Carbon Neutrality in Municipalities: Balancing Individual and District Heating Renewable Energy Solutions

Abstract

1. Introduction

1.1. Nature of the Study

1.2. Comparison of DH and IH

2. Methodology

2.1. Case Study

2.1.1. DH System

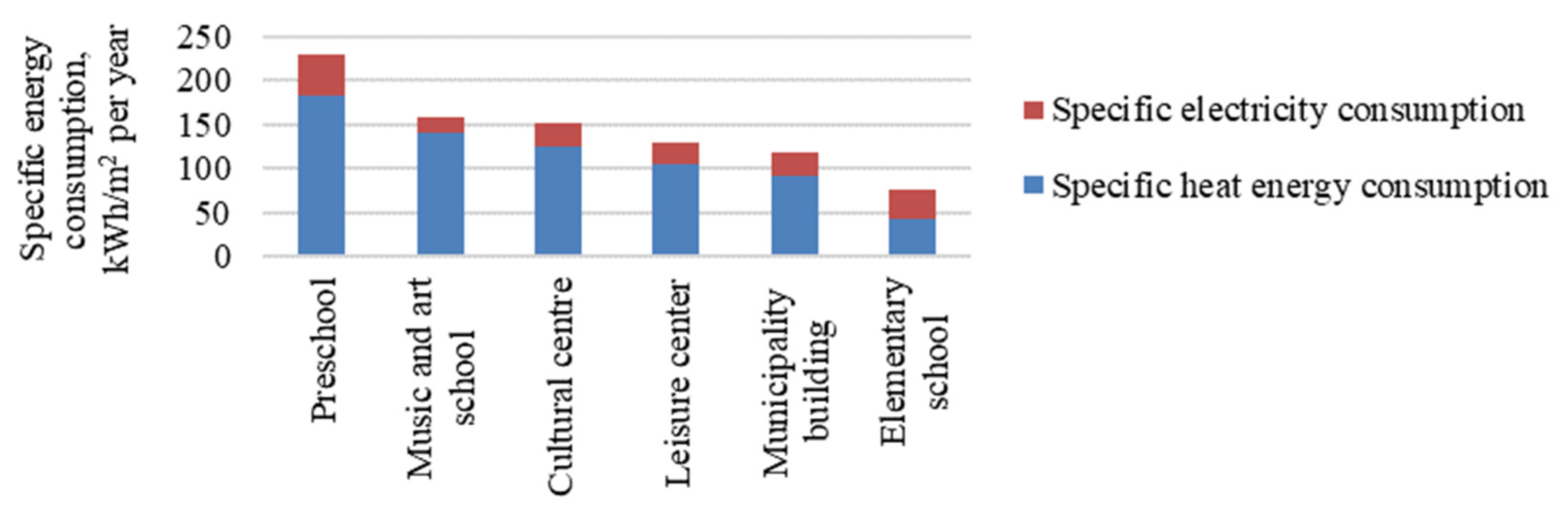

2.1.2. Municipality Buildings

2.2. Development Scenarios

2.2.1. District Heating System

2.2.2. Individual Heating Solutions

2.3. Decision-Making Analyses

- The identification of the internal and external context that influences the sustainability of the heat supply system

- The calculation of the composite sustainability index

- The analysis of the results and the decision-making process.

2.3.1. Identification of Criteria

- (1)

- The reduction in CO2 emissions depends on the amount of fossil energy replaced and the type of fossil energy (see Equation (4)).

- (2)

- Costs of CO2 reduction (Equation (5)):

- The reduction in CO2 emissions for DH wood chip boiler with flue gas condenser:

- 2.

