An Internet of Things Embedded Sustainable Supply Chain Management of B2B E-Commerce

Abstract

:1. Introduction

- A sustainable framework of the supply chain which includes the order packaging, handling, transportation problems, as well as a problem related to the implantation of IoT facilities in transport vehicles for B2B e-commerce.

- Managing the transportation cost with carbon emission tax, packaging, and handling costs, purchasing cost of RFID tags, and installation cost of IoT facilities in the transport vehicles.

- Attention to supply chain problems with IoT technology adoption in textile industries.

2. Literature Review

2.1. Literature Based on the Internet of Things in the Supply Chain

2.2. Literature Based on the Supply Chain for the Textile Industry

2.3. Literature Based on B2B E-Commerce

2.4. Literature Based on the Solution Approaches

3. Problem Description

- Availability of transport vehicles at 3PLs and products at manufacture are known and satisfy the demands of the wholesalers.

- IoT facilities only for transport vehicles are taken into consideration, assuming that 3PLs, manufacturers, and wholesalers have already installed the IoT system.

- E-commerce platforms work as a mediator for manufacturers and wholesalers.

- The manufacturer and wholesaler have well-established IoT facilities. Given this, we considered the IoT facilities on transport-vehicle- and RFID-tag-related factors in our proposed model.

Mathematical Formulation

4. Solution Approach

5. Case Study

5.1. Input Data for the First Instance

5.2. Output Values

6. Results and Discussion

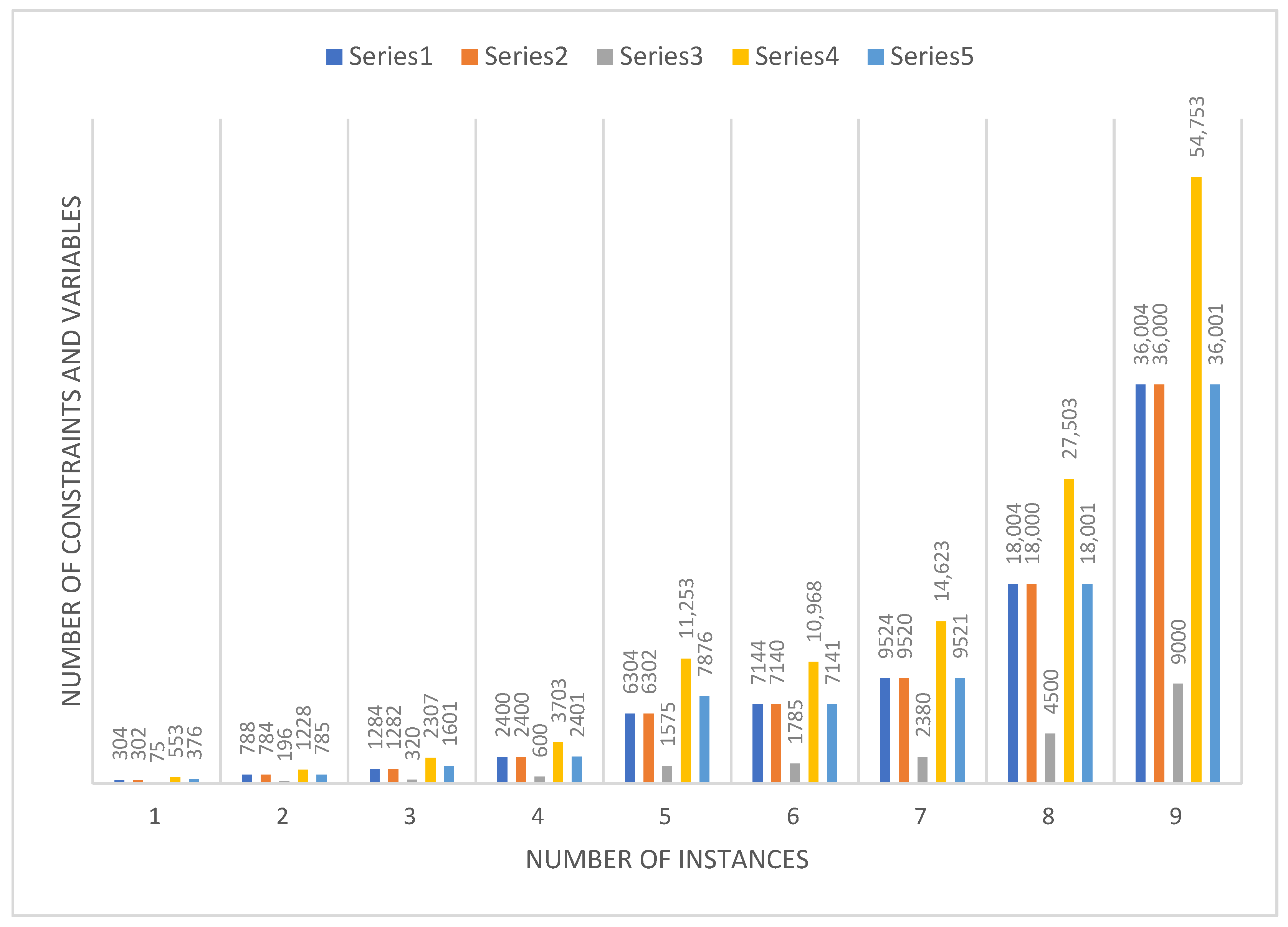

