Abstract

The concept of an eco-industrial park (EIP) that promotes resource sharing, reutilization of waste, and exchange of materials among industries and communities brings significant benefits in terms of environmental, social, and economic aspects. EIP can be accomplished with the aid of blockchain technology to manage data and integration complexity and problem dimensionality. This work proposes the application of blockchain technology in combination with other Industry 4.0 (IR4.0) technologies as enablers for EIP development. We review the international frameworks for EIP and the IR4.0 principles and applications focusing on blockchain technology to evaluate the suitability of blockchain technology integration into the green industrial park concept. An illustrative model of a blockchain-based EIP data management platform has been proposed in this work as a starting point for exploring the full potential of this technology for future EIP applications.

1. Introduction

Over the years, industrial growth and urbanization have resulted in increased greenhouse gas (GHG) emissions, as seen from the efforts for emission reduction [1,2] and a dedicated study of the impact on China [2], resource consumption, and solid waste traced through studies on solid waste metabolism [3,4,5], resource consumption [4] and waste management in the European Union [5]. Industrialization can bring positive impacts through long-term economic growth [6]. Therefore, it is crucial to find strategies that can reduce the negative impacts while promoting economic growth [7]. The concept of an eco-industrial park has emerged as a solution to promote resource efficiency and integration. The term “eco-industrial park” (EIP) refers to controlled industrial regions encouraging cross-industry and community collaboration to minimize environmental impacts, reduce waste and pollution, and effectively share resources [8].

The emergence of Industry 4.0 technologies could potentially become a technological driver for the EIP concept. Industry 4.0 technologies comprise Internet of Things, cyber-physical systems, artificial intelligence, machine learning, blockchain, cloud computing, and many more. Besides the Internet of Things (IoT), blockchain is among the technologies that have received much attention recently. Blockchain technology originates from the world’s first cryptocurrency, Bitcoin, which was established in 2009 by Nakamoto [9], whose real identity remains unknown. As Bitcoin became acceptable to the public in 2017, its underlying technology suggests building trust between two unknown and unrelated parties to the point that sensitive and secure transactions can be carried out across an open network, like the internet, with complete assurance [10] has gained much interest.

The architecture of blockchain technology seems to be a potential solution to the EIP issues, as the collaboration among the communities, industrial partners, policymakers, and service provision bodies needs to be built beforehand. For the resource sharing to come afterward, the lack of trust and privacy-related issues could hinder this process. Blockchain technology promises immutability, transparency, and tamper-proof distributed ledger data recorded afterward. On the other hand, Industry 4.0 provides digitization, data exchange, and seamless communication between machines and automation technology with the utilization of the internet. The integration of these technologies can help make EIP development viable. This article reviews the international framework of the EIP under the United Nations Industrial Development Organization (UNIDO) [8] by examining the concept, requirements, drivers, and development barriers. The article also examines the development of IR4.0 technologies focusing on the principles and applications of blockchain technology for the development of EIPs.

The article is organized as follows. Section 2 describes the framework of an EIP in terms of its benefits, drivers, barriers, and implementation that require significant effort and support from various parties. Section 3 presents an introductory view of Industry 4.0, the fundamental of blockchain technology principles, and some industrial applications of blockchain. Section 4 discusses the combination of Industry 4.0 and blockchain technology, the fit assessment of blockchain framework, and a blockchain-based data management platform concept with an illustration model as the potential application of blockchain technology in the EIP. Finally, Section 5 presents the conclusions and recommendations of this study.

2. Eco-Industrial Park

This section presents the international framework of an EIP [8] together with its practitioners’ guide [11] in the development steps from a national level to an industrial level. These would serve as the main guideline for all stakeholders to develop new or convert their existing industrial park into an EIP.

