Resistive Switching Property of Raw Organic Cow Milk for Memory Application

Abstract

:1. Introduction

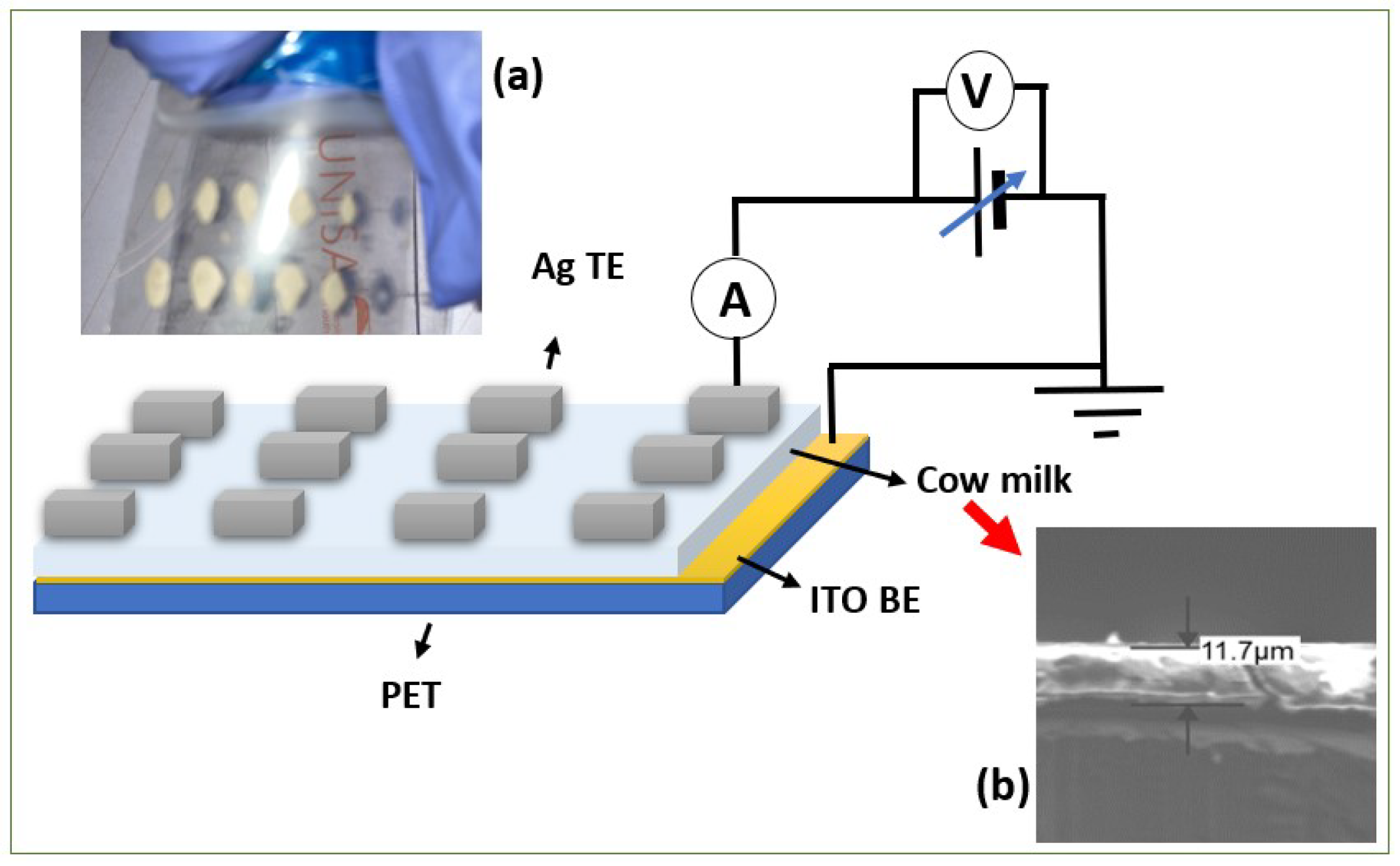

2. Materials and Methods

- PET-ITO/Cow-milk(S1)/Ag

