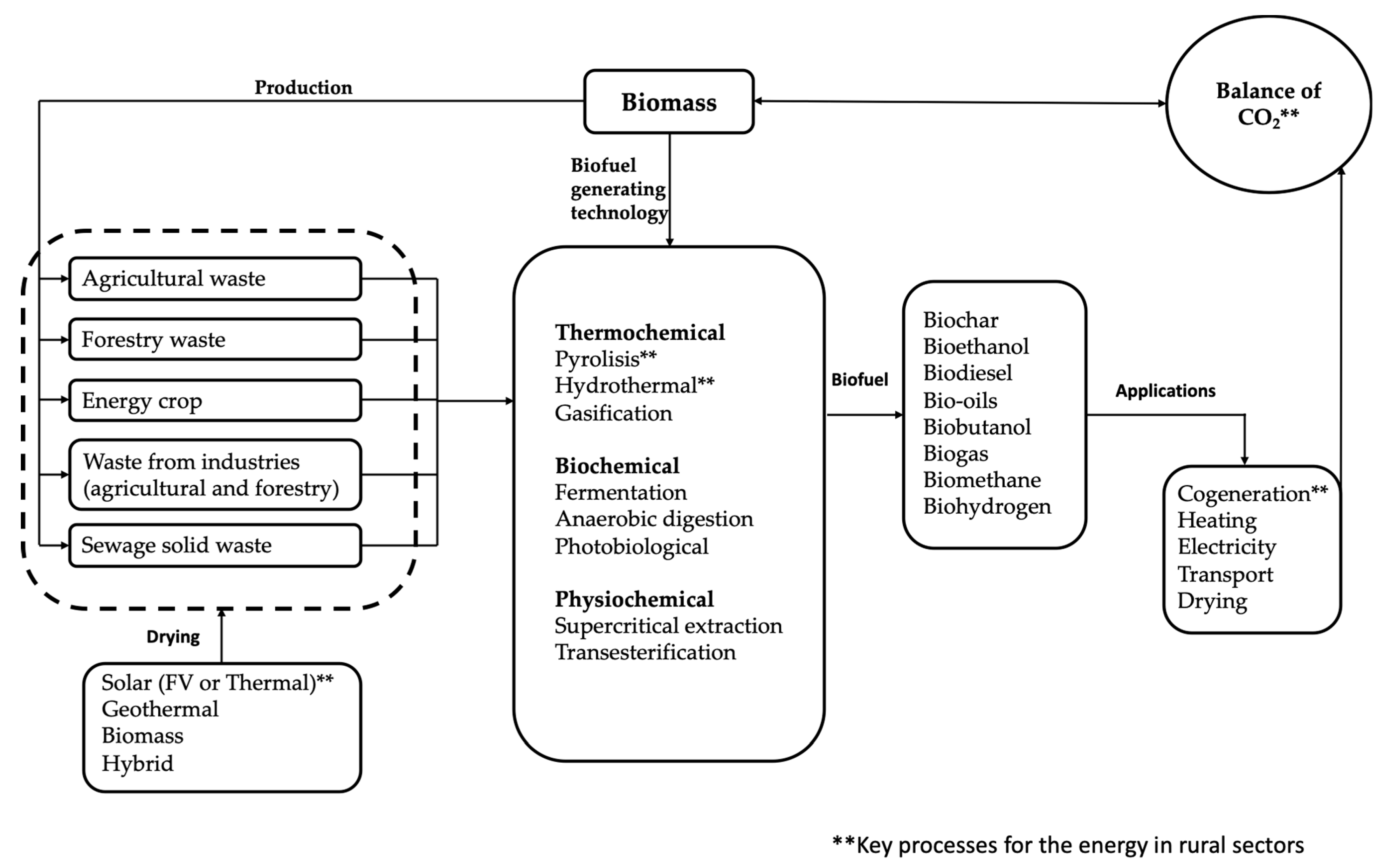

Key Processes for the Energy Use of Biomass in Rural Sectors of Latin America

Abstract

1. Introduction

2. Preprocessing: Drying Biomass Using Renewable Energy

3. Thermochemical Processes

3.1. Pyrolysis Technologies

3.2. Hydrothermal Methods

4. Cogeneration in Rural Sectors

5. Balance of CO2 Fixation in Forest Plantations

- (a)

- Balance of CO2 fixation of the case study (Zone A): establishment located in the zone of Isla del Partido de Campana. This establishment was chosen for its accessible location by land, typical conditions in terms of forest production. It has a total area of 10,000 ha, of which 5000 ha are productive for the forestry sector, and 2000 ha are degraded, some of which are also used for livestock. The 5000 ha under cultivation are forested with American Willow (Salix babylonica CV sacramenta), which turns out to be the predominant clone in the area, and Poplar. The property has a production of 7000 tons/month (average 2004–2006), which represents a total of 84,000 tons/year. This corresponds to an annual average of 16.8 tons/ha*year. In this zone, a harvest yielded an approximate amount of 205 tons/ha, leaving an amount of 55 tons/ha as woody residues [138]. Table 4 shows the use of wood by area.

- (b)

- Extension of the CO2 balance to island areas (Zone B): taking into account the island areas of the Zarate and Campana districts and the forestry activities carried out in both regions. The insular sector of the Partido de Zárate covers a little more than 55,600 ha of delta Surface. The soils of the lower parts, called wetland soils, are often flooded and covered with partially decomposed organic matter, which gives them an acid character. Under natural conditions, the interior of the islands is not very suitable for traditional productive activities. It occupies an area of 66,400 ha. This area is affected by the iteration of two floods, the one caused by the Paraná River and the one caused by the Río de la Plata. The forested area is approximately 35% of the total area of the island. Fundamentally, this geographical area is of great importance in terms of biomass production and biodiversity reserve.

