Comparison between MICP-Based Bio-Cementation Versus Traditional Portland Cementation for Oil-Contaminated Soil Stabilisation

Abstract

:1. Introduction

2. Materials and Methods

2.1. Testing Materials and Sample Preparation

2.2. Bacterial Culture and Cementation Solution

2.3. Treatment Method

2.4. Testing Method

2.4.1. Unconfined Compressive Strength

2.4.2. Consolidated Undrained Triaxial Test

2.4.3. Calcium Carbonate Content

2.4.4. Scanning Electron Microscopy (SEM) Analysis

2.4.5. Permeability Test

3. Results and Discussion

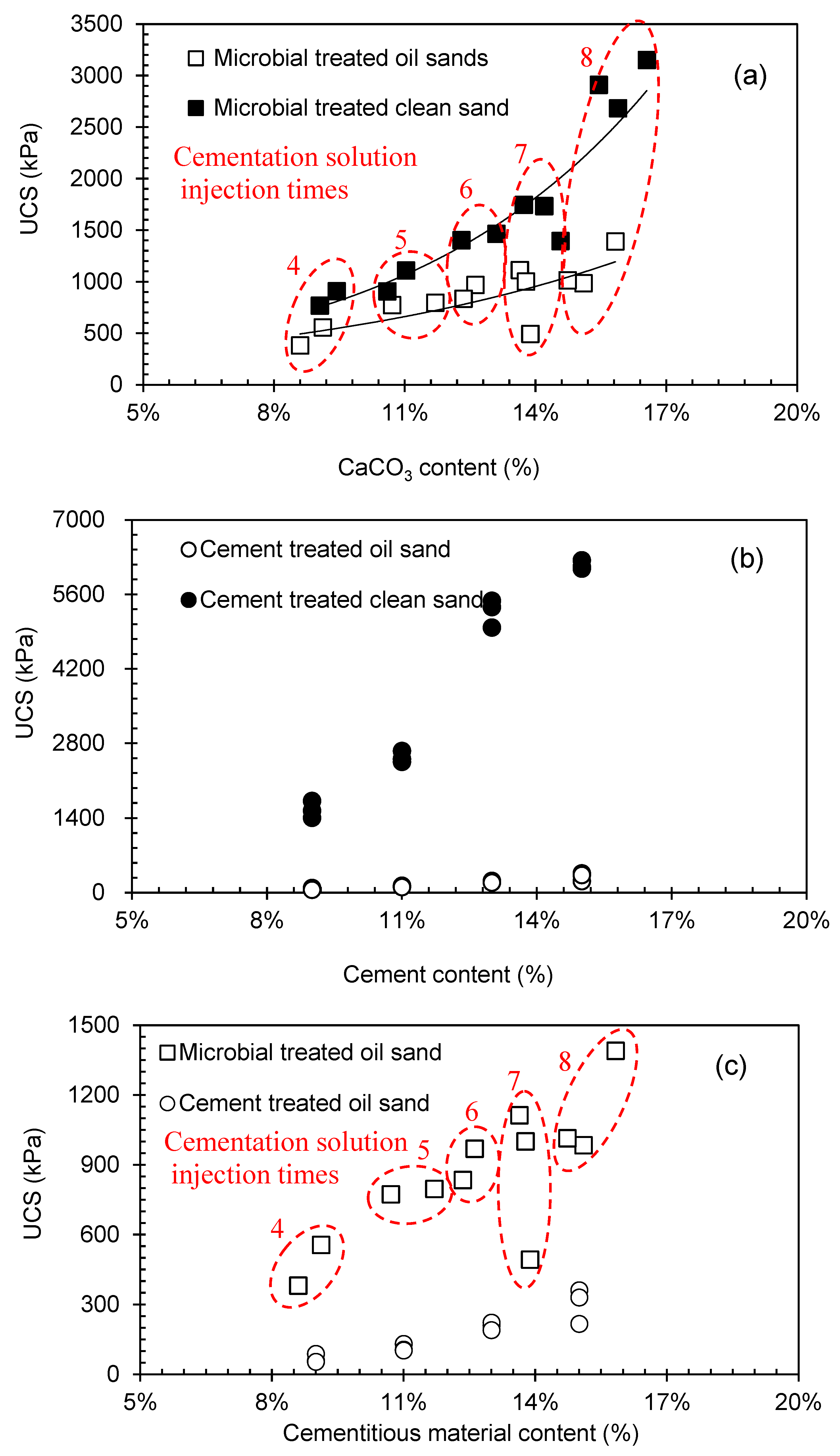

3.1. Effect of Oil Contamination on UCS of Treated Soil

3.2. Permeability