- Cost of CO2 reduction for DH wood chip boiler with flue gas condenser:

2.3.2. Data Normalization

2.3.3. Weighting of Indicators

2.3.4. Aggregation of Indicators into CSI

3. Results and Discussion

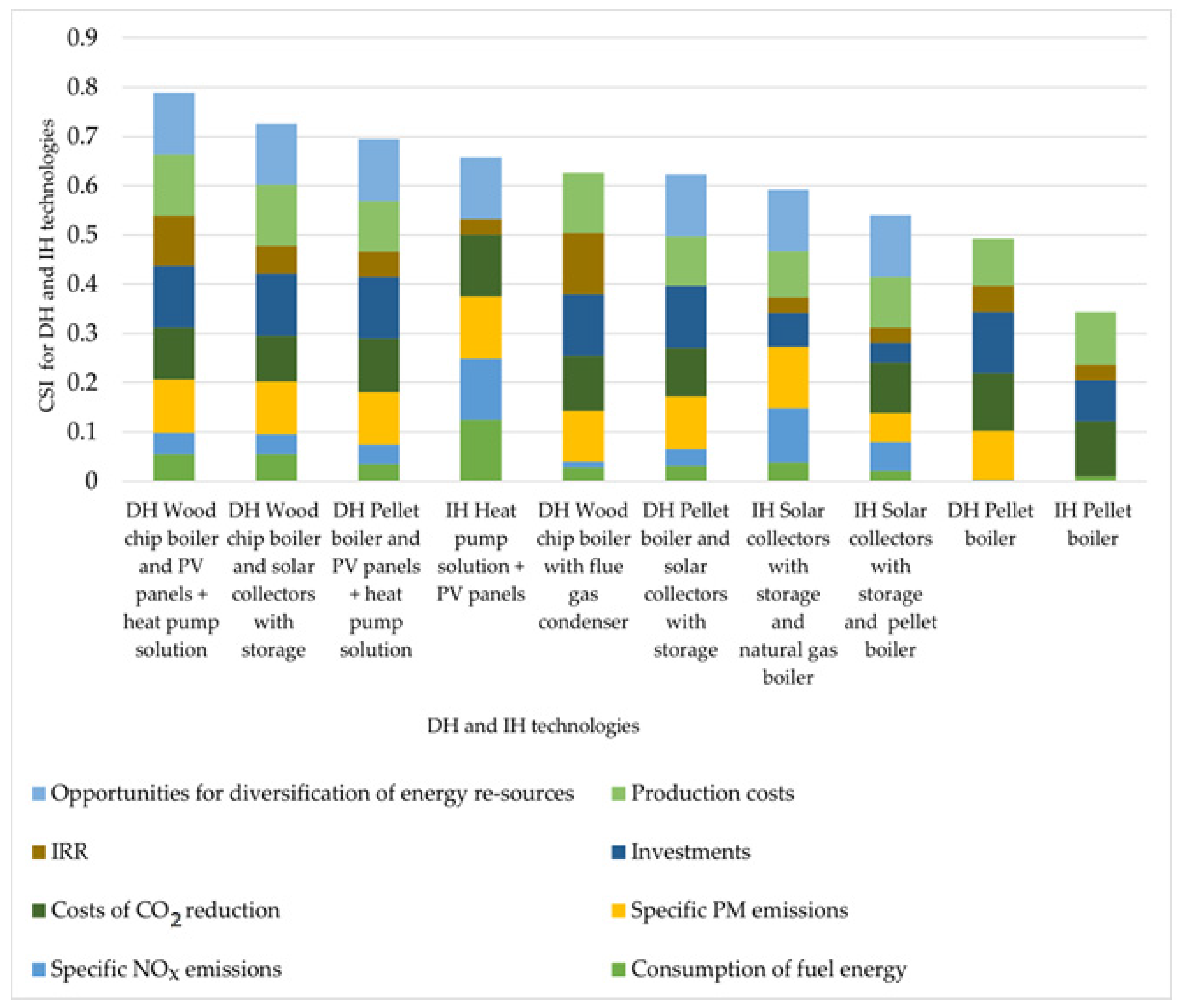

Assessment of Alternatives in DH and IH

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Individual heating | IH |

| District heating | DH |

| Composite sustainability index | CSI |

| Renewable energy sources | RES |

| Particulate matter emissions | PM emissions |

Appendix A

| Parameter | Value | Unit |

|---|---|---|

| Technology creators | ||

| Natural gas boiler efficiency | 90 | % |

| Chip boiler efficiency | 87 | % |

| Pellet boiler efficiency | 85 | % |

| Diesel boiler efficiency | 90 | % |

| Solar panel area | 1.92 | m2 |

| Power of one solar panel | 405 | W |

| Nominal efficiency of solar panels | 0.211 | |

| Loss factor of solar panels | 0.95 | |

| Nominal efficiency of the solar collector | 78.8 | % |

| Maximum efficiency of the solar collector | 0.89 | % |

| The average temperature of the solution circulating in the solar collector at the given hour | 70 | °C |

