Effects of Multiple Defects on Welded Joint Behaviour under the Uniaxial Tensile Loading: Fem and Experimental Approach

Abstract

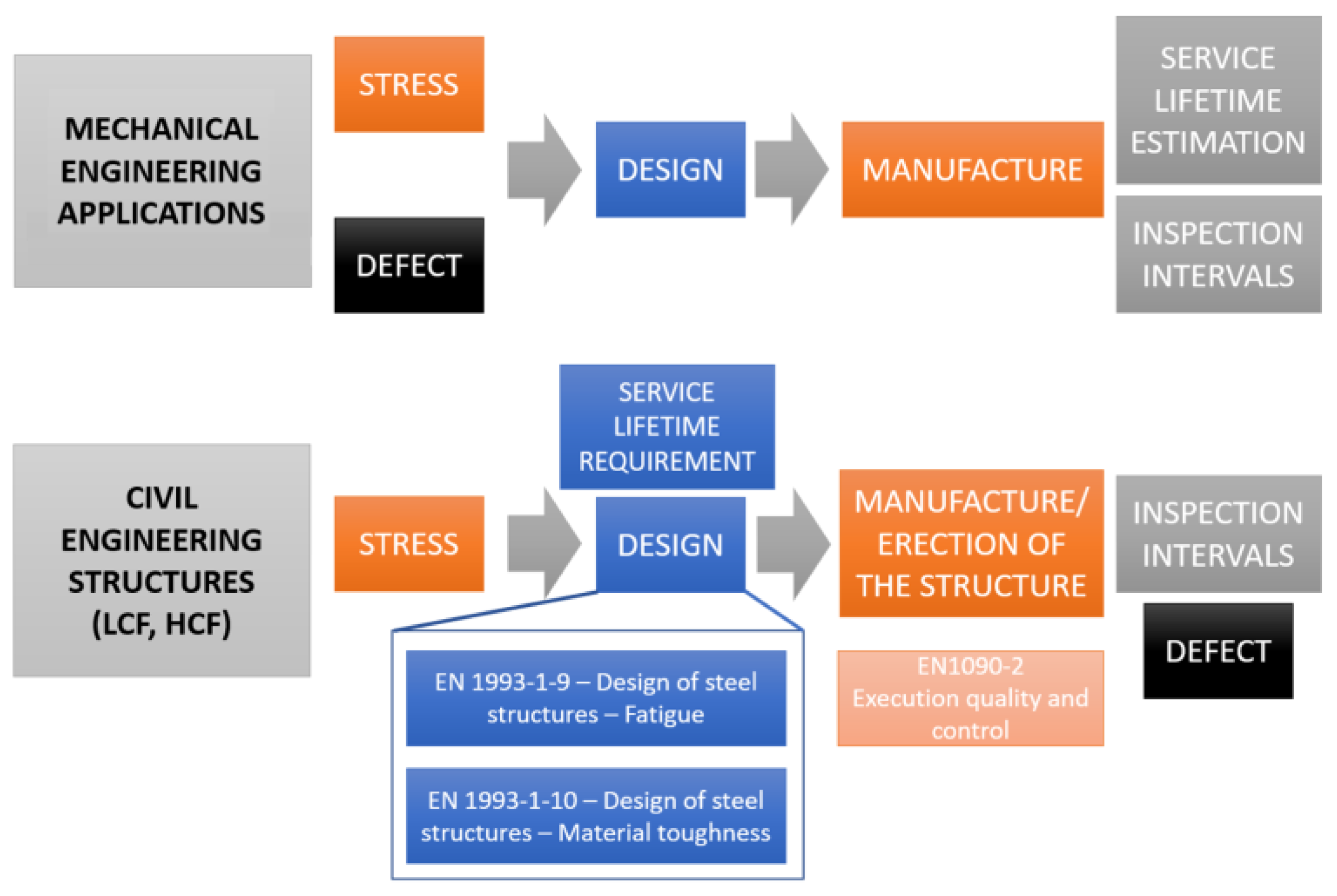

:1. Introduction

2. Materials and Methods

2.1. Welding Procedure

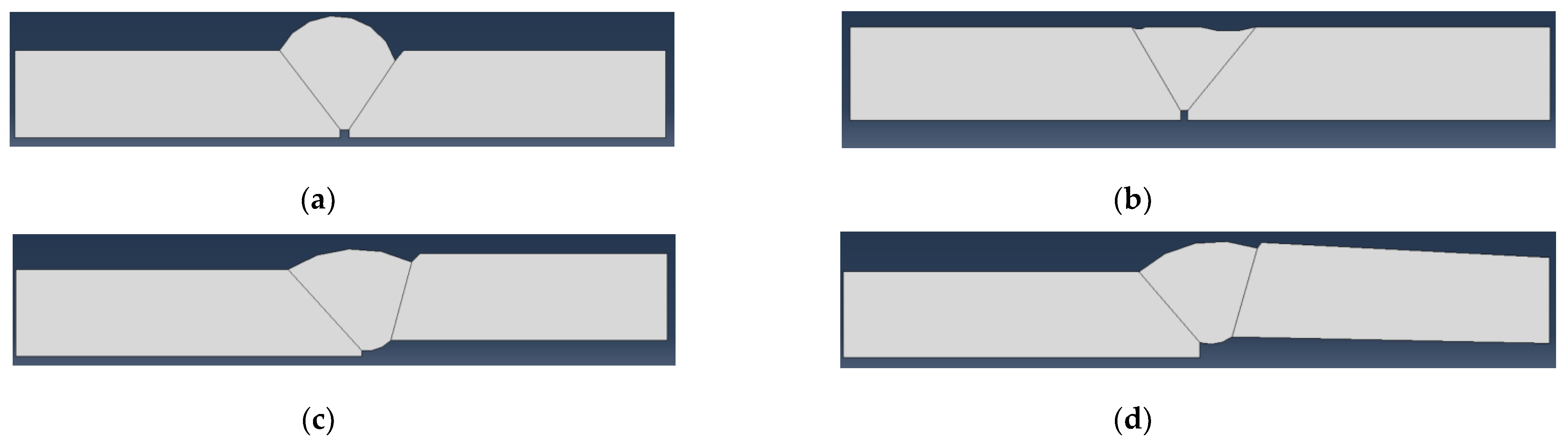

- Excess weld metal, weld face undercut and incomplete root penetration, which represent plates for Group 1 specimens;

- Incomplete root penetration and weld face sagging, which represent plates for Group 2 specimens;

- Excess weld metal, weld face undercut and misalignment, which represent plates for Group 3 specimens;