- PET-ITO/Cow-milk(S2)/Ag, and

- PET-ITO/Cow-milk(S3)/Ag

3. Results

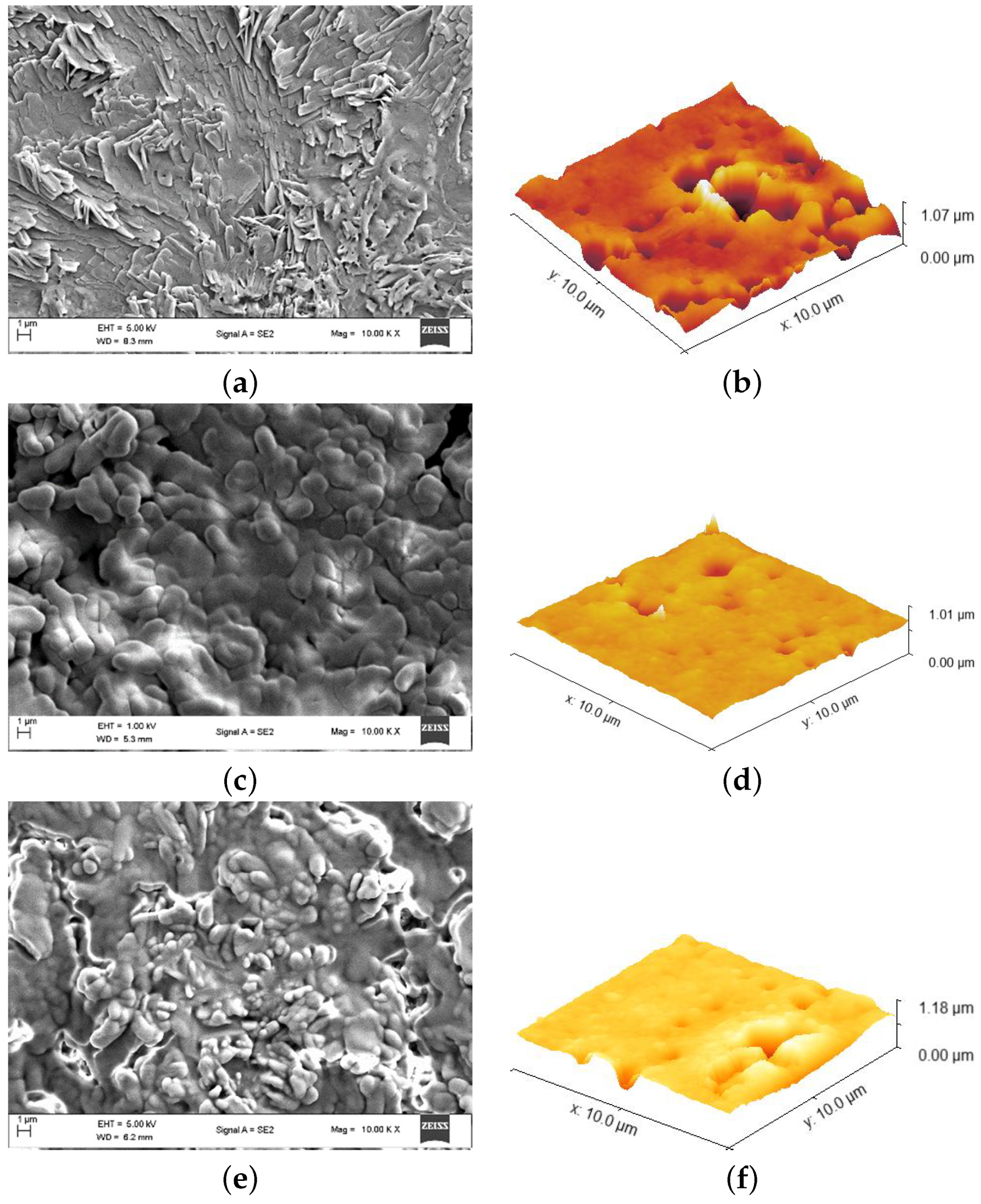

3.1. Morphology and Topography

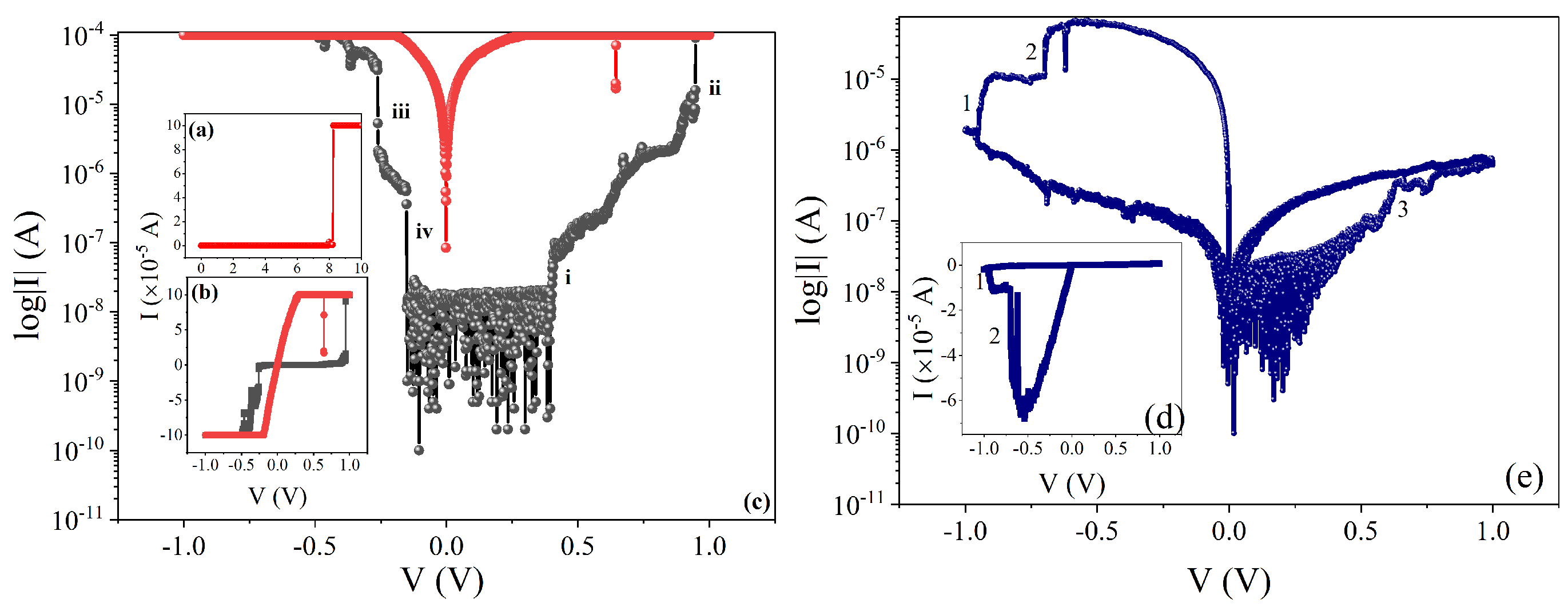

