Cold Ironing Implementation Overview in European Ports—Case Study—Croatian Ports

Abstract

1. Introduction

2. Environmental Incentives and the Legal Framework—European Union and the Republic of Croatia

- The National Development Strategy of the Republic of Croatia until 2030 defines, among others, the application and development of green and sustainable technologies in various economic sectors in line with the European Green Deal [38];

- The Energy Development Strategy of the Republic of Croatia until 2030, with a view to 2050, discusses a vision of a low-carbon economy. The strategy defines the pace of energy sector changes in technologies, devices, transportation, energy consumption, and other factors. It also indicates Croatia’s contribution to the global reduction of greenhouse gas emissions in accordance with international commitments [39,40];

- The Transport Development Strategy of the Republic of Croatia for the period from 2014 to 2030 discusses the sustainability of ports by reducing their impact on the environment through increased energy efficiency, promoting the use of alternative fuels and establishing emission control areas. The aim is to ensure the long-term sustainability of the maritime sector, modernize port superstructure and infrastructure, and promote the use of renewable energy sources in the port sector. This also includes the establishment of a “clean air” program in order to reduce ship emissions in ports [41];

- The Croatian Strategy for Hydrogen by 2050 is consistent with the goals of the European Green Deal Strategy and the European Strategy for Hydrogen. The strategy explicitly mentions the supply of electricity to ships at berth and highlights the application of cold ironing technology as an important element in ports with a significant number of cruise calls such as Dubrovnik, Split, and Zadar [42].

3. Implementation Advantages and Challenges

- The port of Rijeka is a development-oriented port with specialized basins for handling various types of cargo. It is the largest Croatian port in terms of transportation and handles a wide range of cargoes, including containers, bulk cargo, and crude and refined petroleum products. The port can accommodate several vessels, such as tankers, bulk carriers, container ships, general cargo vessels, passenger ships, and ro-ro vessels;

- Zadar is a vital transportation hub in Croatia that connects continental traffic routes, maritime routes, railways, highways, and airports. The port meets international, national, and local requirements, including tourism, and the ferry terminal serves as the primary link to nearby islands and other coastal destinations. The Zadar Port Authority governs different port areas, including passenger terminals, cargo, and fishing ports;

- The port of Šibenik operates handling, transport, and storage machinery and has the necessary railway, road, electrical, and telephone infrastructure. It features terminals for bulk and general cargo and passengers;