- Incomplete root penetration, misalignment and weld face undercut, which represent plates for Group 4 specimens.

2.2. Specimen Preparation (for Tensile Testing)

2.3. Tensile Testing

- group 1: from 8–10%;

- group 2: from 13–16%;

- group 3: from 18–21%;

- group 4: from 8–23%.

2.4. Strain Measuring Using Digital Image Correlation

3. FEM Analysis

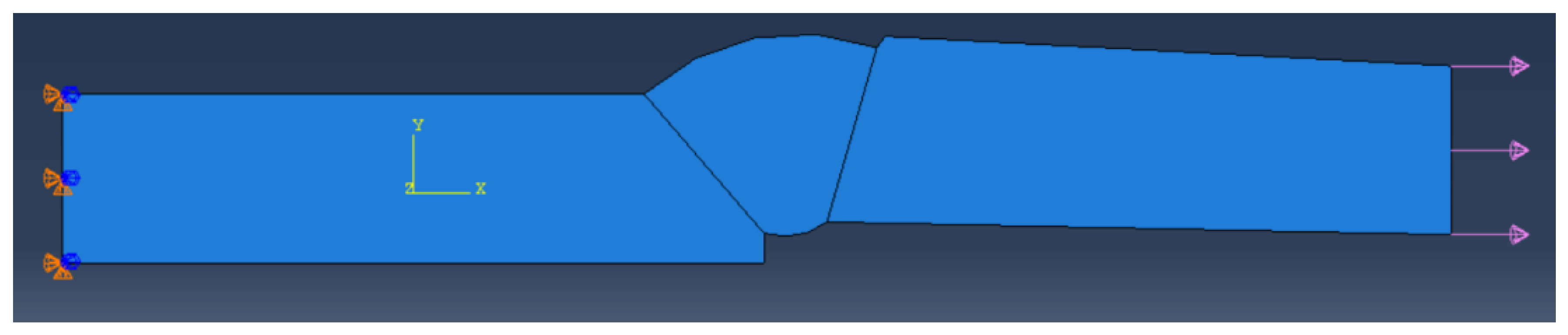

3.1. Setup and Boundary Condition

- Yield stress (Re) values for the parent material ranged from 275 MPa (Group 3) to 330 MPa (Group 2);

