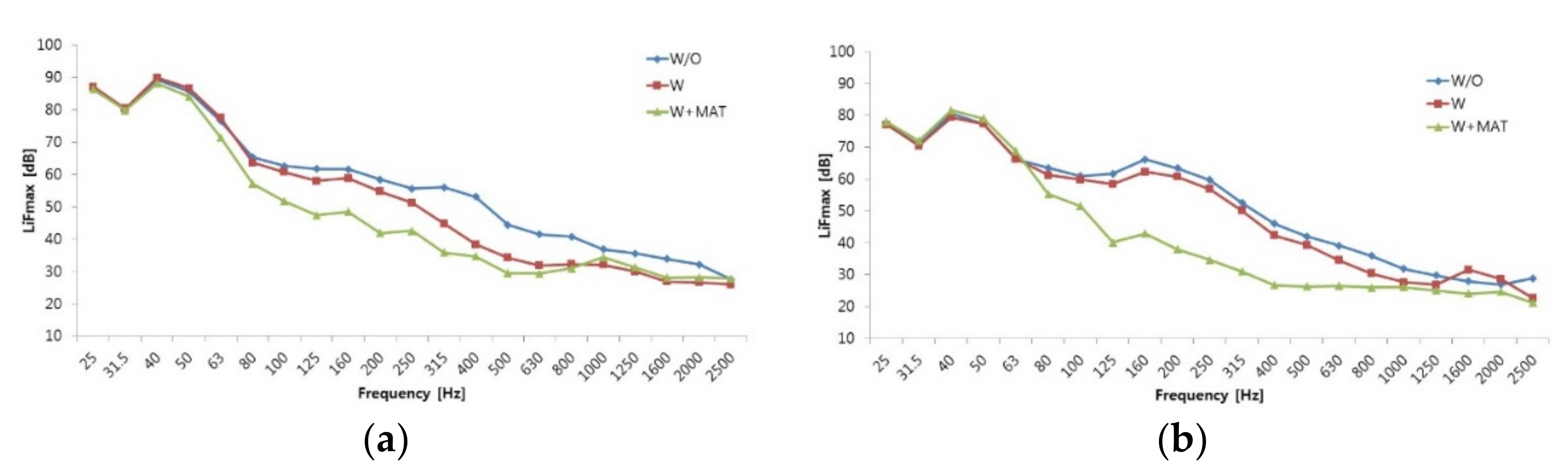

3.2. Experiment II in the Actual Apartment Building

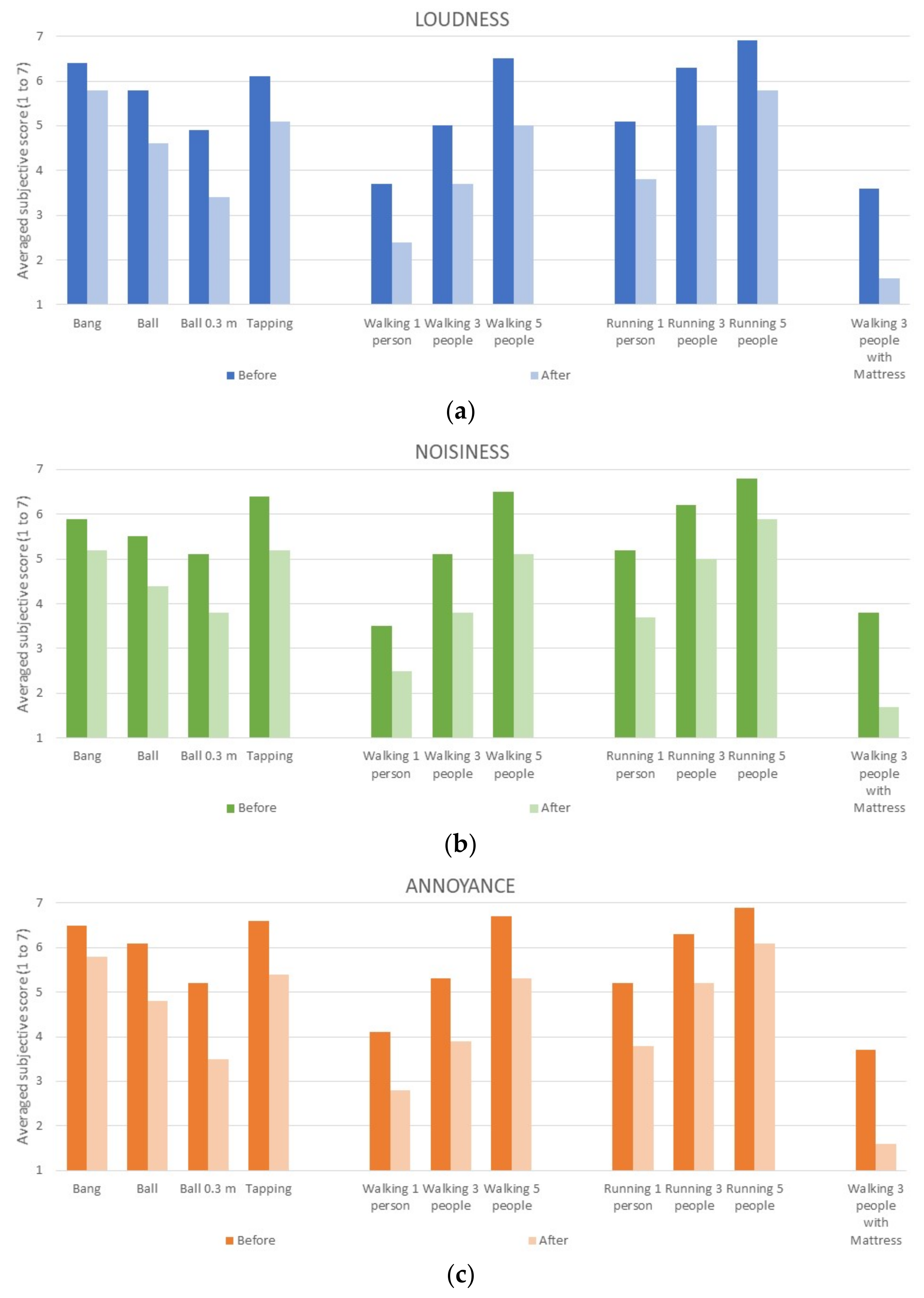

3.3. Subjective Impression of the Reduced Impact Sounds from the Field Questionnaire Survey

4. Conclusions

- For the flat-type ceiling, application of multi-perforated gypsum boards without backing porous type sound absorbers can reduce heavy-weight floor impact noise up to 3 and 4 dB, respectively, for bang machine and rubber ball as sound sources.

- For the flat-type ceiling, the application of multi-perforated gypsum boards with backing porous type sound absorbers can reduce heavy-weight floor impact noise up to 4 and 5 dB, respectively, for bang machine and rubber ball as sound sources.

- For the flat-type ceiling, there was no significant difference of not more than 1 dB on heavy-weight floor impact noise according to thickness variation of non-perforated gypsum boards or perforation pattern variations.

- For the coffered-type ceiling with bang machine, application of multi-perforated gypsum boards only on the central coffered area can reduce heavy-weight floor impact noise by 1 dB.

- For the coffered-type ceiling with rubber ball, the application area of multi-perforated gypsum boards showed a proportional relationship with a reduced level of heavy-weight floor impact noise by up to 4 dB.