3.2. Transport and Memory Study

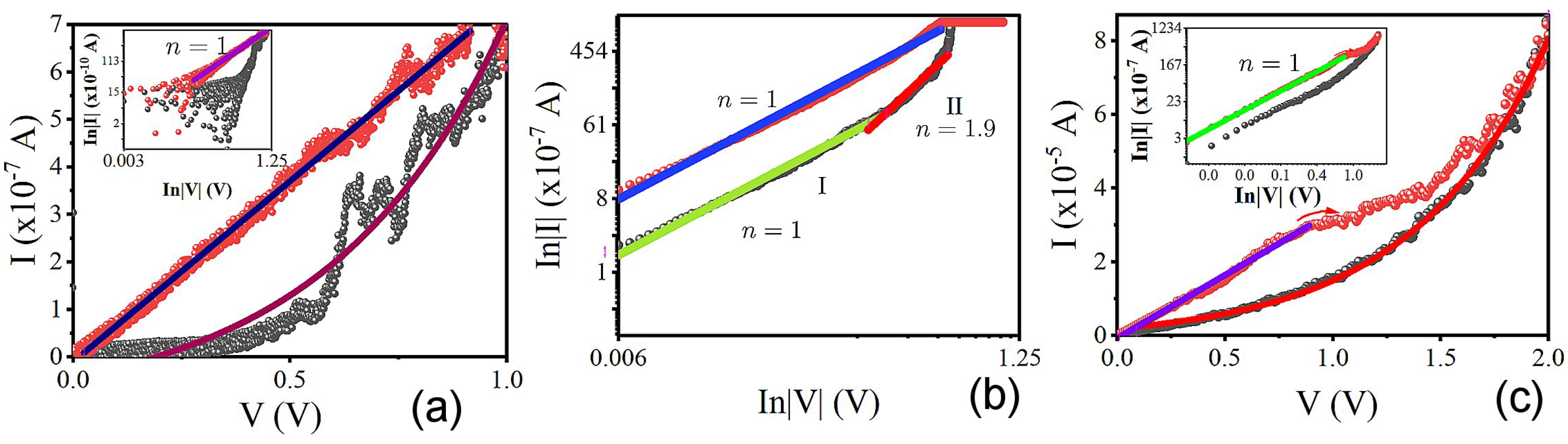

3.3. Conduction Mechanism Analysis

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ReRAM | Resistive Switching Memory |

