Analysis and Verification of Load–Deformation Response for Rocking Self-Centering Bridge Piers

Abstract

:1. Introduction

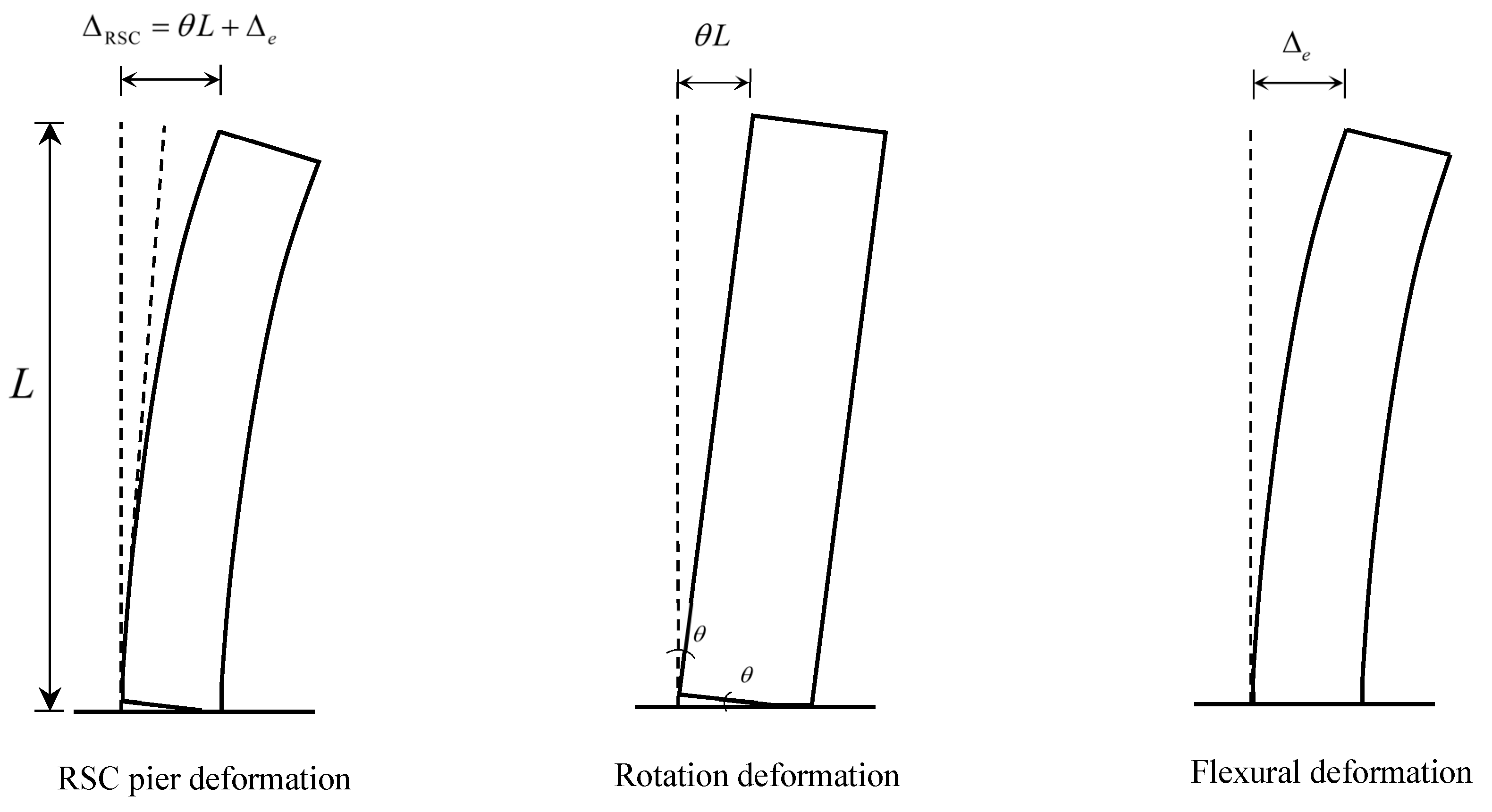

2. Analysis of the Lateral Force–Displacement Response of RSC Bridge Piers

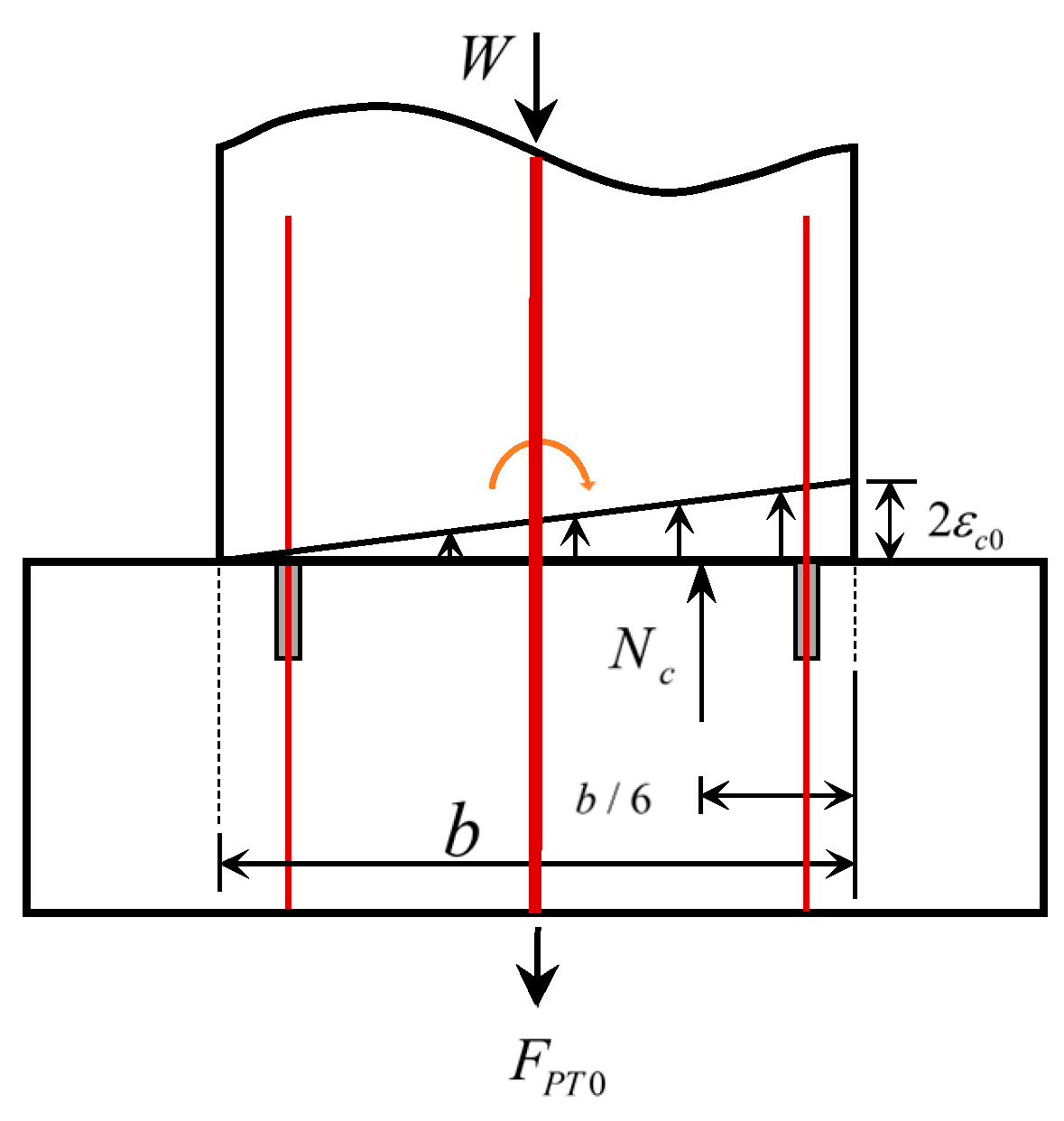

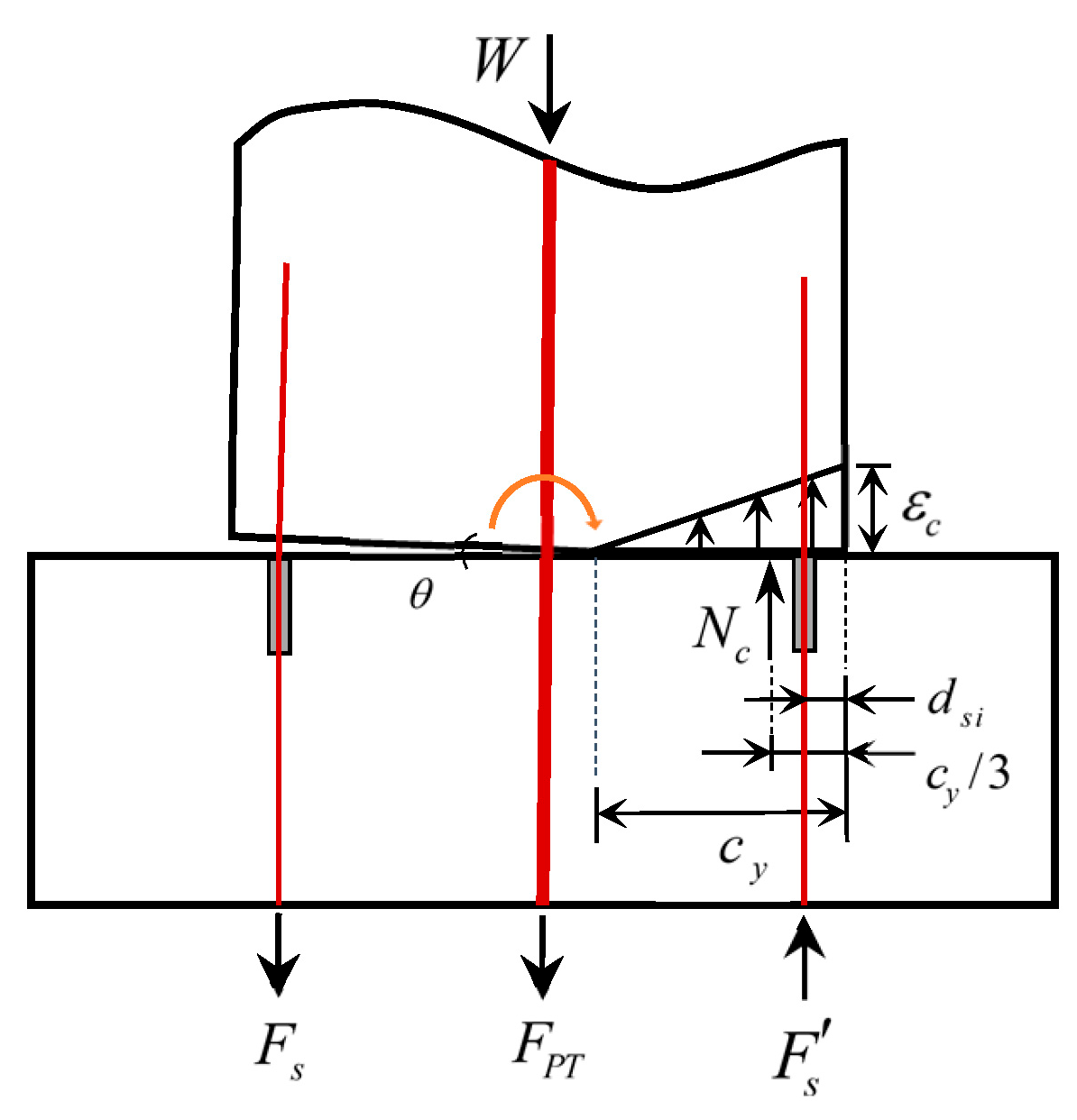

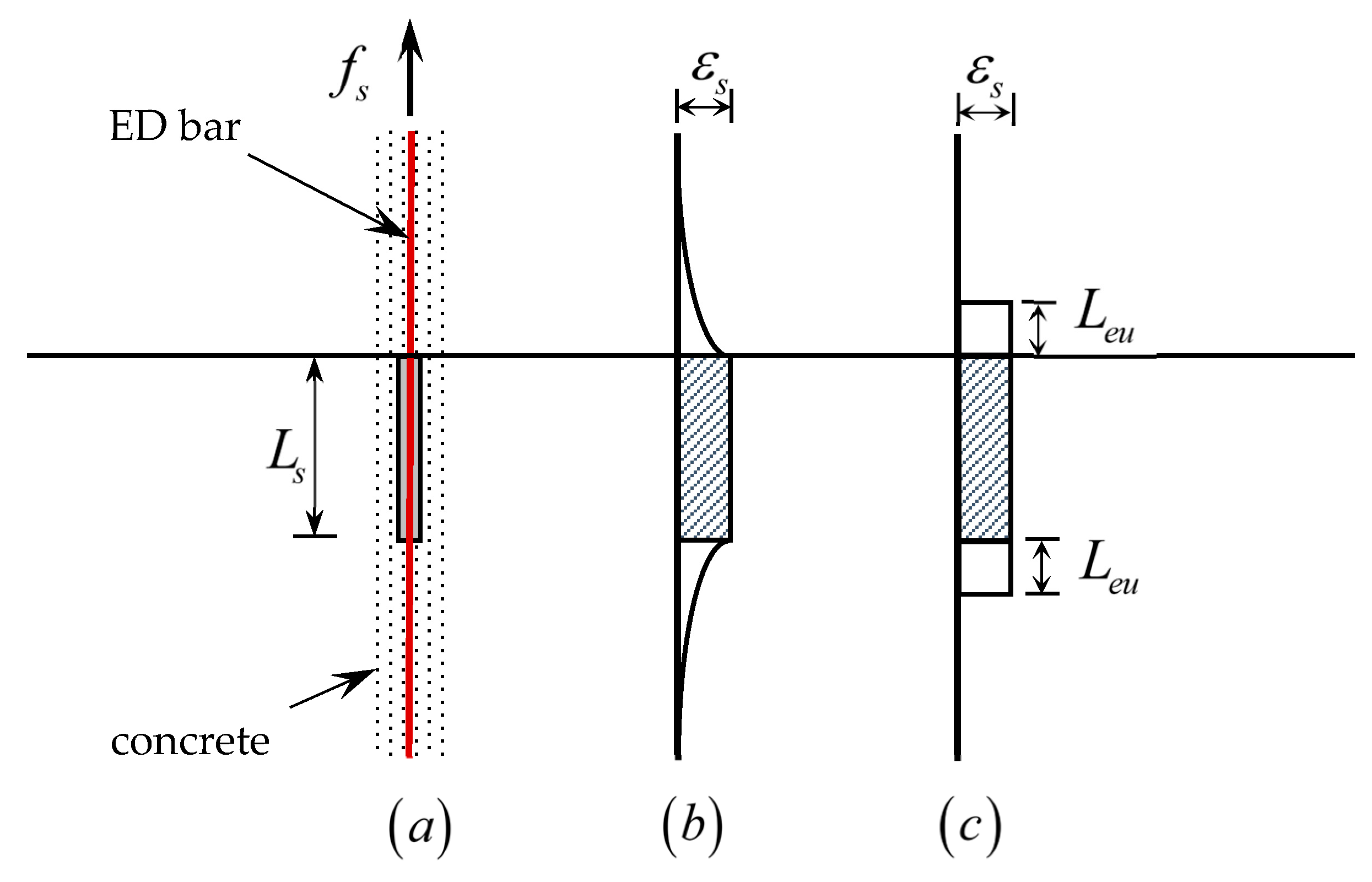

2.1. Analysis Method of the Force Distribution and Behavior of RSC Bridge Piers

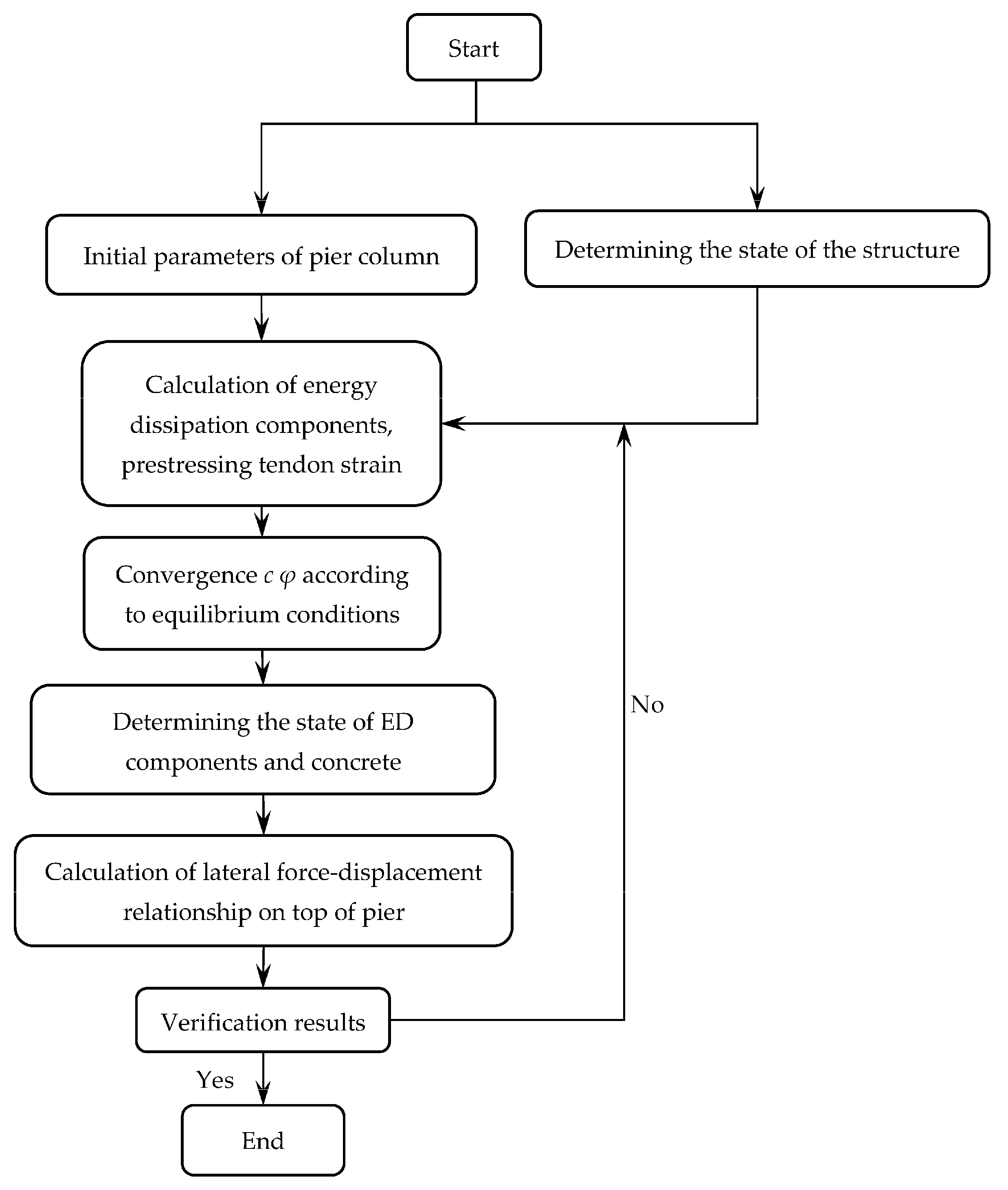

2.2. Calculation Procedure for the Top Force and Displacement of RSC Bridge Pier

2.2.1. Decompression Status

