Crack Propagation and Failure Mechanism of Modeled Recycled Concrete under Shear Stress

Abstract

:1. Introduction

2. Materials and Methods

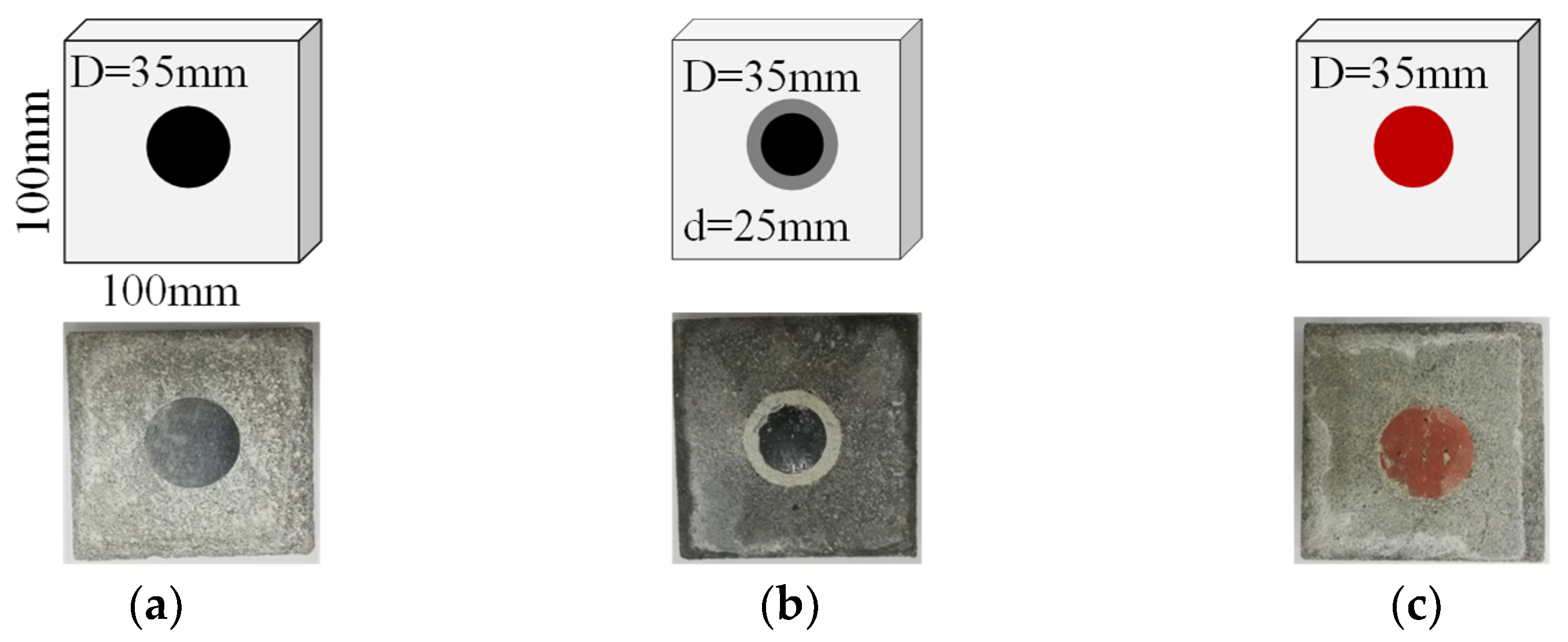

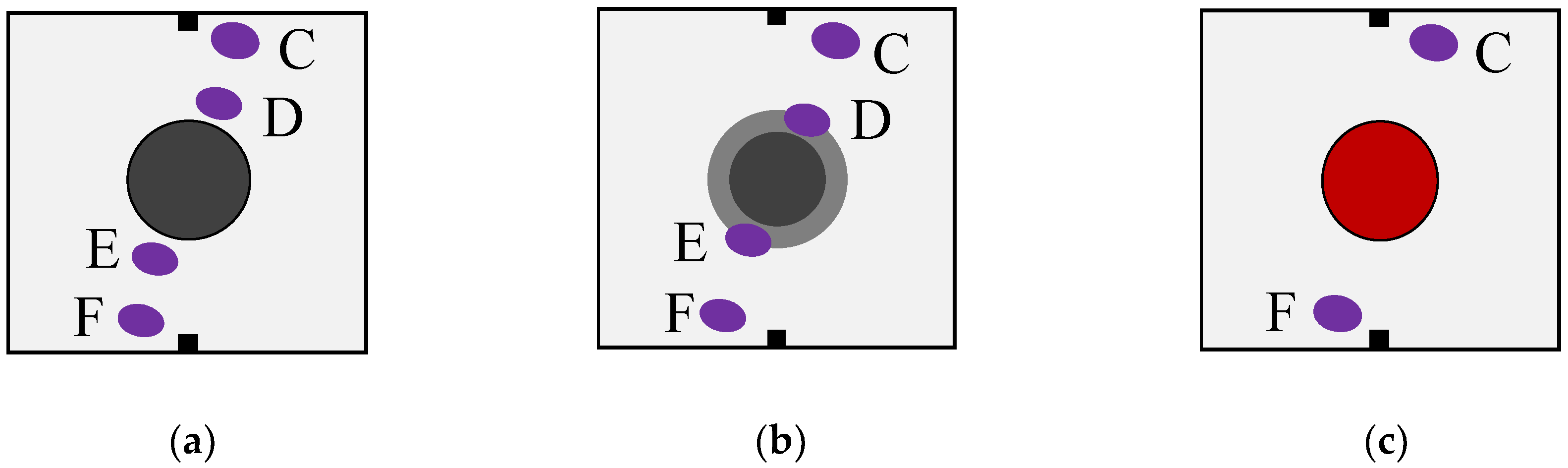

2.1. Modeled Concrete

2.2. Mechanical Properties of Each Phase

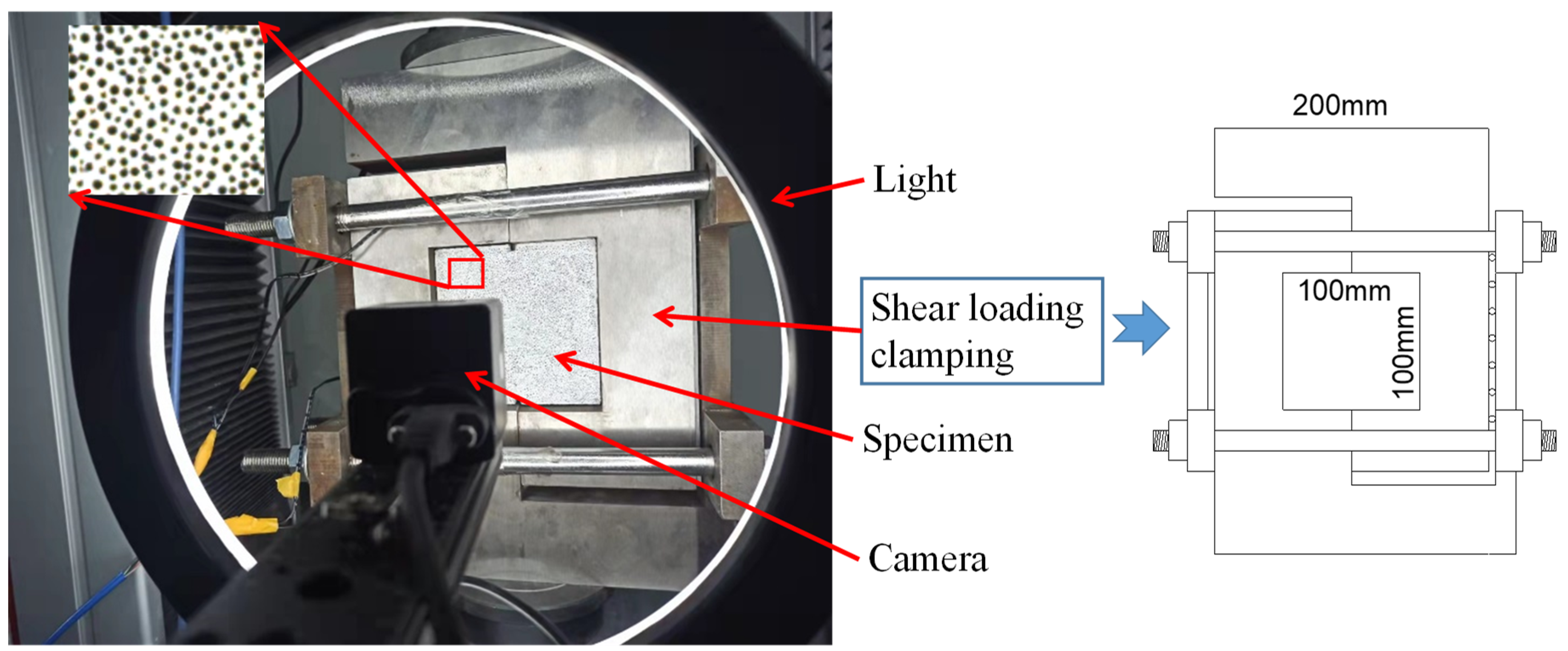

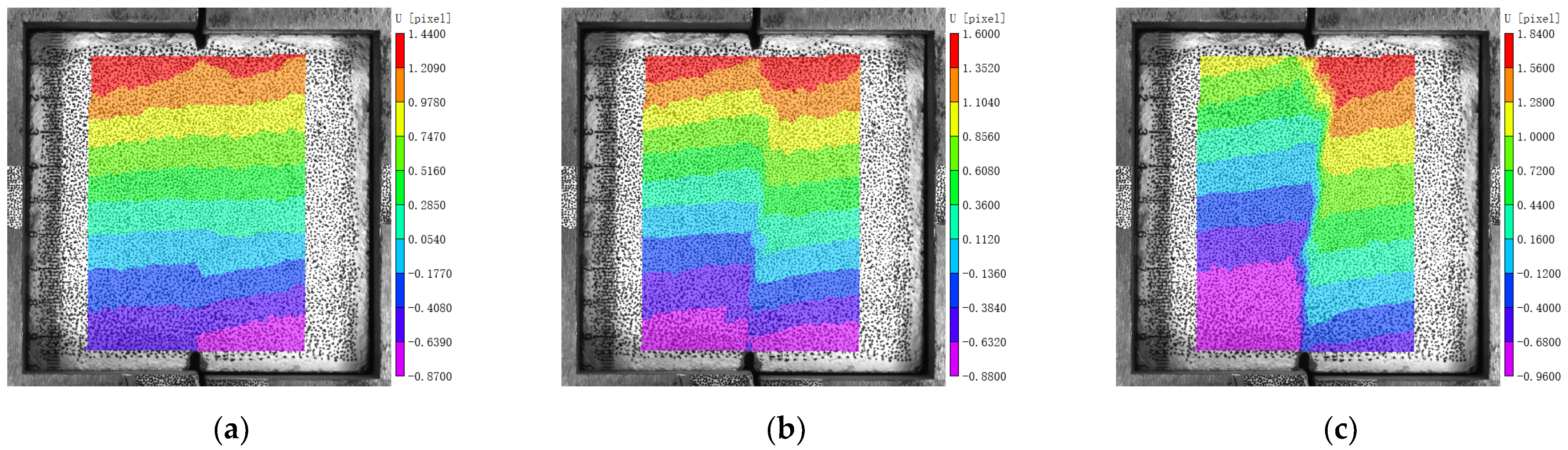

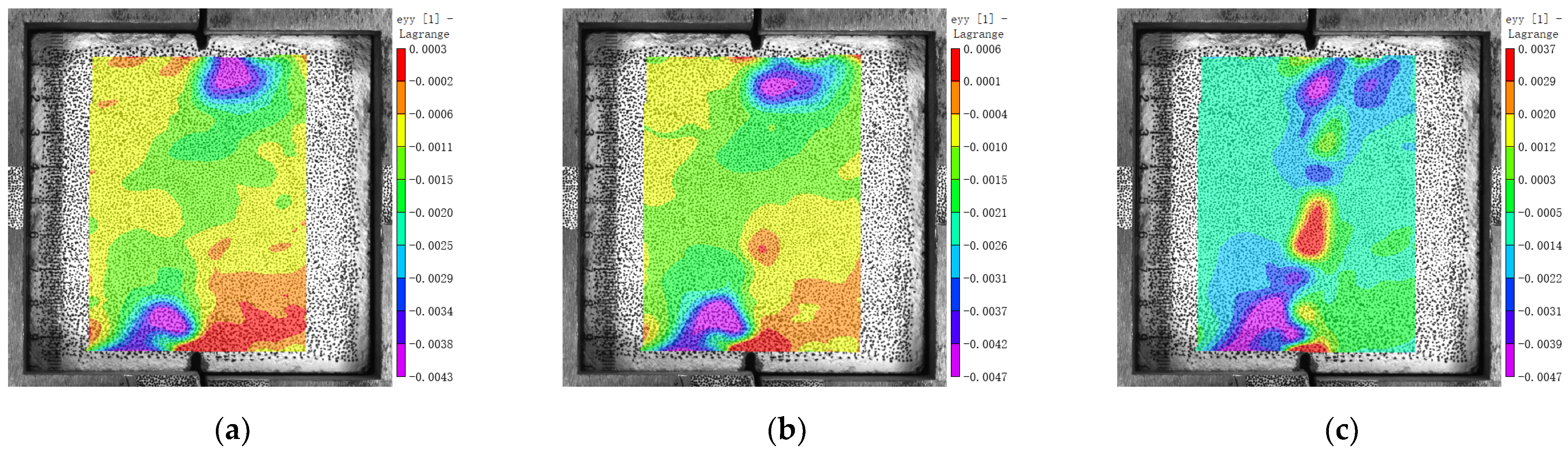

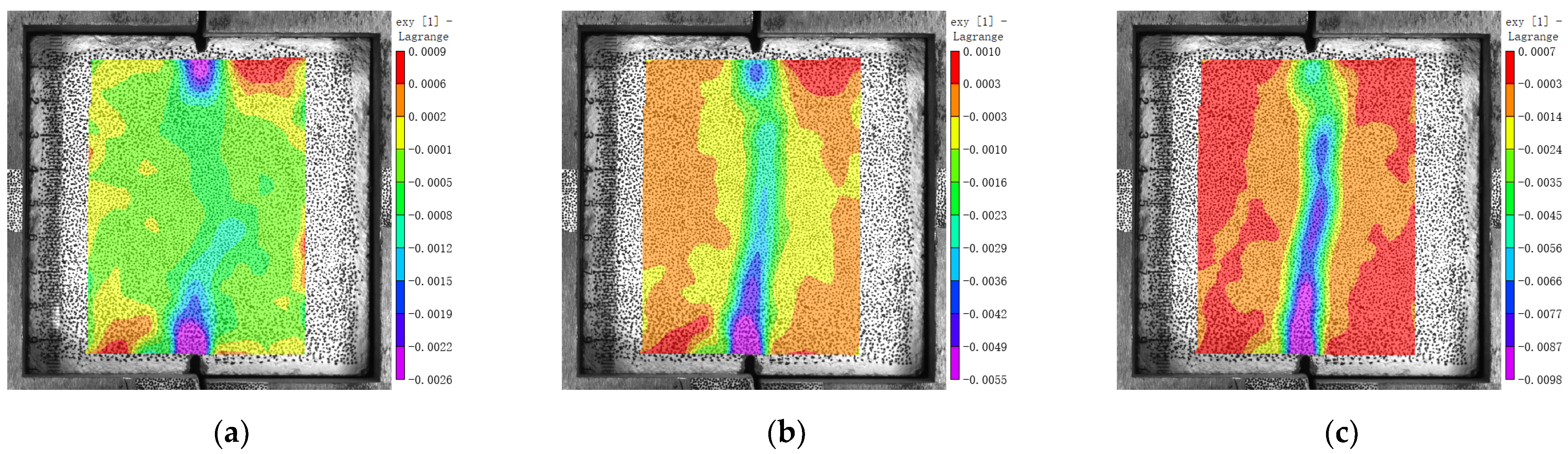

2.3. Digital Image Correlation

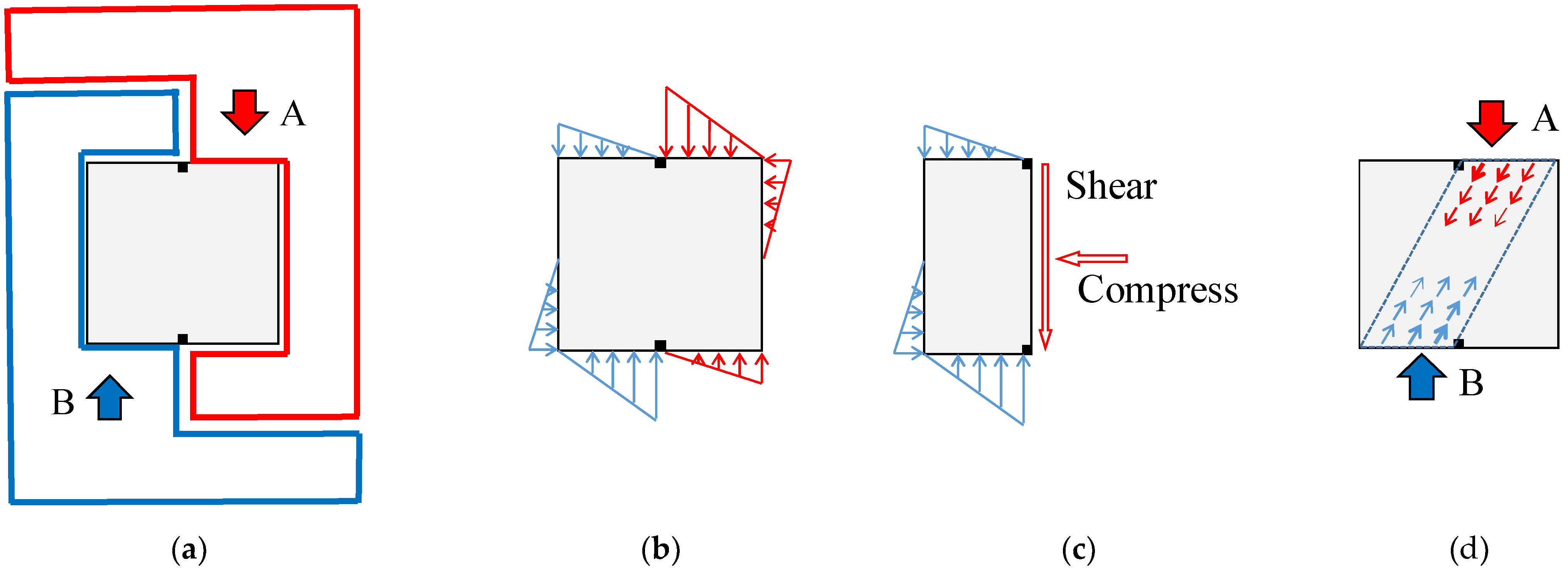

2.4. Testing Procedure

3. Results and Discussion