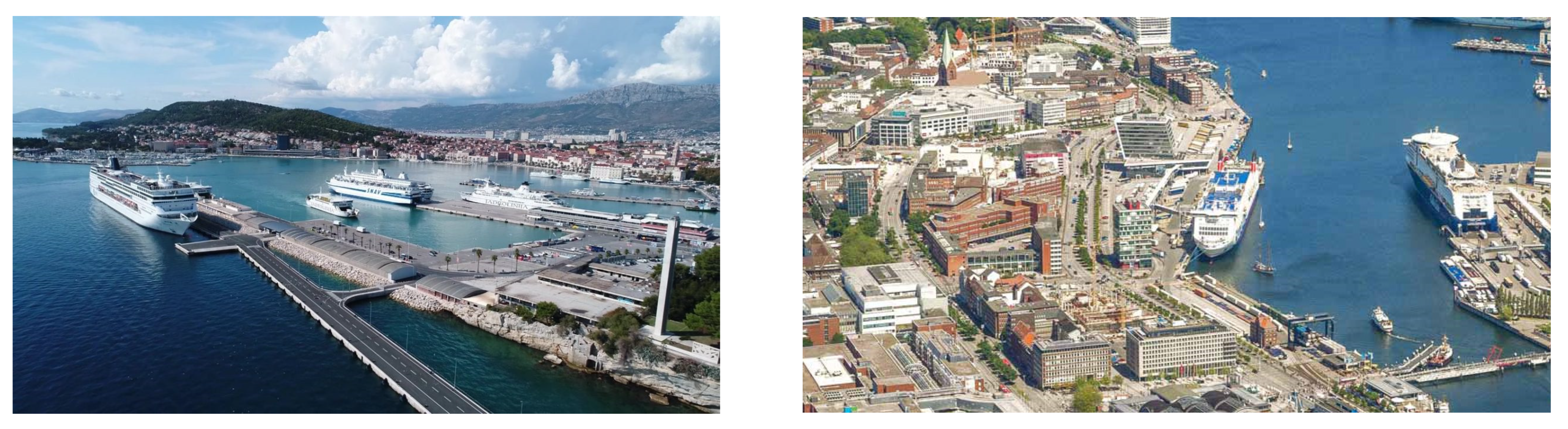

- Split is the largest passenger port in the Republic of Croatia, and national and international traffic has been continuously increasing, indicating further growth trends. The port handles more than 5 million passengers and 730 thousand vehicles annually;

- The Port of Ploče serves as the main gateway to the Pan-European Corridor Vc and is the second-largest port in Croatia regarding annual cargo volumes, just behind the Port of Rijeka. The port terminals facilitate different types of cargo, including general, container, dry bulk, and liquid cargo;

- Finally, the Port of Dubrovnik plays a critical role in international passenger transport and is one of the most significant cruise ports in the Mediterranean area. The port primarily focuses on passenger transport in international and domestic freight, and the reconstructed port terminals are predominantly used for ferries and cruise vessels.

3.1. Advantages

3.2. Challenges

4. Methodology

5. Results

6. Discussion

- Conducting a thorough feasibility study to assess the costs, benefits, and environmental impacts of implementing cold ironing in Croatian state-owned ports;

- Collaborating with other ports in the European Union, particularly those located on the Adriatic Sea, to evaluate and quantify the effects of cold ironing on the entire cluster of ports. This could facilitate the sharing of best practices and resources among ports;

- Developing a comprehensive cold ironing implementation strategy that considers the unique challenges and requirements of the technology;

- Investing in necessary infrastructure and providing workforce training that ensures ports are fully equipped to handle the technological, environmental, and safety challenges of cold ironing;

- Engaging with various ministries of the Republic of Croatia to ensure that implementing the technology aligns with relevant policies and regulations.

- Government-led framework: The government can lead the cold ironing implementation by providing funding, creating policies and measures, and setting up viable infrastructure. This approach can help ensure compliance with emission policies and promote the adoption of green port technologies;

- Private sector-led framework: Private companies operating in Croatian ports can invest in cold ironing technology and collaborate with other stakeholders to drive its adoption. This approach could also include collaboration with the ship owners considering their interest in the technology;

- Public–private partnership (PPP) framework: the government and private sector can collaborate to implement cold ironing technology, combining public funding and private sector expertise;

- Multi-stakeholder framework: Various stakeholders, including government, private sector, and academia, can work together to implement cold ironing technology. This approach can help address the unique challenges of implementing cold ironing technology and ensure a coordinated effort towards decarbonization goals.

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

Survey

“High Voltage Shore Connections in Croatian State-Owned Ports”—1st Part

- Choose the State-owned port:

| □ Rijeka | □ Zadar | □ Šibenik | □ Split | □ Ploče | □ Dubrovnik |

- 2.

- What is the current form of the shore-power supply for vessels in your port? (multiple choice question)

| □ High voltage connection (AC)—more than 1kV | □ Low voltage connection (AC)—less than 1 kV | □ DC connection | □ No power supply |

- 3.

- What kind of ships can be linked to your harbour’s on-shore power supply (conventional connection)? (multiple choice question)

| □ RoPax/ RoRo ships | □ Bulk carriers | □ Tankers | □ Cruise | □ Excursion boats | □ Nautical tourism vessels | □ Smaller private boats | □ Catamarans (speedboat lines) | □ Other: |

- 4.

- Are there plans to implement a cold ironing technology (Cold ironing/On-shore power supply) in your port?

| □ Yes | □ No |

- 5.