2.2.2. Yield Status

2.2.3. Ultimate Status

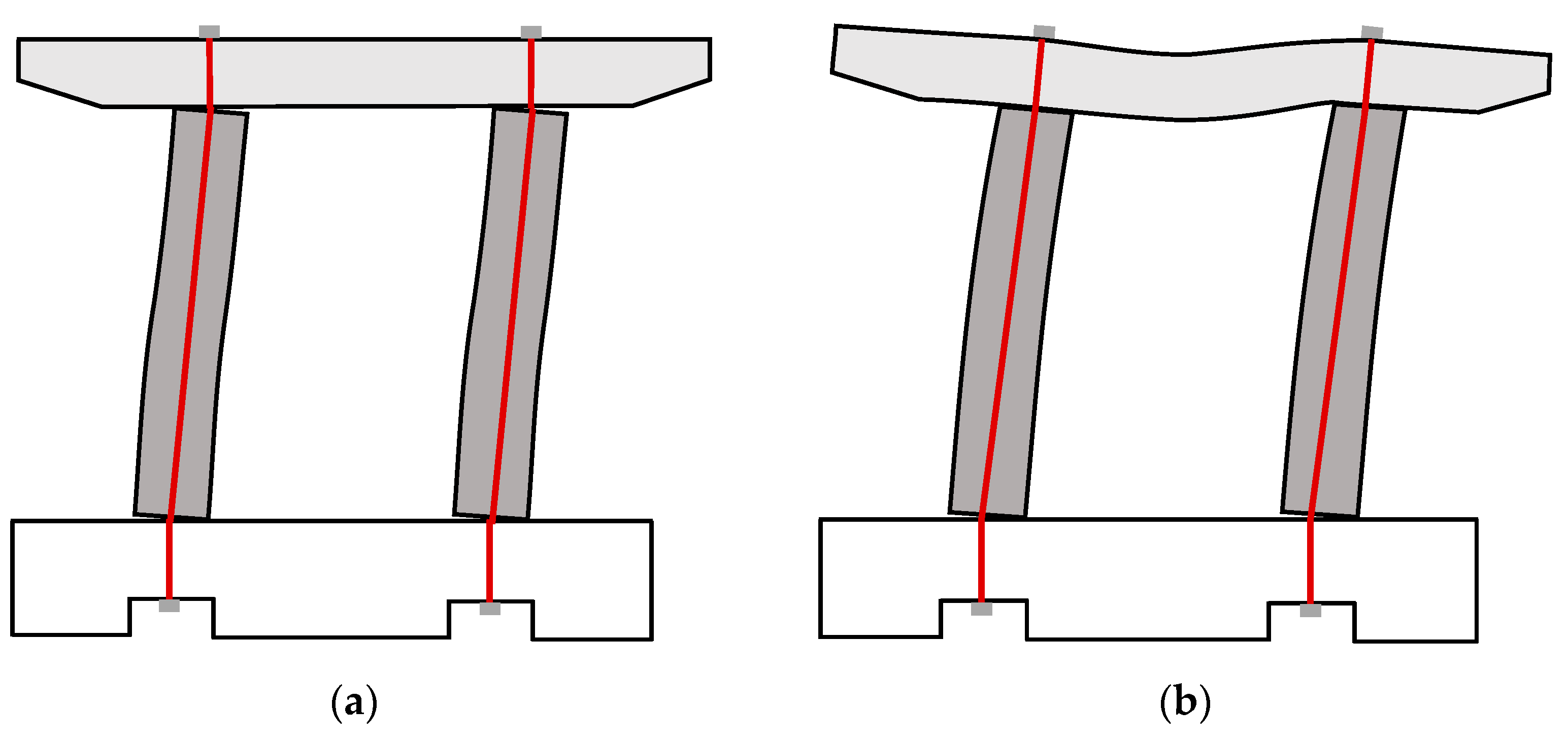

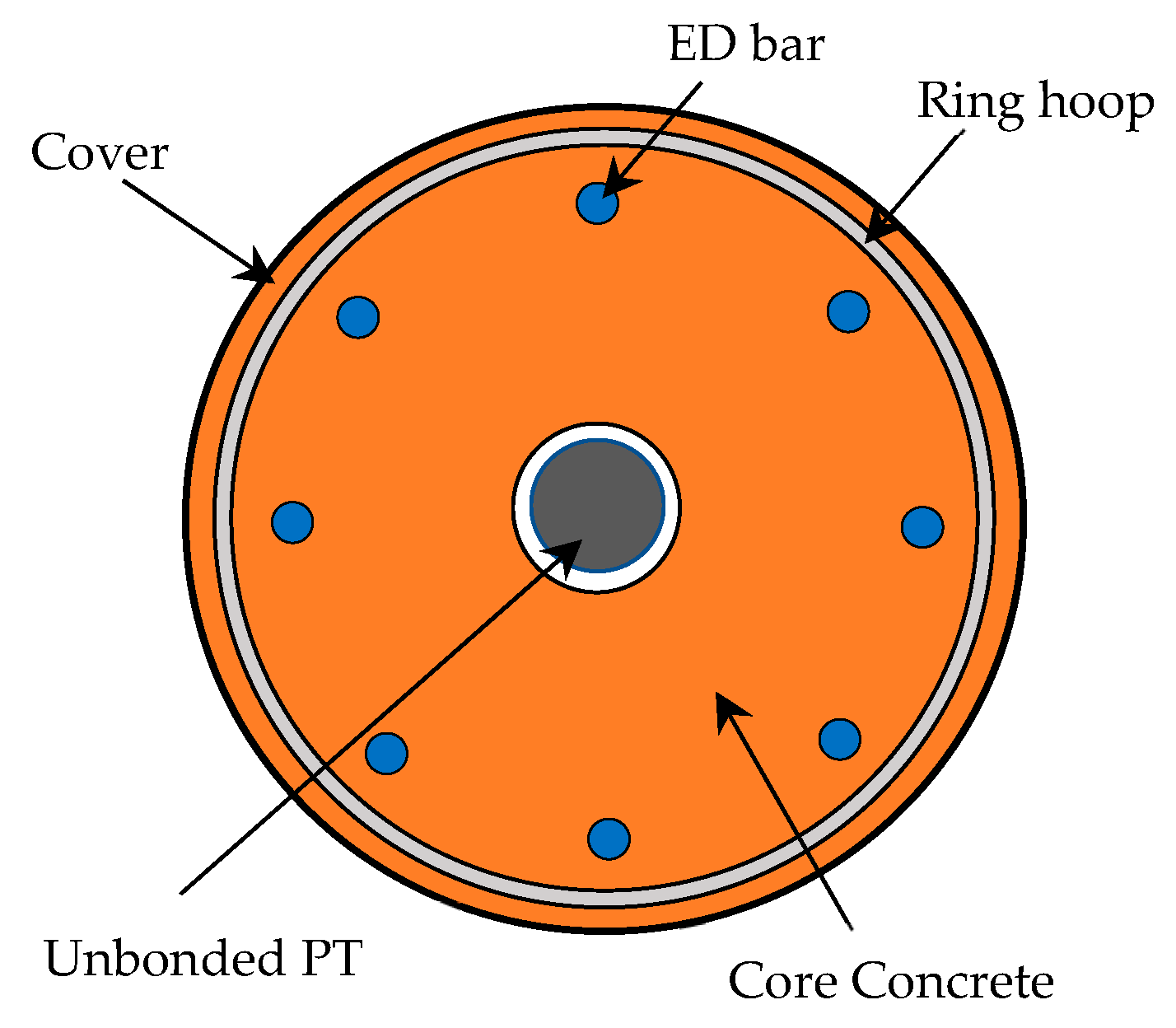

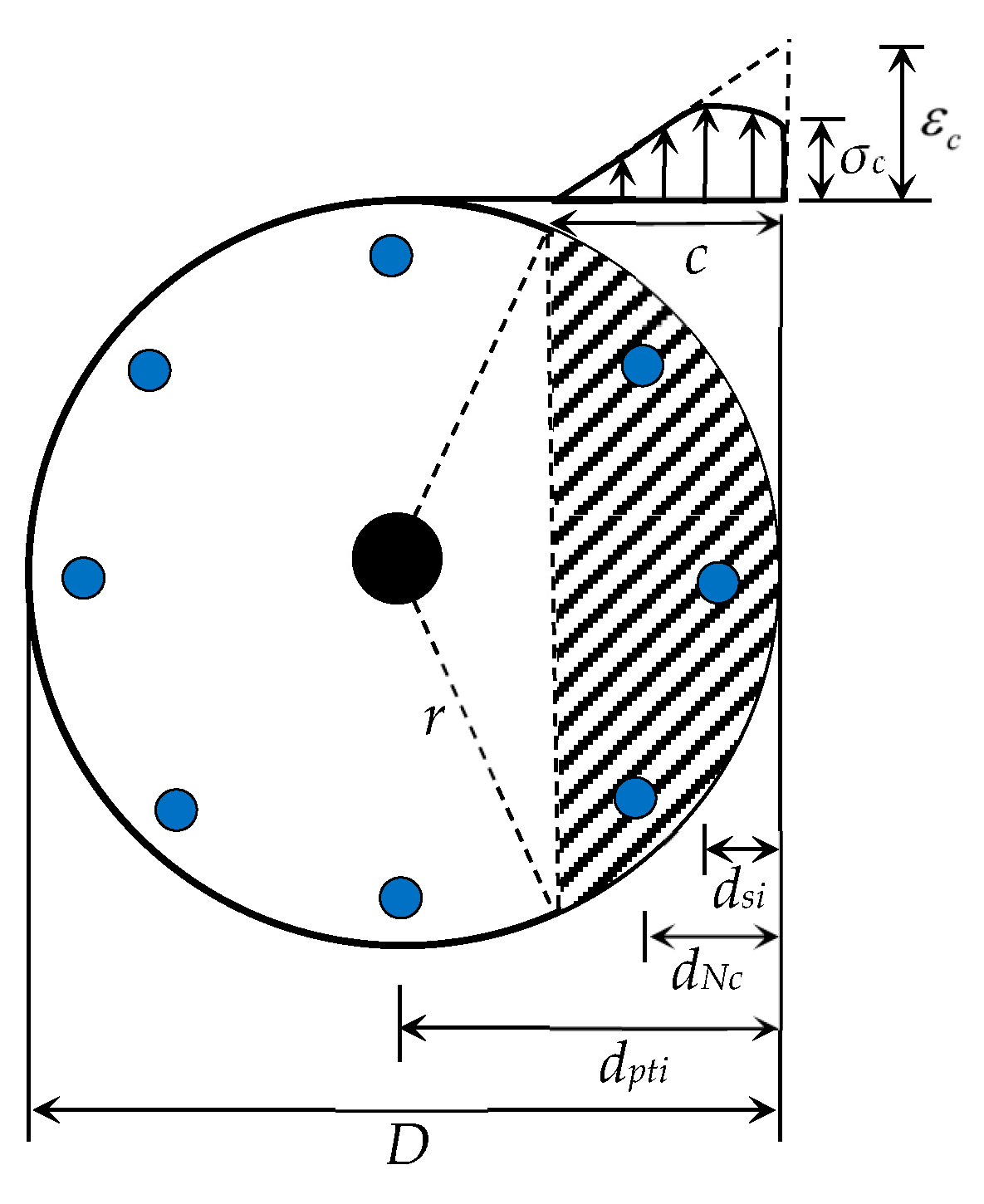

2.2.4. Double-Column Pier and Circular Pier

2.2.5. Flowchart of Calculation Procedure

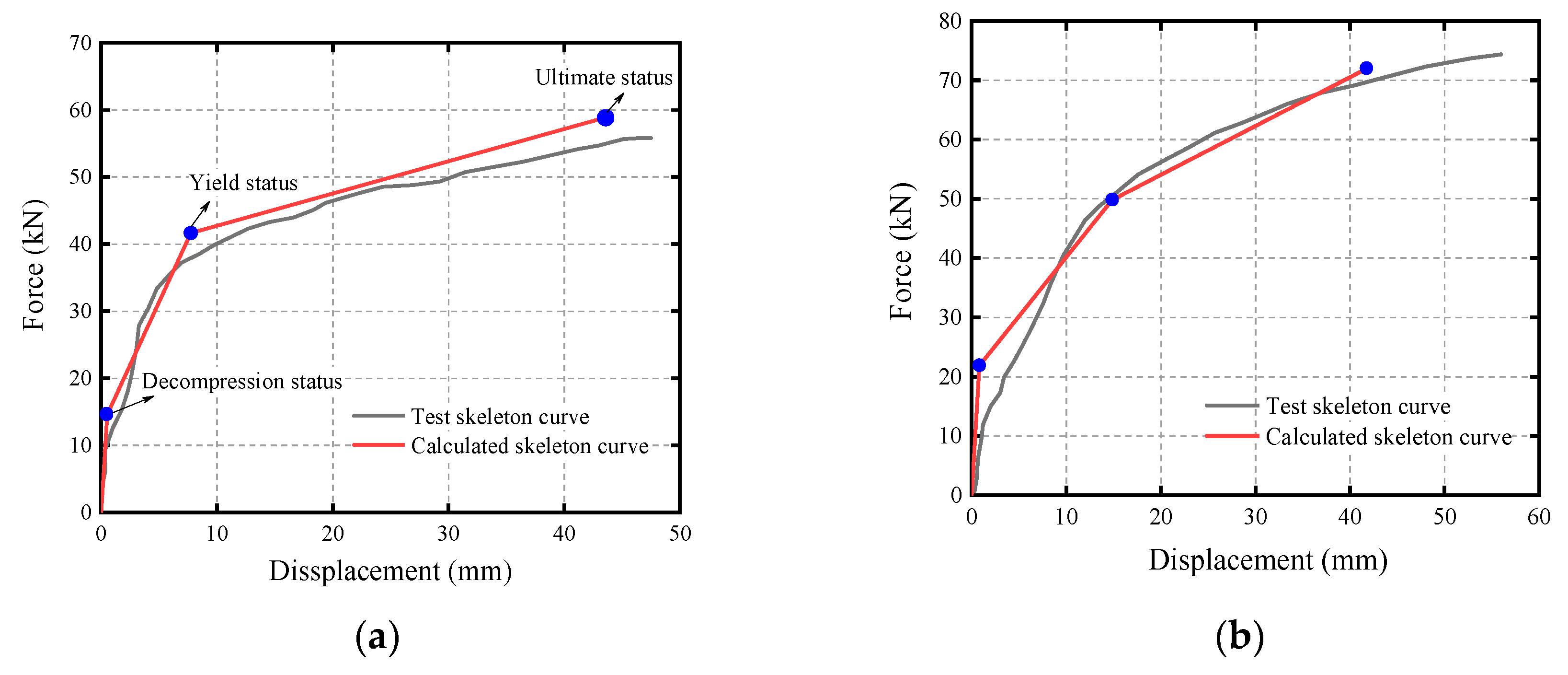

3. Verification of the Proposed Method

4. Conclusions

- (1)

- This article simplifies the force–deformation response of the RSC bridge piers into three stages by analyzing the whole load–deformation condition and making reasonable assumptions. The proposed method presents an