| Absorption area of the solar collector | 1.78 | m2 |

| Solar panel area | 2.05 | m2 |

| Technology costs | ||

| Pellet boiler | 526.803.94 × x(−0.299) | EUR/kW |

| Pellet boiler with hydraulic system | 104.0117.4 × x(−0.349) | EUR/kW |

| 40 | % |

| 45 | % |

| 6 | % |

| 9 | % |

| Chipped boiler house | −4081.6 × x3 + 74,447.43 × x2 − 452,854.13 × x + 1,151,845.31 | EUR/kW |

| 33 | % |

| 45 | % |

| 6 | % |

| 16 | % |

| Flue gas condenser | 100 | EUR/kW |

| Heat pump (technology + installation) | 266.36 | EUR/kW |

| Solar panels (technology + installation) | y = 5883.3086467157x − 0.3743667246 1 | EUR/kW |

| Solar collectors (high-power projects) | 155.4 | EUR/m2 |

| Solar collectors (low-power projects) | 275.3 | EUR/m2 |

| Thermal energy storage (large-capacity projects) | 113.8 | EUR/m3 |

| Thermal energy storage (low-capacity projects) | 735 | EUR/m3 |

| The heating unit of the building | 50 | EUR/kW |

| CSS pipeline (metal pipe) | =1.3756 × x + 150.89 2 | EUR/m |

| Fuel indicators | ||

| The lowest heat of combustion of natural gas | 9.5 | MWh/1000 m3 |

| The lowest heat of combustion of wood chips | 0.7 | MWh/t |

| The lowest heat of combustion of pellets | 5 | MWh/t |

| The lowest heat of combustion of diesel fuel | 9.91 | Mwh/m3 |

| Cost of energy resources | ||

| The price of natural gas | 90.00 | EUR/MWh |

| Chip price | 32.00 | EUR/MWh |

| The price of pellets | 64.00 | EUR/MWh |

| Electricity tariff | 300.00 | EUR/MWh |

| Electricity price for electricity transferred to the network (within the Net settlement system) | 250.00 | EUR/MWh |

| Electricity received from the network (within the Net settlement system) | 50.00 | EUR/MWh |

| The price of diesel fuel | 93.24 | EUR/MWh |

| Heat energy production indicators | ||

| Service costs | ||

| Natural gas | 12.500 | EUR/MW gadā 3 |

| A splinter | 20.000 | EUR/MW gadā |

| Granules | 17.500 | EUR/MW gadā |

| Diesel fuel | 12.500 | EUR/MW gadā |

| Administrative costs and salaries | ||

| Natural gas | 15.000 | EUR/MW gadā |

| A splinter | 25.000 | EUR/MW gadā |

| Granules | 20.000 | EUR/MW gadā |

| CO2 taxes | ||

| Natural gas | 15 | EUR/tCO2 |

| A splinter | 0 | EUR/MWh (saražoto) |

| Granules | 0 | EUR/MWh (saražoto) |

| Additional costs (not fuel) | ||

| Natural gas | 20.0 | % |

| A splinter | 50.0 | % |

| Granules | 30.0 | % |

Appendix B

References

- European Union. REPowerEU: A Plan to Rapidly Reduce Dependence on Russian Fossil Fuels and Fast Forward the Green Transition. Available online: https://ec.europa.eu/commission/presscorner/detail/en/ip_22_3131 (accessed on 22 April 2023).

- European Commision. Assessment of the Final National Energy and Climate Plan of Latvia; European Commision: Brussels, Belgium, 2020. [Google Scholar]

- Cabinet of Ministers. National Energy and Climate Plan of the Republic of Latvia for 2021–2030; European Commision: Brussels, Belgium, 2020. [Google Scholar]

- Hoang, A.T.; Pham, V.V.; Nguyen, X.P. Integrating renewable sources into energy system for smart city as a sagacious strategy towards clean and sustainable process. J. Clean. Prod. 2021, 305, 127161. [Google Scholar] [CrossRef]