6.1. Computational Experiments

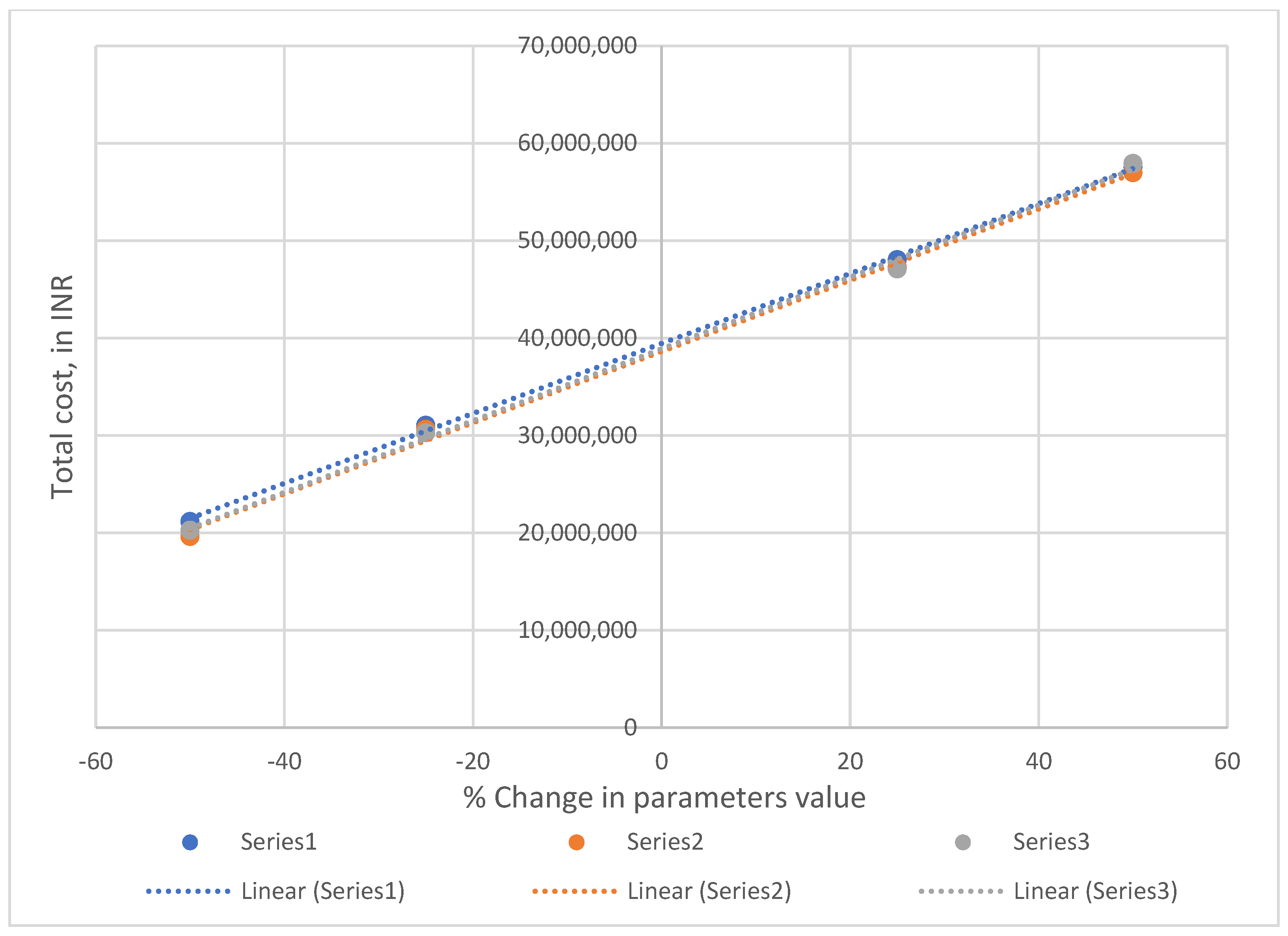

6.2. Sensitivity Analysis

6.3. Discussion

6.4. Managerial Implications

7. Conclusions and Future Work

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, Z. Growth Rate of Textile Industry across India FY 2010-FY 2020 This Statistic Illustrates the Growth Rate of Textile Industry across India from Fiscal Year 2010 to Fiscal Year 2020. The Growth Rate of Textile Industry across India Was Estimated to Be 8. 2022. Available online: https://www.statista.com/statistics/878411/india-growth-rate-of-textile-industry/ (accessed on 1 April 2022).

- Anitha, K.; Reddy, K.P.; Krishnamoorthy, N.; Jaiswal, S. IoT’s in Enabling the Supply Chain Visibility and Connectivity and Optimization of Performance. Mater. Today Proc. 2021. [Google Scholar] [CrossRef]

- Khan, I.S.; Ahmad, M.O.; Majava, J. Industry 4.0 and Sustainable Development: A Systematic Mapping of Triple Bottom Line, Circular Economy and Sustainable Business Models Perspectives. J. Clean. Prod. 2021, 297, 126655. [Google Scholar] [CrossRef]

- Sarkar, B.D.; Shankar, R. Understanding the Barriers of Port Logistics for Effective Operation in the Industry 4.0 Era: Data-Driven Decision Making. Int. J. Inf. Manag. Data Insights 2021, 1, 100031. [Google Scholar] [CrossRef]

- Deepu, T.S.; Ravi, V. Supply Chain Digitalization: An Integrated MCDM Approach for Inter-Organizational Information Systems Selection in an Electronic Supply Chain. Int. J. Inf. Manag. Data Insights 2021, 1, 100038. [Google Scholar] [CrossRef]