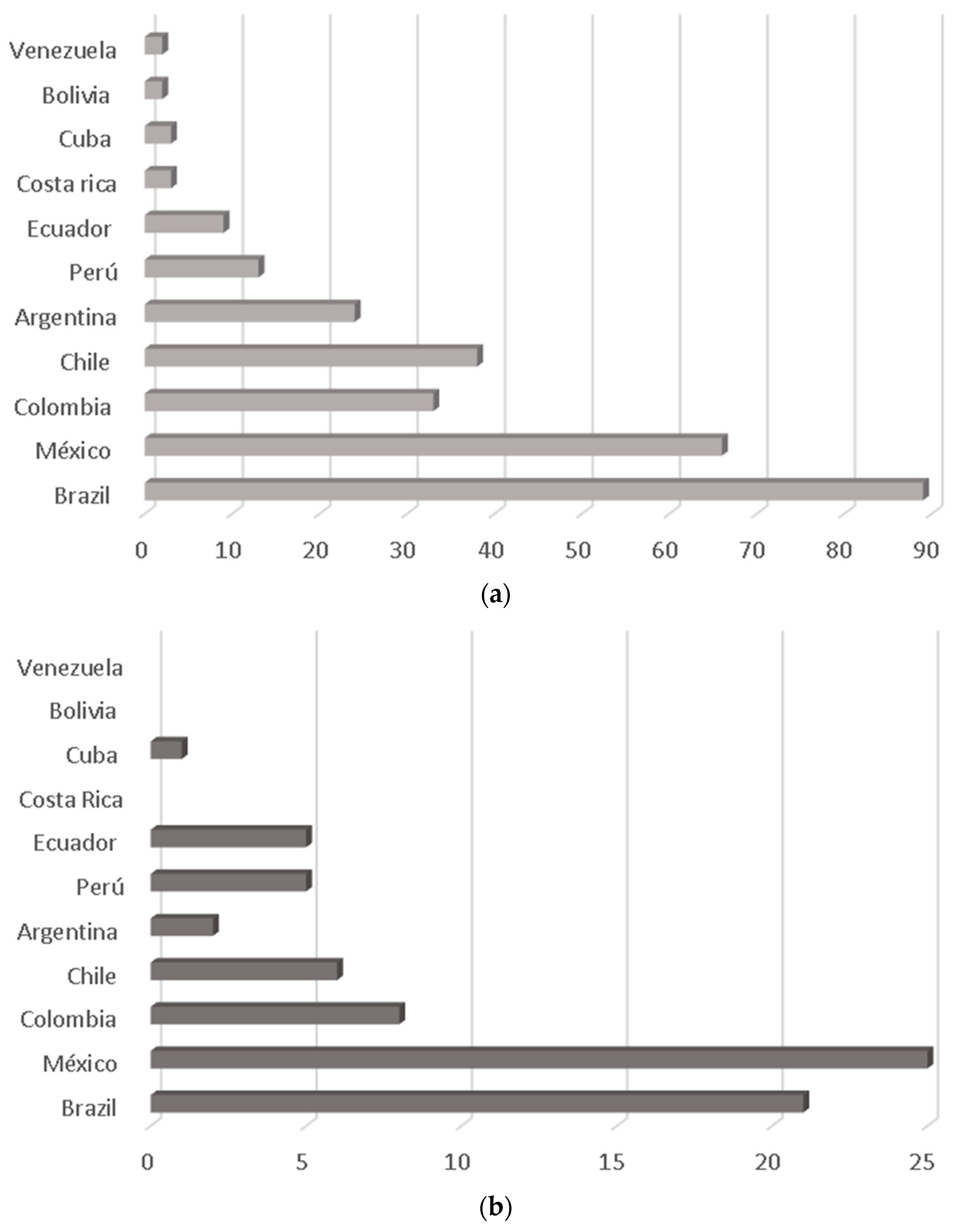

6. Discussion

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- International Labour Organization (ILO). Rural Sector and Local Development in Latin America and the Caribbean; ILO, United Nations: Geneva, Switzerland, 2022; Available online: https://www.ilo.org/americas/temas/sector-rural-y-desarrollo-local/lang--es/index.htm (accessed on 13 January 2022).

- Bárcena, A. (Executive Secretary of the Economic Commission for Latin America and the Caribbean (CEPAL)). Personal communication, Energy Week in Latin America. 2021. Available online: https://www.cepal.org/es/noticias/america-latina-caribe-tiene-todas-condiciones-convertirse-un-hub-energia-renovable-gran (accessed on 13 January 2022). (In Spanish).

- Rincon-Martínez, J.; Silva-Lora, E. (Eds.) Bioenergía: Fuentes, Conversión y Sustentabilidad. In Red Iberoamericana de Aprovechamiento de Residuos Orgánicos en Produccion de Energía; CYTED: Huntingdon, UK, 2015; ISBN 978-958-58880-0-5. [Google Scholar]

- [Data Set] Latin American Energy Organization (OLADE). Energy Information System of Latin America and the Caribbean (sieLAC). Available online: http://sielac.olade.org/ (accessed on 13 January 2022).

- Merino, I.; Herrera, I.; Valdés, H. Environmental Assessment of Energy Scenarios for a Low-Carbon Electrical Network in Chile. Sustainability 2019, 11, 5066. [Google Scholar] [CrossRef]

- Economic Commission for Latin America and the Caribbean (CEPAL). La pérdida de los bosques de América Latina y el Caribe 1990–2020: Evidencia estadística. In Temas estadisticos de la CEPAL; CEPAL, UN: Washigton, DC, USA, 2021. (In Spanish) [Google Scholar]

- Economic Commission for Latin America and the Caribbean (CEPAL); Food and Agriculture Organization of the United Nations (FAO); Inter-American Institute for Cooperation on Agriculture (IICA). Perspectivas de la Agricultura y del Desarrollo Rural en las Américas: Una mirada hacia América Latina y el Caribe 2021-2022/CEPAL, FAO e IICA; IICA: San Jose, Costa Rica, 2021; p. 132. ISBN 978-92-9248-920-5. (In Spanish) [Google Scholar]

- Messina, D. Contribuciones Determinadas a Nivel Nacional del Sector Eléctrico en América Latina y el Caribe: Análisis de la Transición Hacia el Uso Sostenible de las Fuentes Energéticas; Documentos de Proyectos (LC/TS.2020/110); Comisión Económica para América Latina y el Caribe (CEPAL): Santiago, Chile, 2020; Available online: https://repositorio.cepal.org/bitstream/handle/11362/46034/1/S2000548_es.pdf. (accessed on 7 March 2022). (In Spanish)

- International Renewable Energy Agency (IRENA). Renewable Energy Market Analysis: Latin America; IRENA: Abu Dhabi, United Arab Emirates, 2016. [Google Scholar]

- Irfan, M.; Zhao, Z.Y.; Panjwani, M.K.; Mangi, F.H.; Li, H.; Jan, A.; Ahmad, M.; Rehman, A. Assessing the energy dynamics of Pakistan: Prospects of biomass energy. Energy Rep. 2020, 6, 80–93. [Google Scholar] [CrossRef]

- Carta-Gonzalez, J.A. Central de Energías Renovables: Generación Eléctica con Energías Renovables, 2nd ed.; Pearson Educacion: Madrid, Spain, 2013; pp. 521–536. (In Spanish) [Google Scholar]

- Diaz-Velilla, J.P. Sistemas de Energías Renovables, 1st ed.; Paraninfo: Madrid, Spain, 2015; pp. 209–217. [Google Scholar]

- Barrera-Hernández, J.C.; Ramirez-Contreras, N.E.; Garcia-Núñez, J.A. Combustión de biomasa: Conceptos, tecnologías y aplicaciones en la agroindustria de la palma de aceite. Rev. Palmas 2018, 39, 24–44. [Google Scholar]

- Alegría-Castellanos, P. Identificación y Control de un Gasificador de Lecho Fluidizado. Master’s Thesis, Facultad de Ingeniería, Universidad de Piura, Piura, Peru, 2017. (In Spanish). [Google Scholar]

- Cortázar-Dueñas, M. Estudio Comparativo de Tecnologías Comerciales de Valorización de Residuos Sólidos Urbanos. Master’s Thesis, Facultad de Ciencia y Tecnología, Universidad del Pais Vasco, Bilbao, Spain, 2014. (In Spanish). [Google Scholar]

- Baray-Guerrero, M. Pirolisis a Baja Temperatura de la Pomasa de Manzana Para la Producción de Biocombustibles. Ph.D. Thesis, Centro de investigación en materiales avanzados, Departamento de estudios de posgrado, Chihuahua, Mexico, 2016. (In Spanish). [Google Scholar]

- Esaclona, R.F.; Suarez-Rodríguez, J.A.; Beatón, P.A. Pirólisis autotérmica en lecho fluidizado de aserrín de algarrobo. Tecnol. Química 2010, 30, 95–101. (In Spanish) [Google Scholar]

- Biller, P.; Ross, A.B. Production of biofuels via hydrothermal conversion. In Handbook of Biofuels Production: Processes and Technologies, 2nd ed.; Elsevier Inc.: Amsterdam, The Netherlands, 2016; pp. 509–547. [Google Scholar] [CrossRef]

- Hitzl, M.; Corma, A.; Pomares, F.; Renz, M. The hydrothermal carbonization (HTC) plant as a decentral biorefinery for wet biomass. Catal. Today 2015, 257, 154–159. [Google Scholar] [CrossRef]

- Kruse, A. Hydrothermal biomass gasification. J. Supercrit. Fluid. 2009, 47, 391–399. [Google Scholar] [CrossRef]

- Zabaleta, R.S.; Viera, M.V.A.; Aldana, M.D.M. Diseño de un biodigestor tubular para zonas rurales de la Región Piura. In Proceedings of the XXIV Simposio Peruano de Energía Solar y del Ambiente, Huaraz, Peru, 13–17 November 2017; Volume XXIV, pp. 1–22. (In Spanish). [Google Scholar]

- FAO. Guía Teórico-Práctica Sobre el Biogás y los Biodigestores; Colección Documento Técnico: Buenos Aires, Argentina, 2019. (In Spanish) [Google Scholar]

- Kovalev, A.A.; Kovalev, D.A.; Zhuravleva, E.A.; Katraeva, I.V.; Panchenko, V.; Fiore, U.; Litti, Y.V. Two-stage anaerobic digestion with direct electric stimulation of methanogenesis: The effect of a physical barrier to retain biomass on the surface of a carbon cloth-based biocathode. Renew. Energy 2022, 181, 966–977. [Google Scholar] [CrossRef]

- Marchenko, O.; Solomin, S.; Kozlov, A.; Shamanskiy, V.; Donskoy, I. Economic Efficiency Assessment of Using Wood Waste in Cogeneration Plants with Multi-Stage Gasification. Appl. Sci. 2020, 10, 7600. [Google Scholar] [CrossRef]

- La Scalia, G.; Adelfio, L.; La Fata, C.M.; Micale, R. Economic and Environmental Assessment of Biomass Power Plants in Southern Italy. Sustainability 2022, 14, 9676. [Google Scholar] [CrossRef]