2.1. Eco-Industrial Park Framework

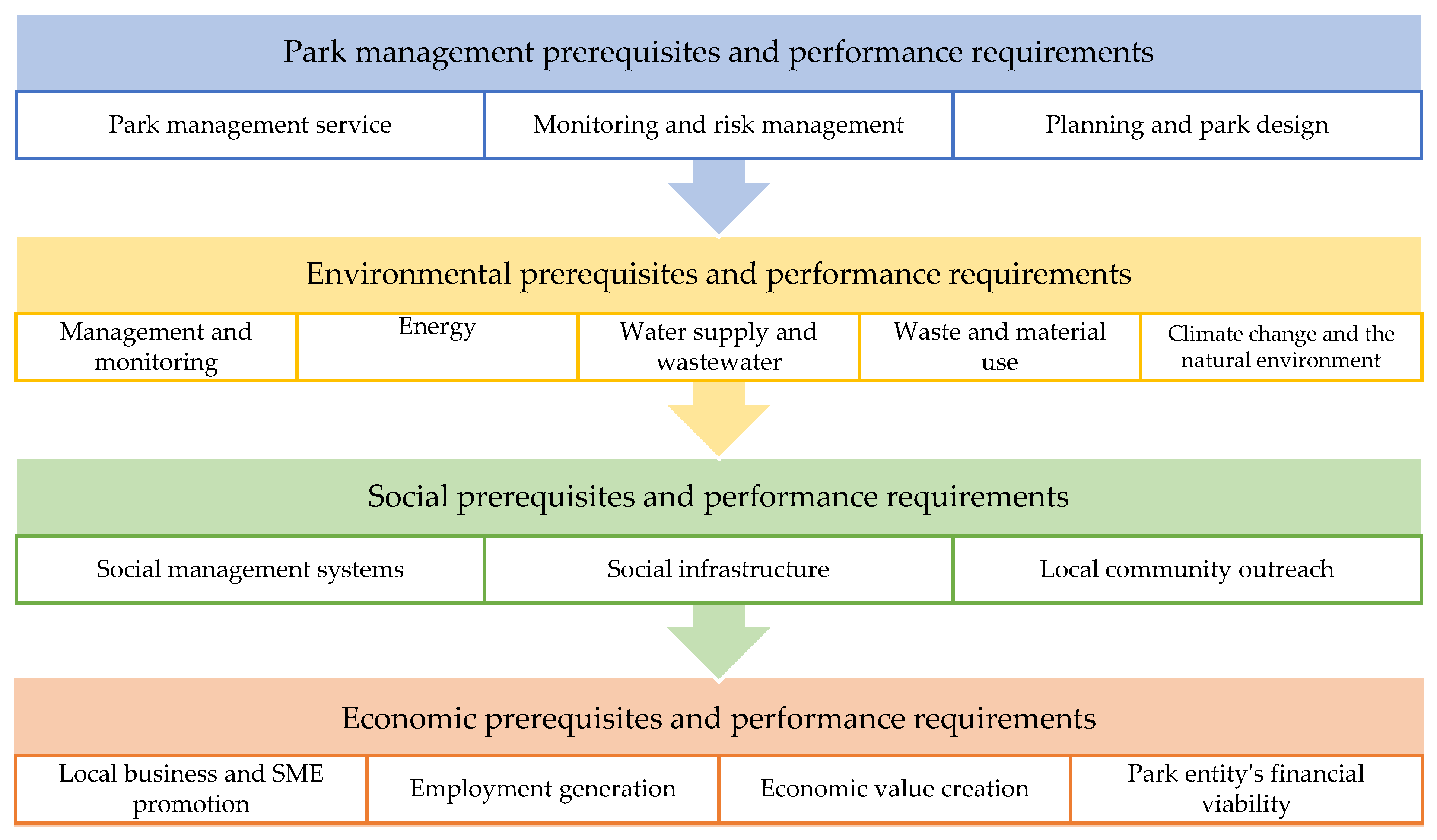

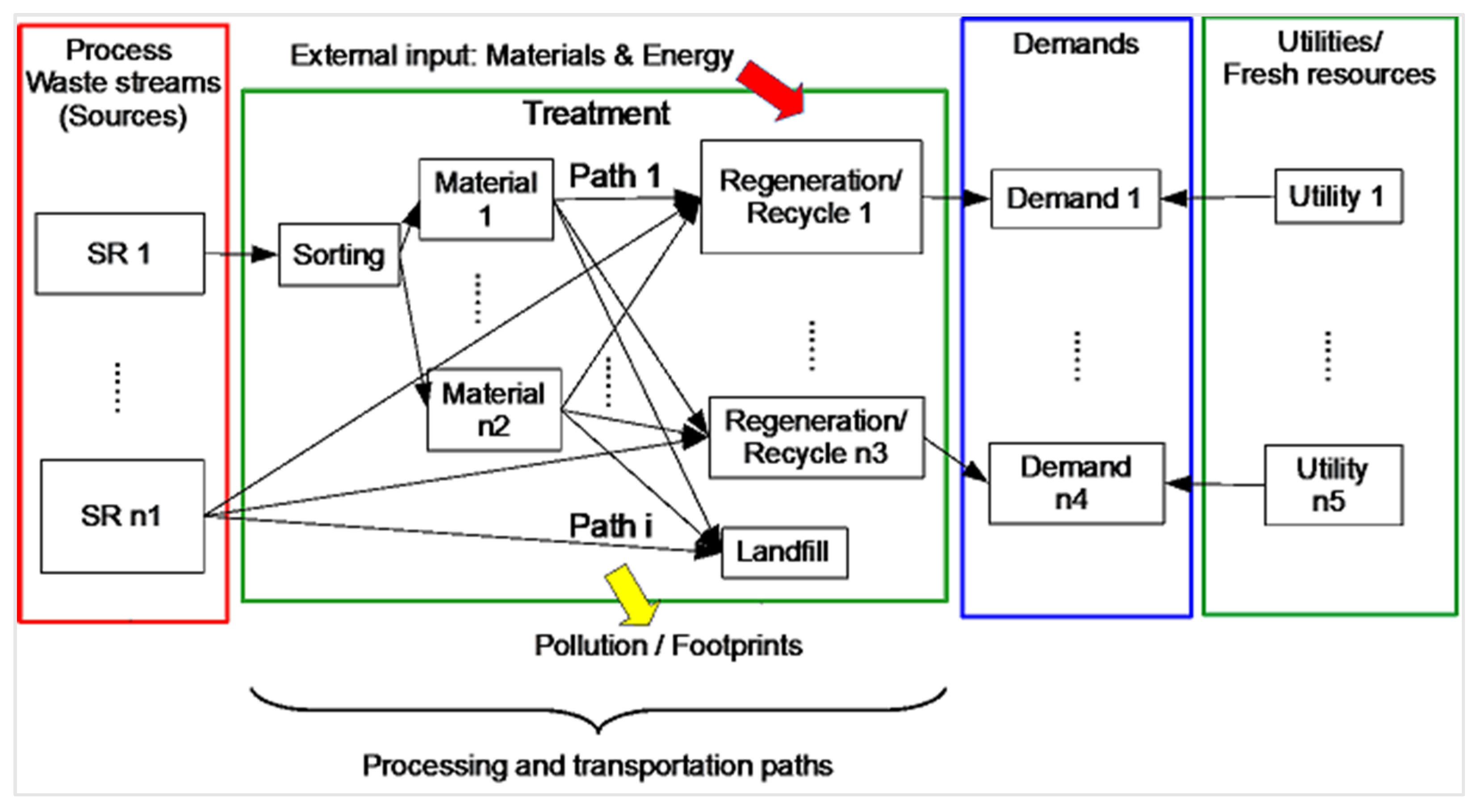

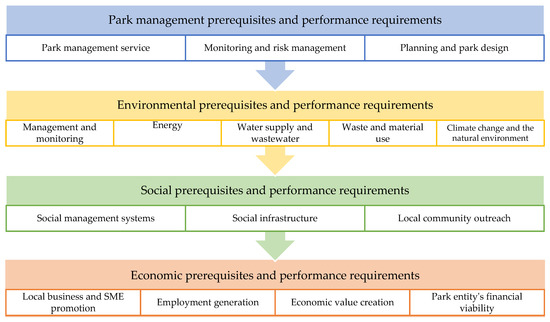

The UNIDO, in partnership with the World Bank Group and GIZ, published the first edition of the worldwide framework for EIPs in 2017, while a revised edition was published in 2021 [8]. The goal of the framework is to standardize, on a global scale, the criteria and performance levels that must be met by industrial parks for them to be designated EIPs. In addition, the organization aims to assist stakeholders in developing and transitioning to EIPs—engaging, encouraging, and consistently recognizing EIPs—and providing benchmarks to enhance the performance, sustainability, and inclusivity of the industrial sector. The framework takes an inclusive approach and creates a mutual understanding of EIPs in four key categories of prerequisite and performance requirements, as depicted in Figure 1. These categories include park management, environmental, social, and economic. The first section of the framework presents the concept, benefits, drivers of EIP implementation, and the barriers that hinder its development process. The second and third sections discuss the approach to defining performance requirements for EIPs that covers the categories mentioned previously, followed by the future prospects of the EIP.

Figure 1.

Prerequisites and performance requirements of eco-industrial park.

An EIP is a managed industrial area that encourages cooperation between different sectors and communities to improve economic, social, and environmental performance. In addition, this concept has been developed to address other interrelated issues, including resource-efficient and cleaner production, industrial symbiosis, climate change, pollution, social norms, shared infrastructure, improved risk management, and shared resources like land and ecosystem services. The primary motivations of EIPs are to reduce environmental impacts, promote efficiency gains and cost-effectiveness, facilitate community cohesiveness, build resilience to many threats, increase access to financing and technical assistance, and boost competitiveness. International industry practice and experience have shown that various economic, environmental, and social benefits have emerged from the EIP. These advantages may extend beyond what is typically expected in a business case. The advantages of the EIP extend beyond monetary considerations. They also help mitigate risks associated with obtaining necessary resources and proper authorization. In addition, they boost competitiveness, advance business growth, and enhance credibility. The EIP case studies conducted by the UNIDO also highlighted several advantages, such as improved access to financing and technical assistance, as well as policy, economic, and societal benefits.

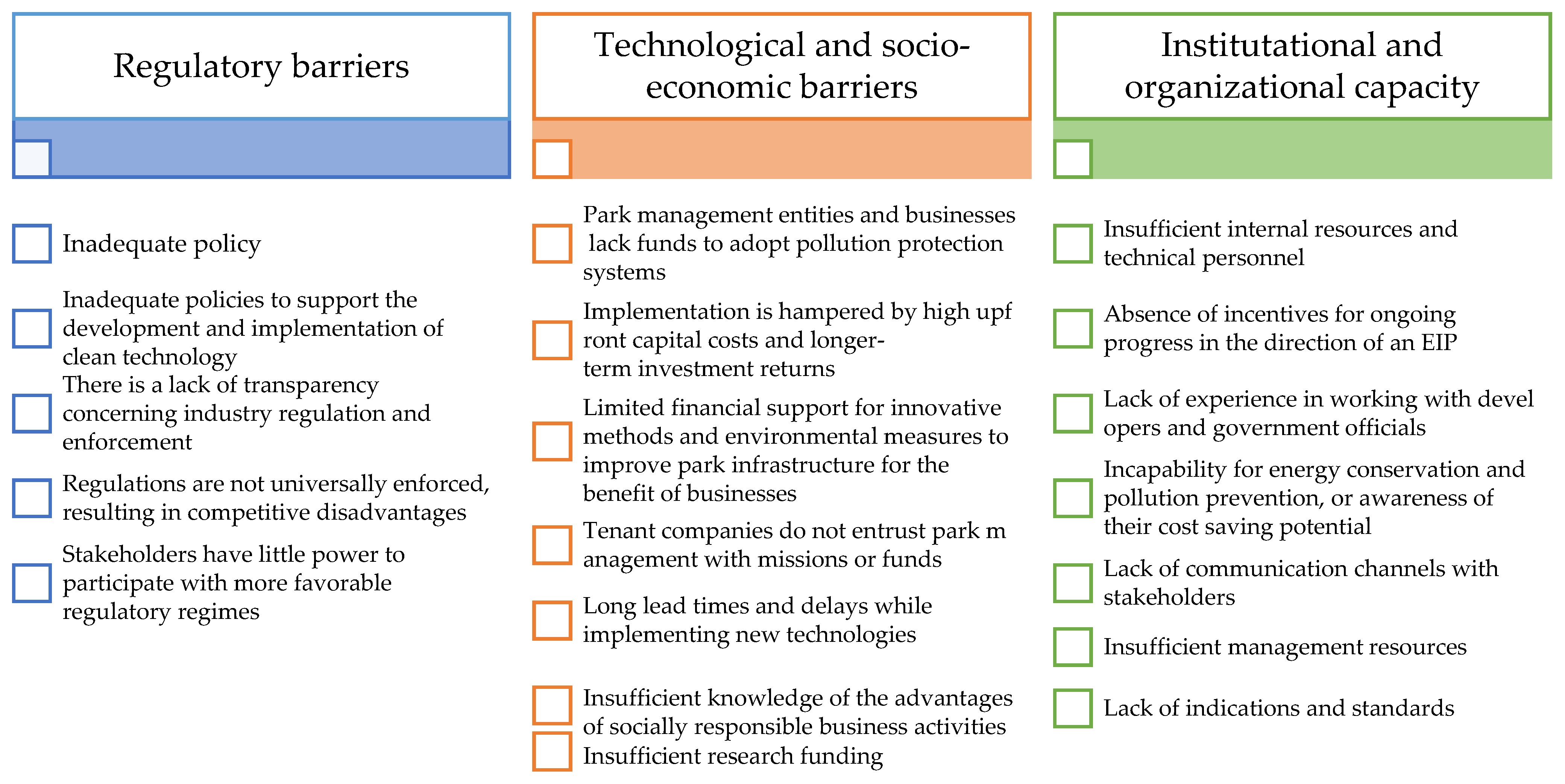

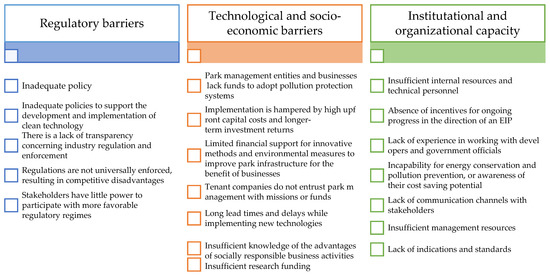

Moreover, establishing an EIP framework and strategic planning may help mitigate some of the challenges associated with its implementation. Many industrial parks have made progress toward sustainability, but only a few mature EIPs exist. As a result, park owners, operators, and businesses face various internal and external challenges, from technological limitations to poor management. An overview of some of the significant challenges for eco-industrial development, including the legislative, technological, and socioeconomic barriers and also institutional and organizational capability, are briefly discussed in Figure 2. These barriers urge different levels of parties to find solutions to foster the successful development of EIPs.