- Geissbauer, R.; Vedsø, J.; Schrauf, S. A Strategist’s Guide to Industry 4.0: Global Businesses Are about to Integrate Their Operations into a Seamless Digital Whole, and Thereby Change the World; PWC: London, UK, 2016; pp. 1–15. [Google Scholar]

- Tan, W.C.; Sidhu, M.S. Review of RFID and IoT Integration in Supply Chain Management. Oper. Res. Perspect. 2022, 9, 100229. [Google Scholar] [CrossRef]

- Bencic, F.M.; Skocir, P.; Zarko, I.P. DL-Tags: DLT and Smart Tags for Decentralized, Privacy-Preserving, and Verifiable Supply Chain Management. IEEE Access 2019, 7, 46198–46209. [Google Scholar] [CrossRef]

- Zhou, Z.; Liu, Y.; Yu, H.; Chen, Q. Logistics Supply Chain Information Collaboration Based on FPGA and Internet of Things System. Microprocess. Microsyst. 2021, 80, 103589. [Google Scholar] [CrossRef]

- Chen, Y.-T.; Sun, E.-W.; Chang, M.-F.; Lin, Y.-B. Pragmatic Real-Time Logistics Management with Traffic IoT Infrastructure: Big Data Predictive Analytics of Freight Travel Time for Logistics 4.0. Int. J. Prod. Econ. 2021, 238, 108157. [Google Scholar] [CrossRef]

- Hassija, V.; Chamola, V.; Saxena, V.; Jain, D.; Goyal, P.; Sikdar, B. A Survey on IoT Security: Application Areas, Security Threats, and Solution Architectures. IEEE Access 2019, 7, 82721–82743. [Google Scholar] [CrossRef]

- Ayaz, M.; Ammad-Uddin, M.; Sharif, Z.; Mansour, A.; Aggoune, E.H.M. Internet-of-Things (IoT)-Based Smart Agriculture: Toward Making the Fields Talk. IEEE Access 2019, 7, 129551–129583. [Google Scholar] [CrossRef]

- Abbasi, W.A.; Wang, Z.; Zhou, Y.; Hassan, S. Research on Measurement of Supply Chain Finance Credit Risk Based on Internet of Things. Int. J. Distrib. Sens. Netw. 2019, 15, 15. [Google Scholar] [CrossRef]