- Ali, A.; Iqbal, T.; Cheema, M.J.M.; Afzal, A.; Yasin, M.; Haq, Z.u.; Malik, A.M.; Khan, K.S. Development of a Low-Cost Biomass Furnace for Greenhouse Heating. Sustainability 2021, 13, 5152. [Google Scholar] [CrossRef]

- KC, R.; Föhr, J.; Gyawali, A.; Ranta, T. Investment and Profitability of Community Heating Systems Using Bioenergy in Finland: Opportunities and Challenges. Sustainability 2021, 13, 11757. [Google Scholar] [CrossRef]

- Syrbe, R.-U.; Han, T.T.; Grunewald, K.; Xiao, S.; Wende, W. Residential Heating Using Woody Biomass in Germany—Supply, Demand, and Spatial Implications. Land 2022, 11, 1937. [Google Scholar] [CrossRef]

- Figaj, R.; Żołądek, M.; Homa, M.; Pałac, A. A Novel Hybrid Polygeneration System Based on Biomass, Wind and Solar Energy for Micro-Scale Isolated Communities. Energies 2022, 15, 6331. [Google Scholar] [CrossRef]

- Wang, Z.X.; Li, H.Y.; Zhang, X.F.; Wang, L.W.; Du, S.; Fang, C. Performance analysis on a novel micro-scale combined cooling, heating and power (CCHP) system for domestic utilization driven by biomass energy. Renew. Energy 2020, 156, 1215–1232. [Google Scholar] [CrossRef]

- Wang, K.; Zhang, J.; Wu, S.; Wu, J.; Xu, K.; Liu, J.; Ning, X.; Wang, G. Feasibility Analysis of Biomass Hydrochar Blended Coal Injection for Blast Furnace. Sustainability 2022, 14, 10885. [Google Scholar] [CrossRef]

- Malico, I.; Pereira, R.N.; Gonçalves, A.C.; Sousa, A.M. Current status and future perspectives for energy production from solid biomass in the European industry. Renew. Sust. Energy Rev. 2019, 112, 960–977. [Google Scholar] [CrossRef]

- Sanderson, M.A.; Adler, P.; Martin, N.P. Biomass, energy, and industrial uses of forages. In Forages: The Science of Grassland Agriculture, II, 7th ed.; Wiley Online Library: Hoboken, NJ, USA, 2020; Volume 2, pp. 789–799. [Google Scholar] [CrossRef]

- Zhao, Z.Y.; Zuo, J.; Wu, P.H.; Yan, H.; Zillante, G. Competitiveness assessment of the biomass power generation industry in China: A five forces model study. Renew. Energy 2016, 89, 144–153. [Google Scholar] [CrossRef]

- International Energy Agency (IEA). Technology Roadmap—Solar Thermal Electricity 2014; IEA: Paris, France, 2014; Available online: https://www.iea.org/reports/technology-roadmap-solar-thermal-electricity-2014 (accessed on 10 March 2022).

- Ellabban, O.; Abu-Rub, H.; Blaabjerg, F. Renewable energy resources: Current status, future prospects and their enabling technology. Renew. Sust. Energy Rev. 2014, 39, 748–764. [Google Scholar] [CrossRef]

- Field, C.B.; Campbell, J.E.; Lobell, D.B. Biomass energy: The scale of the potential resource. Trends Ecol. Evol. 2008, 23, 65–72. [Google Scholar] [CrossRef]

- Lamnatou, C.; Chemisana, D. Concentrating solar systems: Life Cycle Assessment (LCA) and environmental issues. Renew. Sust. Energy Rev. 2017, 78, 916–932. [Google Scholar] [CrossRef]

- Sansaniwal, S.K.; Sharma, V.; Mathur, J. Energy and exergy analyses of various typical solar energy applications: A comprehensive review. Renew. Sust. Energy Rev. 2018, 82, 1576–1601. [Google Scholar] [CrossRef]

- Bennamoun, L.; Belhamri, A. Design and simulation of a solar dryer for agriculture products. J. Food Eng. 2003, 59, 259–266. [Google Scholar] [CrossRef]

- Kalogirou, S.A.; Karellas, S.; Braimakis, K.; Stanciu, C.; Badescu, V. Exergy analysis of solar thermal collectors and processes. Prog. Energy Combust. 2016, 56, 106–137. [Google Scholar] [CrossRef]

- International Energy Agency (IEA). Renewables 2020: Analysis and Forecast to 2025; OECD Publishing: Paris, France, 2020. [Google Scholar] [CrossRef]

- Altobelli, F.; Condorí, M.; Duran, G.; Martinez, C. Solar dryer efficiency considering the total drying potential. Application of this potential as a resource indicator in north-western Argentina. Sol. Energy 2014, 105, 742–759. [Google Scholar] [CrossRef]

- da Silva, G.M.; Ferreira, A.G.; Coutinho, R.M.; Maia, C.B. Thermodynamic analysis of a sustainable hybrid dryer. Sol. Energy 2020, 208, 388–398. [Google Scholar] [CrossRef]

- Delgado-Plaza, E.; Peralta-Jaramillo, J.; Quilambaqui, M.; Gonzalez, O.; Reinoso-Tigre, J.; Arevalo, A.; Arancibia, M.; Paucar, M.; Velázquez-Martí, B. Thermal evaluation of a hybrid dryer with solar and geothermal energy for agroindustry application. Appl. Sci. 2019, 9, 4079. [Google Scholar] [CrossRef]

- Manrique, R.; Vásquez, D.; Chejne, F.; Pinzón, A. Energy analysis of a proposed hybrid solar–biomass coffee bean drying system. Energy 2020, 202, 117720. [Google Scholar] [CrossRef]

- Duran, G.; Condorí, M.; Altobelli, F. Simulation of a passive solar dryer to charqui production using temperature and pressure networks. Sol. Energy 2015, 119, 310–318. [Google Scholar] [CrossRef]

- Condorı, M.; Saravia, L. Analytical model for the performance of the tunnel-type greenhouse drier. Renew. Energy 2003, 28, 467–485. [Google Scholar] [CrossRef]

- Messina, S.; González, F.; Saldaña, C.; Peña-Sandoval, G.R.; Tadeo, H.; Juárez-Rosete, C.R.; Nair, P.K. Solar powered dryers in agricultural produce processing for sustainable rural development worldwide: A case study from Nayarit-Mexico. Clean. Circul. Bioecon. 2022, 3, 100027. [Google Scholar] [CrossRef]

- Constantino-Robles, C.D.; Romero-Eredia, J.A.; Sevilla-Camacho, P.Y.; Robles-Ocampo, J.B.; Sol-Montejo, L.J.; Rodríguez-Reséndiz, J.; Perez-Sariñana, B.Y. Novel hybrid solar dryer for medicinal plants: An experimental evaluation (Tithonia diversifolia Gray). Sustain. Energy Technol. 2022, 51, 101950. [Google Scholar] [CrossRef]

- Cetina-Quiñones, A.J.; López, J.L.; Ricalde-Cab, L.; El Mekaoui, A.; San-Pedro, L.; Bassam, A. Experimental evaluation of an indirect type solar dryer for agricultural use in rural communities: Relative humidity comparative study under winter season in tropical climate with sensible heat storage material. Sol. Energy 2021, 224, 58–75. [Google Scholar] [CrossRef]

- Masera, O.; Coralli, F.; García, C.; Riegelhaupt, E.; Arias, T.; Vega, J.; Diaz, R.; Guerrero, G.; Cecotti, L. La bioenergía en México: Situación actual y perspectivas. Red Mex. Bioenergía 2011, 22, 118–125. (In Spanish) [Google Scholar]

- Colantoni, A.; Evic, N.; Lord, R.; Retschitzegger, S.; Proto, A.R.; Gallucci, F.; Monarca, D. Characterization of biochars produced from pyrolysis of pelletized agricultural residues. Renew. Sust. Energy Rev. 2016, 64, 187–194. [Google Scholar] [CrossRef]

- Nguyen, Q.N.; Cloutier, A.; Achim, A.; Stevanovic, T. Effect of process parameters and raw material characteristics on physical and mechanical properties of wood pellets made from sugar maple particles. Biomass Bioenergy 2015, 80, 338–349. [Google Scholar] [CrossRef]

- Nikolaidis, P.; Poullikkas, A. A comparative overview of hydrogen production processes. Renew. Sust. Energy Rev. 2017, 67, 597–611. [Google Scholar] [CrossRef]

- Rodrigues, T.; Junior, A.B. Charcoal: A discussion on carbonization kilns. J. Anal. Appl. Pyrolysis 2019, 143, 104670. [Google Scholar] [CrossRef]

- Batalla, M.D.; Asencios, A.G.; Yepes, D.S.; Mora, E.G. El carbón vegetal: Alternativa de energía y productos químicos. Xilema 2010, 23, 95–103. [Google Scholar] [CrossRef]

- Guardado, M.; Rodríguez, J.; Monge, L. Evaluación de la Calidad del Carbón Vegetal Producido en Hornos de Retorta y Hornos Metálicos Portátiles en el Salvador. Engineer’s Thesis, Facultad de Ingeniería y Arquitectura, Universidad Centroamericana “José Simeón Cañas”, Antiguo Cuscatlán, El Salvador, 2010. Available online: https://xdoc.mx/documents/oct-2010-evaluacion-de-la-calidad-del-carbon-vegetal-producido-en-60348e2d42742 (accessed on 8 March 2022). (In Spanish).

