Cost Analysis of Implementing In-Pipe Hydro Turbine in the United Arab Emirates Water Network

Abstract

:1. Introduction

2. Materials and Methods

2.1. In-Pipe Hydropower Plant Capacity

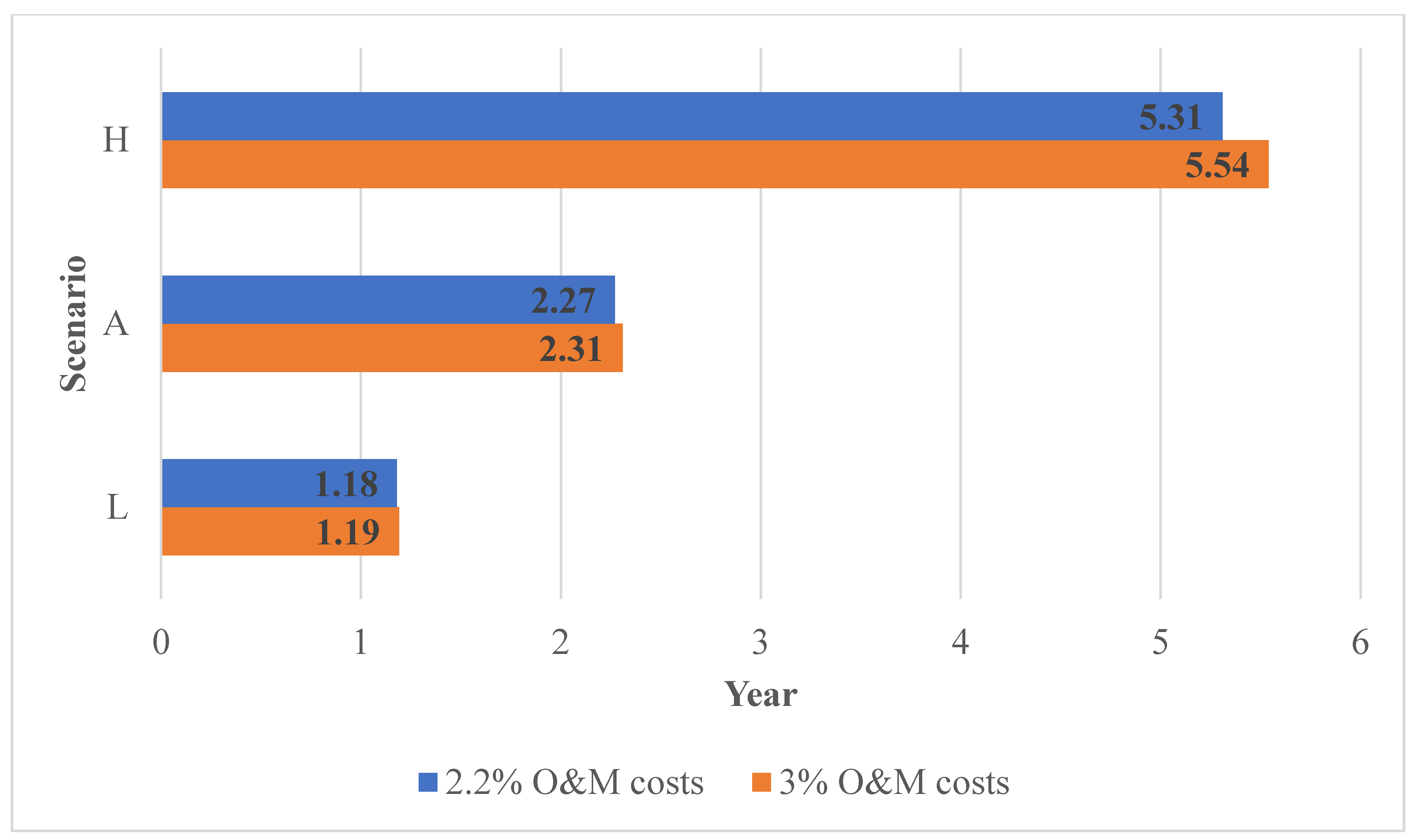

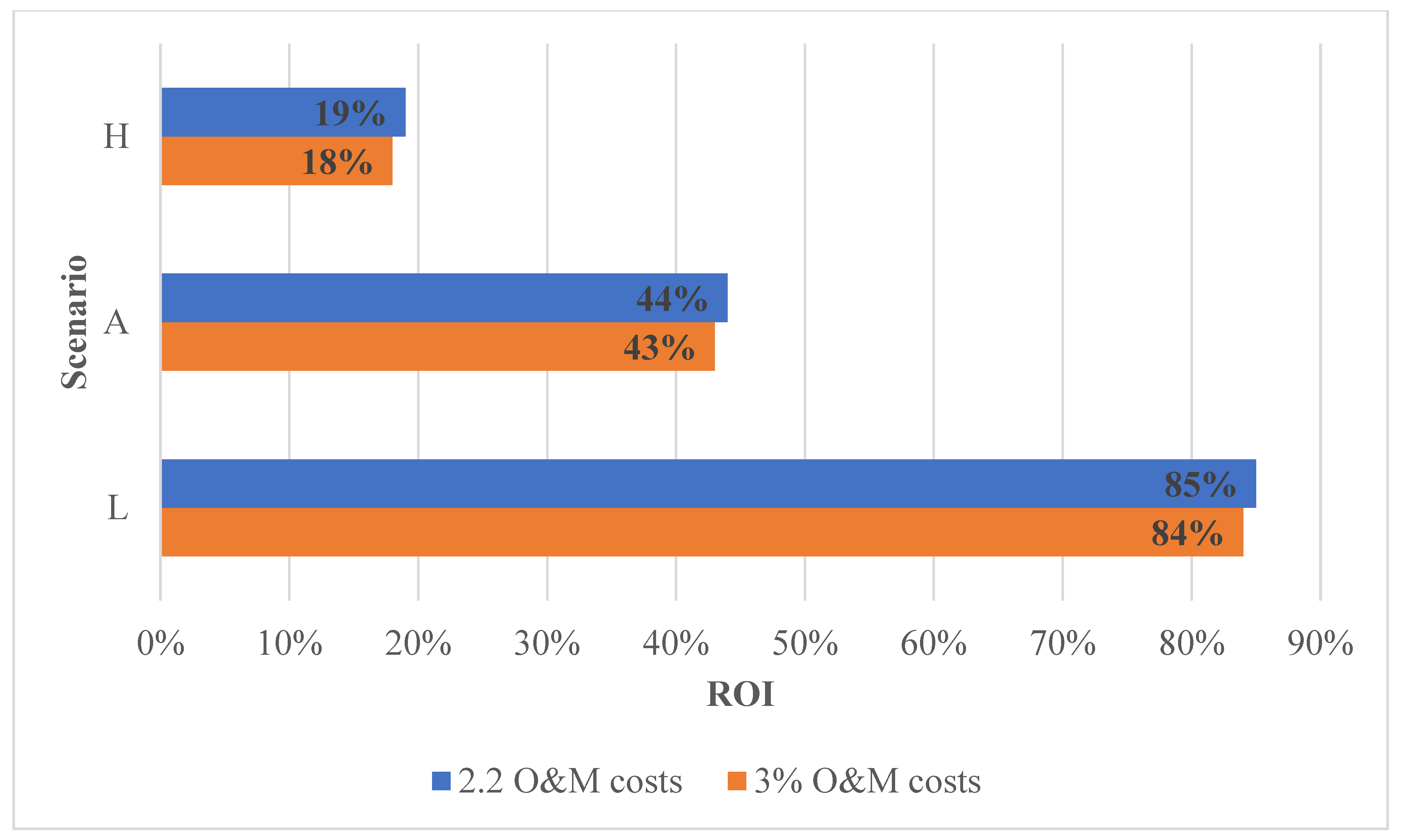

2.2. Economic Analysis

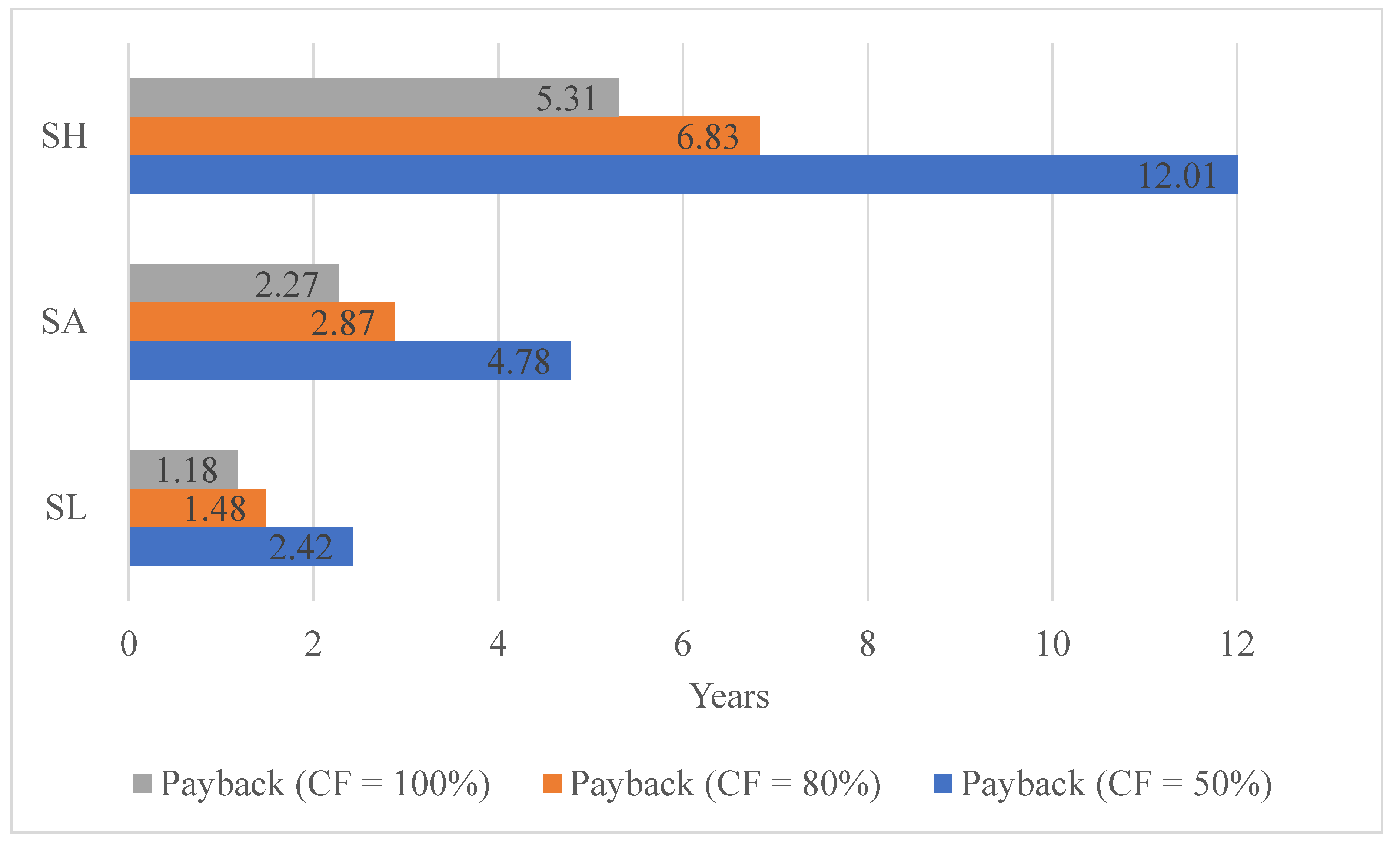

2.3. Plant Capacity Factor

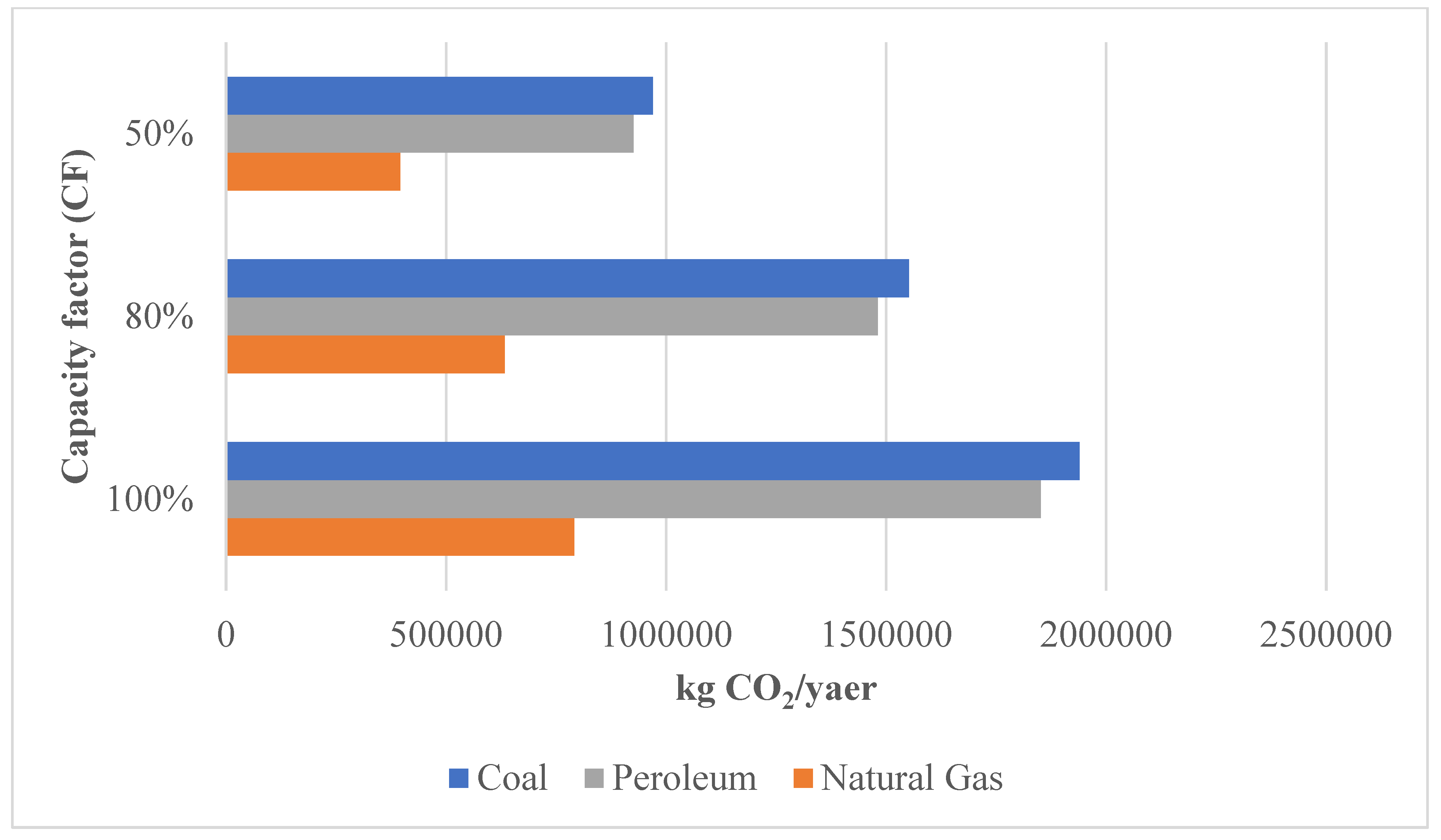

2.4. CO2 Emissions Reduction

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Almuhtady, A.; Alshwawra, A.; Alfaouri, M.; Al-Kouz, W.; Al-Hinti, I. Investigation of the trends of electricity demands in Jordan and its susceptibility to the ambient air temperature towards sustainable electricity generation. Energy Sustain. Soc. 2019, 9, 1–8. [Google Scholar] [CrossRef] [Green Version]