- For adding perforated gypsum board modules on coffered-type ceiling with non-perforated gypsum boards, Type A pattern was effective to reduce heavy-weight impact noise for bang machine source by up to 1 dB and Type D for rubber ball by up to 4 dB.

- As for finishing method of coffered ceiling surfaces, wallpaper finish was not effective, but water-based painting finish was effective to reduce heavy-weight impact noise by 1 dB.

- For the coffered-type ceiling, removal of backing non-woven fabric offset the reduction effects of multi-perforated gypsum boards on heavy-weight floor impact noise only for bang machine source.

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chen, H.; Jia, B.; Lau, S.S.Y. Sustainable urban form for Chinese compact cities: Challenges of a rapid urbanized economy. Habitat Int. 2008, 32, 28–40. [Google Scholar] [CrossRef]

- Cheshmehzangi, A. Housing and health evaluation related to general comfort and indoor thermal comfort satisfaction during the COVID-19 lockdown. J. Hum. Behav. Soc. Environ. 2021, 31, 184–209. [Google Scholar] [CrossRef]

- Rasmussen, B. Acoustic classification schemes in Europe—Applicability for new, existing and renovated housing. In Proceedings of the BNAM 2016, Stockholm, Sweden, 18–21 April 2016. [Google Scholar]

- ISO/TS 19488; Acoustics—Acoustic Classification of Dwellings. International Organization for Standardization: Geneva, Switzerland, 2021.