- Bustamante-García, V.; Carrillo-Parra, A.; González-Rodríguez, H.; Ramírez-Lozano, R.G.; Corral-Rivas, J.J.; Garza-Ocañas, F. Evaluation of a charcoal production process from forest residues of Quercus sideroxyla Humb., & Bonpl. in a Brazilian beehive kiln. Ind. Crop. Prod. 2013, 42, 169–174. [Google Scholar] [CrossRef]

- Arias-Chalico, T. Tecnologías de producción de carbón vegetal. Naturaleza y Desarrollo NYDE AC. 2015. Available online: http://rembio.org.mx/wp-content/uploads/2015/01/Curso-BCS-7.pdf (accessed on 10 March 2022). (In Spanish).

- Valdes, H.; Vilches, J.; Felmer, G.; Hurtado, M.; Figueroa, J. Artisan brick kilns: State-of-the-art and future trends. Sustainability 2020, 12, 7724. [Google Scholar] [CrossRef]

- Flores, R.; Quinteros, H. Diseño de Horno Tipo Retorta Para Elaborar Carbón Vegetal. Ph.D. Thesis, Facultad de Ingeniería y Arquitectura, Universidad Centroamericana, José Simeón Cañas, Antiguo Cuscatlán, El Salvador, 2008. (In Spanish). [Google Scholar]

- Pandey, A.; Bhaskar, T.; Stöcker, M.; Sukumaran, R. (Eds.) Recent Advances in Thermochemical Conversion of Biomass, 1st ed.; Elsevier: Trivandrum, India, 2015. [Google Scholar]

- Bridgwater, A.V. Review of fast pyrolysis of biomass and product upgrading. Biomass Bioenergy 2012, 38, 68–94. [Google Scholar] [CrossRef]

- Cantero-Tubilla, B.; Cantero, D.A.; Martinez, C.M.; Tester, J.W.; Walker, L.P.; Posmanik, R. Characterization of the solid products from hydrothermal liquefaction of waste feedstocks from food and agricultural industries. J. Supercrit. Fluid. 2018, 133, 665–673. [Google Scholar] [CrossRef]

- Cai, L.; Gao, D.; Chen, T.; Liu, H.T.; Zheng, G.; Yang, Q.W. Moisture variation associated with water input and evaporation during sewage sludge bio-drying. Bioresour. Technol. 2012, 117, 13–19. [Google Scholar] [CrossRef] [PubMed]

- Barampouti, E.; Mai, S.; Malamis, D.; Moustakas, K.; Loizidou, M. Liquid biofuels from the organic fraction of municipal solid waste: A review. Renew. Sust. Energy Rev. 2019, 110, 298–314. [Google Scholar] [CrossRef]

- Peterson, A.A.; Vogel, F.; Lachance, R.P.; Fröling, M.; Antal, M.J., Jr.; Tester, J.W. Thermochemical biofuel production in hydrothermal media: A review of sub-and supercritical water technologies. Energy Environ. Sci. 2008, 1, 32–65. [Google Scholar] [CrossRef]

- Kruse, A.; Funke, A.; Titirici, M.M. Hydrothermal conversion of biomass to fuels and energetic materials. Curr. Opin. Chem. Biol. 2013, 17, 515–521. [Google Scholar] [CrossRef]

- Kruse, A.; Dahmen, N. Water–A magic solvent for biomass conversion. J. Supercrit. Fluid. 2015, 96, 36–45. [Google Scholar] [CrossRef]

- Tekin, K.; Karagöz, S.; Bektaş, S. A review of hydrothermal biomass processing. Renew. Sust. Energy Rev. 2014, 40, 673–687. [Google Scholar] [CrossRef]

- Matsumura, Y. Hydrothermal Gasification of Biomass. In Recent Advances in Thermochemical Conversion of Biomass; Elsevier: Amsterdam, The Netherlands, 2015; pp. 251–267. ISBN 978-0-444-63-63289-0. [Google Scholar]

- Garcia Alba, L.; Torri, C.; Samorì, C.; Van Der Spek, J.; Fabbri, D.; Kersten, S.R.; Brilman, D.W. Hydrothermal treatment (HTT) of microalgae: Evaluation of the process as conversion method in an algae biorefinery concept. Energy Fuel. 2012, 26, 642–657. [Google Scholar] [CrossRef]

- Chand, R.; Borugadda, V.B.; Qiu, M.; Dalai, A.K. Evaluating the potential for bio-fuel upgrading: A comprehensive analysis of bio-crude and bio-residue from hydrothermal liquefaction of agricultural biomass. Appl. Energy 2019, 254, 113679. [Google Scholar] [CrossRef]

- Cao, L.; Zhang, C.; Chen, H.; Tsang, D.C.; Luo, G.; Zhang, S.; Chen, J. Hydrothermal liquefaction of agricultural and forestry wastes: State-of-the-art review and future prospects. Bioresour. Technol. 2017, 245, 1184–1193. [Google Scholar] [CrossRef]

- Zhang, C.; Duan, P.; Xu, Y.; Wang, B.; Wang, F.; Zhang, L. Catalytic upgrading of duckweed biocrude in subcritical water. Bioresour. Technol. 2014, 166, 37–44. [Google Scholar] [CrossRef]

- Demus, T.; Reichel, T.; Schulten, M.; Echterhof, T.; Pfeifer, H. Increasing the sustainability of steel production in the electric arc furnace by substituting fossil coal with biochar agglomerates. Ironmak. Steelmak. 2016, 43, 564–570. [Google Scholar] [CrossRef]

- Karagöz, S.; Bhaskar, T.; Muto, A.; Sakata, Y. Comparative studies of oil compositions produced from sawdust, rice husk, lignin and cellulose by hydrothermal treatment. Fuel 2005, 84, 875–884. [Google Scholar] [CrossRef]

- Bhaskar, T.; Sera, A.; Muto, A.; Sakata, Y. Hydrothermal upgrading of wood biomass: Influence of the addition of K2CO3 and cellulose/lignin ratio. Fuel 2008, 87, 2236–2242. [Google Scholar] [CrossRef]

- Gao, P.; Zhou, Y.; Meng, F.; Zhang, Y.; Liu, Z.; Zhang, W.; Xue, G. Preparation and characterization of hydrochar from waste eucalyptus bark by hydrothermal carbonization. Energy 2016, 97, 238–245. [Google Scholar] [CrossRef]

- Yusuf, I.; Flagiello, F.; Ward, N.I.; Arellano-García, H.; Avignone-Rossa, C.; Felipe-Sotelo, M. Valorisation of banana peels by hydrothermal carbonisation: Potential use of the hydrochar and liquid by-product for water purification and energy conversion. Bioresour. Technol. Rep. 2020, 12, 100582. [Google Scholar] [CrossRef]

- Zhang, Y.; Minaret, J.; Yuan, Z.; Dutta, A.; Xu, C.C. Mild hydrothermal liquefaction of high water content agricultural residue for bio-crude oil production: A parametric study. Energies 2018, 11, 3129. [Google Scholar] [CrossRef]

- Rodríguez, A.; Moral, A.; Sánchez, R.; Requejo, A.; Jiménez, L. Influence of variables in the hydrothermal treatment of rice straw on the composition of the resulting fractions. Bioresour. Technol. 2009, 100, 4863–4866. [Google Scholar] [CrossRef]

- Zhu, Z.; Rosendahl, L.; Toor, S.S.; Yu, D.; Chen, G. Hydrothermal liquefaction of barley straw to bio-crude oil: Effects of reaction temperature and aqueous phase recirculation. Appl. Energy 2015, 137, 183–192. [Google Scholar] [CrossRef]