3.3. Microstructure Analysis

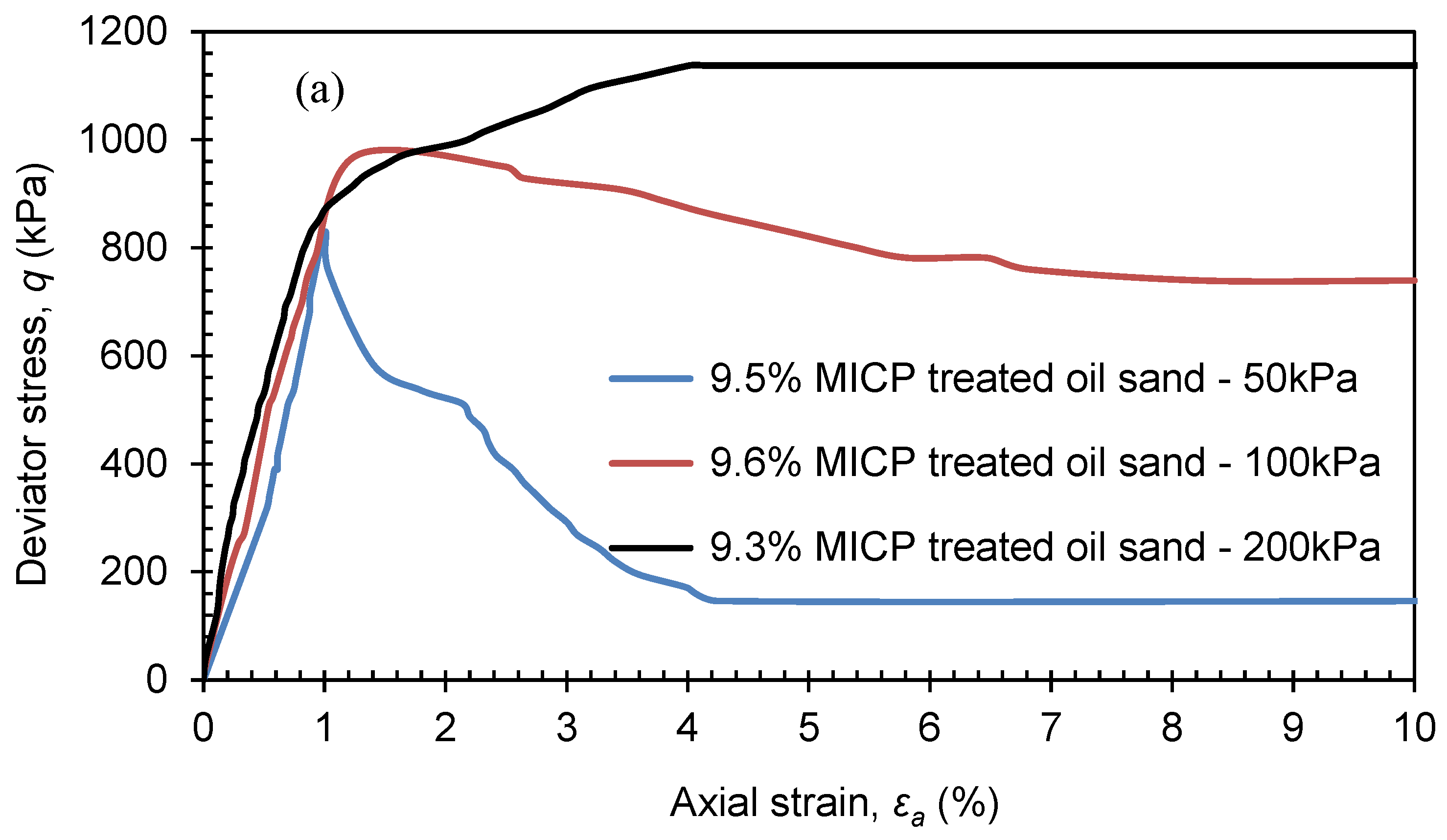

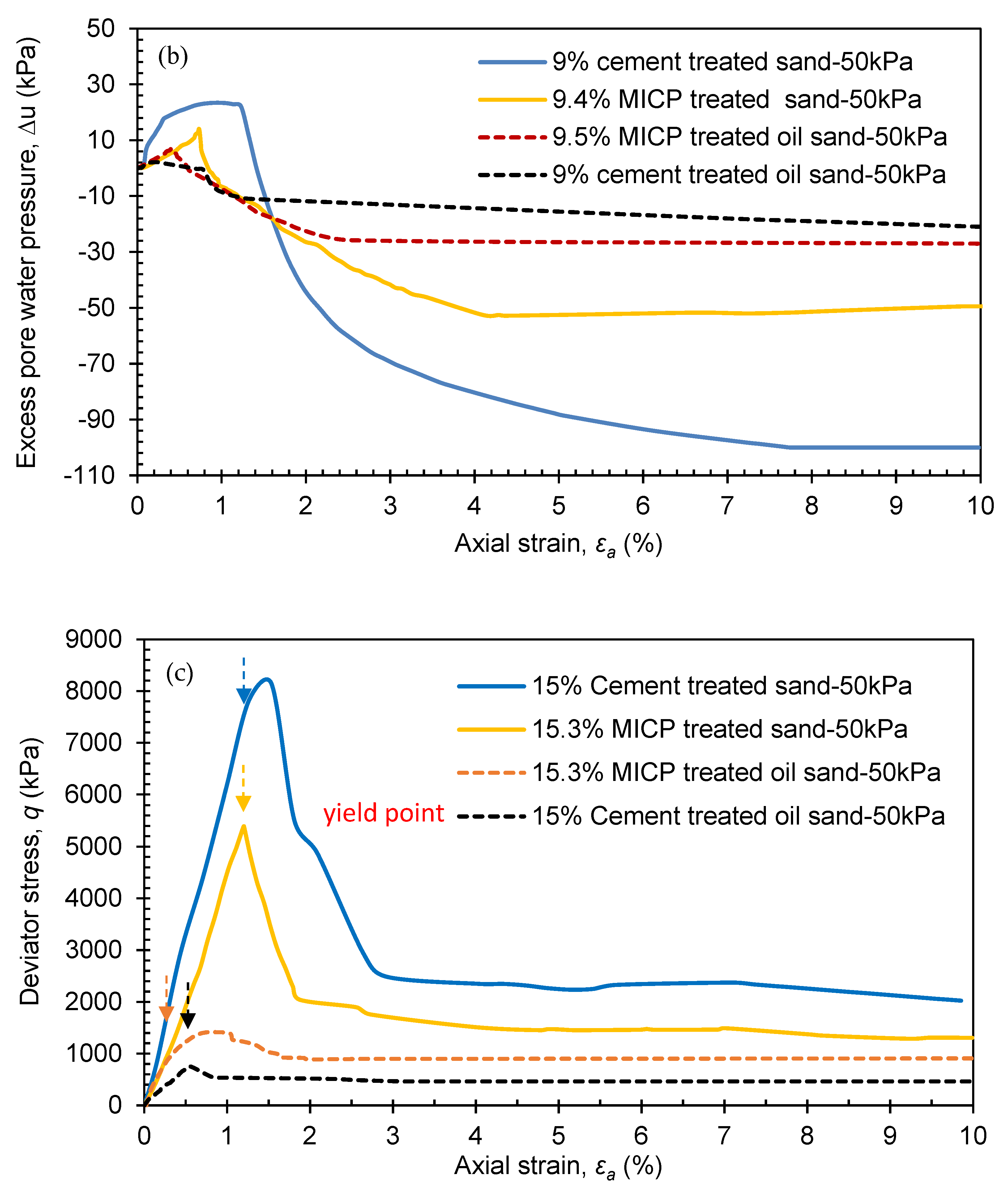

3.4. Undrained Triaxial Shear Behaviour

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Dorian, J.P.; Franssen, H.T.; Simbeck, D.R. Global challenges in energy. Energy Policy 2006, 34, 1984–1991. [Google Scholar] [CrossRef]