- Could you estimate the anticipated duration for the construction and eventual functioning of the on-shore power supply?

| □ Less than 1 year | □ Between 1 and 5 years | □ More than 5 years | □ Not defined |

- 6.

- The cold ironing technology infrastructure should be financed by:

| □ Port funds | □ Independently using EU funds | □ Port funds with state co-financing | □ Port funds with EU co-financing | □ State and/or EU funds | □ Other: |

- 7.

- Have any ship owners whose vessels dock at your port indicated an interest in a high-voltage connection from the mainland? If yes, kindly specify the type of ship they operate. (multiple choice question)

| □ RoPax/ RoRo ships | □ Bulk carriers | □ Tankers | □ Cruise | □ Excursion boats | □ Nautical tourism vessels | □ Smaller private boats | □ Catamarans (speedboat lines) | □ Other: |

- 8.

- Do you think that the rise in the prices of energy products, especially electricity, prompted by the current various global events, will affect the port’s operations?

| □ Strongly Agree | □ Agree | □ Neutral | □ Disagree | □ Strongly disagree | □ Unable to estimate |

References

- Spengler, T.; Tovar, B. Potential of Cold-Ironing for the Reduction of Externalities from in-Port Shipping Emissions: The State-Owned Spanish Port System Case. J. Environ. Manag. 2021, 279, 111807. [Google Scholar] [CrossRef] [PubMed]

- United Nations Conference on Trade and Development (UNCTAD). Review of Maritime Transport—2018. Available online: https://unctad.org/system/files/official-document/rmt2018_en.pdf (accessed on 28 October 2022).

- Abdaoui, A. Feasibility Study of Cold Ironing from Renewable Sources in the Nordic Region: Case Study: Port of Kapellskär in Stockholm. Master’s Thesis, World Maritime University, Malmö, Sweden, 2021. [Google Scholar]

- Lam, J.S.L.; Notteboom, T. The Greening of Ports: A Comparison of Port Management Tools Used by Leading Ports in Asia and Europe. Transp. Rev. 2014, 34, 169–189. [Google Scholar] [CrossRef]

- European Commission. The European Green Deal. Available online: https://ec.europa.eu/commission/presscorner/detail/en/ip_19_6691 (accessed on 1 September 2022).

- Jeong, B.; Kim, K. Characteristics of Economic and Environmental Benefits of Shore Power Use by Container-Ship Size. J. Mar. Sci. Eng. 2022, 10, 622. [Google Scholar] [CrossRef]

- Reusser, C.A.; Pérez, J.R. Evaluation of the Emission Impact of Cold-Ironing Power Systems, Using a Bi-Directional Power Flow Control Strategy. Sustainability 2020, 13, 334. [Google Scholar] [CrossRef]

- Marine Environment Protection Committee. Annex 19—Resolution MEPC.203(62). Available online: https://wwwcdn.imo.org/localresources/en/OurWork/Environment/Documents/Technical%20and%20Operational%20Measures/Resolution%20MEPC.203%2862%29.pdf. (accessed on 3 February 2023).

- International Maritime Organization (IMO). Towards Green and Efficient Navigation. Available online: https://wwwcdn.imo.org/localresources/en/OurWork/PartnershipsProjects/Documents/DPP-Factsheets/DPP%20one-page%20fact%20sheets_(25-10-21)_FINAL_ONLINE_NEXT%20GEN.pdf (accessed on 3 February 2023).

- NextGEN. Towards Green and Efficient Navigation. Available online: https://nextgen.imo.org/projects (accessed on 3 February 2023).

- Sornn-Friese, H.; Poulsen, R.T.; Nowinska, A.U.; de Langen, P. What Drives Ports around the World to Adopt Air Emissions Abatement Measures? Transp. Res. D Transp. Environ. 2021, 90, 102644. [Google Scholar] [CrossRef]

- Safety4Sea. Cold Ironing: The Role of Ports in Reducing Shipping Emissions. Available online: https://safety4sea.com/cm-cold-ironing-the-role-of-ports-in-reducing-shipping-emissions/ (accessed on 30 March 2023).