- Long, J.; Li, Y.; Zhang, X.; Tang, L.; Song, C.; Wang, F. Comparative investigation on hydrothermal and alkali catalytic liquefaction of bagasse: Process efficiency and product properties. Fuel 2016, 186, 685–693. [Google Scholar] [CrossRef]

- Yeoh, K.H.; Shafie, S.A.; Al-Attab, K.A.; Zainal, Z.A. Upgrading agricultural wastes using three different carbonization methods: Thermal, hydrothermal and vapothermal. Bioresour. Technol. 2018, 265, 365–371. [Google Scholar] [CrossRef] [PubMed]

- Yang, L.; Nazari, L.; Yuan, Z.; Corscadden, K.; Xu, C.C. Hydrothermal liquefaction of spent coffee grounds in water medium for bio-oil production. Biomass Bioenergy 2016, 86, 191–198. [Google Scholar] [CrossRef]

- Peng, W.; Wu, C.; Wu, S.; Wu, Y.; Gao, J. The effect of heterogeneous catalysts on hydrothermal liquefaction of corn stalk under CO atmosphere. Energy Sources Part A Recovery Util. Environ. Eff. 2014, 36, 1388–1394. [Google Scholar] [CrossRef]

- Chen, J.; Wang, L.; Zhang, B.; Li, R.; Shahbazi, A. Hydrothermal liquefaction enhanced by various chemicals as a means of sustainable dairy manure treatment. Sustainability 2018, 10, 230. [Google Scholar] [CrossRef]

- Lu, J.; Watson, J.; Zeng, J.; Li, H.; Zhu, Z.; Wang, M.; Zhang, Y.; Liu, Z. Biocrude production and heavy metal migration during hydrothermal liquefaction of swine manure. Process Saf. Environ. 2018, 115, 108–115. [Google Scholar] [CrossRef]

- Cárdenas-Aguiar, E.; Gasco, G.; Paz-Ferreiro, J.; Mendez, A. Thermogravimetric analysis and carbon stability of chars produced from slow pyrolysis and hydrothermal carbonization of manure waste. J. Anal. Appl. Pyrolysis 2019, 140, 434–443. [Google Scholar] [CrossRef]

- Smith, A.M.; Ross, A.B. Production of bio-coal, bio-methane and fertilizer from seaweed via hydrothermal carbonisation. Algal Res. 2016, 16, 1–11. [Google Scholar] [CrossRef]

- Saqib, N.U.; Sharma, H.B.; Baroutian, S.; Dubey, B.; Sarmah, A.K. Valorisation of food waste via hydrothermal carbonisation and techno-economic feasibility assessment. Sci. Total Environ. 2019, 690, 261–276. [Google Scholar] [CrossRef]

- Kargbo, H.; Harris, J.S.; Phan, A.N. “Drop-in” fuel production from biomass: Critical review on techno-economic feasibility and sustainability. Renew. Sustain. Energy Rev. 2021, 135, 110168. [Google Scholar] [CrossRef]

- CPL Industries, Turning Organic Waste into Renewable Fuel. Available online: https://cplindustries.co.uk/htc-hydrothermal-carbonisation/ (accessed on 2 November 2022).

- SunCoal, SunCoal Industries—High-Value Carbon from Biomass. Available online: https://www.suncoal.com (accessed on 2 November 2022).

- Terra Nova, Terra Nova Energy Together We Pioneer Sustainability. Available online: https://www.terranova-energy.com/en/ (accessed on 2 November 2022).

- Ingelia. Available online: https://ingelia.com (accessed on 2 November 2022).

- Licella, Cat HTR Technology. Available online: https://www.licella.com/ (accessed on 2 November 2022).

- Geniguel, Clean Conversion of Wet Waste to Fuel. 2020. Available online: http://www.genifuel.com/index.html (accessed on 2 November 2022).

- Circlianordic, Most Energy-Efficient Solution. Available online: https://circlianordic.com/# (accessed on 2 November 2022).

- Merrik, Hydrothermal Liquefaction. Available online: https://www.merrick.com/wp-content/uploads/2020/11/Merrick-Hydrothermal-Liquefaction.pdf (accessed on 2 November 2022).

- Steeper Energy, Executive Summary. Available online: https://steeperenergy.com/ (accessed on 2 November 2022).

- Lopez, J. CDMX Transformará Toneladas de Basura en Carbón y Electricidad. Excelsior 2022. Available online: https://www.excelsior.com.mx/comunidad/cdmx-transformara-toneladas-de-basura-en-carbon-y-electricidad/1495653 (accessed on 2 November 2022).

- Gobierno de la Ciudad de México. Planta de Carbonización Hidrotermal Web Site Gob. De La Ciudad. De Mex. 2022. Available online: https://gobierno.cdmx.gob.mx/noticias/planta-de-carbonizacion-hidrotermal/ (accessed on 2 November 2022).

- Feng, S.; Wei, R.; Leitch, M.; Xu, C.C. Comparative study on lignocellulose liquefaction in water, ethanol, and water/ethanol mixture: Roles of ethanol and water. Energy 2018, 155, 234–241. [Google Scholar] [CrossRef]

- Jiang, W.; Lyu, G.; Wu, S.; Lucia, L.A. Near-critical water hydrothermal transformation of industrial lignins to high value phenolics. J. Anal. Appl. Pyrolysis 2016, 120, 297–303. [Google Scholar] [CrossRef]

- Singh, R.; Prakash, A.; Dhiman, S.K.; Balagurumurthy, B.; Arora, A.K.; Puri, S.K.; Bhaskar, T. Hydrothermal conversion of lignin to substituted phenols and aromatic ethers. Bioresour. Technol. 2014, 165, 319–322. [Google Scholar] [CrossRef]

- Cuña, A.; Plascencia, C.R.; da Silva, E.L.; Marcuzzo, J.; Khan, S.; Tancredi, N.; Baldan, M.R.; de Fraga Malfatti, C. Electrochemical and spectroelectrochemical analyses of hydrothermal carbon supported nickel electrocatalyst for ethanol electro-oxidation in alkaline medium. Appl. Catal. B Environ. 2017, 202, 95–103. [Google Scholar] [CrossRef]

- Valdés, H.; Leon, G. Cogeneration Process Technical Viability for an Apartment Building: Case Study in Mexico. Processes 2019, 7, 93. [Google Scholar] [CrossRef]

- Buker, M.S.; Kaplan, M. Performance investigation of a residential type micro-cogeneration system-Energy and Economic analysis. In Proceedings of the 2019 3rd International Symposium on Multidisciplinary Studies and Innovative Technologies (ISMSIT), Ankara, Turkey, 11–13 October 2019; pp. 1–9. [Google Scholar] [CrossRef]

- Kalina, J.; Świerzewski, M.; Szega, M. Simulation based performance evaluation of biomass fired cogeneration plant with ORC. Energy Procedia 2017, 129, 660–667. [Google Scholar] [CrossRef]

- Vellini, M.; Gambini, M.; Stilo, T. High-efficiency cogeneration systems for the food industry. J. Clean. Prod. 2020, 260, 121133. [Google Scholar] [CrossRef]

- Caglayan, H.; Caliskan, H. Energy, exergy and sustainability assessments of a cogeneration system for ceramic industry. Appl. Term. Eng. 2018, 136, 504–515. [Google Scholar] [CrossRef]

- Accurso, F.; Gandiglio, M.; Santarelli, M.; Buunk, J.; Hakala, T.; Kiviaho, J.; Modena, S.; Munch, M.; Varkaraki, E. Installation of fuel cell-based cogeneration systems in the commercial and retail sector: Assessment in the framework of the COMSOS project. Energy Convers. Manag. 2021, 239, 114202. [Google Scholar] [CrossRef]

- Bazregari, M.J.; Gholinejad, M.; Peydayesh, Y.; Norouzi, N.; Fani, M. Exergoeconomic Analysis of the Cycle of Cogeneration of Power, Cooling and Freshwater for a Residential Complex in Iran. Int. J. Air-Cond. Refrig. 2021, 29, 2150030. [Google Scholar] [CrossRef]

- Silva, H.C.N.; Dutra, J.C.C.; Costa, J.A.P.; Ochoa, A.A.V.; Dos Santos, C.A.C.; Araújo, M.M.D. Modeling and simulation of cogeneration systems for buildings on a university campus in Northeast Brazil-A case study. Energy Convers. Manag. 2019, 186, 334–348. [Google Scholar] [CrossRef]