- LoVerde, J.; Dong, W. Developing Classifications using a Dual-Rating Method of Evaluating Impact Noise. In Proceedings of the INTER-NOISE 2018, Chicago, IL, USA, 26–29 August 2018; pp. 4569–4577. [Google Scholar]

- Jeong, J.H.; Kim, Y.H.; Ryu, J.K.; Kim, K.H. Classification scheme of floor impact sound insulation by rubber ball. In Proceedings of the INTER-NOISE 2020, Seoul, Korea, 23–26 August 2020; pp. 1139–1142. [Google Scholar]

- Shieko, M.; Lemos, E.; Monteiro, C. An approach on how an acoustic classification scheme for dwellings can be adopted in Brazil. In Proceedings of the Euronoise 2018, Crete, Greece, 27–31 May 2018; pp. 1133–1136. [Google Scholar]

- Jeon, J.Y.; Hong, J.Y.; Kim, S.M.; Lee, P.J. Classification of heavy-weight floor impact sounds in multi-dwelling houses using an equal-appearing interval scale. Build. Environ. 2015, 94, 821–828. [Google Scholar] [CrossRef]

- Brunskog, J.; Hwang, H.D.; Jeong, C.H. Subjective response to foot-fall noise, including localization of the source position. Acta Acust. United Acust. 2011, 97, 904–908. [Google Scholar] [CrossRef]

- Kim, K.W.; Shin, H.K. Floor Impact Sound Performance Variation in Old Apartment Housing. In Proceedings of the INTER-NOISE 2019, Madrid, Spain, 16–19 June 2019; pp. 5823–5828. [Google Scholar]

- Lee, W.H.; Song, G.G.; Kim, Y.H.; Yoon, Y.J. Reduction performance of floor impact sound of the existing apartment buildings in Korea. J. Acoust. Soc. Am. 2017, 141, 3775. [Google Scholar] [CrossRef]

- Kim, Y.H.; Song, G.G.; Lee, W.H.; Seo, J.B.; Kim, M.J.; Jeong, J.H.; Ryu, J.K.; Kim, K.H. A guideline of heavy-weight floor impact noise reduction for retrofitted apartment buildings in Korea. In Proceedings of the INTER-NOISE 2017, Hong Kong, China, 27–30 August 2017; pp. 5471–5478. [Google Scholar]

- Alonso, A.; Patricio, J.; Suárez, R.; Escandón, R. Acoustical retrofit of existing residential buildings: Requirements and recommendations for sound insulation between dwellings in Europe and other countries worldwide. Build. Environ. 2020, 174, 106771. [Google Scholar] [CrossRef]

- Maderuelo-Sanz, R.; Martín-Castizo, M.; Vílchez-Gómez, R. The performance of resilient layers made from recycled rubber fluff for impact noise reduction. Appl. Acoust. 2011, 72, 823–828. [Google Scholar] [CrossRef]

- Bouttout, A. Experimental study of the impact noise through concrete floor with resilient layers. J. Acoust. Soc. Am. 2017, 142, 2517. [Google Scholar] [CrossRef]

- Kim, Y.H.; Song, G.G.; Bae, S.K. Application of ETPU materials for reducing floor impact noises. In Proceedings of the Euronoise 2018, Crete, Greece, 27–31 May 2018; pp. 1723–1726. [Google Scholar]

- Cho, H.M.; Kim, S.T.; Kim, M.J. Experimental Study on the Reduction Performance of Floor Impact Sound according to Reduction Method of Floor Structure Layers in Aged-Apartment. In Proceedings of the INTER-NOISE 2018, Chicago, IL, USA, 26–29 August 2018; pp. 2753–2758. [Google Scholar]

- Ryu, J.K.; Song, H.S.; Kim, Y.H. Effect of the suspended ceiling with low-frequency resonant panel absorber on heavyweight floor impact sound in the building. Build. Environ. 2018, 139, 1–7. [Google Scholar] [CrossRef]

- Park, H.G.; Mun, D.H. Characteristics of Floor Impact Noise Insulation for No Hanger Ceiling Structure in Apartment Building. Proc. Korean Soc. Noise Vib. Eng. 2014, 208–213. Available online: http://www.koreascience.or.kr/article/CFKO201431749164412.view (accessed on 18 March 2022).