- Rao, S.; Rao, K.S. Ground Heave from Caustic Soda Solution Spillage—A Case Study. Soils Found. 1994, 34, 13–18. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rahman, Z.A.; Hamzah, U.; Taha, M.R.; Ithnain, N.S.; Ahmad, N. Influence of Oil Contamination on Geotechnical Properties of Basaltic Residual Soil. Am. J. Appl. Sci. 2010, 7, 954–961. [Google Scholar] [CrossRef] [Green Version]

- Cheng, L.; Shahin, M. Stabilisation of oil-contaminated soils using microbially induced calcite crystals by bacterial flocs. Géotechnique Lett. 2017, 7, 146–151. [Google Scholar] [CrossRef]

- Jamrah, A.; Al-Futaisi, A.; Hassan, H.; Al-Oraimi, S. Petroleum contaminated soil in Oman: Evaluation of bioremediation treatment and potential for reuse in hot asphalt mix concrete. Environ. Monit. Assess. 2006, 124, 331–341. [Google Scholar] [CrossRef]

- Shin, E.; Lee, J.; Das, B. Bearing Capacity of a Model Scale Footing on Crude Oil-Contaminated Sand. Geotech. Geol. Eng. 1999, 17, 123–132. [Google Scholar] [CrossRef]

- Wu, J.; Wang, X.-B.; Wang, H.-F.; Zeng, R.J. Microbially induced calcium carbonate precipitation driven by ureolysis to enhance oil recovery. RSC Adv. 2017, 7, 37382–37391. [Google Scholar] [CrossRef] [Green Version]

- Azadi, M.; Taghichian, A.; Taheri, A. Optimization of cement-based grouts using chemical additives. J. Rock Mech. Geotech. Eng. 2017, 9, 623–637. [Google Scholar] [CrossRef]

- Lemaire, K.; Deneele, D.; Bonnet, S.; Legret, M. Effects of lime and cement treatment on the physicochemical, microstructural and mechanical characteristics of a plastic silt. Eng. Geol. 2013, 166, 255–261. [Google Scholar] [CrossRef]

- Xiao, H.; Lee, F.H.; Chin, K.G. Yielding of cement-treated marine clay. Soils Found. 2014, 54, 488–501. [Google Scholar] [CrossRef]

- Chu, J.; Ivanov, V.; He, J.; Naeimi, M.; Li, B.; Stabnikov, V. Development of Microbial Geotechnology in Singapore. Geo-Frontiers 2011, 2011, 4070–4078. [Google Scholar] [CrossRef] [Green Version]

- Choi, S.-G.; Chae, K.; Park, S. Field Study for Application of Soil Cementation Method Using Alkaliphilic Microorganism and Low-cost Badge. J. Korean Geotech. Soc. 2015, 31, 37–46. [Google Scholar] [CrossRef] [Green Version]

- Al-Rawas, A.; Hassan, H.F.; Taha, R.; Hago, A.W.; Al-Shandoudi, B.; Al-Suleimani, Y. Stabilization of oil-contaminated soils using cement and cement by-pass dust. Manag. Environ. Qual. Int. J. 2005, 16, 670–680. [Google Scholar] [CrossRef]

- DeJong, J.T.; Mortensen, B.M.; Martinez, B.C.; Nelson, D.C. Bio-mediated soil improvement. Ecol. Eng. 2010, 36, 197–210. [Google Scholar] [CrossRef]

- Amin, M.; Zomorodian, S.M.A.; O’Kelly, B.C. Reducing the hydraulic erosion of sand using microbial-induced carbonate precipitation. Proc. Inst. Civ. Eng.-Ground Improv. 2017, 170, 112–122. [Google Scholar] [CrossRef]

