Abstract

Safety on construction sites is now a top priority for the construction industry all around the world. Construction labor is often seen as hazardous, putting employees at risk of serious accidents and diseases. The use of Industrial Revolution (IR) 4.0 advanced technologies such as robotics and automation, building information modelling (BIM), augmented reality and virtualization, and wireless monitoring and sensors are seen to be an effective way to improve the health and safety of construction workers at the job site, as well as to ensure construction safety management in general. The main aim of this research was to analyze the IR-4.0-related technologies for improving the health and safety problems in the construction industry of Malaysia by utilizing the analytical hierarchy process (AHP) technique. IR-4.0-related technologies show great potential in addressing the construction industry’s existing health and safety problems from the perspective of civil engineering practitioners and industry experts. This research adopted the analytical hierarchy process (AHP) for quantitative analysis of data collected through the survey questionnaire approach. The findings of the study indicate that from matrix multiplication, the highest importance among the criteria and the alternatives was for BIM with a score of 0.3855, followed by wireless monitoring and sensors (0.3509). This research suggests that building information modelling (BIM) and integrated systems had the greatest potential as advanced technology and should be prioritized when it comes to introducing it to the construction industry to improve the current health and safety performances.

1. Introduction

Evolution in science and technology has always been of paramount significance since the advent of the Industrial Revolution [1]. This hunger and appetite of humans to evolve further have assisted mankind to go the extra mile [2]. Since the initiation of the industrial revolution in the 1700s, each industrial revolution has played a key part in the growth of today’s development [3]. Mechanical looms, powered by water and steam on mechanical equipment, were first introduced in the First Industrial Revolution (IR 1.0) in the 1700s, and they replaced agricultural sectors, further increasing the economic structure. Furthermore, the Second Industrial Revolution (IR 2.0) between 1870 and 1914 was marked by dense innovation based on valuable knowledge being mapped onto technology that propelled the industry forward with low-cost, high-efficiency mass production of steel, telegraphs, and railways [4]. Similarly, electrical energy was also introduced in the 1870s, resulting in the formation of a large system known as mass production. The Internet, information technology (IT), and the widespread access to personal computers in the late 1950s ushered in a new digital revolution in which mechanical and analogue procedures were digitized, and mass manufacturing gave way to mass customization [5]. Consequently, with the emergence of electronics in the 1970s, the Third Industrial Revolution (IR 3.0) began. This changed the fate of mankind in the sense that microchips and supercomputers revolutionized almost every industry. The human hunger for evolution in science and technology did not stop here. In the late 19th or early 20th century, large amounts of research in science and technology gave birth to the fourth industrial revolution. Thus, the Fourth Industrial Revolution (IR 4.0) is based on the Digital Revolution, which connects technology and people. Research on the Fourth Industrial Revolution is relatively new and includes robotics and automation, smart factories, augmented and virtual reality, artificial intelligence, integrated systems, BIM, and cloud computing [6].

Significantly, in Malaysia, the Ministry of Works, in conjunction with parties with interests in the construction industry and through Construction Industry Development Board (CIDB) is preparing a Construction Strategy Plan 4.0 (2021–2050) to help the industry adapt to the changes [7]. In all fields of industry, notably in the construction industry, health and safety issues are of great concern [8]. Even though the construction industry is constantly changing due to new methods, equipment, and machinery, it is never without safety issues, including fatalities [9]. Over the years, most countries, including Malaysia, have created safety and health legislation. The Occupational Safety and Health Act [10] regulates safety and health issues in the construction industry in Malaysia [11]. The Social Security Organization’s data, on the other hand, revealed that there had been a wave of construction site accidents. In 2016, 7338 accidents were reported, up from 4330 in 2011, indicating a 69.47% increase [12]. Furthermore, the construction industry continues to be the leading cause of fatal accidents, with a fatality rate of 14.57 per 10,000 persons [13].

However, Industry 4.0 has been around for a while in the construction industry, and the technologies are at various stages of development [14]. Industry 4.0 or IR 4.0 is the fourth industrial revolution in which human–machine interaction is achieved. Key technologies in IR 4.0 include: building information modelling (BIM), cloud computing, artificial intelligence, robotics, 3D printing, and modularization, which have advanced greatly, while other technologies such as augmented, virtual, and mixed reality are still being improved and may have an impact on the industry’s long-term viability [15]. These advanced technologies can make the construction site much safer and more productive for the project teams, thus avoiding hazardous incidents on sites. Despite having access to these technologies, the application of IR 4.0 in the construction industry is still woefully weak. Within the construction industry, IR 4.0 methods have been applied, and the procedures have exhibited considerable impacts across different platforms [16]. Nonetheless, all parties involved must resolve the issues that arose to assure a successful implementation. The social factor has been recognized as the most important factor influencing successful implementation; nevertheless, the other contributing factors imply that these factors are interconnected and should be addressed at the same time.

The construction industry had the greatest number of occupational fatalities examined out of any Malaysian industry sector in 2018 [17]. In addition, the construction industry was responsible for 118 deaths (45.4%) in total. Poor safety performance in the construction industry is one of the leading causes of work-related injuries and death. In many nations, including Malaysia, the construction industry continues to be one of the most dangerous places to work when compared to other industries, with one of the highest rates of fatal occupational accidents [18]. Because of the complicated nature of the construction site and the activities that take place there, safety work becomes more difficult. Occupational Safety and Health (OSH) in the construction sector has been recognized as a top priority topic since it is the most dangerous industry with complicated and aggressive methods, resulting in large numbers of accidents and deaths among construction employees and the general public [19].

Furthermore, the utilization of a multidisciplinary workforce adds to the complexity, as does the problem of controlling the borders between disciplines and the characteristics of worker behavior, which are not as uniform as in manufacturing industries [20]. Accidents can occur as a result of workers’ dangerous actions, which are difficult to monitor and manage. Therefore, safety should be prioritized throughout the design process, as well as downstream operations such as the construction phases by utilizing IR-4.0-related methods and tools [21]. While other economic sectors have experienced significant technological transformations, the construction industry continues to fall behind in several areas, including occupational health and safety [22]. However, in the view of published literature and given the official statistics and figures on the safety performance in the Malaysian construction industry [12,17,18], it is clear to see that a necessary upgrade in technology is needed to replace existing and long-standing safety technologies that are outdated and to mitigate the worrying upward trend of accidents in the recent years [8]. The published literature justifies the urgency of the utilization of the latest tools and methods for safe construction industry practices [23].

Therefore, to bridge this research gap, the current study was undertaken. The main aim of this research was to analyze the IR-4.0-related technologies for improving the health and safety problems in the construction industry of Malaysia by utilizing the analytical hierarchy process (AHP) technique. The findings of the study will assist in examining how the technology application in Industrial Revolution 4.0 may overcome the limitations and unsatisfactory safety performances that are typically encountered in the construction industry. The significant findings of the study will expand the body of knowledge by proposing a framework through AHP, which will guide top management, all stakeholders, and key decisionmakers to establish an effective and safe environment in the organizations and assist policymakers to strive for the incorporation of safe work practices on construction sites.

2. Literature Review

Health and safety are a common necessity for all branches of industry, business, and commerce including information technology businesses, traditional industries, the National Health Service, care homes, schools, universities, leisure facilities, and offices. Globally, many legislation acts or regulations have been crafted throughout the years to help solidify the health and safety standards in all branches of industry. Occupational Health and Safety (OHS) is a multidisciplinary field concerned with the prevention of occupational risks inherent to each work activity or job. The fundamental goal is the promotion and maintenance of the highest degree of safety and health at work, therefore creating conditions to avoid the occurrence of work accidents and illness [8]. As a result, OHS is more than just preventing work accidents or occupational diseases, but is also the consequence of taking actions to identify their causes (hazards existent in the workplace) and putting in place suitable preventive OHS control measures. According to Zid et al. (2018) [24], Occupational Health and Safety (OHS) is concerned primarily with safeguarding employees in the workplace against accidents, injuries, and harmful exposure [25]. While accidents can occur at any given moment, it is the employer’s responsibility to ensure that precautions are taken to decrease the likelihood of mishaps and to maintain a safe working environment.

