Evaluation of Water Level in Flowing Channels Using Ultrasonic Sensors

Abstract

:1. Introduction

2. Materials and Methods

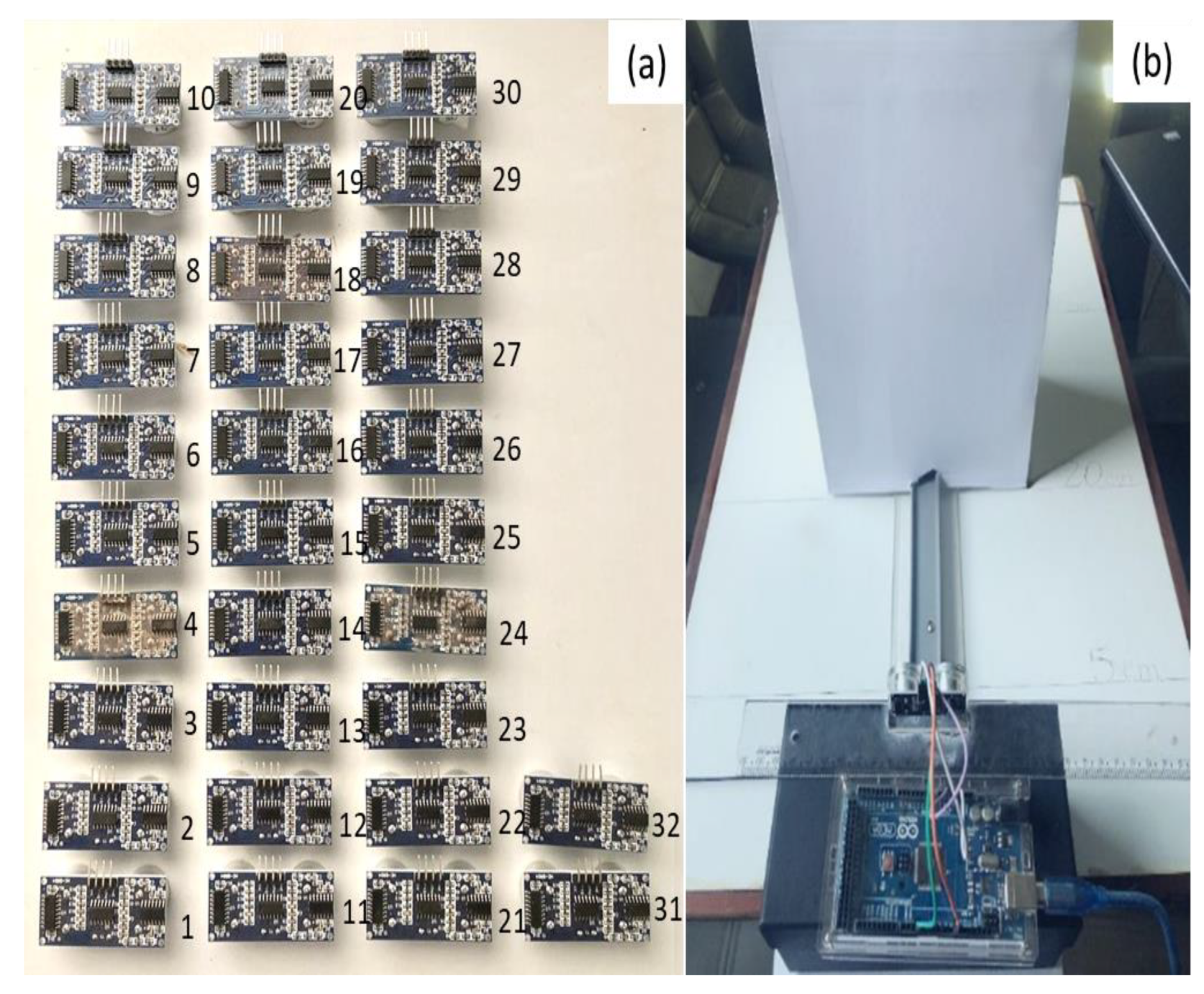

2.1. Hardware Components Description—Ultrasonic Sensor and Arduino

2.2. Bench Tests

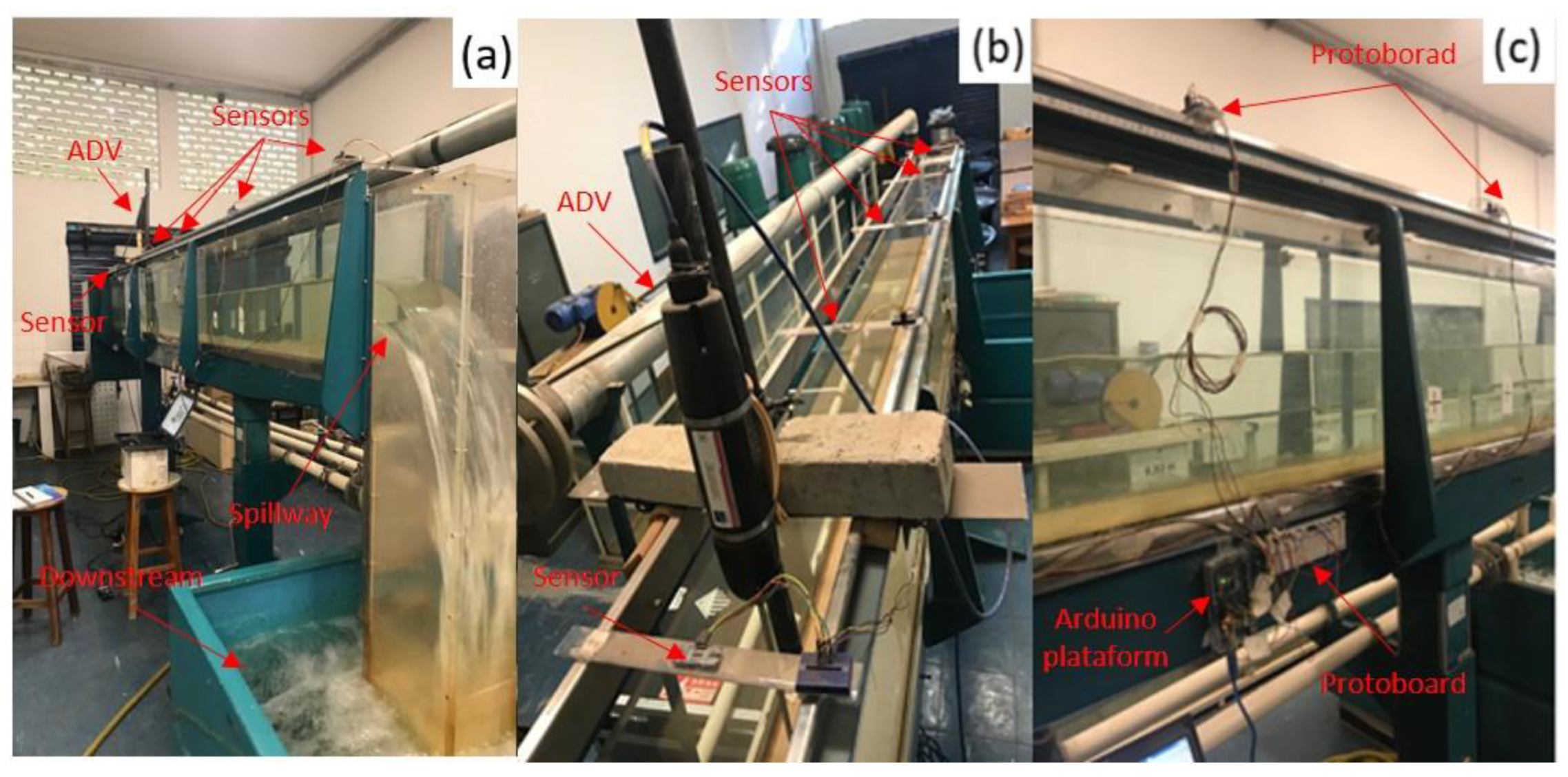

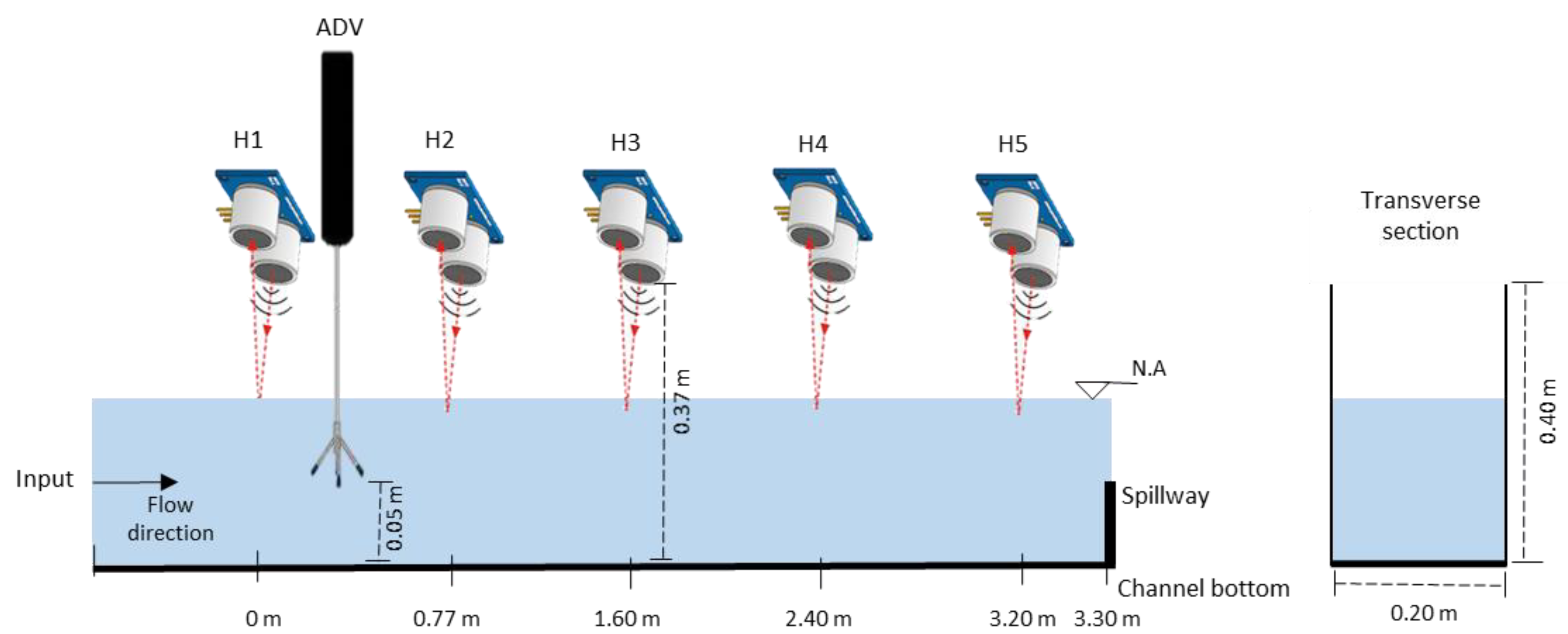

2.3. Experimental Set-Up and Monitoring of Flow Events in the Channel

3. Results

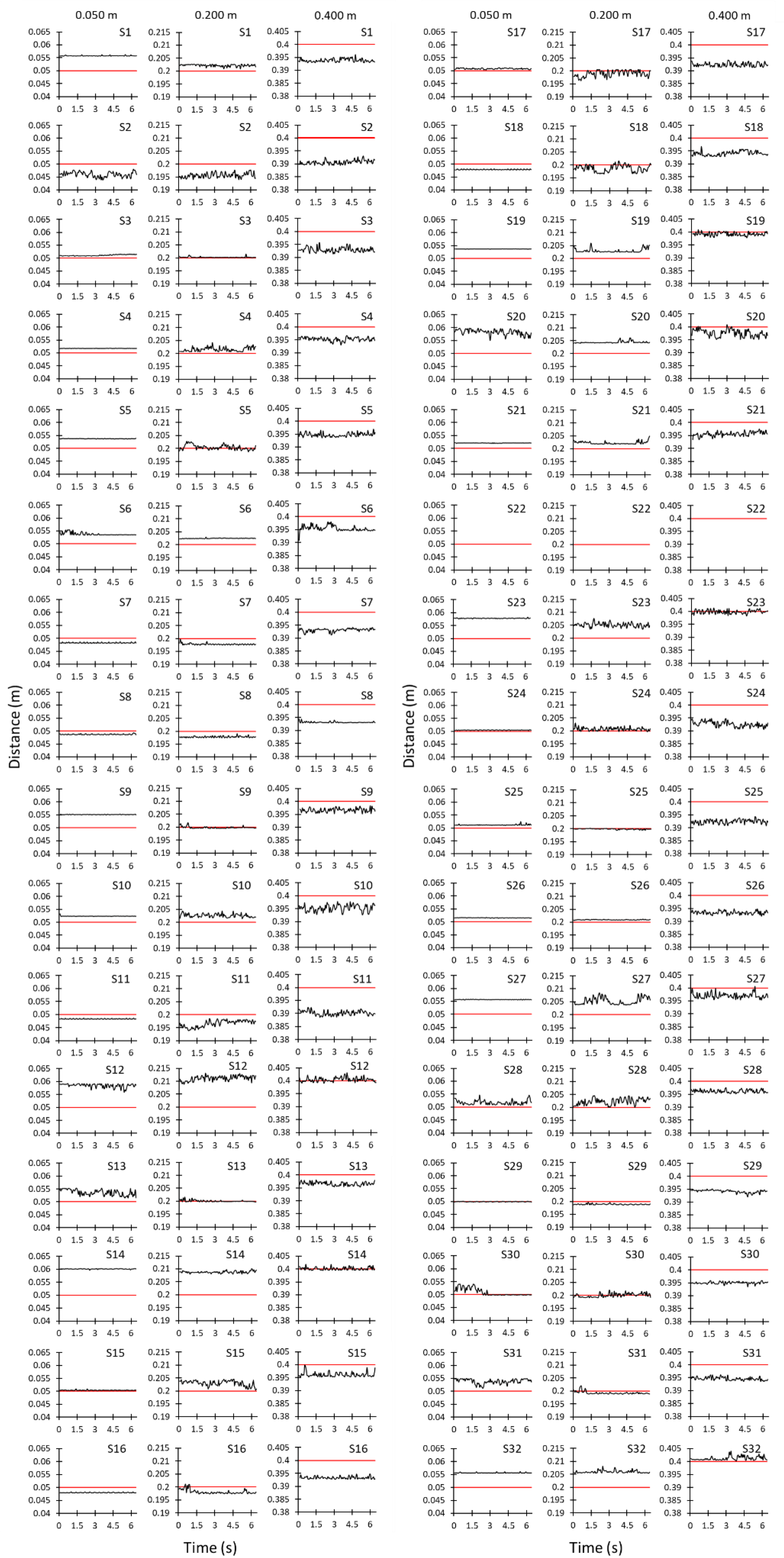

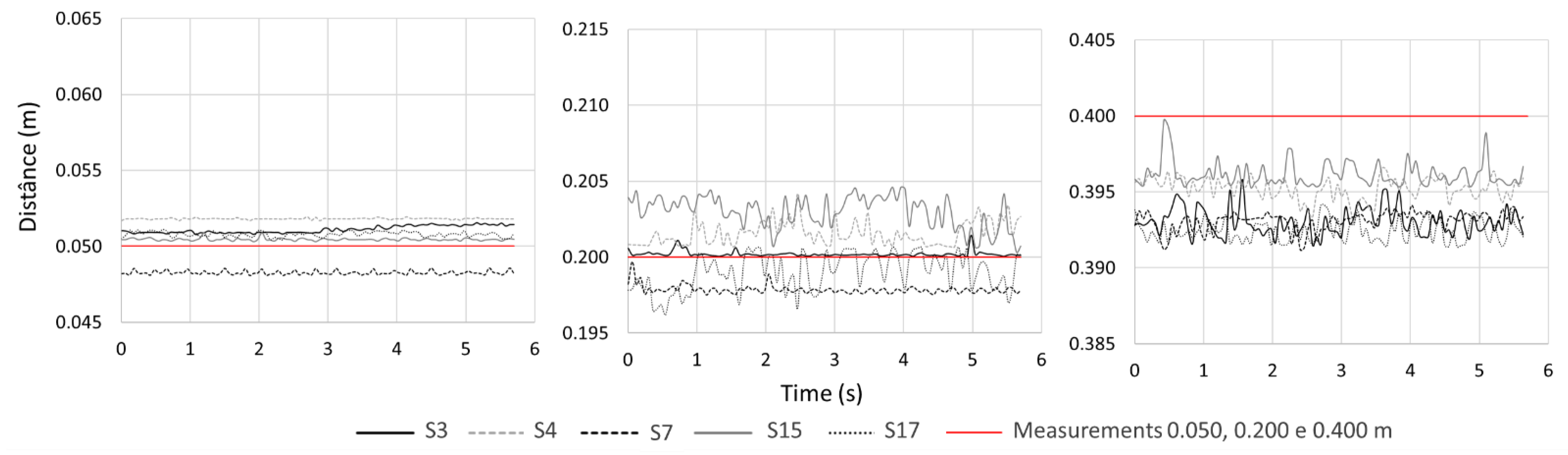

3.1. Bench Test

3.2. Evaluation of the Monitored Events

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Algorithm A1: Script on Arduino without Kalman Filter Application. |

| #include <Ultrasonic.h> #define echoPin_1 3 //pin 3 receives the echo pulse #define trigPin_1 4 //pin 4 sends the pulse to generate the echo #define echoPin_2 5 //pin 5 receives the echo pulse #define trigPin_2 6 //pin 6 sends the pulse to generate the echo #define echoPin_3 7 //pin 7 receives the echo pulse #define trigPin_3 8 //pin 8 sends the pulse to generate the echo #define echoPin_4 9 //pin 9 receives the echo pulse #define trigPin_4 10 //pin 10 sends the pulse to generate the echo #define echoPin_5 11 //pin 3 receives the echo pulse #define trigPin_5 12 //pin 12 sends the pulse to generate the echo int myCounter = 0; //declare your variable myCounter and set to 0 int servoControlPin = 6; //dervo control line is connected to pin 6 float pingTime_1; //time for ping to travel from sensor to target and return float pingTime_2; //time for ping to travel from sensor to target and return float pingTime_3; //time for ping to travel from sensor to target and return float pingTime_4; //time for ping to travel from sensor to target and return float pingTime_5; //time for ping to travel from sensor to target and return float targetDistance_1; //distance to target in inches—sensor 1 float targetDistance_2; //distance to target in inches—sensor 2 float targetDistance_3; //distance to target in