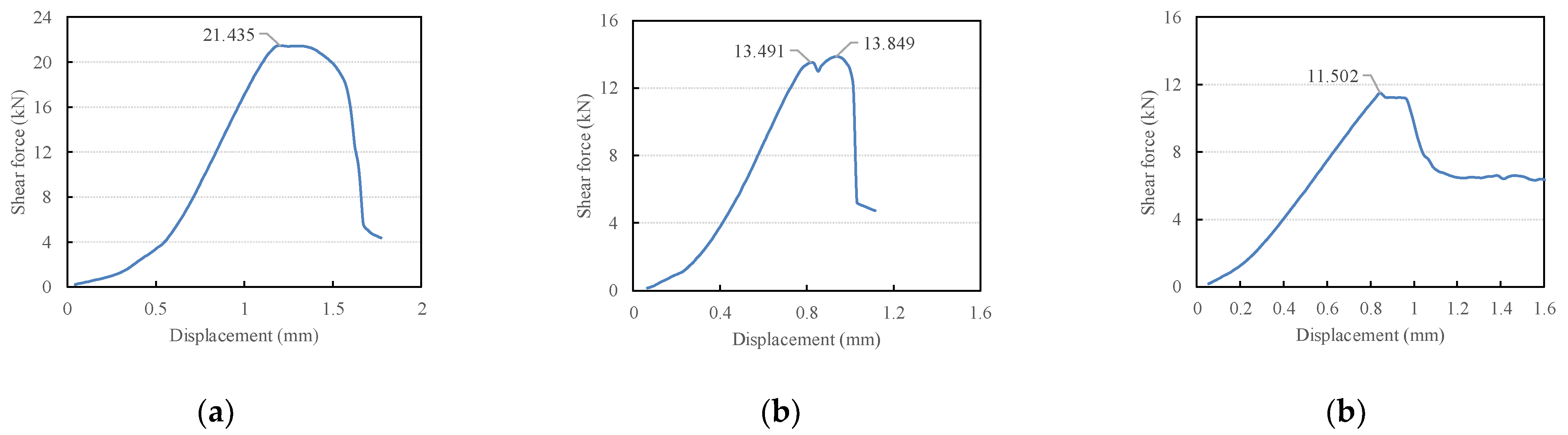

3.1. Mechanical Properties and Failure Modes

3.2. Modeled Natural Concrete

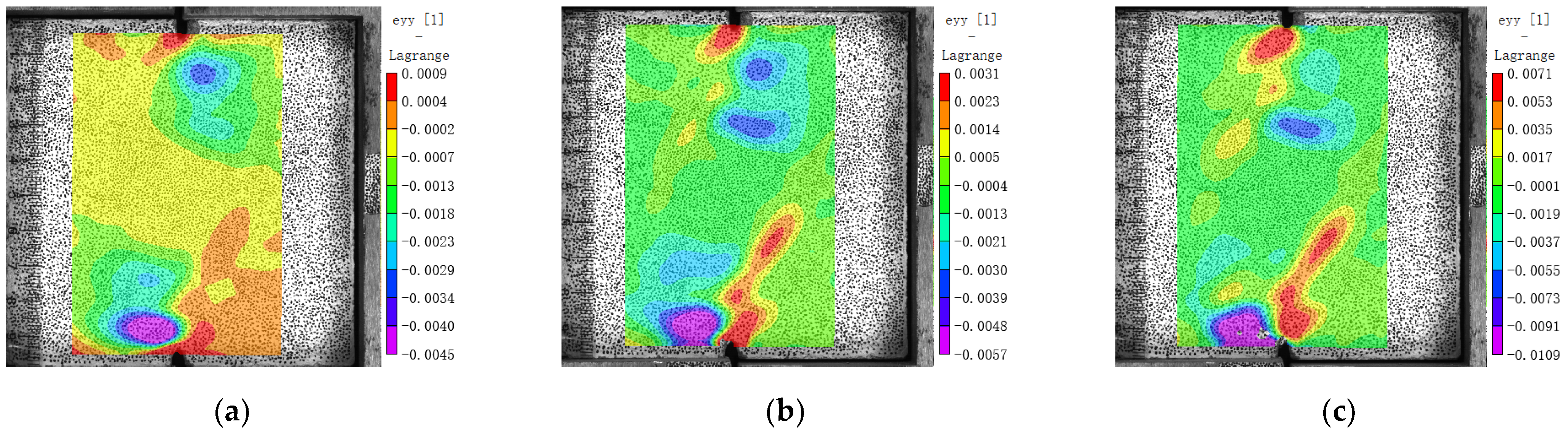

3.3. Modeled Recycled Concrete

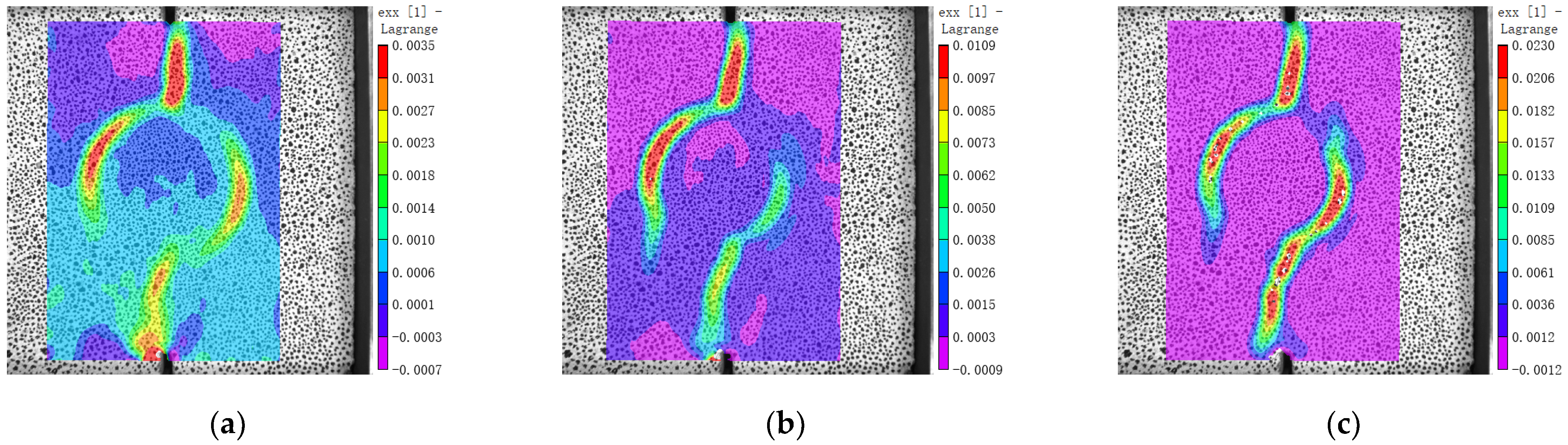

3.4. Modeled Brick Aggregate Concrete

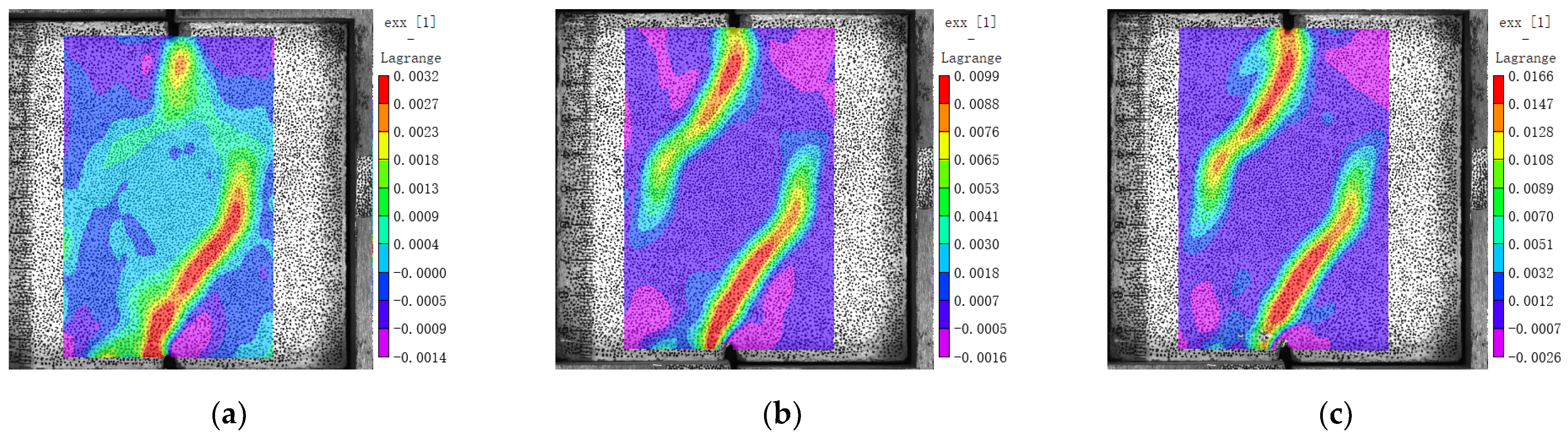

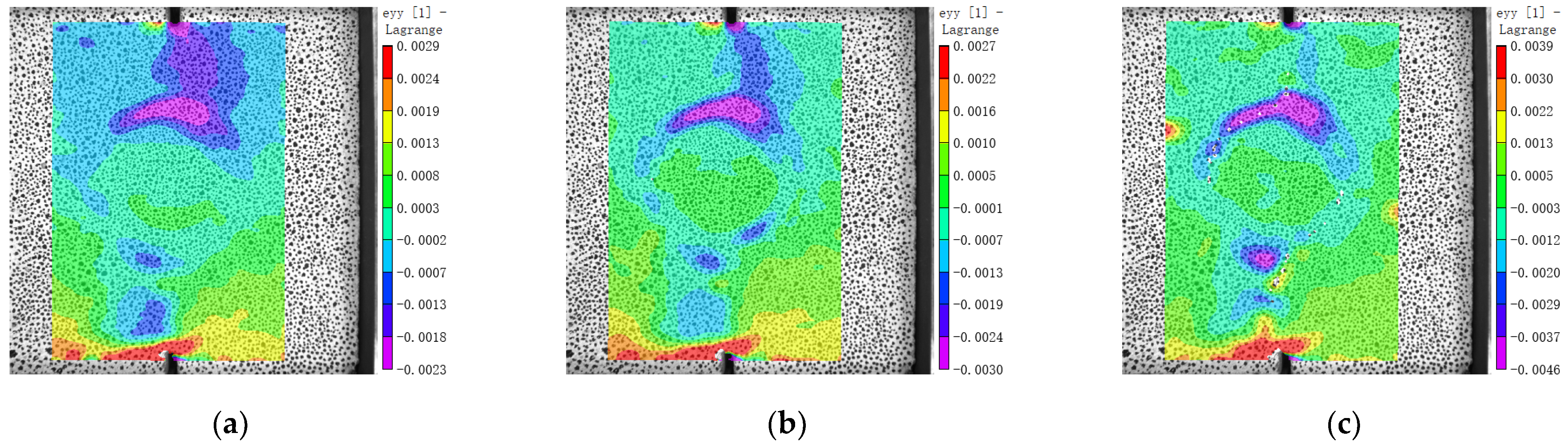

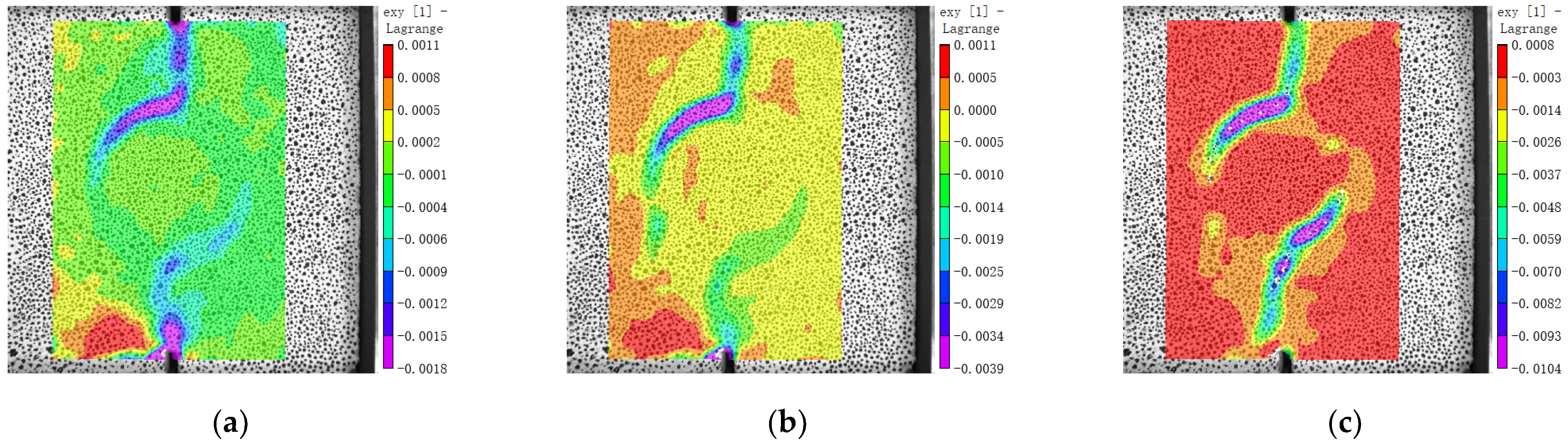

3.5. Internal Force and Strain Concentration

4. Conclusions

- The shear strength of MNC is the highest, followed by MRC, and the shear strength of MBC is the lowest. The strength of natural aggregate