- Tensile strength (Rm) values for the parent material ranged from 400–460 MPa, with both limit values taken from group 4 specimens;

- Yield stress for the weld metal was assumed to be 460 MPa in all four cases, since it was much higher due to overmatching and a more detailed approach to defining its values would not have any noticeable effect on the calculations;

- Tensile strength for the weld metal was adopted as 600 MPa for all four groups, following the same logic as in the case or Re.

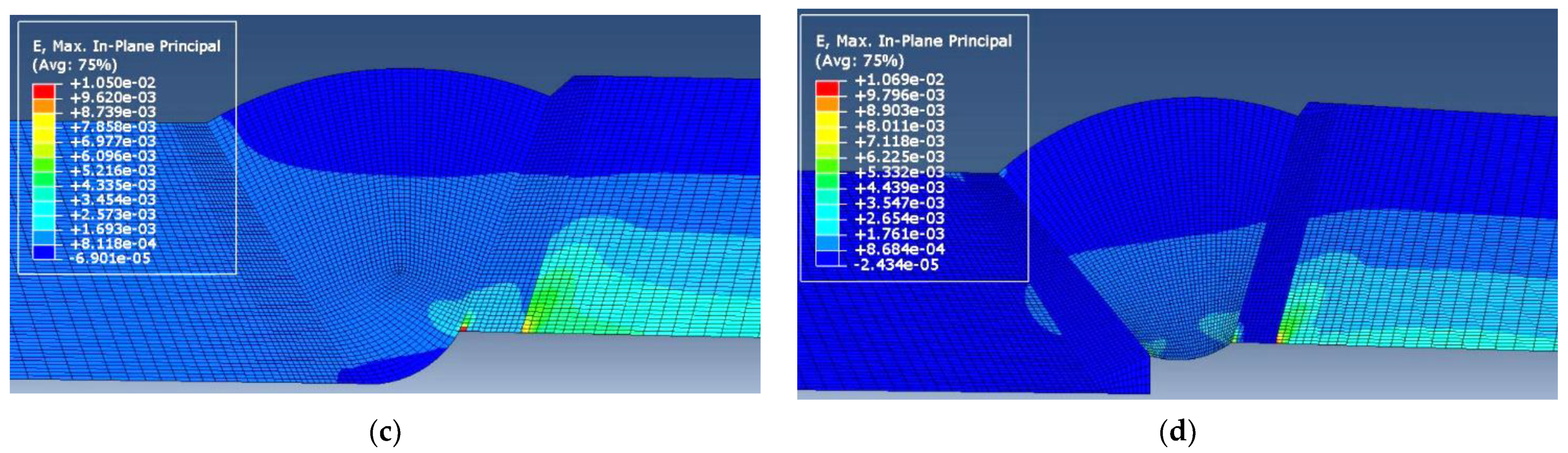

3.2. Results

4. Validation of Proposed Method for Determining Tensile Properties of HAZ

4.1. Hardness Measuring

4.2. Microstructural Analysis

5. Conclusions

- It was concluded that different defect combinations can cause significant stress concentration which could lead to occurrence of plastic strain in welded joints, even at lower load levels;

- Iterative method for determining the mechanical tensile properties of the HAZ by comparison with DIC strain results showed satisfying levels of accuracy, with strain values ranging from 0.6 to 1.07%, which correspond to the moment when both real specimens and numerical models started showing plastic behaviour;

- The presented approach is universally applicable to different types of steels, whereas the other method uses varying empirical equations which depend on the type of steel.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Đorđević, B.; Sedmak, S.; Tanasković, D.; Gajin, M.; Vučetić, F. Failure analysis and numerical simulation of slab carrying clamps. Frat. Ed Integrità Strutt. 2021, 55, 336–344. [Google Scholar] [CrossRef]

- Sedmak, S.; Grabulov, V.; Momcilovic, D. Chronology of lost structural integrity initiated from manufacturing defects in welded structures. Struct. Integr. Life 2009, 9, 39–50. [Google Scholar]