- Vialetto, G.; Noro, M.; Rokni, M. Thermodynamic investigation of a shared cogeneration system with electrical cars for northern Europe climate. J. Sustain. Dev. Energy Water Environ. Syst. 2017, 5, 590–607. [Google Scholar] [CrossRef]

- Rad, E.A.; Maddah, S.; Mohammadi, S. Designing and optimizing a novel cogeneration system for an office building based on thermo-economic and environmental analyses. Renew. Energy 2020, 151, 342–354. [Google Scholar] [CrossRef]

- Simpson, M.C.; Chatzopoulou, M.A.; Oyewunmi, O.A.; Markides, C.N. Technoeconomic analysis of internal combustion engine-organic Rankine cycle cogeneration systems in energy-intensive buildings. Energy Procedia 2019, 158, 2354–2359. [Google Scholar] [CrossRef]

- Lamidi, R.O.; Jiang, L.; Wang, Y.; Pathare, P.B.; Aguilar, M.C.; Wang, R.; Eshoul, N.M.; Roskilly, A.P. Techno-Economic Analysis of a Cogeneration System for Post-Harvest Loss Reduction: A Case Study in Sub-Saharan Rural Community. Energies 2019, 12, 872. [Google Scholar] [CrossRef]

- Kallio, S.; Siroux, M. Hybrid renewable energy systems based on micro-cogeneration. Energy Rep. 2022, 8, 762–769. [Google Scholar] [CrossRef]

- Kryzia, D.; Kuta, M.; Matuszewska, D.; Olczak, P. Analysis of the Potential for Gas Micro-Cogeneration Development in Poland Using the Monte Carlo Method. Energies 2020, 13, 3140. [Google Scholar] [CrossRef]

- Ahrenfeldt, J.; Thomsen, T.P.; Henriksen, U.; Clausen, L.R. Biomass gasification cogeneration-A review of state of the art technology and near future perspectives. Appl. Therm. Eng. 2013, 50, 1407–1417. [Google Scholar] [CrossRef]

- Abbas, T.; Issa, M.; Ilinca, A. Biomass cogeneration technologies: A review. J. Sustain. Bioenergy Syst. 2020, 10, 1–15. [Google Scholar] [CrossRef]

- Sorgulu, F.; Dincer, I. Development and assessment of a biomass-based cogeneration system with desalination. Appl. Therm. Eng. 2021, 185, 116432. [Google Scholar] [CrossRef]

- La Villetta, M.; Costa, M.; Cirillo, D.; Massarotti, N.; Vanoli, L. Performance analysis of a biomass powered micro-cogeneration system based on gasification and syngas conversion in a reciprocating engine. Energy Convers. Manag. 2018, 175, 33–48. [Google Scholar] [CrossRef]

- Celebi, A.D.; Sharma, S.; Ensinas, A.V.; Maréchal, F. Next generation cogeneration system for industry-Combined heat and fuel plant using biomass resources. Chem. Eng. Sci. 2019, 204, 59–75. [Google Scholar] [CrossRef]

- Ding, H.; Li, J.; Heydarian, D. Energy, exergy, exergoeconomic, and environmental analysis of a new biomass-driven cogeneration system. Sustain. Energy Technol. Assess. 2021, 45, 101044. [Google Scholar] [CrossRef]

- Fan, W.; Huang, L.; Tan, Z.; Xue, F.; De, G.; Song, X.; Cong, B. Multi-objective Optimal Model of Rural Multi-energy Complementary System with Biogas Cogeneration and Electric Vehicle Considering Carbon Emission and Satisfaction. Sustain. Cities Soc. 2021, 74, 103225. [Google Scholar] [CrossRef]

- Linares-Lujan, G.A.; Echeverria-Perez, C.; Cespedes-Aguilar, T. Energy potential of the rural area of “La Libertad” department (Peru) produced by biogas obtained from human waste. Rev. Tecnol. Marcha 2017, 30, 108–117. [Google Scholar] [CrossRef][Green Version]

- Zhang, Y.; Wang, P. Effect of population age structure on capacity for biomass cogeneration: A case study of a rural area in China. Build. Environ. 2020, 170, 106601. [Google Scholar] [CrossRef]

- Robert, M. Captura de Carbono en los Suelos Para un Mejor Manejo de la Tierra. Informes Sobre Recursos Mundiales de Suelos; Food and Agriculture Organization of the United Nations: Rome, Italy, 2002; p. 96. ISBN 92-5-304690-2. (In Spanish) [Google Scholar]

- Terrer, C.; Phillips, R.P.; Hungate, B.A.; Rosende, J.; Pett-Ridge, J.; Craig, M.E.; van Groenigen, K.J.; Keenan, T.F.; Sulman, B.N.; Stocker, B.D.; et al. A trade-off between plant and soil carbon storage under elevated CO2. Nature 2021, 591, 599–603. [Google Scholar] [CrossRef]

- Nair, P.R.; Nair, V.D.; Kumar, B.M.; Showalter, J.M. Carbon sequestration in agroforestry systems. Adv. Agron. 2010, 108, 237–307. [Google Scholar] [CrossRef]

- Kongsager, R.; Napier, J.; Mertz, O. The carbon sequestration potential of tree crop plantations. Mitig. Adapt. Strateg. Glob. Chang. 2013, 18, 1197–1213. [Google Scholar] [CrossRef]

- Montero, G.; Ruiz-Peinado, R.; Munoz, M. Producción de biomasa y fijación de CO2 por los bosques españoles. In Monografias INIA: Serie Forestal; Nº13-2005; INIA-Instituto Nacional de Investigación y Tecnología Agraria y Alimentaria: Madrid, Spain, 2005; p. 270. (In Spanish) [Google Scholar]

- García, C.; Torres, J.L.; Odobez, N. Biomasa y Energía para el Desarrollo Sustentable del Delta (Residuos de la Biomasa Forestal en Zonas Aisladas), 3rd ed.; de la conferencia y exposición, sobre la energía de la madera; ITEBE: Lons le Saunier, France, 2002. (In Spanish) [Google Scholar]

- Norverto, C.A. La fijación de CO2 en plantaciones forestales y en productos de madera en Argentina. Forest Development Project (SAGPyA-BIRF). 2003. Available online: https://www.fao.org/3/XII/0043-B2.htm (accessed on 2 November 2022). (In Spanish).

- [Data Set] Secretaria de Energía. Datos Energía, Ministerios de Economía, Uruguay. Available online: http://datos.minem.gob.ar/dataset/7d47693a-c533-4e76-ae24-374c3205715a/archivo/f129bed1-de7d-48a1-944c-f98e52de38e5. (accessed on 10 March 2022). (In Spanish).

- World Bank. State and Trends of Carbon Pricing 2020; World Bank: Washington, DC, USA, 2020; Available online: https://openknowledge.worldbank.org/handle/10986/33809 (accessed on 4 November 2022).

- Donofrio, S.; Maguire, P.; Zwick; Merry, W. Ecosystem Marketplace Insights Brief, Voluntary Carbon and the Post-Pandemic Recovery. A Special Climate Week NYC 2020 Installment of Ecosystem Marketplace’s State of Voluntary Carbon Markets 2020 Report; Forest Trends Association: Washington, DC, USA, 21 September 2020; Available online: https://wecprotects.org/wp-content/uploads/2020/11/EM-Voluntary-Carbon-and-Post-Pandemic-Recovery-2020.pdf (accessed on 11 March 2022).

- Zhongming, Z.; Wei, L. Future Demand, Supply and Prices for Voluntary Carbon Credits–Keeping the Balance. UCL, Trove Research, Liebreich Associates. 2021. Available online: https://trove-research.com/wp-content/uploads/2021/06/Trove-Research-Carbon-Credit-Demand-Supply-and-Prices-1-June-2021.pdf (accessed on 11 March 2022).

- World Bank. State and Trends of Carbon Pricing 2021; World Bank: Washington, DC, USA, 2021; Available online: https://openknowledge.worldbank.org/handle/10986/35620 (accessed on 5 November 2022).

- [Data Set] Delta Forestal. Información técnica. Available online: http://deltaforestal.blogspot.com/p/precios-forestales.html (accessed on 11 March 2022). (In Spanish).