inches—sensor 3 float targetDistance_4; //distance to target in inches—sensor 4 float targetDistance_5; //distance to target in inches—sensor 5 float distanciaMedia_1 = 0; //average reading distance—sensor 1 float distanciaMedia_2 = 0; //average reading distance—sensor 2 float distanciaMedia_3 = 0; //average reading distance—sensor 3 float distanciaMedia_4 = 0; //average reading distance—sensor 4 float distanciaMedia_5 = 0; //average reading distance—sensor 5 float speedOfSound = 346; //speed of sound in m/s at 20 °C int leituras = 10; //number of readings to find the average int k = 1; //read counter float distancia_1[11] = {0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0}; float distancia_2[11] = {0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0}; float distancia_3[11] = {0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0}; float distancia_4[11] = {0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0}; float distancia_5[11] = {0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0}; // starting the function and passing the pins int t = 0; void setup() { Serial.begin(9600); //start the serial port pinMode(echoPin_1, INPUT); //sets pin 3 as input (receives) pinMode(trigPin_1, OUTPUT); //sets pin 4 as output (send) pinMode(echoPin_2, INPUT); //sets pin 5 as input (receives) pinMode(trigPin_2, OUTPUT); //sets pin 6 as output (send) pinMode(echoPin_3, INPUT); //sets pin 7 as input (receives) pinMode(trigPin_3, OUTPUT); //sets pin 8 as output (send) pinMode(echoPin_4, INPUT); //sets pin 9 as input (receives) pinMode(trigPin_4, OUTPUT); //sets pin 10 as output (send) pinMode(echoPin_5, INPUT); //sets pin 11 as input (receives) pinMode(trigPin_5, OUTPUT); //sets pin 12 as output (send) } void loop() { digitalWrite(trigPin_1, LOW); //set trigger pin low delayMicroseconds(10); // the sum of everything is 2 milliseconds 1975 + 15 + 10 microseconds digitalWrite(trigPin_1, HIGH); //set trigPin high delayMicroseconds(20); //delay in high state