- Milovanović, N.; Sedmak, A.; Arsic, M.; Sedmak, S.A.; Božić, Ž. Structural integrity and life assessment of rotating equipment. Eng. Fail. Anal. 2020, 113, 104561. [Google Scholar] [CrossRef]

- Li, G.; Cai, Q.; Lu, X.; Zhu, X.; Xu, S. Failure analysis of cracking in the welded joints of hydrogen reformer outlet pigtail tubes. Eng. Fail. Anal. 2022, 137, 106257. [Google Scholar] [CrossRef]

- Jeremić, L.; Sedmak, A.; Petrovski, B.; Đorđević, B.; Sedmak, S. Structural integrity assessment of welded pipeline designed with reduced safety. Tech. Gaz. 2020, 27, 1461–1466. [Google Scholar] [CrossRef]

- Bošnjak, S.; Arsić, M.; Savićević, S.; Milojević, G.; Arsić, D. Fracture analysis of the pulley of a bucket wheel boom hoist system. Eksploat. I Niezawodn.—Maint. Reliab. 2016, 18, 155–163. [Google Scholar] [CrossRef]

- Soret, C.; Madi, Y.; Gaffard, V.; Besson, J. Local approach to fracture applied to the analysis of a full size test on a pipe containing a girth weld defect. Eng. Fail. Anal. 2017, 82, 404–419. [Google Scholar] [CrossRef]

- Rizvi, S.; Alib, W. Welding defects, Causes and their Remedies: A Review. Teknomekanik 2019, 2, 39–47. [Google Scholar] [CrossRef]

- Popović, O.; Prokić-Cvetković, R.; Radović, L.; Burzić, Z.; Arsić, D. The effect of heat input on the fracture behavior of surface weld metal of rail steel. Struct. Integr. Life 2020, 20, 77–81. [Google Scholar]

- Tanasković, D.; Đorđević, B.; Gajin, M.; Aranđelović, M.; Gostović, N.; Milovanović, N. Repair welding procedure and techno-economic analysis of burner pipe. Struct. Integr. Life 2021, 21, 85–90. [Google Scholar]

- Hariprasath, P.; Sivaraj, P.; Balasubramanian, V.; Pilli, S.; Sridhar, K. Effect of welding processes on high cycle fatigue behavior for naval grade HSLA joints: A fatigue strength prediction. Eng. Fail. Anal. 2022, 142, 106783. [Google Scholar] [CrossRef]

- Madhvacharyula, A.S.; Pavan, A.V.S.; Gorthi, S.; Chitral, S.; Venkaiah, N.; Kiran, D.V. In situ detection of welding defects: A review. Weld World 2022, 66, 611–628. [Google Scholar] [CrossRef]

- Hao, S. I-35W bridge collapse. J. Bridge Eng. 2010, 15, 608–614. [Google Scholar] [CrossRef]

- Cerit, M.; Kokumer, O.; Genel, K. Stress concentration effects of undercut defect and reinforcement metal in butt-welded joint. Eng. Fail. Anal. 2010, 17, 571–578. [Google Scholar] [CrossRef]

- Kozak, D.; Konjatić, P.; Matejiček, F.; Damjanović, D. Weld misalignment influence on the structural integrity of cylindrical pressure vessel. Struct. Integr. Life 2010, 10, 153–159. [Google Scholar]

- Dimić, I.; Arsić, M.; Međo, B.; Stefanović, A.; Grabulov, V.; Rakin, M. Effect of welded joint imperfection on the integrity of pipe elbows subjected to internal pressure. Teh. Vjesn. 2013, 20, 285–290. [Google Scholar]

- Ottersböck, M.J.; Leitner, M.; Stoschka, M. Characterisation of actual weld geometry and stress concentration of butt welds exhibiting local undercuts. Eng. Struct. 2021, 240, 112266. [Google Scholar] [CrossRef]

- Petrović, A.; Maneski, T.; Trišović, N.; Ignjatović, D.; Dunjić, M. Identification of crack initiation cause in pylons construction of the excavator SchRs630. Tech. Gaz. 2018, 25, 486–491. [Google Scholar]

