Optimization, Characterization, and Biological Applications of Silver Nanoparticles Synthesized Using Essential Oil of Aerial Part of Laggera tomentosa

Abstract

:1. Introduction

2. Materials and Methods

2.1. Plant Material and Chemicals

2.2. Isolation and Characterization of Essential Oils

2.3. Methodology for AgNPs Synthesis and Characterization

2.4. Potential Applications of LTEO-AgNPs

2.5. Statistical Analysis

3. Results and Discussion

3.1. Instrumental Analyses of LTEO

3.2. Optimization, Synthesis, and Characterization of LTEO-AgNPs

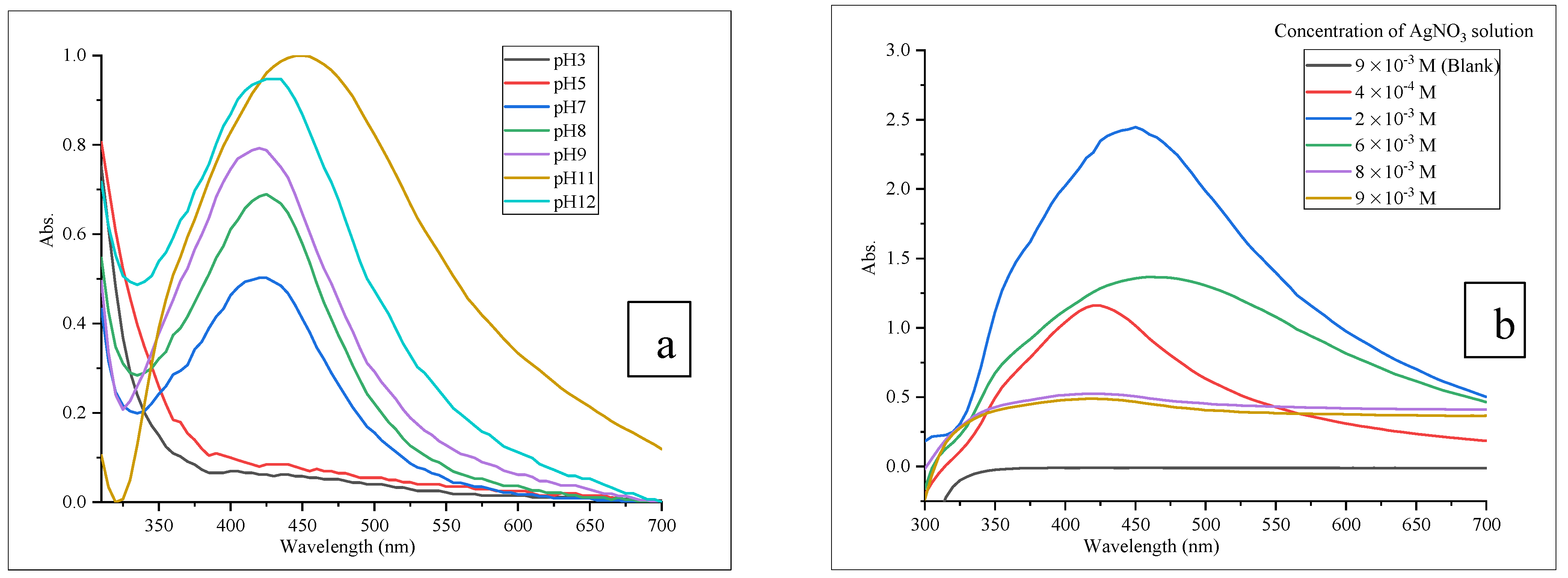

3.2.1. Optimization Process

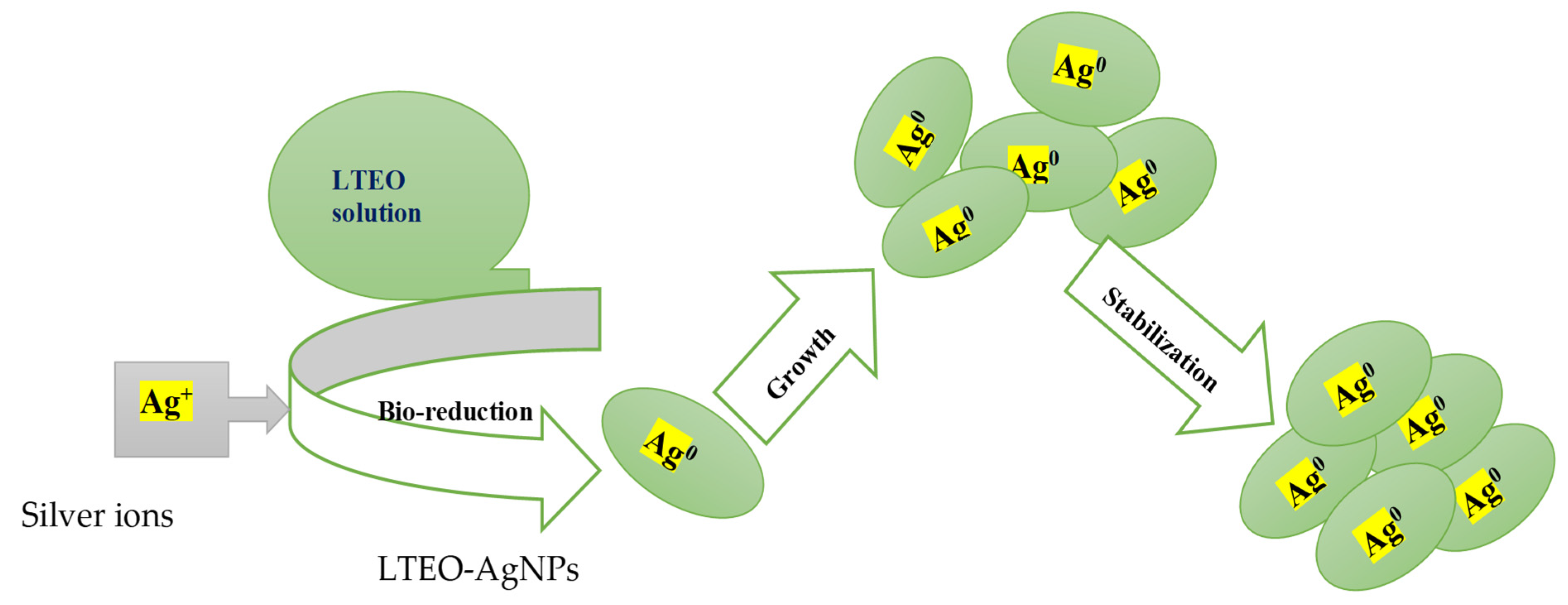

3.2.2. Synthesis of LTEO-AgNPs

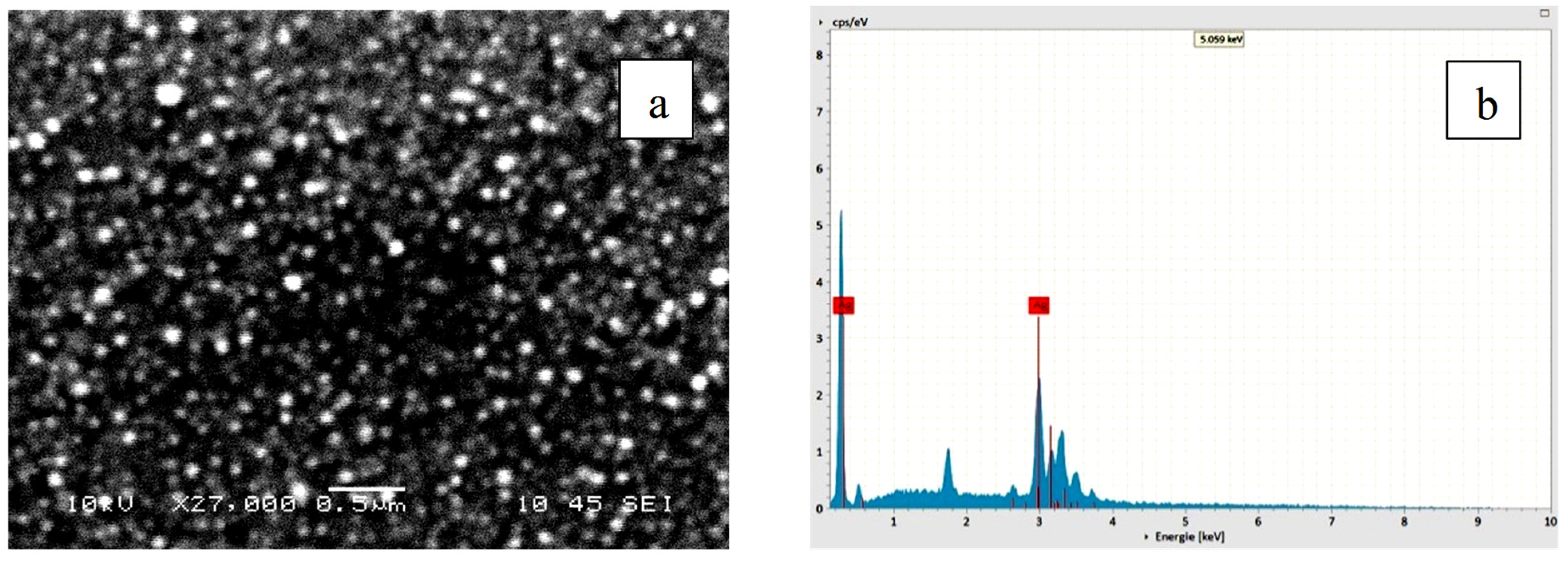

3.2.3. Characterization of LTEO-AgNPs

3.3. Applications of LTEO-AgNPs

3.3.1. Antibacterial Activity