According to the writers’ scientific fields and nationalities, there are a variety of definitions used in occupational health and safety literature [26]. However, in the current study context, the definition of the accident as outlined by OSHA, i.e., an unforeseen incident that causes property damage or personal injury is referred to as an accident [27], will be used. The construction industry involves high risk due to its production processes, labor-intensive characteristics, and financial losses on a large scale in the event of occupational accidents due to risks and hazards [18]. One in five worker deaths in the private sector occurred in construction in 2019, accounting for almost 20% (1061) of all worker fatalities [28]. Moreover, construction-related illnesses and injuries cost Great Britain’s economy approximately GBP 16.2 billion in 2018–2019. The majority of these expenses—59%, or GBP 9.56 billion—were borne by the hurt or ill people themselves. Compared to 2018, the overall cost of injuries in the construction industry increased by 34% in 2020, and the fatal injuries rate in the construction industry as compared to other sectors is four times more [29]. Some of the most common hazards in the construction industry include falls from height, falling objects, exposure to dangerous substances, dust inhalation, working in confined spaces, and being hit in vehicle accidents [30,31,32]. Safety is a vital part of finishing a project on or under budget. Downtime is costly for companies, as is finding replacement workers when someone cannot do their job after an accident [20]. Worker’s compensation claims and lawsuits can drive up a company’s insurance costs. Focusing on safety helps keep your costs low. Safety and health should always be strictly adhered to at construction sites because it protects the public, reduces work-related accidents, and decreases time and money lost after an accident [33].

2.1. Health and Safety in the Construction Industry in Malaysia

The construction industry has generally met the obstacles of rapid physical expansion and development throughout this time. According to Abdul-Aziz and Hussin (2003) [34], even though other economic sectors have experienced significant transformations [35], the construction industry continues to lag in many areas including occupational health and safety. A survey conducted by Saifullah and Ismail (2012) [36] about research priorities in occupational health and safety in Malaysia highlighted that construction is one of two economic prospects that should be given top priority (the other being plantation). In contrast, the Malaysian construction industry’s safety record has remained stubbornly low, despite many efforts.

The Construction Industry Development Board (CIDB), which has been in existence since 1995, was established to ensure that Malaysia’s construction industry develops in a manner that is consistent with national aspirations [37]. CIDB has undertaken several projects, including the “green card” program, which was launched in May 2000 with a Malaysian ringgit (MYR) 16 million budget. All CIDB-registered site personnel are required to attend a one-day safety training led by CIDB staff or CDIB-accredited independent trainers, after which they are awarded a green registration card (as opposed to a white registration card for those who have not). Green card holders are automatically covered against industrial accidents through a CIDB-arranged insurance policy. Before beginning any construction job, contractors must obtain Workmen’s Compensation Insurance (WCI) coverage. Every worker on the job, including subcontractors, is covered by the policy. Industrial accidents, occupational illness, and commuting accidents are covered by the Employment Injury Insurance Scheme, whereas invalidity or death from any cause is covered by the Invalidity Pension Scheme [38].

The construction industry is regarded as the most hazardous in terms of Occupational Health and Safety (OHS) due to the nature of the process involved [22]. According to the Department of Safety and Health Malaysia’s (DOSH) statistics on fatal accidents, the Malaysian construction industry had the highest number of fatalities during the study period, making it the most critical sector that requires effective OHS management to reduce the significant number of fatalities on construction sites [39]. In 2018 alone, there was a record high of 118 worker fatalities in the Malaysian construction industry.

2.2. Technological Application in Industrial Revolution 4.0

Since the days of hard helmets and safety glasses, digital technology has been used in construction. The use of big data, technological brilliance, and construction has improved worker safety on construction sites in recent years [40]. Several studies have highlighted digital technologies such as BIM, VR and AR, drones, GIS, automation and robots, unmanned equipment, sensing and warning systems, and 4D CAD as useful solutions for accident prevention and project delivery [41,42,43,44,45,46]. The next subsections go through these technologies in depth.

2.2.1. Robotics and Automation

Construction is a labor-intensive sector of the economy. Being one of the least mechanized businesses, the construction industry is far behind in embracing robots, automation, and digital technology [47]. The newest innovations in the building construction sector, including robots and artificial intelligence, are now the talk of the town. By using such technology, the building may be completed more quickly and accurately while also conserving time, money, and other resources. Robotics technology in construction enables construction professionals with quality-assured outputs and decreased human mistakes in a fast-paced building process [48].

Thus, numerous studies have suggested that robots and automation can alleviate construction-related health and safety concerns. Robotic technologies are currently being employed to complete risky and difficult tasks [49]. Robotics and automation, according to Zanchettin et al. (2018) [50], are most successful in operations that need speed and repetition and are carried out in adverse settings. Construction workers are particularly vulnerable to overexertion diseases and injuries as a result of these activities. The use of robotic devices to speed up and automate building operations is a recent theme right now [51]. Different kinds of robotic systems have been created to improve construction project quality, productivity, worker health, and other safety issues [42]. Robots are used in the autonomous installation and collection of heavy construction materials, which typically demand huge manpower, as well as the building of structures such as skyscraper towers, which are controlled by computers on site and rely on improved recognition and control [50]. Exoskeletons, welding robots, and forklift robots are just a few of the new robotic technologies that have recently been created and can be used in construction. Wearable robotics, such as exoskeletons for decreasing lower back stress, are used while lifting and moving large things and are often used by elderly employees. The AWN-03 Suit detects worker movement and offers back, shoulder, and thigh support. Signals are delivered to the motors, which rotate the gears when the hip and spine are moved, reducing the amount of energy required. Another wearable robotics gear that improves users’ strength and endurance is the FORTIS Exoskeleton. Robotic arms are made out of aluminum servo brackets and resemble human arms in appearance. Its ergonomic tool arms are made up of radial distance infrared sensors and a USB camera that records angles and gives the arms input on whether or not they can lift an object [43]. Robotic arms have been discovered to be useful for improving worker comfort and safety by stabilizing and bracing, reaching and transferring, and decreasing effort in repetitive tasks.

2.2.2. Augmented Reality and Virtualization

Despite being one of the largest and oldest sectors in the world, construction struggles frequently to adopt new tools. Nevertheless, innovation is a vital resource for the building sector. Another innovative development in the construction sector is augmented reality, which is a priceless tool for all facets of this sector. It makes use of cutting-edge camera and sensor technologies that blend digital components, audio, and sensory input. They all support the real-time presentation of the data [52].

Unlike virtual reality, which employs computer-generated images to imitate real-life events, augmented reality uses technology to improve reality [53]. However, if such interactions are integrated into programs and mobile devices, improvements may be seen [54]. As people walk around building sites with mobile devices or special helmets, augmented reality projects 3D images on their physical environment, employing GPS and cameras to show real-time data geospatially and provide updated user feedback [46]. This technology might be used to perform safety training by allowing employees to wear augmented reality headsets to receive virtual exercises, instructions, and safety situations with minimum training expenses and downtime.

A virtual reality experience is a computer-generated simulation of a real-life scenario or setting. It creates realistic visuals and sound, giving the user the impression that they are experiencing the simulated world [55]. Virtual reality has been used by the safety team in construction to review safety tie-off points and coordinate major crane picks over occupied facilities that cannot be disrupted, allowing for an effective means of visualizing and communicating the impact of major construction activities in existing facilities that may be overlooked when viewing through traditional techniques [56]. Virtual reality also offers a realistic work environment that may be used for construction safety instruction [43]. These advantages include the ability to conduct safety exercises in the absence of a certified safety administrator by merely replicating the training environment on a computer. Traditional paper-based handouts, video cassettes, or slide displays, according to [57], do not adequately communicate electric dangers to trainees and do not give enough opportunities for trainees to interact in activities. This type of interactive training incorporates a real-world scenario into the training in the form of an “it might happen to you” scenario, allowing the learner to link these rules and circumstances to real-life scenarios involving life and death.