- IEA. Key World Energy Statistics 2018; International Energy Agency (IEA): Paris, France, 2018. [Google Scholar]

- Alshwawra, A.; Almuhtady, A. Impact of regional conflicts on Energy Security in Jordan. Int. J. Energy Econ. Policy 2020, 10, 45–50. [Google Scholar] [CrossRef]

- Sakhrieh, A.; Al Asfar, J.; Ghandour, A.; Adel, A. Improving Photovoltaic Systems in Jordan Using TRIZ Principle—Overview and Case Study. Int. J. Energy Econ. Policy 2022, 12, 73–78. [Google Scholar] [CrossRef]

- Hammad, A.; Batayneh, S. Design and installation of grid interactive solar system for building of ministry of energy and mineral resources. In Proceedings of the 13th International Conference on Clean Energy (ICCE-2014), Istanbul, Turkey, 8–12 June 2014. [Google Scholar]

- Rossi, M.; Renzi, M.; Štefan, D.; Muntean, S. Small-Scale Hydropower and Energy Recovery Interventions: Management, Optimization Processes and Hydraulic Machines Applications. Sustainability 2022, 14, 11645. [Google Scholar] [CrossRef]

- Bonthuys, G.J.; van Dijk, M.; Cavazzini, G. Optimizing the Potential Impact of Energy Recovery and Pipe Replacement on Leakage Reduction in a Medium Sized District Metered Area. Sustainability 2021, 13, 12929. [Google Scholar] [CrossRef]

- Itani, Y.; Soliman, M.R.; Kahil, M. Recovering energy by hydro-turbines application in water transmission pipelines: A case study west of Saudi Arabia. Energy 2020, 211, 118613. [Google Scholar] [CrossRef]

- Berrada, A.; Bouhssine, Z.; Arechkik, A. Optimisation and economic modeling of micro hydropower plant integrated in water distribution system. J. Clean. Prod. 2019, 232, 877–887. [Google Scholar] [CrossRef]

- Aster, N. What is the Water-Energy Nexus? TriplePundit. Available online: https://www.triplepundit.com/story/2012/what-water-energy-nexus/59796 (accessed on 2 October 2021).

- Misbah, M.; Gharbe, N. Renewable Energy from Great Man-Made River Generating Hydrokinetic Energy from Water movements through Pipes by using Lucid Pipe Power System. In Proceedings of the 5th Scientific Conference of Environment and Sustainable Development in the Arid and Semi- Arid Regions (ICESD), Ajdabiya, Libya, 23–25 July 2018; Volume 05, pp. 1188–1197. [Google Scholar]

- Power, C.; McNabola, A.; Coughlan, P. Development of an evaluation method for hydropower energy recovery in wastewater treatment plants: Case studies in Ireland and the UK. Sustain. Energy Technol. Assess. 2014, 7, 166–177. [Google Scholar] [CrossRef]

- Crespo Chacón, M.; Rodríguez Díaz, J.A.; García Morillo, J.; McNabola, A. Hydropower energy recovery in irrigation networks: Validation of a methodology for flow prediction and pump as turbine selection. Renew. Energy 2020, 147, 1728–1738. [Google Scholar] [CrossRef]

- Meirelles Lima, G.; Brentan, B.M.; Luvizotto, E. Optimal design of water supply networks using an energy recovery approach. Renew. Energy 2018, 117, 404–413. [Google Scholar] [CrossRef]

- Coelho, B.; Andrade-Campos, A. Efficiency achievement in water supply systems—A review. Renew. Sustain. Energy Rev. 2014, 30, 59–84. [Google Scholar] [CrossRef]

- Du, J.; Yang, H.; Shen, Z.; Chen, J. Micro hydro power generation from water supply system in high rise buildings using pump as turbines. Energy 2017, 137, 431–440. [Google Scholar] [CrossRef]

- Aziz, M.S.; Khan, M.A.; Jamil, H.; Jamil, F.; Chursin, A.; Kim, D.H. Design and Analysis of In-Pipe Hydro-Turbine for an Optimized Nearly Zero Energy Building. Sensors 2021, 21, 8154. [Google Scholar] [CrossRef]