- Cheng, L.; Shahin, M.A.; Mujah, D. Influence of Key Environmental Conditions on Microbially Induced Cementation for Soil Stabilization. J. Geotech. Geoenvironmental Eng. 2017, 143, 04016083. [Google Scholar] [CrossRef] [Green Version]

- Choi, S.G.; Chu, J.; Brown, R.C.; Wang, K.; Wen, Z. Sustainable Biocement Production via Microbially Induced Calcium Carbonate Precipitation: Use of Limestone and Acetic Acid Derived from Pyrolysis of Lignocellulosic Biomass. ACS Sustain. Chem. Eng. 2017, 5, 5183–5190. [Google Scholar] [CrossRef]

- Liu, L.; Liu, H.; Xiao, Y.; Chu, J.; Xiao, P.; Wang, Y. Biocementation of calcareous sand using soluble calcium derived from calcareous sand. Bull. Eng. Geol. Environ. 2017, 77, 1781–1791. [Google Scholar] [CrossRef]

- Lai, Y.; Yu, J.; Liu, S.; Liu, J.; Wang, R.; Dong, B. Experimental study to improve the mechanical properties of iron tailings sand by using MICP at low pH. Constr. Build. Mater. 2020, 273, 121729. [Google Scholar] [CrossRef]

- Xiao, P.; Liu, H.; Xiao, Y.; Stuedlein, A.W.; Evans, T.M. Liquefaction resistance of bio-cemented calcareous sand. Soil Dyn. Earthq. Eng. 2018, 107, 9–19. [Google Scholar] [CrossRef]

- Xiao, Y.; Zhao, C.; Sun, Y.; Wang, S.; Wu, H.; Chen, H.; Liu, H. Compression behavior of MICP-treated sand with various gradations. Acta Geotech. 2020, 16, 1391–1400. [Google Scholar] [CrossRef]

- Zhang, Z.-J.; Li, B.; Hu, L.; Zheng, H.-M.; He, G.-C.; Yu, Q.; Wu, L.-L. Experimental Study on MICP Technology for Strengthening Tail Sand under a Seepage Field. Geofluids 2020, 2020, 8819326. [Google Scholar] [CrossRef]

- Chu, J.; Ivanov, V.; Naeimi, M.; Stabnikov, V.; Liu, H.-L. Optimization of calcium-based bioclogging and biocementation of sand. Acta Geotech. 2013, 9, 277–285. [Google Scholar] [CrossRef]

- Cheng, L.; Cord-Ruwisch, R.; Shahin, M. Cementation of sand soil by microbially induced calcite precipitation at various degrees of saturation. Can. Geotech. J. 2013, 50, 81–90. [Google Scholar] [CrossRef] [Green Version]

- Cheng, L.; Cord-Ruwisch, R. Upscaling Effects of Soil Improvement by Microbially Induced Calcite Precipitation by Surface Percolation. Geomicrobiol. J. 2014, 31, 396–406. [Google Scholar] [CrossRef] [Green Version]

- Ismail, M.A. Strength and Deformation Behaviour of Calcite-Cemented Calcareous Soil. Ph.D. Thesis, University of Western Australia, Perth, Australia, 2000. [Google Scholar]

- Ivanov, V.; Chu, J. Applications of microorganisms to geotechnical engineering for bioclogging and biocementation of soil in situ. Rev. Environ. Sci. Bio/Technol. 2008, 7, 139–153. [Google Scholar] [CrossRef]

- Lin, H.; Suleiman, M.T.; Brown, D.G.; Kavazanjian, E. Mechanical Behavior of Sands Treated by Microbially Induced Carbonate Precipitation. J. Geotech. Geoenvironmental Eng. 2016, 142, 04015066. [Google Scholar] [CrossRef]

- Liu, L.; Liu, H.; Stuedlein, A.; Evans, T.M.; Xiao, Y. Strength, stiffness, and microstructure characteristics of biocemented calcareous sand. Can. Geotech. J. 2019, 56, 1502–1513. [Google Scholar] [CrossRef]

- Lium, D.M.A.B. Biologically Induced Cementation for Soil Stabilisation. Ph.D. Thesis, Curtin University, Perth, Australia, 2019. [Google Scholar]