digitalWrite(trigPin_1, LOW); //ping has now been sent delayMicroseconds(10); //delay in high state pingTime_1 = pulseIn(echoPin_1, HIGH); //pingTime is presented in microseconds digitalWrite(trigPin_2, LOW); //set trigger pin low delayMicroseconds(10); //the sum of everything is 2 milliseconds 1975 + 15 + 10 microseconds digitalWrite(trigPin_2, HIGH); //set trigPin high delayMicroseconds(20); //delay in high state digitalWrite(trigPin_2, LOW); //ping has now been sent delayMicroseconds(10); //delay in high state pingTime_2 = pulseIn(echoPin_2, HIGH); //pingTime is presented in microseconds digitalWrite(trigPin_3, LOW); //set trigger pin low delayMicroseconds(10); //the sum of everything is 2 milliseconds 1975 + 15 + 10 microseconds digitalWrite(trigPin_3, HIGH); //set trigPin high delayMicroseconds(20); //delay in high state digitalWrite(trigPin_3, LOW); //ping has now been sent delayMicroseconds(10); //delay in high state pingTime_3 = pulseIn(echoPin_3, HIGH); //pingTime is presented in microseconds digitalWrite(trigPin_4, LOW); //set trigger pin low delayMicroseconds(10); //the sum of everything is 2 milliseconds 1975 + 15 + 10 microseconds digitalWrite(trigPin_4, HIGH); //set trigPin high delayMicroseconds(20); //delay in high state digitalWrite(trigPin_4, LOW); //ping has now been sent delayMicroseconds(10); //delay in high state pingTime_4 = pulseIn(echoPin_4, HIGH); //pingTime is presented in microseconds digitalWrite(trigPin_5, LOW); //set trigger pin low delayMicroseconds(10); //the sum of everything is 2 milliseconds 1975 + 15 + 10 microseconds digitalWrite(trigPin_5, HIGH); //set trigPin high delayMicroseconds(20); //delay in high state digitalWrite(trigPin_5, LOW); //ping has now been sent delayMicroseconds(10); //delay in high state pingTime_5 = pulseIn(echoPin_5, HIGH); //pingTime is presented in microseconds pingTime_1 = pingTime_1/1000000; //convert pingTime to seconds by dividing by 1000000 (microseconds in a second) pingTime_2 = pingTime_2/1000000; //convert