- Liu, C.; Feng, Y.; Lin, D.; Wu, L.; Guo, M. Iot Based Laundry Services: An Application of Big Data Analytics, Intelligent Logistics Management, and Machine Learning Techniques. Int. J. Prod. Res. 2020, 58, 5113–5131. [Google Scholar] [CrossRef]

- Rejeb, A.; Simske, S.; Rejeb, K.; Treiblmaier, H.; Zailani, S. Internet of Things Research in Supply Chain Management and Logistics: A Bibliometric Analysis. Internet Things 2020, 12, 100318. [Google Scholar] [CrossRef]

- Ekren, B.Y.; Mangla, S.K.; Turhanlar, E.E.; Kazancoglu, Y.; Li, G. Lateral Inventory Share-Based Models for IoT-Enabled E-Commerce Sustainable Food Supply Networks. Comput. Oper. Res. 2021, 130, 105237. [Google Scholar] [CrossRef]

- Muthu, S.S. Sustainability in the Textile Industry: Textile Science and Clothing Technology; Springer: Berlin/Heidelberg, Germany, 2017; ISBN 9789811026386. [Google Scholar]

- Acar, E.; Kiliç, M.; Güner, M. Measurement of Sustainability Performance in Textile Industry by Using a Multi-Criteria Decision-Making Method. Tekst. Konfeksiyon 2015, 25, 3–9. [Google Scholar]

- Shen, B.; Li, Q.; Dong, C.; Perry, P. Sustainability Issues in Textile and Apparel Supply Chains. Sustainability 2017, 9, 1592. [Google Scholar] [CrossRef] [Green Version]

- Kazancoglu, I.; Kazancoglu, Y.; Yarimoglu, E.; Kahraman, A. A Conceptual Framework for Barriers of Circular Supply Chains for Sustainability in the Textile Industry. Sustain. Dev. 2020, 28, 1477–1492. [Google Scholar] [CrossRef]

- Oelze, N. Sustainable Supply Chain Management Implementation-Enablers and Barriers in the Textile Industry. Sustainability 2017, 9, 1435. [Google Scholar] [CrossRef] [Green Version]

- Nunes, L.J.R.; Godina, R.; Matias, J.C.D.O. Technological Innovation in Biomass Energy for the Sustainable Growth of Textile Industry. Sustainability 2019, 11, 528. [Google Scholar] [CrossRef] [Green Version]

- Muthu, S.S.; Gardetti, M.A. Sustainability in the Textile and Apparel Industries: Sourcing Synthetic and Novel Alternative Raw Materials: Sustainable Textiles: Production, Processing, Manufacturing & Chemistry; Springer: Berlin/Heidelberg, Germany, 2020; ISBN 978-3-030-38013-7. [Google Scholar]

- Sadowski, A.; Dobrowolska, B.; Skowron-Grabowska, B.; Bujak, A. Polish Textile and Apparel Industry: Global Supply Chain Management Perspective. Autex Res. J. 2021, 21, 262–271. [Google Scholar] [CrossRef]

- Hempel, P.S.; Kwong, Y.K. B2B E-Commerce in Emerging Economies: I-Metal.Com’s Non-Ferrous Metals Exchange in China. J. Strateg. Inf. Syst. 2001, 10, 335–355. [Google Scholar] [CrossRef]

- Claycomb, C.; Iyer, K.; Germain, R. Predicting the Level of B2B E-Commerce in Industrial Organizations. Ind. Mark. Manag. 2005, 34, 221–234. [Google Scholar] [CrossRef]

- Ma, S.; Li, G.; Liu, M. Procurement Competition in the Presence of IoT-Enabled B2B E-Commerce. Electron. Commer. Res. Appl. 2021, 49, 101091. [Google Scholar] [CrossRef]

- Prajapati, D.; Chan, F.T.S.; Daultani, Y.; Pratap, S. Sustainable Vehicle Routing of Agro-Food Grains in the e-Commerce Industry. Int. J. Prod. Res. 2022, 1–26. [Google Scholar] [CrossRef]

- Zhang, M.; Pratap, S.; Zhao, Z.; Prajapati, D.; Huang, G.Q. Forward and Reverse Logistics Vehicle Routing Problems with Time Horizons in B2C E-Commerce Logistics. Int. J. Prod. Res. 2020, 59, 6291–6310. [Google Scholar] [CrossRef]