concrete is high, and the bite effect is the strongest. The recycled aggregate also contains a natural aggregate, which also contributes to the bite effect in shear failure. The strength and elastic modulus of brick aggregate is lower than that of the hardened mortar, so there is no bite effect in MBC.

- The failure mechanism of MNC is that the cracks develop from notches and pass through the ITZ. The failure law of MRC is similar, but the cracks will pass through the old mortar from the new ITZ and continue to develop in the old ITZ. MBC cracks propagate and develop from the inside of the aggregate and run through the whole aggregate

- When MNC is close to failure under shear, there are four vertical strain concentration zones along the compressive stress trace; two of them are near the loading end and two near the natural aggregate. MRC also has four strain concentration zones along the compressive stress zone, two near the loading end and two in the old mortar near the natural aggregate. MBC has only two strain concentration areas along the compressive stress zone, and there is no strain concentration area near the brick aggregate because the elastic modulus of the brick aggregate is less than that of the surrounding hardened mortar.

- The fixture designed in this paper can easily apply a shear force to the square specimen. Although there is orthogonal pressure to the shear plane, the pressure is small and does not affect the study of the specimen’s shear failure mechanism. In the future, the experimental setup can be improved to strudy pure shear or controllable compression shear.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Xiao, J.; Li, W.; Fan, Y.; Huang, X. An overview of study on recycled aggregate concrete in China (1996–2011). Constr. Build. Mater. 2012, 31, 364–383. [Google Scholar] [CrossRef]