3.3.2. Seeds Germination and Seedlings Growth

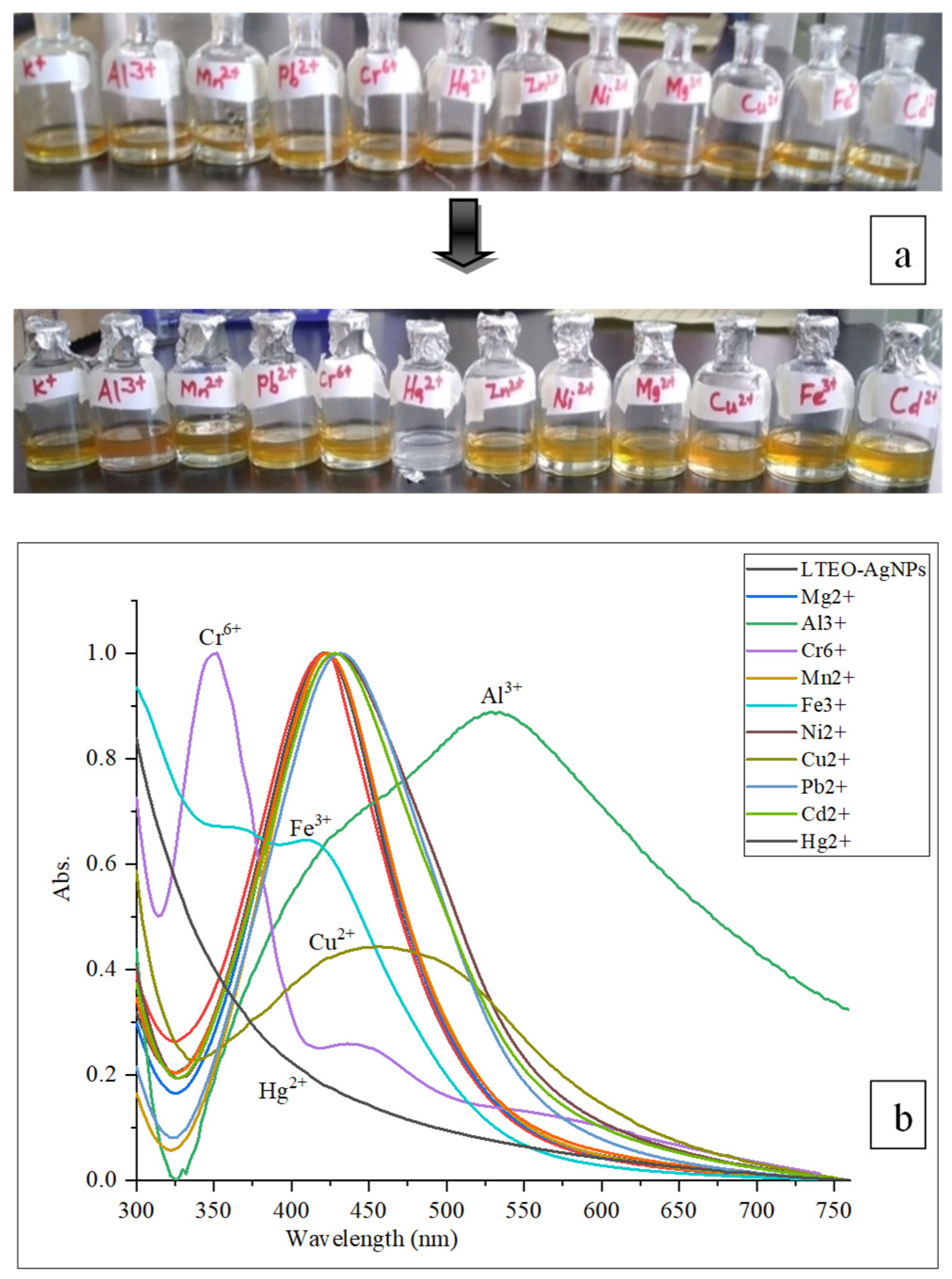

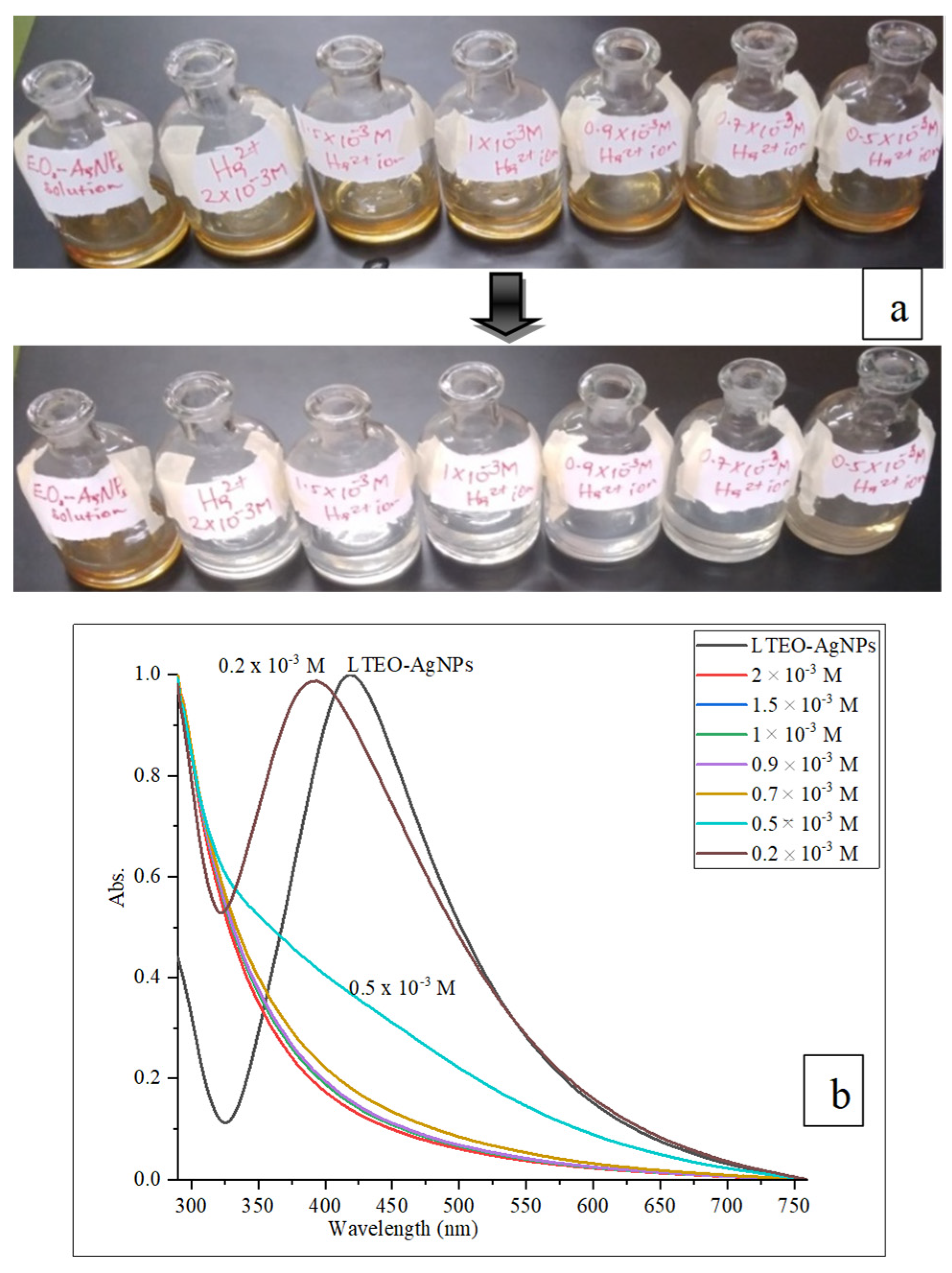

3.3.3. Colorimetric Detection of Metal Ions

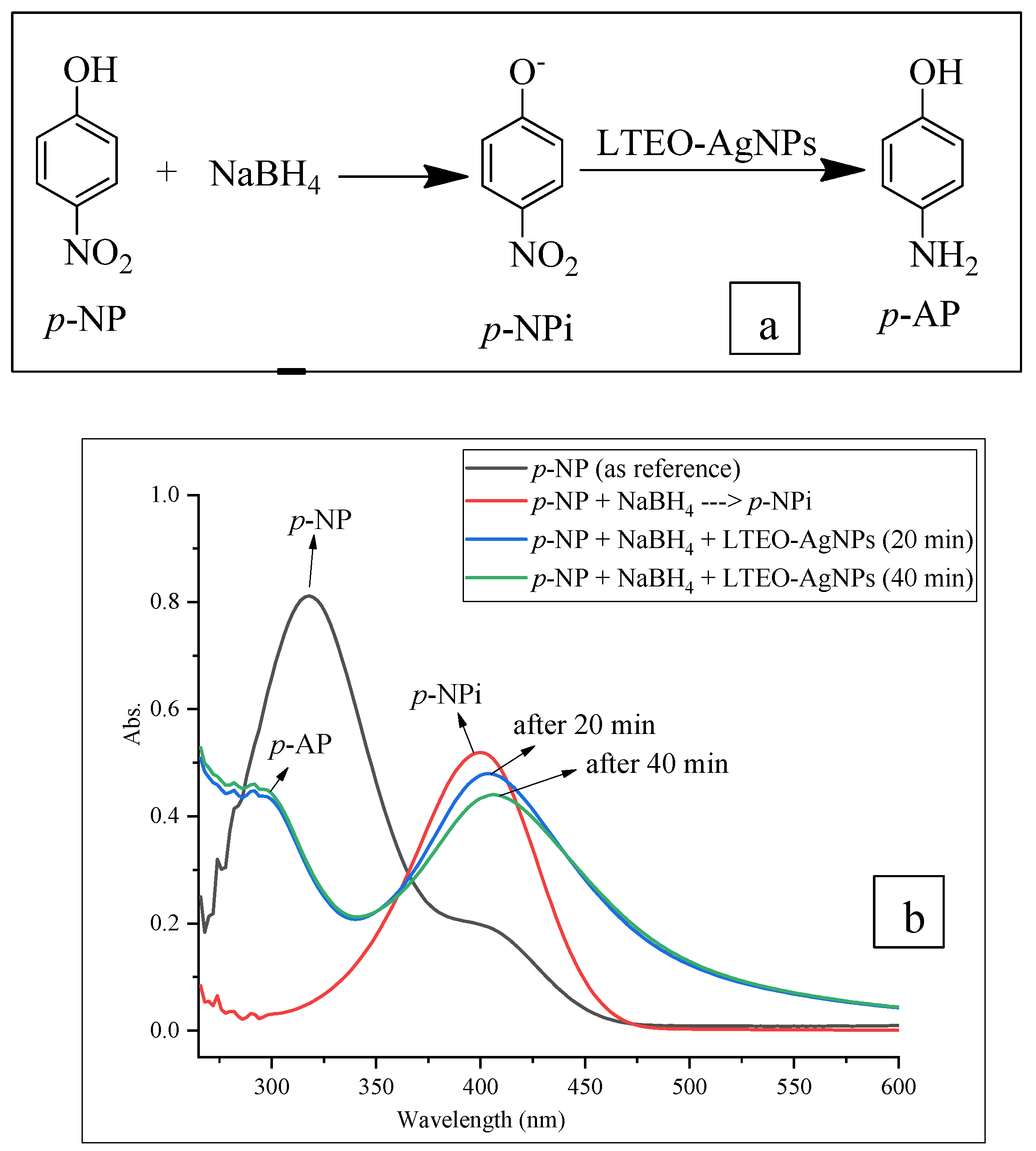

3.3.4. Catalytic Reduction Activity

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Singh, J.; Dutta, T.; Kim, K.H.; Rawat, M.; Samddar, P.; Kumar, P. Green synthesis of metals and their oxide nanoparticles: Applications for environmental remediation. J. Nanobiotechnol. 2018, 16, 84. [Google Scholar] [CrossRef] [PubMed]

- Balashanmugam, P.; Kalaichelvan, P.T. Biosynthesis characterization of silver nanoparticles using Cassia roxburghii DC. aqueous extract, and coated on cotton cloth for effective antibacterial activity. Int. J. Nanomed. 2015, 10, 87–97. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Khandel, P.; Yadaw, R.K.; Soni, D.K.; Kanwar, L.; Shahi, S.K. Biogenesis of metal nanoparticles and their pharmacological applications: Present status and application prospects. J. Nanostruc. Chem. 2018, 8, 217–254. [Google Scholar] [CrossRef] [Green Version]

- Pantidos, N.; Horsfall, L.E. Biological synthesis of metallic nanoparticles by bacteria, fungi and plants. J. Nanomed. Nanotechnol. 2014, 5, 1000233. [Google Scholar] [CrossRef]

- Habibullah, G.; Viktorova, J.; Ruml, T. Current strategies for noble metal nanoparticle synthesis. Nanosc. Res. Lett. 2021, 16, 47. [Google Scholar] [CrossRef]

- Rashmi, V.; Prabhushankar, H.B.; Sanjay, K.R. Centella asiatica L. callus mediated biosynthesis of silver nanoparticles, optimization using central composite design, and study on their antioxidant activity. Plant Cell Tissue Org. Cult. 2021, 146, 515–529. [Google Scholar] [CrossRef]

- Bhumi, G.; Linga, R.M.; Savithramma, N. Green synthesis of silver nanoparticles from the leaf extract of Adhatoda vasica nees and assessment of its antibacterial activity. Asian J. Pharm. Clin. Res. 2015, 8, 62–67. [Google Scholar]

- Kumar, B. Green synthesis of gold, silver, and iron nanoparticles for the degradation of organic pollutants in wastewater. J. Compos. Sci. 2021, 5, 219. [Google Scholar] [CrossRef]

- Saeed, S.A. Silver nanoparticles (AgNPs) from plant extracts. Life App. Sci. 2019, 70, 70–95. [Google Scholar] [CrossRef]

- Sana, S.S.; Li, H.; Zhang, Z.; Sharma, M.; Usmani, Z.; Hou, T.; Netala, V.R.; Wang, X.; Gupta, V.K. Recent advances in essential oils-based metal nanoparticles: A review on recent developments and biopharmaceutical applications. J. Mol. Liq. 2021, 333, 115951. [Google Scholar] [CrossRef]

