Trade-Off Analyses of Food Loss and Waste Reduction and Greenhouse Gas Emissions in Food Supply Chains

Abstract

:1. Introduction

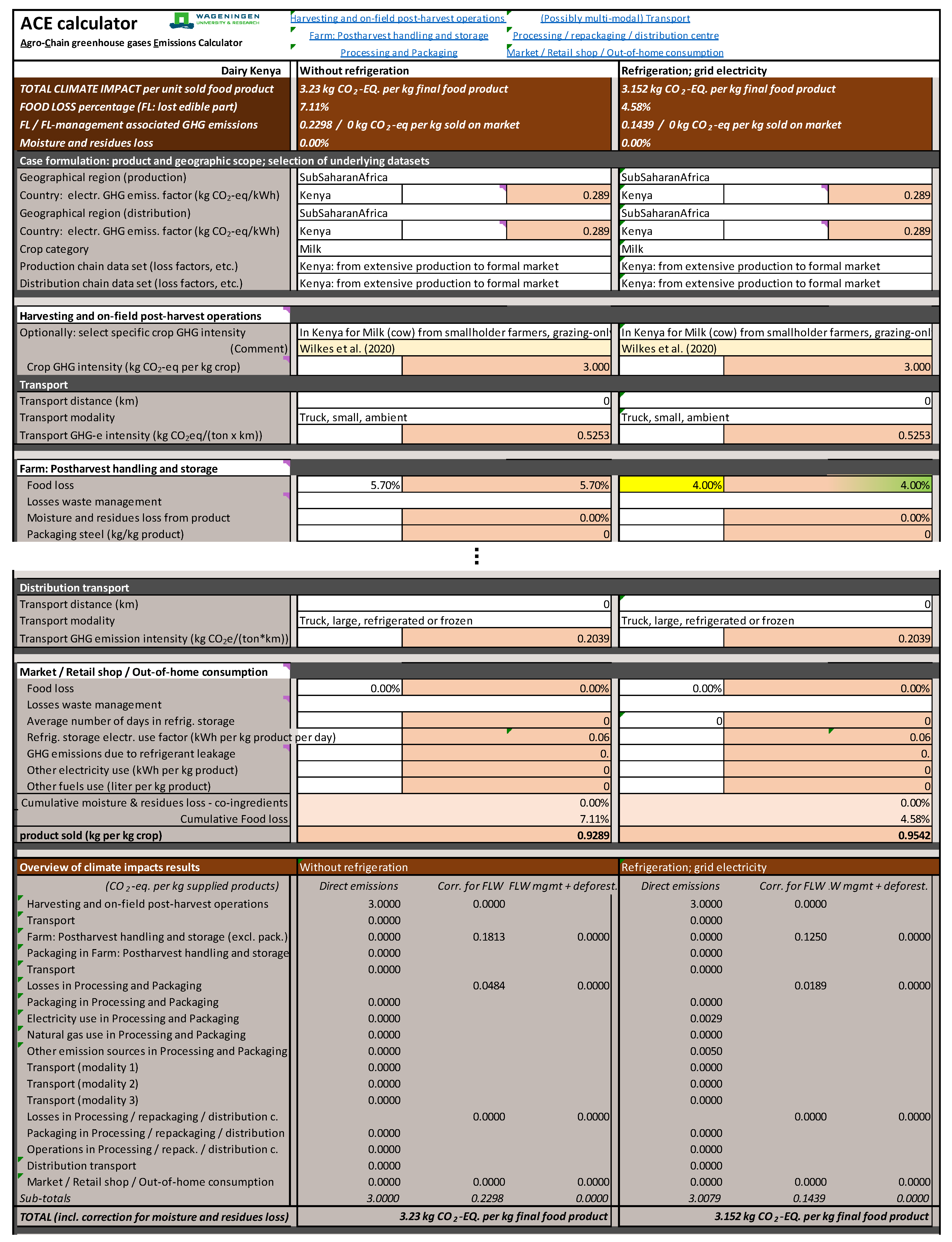

2. Method: Agro-Chain Greenhouse Gas Emissions (ACE) Calculator

2.1. Problem Statement: Assessing GHG Emissions of Food Supply

- A specification of the food supply chain, including geographic locations of production and final market, transportation distances and modalities, use of energy (for cooling and other operations) and fuels, other inputs (including packaging material), FLW percentage per chain stage, and FLW management practices. These parameters are case-specific and must be provided per case study;In scenario studies on FLW-reducing interventions, the inputs (such as packaging material used and refrigeration energy use) or logistic parameters may vary between the scenarios;

- GHG emission intensities of inputs and residue management: crop production, electricity, fuels, packaging materials (plastics, steel, aluminum, glass, …), and loss/waste management options.