- Garg, R.; Kiwelekar, A.W.; Netak, L.D.; Ghodake, A. I-Pulse: A NLP Based Novel Approach for Employee Engagement in Logistics Organization. Int. J. Inf. Manag. Data Insights 2021, 1, 100011. [Google Scholar] [CrossRef]

- Kushwaha, A.K.; Kar, A.K.; Dwivedi, Y.K. Applications of Big Data in Emerging Management Disciplines: A Literature Review Using Text Mining. Int. J. Inf. Manag. Data Insights 2021, 1, 100017. [Google Scholar] [CrossRef]

- Konstantakopoulos, G.D.; Gayialis, S.P.; Kechagias, E.P.; Papadopoulos, G.A.; Tatsiopoulos, I.P. An Algorithmic Approach for Sustainable and Collaborative Logistics: A Case Study in Greece. Int. J. Inf. Manag. Data Insights 2021, 1, 100010. [Google Scholar] [CrossRef]

- Atabaki, M.S.; Khamseh, A.A.; Mohammadi, M. A Priority-Based Firefly Algorithm for Network Design of a Closed-Loop Supply Chain with Price-Sensitive Demand. Comput. Ind. Eng. 2019, 135, 814–837. [Google Scholar] [CrossRef]

- Yadollahinia, M.; Teimoury, E.; Paydar, M.M. Tire Forward and Reverse Supply Chain Design Considering Customer Relationship Management. Resour. Conserv. Recycl. 2018, 138, 215–228. [Google Scholar] [CrossRef]

- Prajapati, D.; Zhou, F.; Zhang, M.; Chelladurai, H.; Pratap, S. Sustainable Logistics Network Design for Multi-Products Delivery Operations in B2B e-Commerce Platform. Sādhanā 2021, 0123456789, 1–13. [Google Scholar] [CrossRef]

- Prajapati, D.; Kumar, M.M.; Pratap, S.; Chelladurai, H.; Zuhair, M. Sustainable Logistics Network Design for Delivery Operations with Time Horizons in B2B E-Commerce Platform. Logistics 2021, 5, 61. [Google Scholar] [CrossRef]

- Dwivedi, A.; Jha, A.; Prajapati, D.; Sreenu, N.; Pratap, S. Meta-Heuristic Algorithms for Solving the Sustainable Agro-Food Grain Supply Chain Network Design Problem Supply Chains. Mod. Supply Chain Res. Appl. 2020, 7, 2631–3971. [Google Scholar] [CrossRef]

- Li, G. Development of Cold Chain Logistics Transportation System Based on 5G Network and Internet of Things System. Microprocess. Microsyst. 2021, 80, 103565. [Google Scholar] [CrossRef]

| Authors Name | IoT | Supply Chain | Logistics | Model | Textile | Sustain-ability | E-Commerce |

|---|---|---|---|---|---|---|---|

| Abbasi et al. [13] | √ | √ | |||||

| Liu et al. [14] | √ | √ | |||||

| Rejeb et al. [15] | √ | ||||||

| Ekren et al. [16] | √ | √ | |||||

| Zhou et al. [9] | √ | √ | √ | ||||

| Anitha et al. [2] | √ | √ | |||||

| Konstantakopoulos et al. [32] | √ | √ | |||||

| Khan et al. [3] | √ | ||||||

| Kazancoglu et al. [20] | √ | √ | √ | ||||

| Ma et al. [27] | √ | √ | √ | ||||

| Oelze [21] | √ | √ | √ | ||||

| Nunes et al. [22] | √ | √ | |||||

| Current study | √ | √ | √ | √ | √ | √ | √ |

| d_mw | w1 | w2 | w3 | w4 | w5 |

|---|---|---|---|---|---|

| m1 | 758 | 985 | 986 | 789 | 796 |

| m2 | 896 | 875 | 658 | 964 | 785 |

| m3 | 689 | 785 | 589 | 478 | 968 |

| A_mr | r1 | r2 | r3 | r4 | r5 |

|---|---|---|---|---|---|

| m1 | 50,000 | 10,000 | 40,000 | 70,000 | 15,000 |

| m2 | 90,000 | 80,000 | 90,000 | 78,000 | 84,600 |

| m3 | 98,700 | 68,900 | 10,000 | 79,990 | 60,000 |

| dem_wr | r1 | r2 | r3 | r4 | r5 |

|---|---|---|---|---|---|

| w1 | 100 | 150 | 24 | 310 | 42 |

| w2 | 50 | 140 | 150 | 30 | 41 |

| w3 | 200 | 160 | 160 | 180 | 160 |

| w4 | 30 | 260 | 170 | 190 | 32 |

| w5 | 35 | 28 | 180 | 210 | 39 |

| Sr. No. | Instances m-w-r | Number of Variables | Number of Constraints | Total Cost, INR | Elapsed Time, s | |||