- Radonja, R.; Cuculić, A.; Valčić, M. Introducing the ASAP Project (Adriatic Sea Area Protection). Pomor. Sci. J. Marit. Res. 2011, 25, 487–499. [Google Scholar]

- Runko Luttenberger, L.; Ančić, I.; Šestan, A. The Viability of Short-Sea Shipping in Croatia. Brodogr. Teor. I Praksa Brodogr. I Pomor. Teh. 2013, 64, 472–481. [Google Scholar]

- Cuculić, A.; Vučetić, D.; Tomas, V. High Voltage Shore Connection Implementation in Croatian Ports. Pomorstvo 2013, 27, 105–116. [Google Scholar]

- Martínez-López, A.; Romero-Filgueira, A.; Chica, M. Specific Environmental Charges to Boost Cold Ironing Use in the European Short Sea Shipping. Transp. Res. D Transp. Environ. 2021, 94, 102775. [Google Scholar] [CrossRef]

- Kose, S.; Sekban, D.M. Emphasizing the Importance of Using Cold-Ironing Technology by Determining the Share of Hotelling Emission Value within the Total Emission. Transp. Saf. Environ. 2022, 4, tdac010. [Google Scholar] [CrossRef]

- Innes, A.; Monios, J. Identifying the Unique Challenges of Installing Cold Ironing at Small and Medium Ports—The Case of Aberdeen. Transp. Res. D Transp. Environ. 2018, 62, 298–313. [Google Scholar] [CrossRef]

- Winkel, R.; Weddige, U.; Johnsen, D.; Hoen, V.; Papaefthimiou, S. Shore Side Electricity in Europe: Potential and Environmental Benefits. Energy Policy 2016, 88, 584–593. [Google Scholar] [CrossRef]

- Colarossi, D.; Principi, P. Feasibility Study of a Cold Ironing System and District Heating in Port Area; Department of Industrial Engineering and Mathematic Sciences: Ancona, Italy, 2020; pp. 666–675. [Google Scholar] [CrossRef]

- Winkel, R.; Weddige, U.; Johnsen, D.; Hoen, V.; Papaefthymiou, G. Potential for Shore Side Electricity in Europe. Project number: TRANL14441. 2015. Available online: https://www.scribd.com/document/366724117/Ecofys-2014-Potential-for-Shore-Side-Electricity-in-Europe (accessed on 31 August 2022). Project number: TRANL14441.

- Karakatsanis, E.V. Implementation of Cold Ironing in Modern Ports. Master’s Thesis, National Technical University of Athens, Athens, Greece, 2021. [Google Scholar]

- Ericsson, P.; Fazlagic, I. Shore-Side Power Supply—A Feasibility Study and a Technical Solution for an On-Shore Electrical Infrastructure to Supply Vessels with Electric Power While in Port. Master’s Thesis, Chalmers University of Technology, Goteborg, Sweden, 2008. [Google Scholar]

- Zis, T.P.V. Prospects of Cold Ironing as an Emissions Reduction Option. Transp. Res. Part A Policy Pract. 2019, 119, 82–95. [Google Scholar] [CrossRef]

- Wang, H.; Mao, X.; Rutherford, D.; Francisco, S. Costs and Benefits of Shore Power at the Port of Shenzhen. Washington, United States of America: International Council on Clean Transportation. 2015. Available online: https://theicct.org/sites/default/files/publications/ICCT-WCtr_ShorePower_201512a.pdf (accessed on 2 February 2023).

- Ship Technology. Port of Dunkirk Opens Cold Ironing Facilities. Available online: https://www.ship-technology.com/news/port-of-dunkirk-cold-ironing-facilities/ (accessed on 2 September 2022).