Figure 2.

Key barriers to eco-industrial parks adapted from [8].

2.2. Development of Eco-Industrial Parks

The terms “industrial symbiosis” and “EIP” are sometimes used interchangeably when considering their advantages from an environmental, social, and economic standpoint. Industrial symbiosis is a collaborative strategy in which numerous independently operating businesses collaborate to exchange waste or by-products, energy, and water in addition to sharing resources and infrastructure, which is advantageous to all parties in terms of the environment and economy [12,13,14]. Industrial symbiosis is said to be a component of EIPs [15]. Therefore, it is not surprising that many of the current EIPs feature it. As a result, they have identical goals and encounter similar obstacles to achieving environmental, social, and economic gains.

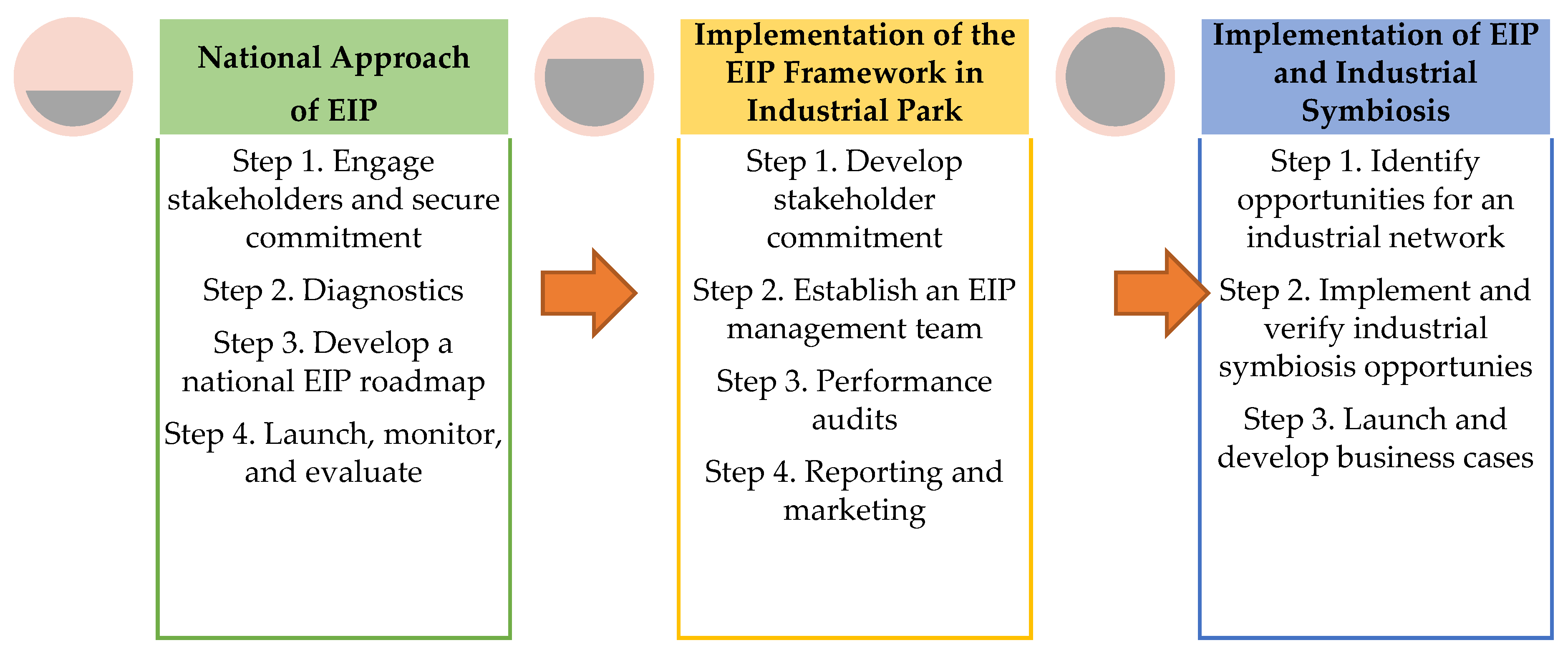

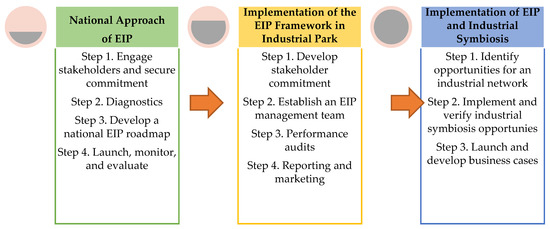

To support the framework [8], the same organizations published a practitioner’s guide [11] and practitioner’s guide toolbox [16] that indicates step-by-step explanations and a toolbox for EIP development at different levels, as depicted in Figure 3. The development of EIPs begins with the adoption of the international framework at the national level. It is then followed by the implementation of the framework at the industrial park level. Finally, the most crucial step is the implementation of industrial symbiosis. There is a wealth of literature that highlights the significant efforts made in the search for the finest tools, methodologies, and approaches to support the step of identifying opportunities for an industrial symbiosis network, including the review of industrial symbiosis tools [17,18,19], EIP optimization [20,21,22,23,24,25], and studies of industrial symbiosis fostering steps [26,27].

Figure 3.

Development steps of EIPs adapted from [11].

However, considering these huge efforts in developing EIPs, they demand a significant amount of collaboration and contributions from parties at all levels in such research institutions, industrial partners, policymakers, service providers, and others involved with high commitment. All the involved parties must give sufficient data. The most effective methods, technologies, and tools to find opportunities for an industrial symbiosis network need to be explored. Sufficient data should include access to a considerable quantity of supporting material. The information must include facts and specific information about the EIP members. As the EIP is home to a sizable number of organizations and businesses that collaborate closely, the data could have characteristics such as large volume, distributed storage, syntax heterogeneity, semantic heterogeneity, and privacy [15]. Lack of trust, unclear advantages, unfamiliarity with the concept of industrial symbiosis, and inadequate information exchange are some of the main issues that have been highlighted as impeding the development of the EIP [28,29,30]. Therefore, a technological approach to eliminate this constraint is urgently needed.

3. Industry 4.0 Technology

Industry 4.0 is a technological development that emphasizes the utilization of the internet, data exchange, and digitization to automation systems in industries. This section presents Industry 4.0 with its exponential technologies, such as blockchain and its application in industries.

3.1. Industrial Revolution 4.0

The industrial revolution or Industry 4.0 mainly refers to the integration of the internet into the industry through digitization and the interconnectivity between machines and cloud storage via a wireless connection that allows less human intervention in the decision-making process and increases efficiency as the system can work autonomously [9]. Among the core technologies that work together to make the vision of Industry 4.0 become a reality are the IoT, blockchain, artificial intelligence, augmented reality, cyber-physical systems, big-data analytics, and cloud computing [31]. The IoT is a network that connects “things” (also known as IoT devices) that are equipped with remote sensing or actuation capabilities and have the potential to share data with other connected devices and applications, either directly or indirectly [31]. The IoT presents several benefits, such as automated data and real-time collection that were previously made manually and subjected to human error, and improved productivity by increasing machine utilization, thus increasing process efficiency and reducing cost [32]. However, the increase in connectivity and automation poses some issues, as the IoT has a lack of security in its fundamental technology; thus, combining the IoT with blockchain is the best approach. The fundamental principles of blockchain technology together with its industrial applications are discussed in the following section.

3.2. Fundamental Principles of Blockchain

Blockchain technology is an excellent candidate for incorporation into industrial plants, given its primary characteristics, which include immutability, traceability, and information trustworthiness. Given the integration of blockchain and Industry 4.0, blockchain technology may increase Industry 4.0’s efficiency, security, and provenance regarding the linked data of goods, assets, and activities. Blockchain manages corporate transactions, integrates disparate systems, and increases the traceability of an individual’s assets.

Blockchain is a decentralized, shared database that stores a continuously growing log of transactions in sequential order. In other words, the data structure is a database capable of storing digital transactions, data records, and executables. Transactions are aggregated into larger structures known as blocks, which are time-stamped and cryptographically linked to previous blocks to create a chain of records that establishes the chronological order of events, or the “blockchain.” Apart from describing the data structure itself, the term is commonly used in the literature as digital consensus systems, algorithms, and application domains constructed on such architectures [33].