2.2.3. Building Information Modelling (BIM)

Building information modeling (BIM) is a critical and sometimes required procedure used all over the world to guarantee that the planning, design, and construction of buildings are extremely efficient and collaborative [58]. It has clearly stated aims and objectives that are advantageous to everyone who progresses through the stages. Undoubtedly, the building will become much more digital and collaborative in the future. Four-dimensional, five-dimensional, and even six-dimensional BIM will start to participate in the process as BIM grows more complex [59].

Sun et al. (2017) [60] suggested that BIM might be used to efficiently complete construction tasks to solve difficulties originating from the perplexing nature of construction sites and projects. The BIM system is used as a supporting technology for health and safety planning and management on construction sites [57]. BIM allows for a visual evaluation of the construction site and the identification of possible risks [44]. Site workers may have a better grasp of the actual site circumstances by using the BIM model to perform visual safety training. Before carrying out construction operations, construction workers are given enough time and knowledge to plan and manage their safety. By verifying data-collecting procedures using sensors, the BIM can effectively minimize the risk of site accidents (Fargnoli and Lombardi, 2020) [61]. One of the primary benefits of BIM adoption is its ability to represent and manage visuals as well as automatically analyze designs, create drawings, reports, design schedules, and manage facilities. Furthermore, BIM technology is successful not only in the design phase but also in the operation phases, notably for construction process simulation [62].

2.2.4. Wireless Monitoring and Sensors

The acceptance of new technology in the construction sector is a long process, much like new standards and laws. In reality, the industry’s failure to stay up with technology is one of the key reasons why adopting new standards and regulations may be so difficult. Construction decisionmakers are reluctant to abandon conventional design, construction, and testing techniques. The use of smart technology in the building is crucial in a world where everything is becoming more linked and new systems are being built for every aspect of life [63]. More precisely, the use of sensors and other tools is crucial for keeping track of and evaluating the structural [47] and material characteristics of concrete.

Through real-time monitoring of structures or building components, sensors play an important role in establishing construction safety [56]. By monitoring the whole environment on construction projects, sensor-based technologies have been deployed to avoid incidents and worker–equipment collisions. Sensor-integrated location, vision-oriented sensing, and wireless sensor networks are some of the sensor technologies used in construction safety management [45]. Wireless sensor networks improve and facilitate information flow among design teams on building sites. Because of the complexity of the building environment, network circulation is challenging; nevertheless, wireless networks offer answers to this challenge. Visual inspection methods used to monitor bridge building projects do not offer thorough and trustworthy information [64].

2.3. Industrial Revolution 4.0 as a Solution to Overcoming Current Health and Safety Issues

IR 4.0 is a concept that aims to digitize industrial processes to create a flexible yet vast production and service network without any employee’s safety being jeopardized. The introduction of IR 4.0 creates an environment in which all mechanized automation will be networked via technological advancements to function and share information with reduced risks directed at workers, hence increasing the efficiency and safety of workers [16]. The advantages are obvious because of its introduction, since it enhances product quality, reduces time to market, improves operational performance, and enhances health and safety.

The use of various safety technologies on construction sites, such as 3D and 4D CAD, RFID, augmented reality, virtual reality, building information modelling, smart sensor and wireless technology, online databases, robotics, and automation, has significantly improved the effectiveness of health and safety management [46]. By keeping people away from hazardous work environments, new technology can be leveraged to establish a safe workplace [65]. For instance, it is possible to track chemical leaks or employee mishaps in real time by using a deep-learning algorithm to detect human behavior patterns using surveillance cameras. The appropriate system can promptly notify the operator, safety officer, or responsible department of a potentially hazardous situation to help avoid an accident [66].

However, collaborative robots are one of the numerous technologies that Industry 4.0 has adopted. Using them has many benefits, including the reduction of the need for physical labor in many tasks that were previously handled by people. However, the psychological costs of increasing worker monitoring and demands must also be thoroughly assessed. If human factors issues are not carefully considered throughout the process, the decision-making needs for human–robot interaction may potentially have certain hazards [67].

3. Methodology

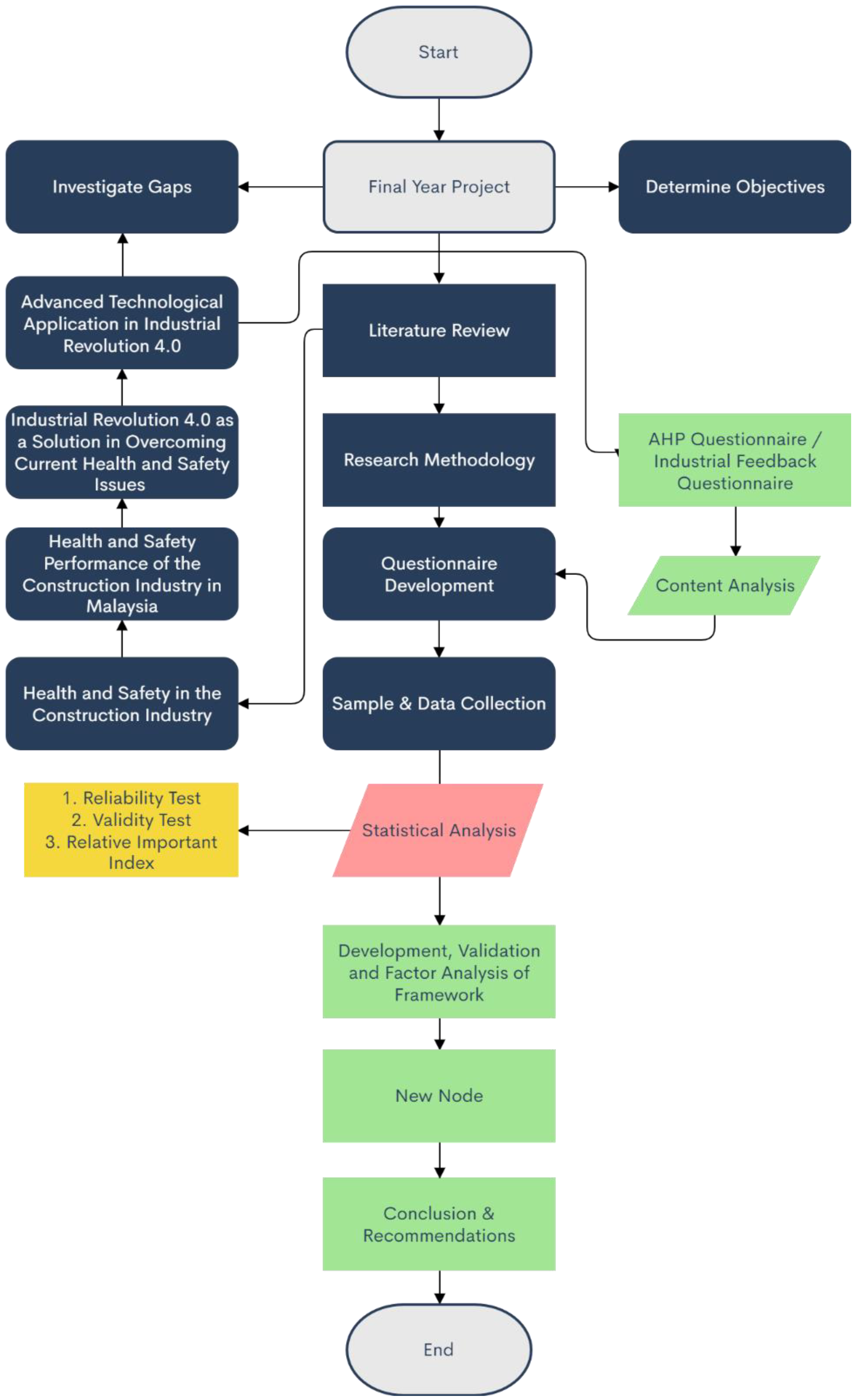

The defined objectives were attained using a thorough research technique that included three qualitative stages, as indicated in Figure 1.

Figure 1.

Methodology flowchart.

A thorough review of the published literature was carefully obtained from the literature that helped to identify the advanced technological applications of IR 4.0 towards safe construction practices in the first phase, and furthermore, to replace out-of-date and long-standing traditional health and safety technologies, tools, and procedures to improve their health and safety performance. The study was supported by a semi-structured interview and a feedback questionnaire to collect feedback and opinions from industry experts.