- De Oliveira Brisola Maciel, M.V.; da Rosa Almeida, A.; Machado, M.H.; Elias, W.C.; da Rosa, C.G.; Teixeira, G.L.; Noronha, C.M.; Bertoldi, F.C.; Nunes, M.R.; de Armas, R.D.; et al. Green synthesis, characteristics and antimicrobial activity of silver nanoparticles mediated by essential oils as reducing agents. Biocatal. Agric. Biotechnol. 2020, 28, 101746. [Google Scholar] [CrossRef]

- Pryshchepa, O. Silver nanoparticles: Synthesis, investigation techniques, and properties. Adv. Colloid. Interface Sci. 2020, 284, 87–100. [Google Scholar] [CrossRef] [PubMed]

- Salayová, A.; Bedlovičová, Z.; Daneu, N. Green synthesis of silver nanoparticles with antibacterial activity using various medicinal plant extracts: Morphology and antibacterial efficacy. Nanomaterials 2021, 11, 1005. [Google Scholar] [CrossRef] [PubMed]

- Tarannum, N.; Divya, G.Y.K. Facile green synthesis and applications of silver nanoparticles: A state-of-the-art review. RSC Adv. 2019, 9, 34926–34948. [Google Scholar] [CrossRef] [Green Version]

- Sharifi-Rad, M.; Pohl, P.; Epifano, F. Phytofabrication of silver nanoparticles (AgNPs) with pharmaceutical capabilities using Otostegia persica (burm.) boiss. leaf extract. Nanomaterials 2021, 11, 1045. [Google Scholar] [CrossRef]

- Bhardwaj, K.; Dhanjal, D.S.; Sharma, A.; Nepovimova, E.; Kalia, A.; Thakur, S.; Bhardwaj, S.; Chopra, C.; Singh, R.; Verma, R.; et al. Conifer-derived metallic nanoparticles: Green synthesis and biological applications. Int. J. Mol. Sci. 2020, 21, 9028. [Google Scholar] [CrossRef]

- Ahmed, A.A.Q.; Xiao, L.; McKay, T.J.M.; Yang, G. Green Metal-Based Nanoparticles Synthesized Using Medicinal Plants and Plant Phytochemicals against Multidrug-Resistant Staphylococcus aureus. In Green Synthesis in Nanomedicine and Human Health; CRC Press: Boca Raton, FL, USA, 2021; pp. 181–246. [Google Scholar]

- Vilas, V.; Philip, D.; Mathew, J. Biosynthesis of Au and Au/Ag alloy nanoparticles using Coleus aromaticus essential oil and evaluation of their catalytic, antibacterial and antiradical activities. J. Mol. Liq. 2016, 221, 179–189. [Google Scholar] [CrossRef]

- Sepahvand, R.; Delfan, B.; Ghanbarzadeh, S.; Rashidipour, M.; Veiskarami, G.H.; Ghasemian-Yadegari, J. Chemical composition, antioxidant activity and antibacterial effect of essential oil of the aerial parts of Salvia sclareoides. Asian Pac. J. Trop. Med. 2014, 7, 491–496. [Google Scholar] [CrossRef] [Green Version]

- Bampouli, A.; Kyriakopoulou, K.; Papaefstathiou, G.; Louli, V.; Krokida, M.; Magoulas, K. Comparison of different extraction methods of Pistacia lentiscus var. chia leaves: Yield, antioxidant activity and essential oil chemical composition. J. App. Res. Med. Aromat. Plants 2014, 1, 81–91. [Google Scholar] [CrossRef]

- Abdellatif, F.; Hassani, A. Chemical composition of the essential oils from leaves of Melissa officinalis extracted by hydrodistillation, steam distillation, organic solvent, and microwave hydrodistillation. J. Mater. Environ. Sci. 2015, 6, 207–213. [Google Scholar]

- Chamorro, E.R.; Zambón, S.N.; Morales, W.G.; Sequeira, A.F.; Velasco, G.A. Study of the chemical composition of essential oils by gas chromatography. In Gas Chromatography in Plant Science, Wine Technology, Toxicology and Some Specific Applications; IntechOpen: London, UK, 2012; pp. 307–324. [Google Scholar] [CrossRef] [Green Version]

- Vasile, B.S.; Birca, A.C.; Musat, M.C.; Holban, A.M. Wound dressings coated with silver nanoparticles and essential oils for the management of wound infections. Materials 2020, 13, 1682. [Google Scholar] [CrossRef]

- Mothana, R.A.; Alsaid, M.S.; Al-Musayei, N.M. Phytochemical analysis and in vitro antimicrobial and free-radical-scavenging activities of the essential oils from Euryops arabicus and Laggera decurrens. Molecules 2011, 16, 5149–5158. [Google Scholar] [CrossRef] [PubMed]

- Lia, X.; Huoa, C.; Shi, Q.; Kiyota, H. Chemical constituents of the plants from the Genus Laggera. Chem. Biobivers. 2007, 4, 105–111. [Google Scholar] [CrossRef] [PubMed]

- Omoregie, E.H.; Oluyemisi, K.F.; Koma, O.S.; Ibumeh, O.J. Chemical constituents of the essential oil of Laggera pterodonta (DC.) Sch. Bip. from North-Central Nigeria. J. App. Pharm. Sci. 2012, 2, 198–202. [Google Scholar] [CrossRef] [Green Version]

- Gebreheiwot, K.; Amenu, D.; Asfaw, N. Cuathemone sesquiterpenes and flavones from Laggera tomentosa endemic to Ethiopia. Bull. Chem. Soc. Ethiop. 2010, 24, 267–271. [Google Scholar] [CrossRef] [Green Version]

- Asfaw, N.; Storesund, H.J.; Aasen, A.J. Constituents of the essential oil of Laggera constituents of the essential oil of Laggera tomentosa Sch. Bip. ex Oliv. et Hiern endemic to Ethiopia. J. Essent. Oil Res. 2011, 15, 102–105. [Google Scholar] [CrossRef]