- Bošnjak, S.M.; Arsić, M.A.; Zrnić, N.Đ.; Rakin, M.P.; Pantelić, M.P. Bucket wheel excavator: Integrity assessment of the bucket wheel boom tie-rod welded joint. Eng. Fail. Anal. 2011, 18, 212–222. [Google Scholar] [CrossRef]

- Jallouf, S.; Casavola, K.; Pappalettere, C.; Pluvinage, G. Assessment of undercut defect in a laser welded plate made of Ti–6Al–4V titanium alloy with probabilistic domain failure assessment diagram. Eng. Fail. Anal. 2016, 59, 17–27. [Google Scholar] [CrossRef]

- Milovanović, A.M.; Mijatović, T.; Diković, L.; Trumbulović, L.; Drndarević, B. Structural Integrity Analysis of a Cracked Pressure Vessel. Struct. Integr. Life 2021, 21, 285–289. [Google Scholar]

- Jeremić, A.; Sedmak, N.; Milovanović, N.; Milošević, N.; Sedmak, S. Assessment of integrity of pressure vessels for compressed air. Struct. Integr. Life 2021, 21, 3–6. [Google Scholar]

- Kirin, S.; Jeremić, L.; Sedmak, A.; Martić, I.; Sedmak, S.; Vučetić, I.; Golubović, T. Risk based analysis of RHPP penstock structural integrity. Frat. Ed Integrità Strutt. 2020, 14, 345–352. [Google Scholar] [CrossRef]

- Kozak, D.; Damjanović, D.; Katinić, M. Integrity assessment of the butt weld joint with defect according to EN ISO 6520-1, series 400. Struct. Integr. Life 2016, 16, 120–124. [Google Scholar]

- Radu, D.; Sedmak, A.; Sedmak, S.; Li, W. Engineering critical assessment of steel shell structure elements welded joints under high cycle fatigue. Eng. Fail. Anal. 2020, 114, 104578. [Google Scholar] [CrossRef]

- Li, Y.; Lu, P.; Wang, B.; Hu, X.; Song, X.; Xiang, Q. Fracture performance testing and modeling of butt weld metal. Eng. Fail. Anal. 2022, 139, 106489. [Google Scholar] [CrossRef]

- Yang, Y.; Liu, X.; Wu, K.; Sui, Y.; Feng, Q.; Wang, D.; Zhang, H. Full-scale experimental investigation of the fracture behaviours of welding joints of APL X80 wide plate based on DIC technology. Eng. Fail. Anal. 2022, 131, 105832. [Google Scholar] [CrossRef]

- Milosevic, N.; Younise, B.; Sedmak, A.; Travica, M.; Mitrovic, A. Evaluation of true stress–strain diagrams for welded joints by application of Digital Image Correlation. Eng. Fail. Anal. 2021, 128, 105609. [Google Scholar] [CrossRef]

- Milošević, N.; Sedmak, A.; Bakić, G.; Lazić, V.; Milošević, M.; Mladenović, G.; Maslarević, A. Determination of the actual stress–strain diagram for undermatching welded joint using DIC and FEM. Materials 2021, 14, 4691. [Google Scholar] [CrossRef]

- Molski, K.L.; Tarasiuk, P. Stress concentration factors for welded plate T-Joints subjected to tensile, bending and shearing Loads. Materials 2021, 14, 546. [Google Scholar] [CrossRef]

- Khalaj, G.; Pouraliakbar, H.; Mamaghani, K.R.; Khalaj, M.J. Modeling the correlation betweenheat treatment, chemicalcomposition and bainite fractionof pipeline steels by means ofartificial neural networks. Neural Netw. World 2013, 23, 351–367. [Google Scholar] [CrossRef] [Green Version]

- Khalaj, G.; Khoeini, M.; Khakian-Qom, M. ANN-based prediction of ferrite fraction in continuous cooling of microalloyed steels. Neural Comput. Appl. 2013, 23, 769–777. [Google Scholar] [CrossRef]

- Khalaj, G.; Azimzadegan, T.; Khoeini, M.; Etaat, M. Artificial neural networks application to predict the ultimate tensile strength of X70 pipeline steels. Neural Comput. Appl. 2012, 23, 2301–2308. [Google Scholar] [CrossRef]

- Jovičić, R.; Sedmak, S.; Tatić, U.; Lukić, U.; Walid, M. Stress state around imperfections in welded joints. Struct. Integr. Life 2015, 15, 27–29. [Google Scholar]