The next step involved creating an AHP and industry feedback questionnaire that had been narrowed down for use in determining the extent of advanced technological applications of IR 4.0 deployment in enterprises and on construction sites. In the second phase, the developed questionnaires were circulated to the industry experts (who included general civil engineering practitioners) to obtain their input on the adoption of advanced technological applications of IR 4.0 for safe construction practices.

In the third and final phase, the gathered data were analyzed using the analytical hierarchy process (AHP), followed by its application and pertinent discussions. The details of the adopted methodology are explained further in the subsequent sections.

3.1. Industrial Expert Feedback Analysis Questionnaire Design

The semi-structured interview and industrial feedback questionnaire approach were utilized to achieve the study objectives. Three key respondents were interviewed in a semi-structured interview to collect relevant feedback and comments. Lecturers with an academic background, an engineer from a contractor company, and a consulting company’s engineer were the three main acquired interviewees. Interviewees were chosen on the basis of slightly different criteria than the targeted survey respondents, for instance, they work in the construction industry and have extensive civil engineering teaching experience. This approach was chosen to ensure that data collected from the interviews were based on accurate information and knowledge through the company’s work in the field. Interview invites were issued to the author’s networks, who were also asked to recommend additional people for the interview. A virtual meeting was organized due to the current COVID-19 pandemic to obtain important input from these experts, including feedback and recommendations. These suggestions and opinions are critical to the success of this research project. A total of 18 open-ended questions were developed and were divided into four main sections, allowing respondents to offer comprehensive examples from their own experiences about the poor safety performance experienced in the Malaysian construction industry and how we can use technologies from Industrial Revolution 4.0 as a potential solution to the problem. This would aid in the discovery of new obstacles and technological applications in Industrial Revolution 4.0 that were not covered in the literature study and are relevant to the Malaysian construction industry.

Moreover, the feedback questionnaire survey was conducted online through the Microsoft Forms platform whereby the survey was properly administered and distributed personally to targeted respondents via email; current connections; and LinkedIn, a professional networking platform. Although this method consumes a large amount of time rather than just posting the questionnaire link via a public online platform, this approach was adopted to ensure the quality and reliability of the data collected. Of 60 private messages sent through LinkedIn, 120 emails, and WhatsApp messages sent to connections, there were only 15 responses, which meant a response rate of 8.33%. The lack of response was closely related to two factors, namely, the COVID-19 pandemic and the busy schedule of industrial experts.

The questions were designed in the view of a literature review to identify whether the findings from those studies are still applicable and remain relevant to the industry. Consequently, the collected data are expected to be in descriptive, continuous, and free-form responses, whereby the descriptive data are obtained from multiple choice questions, the continuous data are based on a 5-point Likert scale, and the free-form response was collected from open-ended questions.

3.2. Analytical Hierarchy Process (AHP) Questionnaire Design

The analytic hierarchy process questionnaire survey technique was carried out in the current study. The AHP method is a mathematical decision-based tool [68] for solving complex and ambiguous issues in policy and decision making. AHP helps break down the complex problem into a hierarchy of simple criteria and sub-criteria and makes analysis easier with the help of a relative analysis. One of the key significance of the AHP method is the subjective- and objective-based problem evaluation [69]. This method is primarily composed of breaking down a multi-criteria into discrete levels of hierarchy with the top hierarchy as the goal, mid-level as criteria, sub-criteria, and lower levels as an alternative [70]. Therefore, the AHP is considered the most suitable for the current study.

The analytic hierarchy process (AHP) is a math- and psychology-based approach for organizing and evaluating complicated choices. It consists of three parts: the aim or problem you are attempting to address, all viable solutions (referred to as alternatives), and the criteria you will use to evaluate the alternatives. The AHP provides a solid basis for a necessary conclusion by outlining its criteria and alternate alternatives and connecting those elements to the larger goal. The numerical priority for each of the alternative alternatives is computed in the last phase of the procedure. On the basis of the values of all users, these figures reflect the most requested solutions. When it comes to making decisions on complicated problems with high stakes, the AHP comes in handy. It differs from previous decision-making approaches in that it quantifies criteria and alternatives that are impossible to quantify with concrete statistics in the past. Rather than prescribing a “right” solution, the AHP assists decisionmakers in identifying the option that best fits their values and understanding of the situation. The AHP differs from a traditional poll or meeting in that it removes bias from the decision-making process. An analytic hierarchy process (AHP) survey had been performed to obtain feedback and insights from a limited group of people. The analytic hierarchy process (AHP) questionnaire survey is made up of 25 questions and it was further divided into six sections. The six sections contain varying pairwise comparisons between each alternative (advanced technologies). The alternatives were evaluated against four main constraints or criteria to output the alternatives that show the highest popularity in a ranked order. This was then circulated among 250 respondents. This section is critical for any survey of this type since it helps to improve the understanding of the overall results and provides extra important feedback and suggestions. For the analytic hierarchy process (AHP) questionnaire survey, online questionnaire survey platforms such as Google Form had been used to conduct the survey questions and collect feedback from respondents. Moreover, there were no precise figures for any organization, role, gender, etc., in the sample used for this study, which consisted of Malaysian civil engineers who were picked at random. A total of 250 full responses were obtained from 300 invites, for an overall response percentage of 83.3%. Because this sample size was more than the required minimum of 96, it is considered representative and significant for further analysis.

The analytical hierarchy process (AHP) was conducted on the first questionnaire that was targeted toward civil engineering practitioners to evaluate their responses. The analytical hierarchy process (AHP) began by defining the alternatives that needed to be evaluated. The alternatives in this study were represented by four types of advanced technologies, namely, “robotics and automation”, “augmented reality and virtualization”, “building information modelling (BIM)”, and “wireless monitoring and sensors”. These alternatives are the different criteria that solutions must be evaluated against.

The next step taken was defining the problem and the criteria. According to the analytical hierarchy process (AHP) methodology, a problem is a related set of sub-problems. Therefore, dividing the problem into a hierarchy of smaller problems is the foundation of the AHP technique. In the process of breaking down the sub-problem, criteria to evaluate the solutions emerge. The problem, in this case, was identified to be the deteriorating health and safety performances in the Malaysian construction industry while the criteria or constraints that the four advanced technologies were bounded by were “cost”, “innovation”, “ecosystem”, and “interoperability”.

The third step taken was establishing a priority amongst criteria using pairwise comparison. This priority scale was set with a scale of numbers ranging from 1 to 10, where 1 represents the two alternatives having an equal amount of importance and 10 verifies that the first alternative has extremely high importance when compared to the second alternative. The priority scale used is shown in Table 1.

Table 1.

Priority scale table.

The questions for the analytical hierarchy process (AHP) questionnaire directed toward civil engineering practitioners follow an order of four questions for each of the six sections. In this order, all alternatives will be able to be compared with each other once. The four questions contain a criterion each for which the pairwise comparison is to be compared concerning selected criteria. Each alternative is compared against the remaining three alternatives only once concerning the given criteria.

3.3. Sample Selection and Data Analysis

The semi-structured interview, industrial experts’ feedback analysis, and the analytic hierarchy process (AHP) were utilized to gather information for the study. The first method, a semi-structured interview, was performed with 15 interviewees, who included academic professionals, contractors, and consultants. Academicians offered input from a theoretical standpoint, while construction industry stakeholders provided feedback from a practical standpoint. The analytic hierarchy process (AHP), the second technique, primarily targeted general civil engineering practitioners as respondents. A series of questionnaires was sent to them to obtain important feedback and insight for this project.

The semi-structured interview was performed with 15 industrial experts, and the feedback and remarks were compiled. A total of 50 completed surveys were given to civil engineering practitioners in the industry. We utilized the analytical hierarchy process (AHP) to analyze the information collected through the questionnaire crafted for its purpose. The AHP is a systematic approach for organizing and analyzing complicated choices that are based on mathematics and psychology. This method will provide detailed and thorough conclusions on the study and other key results. Throughout this research project, the industrial expert’s feedback questionnaire was used to analyze data and was subsequently verified using the Cronbach’s alpha test, validity test, and AHP.