- Port of Hamburg. Shore Power Facility for Containerships at Hamburg’s Burchardkai and Tollerort Terminals. Available online: https://www.hafen-hamburg.de/en/press/news/landstrom-fuer-containerschiffe-in-hamburg/ (accessed on 2 September 2022).

- Ship Technology. Port of Kiel Launches Emission-Free Shore-Based Plant to Power Ships. Available online: https://www.ship-technology.com/news/port-of-kiel-shore-based-plant/ (accessed on 2 September 2022).

- Baltic Transport Journal. Bergen’s First Cruise Ship Cold Ironing. Available online: https://baltictransportjournal.com/index.php?id=2216 (accessed on 2 September 2022).

- Costa, N.; Williamsson, J.; Ekholm, J.; Santén, V.; Rogerson, S.; Borgh, M. Connecting Vessels to Shoreside Electricity in Sweden; SSPA Report No: RR41199360-01-00-A; Trafikverket—Swedish Transport Administration: Borlänge, Sweden, 2022. [Google Scholar]

- Ports of Stockholm. Onshore Power Connection for Vessels. Available online: https://www.portsofstockholm.com/about-us/environmental-work/environmental-measures/onshore-power-connection/ (accessed on 2 September 2022).

- Offshore Energy. UK’s Port of Southampton Opens Its First Shore Power Facility. Available online: https://www.offshore-energy.biz/uks-port-of-southampton-opens-its-first-shore-power-facility/?fbclid=IwAR2Fwm559qmExxGW1vt7pVjlGbcbloKAVLE16i6WPvRvelxRhwAaoSMmMds (accessed on 2 September 2022).

- Chen, J.; Zheng, T.; Garg, A.; Xu, L.; Li, S.; Fei, Y. Alternative Maritime Power Application as a Green Port Strategy: Barriers in China. J. Clean. Prod. 2019, 213, 825–837. [Google Scholar] [CrossRef]

- European Community Shipowners’ Associations (ECSA). A Green Deal for the European Shipping Industry. Available online: https://www.ecsa.eu/sites/default/files/publications/2020%20ECSA%20Position%20Paper%20-%20A%20Green%20Deal%20for%20the%20European%20shipping%20industry.pdf (accessed on 1 September 2022).

- European Sea Ports Organisation (ESPO). Environmental Report 2019—EcoPortsinSights 2019. Available online: https://www.espo.be/media/Environmental%20Report-2019%20FINAL.pdf (accessed on 1 September 2022).

- European Parliament. European Green Deal-Fuel EU Maritime-Sustainable Maritime Fuels. Available online: https://www.europarl.europa.eu/legislative-train/theme-a-european-green-deal/file-fuel-eu-maritime (accessed on 1 September 2022).

- European Maritime Safety Agency (EMSA). Shore-Side Electricity-Guidance to Port Authorities and Administrations. Available online: https://emsa.europa.eu/we-do/safety/ship-safety-standards/download/7259/4799/23.html (accessed on 2 September 2022).

- Official Gazette. National Development Strategy of the Republic of Croatia until 2030. Available online: https://narodne-novine.nn.hr/clanci/sluzbeni/2021_02_13_230.html (accessed on 2 September 2022).

- Šimić, I.; Dominiković Cecelja, I.; Turković, M.; Ercegovac, V.; Vrana, K.; Dropiluć Vejin, P.; Domitrović, D.; Leib, B.; Trstenjak, J.; Komušanac, I. Guide for the Development and Implementation of Renewable Energy Projects in Croatia. Available online: https://oie.hr/wp-content/uploads/2022/02/RESC-EBRD-Guide-for-develop.-impl.-of-RES-projects-in-Croatia.pdf (accessed on 2 September 2022).

- Official Gazette. Energy Development Strategy of the Republic of Croatia until 2030 with a Look at the Year 2050. Available online: https://narodne-novine.nn.hr/clanci/sluzbeni/2020_03_25_602.html (accessed on 2 September 2022).