2.2. Explanation of the Agro-Chain Greenhouse Gas Emissions (ACE) Calculator

- Crop GHG emission intensities

- Average/typical values are provided for all crop categories (FAOSTAT [18] coding), detailed per global geographical region: Europe; North America and Oceania; Industrialized Asia; Sub-Saharan Africa; North Africa, West and Central Asia; South and Southeast Asia; and Latin America. These datasets are derived from the review by [1];

- More specific values for a country or specific farming situation (e.g., smallholder production) are derived from dedicated studies and from [18] for rice and animal products.

- Loss factors along supply chains

- Average/typical values are provided per crop category, specified per the aforementioned global region, again derived from the review by [1];

- For situation-specific analysis, more dedicated data may be required. More specific data for a small number of situations is given, but it is recommended to gather more specific information from other sources. Good examples of inventories that aggregate findings from diverse studies include the African Post-harvest Losses Information System APHLIS [19] and the Post-Harvest Loss Information System SIPPOC [20].

- Typical GHG emission intensities for transportation modalities: since often the emission standard of the actual vehicle used in a shipment is not known, average GHG emission intensities are recommended. These are specified for diverse sizes of road vehicles (from small vans to large trucks), bulk and containerized sea transport, and continental and intercontinental air freight. The GHG emission intensities were largely derived from [23,24];

- Electricity: for a large number of countries (average), GHG emission factors are provided in the tool (GHG emissions associated with production [35,36,37] and transmission and distribution [38]). In addition, typical GHG emission factors are provided for a number of renewable energy sources [39,40];

- Fuels: well-to-wheel GHG emission factors are included [28] (the actual well-to-wheel emission factor may vary slightly among countries/regions, but the differences are relatively small—less than 5%—and therefore neglected).

- Geographic region and country of production and delivery;

- Crop;

- Transportation distances and modalities;

- Packaging materials used;

- Electricity use: the actual electricity use per unit material is material/process/situation-specific and, therefore, must be specified by the user. A provision is included for refrigerated storage because it is broadly adopted in food supply chains; if electricity use for refrigerated storage is not specified, a default electricity use of 1 kWh per ton per day is suggested (estimated from [41]).

| Aggregation level of data | Averages for crop category per geographical region | Specific data for a dedicated crop, chain configuration and/or specific country | Specifically defined unit operations along the chain | |||

| Example | Roots and Tubers, Sub-Saharan Africa | Cassava Sub-Saharan Africa | Cassava Mozambique | Potato Kenya | Cassava Mozambique, traditional processing | Cassava Mozambique, mobile processing unit |

| Specific data source crop GHG emission factor | Average data (we used values from [1]) | Reference data sets such as FAO emissions database [18]. Dedicated literature source (country/chain study); see, e.g., [42,43]. Calculated value through an external calculator (e.g., Cool Farm Tool [15] or the Quantis Food Loss and Waste Value Calculator [17]. | Dedicated literature source (country/chain study). Calculated value through an external calculator | |||

| Specific data source FLW factors along the chain | Average data (we used values from [1]) | Reference data sets like APHLIS [19] and SIPPOC [20]. Dedicated literature source. Direct measurements. | Dedicated literature source. Expert estimate of the effect of the intervention on FLW. Direct measurements. | |||

| Typical use | Estimating average FLW and food supply GHG emissions at the food category level | Assessing/comparing different supply chain types or crop types that fulfill a nutritional need. | Assessing/comparing net effects of different technology options. | |||

2.3. Conceptual Comparison with Existing Approaches

- Estimating environmental impact per unit lost food: effects of destinations, including waste management options (EPA Waste Reduction Model);

- Estimating environmental impact per unit lost food, including impacts of their agricultural production and effect of destinations of the lost product (for distinct food types: FLW Value Calculator, for distinct food basket types: ReFED US Impact Calculator);

- Estimating impacts of crop–livestock production, including first-level processing (storage, packaging, grading) and transport (Cool Farm Tool);

- Estimating GHG emissions of purchased foods, based on typical GHG emission intensities of food products, not specified to origin (Cool Food Calculator).