- Yilma, H.G.; Fekade, B.T.; Abiy, A.G.; Sileshi, D.G.; Mesfin, G.T.; Archana, B.; Rakesh, K.B. Chemical compositions of essential oil from aerial parts of Cyclospermum leptophyllum and its application as antibacterial activity against some food spoilage bacteria. J. Chem. 2022, 2022, 5426050. [Google Scholar] [CrossRef]

- Getahun, T.; Sharma, V.; Kumar, D.; Gupta, N. Chemical composition, and antibacterial and antioxidant activities of essential oils from Laggera tomentosa Sch. Bip. ex Oliv. et Hiern (Asteraceae). Turk. J. Chem. 2020, 44, 1539–1548. [Google Scholar] [CrossRef] [PubMed]

- Chahardoli, A.; Hajmomeni, P.; Ghowsi, M.; Qalekhani, F.; Shokoohinia, Y.; Fattahi, A. Optimization of quercetin-assisted silver nanoparticles synthesis and evaluation of their hemocompatibility, antioxidant, anti-inflammatory, and antibacterial effects. Adv. Sci. News 2021, 2100075, 2100075. [Google Scholar] [CrossRef] [PubMed]

- Saha, N.; Trivedi, P.; Dutta, G.S. Surface plasmon resonance (SPR) based optimization of biosynthesis of silver nanoparticles from rhizome extract of Curculigo orchioides Gaertn. and its antioxidant potential. J. Clust. Sci. 2016, 27, 1893–1912. [Google Scholar] [CrossRef]

- Kartini, K.; Alviani, A.; Anjarwati, D.; Fanany, A.F. Process optimization for green synthesis of silver nanoparticles using Indonesian medicinal plant extracts. Processes 2020, 8, 998. [Google Scholar] [CrossRef]

- Haque, M.A.; Hossain, M.S.; Akanda, M.R.; Haque, A.; Naher, S. Procedure optimization of Limonia acidissima leaf extraction and silver nanoparticle synthesis for prominent antibacterial activity. ChemistrySelect 2019, 4, 14276–14280. [Google Scholar] [CrossRef]

- Gul, A.R.; Shaheen, F.; Rafique, R.; Bal, J.; Waseem, S.; Park, T.J. Grass-mediated biogenic synthesis of silver nanoparticles and their drug delivery evaluation: A biocompatible anti-cancer therapy. Chem. Eng. J. 2021, 407, 127202. [Google Scholar] [CrossRef]

- Budhani, S.; Egboluche, N.P.; Arslan, Z.; Yu, H.; Deng, H. Phytotoxic effect of silver nanoparticles on seed germination and growth of terrestrial plants. J. Environ. Sci. Health—Part C 2019, 37, 330–355. [Google Scholar] [CrossRef]

- Kalam, A.; Al-Sehemi, A.G.; Alrumman, S. Colorimetric optical chemosensor of toxic metal ion (Hg2+) and biological activity using green synthesized AgNPs. Green Chem. Lett. Rev. 2018, 11, 484–491. [Google Scholar] [CrossRef] [Green Version]

- Li, P.; Wang, Y.; Huang, H.; Ma, S.; Yang, H.; Xu, Z.L. High efficient reduction of 4-nitrophenol and dye by filtration through AgNPs coated PAN-Si catalytic membrane. Chemosphere 2021, 263, 127995. [Google Scholar] [CrossRef] [PubMed]

- Kapoor, S.; Sood, H.; Saxena, S.; Chaurasia, O.P. Green synthesis of silver nanoparticles using Rhodiola imbricata and Withania somnifera root extract and their potential catalytic, antioxidant, cytotoxic, and growth-promoting activities. Bioprocess Biosyst. Eng. 2022, 45, 365–380. [Google Scholar] [CrossRef]

- Ahmad, B.; Ali, J.; Bashir, S. Optimization and effects of different reaction conditions for the bioinspired synthesis of silver nanoparticles using Hippophae rhamnoides Linn. leaves aqueous extract. World Appl. Sci. J. 2013, 22, 836–843. [Google Scholar] [CrossRef]

- Alzahrani, E.; Welham, K. Optimization preparation of the biosynthesis of silver nanoparticles using watermelon and study of its antibacterial activity. Int. J. Basic Appl. Sci. 2014, 3, 392. [Google Scholar] [CrossRef] [Green Version]

- Arya, G.; Kumari, R.M.; Gupta, N.; Kumar, A.; Chandra, R.; Nimesh, S. Green synthesis of silver nanoparticles using Prosopis juliflora bark extract: Reaction optimization, antimicrobial and catalytic activities. Artif. Cells Nanomed. Biotechnol. 2018, 46, 985–993. [Google Scholar] [CrossRef] [Green Version]

- Ahmed, F.; Kabir, H.; Xiong, H. Dual colorimetric sensor for Hg2+/Pb2+ and an efficient catalyst based on silver nanoparticles mediating by the root extract of Bistorta amplexicaulis. Front. Chem. 2020, 8, 591958. [Google Scholar] [CrossRef]

- Ramdath, S.; Mellem, J.; Mbatha, L.S. Anticancer and antimicrobial activity evaluation of cowpea-porous-starch-formulated silver nanoparticles. J. Nanotechnol. 2021, 2021, 5525690. [Google Scholar] [CrossRef]

- Nomura, K.; Terwilliger, P.; Roy, K.; Srivastwa, A.K.; Ghosh, C.K. Anticoagulant, thrombolytic, and antibacterial activities of Euphorbia acruensis latex-mediated bioengineered silver nanoparticles. Green Process. Synth. 2019, 8, 590–599. [Google Scholar]

- Vijayakumar, S.; Malaikozhundan, B.; Parthasarathy, A.; Saravanakumar, K.; Wang, M.H.; Vaseeharan, B. Nano biomedical potential of biopolymer chitosan-capped silver nanoparticles with special reference to antibacterial, antibiofilm, anticoagulant, and wound dressing material. J. Clust. Sci. 2020, 31, 355–366. [Google Scholar] [CrossRef]