- Government of the Republic of Croatia. Transport Development Strategy of the Republic of Croatia for the Period from 2014 to 2030. Available online: https://mmpi.gov.hr/UserDocsImages/arhiva/Strategija_prometnog_razvoja_VRH1-studeni.pdf (accessed on 2 September 2022).

- Official Gazette. Croatian Strategy for Hydrogen by 2050. Available online: https://narodne-novine.nn.hr/clanci/sluzbeni/2022_03_40_492.html (accessed on 2 September 2022).

- Four Ports Onshore Power in Baltic Seaports. Available online: https://four-ports.eu/ (accessed on 6 September 2022).

- Port of Split. Available online: https://portsplit.hr/en/port-of-split-infrastructure-rehabilitation-project-the-construction-of-outer-berths/ (accessed on 28 March 2023).

- Port of Kiel. Available online: https://www.portofkiel.com/harbours-terminals.html (accessed on 2 December 2022).

- Ministry of Sea, Transport and Infrastructure. Ports. Available online: https://mmpi.gov.hr/sea/ports/8460 (accessed on 31 March 2023).

- Maps Croatia. Croatian Offline Map. Available online: https://hr.maps-croatia.com/hrvatska-offline-kartica (accessed on 5 May 2023).

- Caprara, G.; Armas, V.; de Mesquita Sousa, D.; Kermani, M.; Martirano, L. An Energy Storage System to Support Cruise Ships Cold Ironing in the Port of Civitavecchia. In Proceedings of the 2021 IEEE International Conference on Environment and Electrical Engineering and 2021 IEEE Industrial and Commercial Power Systems Europe (EEEIC/I&CPS Europe), Bari, Italy, 7–10 September 2021. [Google Scholar] [CrossRef]

- Canepa, M.; Ballini, F.; Dalaklis, D.; Frugone, G.; Sciutto, D. Cold Ironing: Socio-Economic Analysis in the Port of Genoa. Logistics 2023, 7, 28. [Google Scholar] [CrossRef]

- Hall, W.J. Assessment of CO2 and Priority Pollutant Reduction by Installation of Shoreside Power. Resour. Conserv. Recycl. 2010, 54, 462–467. [Google Scholar] [CrossRef]

- Abu Bakar, N.N.; Bazmohammadi, N.; Vasquez, J.C.; Guerrero, J.M. Electrification of Onshore Power Systems in Maritime Transportation towards Decarbonization of Ports: A Review of the Cold Ironing Technology. Renew. Sustain. Energy Rev. 2023, 178, 113243. [Google Scholar] [CrossRef]

- Zis, T.; North, R.J.; Angeloudis, P.; Ochieng, W.Y.; Bell, M.G.H. Evaluation of Cold Ironing and Speed Reduction Policies to Reduce Ship Emissions near and at Ports. Marit. Econ. Logist. 2014, 16, 371–398. [Google Scholar] [CrossRef]

- Yu, J.; Voß, S.; Tang, G. Strategy Development for Retrofitting Ships for Implementing Shore Side Electricity. Transp. Res. D Transp. Environ. 2019, 74, 201–213. [Google Scholar] [CrossRef]

- Marinello, S.; Balugani, E.; Rimini, B. Sustainability of Logistics Infrastructures: Operational and Technological Alternatives to Reduce the Impact on Air Quality. In Proceedings of the Summer School F. Turco—Industrial Systems Engineering; University of Bergamo: Bergamo, Italy, 2021. [Google Scholar]

- The Territorial Needs Assessments for the Port of Ploče. Available online: www.italy-croatia.eu/acronym (accessed on 10 May 2023).

- Piccoli, T.; Fermeglia, M.; Bosich, D.; Bevilacqua, P.; Sulligoi, G. Environmental Assessment and Regulatory Aspects of Cold Ironing Planning for a Maritime Route in the Adriatic Sea. Energies 2021, 14, 5836. [Google Scholar] [CrossRef]

- European Commission. Ports 2030—Gateways for the Trans European Transport Network. Available online: https://ec.europa.eu/transport/infrastructure/tentec/tentec-portal/site/brochures_images/ports2013_brochure_lowres.pdf (accessed on 11 May 2023).