pingTime to seconds by dividing by 1000000 (microseconds in a second) pingTime_3 = pingTime_3/1000000; //convert pingTime to seconds by dividing by 1000000 (microseconds in a second) pingTime_4 = pingTime_4/1000000; //convert pingTime to seconds by dividing by 1000000 (microseconds in a second) pingTime_5 = pingTime_5/1000000; //convert pingTime to seconds by dividing by 1000000 (microseconds in a second) targetDistance_1 = 1000 * speedOfSound * pingTime_1/2; //total distance in m targetDistance_2 = 1000 * speedOfSound * pingTime_2/2; //total distance in m targetDistance_3 = 1000 * speedOfSound * pingTime_3/2; //total distance in m targetDistance_4 = 1000 * speedOfSound * pingTime_4/2; //total distance in m targetDistance_5 = 1000 * speedOfSound * pingTime_5/2; //total distance in m //targetDistance = targetDistance/2; //consider the round-trip interval //targetDistance= targetDistance*1000; //convert distance to mm //Serial.print(targetDistance_4); //Serial.print(“ “); //Serial.println(targetDistance_5); distancia_1[k] = distancia_1[k−1] + targetDistance_1; distancia_2[k] = distancia_2[k−1] + targetDistance_2; distancia_3[k] = distancia_3[k−1] + targetDistance_3; distancia_4[k] = distancia_4[k−1] + targetDistance_4; distancia_5[k] = distancia_5[k−1] + targetDistance_5; if (k >= leituras) { distanciaMedia_1 = distancia_1[k]/leituras; distanciaMedia_2 = distancia_2[k]/leituras; distanciaMedia_3 = distancia_3[k]/leituras; distanciaMedia_4 = distancia_4[k]/leituras; distanciaMedia_5 = distancia_5[k]/leituras; Serial.print(millis()); Serial.print(“ “); Serial.print(distanciaMedia_1); Serial.print(“ “); Serial.print(distanciaMedia_2); Serial.print(“ “); Serial.print(distanciaMedia_3); Serial.print(“ “); Serial.print(distanciaMedia_4); Serial.print(“ “); Serial.println(distanciaMedia_5); t++; k = 0; } k++; //double distancia = (ultrasonic.Ranging(CM)); //serial.print(t); //serial.print(“ “); //serial.println(distancia); //delay(5); //wait 0.1 s to read again } |