analysis and calculation procedure for the RSC bridge piers in decompression, yielding, and ultimate status. Compared to other methods, such as the equivalent plastic hinge model, the proposed method is more consistent with the actual load–deformation response of the RSC bridge piers and is simpler to calculate, thus reducing the application difficulty in engineering. However, some limiting factors may affect its accuracy when providing guidance for engineering practice, such as material properties, manufacturing defects, forms of seismic loading, etc.

- (2)

- The accuracy of the method is verified by comparing the calculated force–displacement relationship of the RSC bridge piers with the tested skeleton curves of six single-column piers and two double-column piers. The proposed method can serve as an easy and powerful tool to evaluate loading–deformation curves that have good agreement with the experiments. The proposed formula for force–displacement relationship in this article reveals the force mechanism and characteristics of structural rocking behavior, providing a calculation idea for seismic design of the RSC bridge and a theoretical basis for the engineering application of RSC bridge piers.

- (3)

- The number of specimens used to validate the method is relatively limited in this article. More specimens may be required to more comprehensively validate the proposed method in future research, as well as to further discuss the hysteresis rules associated with this method. Although researchers have studied the seismic behavior of RSC piers, further theoretical research and analysis are needed to fully understand its mechanical properties and performance characteristics, especially for complex structures (such as double-column piers, multicolumn piers, etc.) and complex load effects. Moreover, most of the existing RSC bridge piers are based on theoretical analysis and small-sample tests, lacking long-term performance research and actual measurement data, particularly in terms of durability and fatigue. Subsequent research should be focused on these shortcomings.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Caltrans SDC. Seismic Design Criteria Version 2.0; Caltrans: Sacramento, CA, USA, 2019. [Google Scholar]

- BS EN 1998-1:2004; Eurocode 8: Design of Structures for Earthquake Resistance: Part 1. BSI: London, UK, 2005.