| TE | Top electrode |

| BE | Bottom electrode |

| SCLCM | Space charge-limited conduction mechanism |

| CBCM | Conductive bridge conduction mechanism |

References

- Hickmott, T.W. Low-Frequency Negative Resistance in Thin Anodic Oxide Films. J. Appl. Phys. 1962, 33, 2669–2682. [Google Scholar] [CrossRef]

- Tseng, R.J.; Tsai, C.; Ma, L.; Ouyang, J.; Ozkan, C.S.; Yang, Y. Digital memory device based on tobacco mosaic virus conjugated with nanoparticles. Nat. Nanotechnol. 2006, 1, 72–77. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.Y.; Qian, Q.; Zhu, X.; Li, Y.Y.; Zhang, M.; Li, J.; Ma, C.; Li, H.; Lu, J.; Zhang, Q. Recent advances in organic-based materials for resistive memory applications. InfoMat 2020, 2, 995–1033. [Google Scholar] [CrossRef]

- Jeong, D.S.; Thomas, R.; Katiyar, R.S.; Scott, J.F.; Kohlstedt, H.; Petraru, A.; Hwang, C.S. Emerging memories: Resistive switching mechanisms and current status. Rep. Prog. Phys. 2012, 75, 076502. [Google Scholar] [CrossRef]

- Vallabhapurapu, S.; Sangani, L.D.V.; Krishna, M.G.; Das, J.; Srinivasan, A.; Srinivasu, V.V. Optical and resistive switching properties of Chitosan-aluminum-doped zinc oxide composite thin films for transparent resistive random access memory application. J. Mater. Sci. Mater. Electron. 2021, 32, 3556–3565. [Google Scholar] [CrossRef]

- Dlamini, Z.W.; Vallabhapurapu, S.; Wu, S.; Mahule, T.S.; Srivivasan, A.; Vallabhapurapu, V.S. Resistive switching memory based on chitosan/polyvinylpyrrolidone blend as active layers. Solid State Commun. 2022, 345, 114677. [Google Scholar] [CrossRef]

- Hwang, S.W.; Song, J.K.; Huang, X.; Cheng, H.; Kang, S.K.; Kim, B.H.; Kim, J.H.; Yu, S.; Huang, Y.; Rogers, J.A. High-Performance Biodegradable/Transient Electronics on Biodegradable Polymers. Adv. Mater. 2014, 26, 3905–3911. [Google Scholar] [CrossRef]

- Hosseini, N.R.; Lee, J.S.S. Biocompatible and Flexible Chitosan-Based Resistive Switching Memory with Magnesium Electrodes. Adv. Funct. Mater. 2015, 25, 5586–5592. [Google Scholar] [CrossRef]

- Guo, Y.; Hu, W.; Zeng, F.; Zhang, C.; Peng, Y.; Guo, Y. Ultrafast degradable resistive switching memory based on α-lactose thin films. Org. Electron. 2020, 83, 105750. [Google Scholar] [CrossRef]

- Lv, F.; Ling, K.; Zhong, T.; Liu, F.; Liang, X.; Zhu, C.; Liu, J.; Kong, W. Multilevel Resistive Switching Memory Based on a CH3NH3PbI 3-xClx Film with Potassium Chloride Additives. Nanoscale Res. Lett. 2020, 15, 126. [Google Scholar] [CrossRef]

- Dlamini, Z.W.; Vallabhapurapu, S.; Mahule, T.S.; Vallabhapurapu, V.S. Electrical conduction and resistive switching in cow milk-based devices prepared using the spin-coat method. AIP Adv. 2022, 12, 095321. [Google Scholar] [CrossRef]

- Dlamini, Z.W.; Vallabhapurapu, S.; Daramola, O.A.; Tseki, P.F.; Krause, R.W.M.; Siwe-Noundou, X.; Mahule, T.S.; Vallabhapurapu, S.V. Conduction and Resistive Switching in Dropcast CdTe/CdSe Core-Shell Quantum Dots Embedded Chitosan Composite. Iran. J. Sci. Technol. Trans. A Sci. 2022, 46, 709–716. [Google Scholar] [CrossRef]