Appendix B

References

- Mulik, S.S.; Patange, A.D.; Jegadeeshwaran, R.; Pardeshi, S.S.; Rahegaonkar, A. Development and Experimental Assessment of a Fluid Flow Monitoring System Using Flow Sensor and Arduino Interface. In Innovative Design, Analysis and Development Practices in Aerospace and Automotive Engineering; Lecture Notes in Mechanical Engineering; Gascoin, N., Balasubramanian, E., Eds.; Springer: Singapore, 2021; pp. 115–122. [Google Scholar] [CrossRef]

- Dobriyal, P.; Badola, R.; Tuboi, C.; Hussain, S.A. A review of methods for monitoring streamflow for sustainable water resource management. Appl. Water Sci. 2017, 7, 2617–2628. [Google Scholar] [CrossRef] [Green Version]

- Le Coz, J.; Hauet, A.; Pierrefeu, G.; Dramais, G.; Camenen, B. Performance of image-based velocimetry (LSPIV) applied to flash-flood discharge measurements in Mediterranean rivers. J. Hydrol. 2010, 394, 42–52. [Google Scholar] [CrossRef] [Green Version]

- Rozos, E.; Dimitriadis, P.; Mazi, K.; Lykoudis, S.; Koussis, A. On the Uncertainty of the Image Velocimetry Method Parameters. Hydrology 2020, 7, 65. [Google Scholar] [CrossRef]