- Pontes-Quero, G.M.; Benito-Garzón, L.; Pérez Cano, J.; Aguilar, M.R.; Vázquez-Lasa, B. Amphiphilic polymeric nanoparticles encapsulating curcumin: Antioxidant, anti-inflammatory, and biocompatibility studies. Mater. Sci. Eng. C 2021, 121, 111793. [Google Scholar] [CrossRef] [PubMed]

- Quintero-Quiroz, C.; Acevedo, N.; Zapata-Giraldo, J. Optimization of silver nanoparticle synthesis by chemical reduction and evaluation of its antimicrobial and toxic activity. Biomater. Res. 2019, 23, 27. [Google Scholar] [CrossRef] [PubMed]

- Li, C.; Chen, D.; Xiao, H. Green synthesis of silver nanoparticles using Pyrus betulifolia Bunge and their antibacterial and antioxidant activity. Mater. Today Commun. 2021, 26, 102–108. [Google Scholar] [CrossRef]

- Tsegay, M.G.; Gebretinsae, H.G.; Sackey, J.; Maaza, M.; Nuru, Z.Y. Green synthesis of khat mediated silver nanoparticles for efficient detection of mercury ions. Mater. Today: Proc. 2021, 36, 368–373. [Google Scholar] [CrossRef]

- Agnihotri, S.; Sillu, D.; Sharma, G.; Arya, R.K. Photocatalytic and antibacterial potential of silver nanoparticles derived from pineapple waste: Process optimization and modeling kinetics for dye removal. Appl. Nanosci. 2018, 8, 2077–2092. [Google Scholar] [CrossRef]

- Jain, S.; Mehata, M.S. Medicinal plant leaf extract and pure flavonoid mediated green synthesis of silver nanoparticles and their enhanced antibacterial property. Sci. Rep. 2017, 7, 15867. [Google Scholar] [CrossRef] [Green Version]

- Sang, S.; Li, D.; Zhang, H. Facile synthesis of AgNPs on reduced graphene oxide for highly sensitive simultaneous detection of heavy metal ions. RSC Adv. 2017, 7, 21618–21624. [Google Scholar] [CrossRef] [Green Version]

- Ibrahim, H.M.; Zaghloul, S.; Hashem, M.; El-Shafei, A. A green approach to improve the antibacterial properties of cellulose-based fabrics using Moringa oleifera extract in the presence of silver nanoparticles. Cellulose 2021, 28, 549–564. [Google Scholar] [CrossRef]

- Iqbal, M.; Raja, N.I.; Mashwani, Z.U.R.; Hussain, M.; Ejaz, M.; Yasmeen, F. Effect of silver nanoparticles on growth of wheat under heat stress. Iran J. Sci. Technol. Trans A Sci. 2019, 43, 387–395. [Google Scholar] [CrossRef]

- Awada, M.A.; Hendib, A.A.; Ortashic, K.M.; Alzahranid, B.; Solimane, D.; Alanazid, A.; Alenazid, W.; Tahaf, R.M.; Ramadang, R.; El-Tohamyh, M.; et al. Biogenic synthesis of silver nanoparticles using Trigonella foenum-graecum seed extract: Characterization, photocatalytic, and antibacterial activities. Sens. Actuator A 2021, 323, 112670. [Google Scholar] [CrossRef]

- Tufail, M.S. Silver nanoparticles and their applications: A comprehensive review. Pure Appl. Biol. 2021, 11, 315–330. [Google Scholar] [CrossRef]

- Chitra, K. Effects of silver nanoparticles on seed germination and seedling growth of radish (Raphanus sativus L.). J. Env. Sci. Toxicol. Food Technol. 2017, 11, 604–608. [Google Scholar] [CrossRef]

- Azimpanah, R.; Solati, Z.; Hashemi, M. Green synthesis of silver nanoparticles and their applications as colorimetric probe for determination of Fe3+ and Hg2+ ions. IET Nanobiotechnol. 2017, 12, 673–677. [Google Scholar] [CrossRef]

- Chen, J.; Liu, Y.; Xiong, Y. Konjac glucomannan reduced-stabilized silver nanoparticles for mono-azo and di-azo contained wastewater treatment. Inorg. Chim. Acta 2021, 515, 120058. [Google Scholar] [CrossRef]

- Albukhari, S.M.; Ismail, M.; Akhtar, K.; Danish, E.Y. Catalytic reduction of nitrophenols and dyes using silver nanoparticles @cellulose polymer paper for the resolution of wastewater treatment challenges. Colloids Surf. A Physicochem. Eng. Asp. 2019, 577, 548–561. [Google Scholar] [CrossRef]

- Yang, W.; Hu, W.; Zhang, J. Tannic acid/Fe3+ functionalized magnetic graphene oxide nanocomposite with high loading of silver nanoparticles as ultra-efficient catalyst and disinfectant for wastewater treatment. J. Chem. Eng. 2021, 405, 126629. [Google Scholar] [CrossRef]

- Horta-Fraijo, P.; Smolentseva, E.; Simakov, A.; José-Yacaman, M.; Acosta, B. Ag nanoparticles in A4 zeolite as efficient catalysts for the 4-nitrophenol reduction. Microporous Mesoporous Mater. 2021, 312, 110707. [Google Scholar] [CrossRef]

- Ismail, M.; Khan, M.I.; Khan, S.B.; Akhtar, K.; Khan, M.A.; Asiri, A.M. Catalytic reduction of picric acid, nitrophenols, and organic azo dyes via green synthesized plant supported Ag nanoparticles. J. Mol. Liq. 2018, 268, 87–101. [Google Scholar] [CrossRef]

| Test Microorganism | Zone of Inhibition Diameter (ZID) * in mm | ||||||

|---|---|---|---|---|---|---|---|

| Cipro. (5 µg/mL) | LTEO Sol. (30%) | LTEO-AgNPs (Full Strength) | 50% LTEO-AgNPs | 25% LTEO-AgNPs | 12.5% LTEO-AgNPs | 6.25% LTEO-AgNPs | |

| S. aureus | 26.00 ± 0.00 | 24.33 ± 0.58 | 21. 00 ± 1.00 | 20.67 ± 0.58 | 12.67 ± 0.58 | 9.00 ± 0.00 | 9.00 ± 0.00 |