3.4. Reliability and Validity Test

The Cronbach’s alpha coefficient, which ranges from 0 to 1, was used to assess data dependability. The higher the number, the more reliable the data. The examination of the coefficient of internal accuracy of data used in statistics is a measure of reliability. The presence of a “high” alpha score does not imply that the test is one-dimensional [71]. Aside from that, rather than a statistical test using SPSS, this test is a coefficient of reliability or consistency. If the coefficient value surpasses 0.6 throughout this examination, the calculating procedure is considered trustworthy.

In most cases, the validity test is used to compute the degree to be assessed. The criterion that distinguishes it from the durability test is different. As a result, when the validity and reliability of the data measure have been validated, further analysis can be carried out. The square root of the measure’s reliability establishes an upper bound for its resemblance to any other example; for example, a measure with a reliability score of 0.65 will never correlate higher than 0.81 with another test.

4. Results

The industrial expert’s feedback questionnaire managed to obtain 15 responses from a wide range of states in Malaysia, which included four in the Federal Territories, three in Selangor, one in Perak, one in Penang, one in Pahang, one in Negeri Sembilan, one in Kedah, and two in Johor. The designation of respondents had project engineers and consultants as its majority, which gave this survey higher reliability in terms of input and experience. These respondents had a minimum qualification of a BSc, which included five of them, alongside four MScs, three Ph.D. holders, and three remaining others. The working experience of the respondents was also beneficial to this survey as seven of them had experience of 1–5 years, four of them had experience of 6–10 years, three of them had experience of 11–15 years, and one of them had experience of 16–20 years. These respondents had been involved in various project types, which included residential, non-residential, infrastructure, industrial, commercial, and others. The key outcome from this section was that the experts suggested USD 25,000–60,000 to be used annually on advanced technology to improve health and safety performances at project and construction sites with proven results that are well above the cost of implementation for the four advanced technologies under study.

Moreover, the majority of industrial experts suggested that accidents in the construction industry occur often and that the health and safety performances of the construction industry have deteriorated. This feedback is significant as it portrays the alarming occurrence frequency of accidents in the Malaysian construction industry. Apart from that, these experts also suggest that traditional health and safety procedures, methods, and personal protective equipment (PPE) are not as effective. It is highly suggested that more effort should be made in the industry to improve traditional health and safety technologies. Moreover, most respondents disagreed with the statement, suggesting that the replacement of old health and safety methods, procedures, and personal protective equipment (PPE) is too costly or risky. These data can be highly related to the construction industry’s incompetence in reducing the health and safety risks of workers on site.

Thus, it was verified that the respondents chosen for this survey knew the topic of advanced technologies. It was also found that two respondents attended high-level training courses to better understand advanced technologies. The other respondents included five who had medium-level training, six who had basic-level training, and two who did not attend any sort of training on advanced technologies. It is also suggested that some forms of advanced technologies were used occasionally in projects during their tenure in their company. A list of 12 statements portraying the capabilities of the four advanced technologies was provided to respondents in this section. The 12 statements were divided into four parts, and three of the statements were related to one of the types of advanced technology which included robotics and automation, building information modelling (BIM), augmented reality and virtualization, and wireless monitoring and sensors. All 12 questions obtained strong agreements; however, the statement designated for robotics had a 6.7% disagreement from the respondents in terms of using it to reduce the need for workers to lift or carry heavy objects. This feedback is strongly believed to be based on worker employment rates with the potential emergence of robotics and automation into the industry.

Consequently, the appropriate level of importance was selected for each criterion of advanced technologies to be used in the construction industry. The four criteria included cost, innovativeness, interoperability, and ecosystem. It was highlighted that cost is the criteria that are most favored or given the most importance by industrial experts when selecting advanced technology, which could potentially improve the health and safety performance of the construction industry. This level of importance was followed by innovativeness, interoperability, and ecosystem, consecutively. This outcome was highly expected as the cost is a crucial factor in the construction industry. The industrial experts were also asked to rank the four advanced technologies in the order which shows the most promise in improving the health and safety performance in the construction industry. Building information modelling obtained the highest rank, followed by wireless monitoring and sensors, robotics and automation, and augmented reality and virtualization.

A list of 12 statements portraying the capabilities of the four advanced technologies was provided to respondents in this section. The 12 statements were divided into four parts, and three of the statements were related to one of the types of advanced technology, which included robotics and automation, building information modelling (BIM), augmented reality and virtualization, and wireless monitoring and sensors. All 12 questions obtained strong agreements; however, two statements designated for robotics and automation picked up disagreements by 6.7% each. The disagreements were in terms of using automated systems to respond faster to emergencies and using exoskeletons for workers to complete tasks. These disagreements are highly believed to be based on worker employment rates with the potential emergence of robotics and automation into the industry.

4.1. Reliability and Validity Test

The Cronbach’s alpha value, which assesses the internal consistency and reliability of data, was 0.74, as shown in Table 2. For additional analysis, values between 0.7 and 0.95 are acceptable [72].

Table 2.

Cronbach’s alpha value.

The validity test, which is used to compute the degree to be assessed and will indicate how useful it is in a certain circumstance, was 0.86. The value implies that the test, survey, or measuring method includes all pertinent aspects of the subject it seeks to assess.

4.2. Analytical Hierarchy Process (AHP)

At the very start of pairwise comparison, criteria are compared in relation to the main goal, followed by a sub-criteria comparison with project health and safety criteria, consecutively. To compare the importance of one criterion to the other, each cluster is compared in pairs with all its links or connections. The reliability of subjective input can be evaluated by the consistency ratio in the pairwise comparison matrix. It should be less than 0.1, otherwise it should be re-evaluated [73]. The value of 0.046, as shown in Table 3, for the comparison of criteria for reliable and consistent data is well within the acceptable range.

Table 3.

Consistency ratio calculation.

Furthermore, in the analytical hierarchy process (AHP) survey given in Appendix A, responders were allowed to identify which criteria are the most important when evaluating a new technology for industrial application and which type of advanced technology should be prioritized for use in the construction industry for the improvement of health and safety of workers on site. Table 4 represents the calculated level of importance among each of the four criteria.

Table 4.

Level of importance among the criteria.

The results presented in Table 4, Table 5, Table 6, Table 7, Table 8, Table 9, Table 10, Table 11, Table 12, Table 13 and Table 14 need to be read from two different perspectives i.e., horizontally and vertically. In the horizontal direction, each variable on the leftmost column is compared with each variable horizontally. Conversely, their vertical scores were totaled and are presented in the last rows. The variable with the highest total score (score calculated after adding vertical scores of each variable) is considered more significant as compared to other variables with lesser scores. The same sense was adopted in all subsequent tables, and due to replication of information, it is explained at this location.

Table 5.

Level of importance of alternatives for cost.

Table 6.

Level of importance of alternatives for innovation.

Table 7.

Level of importance of alternatives for the ecosystem.

Table 8.

Level of importance of alternatives for interoperability.

Table 9.

The average level of importance among the criteria.

Table 10.

The average level of importance of alternatives for cost.

Table 11.

The average level of importance of alternatives for innovation.

Table 12.

The average level of importance of alternatives for the ecosystem.

Table 13.

The average level of importance of alternatives for interoperability.

Table 14.

Matrix multiplication of the average level of importance among the criteria and the alternatives.

The results from Table 4 indicate that the criteria of innovation had the highest total score of 14, followed by ecosystem (9.33) and interoperability (8.83). The cost has the lowest total value of 1.47 when compared vertically. Similarly, cost criteria showed the highest values when compared horizontally with other criteria, i.e., innovation (8), ecosystem (5), and interoperability (7). Moreover, Table 5, Table 6, Table 7 and Table 8 represent the level of importance of each alternative to each of the four criteria.

As shown in Table 5, robotics and automation had the highest level of importance of alternatives for the cost (17.5), followed by augmented reality and virtualization (12), and then by wireless monitoring and sensors (4.27). The lowest importance was shown for BIM (1.96).