2.4. Limitations of the ACE Calculator

3. Analyzing Climate Impact Effects of Interventions in Supply Chains

- Applying refrigeration or lowering the storage temperature in the chain (which may result in extended retail shelf life and reduction of FLW but will lead to an increase in energy use);

- Applying protective packaging (which may lead to a reduction of losses, but at the cost of using packaging materials);

- Transfer processing to a location near the crop production (this may lead to a reduction of transportation, but at the cost of increasing energy use: a regional, small-scale facility generally has lower energetic efficiency than a large-scale centralized processing facility).

4. Results—Case Studies on Effects of FLW Reductions on GHG Emissions

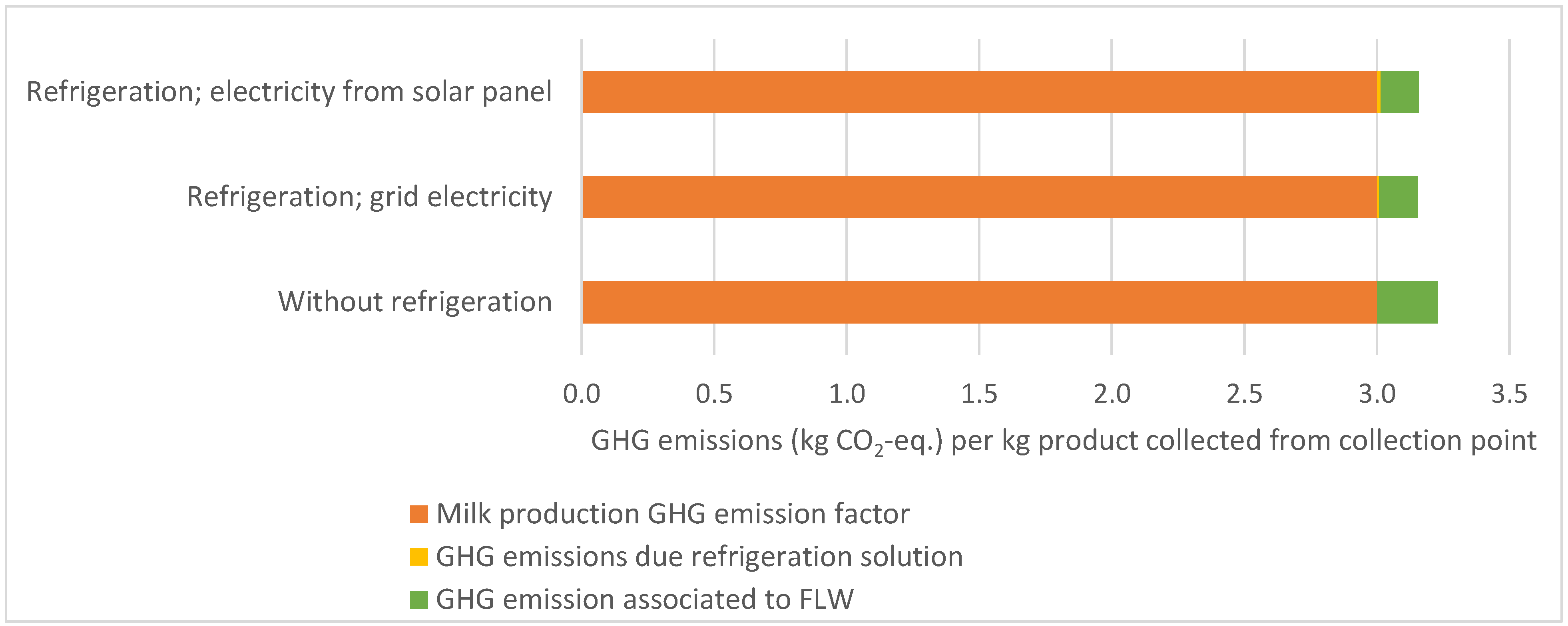

4.1. Case Study: Cooling in Milk Collection Chains in Kenya

4.2. Case Study: Lowering the Storage Temperature for Bovine Meat in The Netherlands

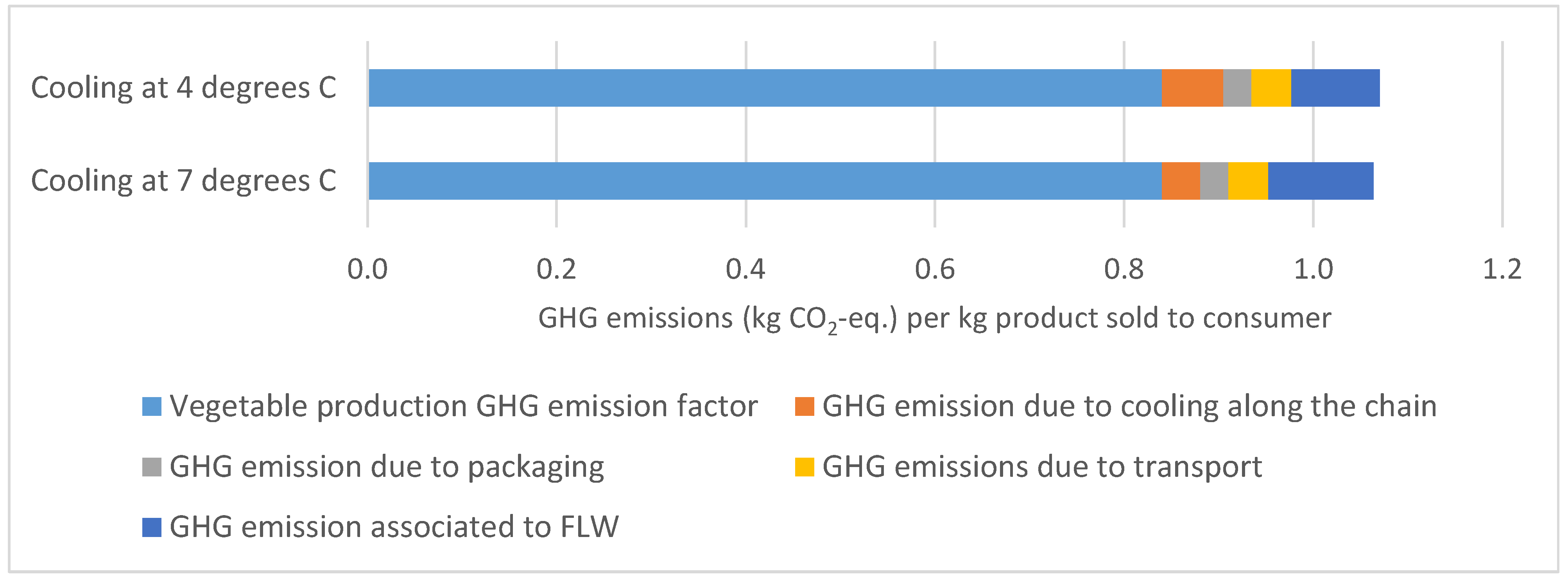

4.3. Case Study: Lowering the Keeping Temperature for Packaged Fresh-Cut Vegetables in The Netherlands

4.4. Case Study: Effects of Modified Atmosphere Packaging in Melon Shipping from Honduras to UK

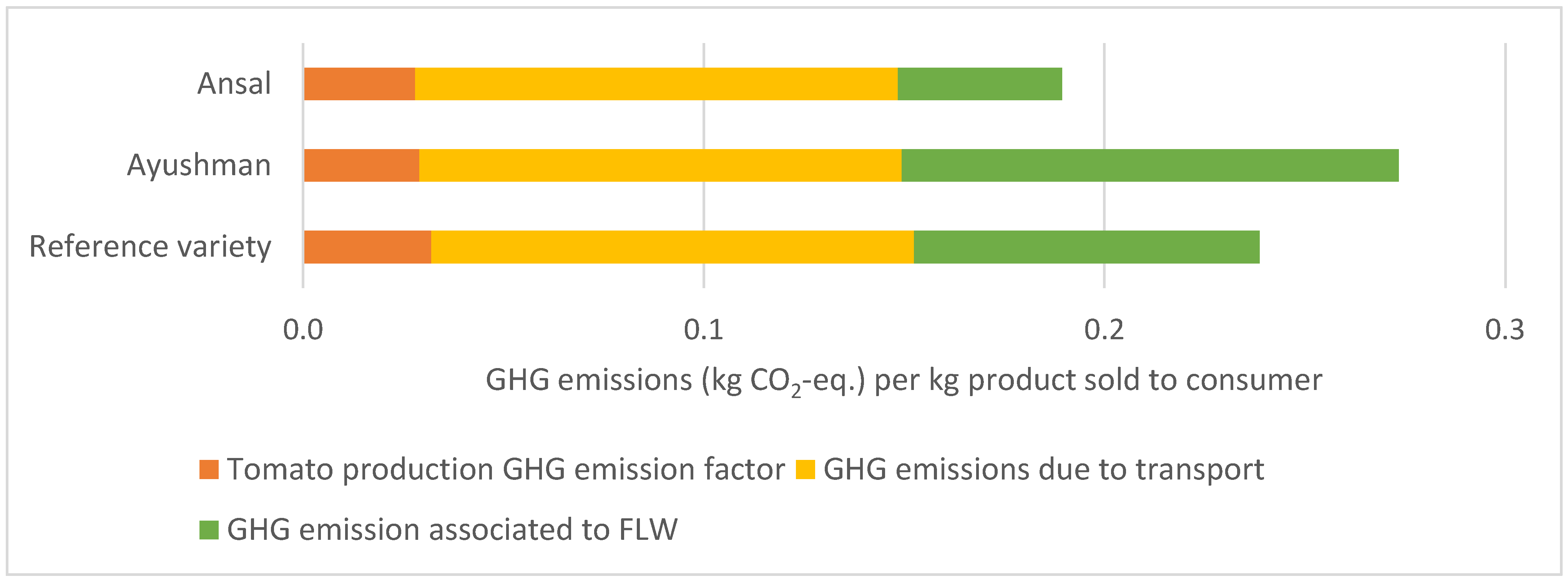

4.5. Case Study: Tomato Varieties for Traditional Smallholder Chains in India