- De Oliveira, F.A.; Pereira, T.S.R.; Soares, A.K.; Formiga, K.T.M. Uso de modelo hidrodinâmico para determinação da vazão a partir de medições de nível. Rev. Bras. De Recur. Hídricos RBRH 2016, 21, 707–718. [Google Scholar] [CrossRef] [Green Version]

- Muste, M.; Fujita, I.; Hauet, A. Large-scale particle image velocimetry for measurements in riverine environments. Water Resour. Res. 2008, 44, 1–14. [Google Scholar] [CrossRef] [Green Version]

- Meier, R.; Tscheikner-Gratl, F.; Steffelbauer, D.B.; Makropoulos, C. Flow Measurements Derived from Camera Footage Using an Open-Source Ecosystem. Water 2022, 14, 424. [Google Scholar] [CrossRef]

- Zhang, G.; Valero, D.; Bung, D.; Chanson, H. On the estimation of free-surface turbulence using ultrasonic sensors. Flow Meas. Instrum. 2018, 60, 171–184. [Google Scholar] [CrossRef] [Green Version]

- Ali, A.S.; Zanzinger, Z.; DeBose, D.; Stephens, B. Open Source Building Science Sensors (OSBSS): A low-cost Arduino-based platform for long-term indoor environmental data collection. Build. Environ. 2016, 100, 114–126. [Google Scholar] [CrossRef] [Green Version]

- Kondaveeti, H.K.; Kumaravelu, N.K.; Vanambathina, S.D.; Mathe, S.E.; Vappangi, S. A systematic literature review on prototyping with Arduino: Applications, challenges, advantages, and limitations. Comput. Sci. Rev. 2021, 40, 100364. [Google Scholar] [CrossRef]

- Varun, K.S.; Kumar, K.A.; Chowdary, V.R.; Raju, C.S.K. Water Level Management Using Ultrasonic Sensor (Automation). Int. J. Comput. Sci. Eng. 2018, 6, 799–804. [Google Scholar] [CrossRef]

- Gunawan, G.; Sari, M.; Surbakti, B.; Ginting, A. Design of Automatic Plant Areas Using Humidity Sensor Based on Internet of Thing. J. Phys. Conf. Ser. 2019, 1361, 12063. [Google Scholar] [CrossRef]

- Lestariningsih, T.; Artono, B.; Hidayatullah, N.; Kusbandono, H. Microcontroller and Android HMI Based Water Level and Control System. EAI Endorsed Trans. Internet Things 2019, 5, 162807. [Google Scholar] [CrossRef]

- Siswanto; Rojikin, I.; Gata, W. Pemanfaatan Sensor Suhu DHT-22, Ultrasonik HC-SR04 Untuk Mengendalikan Kolam Dengan Notifikasi Email. J. RESTI Rekayasa Sist. Dan Teknol. Informasi 2019, 3, 544–551. [Google Scholar] [CrossRef] [Green Version]

- Krishnaveni, M.; Kumar, S.K.P.; Muthusamy, E.A.; Kowshick, J.; Arunya, K.G. Real-time monitoring of water level and storage dynamics of irrigation tank using IoT. H2Open J. 2020, 3, 392–400. [Google Scholar] [CrossRef]

- Baskhara, H.A.; Anwar, S. Design of Water Level Monitoring using Ultrasonic Sensor. J. Phys. Conf. Ser. 2021, 1772, 012001. [Google Scholar] [CrossRef]

- Jan, F.; Min-Allah, N.; Saeed, S.; Iqbal, S.Z.; Ahmed, R. IoT-Based Solutions to Monitor Water Level, Leakage, and Motor Control for Smart Water Tanks. Water 2022, 14, 309. [Google Scholar] [CrossRef]

- Drage, J.; Kennedy, G. Building a Low-Cost, Internet-of-Things, Real-Time Groundwater Level Monitoring Network. Ground Water Monit. Remediat. 2020, 40, 67–73. [Google Scholar] [CrossRef]

- Sahoo, A.K.; Udgata, S. A Novel ANN-Based Adaptive Ultrasonic Measurement System for Accurate Water Level Monitoring. IEEE Trans. Instrum. Meas. 2020, 69, 3359–3369. [Google Scholar] [CrossRef]

- Olisa, S.C.; Asiegbu, C.N.; Olisa, J.E.; Ekengwu, B.O.; Shittu, A.A.; Eze, M.C. Smart two-tank water quality and level detection system via IoT. Heliyon 2021, 7, e07651. [Google Scholar] [CrossRef]

- Zuo, F.; Liu, Y. Application of Multiparameter Kalman Filter in Ultrasonic Water Meter. Wirel. Commun. Mob. Comput. 2022, 2022, 3580376. [Google Scholar] [CrossRef]

- Selvan, M.; Roy, A.; Singh, K.; Kumar, A. Automatic water level indicator using ultrasonic sensor and GSM module. Int. J. Adv. Res. Innov. Ideas Educ. IJARIIE 2018, 4, 261–269. [Google Scholar]

- Bello, M.; Gana, S.; Faruk, M.; Umar, M. Autonomous ultrasonic based water level detection and control system. Niger. J. Technol. NIJOTECH 2018, 37, 508–513. [Google Scholar] [CrossRef] [Green Version]

- Bae, I.; Ji, U. Outlier Detection and Smoothing Process for Water Level Data Measured by Ultrasonic Sensor in Stream Flows. Water 2019, 11, 951. [Google Scholar] [CrossRef] [Green Version]