- Kata, R.; Cyran, K.; Dybka, S.; Lechwar, M.; Pitera, R. The Role of Local Government in Implementing Renewable Energy Sources in Households (Podkarpacie Case Study). Energies 2022, 15, 3163. [Google Scholar] [CrossRef]

- Thellufsen, J.Z.; Lund, H.; Sorknæs, P.; Østergaard, P.A.; Chang, M.; Drysdale, D.; Nielsen, S.; Djørup, S.R.; Sperling, K. Smart energy cities in a 100% renewable energy context. Renew. Sustain. Energy Rev. 2020, 129, 109922. [Google Scholar] [CrossRef]

- Liu, W.; Best, F.; Crijns-Graus, W. Exploring the pathways towards a sustainable heating system—A case study of Utrecht in the Netherlands. J. Clean. Prod. 2021, 280, 125036. [Google Scholar] [CrossRef]

- Neij, L.; Heiskanen, E. Municipal climate mitigation policy and policy learning—A review. J. Clean. Prod. 2021, 317, 128348. [Google Scholar] [CrossRef]

- Barton, J.; Davies, L.; Dooley, B.; Foxon, T.J.; Galloway, S.; Hammond, G.P.; O’grady, Á.; Robertson, E.; Thomson, M. Transition pathways for a UK low-carbon electricity system: Comparing scenarios and technology implications. Renew. Sustain. Energy Rev. 2018, 82, 2779–2790. [Google Scholar] [CrossRef]

- Askeland, K.; Bozhkova, K.N.; Sorknæs, P. Balancing Europe: Can district heating affect the flexibility potential of Norwegian hydropower resources? Renew. Energy 2019, 141, 646–656. [Google Scholar] [CrossRef]

- Gebremedhin, A. Introducing District Heating in a Norwegian town—Potential for reduced Local and Global Emissions. Appl. Energy 2012, 95, 300–304. [Google Scholar] [CrossRef]

- Yoon, T.; Ma, Y.; Rhodes, C. Individual Heating systems vs. District Heating systems: What will consumers pay for convenience? Energy Policy 2015, 86, 73–81. [Google Scholar] [CrossRef]

- Gudmundsson, O.; Thorsen, J.E.; Zhang, L. Cost analysis of district heating compared to its competing technologies. Trans. Ecol. Environ. 2013, 176, 1743–3541. [Google Scholar]

- Wang, K.; Nakao, S.; Thimmaiah, D.; Hopke, P.K. Emissions from in-use residential wood pellet boilers and potential emissions savings using thermal storage. Sci. Total Environ. 2019, 676, 564–576. [Google Scholar] [CrossRef] [PubMed]

- Safarzadeh, S.; Rasti-barzoki, M.; Hejazi, S.R. A review of optimal energy policy instruments on industrial energy efficiency programs, rebound effects, and government policies. Energy Policy 2020, 139, 111342. [Google Scholar] [CrossRef]

- Balode, L.; Dolge, K.; Blumberga, D. The Contradictions between District and Individual Heating towards Green Deal Targets. Sustainability 2021, 13, 3370. [Google Scholar] [CrossRef]

- Dochev, I.; Peters, I.; Seller, H.; Schuchardt, G.K. Analysing district heating potential with linear heat density. A case study from Hamburg. Energy Procedia 2018, 149, 410–419. [Google Scholar] [CrossRef]

- Li, H.; Nord, N. Transition to the 4th generation district heating—Possibilities, bottlenecks, and challenges. Energy Procedia 2018, 149, 483–498. [Google Scholar] [CrossRef]

- Kristensen, M.H.; Petersen, S. District heating energy efficiency of Danish building typologies. Energy Build. 2021, 231, 110602. [Google Scholar] [CrossRef]

- Pakere, I.; Romagnoli, F.; Blumberga, D. Introduction of small-scale 4th generation district heating system. Methodology approach. Energy Procedia 2018, 149, 549–554. [Google Scholar] [CrossRef]

- IRENA. Renewable Energy in District Heating and Cooling with Co-Generation of Heat and Power; IRENA: Masdar City, United Arab Emirates, 2017. [Google Scholar]

- Balode, L.; Dolge, K.; Lund, P.D.; Blumberga, D. How to Assess Policy Impact in National Energy and Climate Plans. Environ. Clim. Technol. 2021, 25, 405–421. [Google Scholar] [CrossRef]

- Aarhus University. Emission Factors per GJ Fuel Input. Available online: https://envs.au.dk/fileadmin/envs/Emission_inventories/Emission_factors/Emf_internet_energy_GHG.htm (accessed on 8 May 2023).