Blockchains run on digital networks. In such networks, data transmission is equivalent to copying data from one site to another, similar to the Bitcoin network. This is equivalent to moving digital currency from one user’s electronic wallet to another. The primary challenge is ensuring that coins are spent only once and that there is no double-spending. A central authority, such as a central bank, typically functions as a trusted intermediary between transacting parties and is responsible for storing, safeguarding, and keeping the ledger up to date. If multiple parties need to write into the ledger simultaneously, a central authority executes concurrency control and consolidates ledger modifications. On occasion, central administration may be impractical or undesirable because it incurs intermediary costs and forces network users to rely on a third party to operate the system [33]. Furthermore, since centralized systems have a single point of failure, they are more susceptible to technological errors and malicious attacks [34].

The fundamental objective of blockchain technology is to eliminate the need for middlemen and replace them with a decentralized network of digital users who collaborate to validate transactions and maintain the ledger’s integrity. In contrast to centralized systems, each participant in the blockchain network has a copy of the distributed ledger or can access it via the public cloud. Consequently, everyone on the network may access the historical log of system transactions and validate their accuracy, enabling high transparency. If central management is eliminated, it will be necessary to devise an efficient method to aggregate and synchronize multiple ledger copies. The validation and ledger consolidation processes vary depending on the type of blockchain. However, in general, network members compare their versions of the ledger intuitively, like distributed voting [35], and consensus on the correct state of the ledger is reached. Dispersed consensus algorithms are a collection of state transition rules that allows an economical set (among whom transition rights are distributed) to complete a safe state update [36]. Table 1 provides numerous examples of consensus algorithms for blockchain.

Table 1.

Blockchain consensus algorithms.

Blockchain also empowers resources through virtual smart contracts that embed autonomous agents in provenance records, quality control, and transactions [43]. Smart contracts are user-defined computer programs that regulate the ledger writing laws. Smart contracts are executable programs that modify the ledger and can be executed automatically if a predetermined condition is met, such as the parties to a transaction honoring their agreement [44]. Legal restrictions and agreement conditions are encoded in computer language along with the terms of the contract. Smart contracts are self-enforcing and tamper-proof, resulting in significant benefits, such as eliminating middlemen [45] and reducing transaction, contracting, enforcement, and compliance costs [46]. Low-value transactions can be more cost-effective, and blockchain can facilitate interoperability between transaction systems [47].

3.3. Blockchain Applications in Various Industries

Blockchain technology has proven its successful implementation in various industrial sectors, as presented in Table 2. Andoni et al. [48] conducted a thorough assessment of the literature and current business cases to enlighten the state-of-the-art and discuss the possible applications of blockchain technology in the energy sector. The study analyzed 140 blockchain research projects and companies to draw a picture of blockchains’ viability and importance in the energy sector. Moreover, Mattila et al. [49] presented a realistic perspective on how to create and illustrate blockchain use cases. Blockchain industry specialists defined six criteria for a sensible blockchain use case used to assess the feasibility of the proposed concept and its technical specifications. Simultaneously, others are exploring how blockchain technology may be used in the distributed energy market [50,51,52,53,54,55,56]. In addition, the work by Maxeiner et al. [57] has prompted a reevaluation of blockchain technology’s potential effects on the chemical industry as industries with high capital expenditures. Industrial symbiosis is among the blockchain case studies in the chemical industry. However, the discussion is very general and limited to the blockchain properties only.

Table 2.

Blockchain applications in various sectors adapted from [57].

4. The Potential Application of Blockchain Technology on EIP Development

This section presents the potential application of blockchain technology in EIP development that covers the combination of Industry 4.0 and blockchain technology, the blockchain fit assessment framework, and the blockchain-based data management platform concept with an illustration model.

4.1. Combination of Industry 4.0 and Blockchain Technology

Data management and connectivity through digitization are the key similarities between Industry 4.0 and blockchain technology. Recent literature combining Industry 4.0 and blockchain technology in general [58] and various applications, such as health care [59], supply chain management [60], automotive supply chain [61], manufacturing [62,63], and specifically combining IoT and blockchain technology prior to the application [64,65]. Earlier, Pan et al. [66] suggested that blockchain technology might assist with integrating Industry 4.0 into EIPs. Hence, combining IoT and blockchain technology into an EIP would be a perfect companion to foster industrial symbiosis.

The IoT allows for the exchange of data between diverse workplaces in a seamless manner. Real-time monitoring systems and data transfer have the potential to optimize and boost productivity, improve product quality, and help businesses become more intelligent and effective [67]. However, for the IoT to develop quickly, there are still technological difficulties to tackle, such as interoperability, security, data analysis and transmission, and information technology (IT) and operation technology (OT) convergence. One of the main challenges is security vulnerability [58].

Thus, this suggests blockchain is the ideal solution for the issue, as it is a distributed, point-to-point, real-time ledger with no central authority. Users can only access and edit the blocks for which they have the private key. Each block is linked to the preceding and next block, and the chain is updated every time [68]. It is hard or impossible to change or delete blocks on the blockchain ledger, hence securing communication and transactions.