- NZ Transport Agency. Bridge Manual, 3rd ed.; NZ Transport Agency: Wellington, New Zealand, 2018. [Google Scholar]

- Piras, S.; Palermo, A.; Saiidi, M.S. State-of-the-Art of Posttensioned Rocking Bridge Substructure Systems. J. Bridge Eng. 2022, 27, 03122001. [Google Scholar] [CrossRef]

- Chou, C.-C.; Chang, H.-J.; Hewes, J.T. Two-plastic-hinge and two dimensional finite element models for post-tensioned precast concrete segmental bridge columns. Eng. Struct. 2013, 46, 205–217. [Google Scholar] [CrossRef]

- Sun, Z.; Zhao, T.; Shi, Y.; Wang, D. Research on Numerical Modeling Method for Rocking Self-Centering Bridge Piers. J. Basic Sci. Eng. 2019, 27, 1357–1369. [Google Scholar]

- Eigawady, M.A.; Sha’Lan, A. Seismic Behavior of Self-Centering Precast Segmental Bridge Bents. J. Bridge Eng. 2011, 16, 328–339. [Google Scholar] [CrossRef]

- Zhi-guo, S.; Ming-yang, G.; Bing-jun, S.; Ying-wu, Z. Seismic behavior analyses of rocking self-centering double column bridge bents using external angles. China J. Highw. Transp. 2017, 30, 40–49. [Google Scholar]

- Lu, X.; Liao, W.; Zhang, Y.; Huang, Y. Intelligent structural design of shear wall residence using physics-enhanced generative adversarial networks. Earthq. Eng. Struct. Dyn. 2022, 51, 1657–1676. [Google Scholar] [CrossRef]

- Yan, R.; Wang, S.; Cao, J.; Sun, D. Shipping domain knowledge informed prediction and optimization in port state control. Transp. Res. Part B Methodol. 2021, 149, 52–78. [Google Scholar] [CrossRef]

- Tian, X.; Yan, R.; Wang, S.; Liu, Y.; Zhen, L. Tutorial on prescriptive analytics for logistics: What to predict and how to predict. Electron. Res. Arch. 2023, 31, 2265–2285. [Google Scholar] [CrossRef]

- Lin, K.; Xu, Y.-L.; Lu, X.; Guan, Z.; Li, J. Digital twin-based life-cycle seismic performance assessment of a long-span cable-stayed bridge. Bull. Earthq. Eng. 2023, 21, 1203–1227. [Google Scholar] [CrossRef]

- Bu, Z.; Tang, G. Seismic Performance Investigation of Unbonded Prestressing Precast Segmental Bridge Piers with Energy Dissipation Bars. China Railw. Sci. 2011, 32, 33–40. [Google Scholar]

- Zhan, G.; Xingchong, C.; Mingbo, D.; Jiada, G.; Tianbin, W.; Yongliang, Z. Experimental study and analysis on the seismic performance of new base rocking isolation bridge piers. J. Vib. Shock 2020, 39, 69–74+87. [Google Scholar]

- Jun-wen, W.; Wei-guang, Z.; Jian-zhong, L. Displacement-based aseismic design method for rocking bridge piers with posttensioned tendons. J. Vib. Shock 2014, 33, 106–111. [Google Scholar]

- Qiang, H.; Zhen-lei, J.; Wei-li, H.; Yong-ming, X.; Jun-feng, J.; Xiu-li, D. Seismic Design Method and Its Engineering Application of Self-centering Double-column Rocking Bridge. China J. Highw. Transp. 2017, 30, 169–177. [Google Scholar]

- Housner, G.W. The behavior of inverted pendulum structures during earthquakes. Bull. Seismol. Soc. Am. 1963, 53, 403–417. [Google Scholar] [CrossRef]

- Pampanin, S.; Nigel Priestley, M.J.; Sritharan, S. Analytical Modelling of the Seismic Behaviour of Precast Concrete Frames Designed with Ductile Connections. J. Earthq. Eng. 2001, 5, 329–367. [Google Scholar] [CrossRef]

- Marriott, D.; Pampanin, S.; Palermo, A. Quasi-static and pseudo-dynamic testing of unbonded post-tensioned rocking bridge piers with external replaceable dissipaters. Earthq. Eng. Struct. Dyn. 2009, 38, 331–354. [Google Scholar] [CrossRef]

- Dhakal, R.P.; Maekawa, K. Modeling for postyield buckling of reinforcement. J. Struct. Eng. 2002, 128, 1139–1147. [Google Scholar] [CrossRef]

- Bae, S.; Mieses, A.M.; Bayrak, O. Inelastic buckling of reinforcing bars. J. Struct. Eng. 2005, 131, 314–321. [Google Scholar] [CrossRef]

- Moyer, M.J.; Kowalsky, M.J. Influence of tension strain on buckling of reinforcement in concrete columns. ACI Struct. J. 2003, 100, 75–85. [Google Scholar]

- Bu, Z.-Y.; Ou, Y.-C. Simplified Analytical Pushover Method for Precast Segmental Concrete Bridge Columns. Adv. Struct. Eng. 2013, 16, 805–822. [Google Scholar] [CrossRef]

- GB50010-2010; Code for Design of Concrete Structures. Standards Press: Beijing, China, 2015.

- JTG/T 2231-01-2020; Specifications for Seismic Design of Highway Bridges. Standards Press: Beijing, China, 2020.