- Sedmak, S.A.; Burzić, Z.; Perković, S.; Jovičić, R.; Aranđelović, M.; Radović, L.; Ilić, N. Influence of welded joint microstructures on fatigue behaviour of specimens with a notch in the heat affected zone. Eng. Fail. Anal. 2019, 106, 104162. [Google Scholar] [CrossRef]

- Aranđelović, M.; Sedmak, S.; Jovičić, R.; Kozak, D.; Đorđević, B. Numerical simulation of crack growth in a welded joint with defects. Procedia Struct. Integr. 2021, 33, 850–857. [Google Scholar] [CrossRef]

- Aranđelović, M.; Sedmak, S.; Jovičić, R.; Perković, S.; Burzić, Z.; Đorđević, B.; Radaković, Z. Numerical simulation of welded joint with multiple various defects. Struct. Integr. Life 2021, 21, 103–107. [Google Scholar]

- Aranđelović, M.; Sedmak, S.; Jovičić, R.; Perković, S.; Burzić, Z.; Radu, D.; Radaković, Z. Numerical and experimental investigations of fracture behaviour of welded joints with multiple defects. Materials 2021, 14, 4832. [Google Scholar] [CrossRef]

- Aranđelović, M.; Jeremić, L.; Đorđević, B.; Sedmak, S.A.; Opačić, M. Integrity assessment of ammonia storage tank by non-destructive testing. Struct. Integr. Life 2021, 21, 295–300. [Google Scholar]

- Aranđelović, M. Influence of Multiple Defects on Structural Integrity of Welded Joints. Doctoral Thesis, Faculty of Mechanical Engineering, University of Belgrade, Belgrade, Serbia, 2022. [Google Scholar]

- Jovanović, G.; Glišić, D.; Dikić, S.; Radović, N.; Patarić, A. Cleavage fracture of the air cooled medium carbon microalloyed forging steels with heterogeneous microstructures. Materials 2022, 15, 1760. [Google Scholar] [CrossRef]

- Dikić, S.; Glišić, D.; Fadel, A.; Jovanović, G.; Radović, N. Structure and strength of isothermally heat-treated medium carbon Ti-V microalloyed steel. Metals 2021, 11, 1011. [Google Scholar] [CrossRef]

- Kumar, S.; Sirohi, S.; Pandey, S.M.; Bhatt, D.; Pandey, C. Effect of Single Bevel Groove Geometry on the Impact Strength of Dissimilar Welded Joint of P22 and P91 Steel. Sustainability 2022, 14, 11739. [Google Scholar] [CrossRef]

| Element | C | Si | Mn | P | S | Cu | Al | Cr | Mo | Ni |

|---|---|---|---|---|---|---|---|---|---|---|

| % | 0.137 | 0.014 | 0.662 | 0.009 | <0.001 | 0.020 | 0.034 | 0.024 | 0.004 | 0.011 |

| Nominal Thickness [mm] | Re [MPa] | Rm [MPa] |

|---|---|---|

| ≥3 ≤ 16 | >275 | 410–560 |

| Element | C | Si | Mn | P | S |

|---|---|---|---|---|---|

| % | 0.08 | 0.9 | 1.5 | <0.025 | <0.025 |

| Re [MPa] | Rm [MPa] | Elongation (%) |

|---|---|---|

| >410 | 510–590 | >22 |

| Plate | Layer | Interpass Temperature | Current (A) | Voltage (V) | Welding Speed (mm/s) | Heat Input (kJ/mm) |