- Lemke, C.; Bastini, K. Embracing multiple perspectives of sustainable development in a composite measure: The Multilevel Sustainable Development Index. J. Clean. Prod. 2020, 246, 118884. [Google Scholar] [CrossRef]

- Razmjoo, A.A.; Sumper, A.; Davarpanah, A. Development of sustainable energy indexes by the utilization of new indicators: A comparative study. Energy Rep. 2019, 5, 375–383. [Google Scholar] [CrossRef]

| Parameter | Unit | 2019 | 2020 | 2021 |

|---|---|---|---|---|

| Natural gas consumption | 1000 m3 | 1076.01 | 1024.16 | 1185.29 |

| Share of RES | % | 0% | 0% | 0% |

| Fuel input energy | MWh per year | 10,274.8 | 9756.4 | 11,247.9 |

| Thermal energy produced | MWh per year | 9308.8 | 8764.0 | 10,085.4 |

| Electricity produced | MWh per year | 0 | 0 | 0 |

| Production losses | MWh per year | 965.9 | 992.4 | 1162.5 |

| Efficiency of production | % | 90.6% | 89.8% | 89.7% |

| Thermal energy transferred to users | MWh per year | 7792.0 | 7263.4 | 8617.9 |

| Losses in heating networks | MWh per year | 1516.9 | 1500.6 | 1467.6 |

| Losses in heating networks | % | 16.3% | 17.1% | 14.6% |

| Parameter | Unit | Elementary School | Preschool | Cultural Centre | Music and Art School | Leisure Centre | Office Building |

|---|---|---|---|---|---|---|---|

| Technical condition | - | Renovated | - | - | - | - | Built-in 2020 |

| Heating area | m2 | 7398 | 2643 | 769 | 258 | 150 | 2343 |

| Roof area | m2 | 2301 | 2622 | 460 | 212 | 192 | 2970 |

| Heat consumption | MWh per year | 318 | 486 | 97 | 36 | 16 | 215 |

| Electricity consumption | MWh per year | 237 | 124 | 21 | 5 | 4 | 60 |

| Max heat load | kW | 110 | 130 | 35 | 12 | 10 | 57 |

| Fuel type | - | Natural gas | Natural gas | Natural gas | Natural gas | Natural gas | Natural gas |

| Scenarios | District Heating | Municipal Buildings |

|---|---|---|

| With New Consumers | ||

| 1 boiler house with flue gas condenser | - |

| + | - |

| + | - |

| + | |

| 2 boilers | + |

| + | - |

| - | + |

| + |

|

|

|

|

|

|

|

|

|

|

| No | Indicator | Units | Indicator Description | Impact |

|---|---|---|---|---|

| I1 | Consumption of fuel energy | MWh/MWh | The indicator considers only the consumption of used fuel energy and electricity from grid. Fuel consumption/total energy production in MWh in each of the scenarios.The share of solar collectors and PV panels are not included in the efficiency calculation. Electricity consumption from grid at scenarios with heat pumps also taken into account. | - |

| I2 | Specific NOx emissions | g/MWh | Gram per amount of energy produced in each of the scenarios. | - |

| I3 | Specific PM emissions | g/MWh | Indicates how much PM is produced from each MWh. | - |

| I4 | Costs of CO2 reduction | EUR/t | Depending on the type of energy resource, the amount of CO2 emissions produced varies. Emission factor of 0.202 (CO2), tCO2/MWh. The total investment is divided per ton of CO2. Describes how much to invest in each system. | - |

| I5 | Investments | EUR/MWh | The investment required for the amount of energy produced | - |

| I6 | Internal rate of return | % | Internal rate of return (IRR) or economic rate of return (ERR) characterizes the interest rate at which investments in a given project are effective. If the IRR is greater than the discount rate, then the project is economically beneficial to society. The higher the value, the more efficient the project. | + |

| I7 | Production costs | EUR MWh | Production costs include alternative fuel, electricity, service, and administrative costs. | - |