- Panagopoulos, Y.; Papadopoulos, A.; Poulis, G.; Nikiforakis, E.; Dimitriou, E. Assessment of an Ultrasonic Water Stage Monitoring Sensor Operating in an Urban Stream. Sensors 2021, 21, 4689. [Google Scholar] [CrossRef]

- Cytron Technologies. Product User’s Manual—HC-SR04 Ultrasonic Sensor; Cytron Technologies: Bukit Mertajam, Malaysia, 2013. [Google Scholar]

- Singh, R.; Baz, M.; Gehlot, A.; Rashid, M.; Khurana, M.; Akram, S.; Alshamrani, S.; AlGhamdi, A. Water Quality Monitoring and Management of Building Water Tank Using Industrial Internet of Things. Sustainability 2021, 13, 8452. [Google Scholar] [CrossRef]

- Valentín, M.B.; de Bom, C.R.; de Albuquerque, M.P.; Faria, E.L.; Correia, M.D. Aquisição de imagens ultrassônicas como experimento didático. Rev. Bras. De Ensino Física 2018, 40, e2503. [Google Scholar] [CrossRef] [Green Version]

- Reynolds, O. An Experimental Investigation of the Circumstances Which Determine Whether the Motion of Water Shall Be Direct or Sinuous, and of the Law of Resistance in Parallel Channels. Philos. Trans. R. Soc. London 1883, 174, 935–982. [Google Scholar]

- Kalman, R.E. A New Approach to Linear Filtering and Prediction Problems. J. Basic Eng. 1960, 82, 35–45. [Google Scholar] [CrossRef] [Green Version]

- LeGates, D.R.; McCabe, G.J. Evaluating the use of “goodness-of-fit” Measures in hydrologic and hydroclimatic model validation. Water Resour. Res. 1999, 35, 233–241. [Google Scholar] [CrossRef]

- Lin, L.I.-K. A Concordance Correlation Coefficient to Evaluate Reproducibility. Biometrics 1989, 45, 255–268. [Google Scholar] [CrossRef]

- Dusarlapudi, K.; Chandrika Kota, V.S.P.; Annepu, C.R.; Narayana, M.V. Accuracy analysis of an ultrasonic sensor over an open channel rectangular notch for rainwater harvesting. Int. J. Sci. E Technol. Res. 2020, 9, 2813–2816. [Google Scholar]

- Altman, D.G. Practical Statistics for Medical Research; Chapman and Hall: London, UK, 1991. [Google Scholar]

- McBride, G.B. A Proposal for Concordance Strength Criteria for Lin’s Concordance Correlation Coefficient; NIWA Customer Report: HAM2005-062; ScienceOpen, Inc.: Burlington, MA, USA, 2005. [Google Scholar]

- ISO 748; Hydrometry—Measurement of Liquid Flow in Open Channels Using Current-Meters and Floats. International Organization for Standardization (ISO): Geneva, Switzerland, 2007.

- Muste, M.; Lee, K.; Bertrand-Krajewski, J.-L. Standardized uncertainty analysis for hydrometry: A review of relevant approaches and implementation examples. Hydrol. Sci. J. 2012, 57, 643–667. [Google Scholar] [CrossRef] [Green Version]

- Moriasi, D.N.; Arnold, J.G.; van Liew, M.W.; Bingner, R.L.; Harmel, R.D.; Veith, T.L. Model evaluation guidelines for systematic quantification of accuracy in watershed simulations. Am. Soc. Agric. Biol. Eng. 2007, 50, 885–900. [Google Scholar]

- Harmel, R.D.; Smith, P.K. Consideration of measurement uncertainty in the evaluation of goodness-of-fit in hydrologic and water quality modeling. J. Hydrol. 2007, 337, 326–336. [Google Scholar] [CrossRef]

| Distance (m) | Permissible Error (m) | ±0.003–±0.005 | ||||

|---|---|---|---|---|---|---|

| Sensor | S3 | S4 | S7 | S15 | S17 | |

| 0.050 | Average | 0.051 | 0.052 | 0.048 | 0.050 | 0.051 |

| Standard deviation | 0.0002 | 0.0000 | 0.0001 | 0.0001 | 0.0002 | |

| Absolute error (m) | 0.001 | 0.002 | −0.002 | 0.000 | 0.001 | |

| 0.200 | Average | 0.200 | 0.202 | 0.198 | 0.203 | 0.199 |

| Standard deviation | 0.0002 | 0.0008 | 0.0003 | 0.0011 | 0.0013 | |

| Absolute error (m) | 0.000 | 0.002 | −0.002 | 0.003 | −0.001 | |

| 0.400 | Average | 0.393 | 0.395 | 0.393 | 0.396 | 0.392 |

| Standard deviation | 0.0090 | 0.0007 | 0.0006 | 0.0009 | 0.0007 | |

| Absolute error (m) | −0.007 | −0.005 | −0.007 | −0.004 | −0.008 | |

| EV | Sensor | Q (L s−1) | So (mm−1) | RMSE (m) | PBIAS (%) | RE (%) | Ruler (m) | S Ruler (m) | Sensor (m) | S Sensor (m) | Reynolds |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | H1 | 5 | 0.017 | 0.00306 | 2.17 | 2.38 | 0.125 | 0.00000 | 0.122 | 0.00103 | 10,989.01 |