- Pruyn, J.; Willeijns, J. Cold Ironing: Modelling the Interdependence of Terminals and Vessels in Their Choice of Suitable Systems. J. Shipp. Trade 2022, 7, 1–20. [Google Scholar] [CrossRef]

- Notteboom, T.; Pallis, A.; Rodrigue, J.-P. Port Economics, Management and Policy; Routledge: Oxford, UK, 2022; ISBN 9780367331559. [Google Scholar]

| Country | Port | Implementation Year | Type of Vessel | Reference |

|---|---|---|---|---|

| Belgium | Zeebrugge | 2000 | RoRo | [22] |

| Belgium | Antwerp | 2008 | Container | [23] |

| Finland | Kemi | 2006 | RoPax | [23,24] |

| Finland | Kotka | 2006 | RoPax | [23,24] |

| Finland | Oulu | 2006 | RoPax | [25] |

| France | Dunkirk | 2020 | Container | [26] |

| Germany | Lubeck | 2008 | RoPax | [25] |

| Germany | Hamburg | 2016 | Cruise | [27] |

| Germany | Kiel | 2019 | Cruise | [28] |

| Netherlands | Rotterdam | 2012 | RoPax | [25] |

| Norway | Bergen | 2022 | Cruise | [29] |

| Sweden | Gothenburg | 2000 & 2010 | RoRo, RoPax | [22,30] |

| Sweden | Stockholm | 2006 | RoRo, RoPax, Archipelago ferries | [31] |

| Sweden | Karlskrona | 2010 | RoPax | [22,30] |

| Sweden | Ystad | 2012 | RoPax | [30] |

| Sweden | Trellebrog | 2013 | RoPax | [22,30] |

| UK | Southampton | 2022 | Cruise | [32] |

| State-Owned Port | ||||||

|---|---|---|---|---|---|---|

| Zadar | Šibenik | Split | Ploče | Dubrovnik | ||

| Vessel type | RoPax/RoRo | |||||

| Bulk carriers | ||||||

| Tanker | ||||||

| Cruise | ||||||

| Excursion boat | X | X | X | X | X | |

| Nautical tourism vessels | X | X | X | |||

| Smaller private boats | X | X | X | |||

| Catamarans | X | |||||

| Port | ||||||

|---|---|---|---|---|---|---|

| Zadar | Šibenik | Split | Ploče | Dubrovnik | ||

| Shipowners’ interest for vessel type | RoPax/RoRo | X | ||||

| Bulk carriers | ||||||

| Tanker | ||||||

| Container | X | |||||

| Cruise | X | X | ||||

| Excursion boat | X | X | ||||

| Nautical tourism vessels | X | X | ||||

| Smaller private boats | X | |||||

| Catamarans | ||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Glavinović, R.; Krčum, M.; Vukić, L.; Karin, I. Cold Ironing Implementation Overview in European Ports—Case Study—Croatian Ports. Sustainability 2023, 15, 8472. https://doi.org/10.3390/su15118472

Glavinović R, Krčum M, Vukić L, Karin I. Cold Ironing Implementation Overview in European Ports—Case Study—Croatian Ports. Sustainability. 2023; 15(11):8472. https://doi.org/10.3390/su15118472

Chicago/Turabian StyleGlavinović, Roko, Maja Krčum, Luka Vukić, and Ivan Karin. 2023. "Cold Ironing Implementation Overview in European Ports—Case Study—Croatian Ports" Sustainability 15, no. 11: 8472. https://doi.org/10.3390/su15118472

APA StyleGlavinović, R., Krčum, M., Vukić, L., & Karin, I. (2023). Cold Ironing Implementation Overview in European Ports—Case Study—Croatian Ports. Sustainability, 15(11), 8472. https://doi.org/10.3390/su15118472