| I8 | Opportunities for diversification of utilised energy resources (technology is not limited only to one type of energy resource supply | count | The energy resources are numerically evaluated as to how much it is possible to use the energy resource in each of the scenarios, taking into account the production of electricity and thermal energy. Electricity and solar PV. How many energy sources are included in the solution. The number of energy resources in each of the scenarios describes the diversification of utilised resources. | + |

| 1. | 2. | 3. | 4. | 5. | 6. | 7. | 8. | 9. | 10. | 11. | 12. | 13. | 14. | 15. | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| EUR/year | −1,022,215 | 318,937 | 331,662 | 344,770 | 358,270 | 372,176 | 386,499 | 401,251 | 416,446 | 432,097 | 44,828 | 464,822 | 48,194 | 499,539 | 517,683 |

| DH Wood Chip Boiler with Flue Gas Condenser | DH Wood Chip Boiler and PV Panels + Heat Pump Solution | DH Wood Chip Boiler Additionally, Solar Collectors with Thermal Energy Storage | DH Pellet Boiler | DH Pellet Boiler and PV Panels + Heat Pump Solution | DH Pellet Boiler and Solar Collectors with Thermal Energy Storage | IH Pellet Boiler | IH Heat Pump Solution + PV Panels | IH Solar Collectors with Thermal Energy Storage Natural Gas Boiler | IH Solar Collectors with Thermal Energy Storage Pellet Boiler | |

|---|---|---|---|---|---|---|---|---|---|---|

| I1 MWh/MWh | 0.99 | 0.82 | 0.82 | 1.18 | 0.95 | 0.97 | 1.11 | 0.36 | 0.93 | 1.04 |

| I2 g/MWh | 321 | 228 | 238 | 343 | 242 | 254 | 351 | 0.000001 | 41 | 187 |

| I3 g/MWh | 36 | 28 | 29 | 42 | 30 | 31 | 206 | 0.000001 | 0.00001 | 110 |

| I4 EUR/t CO2 | 592 | 832.8 | 1385.7 | 380.8 | 684.5 | 1145.8 | 587.9 | 19.4 | 5410.8 | 957.6 |

| I5 EUR.thousand./MWh | 0.13 | 0.19 | 0.31 | 0.09 | 0.15 | 0.26 | 94.62 | 284.48 | 126.53 | 193.43 |

| I6 % | 34.45 | 25.74 | 9.40 | 7.75 | 7.29 | −11.57 | 0.01 | 0.4 | −0.1 | 0.03 |

| I7 EUR/MWh | 59.6 | 52.7 | 54.2 | 106.5 | 94.5 | 97.9 | 86.9 | 291.1 | 110.6 | 95.2 |

| I8 Count of resources | 2 | 3 | 3 | 2 | 3 | 3 | 2 | 3 | 3 | 3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Balode, L.; Zlaugotne, B.; Gravelsins, A.; Svedovs, O.; Pakere, I.; Kirsanovs, V.; Blumberga, D. Carbon Neutrality in Municipalities: Balancing Individual and District Heating Renewable Energy Solutions. Sustainability 2023, 15, 8415. https://doi.org/10.3390/su15108415

Balode L, Zlaugotne B, Gravelsins A, Svedovs O, Pakere I, Kirsanovs V, Blumberga D. Carbon Neutrality in Municipalities: Balancing Individual and District Heating Renewable Energy Solutions. Sustainability. 2023; 15(10):8415. https://doi.org/10.3390/su15108415

Chicago/Turabian StyleBalode, Lauma, Beate Zlaugotne, Armands Gravelsins, Oskars Svedovs, Ieva Pakere, Vladimirs Kirsanovs, and Dagnija Blumberga. 2023. "Carbon Neutrality in Municipalities: Balancing Individual and District Heating Renewable Energy Solutions" Sustainability 15, no. 10: 8415. https://doi.org/10.3390/su15108415

APA StyleBalode, L., Zlaugotne, B., Gravelsins, A., Svedovs, O., Pakere, I., Kirsanovs, V., & Blumberga, D. (2023). Carbon Neutrality in Municipalities: Balancing Individual and District Heating Renewable Energy Solutions. Sustainability, 15(10), 8415. https://doi.org/10.3390/su15108415