| H2 | 0.00291 | 2.08 | 2.08 | 0.133 | 0.00083 | 0.130 | 0.00047 | 10,634.83 | |||

| H3 | 0.00578 | 3.99 | 3.99 | 0.141 | 0.00129 | 0.136 | 0.00032 | 10,260.20 | |||

| H4 | 0.00681 | 4.52 | 4.52 | 0.150 | 0.00031 | 0.143 | 0.00046 | 9903.06 | |||

| H5 | 0.00291 | 1.63 | 1.78 | 0.153 | 0.00093 | 0.150 | 0.00092 | 9792.88 | |||

| 2 | H1 | 10 | 0.017 | 0.00552 | 3.34 | 3.34 | 0.156 | 0.00049 | 0.150 | 0.00178 | 19,367.40 |

| H2 | 0.00370 | 2.03 | 2.06 | 0.162 | 0.00096 | 0.159 | 0.00112 | 18,882.42 | |||

| H3 | 0.00526 | 3.06 | 3.06 | 0.170 | 0.00029 | 0.165 | 0.00080 | 18,342.23 | |||

| H4 | 0.00480 | 2.37 | 2.36 | 0.175 | 0.00240 | 0.171 | 0.00099 | 18,033.04 | |||

| H5 | 0.00517 | 2.82 | 2.82 | 0.180 | 0.00000 | 0.175 | 0.00098 | 17,699.12 | |||

| 3 | H1 | 15 | 0.017 | 0.00915 | 4.86 | 4.86 | 0.180 | 0.00130 | 0.172 | 0.00223 | 26,509.01 |

| H2 | 0.00353 | 1.43 | 1.56 | 0.185 | 0.00064 | 0.183 | 0.00229 | 26,063.23 | |||

| H3 | 0.00588 | 2.94 | 2.94 | 0.193 | 0.00082 | 0.188 | 0.00114 | 25,344.79 | |||

| H4 | 0.00605 | 2.95 | 2.95 | 0.201 | 0.00057 | 0.195 | 0.00110 | 24,699.58 | |||

| H5 | 0.00698 | 3.33 | 3.32 | 0.204 | 0.00060 | 0.197 | 0.00132 | 24,469.90 | |||

| 4 | H1 | 20 | 0.017 | 0.00911 | 4.21 | 4.21 | 0.201 | 0.00057 | 0.193 | 0.00311 | 32,914.80 |

| H2 | 0.00568 | 2.55 | 2.55 | 0.206 | 0.00051 | 0.200 | 0.00208 | 32,467.62 | |||

| H3 | 0.00784 | 3.47 | 3.46 | 0.214 | 0.00095 | 0.207 | 0.00220 | 31,558.95 | |||

| H4 | 0.00657 | 2.78 | 2.78 | 0.221 | 0.00066 | 0.215 | 0.00223 | 30,937.19 | |||

| H5 | 0.00388 | 1.63 | 1.63 | 0.222 | 0.00109 | 0.218 | 0.00090 | 30,853.21 | |||

| 5 | H1 | 5–20 | 0.005 | 0.00190 | −0.26 | 0.75 | 0.173 | 0.02161 | 0.173 | 0.02100 | 19,630.75 |

| H2 | 0.00335 | 1.06 | 1.60 | 0.177 | 0.02116 | 0.175 | 0.02241 | 19,820.76 | |||

| H3 | 0.00404 | 1.68 | 1.72 | 0.181 | 0.02175 | 0.178 | 0.02119 | 19,965.64 | |||

| H4 | 0.00506 | 2.19 | 2.24 | 0.185 | 0.02197 | 0.181 | 0.02191 | 20,131.14 | |||

| H5 | 0.00388 | 1.79 | 1.83 | 0.187 | 0.02055 | 0.183 | 0.02048 | 20,200.43 | |||

| 6 | H1 | 5–20 | 0.008 | 0.00195 | −0.72 | 1.08 | 0.153 | 0.02416 | 0.155 | 0.02359 | 24,947.21 |

| H2 | 0.00289 | 1.00 | 1.26 | 0.161 | 0.02434 | 0.159 | 0.02430 | 25,436.61 | |||

| H3 | 0.00221 | 0.79 | 1.08 | 0.168 | 0.02497 | 0.167 | 0.02497 | 25,857.08 | |||

| H4 | 0.00265 | 0.87 | 1.24 | 0.176 | 0.02525 | 0.175 | 0.02537 | 26,328.55 | |||

| H5 | 0.00236 | 0.98 | 1.04 | 0.180 | 0.02362 | 0.178 | 0.02289 | 26,534.77 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pereira, T.S.R.; de Carvalho, T.P.; Mendes, T.A.; Formiga, K.T.M. Evaluation of Water Level in Flowing Channels Using Ultrasonic Sensors. Sustainability 2022, 14, 5512. https://doi.org/10.3390/su14095512

Pereira TSR, de Carvalho TP, Mendes TA, Formiga KTM. Evaluation of Water Level in Flowing Channels Using Ultrasonic Sensors. Sustainability. 2022; 14(9):5512. https://doi.org/10.3390/su14095512

Chicago/Turabian StylePereira, Tatiane Souza Rodrigues, Thiago Pires de Carvalho, Thiago Augusto Mendes, and Klebber Teodomiro Martins Formiga. 2022. "Evaluation of Water Level in Flowing Channels Using Ultrasonic Sensors" Sustainability 14, no. 9: 5512. https://doi.org/10.3390/su14095512

APA StylePereira, T. S. R., de Carvalho, T. P., Mendes, T. A., & Formiga, K. T. M. (2022). Evaluation of Water Level in Flowing Channels Using Ultrasonic Sensors. Sustainability, 14(9), 5512. https://doi.org/10.3390/su14095512