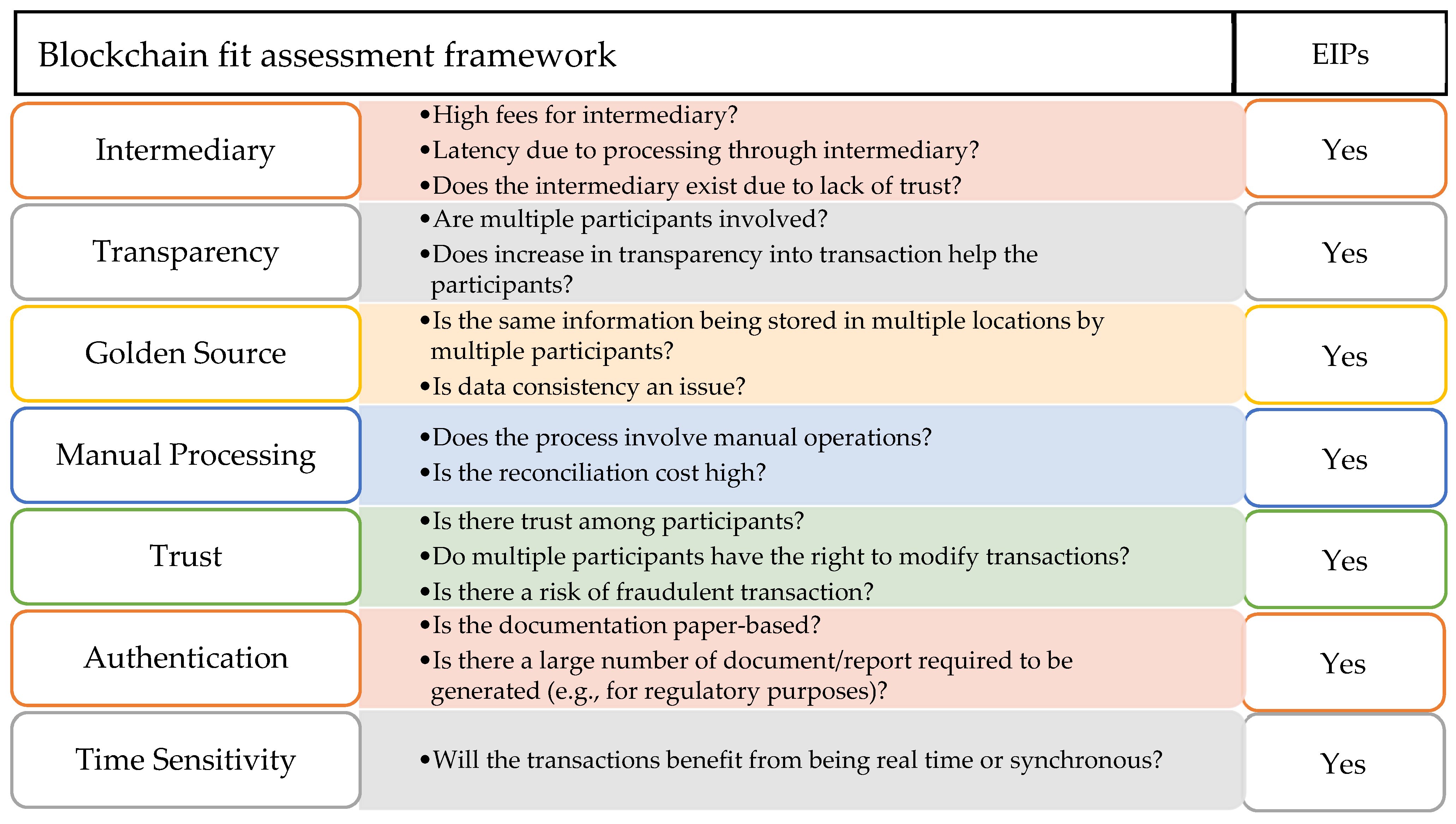

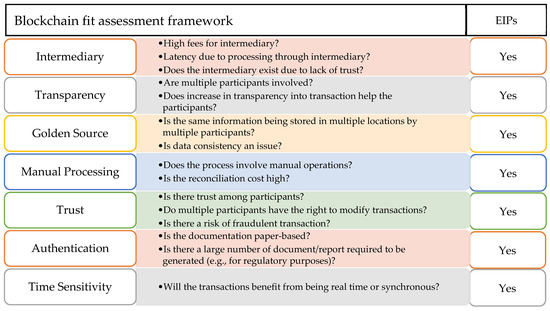

4.2. Blockchain Fit Assessment Framework

The potential application of blockchain in particular sectors can be determined by its fit assessment framework. Greater security, censorship resistance, and transparency are just a few ways blockchain technologies might benefit various uses and applications [35]. The question of whether blockchains are the appropriate technology to handle the challenges of a particular application emerges upon investigating the potential of applying blockchain techniques to that application’s domain. Reviewing the EIP framework, specifically on the critical barriers alongside the attributes of blockchain and its fit assessment framework [69,70], allows one to assess the technology’s potential for use in this setting. As can be seen in Figure 4, a potential partnership exists between blockchain technology and EIP. A blockchain-based solution will benefit in circumstances where there is a need for transactions between many parties with varying degrees of trust, as in an EIP. This technology can be used wherever the exact transaction details are being maintained in several places, such as different databases. Timeliness of data, reconciliation costs, the need for data security, and the need for authentication are all factors in determining whether a blockchain solution is a good fit for EIP development.

Figure 4.

The potential fit of blockchain and eco-industrial parks.

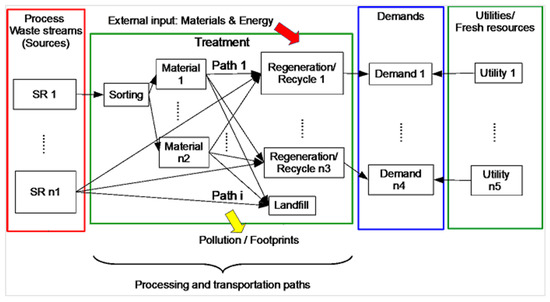

EIP is a variation of a symbiosis network where secondary resources originating from process waste/side products are delivered to process sinks, as discussed in [71]. This is a clear source-sink mapping with possible intermediate processing to adjust the properties of some source streams to match sink requirements, as in Figure 5. The intermediate processing, besides material treatment, may also take the form of energy extraction at various quality levels. The delivery and processing of the secondary raw materials from the sources to the sinks are associated with certain use of energy and auxiliary materials, resulting in some contribution to the footprints tracked within the EIP. The main premise for performing such resource reuse is that the rates of resource intake and footprint contribution of the auxiliary processes are smaller than those for supplying the required streams to the sinks from virgin resources.

Figure 5.

Source-sink mapping with the intermediate process adapted from [71].

As a result of that setup, the EIP forms a network of processes for the transformation and transportation of a set of process streams-both material and energy. Each of the processes and the operations would change the properties of the streams, adding or removing embodied content, e.g., using available energy/exergy or adding embodied GHG Footprint or Water footprint. The operations also inevitably incur certain costs.

Based on the analysis above, the resource transformation and exchange network possess several distinct properties:

- Each operation-transformation or transportation, defines a new state as its outcome.

- Each state defines a set of values for the tracked indicators for the operation outputs.

- Typically, such a set would include the price (or monetary value) of the streams, cost (combining the costs of the main and the auxiliary inputs); Embodied Footprints (e.g., GHG or Water). Other quantities may be tracked, most notably any residual exergy potential or contents of valuable components (e.g., N or P).

This networked set of operations, states, contributions, and values make blockchain technology a very suitable candidate for recording such operations and the transactions based on them. Regardless of the form of the EIP, be it a single separate company or a cooperative of the participating EIP businesses, the technology would establish the right combination of high trustworthiness and detail of the value chain data.

4.3. Blockchain-Based EIP Data Management Platform Concept

A blockchain-based data management platform is one of the potential applications of blockchain in the EIP. The immutability, tamper-proof, transparency, and decentralization of the data storage made possible by blockchain technology make it well suited for the traceability of the resource exchange transaction as a data management platform in the EIP. Additionally, it is possible to specify criteria that must first be satisfied using smart contracts before a transfer can be completed. In this manner, the payment is automated and optimized, as payment reductions can be programmed if not all contract criteria have been satisfied. In other words, the payment is optimized in addition to being automated. A recent study on this automation concept by Krohling et al. [72] employed automated negotiations as a reliable tool to negotiate and enforce term exchange as a peer-to-peer market for utility exchanges in the EIP.

The data management platform should consider the preassessment time, which involves identifying opportunities for industrial symbiosis networks, the monitoring and operation time, and the postassessment time in the development of the EIP. The platform acts as a data-collecting platform and serves as a database platform at the park level during the preassessment period, allowing all stakeholders, particularly industries, to give data on the flow of materials, energy, and waste. The material target, prefeasibility analysis, identification of receiving and supplying enterprises, and network optimization of industrial symbiosis could all be conducted using these data. The platform’s blockchain architecture ensures that the data are secure and immutable, allowing for its storage as subsequent development processes of an EIP might take longer than expected.

The platform can be further utilized as a platform for an industrial symbiosis network or as a resource-sharing platform for monitoring and operating the EIP. Furthermore, it can be used to store every transactional record involving the stakeholders in a tamper-proof manner. As part of the post-evaluation of the EIP, the platform might be used to examine the EIP’s performance because the performance requirements are a crucial indicator of the implementation’s success and future development. Moreover, as the data from EIP participants are in the platform from the beginning, evaluation of the key performance indicator requirements of the EIP is made easy and reliable.