As shown in Table 6, wireless monitoring and sensors had the highest level of importance of alternatives for innovation (14), followed by BIM (12.5), and then by robotics and automation (8.83). The lowest importance for innovation was shown by augmented reality and virtualization (1.38).

Virtual and augmented reality help with safety on the job site as well, as they call attention to important features in the environment, such as temperatures or potentially unsafe conditions. BIM allows construction managers to create better designs and spot problems before they occur, which optimizes the workforce by helping them perform tasks smoothly with reduced safety risks and avoiding delays.

As seen in Table 7, robotics and automation had the highest level of importance as alternatives for the ecosystem (14). The second highest alternative was wireless monitoring and sensors (9.67), followed by augmented reality and virtualization (6). The lowest importance for innovation was shown by BIM (2.46). There was not much emphasis given to having proper R&D sectors in the construction industry, resulting in the old methods persisting, while it takes a long time to implement newer methods such as BIM. Adopting safety sensors to monitor rigidity or structural stability can help reduce work-related incidents that may harm the public such as in LRT construction sites. Advanced technologies are currently underutilized in the Malaysian construction industry due to the high cost involved to invest, and companies are unsure about the returns they will be getting in terms of their investment in advanced technology, despite the many advantages advanced technology holds.

As shown in Table 8, augmented reality and virtualization had the highest level of importance of alternatives for interoperability with a value of 13. The second highest alternative was robotics and automation (12.143), followed by BIM (4.833). The lowest importance for innovation was shown by augmented reality and virtualization (1.792).

Table 9 represents the calculations in obtaining the average value of the level of importance for each of the criteria. The highest average level of importance among the criteria was for cost, with a value of 0.6452, followed by interoperability (0.169).

Conversely, Table 10, Table 11, Table 12 and Table 13 represent the calculations in obtaining the average value of the level of importance for each alternative for each of the four criteria. The final calculations were performed by conducting matrix multiplication between the average values of the level of importance obtained from the criteria and the subsequent alternatives.

Falls, electric shocks, being struck by an object, and being caught between objects are the top safety risks and have remained constant for some time. However, people are now turning to technology for new and innovative answers to make the industry safer. Despite a large proportion of construction managers saying that more needs to be done to improve safety levels, the adoption of technology-led initiatives has remained relatively conservative. The argument is that new technologies have always accelerated the construction business, and therefore it is strange that so many businesses are reluctant to accept them.

The highest average level of importance of alternatives for cost was for wireless monitoring and sensors, with a value of 0.36, as shown in Table 10. This highlights the significance of integrated systems during the execution of construction projects for maintaining the safety and adoption of a safe work environment.

As is shown in Table 11, the highest average level of importance of alternatives for innovation was for augmented reality and virtualization with a value of 0.7023. The construction industry runs on conventional tools, methods, and practices that need to change. Therefore, the utilization of augmented reality and virtualization can play a key role during the inception and planning phases of the project.

As seen in Table 12, the highest average level of importance of alternatives for the ecosystem was for BIM, with a value of 0.4038. For establishing a sound and productive ecosystem, it is very important to use BIM during the execution of construction projects.

Site sensors that can be deployed across a construction site to monitor things such as temperature, noise levels, dust particulates, and volatile organic compounds to help limit exposure to workers can be implemented. Safety training and equipment operator training are two areas where virtual reality (VR) could have a strong impact on the construction industry. With VR, workers could have exposure to environments such as confined spaces or working at height in a safe, controlled environment. Wearables can be used to monitor workers and their environment to make job sites safer. Wearable tech in construction is embedded into apparel and personal protective equipment (PPE) and is already common on construction sites. The apparels and personal protective equipment (PPE) that are already being experimented on include hard hats, gloves, safety vests, and work boots.

Table 13 shows the average level of importance of alternatives for interoperability. The highest value was obtained by wireless monitoring and sensors (0.5171), followed by BIM (0.1985). These results indicate the significance of BIM in construction projects. With the usage of BIM, communication between project teams can be improved, planning can be done effectively, and execution of projects can be undertaken with minimum errors.

Moreover, the results obtained from the analytical hierarchy process (AHP) suggest that civil engineering practitioners opted for building information modelling (BIM) as the advanced technology that provides the most promise in improving the health and safety of the Malaysian construction industry in terms of the four main criteria. Wireless monitoring and sensors, augmented reality and virtualization, and robotics and automation were ranked second, third, and fourth, respectively. The calculated results are shown in Table 14.

5. Discussion

The IR 4.0 in the construction industry system focuses on the physical-to-digital transition and then the digital-to-physical transition to help coordinate, design, and execute built environment infrastructure more effectively and efficiently [74]. IR 4.0 integrates organizations, procedures, and information to effectively plan, build, and operate assets using cyber-physical structures, the internet of things, data, and services to associate the digital layer, comprising BIM and CDE, with the physical layer, comprising the asset, over its entire existence in order to establish an integrated environment incorporating organizations, processes, and information. According to Rastogi, the primary objective of IR 4.0 in construction is to build a digital construction site that uses various techniques to track progression during a project’s life cycle. IR 4.0 implementation in construction would transform not only the construction process, but also the company and project frameworks, transforming the fragmented construction industry into an integrated one [75]. Although it is becoming one of the most profitable industries, the construction industry has among the poorest research and development initiatives. Likewise, employment growth in the AEC has decreased over time, although it has nearly doubled in other sectors [76]. The function of human resources in an IR 4.0 world is shifting from machine operator to strategic decision creator. Robots support humans in dangerous, stressful, and time-consuming tasks, for which humans must be adequately prepared for successful human–machine interaction. Since it is a labor-intensive sector, the construction industry has a significant opportunity to increase productivity through technical advancement (e.g., robot use), particularly for potentially hazardous human labor. Robots are used in restricted ways in the digital building platform, such as 3D printing, structuring walls, placing rebar, welding, and drones [40]. Furthermore, a discussion on IR 4.0 technologies has been presented in detail in the subsequent sections in light of our findings.

5.1. Robotics and Automation

Robotics and automation offer huge potential to enhance productivity, efficiency, and manufacturing flexibility throughout the construction industry, including automating the fabrication of modular homes and building components off site, robotic welding and material handling on building sites, and robot 3D printing of houses and customized structures. As well as making the industry safer and more cost effective, robots are improving sustainability and reducing environmental impact by enhancing the quality and cutting waste. With so few construction businesses using automation today, there is a huge potential for us to transform the industry through robotics [77]. Robots on construction sites can be very useful during high-risk-oriented activities. They can be operated from distant operating rooms. This can significantly reduce the on-site safety incidents, and thus the health and safety of the workers can be considerably ensured.

5.2. Augmented Reality and Virtualisation

Augmented reality (AR) and virtualization have proven their value across multiple industries and have demonstrated that they can be leveraged beyond the realms of gaming and entertainment. As such, the AR/VR market is expected to see a 77% compound annual growth rate (CAGR) from 2019 to 2023. In retail, brands are adopting augmented reality to enrich the online shopping experience, allowing shoppers to see what an item (e.g., a piece of furniture or appliance) might look like in their environment [78]. AR has also been making waves in the construction industry. When leveraged properly, augmented reality can help you win more projects, collaborate with team members, and even improve safety [79]. Taking advantage of augmented reality in construction requires a solid understanding of the technology’s capabilities and technical requirements.

Using augmented reality, designers can place digital models in a real-world setting. This provides a chance to visualize how a building project’s components will look from the outside. As a result, a building or construction site that is now unoccupied might be made to appear to be in use. Before beginning construction, project teams can identify potential problems and avoid errors by using 3D plans instead of traditional paper ones [80]. Additionally, project teams can see exactly where ductwork, pipes, columns, windows, and access points will be installed. It is also simpler to make changes before, during, and after the project. Unable to physically be on the job site, virtual reality offers an innovative alternative that places collaborating teams there. By producing an exact depiction on a computer, virtual reality (VR) simulates an environment. Stakeholders can study a building’s layout by stepping inside the simulation using a VR head-sets. This makes it possible for different teams to organize and plan how to carry out the job successfully and efficiently far in advance of the building project getting underway. Using a realistic and immersive environment, architects may precisely measure the spacing, layout, and materials throughout the entire project [81]. Making knowledgeable selections with confidence is made easier when the project manager can observe a project while it is being completed without a physical structure being there.