|---|---|---|---|---|---|---|

| Root | <150 | 111 | 19.3 | 2.2 | 0.87 | |

| 1 | Fill 1 | <150 | 142 | 22.0 | 3.1 | 0.95 |

| Fill 2 | <150 | 151 | 24.0 | 4.0 | 0.71 | |

| Root | <150 | 112 | 19.0 | 2.3 | 0.88 | |

| 2 | Fill 1 | <150 | 141 | 23.0 | 3.2 | 0.94 |

| Fill 2 | <150 | 149 | 23.9 | 4.1 | 0.70 | |

| Root | <150 | 92 | 18.9 | 1.7 | 0.91 | |

| 3 | Fill 1 | <150 | 112 | 19.6 | 2.7 | 0.74 |

| Fill 2 | <150 | 121 | 20.0 | 3.1 | 1.12 | |

| Root | <150 | 90 | 18.7 | 1.7 | 0.91 | |

| 4 | Fill 1 | <150 | 111 | 19.5 | 2.6 | 0.73 |

| Fill 2 | <150 | 122 | 20.3 | 3.2 | 1.13 |

| Numerical Model | Number of Finite Elements | Number of Nodes |

|---|---|---|

| Group 1 | 10,797 | 11,044 |

| Group 2 | 12,560 | 12,811 |

| Group 3 | 8658 | 8848 |

| Group 4 | 9768 | 9982 |

| Specimen Group | Re [MPa] | Rm [MPa] |

|---|---|---|

| 1 | 404 | 497 |

| 2 | 395 | 505 |

| 3 | 419 | 495 |

| 4 | 390 | 484 |

| Defect | Stress in the Defect Vicinity [MPa] | Stress in the Defect Free Model [MPa] | Stress Concentration Factor | |

|---|---|---|---|---|

| Group 1 model | excess weld metal | 307.9 | 277.9 | 1.108 |

| weld face undercut | 422.9 | 253.8 | 1.667 | |

| incomplete root penetration | 461.2 | 183.6 | 2.512 | |

| Group 2 model | weld face sagging | 312.0 | 168.9 | 1.847 |

| incomplete root penetration | 465.6 | 226.1 | 2.059 | |

| Group 3 model | weld face undercut | 236.9 | 245.7 | 0.964 |

| misalignment | 459.8 | 309.3 | 1.487 | |

| excess weld metal | 268.3 | 291.0 | 0.929 | |

| Group 4 model | weld face undercut | 237.0 | 226.0 | 1.05 |

| misalignment | 431.6 | 309.3 | 1.395 | |

| incomplete root penetration | 470.5 | 309.3 | 1.521 |

| Measuring Points | Measuring Location | ||

|---|---|---|---|

| HAZ (Left) | Weld Metal | HAZ (Right) | |

| 1 | 175 | 183 | 169 |

| 2 | 161 | 180 | 165 |

| 3 | 164 | 182 | 164 |

| Measuring Points | Measuring Location | ||

|---|---|---|---|

| HAZ (Left) | Weld Metal | HAZ (Right) | |

| 1 | 155 | 161 | 156 |

| 2 | 156 | 162 | 157 |

| 3 | 153 | 164 | 155 |

| Measuring Points | Measuring Location | ||

|---|---|---|---|

| HAZ (Left) | Weld Metal | HAZ (Right) | |

| 1 | 158 | 210 | 158 |

| 2 | 158 | 190 | 158 |

| 3 | 161 | 185 | 161 |

| 4 | 158 | 175 | 158 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aranđelović, M.; Petrović, A.; Đorđević, B.; Sedmak, S.; Sedmak, A.; Dikić, S.; Radu, D. Effects of Multiple Defects on Welded Joint Behaviour under the Uniaxial Tensile Loading: Fem and Experimental Approach. Sustainability 2023, 15, 761. https://doi.org/10.3390/su15010761

Aranđelović M, Petrović A, Đorđević B, Sedmak S, Sedmak A, Dikić S, Radu D. Effects of Multiple Defects on Welded Joint Behaviour under the Uniaxial Tensile Loading: Fem and Experimental Approach. Sustainability. 2023; 15(1):761. https://doi.org/10.3390/su15010761

Chicago/Turabian StyleAranđelović, Mihajlo, Ana Petrović, Branislav Đorđević, Simon Sedmak, Aleksandar Sedmak, Stefan Dikić, and Dorin Radu. 2023. "Effects of Multiple Defects on Welded Joint Behaviour under the Uniaxial Tensile Loading: Fem and Experimental Approach" Sustainability 15, no. 1: 761. https://doi.org/10.3390/su15010761

APA StyleAranđelović, M., Petrović, A., Đorđević, B., Sedmak, S., Sedmak, A., Dikić, S., & Radu, D. (2023). Effects of Multiple Defects on Welded Joint Behaviour under the Uniaxial Tensile Loading: Fem and Experimental Approach. Sustainability, 15(1), 761. https://doi.org/10.3390/su15010761