4.6. Case Study: Supplying Dragon Fruit from Vietnam to Europe

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Porter, S.D.; Reay, D.S.; Higgins, P.; Bomberg, E. A half-century of production-phase greenhouse gas emissions from food loss & waste in the global food supply chain. Sci. Total Environ. 2016, 571, 721–729. [Google Scholar] [PubMed]

- IPCC. Climate Change 2014: Mitigation of Climate Change. Contribution of Working Group III to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; Edenhofer, O.R., Pichs-Madruga, Y., Sokona, E., Farahani, S., Kadner, K., Seyboth, A., Adler, I., Baum, S., Brunner, P., Eickemeier, B., et al., Eds.; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2014. [Google Scholar]

- I4CE; Rogissart, L.; Foucherot, C.; Bellassen, V. Food Policies and Climate: A Literature Review, Institute for Climate Economics. 2019. Available online: https://www.i4ce.org/wp-core/wp-content/uploads/2019/03/0306-I4CE2984-PolitiquesAlimentairesEtClimat-Etude24p-VA_V2.pdf (accessed on 25 August 2020).

- Vermeulen, S.J.; Campbell, B.M.; Ingram, J.S.I. Climate Change and Food Systems. Annu. Rev. Environ. Resour. 2012, 37, 195–222. [Google Scholar] [CrossRef]