5.3. Building Information Modelling (BIM)

Moreover, the use of various safety technologies on construction sites, such as building information modelling (BIM), Wireless monitoring and sensors, robotics and automation, and augmented reality and virtualization have gained strong feedback from civil engineering practitioners and industrial experts in the field of construction and have significantly improved the effectiveness of health and safety management [82]. It was apparent that building information modelling (BIM) was ranked first in being the preferred advanced technology to be introduced to the construction industry to improve health and safety performances. Furthermore, it was discovered that combining traditional safety practices and standards with the use of digital health and safety tools and techniques may help site managers, supervisors, and coordinators assure the efficiency of their construction projects. Moreover, worker fatalities and injuries would be significantly reduced. As a result, investing in cutting-edge technologies shows great potential in improving construction site safety. Building information modelling (BIM) should be prioritized when it comes to introducing advanced technologies into the construction industry to improve health and safety performances [83]. Research possibilities are discovered on the basis of an evaluation of the research literature, an analysis of the industrial requirements, and the researcher’s experiences in the relevant fields [82].

The building sector is still in the early stages of adopting the building information modelling (BIM) methodology. Throughout every stage of a building’s life cycle, 2D AutoCAD drawings are still heavily utilized. A significant drive to transfer the entire process into 3D models is being led by architects. Many pilot programs have shown significant time and cost reductions for construction projects [84]. Through BIM, planning the layout of the site, visualizing and simulating construction risks and countermeasures, making decisions quickly and effectively, taking immediate action to stop the use of hazardous chemicals and equipment, and monitoring and controlling site safety can be done effectively. Additionally, it has been noted that automatic safety checking has been rated as the least advantageous feature, which reflects a lack of knowledge about the true advantages of adopting BIM [85]. BIM is one of the most acceptable ways for safety checking with a time- and money-saving quality, and it is applicable for automatic safety checking.

5.4. Wireless Monitoring and Sensors (Cloud Computing)

Construction cloud computing is a developing field that offers several prospects. Even if this list is not all inclusive, some advantages gained from the deployment of cloud computing technology in the construction industry include financial advantages, on-demand scalability of computing resources, secure platforms, vast storage, and facilitation of collaborative practices [86]. Construction companies are starting to employ cloud computing, and there are many prospects for them. For SMEs in the sector to use BIM-enabled software to digitize their operations, cloud services are essential [87]. Cloud computing can be very effective in maintaining safe work environments because of integrated systems. The detection of emergencies and abrupt response can be established with the utilization of cloud computing tools during the life cycle of any construction project, especially in difficult terrains and geographic locations.

6. Conclusions

Despite being the heart of any economy, the construction sector may, like the industrial sector, improve its performance by utilizing IR 4.0 for maintaining a safe work environment. The goal of this study is to investigate the development of IR 4.0 and digitalization in the construction sector for improving safety practices. IR 4.0 is being pushed forward by the creation and adoption of additional technologies that have contributed to its success thus far. The findings of the current study reaffirm that the construction sector is contributing more than its fair share by developing and promoting the usage of digital methodologies such as robotics and automation, augmented reality and virtualization, integrated systems, and BIM. Moreover, IR 4.0 also brings about some repercussions for the construction sector. The use of digital techniques in design and construction has evolved significantly over the last three years and is now the norm for many businesses. The performance gap—a term used to describe the discrepancy between how building designs are evaluated to demonstrate conformity in the virtual world and how structures operate in the real world—has become abundantly obvious. To address this challenge, it will be necessary to reconsider what is needed to train the next generation for the jobs of the future.

According to the findings of the current study, building information modelling (BIM), wireless monitoring and sensors, and robotics and automation have advanced substantially over the recent years, while other technologies such as augmented reality and virtualization are still being improved and may have an impact on the industry’s long-term viability. Despite having access to these technologies, the application of IR 4.0 in the construction industry is still woefully insufficient. Nonetheless, all parties involved must resolve the issues that arose to assure a successful implementation. The social component has been recognized as the most important factor influencing effective implementation; nevertheless, the other contributing variables show that these aspects are interconnected and should be addressed at the same time.

The application of IR 4.0 in the construction sector would boost the industry’s performance to equal that of its counterparts in other industries, such as the manufacturing and automotive industries. The use of various safety technologies on construction sites, such as building information modelling (BIM), wireless monitoring and sensors, robotics and automation, and augmented reality and virtualization have gained strong feedback from civil engineering practitioners and industrial experts in the field of construction and have significantly improved the effectiveness of health and safety management. It was apparent that building information modelling (BIM) was ranked first, and Wireless monitoring and sensors second, followed by augmented reality and virtualization, with robotics and automation being the preferred advanced technology to be introduced into the construction industry to improve health and safety performances. Furthermore, it was discovered that combining traditional safety practices and standards with the use of digital health and safety tools and techniques may help site managers, supervisors, and coordinators assure the efficiency of their construction projects. Moreover, worker fatalities and injuries would be significantly reduced. As a result, investing in cutting-edge technologies improves construction site safety.

The study was limited to the Malaysian construction industry in order to assess its health and safety performances and identify IR 4.0 advanced technologies that can be used to improve it. Because this study was limited to the Malaysian construction industry, a similar study is needed in Southeast Asia to assess the suitability and compatibility of the advanced technologies being studied. This study can be further extended globally by having widespread dissemination of the questionnaires, which can provide an in-depth insight into the subject in other regions that can be contrasted. The comparison will aid in the development of a unified approach that would result in reforms in the construction industry all around the world, on the basis of which updated guidelines can be drafted.

Author Contributions

All authors contributed equally to this research. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not Applicable.

Informed Consent Statement

Not Applicable.

Data Availability Statement

Not Applicable.

Acknowledgments

The authors would like to appreciate the YUTP-FRG 1/2021 project (cost center # 015LC0-369) and the URIF project (cost center # 015LB0-051) in Universiti Teknologi PETRONAS (UTP) awarded to Wesam Alaloul for the support.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A. AHP Survey Questions

Appendix A.1. Health and Safety Performances in the Construction Industry

8. How often do you hear about accidents in the construction industry lately?

- ◯

- Never

- ◯

- Rarely

- ◯

- Sometimes

- ◯

- Often

- ◯

- Always

9. How often do accidents happen at project/construction sites during your tenure?

- ◯

- Never

- ◯

- Rarely

- ◯

- Sometimes

- ◯

- Often

- ◯

- Always

10. How much do you agree with the statements below?

- 1 = Strongly disagree

- 2 = Disagree

- 3 = Maybe

- 4 = Agree

- 5 = Strongly agree

| 1 | 2 | 3 | 4 | 5 | |

| The health and safety performances of the construction industry have deteriorated. | ◯ | ◯ | ◯ | ◯ | ◯ |

| Traditional health and safety procedures, methods, and PPE are not as effective. | ◯ | ◯ | ◯ | ◯ | ◯ |

| More effort should be made in the industry to improve traditional health and safety technologies. | ◯ | ◯ | ◯ | ◯ | ◯ |

| The replacement of old health and safety methods, procedures, and PPE is too costly or risky. | ◯ | ◯ | ◯ | ◯ | ◯ |

Appendix A.2. Advanced Technology Application during the Industrial Revolution 4.0 (IR 4.0)