- Tong, T.; Zhuo, W.; Jiang, X.; Lei, H.; Liu, Z. Research on seismic resilience of prestressed precast segmental bridge piers reinforced with high-strength bars through experimental testing and numerical modelling. Eng. Struct. 2019, 197, 109335. [Google Scholar] [CrossRef]

- Shim, C.; Lee, S.; Park, S.; Koem, C. Experiments on prefabricated segmental bridge piers with continuous longitudinal reinforcing bars. Eng. Struct. 2017, 132, 671–683. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, J.Q.; Tang, Y.C.; Liu, T.X.; Gao, Y.F.; Zhang, J. Seismic behavior of precast segmental UHPC bridge columns with replaceable external cover plates and internal dissipaters. Eng. Struct. 2018, 177, 540–555. [Google Scholar] [CrossRef]

- Mander, J.; Priestley, M. Theoretical Stress-Strain Model for Confined Concrete. J. Struct. Eng. 1988, 114, 1804–1826. [Google Scholar] [CrossRef]

- Shi, Y.; Zhong, Z.; Qin, H.; Han, J.; Sun, Z.; Wang, J. Seismic Performance and Corresponding Design Method of Rocking Self-Centering Bridge Bents Equipped with Lead-Extrusion Dampers. Eng. Mech. 2021, 38, 166–177, 203. [Google Scholar]

- Fang, C.; Liang, D.; Zheng, Y.; Yam, M.C.H.; Sun, R. Rocking bridge piers equipped with shape memory alloy (SMA) washer springs. Eng. Struct. 2020, 214, 110651.1–110651.13. [Google Scholar] [CrossRef]

- Han, Q.; Jia, Z.; Xu, K.; Zhou, Y.; Du, X. Hysteretic behavior investigation of self-centering double-column rocking piers for seismic resilience. Eng. Struct. 2019, 188, 218–232. [Google Scholar] [CrossRef]

- Feng, P.; Qiang, H.-L.; Ye, L.-P. Discussion and definition on yield points of materials, members and structures. J. Eng. Mech. 2017, 34, 36–46. [Google Scholar]

| Test Specimens | Structure Form | ED Components | Ultimate Status |

|---|---|---|---|

| HBD1 | Single-column rectangular rocking pier | ED bar | Failure of ED components |

| HBD2 | Single-column rectangular rocking pier | ED bar | Failure of ED components |

| HBD3 | Single-column rectangular rocking pier | Anti-flexing mild steel | Concrete crush |

| HBD4 | Single-column rectangular rocking pier | Anti-flexing mild steel | Failure of ED components |

| G75W | Single-column with rectangular expansion base round rocking pier | Shape memory alloy (SMA) washer springs | SMA “locked” |

| G140W | Single-column with rectangular expansion base round rocking pier | Shape memory alloy (SMA) washer springs | SMA “locked” |

| TRB-B | Double-column rectangular rocking pier | Mild reinforcing bar | Failure of ED components |

| FRP1 | Double-column round rocking pier | None | Concrete crush |

| Status | Force Displacement | Value | HBD1 | HBD2 | HBD3 | HBD4 | G75W | G140W | TRB-B | FRP1 |

|---|---|---|---|---|---|---|---|---|---|---|

| Decompression | Displacement (mm) | Test | 0.67 | 3.34 | 3.16 | 0.93 | 0.21 | 0.12 | 1.72 | 1.97 |

| Calculation | 0.53 | 0.78 | 0.67 | 1.04 | 0.07 | 0.13 | 3.24 | 1.44 | ||

| Test/ Calculation | 1.26 | 4.28 | 4.72 | 0.89 | 3.00 | 0.92 | 0.53 | 1.37 | ||

| Force (kN) | Test | 10.46 | 19.88 | 19.59 | 15.48 | 1.32 | 1.89 | 196.77 | 11.68 | |

| Calculation | 14.58 | 22.08 | 21.53 | 22.41 | 0.23 | 0.42 | 312.27 | 18.21 | ||

| Test/ Calculation | 0.72 | 0.90 | 0.91 | 0.69 | 5.74 | 4.50 | 0.63 | 0.64 | ||

| Yield | Displacement (mm) | Test | 8.41 | 17.61 | 7.49 | 15.99 | 8.68 | 9.93 | 21.65 | 27.32 |

| Calculation | 7.73 | 14.83 | 8.01 | 8.48 | 10.73 | 10.77 | 16.04 | 18.27 | ||

| Test/ Calculation | 0.92 | 0.84 | 1.07 | 0.53 | 1.24 | 1.08 | 0.74 | 0.67 | ||

| Force (kN) | Test | 38.45 | 54.16 | 31.26 | 47.97 | 36.94 | 53.77 | 494.25 | 54.55 | |

| Calculation | 41.65 | 49.81 | 38.43 | 42.45 | 40.89 | 55.65 | 463.38 | 55.39 | ||

| Test/ Calculation | 1.08 | 0.92 | 1.23 | 0.88 | 1.11 | 1.03 | 0.94 | 1.02 | ||

| Ultimate | Displacement (mm) | Test | 47.48 | 54.87 | 56.07 | 55.64 | 25.86 | 27.32 | 111.60 | 123.88 |

| Calculation | 43.50 | 41.58 | 60.57 | 65.53 | 28.69 | 28.92 | 114.34 | 127.08 | ||

| Test/ Calculation | 0.92 | 0.76 | 1.08 | 1.18 | 1.11 | 1.06 | 1.02 | 1.03 | ||

| Force (kN) | Test | 56.69 | 78.11 | 63.91 | 73.27 | 55.49 | 72.66 | 535.64 | 101.18 | |

| Calculation | 58.82 | 71.83 | 64.25 | 71.64 | 56.74 | 69.71 | 561.04 | 96.58 | ||

| Test/ Calculation | 1.04 | 0.92 | 0.99 | 0.98 | 1.02 | 0.96 | 1.05 | 0.95 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, S.; Sun, Z.; Wang, D. Analysis and Verification of Load–Deformation Response for Rocking Self-Centering Bridge Piers. Sustainability 2023, 15, 8257. https://doi.org/10.3390/su15108257

Wang S, Sun Z, Wang D. Analysis and Verification of Load–Deformation Response for Rocking Self-Centering Bridge Piers. Sustainability. 2023; 15(10):8257. https://doi.org/10.3390/su15108257

Chicago/Turabian StyleWang, Shijie, Zhiguo Sun, and Dongsheng Wang. 2023. "Analysis and Verification of Load–Deformation Response for Rocking Self-Centering Bridge Piers" Sustainability 15, no. 10: 8257. https://doi.org/10.3390/su15108257

APA StyleWang, S., Sun, Z., & Wang, D. (2023). Analysis and Verification of Load–Deformation Response for Rocking Self-Centering Bridge Piers. Sustainability, 15(10), 8257. https://doi.org/10.3390/su15108257