- Dlamini, Z.; Vallabhapurapu, S.; Srinivasan, A.; Wu, S.; Vallabhapurapu, V. Resistive Switching in Polyvinylpyrrolidone/Molybdenum Disulfide Composite-Based Memory Devices. Acta Phys. Pol. A 2022, 141, 439–444. [Google Scholar] [CrossRef]

- Prime, D.; Paul, S. Overview of organic memory devices. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2009, 367, 4141–4157. [Google Scholar] [CrossRef]

- Park, J.; Huh, D.; Son, S.; Kim, W.; Ju, S.; Lee, H. Transparent, Flexible, and Low-Operating-Voltage Resistive Switching Memory Based on Al2Ol3/IZO Multilayer. Glob. Challenges 2022, 6, 2100118. [Google Scholar] [CrossRef]

- Kim, J.; Park, J.; Kim, S. Bipolar Switching Characteristics of Transparent WOX-Based RRAM for Synaptic Application and Neuromorphic Engineering. Materials 2022, 15, 7185. [Google Scholar] [CrossRef]

- Yalagala, B.; Khandelwal, S.; Deepika, J.; Badhulika, S. Wirelessly destructible MgO-PVP-Graphene composite based flexible transient memristor for security applications. Mater. Sci. Semicond. Process. 2019, 104, 104673. [Google Scholar] [CrossRef]

- Vallabhapurapu, S.; Rohom, A.; Chaure, N.B.; Tu, C.; Du, S.; Srinivasu, V.V.; Srinivasan, A. Hopping conductivity-mediated O-shaped memory behaviour in gelatin–graphene oxide composite films. Appl. Phys. A 2018, 124, 1–5. [Google Scholar] [CrossRef]

- Shen, Z.; Zhao, C.; Qi, Y.; Xu, W.; Liu, Y.; Mitrovic, I.Z.; Yang, L.; Zhao, C. Advances of RRAM devices: Resistive switching mechanisms, materials and bionic synaptic application. Nanomaterials 2020, 10, 1437. [Google Scholar] [CrossRef]

- Yu, S. Resistive Random Access Memory (RRAM). Synth. Lect. Emerg. Eng. Technol. 2016, 2, 1–79. [Google Scholar]

- Dlamini, Z.W.; Vallabhapurapu, S.; Daramola, O.A.; Tseki, P.F.; Krause, R.W.M.; Siwe-Noundou, X.; Mahule, T.S.; Vallabhapurapu, S.V. Resistive Switching in CdTe/CdSe Core–Shell Quantum Dots Embedded Chitosan-Based Memory Devices. J. Circuits Syst. Comput. 2022, 31, 1–16. [Google Scholar] [CrossRef]

- Sun, T.; Tu, J.; Zhou, Z.; Sun, R.; Zhang, X.; Li, H.; Xu, Z.; Peng, Y.; Liu, X.; Wangyang, P.; et al. Resistive switching of self-assembly stacked h-BN polycrystal film. Cell Rep. Phys. Sci. 2022, 3, 100939. [Google Scholar] [CrossRef]

- Lim, E.W.; Ismail, R. Conduction mechanism of valence change resistive switching memory: A survey. Electronics 2015, 4, 586–613. [Google Scholar] [CrossRef]

- Choi, J.; Park, S.; Lee, J.; Hong, K.; Kim, D.H.; Moon, C.W.; Park, G.D.; Suh, J.; Hwang, J.; Kim, S.Y.; et al. Organolead Halide Perovskites for Low Operating Voltage Multilevel Resistive Switching. Adv. Mater. 2016, 28, 6562–6567. [Google Scholar] [CrossRef]

- Zhou, G.; Yao, Y.; Lu, Z.; Yang, X.; Han, J.; Wang, G.; Rao, X.; Li, P.; Liu, Q.; Song, Q. Hydrogen-peroxide-modified egg albumen for transparent and flexible resistive switching memory. Nanotechnology 2017, 28, 425202. [Google Scholar] [CrossRef] [PubMed]

- Zhou, G.; Sun, B.; Zhou, A.; Wu, B.; Huang, H. A larger nonvolatile bipolar resistive switching memory behaviour fabricated using eggshells. Curr. Appl. Phys. 2017, 17, 235–239. [Google Scholar] [CrossRef]

- Qin, S.; Dong, R.; Yan, X.; Du, Q. A reproducible write-(read)n-erase and multilevel bio-memristor based on DNA molecule. Org. Electron. 2015, 22, 147–153. [Google Scholar] [CrossRef]