11. Your knowledge of advanced technologies in the construction industry

- ◯

- No knowledge

- ◯

- Very weak

- ◯

- Weak

- ◯

- Well

- ◯

- Very well

12. Have you attended any training or course to better understand advanced industrial technologies?

- ◯

- Not attended

- ◯

- Basic level

- ◯

- Medium level

- ◯

- High level

- ◯

- Advanced level

13. Did you or your organization use advanced technologies in any project during your tenure?

- ◯

- Never

- ◯

- Rarely

- ◯

- Sometimes

- ◯

- Often

- ◯

- Always

14. How much do you agree with the statements below?

- 1 = Strongly disagree

- 2 = Disagree

- 3 = Maybe

- 4 = Agree

- 5 = Strongly agree

| 1 | 2 | 3 | 4 | 5 | |

| VR provides the opportunity to experience situations that you wouldn’t be able to easily construct for training in a real-life situation. | ◯ | ◯ | ◯ | ◯ | ◯ |

| VR can simulate a construction site module, giving a worker first-hand experience of the job before they even start. | ◯ | ◯ | ◯ | ◯ | ◯ |

| With augmented training, you can also introduce the realistic sensations of heights, distractions, stress, and environmental hazards. | ◯ | ◯ | ◯ | ◯ | ◯ |

| Automation reduces the risk of injury at the operational level by removing workers from dangerous work procedures. | ◯ | ◯ | ◯ | ◯ | ◯ |

| Safety automation software makes it easy for companies to update safety protocols and create a plan of action in the case of an emergency. | ◯ | ◯ | ◯ | ◯ | ◯ |

| Robotics can also be used to reduce the need for workers to lift or carry heavy objects. | ◯ | ◯ | ◯ | ◯ | ◯ |

| BIM allows you to consider and think about hazards and risks earlier within the design as information is shared and coordinated among the project team. | ◯ | ◯ | ◯ | ◯ | ◯ |

| Using 4D scheduling and sequencing with site logistics planning can easily help identify traffic considerations and potential hazards around the site before even breaking ground. | ◯ | ◯ | ◯ | ◯ | ◯ |

| BIM allows doing more prefabrication of materials off site in a safe and controlled environment. | ◯ | ◯ | ◯ | ◯ | ◯ |

| Smart sensors can help site managers detect and make accommodations for work as it begins to shift away from known benchmarks or tolerances. | ◯ | ◯ | ◯ | ◯ | ◯ |

| A sensor embedded in a critical machine lets operators and maintenance personnel identify vibrations, sounds, and other variables that might indicate that the machine, or even a single part within it, is about to fail. | ◯ | ◯ | ◯ | ◯ | ◯ |

| Sensors can be integrated into a BIM model once a building is up to provide data about the structure. | ◯ | ◯ | ◯ | ◯ | ◯ |

Appendix A.3. Potential of Advanced Technology Application during IR 4.0 to Improve Health and Safety Performances in the Construction Industry

15. Please select the appropriate level of importance of each criterion for advanced technologies to be used in the construction industry.

| 1 | 2 | 3 | 4 | 5 | |

| Cost | ◯ | ◯ | ◯ | ◯ | ◯ |

| Innovativeness | ◯ | ◯ | ◯ | ◯ | ◯ |

| Interoperability | ◯ | ◯ | ◯ | ◯ | ◯ |

| Ecosystem | ◯ | ◯ | ◯ | ◯ | ◯ |

16. On the basis of your analysis, rank these advanced technologies in the order of which shows the most promise in improving health and safety performances in the construction industry.

- 1 = first

- 2 = second

- 3 = third

- 4 = fourth

| 1 | 2 | 3 | 4 | |

| Robotics and automation | ◯ | ◯ | ◯ | ◯ |

| Building information modelling (BIM) | ◯ | ◯ | ◯ | ◯ |

| Augmented reality and virtualisation | ◯ | ◯ | ◯ | ◯ |

| Wireless monitoring and sensors | ◯ | ◯ | ◯ | ◯ |

17. How much do you agree with the statements below?

- 1 = Strongly disagree

- 2 = Disagree

- 3 = Maybe

- 4 = Agree

- 5 = Strongly agree

| 1 | 2 | 3 | 4 | 5 | |

| AR typically respond faster to emergencies by providing real-time monitoring. | ◯ | ◯ | ◯ | ◯ | ◯ |

| AR can be used to overlay the digital model on the as-built structure in real time, making it possible to identify any discrepancies that could pose a threat to worker safety. | ◯ | ◯ | ◯ | ◯ | ◯ |

| AR can also provide accurate in-person measurements of physical spaces to make sure everything can fit where it is supposed to be, and changes can be made before mistakes happen. | ◯ | ◯ | ◯ | ◯ | ◯ |

| Automated systems typically respond faster to emergencies by providing real-time monitoring. Situations that had previously been perceived as unavoidable can be taken care of before they even occur. | ◯ | ◯ | ◯ | ◯ | ◯ |

| Robotics reduces workers’ exposure to mechanical hazards that pose a significant risk of injury or death. | ◯ | ◯ | ◯ | ◯ | ◯ |

| Exoskeleton robots can reduce the need for workers to perform repetitive motion tasks, which often lead to musculoskeletal disorders (MSDs). | ◯ | ◯ | ◯ | ◯ | ◯ |

| BIM can focus on each task so workers can better identify the risks; prepare for the work at hand; and, therefore, complete the task more efficiently and safely. | ◯ | ◯ | ◯ | ◯ | ◯ |

| The ability to communicate information visually can break down any language barriers, aid understanding, and reduce accidents. | ◯ | ◯ | ◯ | ◯ | ◯ |

| Using tracking and sensing technology, working fatalities and injuries relating to being struck by moving construction vehicles can be dramatically reduced. | ◯ | ◯ | ◯ | ◯ | ◯ |

| Smart sensors deliver tremendous value because they can wirelessly deliver real-time updates on project status; the location of vehicles, deliveries, and assets; or the condition of various features as they’re built. | ◯ | ◯ | ◯ | ◯ | ◯ |

| Smart sensors can track and monitor the condition of personnel much more easily, read their vitals, and ensure that any emergencies are brought to the attention of all invested parties immediately. | ◯ | ◯ | ◯ | ◯ | ◯ |

| Adding sensing technology could lower insurance premiums since many insurance companies provide discounts if companies engage in activities aimed at reducing workplace injuries and accidents. | ◯ | ◯ | ◯ | ◯ | ◯ |

References

- Jovane, F.; Yoshikawa, H.; Alting, L.; Boer, C.R.; Westkamper, E.; Williams, D.; Tseng, M.; Seliger, G.; Paci, A.M. The Incoming Global Technological and Industrial Revolution towards Competitive Sustainable Manufacturing. CIRP Ann. 2008, 57, 641–659. [Google Scholar] [CrossRef]

- Rozin, V. From Engineering and Technological Process to Post-Cultural Technology. Futur. Hum. Image 2021, 15, 99–109. [Google Scholar] [CrossRef]

- Deane, P.M.; Deane, P.M. The First Industrial Revolution; Cambridge University Press: Cambridge, UK, 1979. [Google Scholar]

- Mokyr, J. Eurocentricity Triumphant. Am. Hist. Rev. 1999, 104, 1241–1246. [Google Scholar] [CrossRef]

- Fisher, T. Welcome to the Third Industrial Revolution: The Mass-Customisation of Architecture, Practice and Education. Archit. Des. 2015, 85, 40–45. [Google Scholar] [CrossRef]

- Lasi, H.; Fettke, P.; Kemper, H.G.; Feld, T.; Hoffmann, M. Industry 4.0. Bus. Inf. Syst. Eng. 2014, 6, 239–242. [Google Scholar] [CrossRef]

- CIBD. IR4.0 in Construction; Malaysia, 2020. Available online: https://www.cidb.gov.my/en/construction-info/technology/ir40-construction (accessed on 23 June 2022).

- Pamidimukkala, A.; Kermanshachi, S. Occupational Health and Safety Challenges in Construction Industry: A Gender-Based Analysis. In Proceedings of the ASCE Construction Research Congress, Arlington, VA, USA, 9–12 March 2022; pp. 9–12. [Google Scholar]

- Al-Emad, N. Construction Workers’ Issues From Worldwide and Saudi Arabia Studies. Int. J. Sustain. Constr. Eng. Technol. 2021, 12, 85–100. [Google Scholar] [CrossRef]

- OSHA. Occupational Safety and Health Act. 1994. Available online: https://science.utm.my/oshe/files/2017/06/APPENDICES.pdf (accessed on 25 June 2022).

- Sapuan, S.M.; Ilyas, R.A.; Asyraf, M.R.M. Occupational Safety and Health Administration in Composite Industry. In Safety and Health in Composite Industry; Springer: Singapore, 2022; pp. 229–252. ISBN 978-981-16-6136-5. [Google Scholar]