- Murali, S.; Amulya, P.R.; Alfiya, P.V.; Delfiya, D.A.; Samuel, M.P. Design and performance evaluation of solar-LPG hybrid dryer for drying of shrimps. Renew. Energy 2020, 147, 2417–2428. [Google Scholar] [CrossRef]

- Song, Y.; Hu, W.; Xu, X.; Huang, Q.; Chen, G.; Han, X.; Chen, Z. Optimal Investment Strategies for Solar Energy Based Systems. Energies 2019, 12, 2826. [Google Scholar] [CrossRef]

- Sami, S.; Etesami, N.; Rahimi, A. Energy and exergy analysis of an indirect solar cabinet dryer based on mathematical modeling results. Energy 2011, 36, 2847–2855. [Google Scholar] [CrossRef]

- Bolaji, B.O.; Olalusi, A.P. Performance evaluation of a mixed-mode solar dryer. Tech. Rep. 2008, 11, 225–231. [Google Scholar]

- Sivipaucar, C.; Curo, H.; Huancahuari, E.; Llantoy, V.; Valderrama, A. Cálculo y Construcción de un Secador Solar por Convección Natural Para el Secado de Plantas Medicinales no Tradicionales; Cedit-Centro de Desarrollo e Investigación en Termofluidos, Universidad Nacional Mayor de San Marcos: Lima, Peru, 2008; pp. 18–30. (In Spanish) [Google Scholar]

- Singh, S.; Kumar, S. Testing method for thermal performance based rating of various solar dryer designs. Sol. Energy 2012, 86, 87–98. [Google Scholar] [CrossRef]

- Sagar, V.R.; Suresh Kumar, P. Recent advances in drying and dehydration of fruits and vegetables: A review. J. Food Sci. Technol. 2010, 47, 15–26. [Google Scholar] [CrossRef]

- Sethi, V.P.; Arora, S. Improvement in greenhouse solar drying using inclined north wall reflection. Sol. Energy 2009, 83, 1472–1484. [Google Scholar] [CrossRef]

- Jairaj, K.S.; Singh, S.P.; Srikant, K. A review of solar dryers developed for grape drying. Sol. Energy 2009, 83, 1698–1712. [Google Scholar] [CrossRef]

- Forson, F.K.; Nazha, M.A.A.; Akuffo, F.O.; Rajakaruna, H. Design of mixed-mode natural convection solar crop dryers: Application of principles and rules of thumb. Renew. Energy 2007, 32, 2306–2319. [Google Scholar] [CrossRef]

- Abdullah, M.O.; Mikie, F.A.; Lam, C.Y. Drying performance and thermal transient study with solar radiation supplemented by forced-ventilation. Int. J. Therm. Sci. 2006, 45, 1027–1034. [Google Scholar] [CrossRef]

- Leon, M.A.; Kumar, S.; Bhattacharya, S.C. A comprehensive procedure for performance evaluation of solar food dryers. Renew. Sustain. Energy Rev. 2002, 6, 367–393. [Google Scholar] [CrossRef]

| Biomass | Process | Technology | Biomass State | Product | Waste | Reference | |

|---|---|---|---|---|---|---|---|

| Industrial agri-food and forestry waste, forestry waste, agricultural waste, energy crops, urban solid waste | Combustion | Direct combustion | Combustion Furnaces: Fixed Bed Combustion, Bubbling Fluidized Bed Combustion, Circulating Fluidized Bed Combustion, Pulverized Fuel Combustion. Grate furnaces: fixed, moving, traveling, rotary and vibratory. Operating temperature: between 700 and 1000 °C. Yield: 80% using dry biomass, 60% wet biomass. Operating pressure: 6–15 kPa. | Dry (moisture less than 13%). Wet (humidity greater than 40%). Calorific power for biomass 18 and 22 MJ/kg Particle size: Grills < 150 mm. Fluidized bed < 100 mm. Combustion of pulverized fuel < 4 mm. | Saturated or superheated steam | Solids (ashes) Inorganic compounds | [11,12,13] |

| Thermochemical | Gasification | Gasifiers: Downdraft: ascending and descending fixed bed types. Updraft: cross flow/fluid bed or fixed bed. Fluidized Bed Gasifiers: bubbling and encircling. Operating temperature: 600–1000 °C. Approximate yield: 85%. Operating pressure: 101–3000 kPa. | Dry (humidity < 15%) | Syngas Low heating value 5.5 MJ/m3 | Solids (ashes) | [11,12,14,15] | |

| Pyrolysis | Pyrolytic oven fluidized bed. Operating temperature: Slow pyrolysis 250–600 °C. Fast pyrolysis 600–1000 °C. Flash pyrolysis can reach 1200 °C. Hydro pyrolysis 550 °C. If municipal solid waste is used, temperatures range between 550 and 1100 °C. Approximate yield: Slow pyrolysis: 40–50% liquid, 10–20% solid, and 20–30% gas. Fast pyrolysis: 60–75% liquid, 15–25 solid, and 10–20 gas. Flash pyrolysis: greater than 80% gas | Dry (humidity < 15%) | Charcoal, liquid fuel, gaseous fuel | Liquid (water, organic compounds), gasses, ashes | [11,16,17] | ||

| Hydrothermal process | Reactor type: Plug flow, batch and continuous stirred tank, operating temperature, pressure, and residence time: Hydrothermal carbonization (HTC): 160–250 °C, 1–4 MPa, hours. Hydrothermal liquefaction (HTL): 250–400 °C, 5–20 MPa, minutes. Hydrothermal gasification (HTG): 400–700 °C, 20–35 MPa, minutes. | Wet | Hydrochar (solid biofuel), Biocrude (liquid biofuel), Fuel gases (CH4 or H2) | Liquid phase (water with polar organic compounds) | [18,19,20] | ||

| Industrial agri-food waste, livestock waste, solid waste and urban wastewater | Biological | Anaerobic digestion | Biodigester: Continuous digesters and discontinuous digesters. Plastic or tubular bag digesters, fixed dome biodigester (Chinese type). Floating dome biodigester (Hindu type). Biomass fermentation: 30 to 90 days depending on the residue. Functional temperature: 30–35 °C. | Wet | Biogas | Biol, compost used for fertilizer | [11,21,22] |

| Thermophilic digestion | Two-stage: Acidogenic bioreactor (the feed tank and acidogenic reactor were cylindrical stainless steel (AISI 321), volume of 12 L) and electromethanogenic reactors (cylindrical tank with a volume of 19 L). Biomass: Solid waste, 26 to 55 days of fermentation for stage. Functional temperature: 50–60 °C. | Wet | Producing biohydrogen and methane | solid and liquid | [23] | ||

| Dryer Type | Description | Product | Drying Characteristics | Reference |

|---|---|---|---|---|

| Solar dryer (Argentina) | Argentina has promoted the development of solar drying systems for agricultural products on an industrial scale. An Indirect solar dryer is analyzed. Consists of a 30-tray chamber and solar collectors with an axial fan that forced the ambient airflow. | Fruits, vegetables. 12 kg capacity | Surface: 2 m2 collector area Drying time: 5.5 h Average Solar Radiation: 807 W/m2 Ambient temperature: 28.1 °C Relative humidity: 43% Drying temperature: variation between 11 °C in relation to the ambient temperature Efficiency: 50% solar collector, 17% drying performance Mass airflow: 0.022 kg/s Total potential: 1800 W | [43] |

| Hybrid dryer (Brazil) | A forced-ventilation solar-cabin hybrid dryer. The solar dryer consists of: drying chamber, solar collector, trays, electrical heater. The system is connected to: photovoltaic module, fans, batteries, charge controller and duct. The dryer is made of wood and covered with galvanized steel sheets and thermal insulation. The absorber plate is made of galvanized steel, painted in black, and covered by a glass cover. The trays are made of galvanized wire mesh painted in black. | Corn 16 kg capacity, 23% moisture content | Surface: 0.51 m2 drying chamber, 1 m2 collector, 1.6 m2 air pre-heating (PV module) Inclination: 20°, collector and PV panel Drying time: 8.5 h Average Solar Radiation: 684 W/m2 Ambient temperature: 22.8 to 33.9 °C Relative humidity: 57 to 28% Drying temperature: 68.9 °C Efficiency: 40% Mass airflow: 0.0103 kg/s Electrical power PV: 270 W | [44] |