- Kim, K.W.; Kang, J.S.; Lee, S.E.; Yang, K.S. Floor Impact Sound Isolation Performance by Composition of Ceiling and Wall. Trans. Korean Soc. Noise Vib. Eng. 2005, 15, 465–473. [Google Scholar]

- Song, H.S.; Ryu, J.K.; Kim, I.H.; Kim, Y.H.; Song, G.G. Evaluation of Impact Sound Insulation by Sound Absorbing Materials inside Ceiling through Mock-up Test in Reverberation Chamber. Proc. Korean Soc. Noise Vib. Eng. 2018, 155. Available online: https://www.dbpia.co.kr/journal/articleDetail?nodeId=NODE07555332 (accessed on 18 March 2022).

- Jeon, J.Y.; Jeong, J.H.; Park, H.J. Subjective Evaluation of Floor Impact Noise Isolation Construction for Floor, Wall and Ceiling. J. Archit. Inst. Korea Plan. Des. 2002, 18, 169–176. [Google Scholar]

- Kim, K.H.; Choi, H.J.; Kim, Y.G. Evaluation of ceiling structure influencing to the floor impact sound. Proc. Korean Soc. Noise Vib. Eng. 2011, 423–424. Available online: http://koreascience.or.kr/article/CFKO201125752339367.page (accessed on 18 March 2022).

- Kim, I.H.; Go, J.C. Effects of Finishing Materials in Wall and Ceiling on Floor Impact Sound. In Proceedings of the INTER-NOISE 2016, Hamburg, Germany, 21–24 August 2016; pp. 7512–7517. [Google Scholar]

- Shin, H.K.; Kim, K.W. Floor Impact Sound Insulation Using Perforated Gypsum Board Ceiling. In Proceedings of the INTER-NOISE 2019, Madrid, Spain, 16–19 June 2019; pp. 5848–5853. [Google Scholar]

- KS F 2810-2; Field Measurements of Floor Impact Sound Insulation of Buildings―Part 2: Method Using Standard Heavy Impact Sources. Korean Agency for Technology and Standards: Eumseong, Korea, 2012.

- ISO 16283-2; Acoustics—Field Measurement of Sound Insulation in Buildings and of Building Elements—Part 2: Impact Sound Insulation. International Organization for Standardization: Geneva, Switzerland, 2018.

- Act No. 2020-212; Criteria for Recognition and Management of Floor Impact Sound Interception Structure in Apartment Houses. Ministry of Land, Infrastructure and Transport: Sejong Special Governing City, Korea, 2020.

- KS F 2863-2; Rating of Floor Impact Sound Insulation for Impact Source in Buildings and Building Elements—Part 1: Floor Impact Sound Insulation against Standard Heavy Impact Source. Korean Agency for Technology and Standards: Eumseong, Korean, 2017.

- ISO 717-2; Acoustics—Rating of Sound Insulation in Buildings and of Building Elements—Part 2: Impact Sound Insulation. International Organization for Standardization: Geneva, Switzerland, 2020.

- Hellman, R.P. Loudness, annoyance, and noisiness produced by single-tone-noise complexes. J. Acoust. Soc. Am. 1982, 72, 62–73. [Google Scholar] [CrossRef] [PubMed]

- Jeon, J.Y.; Ryu, J.K.; Tachibana, H. Review of the Impact Ball in Evaluating Floor Impact Sound. Acta Acust. United Acust. 2006, 92, 777–786. [Google Scholar]

| Pattern Type | Panel Size | Pattern Division in a Panel | Hole Diameter/Width | Hole Shape | Opening Ratio | NRC (Sound Absorption Coefficient at 125 Hz) |