|---|---|---|---|---|---|---|---|---|

| Total | Nonlinear | Integer | Total | Nonlinear | ||||

| 1 | 3-5-5 | 304 | 302 | 75 | 553 | 376 | 6,649,813 | 379.35 |

| 2 | 4-7-7 | 788 | 784 | 196 | 1228 | 785 | 8,827,601 | 489.57 |

| 3 | 5-8-8 | 1284 | 1282 | 320 | 2307 | 1601 | 11,092,980 | 755.11 |

| 4 | 6-10-10 | 2400 | 2400 | 600 | 3703 | 2401 | 17,014,650 | 985.32 |

| 5 | 7-15-15 | 6304 | 6302 | 1575 | 11,253 | 7876 | 38,013,270 | 1254.74 |

| 6 | 7-15-17 | 7144 | 7140 | 1785 | 10,968 | 7141 | 32,123,440 | 1298.56 |

| 7 | 7-17-20 | 9524 | 9520 | 2380 | 14,623 | 9521 | 43,930,680 | 1693.25 |

| 8 | 9-20-25 | 18,004 | 18,000 | 4500 | 27,503 | 18,001 | 70,081,120 | 3145.56 |

| 9 | 12-25-30 | 36,004 | 36,000 | 9000 | 54,753 | 36,001 | 51,912,420 | 15,417.71 |

| 10 | 18-35-45 | 113,404 | 113,400 | 28,350 | 176,678 | 113,401 | 56,587,000 | ------- |

| Cases | Parameters and Percentage Changes | Decreased by 25% | Decreased by 50% | Increased by 25% | Increased by 50% |

|---|---|---|---|---|---|

| First case scenario | Demand | 5,181,534 | 3,465,217 | 8,071,543 | 9,940,140 |

| % Change | 22.08 ↓ | 47.89 ↓ | 21.38 ↑ | 49.48 ↑ | |

| Cost-related parameters | 5,244,707 | 3,396,059 | 7,945,861 | 9,859,677 | |

| % Change | 21.13 ↓ | 48.93 ↓ | 19.49 ↑ | 48.27 ↑ | |

| Purchasing costs related to IoT facilities and RFID tags | 5,371,053 | 3,624,813 | 7,869,388 | 9,733,996 | |

| % Change | 19.23 ↓ | 45.49 ↓ | 18.34 ↑ | 46.38 ↑ | |

| Fifth case scenario | Demand | 31,041,636 | 21,158,186 | 48,033,567 | 57,544,488 |

| % Change | 18.34 ↓ | 44.34 ↓ | 26.36 ↑ | 51.78 ↑ | |

| Cost-related parameters | 30,604,483 | 19,622,450 | 47,284,706 | 56,966,686 | |

| % Change | 19.49 ↓ | 48.38 ↓ | 24.39 ↑ | 49.86 ↑ | |

| Purchasing costs related to IoT facilities and RFID tags | 30,277,569 | 20,272,476 | 47,094,640 | 57,913,216 | |

| % Change | 20.35 ↓ | 46.67 ↓ | 23.89 ↑ | 52.35 ↑ |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Prajapati, D.; Chan, F.T.S.; Chelladurai, H.; Lakshay, L.; Pratap, S. An Internet of Things Embedded Sustainable Supply Chain Management of B2B E-Commerce. Sustainability 2022, 14, 5066. https://doi.org/10.3390/su14095066

Prajapati D, Chan FTS, Chelladurai H, Lakshay L, Pratap S. An Internet of Things Embedded Sustainable Supply Chain Management of B2B E-Commerce. Sustainability. 2022; 14(9):5066. https://doi.org/10.3390/su14095066

Chicago/Turabian StylePrajapati, Dhirendra, Felix T. S. Chan, H. Chelladurai, Lakshay Lakshay, and Saurabh Pratap. 2022. "An Internet of Things Embedded Sustainable Supply Chain Management of B2B E-Commerce" Sustainability 14, no. 9: 5066. https://doi.org/10.3390/su14095066