| S. epidermidis | 34.33 ± 1.15 | 23.33 ± 0.58 | 16.67 ± 0.58 | 14.33 ± 0.58 | 12.00 ± 0.00 | 11.00 ± 0.00 | 9.67 ± 0.58 |

| S. agalactiae | 21.33 ± 1.53 | 13.33 ± 0.58 | 11.67 ± 0.58 | 10.00 ± 0.00 | 9.00 ± 0.00 | 8.67 ± 0.58 | 8.33 ± 0.58 |

| E. coli | 33.33 ± 0.58 | 18.33 ± 0.58 | 20.33 ± 0.58 | 19.00 ± 1.00 | 15.33 ± 0.58 | 12.67 ± 0.58 | 11.00 ± 1.00 |

| P. mirabilis | 39.33 ± 0.58 | 16.33 ± 1.15 | 11.00 ± 1.00 | 11.33 ± 0.58 | 9.00 ± 0.00 | 8.00 ± 0.00 | 8.00 ± 0.00 |

| P. aeruginosa | 31.33 ± 0.58 | 14.67 ± 0.58 | 13.67 ± 0.58 | 13.33 ± 0.58 | 11.67 ± 0.58 | 9.33 ± 0.58 | 8.00 ± 0.00 |

| Test Microorganism | %RZID * | ||||||

|---|---|---|---|---|---|---|---|

| Cipro. | LTEO Sol. (30%) | LTEO-AgNPs (Full Strength) | 50% LTEO-AgNPs | 25% LTEO-AgNPs | 12.5% LTEO-AgNPs | 6.25% LTEO-AgNPs | |

| S. aureus | 100.00 ± 0 | 90.75 ± 3.22 | 72.22 ± 5.56 | 70.37 ± 3.20 | 25.93 ± 3.21 | 5.56 ± 0 | 5.56 ± 0 |

| S. epidermidis | 100.00 ± 0 | 58.27 ± 2.38 | 32.99 ± 3.20 | 24.15 ± 3.34 | 15.21 ± 0.68 | 11.41 ± 0.51 | 6.37 ± 2.33 |

| S. agalactiae | 100.00 ± 0 | 40.60 ± 8.54 | 28.03 ± 7.07 | 15.13 ± 1.69 | 7.56 ± 0.84 | 5.34 ± 4.64 | 2.22 ± 3.85 |

| E. coli | 100.00 ± 0 | 40.77 ± 1.33 | 48.72 ± 2.99 | 43.44 ± 4.12 | 28.97 ± 2.69 | 18.41 ± 2.12 | 11.80 ± 3.70 |

| P. mirabilis | 100.00 ± 0 | 26.57 ± 3.50 | 9.61 ± 3.33 | 10.62 ± 1.63 | 3.20 ± 0.08 | 0.00 | 0.00 |

| P. aeruginosa | 100.00 ± 0 | 28.63 ± 3.14 | 23.94 ± 1.91 | 22.89 ± 2.81 | 15.70 ± 2.33 | 5.74 ± 2.57 | 0.00 |

| Treatment | Seeds Germination (%) | Seedling Elongation (in cm) * | |

|---|---|---|---|

| Root | Shoot | ||

| PD0: Control(DDH2O) | 100.00 ± 0.00 | 15.47 ± 5.53 | 10.22 ± 4.20 |

| PD100: LTEO-AgNPs (100 µL) | 100.00 ± 0.00 | 11.05 ± 7.44 | 8.23 ± 5.60 |

| PD500: LTEO-AgNPs (500 µL) | 93.33 ± 0.00 | 11.63 ± 7.11 | 9.47 ± 5.55 |

| PD1000: LTEO-AgNPs (1000 µL) | 100.00 ± 0.00 | 11.91 ± 3.13 | 9.50 ± 3.55 |

| PD2000: LTEO-AgNPs (2000 µL) | 100.00 ± 0.00 | 17.03 ± 7.02 | 10.23 ± 4.89 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gonfa, Y.H.; Gelagle, A.A.; Hailegnaw, B.; Kabeto, S.A.; Workeneh, G.A.; Tessema, F.B.; Tadesse, M.G.; Wabaidur, S.M.; Dahlous, K.A.; Abou Fayssal, S.; et al. Optimization, Characterization, and Biological Applications of Silver Nanoparticles Synthesized Using Essential Oil of Aerial Part of Laggera tomentosa. Sustainability 2023, 15, 797. https://doi.org/10.3390/su15010797

Gonfa YH, Gelagle AA, Hailegnaw B, Kabeto SA, Workeneh GA, Tessema FB, Tadesse MG, Wabaidur SM, Dahlous KA, Abou Fayssal S, et al. Optimization, Characterization, and Biological Applications of Silver Nanoparticles Synthesized Using Essential Oil of Aerial Part of Laggera tomentosa. Sustainability. 2023; 15(1):797. https://doi.org/10.3390/su15010797

Chicago/Turabian StyleGonfa, Yilma Hunde, Abiy Abebe Gelagle, Bekele Hailegnaw, Samuel Abicho Kabeto, Getachew Adam Workeneh, Fekade Beshah Tessema, Mesfin Getachew Tadesse, Saikh M. Wabaidur, Kholood A. Dahlous, Sami Abou Fayssal, and et al. 2023. "Optimization, Characterization, and Biological Applications of Silver Nanoparticles Synthesized Using Essential Oil of Aerial Part of Laggera tomentosa" Sustainability 15, no. 1: 797. https://doi.org/10.3390/su15010797

APA StyleGonfa, Y. H., Gelagle, A. A., Hailegnaw, B., Kabeto, S. A., Workeneh, G. A., Tessema, F. B., Tadesse, M. G., Wabaidur, S. M., Dahlous, K. A., Abou Fayssal, S., Kumar, P., Adelodun, B., Bachheti, A., & Bachheti, R. K. (2023). Optimization, Characterization, and Biological Applications of Silver Nanoparticles Synthesized Using Essential Oil of Aerial Part of Laggera tomentosa. Sustainability, 15(1), 797. https://doi.org/10.3390/su15010797