| Hybrid dryer (Ecuador) | Solar-geothermal hybrid dryer systems. The systems consists of: drying chamber, solar collector, photovoltaic systems, aerothermal exchangers, and blower. The dryer is made of galvanized steel sheets and polycarbonate. The collector is made of galvanized steel, painted in black, and covered by a glass cover. The geothermal-heat exchanger is made of PVC. | Cocoa 7 kg. 45% moisture content | Surface: 1.5 m2 drying chamber, 0.75 m2 collector, 21 m2 aerothermia Inclination: 10° collector Drying time: 8 h Average Solar Radiation: 450 W/m2 Ambient temperature: 29 to 36 °C Relative humidity: 70% Drying temperature: 50 °C Efficiency: 60% Air velocity: 0.9 to 1.2 m/s Electrical power PV: 110 W Total potential: 2000 W | [45] |

| Hybrid solar-biomass dryer (Colombia) | The prototype dryer consists of a combustion chamber for generating flue gases and a solar panel for generating both electrical and thermal energy. Parts: dryer, trays, fan, solar panels, combustion chamber and heat exchanger. | Coffee bean 90 kg. 40 to 43% initial humidity | Drying time: 24 h Ambient temperature: 22 °C Collector Temperature: 23 to 44 °C Combustion chamber Temperature: 70 °C. Biomass: coffee husk in pelletized and disaggregated Husk moisture: 8.88% Drying temperature: 45 °C Potential thermal: 4.02 kW | [46] |

| Passive solar dryer (Argentina) | Dryer used in rural areas. Parts: drying chamber, chimney and wind turbine. | Fresh meat. 4 kg/m2. Yield of 1 kg of dried per 3 kg of fresh | Surface: 2 m2 drying chamber Drying time: 2 days Average Solar Radiation: 550 W/m2 Inclination: 10° dryer Ambient temperature: 17 to 28 °C Relative humidity: 50% Drying temperature: 40 to 60 °C Flow: 800 m3/s Air velocity: 0.2 to 0.8 m/s | [47] |

| Greenhouse dryer (Argentina) | The dryer consists in a tunnel greenhouse drier functioning as a solar collector and fan. | Red sweet pepper 70% humidity | Surface: 50 m2 Flow: 0.5 kg/s Drying time: 2 days Drying temperature: variant Efficiency: 3% | [48] |

| Hybrid dryer (México) | Solar thermal and PV dryer cabin. The dryer is covered with cellular polycarbonate sheets with a copper chalcogenide semiconductor thin film coating. Parts: drying chamber, resistance, water extractors, electric heaters, PV modules. | Fresh produce fruits 80% humidity Yield of 40 kg of mango | Surface: 36 m2 Drying time: 3 h Average solar radiation: 800 W/m2 Drying temperature: 45–55 °C PV modules power: 30 kWp | [49] |

| Hybrid solar dryer (México) | Dryer used consist in a flat plate collector the air, drying chamber, solar water heater, water pump, drying trays, air inlet. | Medicinal plant 2.5 kg of product, 79% moisture content Reduces the moisture content to the product by 90% | Surface of dry: 1.12 m2 Surface of solar water heater: 1.5 m2 Surface of plate collector: 0.188 m2 Average Solar Radiation: 200 to 800 W/m2 Inclination: 45° collector Ambient temperature: 28 to 35 °C Relative humidity: 20% Capacity to store: 3250 latent heat Drying time: 14 h Drying temperature: 40 to 56 °C Collector Temperature: 55 °C Solar Water heater temperature: 50 °C Efficiency: 17.68 to 57.66% | [50] |

| Solar dryer (México) | Dryer used consist in a flat plate collector the air, drying chamber. thermal storage: beach sand and limestone. | Agricultural product in rural communities 0.89 kg, 96% moisture content | Surface of dry: 0.72 m2 Surface of plate collector: 1.2 m2 Average Solar Radiation: 489 W/m2 Inclination: 21° collector Ambient temperature: 25.8 °C Relative humidity: 80% Charge Energy: 2391 to 5945 kJ Storage efficiency: 70 to 84% Drying time: 22 h Drying temperature: 40 to 70 °C Wind Speed: 0.63 to 0.87 m/s Collector Temperature: 65 °C Efficiency: 3 and 4% of the drying efficiency as compared to conventional | [51] |

| Company | Country | Feedstock | Capacity | Reference |

|---|---|---|---|---|

| HTC | ||||

| CPL Industries | United Kingdom | Landfill waste | - | [95] |

| SunCoal | Germany | Biomass | Pilot plant | [96] |

| Terra Nova | Germany | Wastewater and Organic waste | Industrial scale in China and Mexico | [97] |

| Ingelia | Spain | Biomass | Industrial scale | [98] |

| HTL | ||||

| Licella | Australia | Biomass and plastic | Three scales of pilot plants | [99] |

| Genifuel Corporation | United States | Wet organic wastes | Pilot plants | [100] |

| Circlia Nordic | Denmark | Organic waste | Modular plant | [101] |

| Merrick & Company | India | Algae | 1000 liters of fuel per day | [102] |

| Steeper Energy | Norway | Woody biomass | 30 barrels per day | [103] |

| Destination | Zone A | Zone B (Zarate) | Zone B (Campana) |

|---|---|---|---|

| Pulp and paper production | 50% are 42,000 tons equivalent to 2500 ha BCC: 49,350 tonCO2/year | Rest of the region 2000 ha: 50% (1000 ha) BCC: 19,740 tonCO2/year | 50% (6000 ha) BCC: 118,440 tonCO2/year |

| Sawing for furniture and carpentry | 2% is 1680 tons, equivalent to 100 ha BCC: 3988 tonCO2/year | North Sector 3000 ha: 10% (300 ha) Rest of the Region 2000 ha: 50% (1000 ha) BCC: 51,844 tonCO2/year | 20% (2400 ha) BCC: 95,712 tonCO2/year |

| Agglomerates | 48% are 40,320 tons, equivalent to 2400 ha BCC: 51,840 tonCO2/year | North Sector 3000 ha: 90% (2700 ha) Central Region 3000 ha: 100% | 30% (3600 ha) BCC: 77,760 tonCO2/year |

| Substitution of fossil fuel | Used 17,010 ton/year of crop residues to produce energy, thermal performance of the system of 30% and 3% for drying the wood, the total available will be 4950 tons/year BCC: 9797 tonCO2/year * | - BCC: 15,680 tonCO2/year ** | - BCC: 23,520 tonCO2/year *** |

| Total BCC | 114,975 | 210,384 | 315,432 |

| Destination | Pulp and Paper | Agglomerates | Sawn | Total |

|---|---|---|---|---|

| Production (ton/year) | 159,600 | 196,560 | 63,840 | 420,000 |

| Position on the ground * | Average 4300 USD/ton | 3100 USD/ton | Poplar 5750 USD/ton Willow 4950 USD/ton | |

| Sale (USD/ton) | 41 | 30 | Weighted average 53 | |

| Total (USD/year) | 6,543,600 | 5,896,800 | 3,383,520 | 15,823,920 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Delgado-Plaza, E.; Carrillo, A.; Valdés, H.; Odobez, N.; Peralta-Jaramillo, J.; Jaramillo, D.; Reinoso-Tigre, J.; Nuñez, V.; Garcia, J.; Reyes-Plascencia, C.; et al. Key Processes for the Energy Use of Biomass in Rural Sectors of Latin America. Sustainability 2023, 15, 169. https://doi.org/10.3390/su15010169

Delgado-Plaza E, Carrillo A, Valdés H, Odobez N, Peralta-Jaramillo J, Jaramillo D, Reinoso-Tigre J, Nuñez V, Garcia J, Reyes-Plascencia C, et al. Key Processes for the Energy Use of Biomass in Rural Sectors of Latin America. Sustainability. 2023; 15(1):169. https://doi.org/10.3390/su15010169

Chicago/Turabian StyleDelgado-Plaza, Emerita, Artemio Carrillo, Hugo Valdés, Norberto Odobez, Juan Peralta-Jaramillo, Daniela Jaramillo, José Reinoso-Tigre, Victor Nuñez, Juan Garcia, Carmina Reyes-Plascencia, and et al. 2023. "Key Processes for the Energy Use of Biomass in Rural Sectors of Latin America" Sustainability 15, no. 1: 169. https://doi.org/10.3390/su15010169

APA StyleDelgado-Plaza, E., Carrillo, A., Valdés, H., Odobez, N., Peralta-Jaramillo, J., Jaramillo, D., Reinoso-Tigre, J., Nuñez, V., Garcia, J., Reyes-Plascencia, C., Tancredi, N., Gallardo, F., Merino, I., León, G., Torres, J., Garcia, C., & Sosa-Tinoco, I. (2023). Key Processes for the Energy Use of Biomass in Rural Sectors of Latin America. Sustainability, 15(1), 169. https://doi.org/10.3390/su15010169