- Tam, V.W.Y.; Soomro, M.; Evangelista, A.C.J. A review of recycled aggregate in concrete applications (2000–2017). Constr. Build. Mater. 2018, 172, 272–292. [Google Scholar] [CrossRef]

- Zheng, Y.; Zhuo, J.; Zhang, P. A review on durability of nano-SiO2 and basalt fiber modified recycled aggregate concrete. Constr. Build. Mater. 2021, 304, 124659. [Google Scholar] [CrossRef]

- Liu, Q.; Singh, A.; Xiao, J. Workability and mechanical properties of mortar containing recycled sand from aerated concrete blocks and sintered clay bricks. Resour. Conserv. Recycl. 2020, 157, 104728. [Google Scholar] [CrossRef]

- GB/T 25177-2011; Recycled Coarse Aggregate for Concrete. China Architecture & Building Press: Beijing, China, 2011. (In Chinese)

- GB/T 25176-2011; Recycled Fine Aggregate for Concrete and Mortar. China Architecture & Building Press: Beijing, China, 2011. (In Chinese)

- Zheng, C.; Lou, C.; Du, G.; Li, X.; Liu, Z.; Li, L. Mechanical properties of recycled concrete with demolished waste concrete aggregate and clay brick aggregate. Results Phys. 2018, 9, 1317–1322. [Google Scholar] [CrossRef]