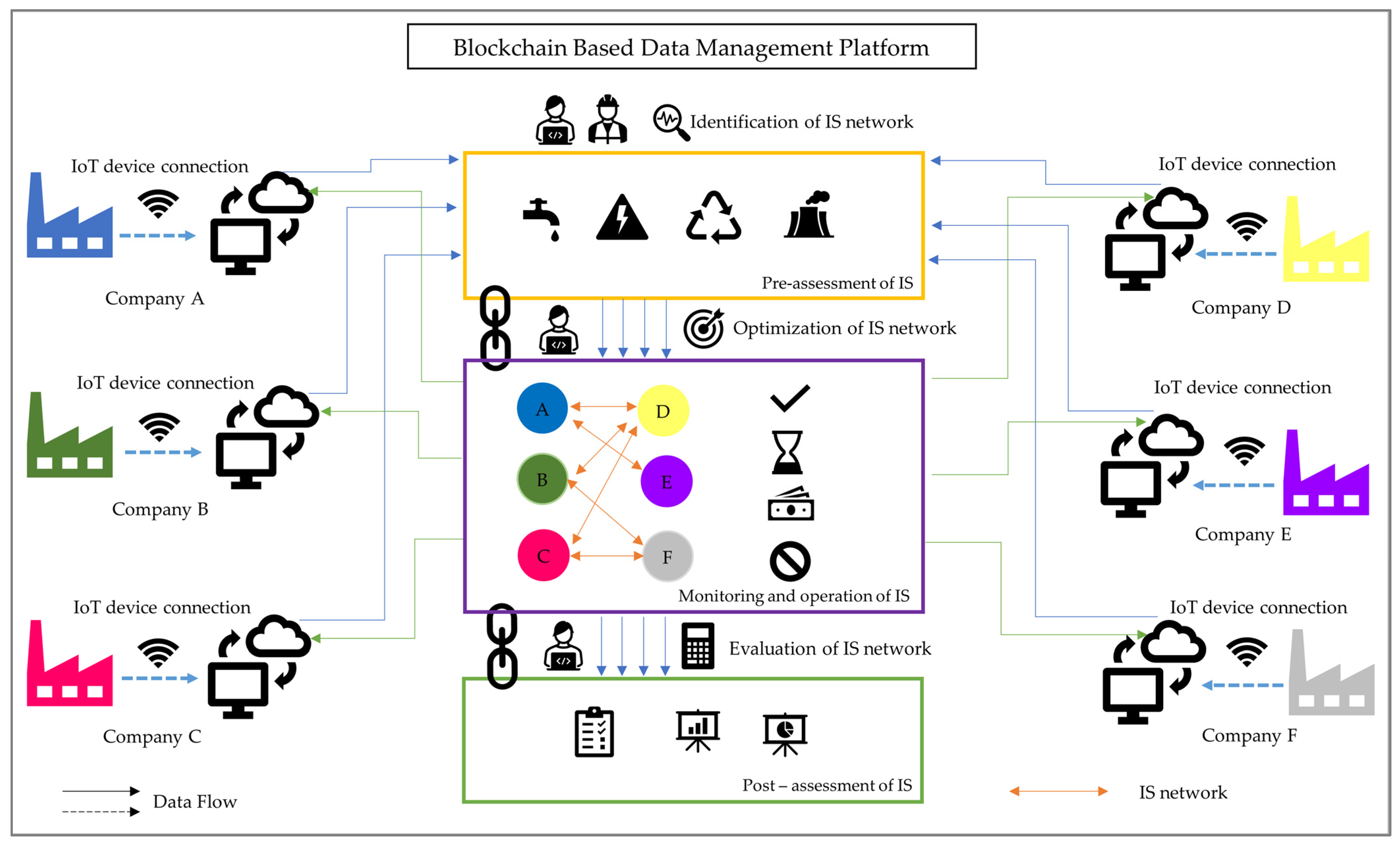

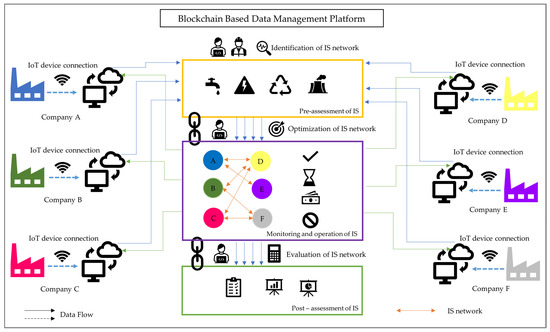

4.4. Blockchain-Based EIP Data Management Platform Illustration Model

An illustration model of the blockchain-based data management platform for an EIP is presented in Figure 6. The model consists of six industrial tenants or companies (companies A–F) at a particular industrial park and a data management platform. Devices with IoT connections are installed at each company to record and store the data of waste generated, emissions, and extra resources (e.g., water and energy) for sharing purposes in their cloud database. The IoT devices could be smart sensors, smart meters, or other types of IoT devices that can receive and share data with cloud storage via an internet connection. The databases are then connected and synced to a blockchain-based data management platform. The administration of the platform could be an appointed industrial park manager as agreed upon by all the tenants. The platform consists of three main layers based on the application.

Figure 6.

Blockchain-based EIP data management platform illustration model.

The first layer would be served during the potential industrial symbiosis network identification or preassessment time. The wastes generated and resource data will be shared in public and accessible to all the tenants as an advertisement and open for sharing. Company A to Company F will share their types and the amount of waste generated together with their extra resources, such as extra heat or water or even their emissions, in this layer of the platform. A potential industrial symbiosis network can then be identified as interested companies will contact each other through the same platform and create mutual understanding on the industrial symbiosis network afterward. The data can also be shared with researchers or research institutions for optimization studies and create more opportunities for resource sharing among the companies. As the recorded data system is based on blockchain architecture, the security of data is secure, as it is tamper-proof and immutable, especially in the process of building the connection between companies, where setting up the industrial symbiosis network and infrastructure might be time-consuming.

The second layer will only be utilized during the operation and monitoring of industrial symbiosis after the optimized industrial symbiosis network is created. Nevertheless, this layer is the most important, as the operation and monitoring of industrial symbiosis in a transparent and decentralized manner can foster the success of the EIP. All companies can view their industrial symbiosis network, exchange information, and create strong relationships using this layer apart from operation and monitoring, and a simple illustration is shown in Figure 6. During the operation of industrial symbiosis, the companies will conduct their online transaction of resources exchange and payment as blockchain has its currency known as cryptocurrency. The decentralized concept is that companies have control over their money and time without relying on the central bank to process the payment on the resource-exchange transaction, which might have some delay. Furthermore, the transaction’s status is updated, and operations can also be made automatically via the function of the smart contract. As mentioned previously, a smart contract is an executable computer program that allows the action to be completed when the conditions are met. The smart contract can be written based on mutual agreement between the companies through a memorandum of agreement. Blockchain technology again contributes to all the recorded transactions in a transparent manner and eases the monitoring of the operation of industrial symbiosis, hence eliminating the lack of trust issues among the companies in the EIP.

The third layer of the data management platform will be used in the post-assessment time of industrial symbiosis for the continuous development of the EIP. The environmental, economic, and social performance of the EIP is evaluated in this layer. The amount of greenhouse gas emissions reduction and the percentage of resources shared with the cost saving due to the industrial symbiosis network are among the key performance indicators that can be recorded using this layer. Since the blockchain is recorded in a “block” and “chain” manner, the data are continuously stored from the beginning of industrial symbiosis identification. Optimization, operation, and monitoring of industrial symbiosis, as well as post-evaluation of industrial symbiosis as immutable, tamper-proof, transparent, and secure ways, allow this technology to assist the development of EIP efficiently.

5. Conclusions

The development of an EIP that promotes a circular economy provides a solution for better environmental, economic, and social growth. The development involves long-term steps that demand huge efforts and commitment from various stakeholders. However, the development process faces various technological and socioeconomic barriers. Specifically, the lack of trust, privacy-related, and data security are among the key challenges in EIP development. The emergence of Industry 4.0 could potentially help resolve the challenges. Integration of blockchain technology into EIP development provides numerous advantages through digitization, automation, immutable, transparent, and tamper-proof architecture. Blockchain-based data management platforms supported by IoT connections could be one of the potential applications of these technologies in the EIP. The platform could prove to be a vital tool in the development of EIPs, as the process comprises numerous steps and high heterogeneity, depending on the industrial sectors.

Notwithstanding their huge potential, integration of the EIP concept and blockchain technology is still in its early stages of development and requires ample research and development efforts for its successful implementation. It is hoped that the review of the EIP concepts in the context of integration with blockchain and IoT and the proposed data management platform would pave the way for further development in the same direction. Further developments of the proposed data management platform require investigations and search for suitable blockchain consensus algorithms to be used, the data network framework for global implementation, the synchronization between the IoT platform and blockchain architecture, and others. Finally, the optimum settings for a combination of blockchain technologies with other Industry 4.0 technologies, such as digital twinning [73,74], cyber-physical systems [75], and the IoT [76] in EIP development, need to be explored.

Author Contributions

S.N.A.A.T.: original draft preparation. S.R.W.A.: conceptualization, project administration, supervision. Z.A.M. and P.S.V.: validation, review, and editing. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Universiti Teknologi Malaysia (UTM) via grant Q.J.130000.2409.08G86.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The authors acknowledge Universiti Teknologi Malaysia (UTM) for funding the research work related to this paper via grant Q.J130000.2409.08G86, UTM Prominent Visiting Researcher Scheme, the Malaysia Ministry of High Education and Universiti Malaysia Perlis under SLAB/SLAI scheme for financial sponsorship of the first author’s doctoral degree studies.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Dong, H.; Ohnishi, S.; Fujita, T.; Geng, Y.; Fujii, M.; Dong, L. Achieving Carbon Emission Reduction through Industrial & Urban Symbiosis: A Case of Kawasaki. Energy 2014, 64, 277–286. [Google Scholar] [CrossRef]

- Liu, X.; Bae, J. Urbanization and Industrialization Impact of CO2 Emissions in China. J. Clean Prod. 2018, 172, 178–186. [Google Scholar] [CrossRef]

- Guan, Y.; Huang, G.; Liu, L.; Zhai, M.; Zheng, B. Dynamic Analysis of Industrial Solid Waste Metabolism at Aggregated and Disaggregated Levels. J. Clean Prod. 2019, 221, 817–827. [Google Scholar] [CrossRef]

- Luzi, A.; Marilungo, E.; Germani, M. Development of a Methodology to Analyze Energy and Resources Consumption along the Product Value Chain. In Proceedings of the Procedia CIRP; Elsevier: Cambridge, UK, 2015; Volume 33, pp. 145–150. [Google Scholar]

- Minelgaitė, A.; Liobikienė, G. Waste Problem in European Union and Its Influence on Waste Management Behaviours. Sci. Total Environ. 2019, 667, 86–93. [Google Scholar] [CrossRef]

- Haraguchi, N.; Martorano, B.; Sanfilippo, M. What Factors Drive Successful Industrialization? Evidence and Implications for Developing Countries. Struct. Change Econ. Dyn. 2019, 49, 266–276. [Google Scholar] [CrossRef]

- Neves, A.; Godina, R.; Azevedo, S.G.; Matias, J.C.O. A Comprehensive Review of Industrial Symbiosis. J. Clean Prod. 2020, 247. [Google Scholar] [CrossRef]

- United Nations Industrial Development Organization UNIDO; Work Bank Group. GIZ—An International Framework for Eco-Industrial Parks. Available online: https://openknowledge.worldbank.org/handle/10986/35110 (accessed on 21 October 2022).

- Nakamoto, S. Bitcoin: A Peer-to-Peer Electronic Cash System. Available online: https://bitcoin.org/bitcoin.pdf (accessed on 30 October 2022).

- Muftic, S.; Sanchez, I. Overview and Analysis of the Concept and Applications of Virtual Currencies. Available online: https://publications.jrc.ec.europa.eu/repository/handle/JRC105207 (accessed on 30 October 2022).