- Ma, G.; He, X.; Jiang, X.; Liu, H.; Chu, J.; Xiao, Y. Strength and Permeability of Bentonite-Assisted Biocemented Coarse Sand. Can. Geotech. J. 2021, 58, 969–981. [Google Scholar] [CrossRef]

- Montoya, B.M.; DeJong, J.T. Stress-Strain Behavior of Sands Cemented by Microbially Induced Calcite Precipitation. J. Geotech. Geoenvironmental Eng. 2015, 141, 04015019. [Google Scholar] [CrossRef]

- Whiffin, V.S.; van Paassen, L.; Harkes, M.P. Microbial Carbonate Precipitation as a Soil Improvement Technique. Geomicrobiol. J. 2007, 24, 417–423. [Google Scholar] [CrossRef]

- Cheng, L.; Shahin, M.A.; Chu, J. Soil bio-cementation using a new one-phase low-pH injection method. Acta Geotech. 2018, 14, 615–626. [Google Scholar] [CrossRef] [Green Version]

- Yang, Y.; Chu, J.; Liu, H.; Cheng, L. Improvement of uniformity of biocemented sand column using CH3COOH-buffered one-phase-low-pH injection method. Acta Geotech. 2022, 228. [Google Scholar] [CrossRef]

- Khosravi, E.; Ghasemzadeh, H.; Sabour, M.R.; Yazdani, H. Geotechnical properties of gas oil-contaminated kaolinite. Eng. Geol. 2013, 166, 11–16. [Google Scholar] [CrossRef]

- Ajagbe, W.O.; Omokehinde, O.S.; Alade, G.A.; Agbede, O.A. Effect of Crude Oil Impacted Sand on compressive strength of concrete. Constr. Build. Mater. 2012, 26, 9–12. [Google Scholar] [CrossRef]

- ASTM D6913/D6913M-17; Standard Test Methods for Particle-Size Distribution (Gradation) of Soils Using Sieve Analysis. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM D2487-17; Standard Practice for Classification of Soils for Engineering Purposes (Unified Soil Classification System). ASTM International: West Conshohocken, PA, USA, 2020.

- Kim, Y.; Roh, Y. Microbially Induced Carbonate Precipitation Using Microorganisms Enriched from Calcareous Materials in Marine Environments and Their Metabolites. Minerals 2019, 9, 722. [Google Scholar] [CrossRef] [Green Version]

- Jain, S.; Arnepalli, D.N. Biochemically Induced Carbonate Precipitation in Aerobic and Anaerobic Environments by Sporo-sarcina pasteurii. Geomicrobiol. J. 2019, 36, 443–451. [Google Scholar] [CrossRef]

- ASTM D2166; Standard Test Method for Unconfined Compressive Strength of Cohesive Soil. ASTM International: West Conshohocken, PA, USA, 2013.

- Cui, M.-J.; Zheng, J.-J.; Zhang, R.-J.; Lai, H.-J.; Zhang, J. Influence of cementation level on the strength behaviour of bio-cemented sand. Acta Geotech. 2017, 12, 971–986. [Google Scholar] [CrossRef]

- ASTM D4767-11; Standard Test Method for Consolidated Undrained Triaxial Compression Test for Cohesive Soils. ASTM International: West Conshohocken, PA, USA, 2020.

- Almabrok, M.H.; Mclaughlan, R.G.; Vessalas, K.; Thomas, P. Effect of oil-contaminated aggregates on cement hydration. Am. J. Eng. Res. 2019, 8, 81–89. [Google Scholar]

- Albayrak, A.T.; Yasar, M.; Gurkaynak, M.A.; Gurgey, I. Investigation of the effects of fatty acids on the compressive strength of the concrete and the grindability of the cement. Cem. Concr. Res. 2005, 35, 400–404. [Google Scholar] [CrossRef]

- Ejeh, S.P.; Uche, O.A.U. Effect of crude oil spill on compressive strength of concrete materials. J. Appl. Sci. Res. 2009, 5, 1756–1761. [Google Scholar]

- Onabolu, O.A. Effect of Hot Crude Oil on Concrete for offshore storage application. Ph.D. Thesis, University of London, London, UK, 1986. [Google Scholar]