- Dang, J.; Zhao, J.; Pang, S.; Zhao, S. Durability and microstructural properties of concrete with recycled brick as fine aggregates. Constr. Build. Mater. 2020, 262, 120032. [Google Scholar] [CrossRef]

- Zong, L.; Fei, Z.; Zhang, S. Permeability of recycled aggregate concrete containing fly ash and clay brick waste. J. Clean. Prod. 2014, 70, 175–182. [Google Scholar] [CrossRef]

- Wong, C.; Mo, K.; Yap, S.; Alengaram, U.J.; Ling, T. Potential use of brick waste as alternate concrete-making materials: A review. J. Clean. Prod. 2018, 195, 226–239. [Google Scholar] [CrossRef]

- Liu, Q.; Xiao, J.; Singh, A. Plastic shrinkage and cracking behavior of mortar containing recycled sand from aerated blocks and clay bricks. Sustainability 2021, 13, 1096. [Google Scholar] [CrossRef]

- Shah, S.P.; Winter, G. Inelastic behavior and fracture of concrete. ACI Mater. J. 1966, 63, 5–28. [Google Scholar]

- Buyukozturk, O.; Nilson, A.H.; Slate, F.O. Stress-strain response and fracture of a concrete model in biaxial loading. ACI Mater. J. 1971, 68, 590–599. [Google Scholar]

- Liu, T.; Nilson, A.H.; Slate, F.O. Stress-strain response and fracture of concrete in uniaxial and biaxial compression. ACIAR Proc. 1972, 69, 291–295. [Google Scholar]

- Maji, A.K.; Shah, S.P. Application of acoustic emission and laser holography to study micro-fracture in concrete. ACI Mater. J. 1989, 112, 83–110. [Google Scholar]

- Lawler, J.S.; Keane, D.T.; Shah, S.P. Measuring three-dimensional damage in concrete under compression. ACI Mater. J. 2001, 98, 465–475. [Google Scholar]

- Tregger, N.; Corr, D.; Graham-Brady, L.; Shah, S. Modeling the effect of meso-scale randomness on concrete fracture. Probabilistic Eng. Mech. 2006, 21, 217–225. [Google Scholar] [CrossRef]

- Xiao, J.; Li, W.; Sun, Z.; Shah, S.P. Crack propagation in recycled aggregate concrete under uniaxial compressive loading. ACI Mater. J. 2012, 109, 451–461. [Google Scholar]

- Liu, Q.; Xiao, J.; Singh, A. Crack Propagation and Failure Characteristics of Modeled Concrete with Natural and Brick Aggregates. J. Renew. Mater. 2021, 9, 1309–1327. [Google Scholar] [CrossRef]

- Bertelsen, I.M.G.; Kragh, C.; Cardinaud, G.; Ottosen, L.M. Quantification of plastic shrinkage cracking in mortars using digital image correlation. Cem. Concr. Res. 2019, 123, 105761. [Google Scholar] [CrossRef]

- Liu, Q.; Xiao, J.; Singh, A. Quantification of plastic shrinkage and cracking in mortars containing different recycled powders using digital image correlation technique. Constr. Build. Mater. 2021, 293, 123509. [Google Scholar] [CrossRef]

- Liu, Q.; Xiao, J.; Sun, J. Experimental study on the failure mechanism of recycled concrete. Cem. Concr. Res. 2011, 41, 1050–1057. [Google Scholar] [CrossRef]

- Mattock, A.H.; Hawkins, N.M. Shear transfer in reinforced concrete-recent research. PCI J. 1972, 17, 55–75. [Google Scholar] [CrossRef]

| Material | Density (kg/m3) | Elastic Modulus (GPa) | Compressive Strength (MPa) | Poisson’s Ratio |

|---|---|---|---|---|

| Natural aggregate | 2560 | 65.0 | 170.1 | 0.160 |

| New mortar | 2180 | 16.3 | 18.5 | 0.170 |

| Old mortar | 2209 | 23.0 | 29.8 | 0.176 |

| Brick aggregate | 1810 | 2.5 | 5.4 | 0.177 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, S.; Peng, S.; Sun, C.; Singh, A.; Cheng, Z.; Tian, Y. Crack Propagation and Failure Mechanism of Modeled Recycled Concrete under Shear Stress. Sustainability 2022, 14, 5552. https://doi.org/10.3390/su14095552

Wang S, Peng S, Sun C, Singh A, Cheng Z, Tian Y. Crack Propagation and Failure Mechanism of Modeled Recycled Concrete under Shear Stress. Sustainability. 2022; 14(9):5552. https://doi.org/10.3390/su14095552

Chicago/Turabian StyleWang, Shijun, Shengjiang Peng, Chang Sun, Amardeep Singh, Ziyun Cheng, and Yunfei Tian. 2022. "Crack Propagation and Failure Mechanism of Modeled Recycled Concrete under Shear Stress" Sustainability 14, no. 9: 5552. https://doi.org/10.3390/su14095552

APA StyleWang, S., Peng, S., Sun, C., Singh, A., Cheng, Z., & Tian, Y. (2022). Crack Propagation and Failure Mechanism of Modeled Recycled Concrete under Shear Stress. Sustainability, 14(9), 5552. https://doi.org/10.3390/su14095552