- United Nations Industrial Development Organization UNIDO; World Bank Group; GIZ; Ministry of Trade, Industry and Energy. A Practitioner’s Handbook for Eco-Industrial Parks. Available online: https://openknowledge.worldbank.org/handle/10986/30458 (accessed on 22 October 2022).

- Lowe, E.A.; Evans, L.K. Industrial Ecology and Industrial Ecosystems. J. Clean Prod. 1995, 3, 47–53. [Google Scholar] [CrossRef]

- Chertow, M.R. Industrial Symbiosis: Literature and Taxonomy, Annual Review of Energy and Environmen. Annu. Rev. Energy Environ. 2000, 25, 313–337. [Google Scholar] [CrossRef]

- Schwarz, E.J.; Steininger, K.W. Implementing Nature’s Lesson: The Industrial Recycling Network Enhancing Regional Development. J. Clean Prod. 1997, 5, 47–56. [Google Scholar] [CrossRef]

- Zhou, L.; Zhang, C.; Karimi, I.A.; Kraft, M. An Ontology Framework towards Decentralized Information Management for Eco-Industrial Parks. Comput. Chem. Eng. 2018, 118, 49–63. [Google Scholar] [CrossRef]

- United Nations Industrial Development Organization UNIDO; World Bank Group; GIZ; Ministry of Trade, Industry and Energy. A Practitioner’s Handbook for Eco-Industrial Parks: Toolbox. Available online: https://openknowledge.worldbank.org/handle/10986/31456 (accessed on 22 October 2022).

- Kastner, C.A.; Lau, R.; Kraft, M. Quantitative Tools for Cultivating Symbiosis in Industrial Parks; a Literature Review. Appl. Energy 2015, 155, 599–612. [Google Scholar] [CrossRef]

- Azevedo, J.; Ferreira, I.; Dias, R.; Ascenço, C.; Magalhães, B.; Henriques, J.; Iten, M.; Cunha, F. Industrial Symbiosis Implementation Potential—An Applied Assessment Tool for Companies. Sustainability 2021, 13, 1420. [Google Scholar] [CrossRef]

- Lawal, M.; Wan Alwi, S.R.; Manan, Z.A.; Ho, W.S. Industrial Symbiosis Tools—A Review. J. Clean Prod. 2021, 280, 124327. [Google Scholar] [CrossRef]

- Boix, M.; Montastruc, L.; Azzaro-Pantel, C.; Domenech, S. Optimization Methods Applied to the Design of Eco-Industrial Parks: A Literature Review. J. Clean Prod. 2015, 87, 303–317. [Google Scholar] [CrossRef]

- Kuznetsova, E.; Zio, E.; Farel, R. A Methodological Framework for Eco-Industrial Park Design and Optimization. J. Clean Prod. 2016, 126, 308–324. [Google Scholar] [CrossRef]

- Valenzuela-Venegas, G.; Vera-Hofmann, G.; Díaz-Alvarado, F.A. Design of Sustainable and Resilient Eco-Industrial Parks: Planning the Flows Integration Network through Multi-Objective Optimization. J. Clean Prod. 2020, 243, 118610. [Google Scholar] [CrossRef]

- Misrol, M.A.; Alwi, S.R.W.; Lim, J.S.; Manan, Z.A. Multi-Objective Optimization of an Integrated Energy-Water-Waste Nexus for Eco-Industrial Park. Chem. Eng. Trans. 2021, 89, 349–354. [Google Scholar] [CrossRef]

- Ramos, M.A.; Rocafull, M.; Boix, M.; Aussel, D.; Montastruc, L.; Domenech, S. Utility Network Optimization in Eco-Industrial Parks by a Multi-Leader Follower Game Methodology. Comput. Chem. Eng. 2018, 112, 132–153. [Google Scholar] [CrossRef]

- Leong, Y.T.; Lee, J.Y.; Tan, R.R.; Foo, J.J.; Chew, I.M.L. Multi-Objective Optimization for Resource Network Synthesis in Eco-Industrial Parks Using an Integrated Analytic Hierarchy Process. J. Clean Prod. 2017, 143, 1268–1283. [Google Scholar] [CrossRef]

- Jayakrishna, K.; Vibha, M.; Jain, S.; Kulatunga, A.K. Fostering Systematic Eco-Innovation in an Industrial Symbiosis Environment Using DEMATEL. Int. J. Ind. Syst. Engineering 2020, 34, 20–42. [Google Scholar] [CrossRef]

- Jato-Espino, D.; Ruiz-Puente, C. Bringing Facilitated Industrial Symbiosis and Game Theory Together to Strengthen Waste Exchange in Industrial Parks. Sci. Total Environ. 2021, 771, 145400. [Google Scholar] [CrossRef] [PubMed]

- Park, J.; Duque-Hernández, J.; Díaz-Posada, N. Facilitating Business Collaborations for Industrial Symbiosis: The Pilot Experience of the Sustainable Industrial Network Program in Colombia. Sustainability 2018, 10, 3637. [Google Scholar] [CrossRef]

- Golev, A.; Corder, G.D.; Giurco, D.P. Barriers to Industrial Symbiosis: Insights from the Use of a Maturity Grid. J. Ind. Ecol. 2015, 19, 141–153. [Google Scholar] [CrossRef]

- Walls, J.L.; Paquin, R.L. Organizational Perspectives of Industrial Symbiosis: A Review and Synthesis. Organ Env. 2015, 28, 32–53. [Google Scholar] [CrossRef]

- Shrivastava, A.; Murali Krishna, K.; Lal Rinawa, M.; Soni, M.; Ramkumar, G.; Jaiswal, S. Inclusion of IoT, ML, and Blockchain Technologies in Next Generation Industry 4.0 Environment. Mater. Today Proc. 2021. [Google Scholar] [CrossRef]

- Patrick Lemay Advantages of Industrial IoT For Manufacturers: The 5 Key Benefits of IIoT. Available online: https://tulip.co/blog/benefits-of-industrial-iot/ (accessed on 27 November 2022).

- James, C.; William, H.S.; Susan, L. Donegan Blockchain Technology: Opportunities and Risks. Available online: https://legislature.vermont.gov/assets/Legislative-Reports/blockchain-technology-report-final.pdf (accessed on 26 October 2022).

- Armbrust, M.; Fox, A.; Griffith, R.; Joseph, A.D.; Katz, R.; Konwinski, A.; Lee, G.; Patterson, D.; Rabkin, A.; Stoica, I.; et al. A View of Cloud Computing. Commun. ACM 2010, 53, 50–58. [Google Scholar] [CrossRef]

- Mattila, J.; On, B.R. The Blockchain Phenomenon-The Disruptive Potential of Distributed Consensus Architectures. Available online: https://brie.berkeley.edu/sites/default/files/juri-mattila-.pdf (accessed on 26 October 2022).

- Sikorski, J.J.; Haughton, J.; Kraft, M. Blockchain Technology in the Chemical Industry: Machine-to-Machine Electricity Market. Appl. Energy 2017, 195, 234–246. [Google Scholar] [CrossRef]

- Back, A. Hashcash-A Denial of Service Counter-Measure. Available online: http://www.hashcash.org/hashcash.pdf (accessed on 25 October 2022).

- Pilkington, M. Blockchain Technology: Principles and Applications. Res. Handb. Digit. Transform. 2015, 11, 1–39. [Google Scholar]

- Lamport, L.; Shostak, R.; Pease, M. The Byzantine Generals Problem. ACM Trans. Program. Lang. Syst. 1982, 4, 382–401. [Google Scholar] [CrossRef]

- Amy Castor A (Short) Guide to Blockchain Consensus Protocols. Available online: https://www.coindesk.com/markets/2017/03/04/a-short-guide-to-blockchain-consensus-protocols/ (accessed on 25 October 2022).

- Mazieres, D. The Stellar Consensus Protocol: A Federated Model for Internet-Level Consensus. Available online: http://www.scs.stanford.edu/17au-cs244b/notes/scp.pdf (accessed on 26 October 2022).

- JB Buntinx What Is Proof of Elapsed Time? Available online: https://themerkle.com/what-is-proof-of-elapsed-time/ (accessed on 30 October 2022).

- Da Silva, T.B.; de Morais, E.S.; de Almeida, L.F.F.; da Rosa Righi, R.; Alberti, A.M. Blockchain and Industry 4.0: Overview, Convergence, and Analysis. In Blockchain Technology for Industry 4.0: Secure, Decentralized, Distributed and Trusted Industry Environment; da Rosa Righi, R., Alberti, A.M., Singh, M., Eds.; Springer: Singapore, 2020; pp. 27–58. ISBN 978-981-15-1137-0. [Google Scholar]

- Swan, M. Blockchain: Blueprint for a New Economy; O’Reilly: Springfield, MO, USA, 2015; ISBN 9781491920497. [Google Scholar]

- Grewal-Carr, V.; Marshall, S. Blockchain Enigma. Paradox. Opportunity. Available online: https://www2.deloitte.com/content/dam/Deloitte/uk/Documents/Innovation/deloitte-uk-blockchain-full-report.pdf (accessed on 30 October 2022).