- Saber, H.; Mazaheri, H.; Ranjbar, H.; Moeini-Aghtaie, M.; Lehtonen, M. Utilization of in-pipe hydropower renewable energy technology and energy storage systems in mountainous distribution networks. Renew. Energy 2021, 172, 789–801. [Google Scholar] [CrossRef]

- Chiaradia, T.; Mukulu, M.; Meder, K. Micro Hydro Power (MHP)—Pros and Cons. Energypedia. Available online: https://energypedia.info/wiki/Micro_Hydro_Power_(MHP)_-_Pros_and_Cons#Micro_Hydro_Cons_-_Disadvantages (accessed on 2 October 2021).

- Liu, M.; Tan, L.; Cao, S. Theoretical model of energy performance prediction and BEP determination for centrifugal pump as turbine. Energy 2019, 172, 712–732. [Google Scholar] [CrossRef]

- Uhunmwangho, R.; Odje, M.; Okedu, K.E. Comparative analysis of mini hydro turbines for Bumaji Stream, Boki, Cross River State, Nigeria. Sustain. Energy Technol. Assess. 2018, 27, 102–108. [Google Scholar] [CrossRef]

- Samora, I.; Manso, P.; Franca, M.; Schleiss, A.; Ramos, H. Energy Recovery Using Micro-Hydropower Technology in Water Supply Systems: The Case Study of the City of Fribourg. Water 2016, 8, 344. [Google Scholar] [CrossRef] [Green Version]

- Sani, A.E. Design and synchronizing of Pelton turbine with centrifugal pump in RO package. Energy 2019, 172, 787–793. [Google Scholar] [CrossRef]

- Zheng, Y.; Sahraei-Ardakani, M. Leveraging existing water and wastewater infrastructure to develop distributed pumped storage hydropower in California. J. Energy Storage 2021, 34, 102204. [Google Scholar] [CrossRef]

- Alshwawra, A.; Almuhtady, A. Impact of turmoil and gas resources in the Eastern Mediterranean on Jordanian Energy Security and foreign policy. Transformation of Turkey’s Defense Industry: Causes, Context and Consequences. Insight Turk. 2020, 22, 237–255. [Google Scholar] [CrossRef]

- Abu Raed, A.; Ahmed, A.; Abdelhamid, A. Biomimicry Approach Design of Petrol Stations with Integrating Renewable Energy in the UAE. In Eco-Architecture IX: Harmonisation between Architecture and Nature, Proceedings of the 9th International Conference on Harmonisation between Architecture and Nature, ARC 2022, Lisbon, Portugal, 12–14 July 2022; WITPres: Billerica, MA, USA; pp. 41–47.

- Sohail, M.; Afrouzi, H.N.; Ahmed, J.; Mehranzamir, K.; Tabassum, M.; Mobin Siddique, M.B. A comprehensive scientometric analysis on hybrid renewable energy systems in developing regions of the world. Results Eng. 2022, 16, 100481. [Google Scholar] [CrossRef]

- The United Arab Emirates’ Government Portal. UAE Energy Strategy 2050—The Official Portal of the UAE Government. Available online: https://u.ae/en/about-the-uae/strategies-initiatives-and-awards/federal-governments-strategies-and-plans/uae-energy-strategy-2050 (accessed on 28 November 2021).

- Rathi, A. UAE Has Built the World’s Largest Water Reserve in Liwa Desert. Quartz. Available online: https://qz.com/1180035/uae-has-built-the-worlds-largest-water-reserve-in-liwa-desert/ (accessed on 19 January 2018).

- IRENA. Renewable Power Generation Costs in 2020. International Renewable Energy Agency: Abu Dhabi, United Arab Emirates. 2021. Available online: https://www.irena.org/publications/2021/Jun/Renewable-Power-Costs-in-2020 (accessed on 28 November 2021).

- Abu Dhabi Distribution Co. Water & Electricity Tariffs 2017. 2018. Available online: https://www.addc.ae/en-US/Business/Documents/02-English.pdf (accessed on 23 November 2021).