- Poore, J.; Nemecek, T. Reducing Food’s Environmental Impacts through Producers and Consumers. Science 2018, 360, 987–992. [Google Scholar] [CrossRef] [PubMed]

- FAO. Food Wastage Footprint Full-Cost Accounting: Final Report; FAO: Rome, Italy, 2014. [Google Scholar]

- UNEP. Food Waste Index Report 2021; United Nations Environment Programme: Nairobi, Kenya, 2021. [Google Scholar]

- Guo, X.; Broeze, J.; Groot, J.; Axmann, H.; Vollebregt, M. A global hotspot analysis on food loss & waste and associated greenhouse gas emissions. Sustainability 2020, 12, 7488. [Google Scholar]

- United Nations General Assembly. Resolution Adopted by the General Assembly on 25 September 2015. 70/1 Transforming Our World: The 2030 Agenda for Sustainable Development; United Nations General Assembly: New York, NY, USA, 2015. [Google Scholar]

- Gustavsson, J.; Cederberg, C.; Sonesson, U.; Otterdijk, R.V.; Meybeck, A. Global Food Losses and Food Waste: Extent, Causes and Prevention; Food and Agriculture Organisation of the United Nations (FAO): Rome, Italy, 2011. [Google Scholar]

- Springmann, M.; Clark, M.; Mason-D’Croz, D.; Wiebe, K.; Bodirsky, B.L.; Lassaletta, L.; De Vries, W.; Vermeulen, S.J.; Herrero, M.; Carlson, K.M.; et al. Options for keeping the food system within environmental limits. Nature 2018, 526, 519–526. [Google Scholar]