- Liu, S.; Dong, S.; Wang, X.; Shi, L.; Xu, H.; Huang, S.; Luo, J. Flexible and fully biodegradable resistance random access memory based on a gelatin dielectric. Nanotechnology 2020, 31, 255204. [Google Scholar] [CrossRef]

- Wang, H.; Zhu, B.; Wang, H.; Ma, X.; Hao, Y.; Chen, X. Ultra-Lightweight Resistive Switching Memory Devices Based on Silk Fibroin. Small 2016, 12, 3360–3365. [Google Scholar] [CrossRef]

- Raeis-Hosseini, N.; Lee, J.S. Controlling the Resistive Switching Behavior in Starch-Based Flexible Biomemristors. ACS Appl. Mater. Interfaces 2016, 8, 7326–7332. [Google Scholar] [CrossRef]

- Sun, B.; Zhu, S.; Mao, S.; Zheng, P.; Xia, Y.; Yang, F.; Lei, M.; Zhao, Y. From dead leaves to sustainable organic resistive switching memory. J. Colloid Interface Sci. 2018, 513, 774–778. [Google Scholar] [CrossRef] [PubMed]

- Qi, Y.; Sun, B.; Fu, G.; Li, T.; Zhu, S.; Zheng, L.; Mao, S.; Kan, X.; Lei, M.; Chen, Y. A nonvolatile organic resistive switching memory based on lotus leaves. Chem. Phys. 2019, 516, 168–174. [Google Scholar] [CrossRef]

- Lim, Z.X.; Sreenivasan, S.; Wong, Y.H.; Zhao, F.; Cheong, K.Y. Filamentary Conduction in Aloe Vera Film for Memory Application. Procedia Eng. 2017, 184, 655–662. [Google Scholar] [CrossRef]

| Active Layer | Estimated Element Content () | Switching Type | Conduction Mechanism | ||||

|---|---|---|---|---|---|---|---|

| Na | Cl | K | Ca | Cu | |||

| Fat-free | 0.44 | 0.51 | - | 0.67 | - | ‘O-type’ | Hopping conduction |

| Medium cream | 2.37 | 4.72 | 7.42 | 5.07 | 1.08 | ‘S-type’ | SCLC |

| Full-cream | 0.31 | 0.88 | 1.13 | 0.91 | 0.42 | ‘O-type’ | Hopping conduction |

| Device | Operating Voltage | Ratio | Retention (s) | Endurance (Cycles) | Conduction Mechanism | Ref. |

|---|---|---|---|---|---|---|

| Ag/cow milk(S2)/ITO | 0.25 | ∼10 | no report | >30 | SCLCM | This work |

| Ag/-lactose/ITO | 0.6 | No report | 5000 | 100 | SCLCM | [9] |

| Mg/albumen/W | 1 | ∼ | ∼ | SCLCM | [25] | |

| Ag/eggshell/FTO | 1.12 | 100 | SCLCM | [26] | ||

| Au/DNA/Au | 0.73 | ∼10 | ∼ | SCLCM | [27] | |

| Mg/gelatin/W | 2.16 | ∼ | ∼ | SCLCM | [28] | |

| Ag/fibroin/Au | 0.7 | 30 | SCLCM | [29] | ||

| Au/starch/ITO | 0.9 | No report | SCLCM | [30] | ||

| Ag/Banyan leaves/Ti | 1 | 50 | No report | SCLCM | [31] | |

| Ag/Lotus leaves/ITO | 3 | 40 | >70 | CBCM 1 | [32] | |

| Ag/Aloe Vera/ITO | 0.75 | > | CBCM | [33] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dlamini, Z.W.; Vallabhapurapu, S.; Vallabhapurapu, V.S. Resistive Switching Property of Raw Organic Cow Milk for Memory Application. Sustainability 2023, 15, 8250. https://doi.org/10.3390/su15108250

Dlamini ZW, Vallabhapurapu S, Vallabhapurapu VS. Resistive Switching Property of Raw Organic Cow Milk for Memory Application. Sustainability. 2023; 15(10):8250. https://doi.org/10.3390/su15108250

Chicago/Turabian StyleDlamini, Zolile Wiseman, Sreedevi Vallabhapurapu, and Vijaya Srinivasu Vallabhapurapu. 2023. "Resistive Switching Property of Raw Organic Cow Milk for Memory Application" Sustainability 15, no. 10: 8250. https://doi.org/10.3390/su15108250