- Hancock, M.; Vaizey, E. Distributed Ledger Technology: Beyond Block Chain. Available online: https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/492972/gs-16-1-distributed-ledger-technology.pdf (accessed on 25 October 2022).

- Guo, Y.; Liang, C. Blockchain Application and Outlook in the Banking Industry. J. Financ. Innov. 2016, 2, 1–24. [Google Scholar]

- Andoni, M.; Robu, V.; Flynn, D.; Abram, S.; Geach, D.; Jenkins, D.; McCallum, P.; Peacock, A. Blockchain Technology in the Energy Sector: A Systematic Review of Challenges and Opportunities. Renew. Sustain. Energy Rev. 2019, 100, 143–174. [Google Scholar] [CrossRef]

- Mattila, J.; Seppälä, T.; Naucler, C.; Stahl, R.; Tikkanen, M.; Bådenlid, A.; Seppälä, J. Industrial Blockchain Platforms: An Exercise in Use Case Development in the Energy Industry. Available online: https://www.etla.fi/wp-content/uploads/ETLA-Working-Papers-43.pdf (accessed on 14 December 2022).

- Capper, T.; Gorbatcheva, A.; Mustafa, M.A.; Bahloul, M.; Schwidtal, J.M.; Chitchyan, R.; Andoni, M.; Robu, V.; Montakhabi, M.; Scott, I.J.; et al. Peer-to-Peer, Community Self-Consumption, and Transactive Energy: A Systematic Literature Review of Local Energy Market Models. Renew. Sustain. Energy Rev. 2022, 162, 112403. [Google Scholar] [CrossRef]

- Moret, F.; Tosatto, A.; Baroche, T.; Pinson, P. Loss Allocation in Joint Transmission and Distribution Peer-to-Peer Markets. IEEE Trans. Power Syst. 2021, 36, 1833–1842. [Google Scholar] [CrossRef]

- Chakraborty, S.; Baarslag, T.; Kaisers, M. Automated Peer-to-Peer Negotiation for Energy Contract Settlements in Residential Cooperatives. Appl. Energy 2020, 259, 114173. [Google Scholar] [CrossRef]

- Khorasany, M.; Mishra, Y.; Ledwich, G. A Decentralized Bilateral Energy Trading System for Peer-to-Peer Electricity Markets. IEEE Trans. Ind. Electron. 2020, 67, 4646–4657. [Google Scholar] [CrossRef]

- Sorin, E.; Bobo, L.; Pinson, P. Consensus-Based Approach to Peer-to-Peer Electricity Markets with Product Differentiation. IEEE Trans. Power Syst. 2019, 34, 994–1004. [Google Scholar] [CrossRef]

- Bai, L.; Crisostomiy, E. Distribution Loss Allocation in Peer-to-Peer Energy Trading in a Network of Microgrids. In Proceedings of the IEEE Power and Energy Society General Meeting, Montreal, QC, Canada, 2–6 August 2020. [Google Scholar]

- Yu, V.F.; Le, T.H.A.; Gupta, J.N.D. Sustainable Microgrid Design with Multiple Demand Areas and Peer-to-Peer Energy Trading Involving Seasonal Factors and Uncertainties. Renew. Sustain. Energy Rev. 2022, 161, 112342. [Google Scholar] [CrossRef]

- Maxeiner, L.S.; Martini, J.-P.; Sandner, P. FSBC Working Paper Blockchain in the Chemical Industry. Available online: http://explore-ip.com/2017_Blockchain-Technology-in-Manufacturing.pdf (accessed on 14 December 2022).

- Aoun, A.; Ilinca, A.; Ghandour, M.; Ibrahim, H. A Review of Industry 4.0 Characteristics and Challenges, with Potential Improvements Using Blockchain Technology. Comput. Ind. Eng. 2021, 162, 107746. [Google Scholar] [CrossRef]

- Qahtan, S.; Yatim, K.; Zulzalil, H.; Osman, M.H.; Zaidan, A.A.; Alsattar, H.A. Review of Healthcare Industry 4.0 Application-Based Blockchain in Terms of Security and Privacy Development Attributes: Comprehensive Taxonomy, Open Issues and Challenges and Recommended Solution. J. Netw. Comput. Appl. 2023, 209, 103529. [Google Scholar] [CrossRef]

- Esmaeilian, B.; Sarkis, J.; Lewis, K.; Behdad, S. Blockchain for the Future of Sustainable Supply Chain Management in Industry 4.0. Resour. Conserv. Recycl. 2020, 163, 105064. [Google Scholar] [CrossRef]

- Ada, N.; Ethirajan, M.; Kumar, A.; Vimal, K.E.K.; Nadeem, S.P.; Kazancoglu, Y.; Kandasamy, J. Blockchain Technology for Enhancing Traceability and Efficiency in Automobile Supply Chain—A Case Study. Sustainability 2021, 13, 13667. [Google Scholar] [CrossRef]

- Leng, J.; Ruan, G.; Jiang, P.; Xu, K.; Liu, Q.; Zhou, X.; Liu, C. Blockchain-Empowered Sustainable Manufacturing and Product Lifecycle Management in Industry 4.0: A Survey. Renew. Sustain. Energy Rev. 2020, 132, 110112. [Google Scholar] [CrossRef]

- Espinoza Pérez, A.T.; Rossit, D.A.; Tohmé, F.; Vásquez, Ó.C. Mass Customized/Personalized Manufacturing in Industry 4.0 and Blockchain: Research Challenges, Main Problems, and the Design of an Information Architecture. Inf. Fusion 2022, 79, 44–57. [Google Scholar] [CrossRef]

- Qian, Y.; Jiang, Y.; Chen, J.; Zhang, Y.; Song, J.; Zhou, M.; Pustišek, M. Towards Decentralized IoT Security Enhancement: A Blockchain Approach. Comput. Electr. Eng. 2018, 72, 266–273. [Google Scholar] [CrossRef]

- Wang, Q.; Zhu, X.; Ni, Y.; Gu, L.; Zhu, H. Blockchain for the IoT and Industrial IoT: A Review. Internet Things 2019, 10, 100081. [Google Scholar] [CrossRef]

- Pan, M.; Sikorski, J.; Kastner, C.A.; Akroyd, J.; Mosbach, S.; Lau, R.; Kraft, M. Applying Industry 4.0 to the Jurong Island Eco-Industrial Park. Energy Procedia 2015, 75, 1536–1541. [Google Scholar] [CrossRef]

- Mustapha Zaouini Nine Challenges of Industry 4.0. Available online: https://iiot-world.com/connected-industry/nine-challenges-of-industry-4-0/ (accessed on 27 November 2022).

- Hiroshi Watanabe Can Blockchain Protect Internet-of-Things? Available online: https://arxiv.org/ftp/arxiv/papers/1807/1807.06357.pdf (accessed on 27 November 2022).

- Baru, S.; Udgirkar, V.; Mishra, D. Blockchain in Public Sector Transforming Government Services through Exponential Technologies. Available online: https://www2.deloitte.com/content/dam/Deloitte/in/Documents/public-sector/in-ps-blockchain-noexp.pdf (accessed on 30 October 2022).

- Deloitte Blockchain Fit Assessement Framework. Available online: https://www2.deloitte.com/content/dam/Deloitte/in/Documents/industries/in-convergence-blockchain-fitment-noexp.pdf (accessed on 30 October 2022).

- Gai, L.; Varbanov, P.S.; van Fan, Y.; Klemeš, J.J.; Romanenko, S.V. Trade-Offs between the Recovery, Exergy Demand and Economy in the Recycling of Multiple Resources. Resour. Conserv. Recycl. 2021, 167, 105428. [Google Scholar] [CrossRef]

- Kröhling, D.E.; Mione, F.; Hernández, F.; Martínez, E.C. A Peer-to-Peer Market for Utility Exchanges in Eco-Industrial Parks Using Automated Negotiations. Expert Syst. Appl. 2022, 191, 116211. [Google Scholar] [CrossRef]

- Haag, S.; Anderl, R. Digital Twin—Proof of Concept. Manuf. Lett. 2018, 15, 64–66. [Google Scholar] [CrossRef]

- Nielsen, C.P.; da Silva, E.R.; Yu, F. Digital Twins and Blockchain—Proof of Concept. Procedia CIRP 2020, 93, 251–255. [Google Scholar] [CrossRef]

- Lee, J.; Bagheri, B.; Kao, H.A. A Cyber-Physical Systems Architecture for Industry 4.0-Based Manufacturing Systems. Manuf. Lett. 2015, 3, 18–23. [Google Scholar] [CrossRef]

- Xie, H.; Zheng, J.; He, T.; Wei, S.; Hu, C. TEBDS: A Trusted Execution Environment-and-Blockchain-Supported IoT Data Sharing System. Future Gener. Comput. Syst. 2022, 140, 321–330. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).