- Khamehchiyan, M.; Charkhabi, A.H.; Tajik, M. Effects of crude oil contamination on geotechnical properties of clayey and sandy soils. Eng. Geol. 2007, 89, 220–229. [Google Scholar] [CrossRef]

- Nakarai, K.; Yoshida, T. Effect of carbonation on strength development of cement-treated Toyoura silica sand. Soils Found. 2015, 55, 857–865. [Google Scholar] [CrossRef] [Green Version]

- Mujah, D.; Cheng, L.; Shahin, M.A. Microstructural and Geomechanical Study on Biocemented Sand for Optimization of MICP Process. J. Mater. Civ. Eng. 2019, 31, 04019025. [Google Scholar] [CrossRef] [Green Version]

- Evangelista, L.; Guedes, M. Microstructural studies on recycled aggregate concrete. In New Trends in Eco-Efficient and Recycled Concrete; Woodhead Publishing: Cambridge, UK, 2019; pp. 425–451. [Google Scholar] [CrossRef]

- Kostecki, P.; Bonazountas, T.M.; Calabrese, E.J. Contaminated Soils; Amherst Scientific Publishers: Amherst, MA, USA, 1997. [Google Scholar]

- Jaho, S.; Sygouni, V.; Rokidi, S.G.; Parthenios, J.; Koutsoukos, P.G.; Paraskeva, C.A. Precipitation of Calcium Carbonate in Porous Media in the Presence of n-Dodecane. Cryst. Growth Des. 2016, 16, 6874–6884. [Google Scholar] [CrossRef]

- Feng, K.; Montoya, B.M. Influence of Confinement and Cementation Level on the Behavior of Microbial-Induced Calcite Precipitated Sands under Monotonic Drained Loading. J. Geotech. Geoenvironmental Eng. 2016, 142, 04015057. [Google Scholar] [CrossRef]

- Feng, K.; Montoya, B.M. Quantifying Level of Microbial-Induced Cementation for Cyclically Loaded Sand. J. Geotech. Geoenvironmental Eng. 2017, 143, 06017005. [Google Scholar] [CrossRef]

| Group | Oil Content | Cementation Solution/Material | Cementation Solution Injection Times/ Material Content | |

|---|---|---|---|---|

| UCS/Permeability | CU | |||

| BOS | 5% | 16 U/mL bacteria culture + 2 mol CS | 4, 5, 6, 7, 8 | 4, 8 |

| BCS | 0% | |||

| PCOS | 5% | 32.5 Portland cement | 9%, 11%, 13%, 15% | 9%, 15% |

| PCS | 0% | |||

| Material | qmax (kPa) (σ3 = 50 kPa) | qmax (kPa) (σ3 = 100 kPa) | qmax (kPa) (σ3 = 200 kPa) | c′ (kPa) | ϕ′ (°) |

|---|---|---|---|---|---|

| Untreated clean sand | 215 | 477 | 723 | 0 | 38.7 |

| Bio-cemented oil-contaminated sand | 828.7 | 971.7 | 1137.4 | 209.7 | 31.2 |

| Portland cement-treated oil-contaminated sand | 140.0 | 227.5 | 352.4 | 24.1 | 25.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yin, J.; Wu, J.-X.; Zhang, K.; Shahin, M.A.; Cheng, L. Comparison between MICP-Based Bio-Cementation Versus Traditional Portland Cementation for Oil-Contaminated Soil Stabilisation. Sustainability 2023, 15, 434. https://doi.org/10.3390/su15010434

Yin J, Wu J-X, Zhang K, Shahin MA, Cheng L. Comparison between MICP-Based Bio-Cementation Versus Traditional Portland Cementation for Oil-Contaminated Soil Stabilisation. Sustainability. 2023; 15(1):434. https://doi.org/10.3390/su15010434

Chicago/Turabian StyleYin, Jie, Jian-Xin Wu, Ke Zhang, Mohamed A. Shahin, and Liang Cheng. 2023. "Comparison between MICP-Based Bio-Cementation Versus Traditional Portland Cementation for Oil-Contaminated Soil Stabilisation" Sustainability 15, no. 1: 434. https://doi.org/10.3390/su15010434