- Alsema, E.A. Environmental Life Cycle Assessment of Solar Home Systems (NWS-E-2000-15); Department of Science Technology and Society, Utrecht University: Utrecht, The Netherlands, 2000. [Google Scholar]

- EIA, Energy Information Agency—Frequently Asked Questions (Faqs)—U.S. Energy Information Administration (EIA). Available online: https://www.eia.gov/tools/faqs/faq.php?id=74&t=11 (accessed on 24 August 2022).

- Ogayar, B.; Vidal, P. Cost determination of the electro-mechanical equipment of a small hydro-power plant. Renew. Energy 2009, 34, 6–13. [Google Scholar] [CrossRef]

- Gudukeya, L.K.; Mbohwa, C. Improving the Efficiencies of Pelton Wheel in Micro-Hydro Power Plants. In Proceedings of the International Conference on Industrial Engineering and Operations Management, Rabat, Morocco, 11–13 April 2017; pp. 1089–1100. [Google Scholar]

- Purdue University. Lucidpipetm Power System. Emerging Construction Technologies; Purdue University: West Lafayette, IN, USA, 2016. [Google Scholar]

| Investment Category | Calculation Method | Installation Costs (2020 USD/kW) |

|---|---|---|

| Low | 5th percentile | 807.00 |

| Average | Weighted average | 1518.00 |

| High | 95th percentile | 3334.00 |

| Name | Investment | O and M Costs |

|---|---|---|

| L1 | Low | 2.2% |

| L2 | Low | 3.0% |

| A1 | Average | 2.2% |

| A2 | Average | 3.0% |

| H1 | High | 2.2% |

| H2 | High | 3.0% |

| Name | Investment | O and M Costs | CF |

|---|---|---|---|

| SL50 | Low | 2.2% | 50% |

| SL80 | Low | 2.2% | 80% |

| SA50 | Average | 2.2% | 50% |

| SA80 | Average | 2.2% | 80% |

| SH50 | High | 2.2% | 50% |

| SH80 | High | 2.2% | 80% |

| Parameter | Value |

|---|---|

| Reservoir volume | 26 billion liters |

| Time required to fill up the reservoir | 26 months |

| Hazen–Williams Coefficient | 140 |

| Pipe segment length | 10 m |

| Pipe inside diameter | 1 m |

| Gross head | 80 m |

| Head loss | 1.938 × 10−3 m |

| Net head | 79.998 m |

| Water flow rate | 0.386 m3/s |

| Water density | 1000 kg/m3 |

| Gravity | 9.810 m/s2 |

| Turbine efficiency | 85% |

| Generator efficiency | 85% |

| Hydraulic Power | 302.775 kW |

| Generation capacity | 218.755 kW |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alawadhi, G.; Almehiri, M.; Sakhrieh, A.; Alshwawra, A.; Al Asfar, J. Cost Analysis of Implementing In-Pipe Hydro Turbine in the United Arab Emirates Water Network. Sustainability 2023, 15, 651. https://doi.org/10.3390/su15010651

Alawadhi G, Almehiri M, Sakhrieh A, Alshwawra A, Al Asfar J. Cost Analysis of Implementing In-Pipe Hydro Turbine in the United Arab Emirates Water Network. Sustainability. 2023; 15(1):651. https://doi.org/10.3390/su15010651

Chicago/Turabian StyleAlawadhi, Ghaya, Meera Almehiri, Ahmad Sakhrieh, Ahmad Alshwawra, and Jamil Al Asfar. 2023. "Cost Analysis of Implementing In-Pipe Hydro Turbine in the United Arab Emirates Water Network" Sustainability 15, no. 1: 651. https://doi.org/10.3390/su15010651

APA StyleAlawadhi, G., Almehiri, M., Sakhrieh, A., Alshwawra, A., & Al Asfar, J. (2023). Cost Analysis of Implementing In-Pipe Hydro Turbine in the United Arab Emirates Water Network. Sustainability, 15(1), 651. https://doi.org/10.3390/su15010651