|---|---|---|---|---|---|---|

| Type A | 0.9 m × 0.9 m | 1 × 2 | 6 mm | Round | 8.7% | 0.50 (0.55) |

| Type B | 10 mm | Square | 17.8% | 0.68 (0.55) | ||

| Type C | 2 × 4 | 6 mm | Round | 5.6% | 0.44 (0.49) | |

| Type D | 1.2 m × 2.4 m | 10 mm | Square | - | ||

| Ceiling Type | Variables | Values |

|---|---|---|

| Flat type | Thickness of gypsum boards | 9.5, 12.5, and 19 mm |

| Perforation pattern | Type A, Type B, and Type C | |

| Infill sound absorber | Glass wool 24K 50T | |

| Coffered type | Installation location | All, center, corner, and none |

| Type of adding specimen | Type A (50T) and Type D (50T, 100T) | |

| Finishing method | Wallpaper and water-based painting | |

| Additional treatments | Perforation on backing gypsum boards, removal of backing non-woven fabric, and additional installation on wall and corner |

| Ceiling Type | Test Cases | Descriptions with Case Number | SNQ Values in dB | |

|---|---|---|---|---|

| Bang Machine | Rubber Ball | |||

| None | Bare ceiling | (1) | 54 | 59 |

| Flat type | Thickness of gypsum boards | (2-1) 9.5 mm | 53 | 58 |

| (2-2) 12.5 mm | 53 | 58 | ||

| (2-3) 19 mm | 53 | 57 | ||

| Perforation pattern | (3-1) Type A profile | 50 | 55 | |

| (3-2) Type B profile | 50 | 55 | ||

| (3-3) Type C profile | 50 | 54 | ||

| Infill sound absorber | (4-1) Type A profile with Glass wool 24K 50T | 49 | 53 | |

| Coffered type | Installation location | (5-1) All non-perforated | 52 | 57 |

| (5-2) Perforated on corner ceiling | 52 | 56 | ||

| (5-3) Perforated on central ceiling | 51 | 54 | ||

| (5-4) Perforated on all ceilings | 51 | 53 | ||

| Type of adding specimen in comparison to (5-1) case | (6-1) Type A profile (50 mm thick) | 51 | 56 | |

| (6-2) Type D profile (50 mm thick) | 52 | 53 | ||

| (6-3) Type D profile (100 mm thick) | 52 | 53 | ||

| Finishing method in comparison to (6-3) case | (7-1) Wallpaper finish | 52 | 53 | |

| (7-2) Water-based painting finish | 51 | 52 | ||

| Additional treatments | (8-1) Perforation on backing gypsum boards in comparison to (7-2) case | 51 | 52 | |

| (8-2) Removal of backing non-woven fabric | 52 | 53 | ||

| (8-3) Additional installation on wall and corner | 49 | N/A | ||

| Ceiling Type | Test Cases | Descriptions with Case Number | SNQ Values in dB | |

|---|---|---|---|---|

| Bang Machine | Rubber Ball | |||

| Flat type | Before installation of the test specimen modules | (9) Actual living condition | 56 | 54 |

| After installation of the test specimen modules | (10-1) Actual living condition with multi-perforated gypsum boards on ceiling and walls of the receiving room | 57 | 52 | |

| (10-2) Floor covering mattress with thickness of 40 mm in the source room floor in addition to (10-1) case | 54 | 49 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, Y.-H. Acoustic Retrofit Approach of an Apartment Living Room Using Multi-Perforated Gypsum Boards in Terms of Heavy-Weight Impact Sounds. Sustainability 2022, 14, 5007. https://doi.org/10.3390/su14095007

Kim Y-H. Acoustic Retrofit Approach of an Apartment Living Room Using Multi-Perforated Gypsum Boards in Terms of Heavy-Weight Impact Sounds. Sustainability. 2022; 14(9):5007. https://doi.org/10.3390/su14095007

Chicago/Turabian StyleKim, Yong-Hee. 2022. "Acoustic Retrofit Approach of an Apartment Living Room Using Multi-Perforated Gypsum Boards in Terms of Heavy-Weight Impact Sounds" Sustainability 14, no. 9: 5007. https://doi.org/10.3390/su14095007

APA StyleKim, Y.-H. (2022). Acoustic Retrofit Approach of an Apartment Living Room Using Multi-Perforated Gypsum Boards in Terms of Heavy-Weight Impact Sounds. Sustainability, 14(9), 5007. https://doi.org/10.3390/su14095007