- Bacenetti, J.; Cavaliere, A.; Falcone, G.; Giovenzana, V.; Banterle, A.; Guidetti, R. Shelf life extension as solution for environmental impact mitigation: A case study for bakery products. Sci. Total Environ. 2018, 627, 997–1007. [Google Scholar] [CrossRef] [PubMed]

- Gutierrez, M.M.; Meleddu, M.; Piga, A. Food losses, shelf life extension and environmental impact of a packaged cheesecake: A life cycle assessment. Food Res. Int. 2017, 91, 124–132. [Google Scholar] [CrossRef]

- Notarnicola, B.; Sala, S.; Anton, A.; McLaren, S.J.; Saouter, E.; Sonesson, U. The role of life cycle assessment in supporting sustainable agri-foodsystems: A review of the challenges. J. Clean. Prod. 2017, 140, 399–409. [Google Scholar] [CrossRef]

- Cool Farm Alliance, Cool Farm Tool. Available online: coolfarmtool.org/coolfarmtool/greenhouse-gases/ (accessed on 1 August 2020).

- FAO. 2023. Available online: https://www.fao.org/in-action/epic/ex-act-tool/suite-of-tools/ex-act/en/ (accessed on 27 February 2023).

- Quantis FLW Value Calculator. Available online: https://www.flwprotocol.org/why-measure/food-loss-and-waste-value-calculator/ (accessed on 18 December 2018).

- FAO. 2020. Available online: www.fao.org/faostat/en/#data (accessed on 1 May 2020).

- APHLIS. 2023. Available online: www.aphlis.net (accessed on 27 February 2023).

- SIPPOC. 2023. Available online: https://sippoc.esalqlog.com.br/ (accessed on 27 February 2023).

- EPA. Documentation for Greenhouse Gas Emission and Energy Factors Used in the Waste Reduction Model (WARM); Management Practices Chapters; U.S. Environmental Protection Agency Office of Resource Conservation and Recovery: Washington, DC, USA, 2018.

- Nordahl, S.L.; Devkota, J.P.; Amirebrahimi, J.; Smith, S.J.; Breunig, H.M.; Preble, C.V.; Satchwell, A.J.; Jin, L.; Brown, N.J.; Kirchstetter, T.W.; et al. Life-Cycle Greenhouse Gas Emissions and Human Health Trade-Offs of Organic Waste Management Strategies. Environ. Sci. Technol. 2020, 54, 9200–9209. [Google Scholar] [CrossRef] [PubMed]

- EcoTransIT. Environmental Methodology and Data Update 2020, Version 2.0; EcoTransIT World: Hanover, Germany, 2021. [Google Scholar]

- IMO. Fourth IMO GHG Study 2020; International Maritime Organization: London, UK, 2020. [Google Scholar]

- RISE. The Carbon Footprint of Carton Packaging 2019, RISE, Pro Carton. 2019. Available online: https://www.procarton.com/wp-content/uploads/2020/03/Carbon-Footprint-Report-2019.pdf (accessed on 25 November 2022).

- Venditti, R. Effect of Methodology on the Life Cycle Analysis of Paper Products; White Paper; North Carolina State University: Raleigh, NC, USA, 2012; Available online: https://faculty.cnr.ncsu.edu/richardvenditti/wp-content/uploads/sites/24/2018/08/WhitePaperLCAMethods272012.pdf (accessed on 25 November 2022).

- ETC/WMGE. Greenhouse Gas Emissions and Natural Capital Implications of Plastics (Including Biobased Plastics); Eionet Report—ETC/WGME 2021/3; European Topic Centre on Waste and Materials in a Green Economy: Copenhagen, Denmark, 2021. [Google Scholar]

- UK Government GHG Conversion Factors for Company Reporting: Conversion Factors 2019. Available online: https://www.gov.uk/government/publications/greenhouse-gas-reporting-conversion-factors-2019 (accessed on 1 February 2023).

- Schmitz, A.; Kamiński, J.; Scalet, B.M.; Soria, A. Energy consumption and CO2 emissions of the European glass industry. Energy Policy 2011, 39, 142–155. [Google Scholar] [CrossRef]

- Garofalo, P.; D’Andrea, L.; Tomaiuolo, M.; Venezia, A.; Castrignanò, A. Environmental sustainability of agri-food supply chains in Italy: The case of the whole-peeled tomato production under life cycle assessment methodology. J. Food Eng. 2017, 200, 1–12. [Google Scholar] [CrossRef]

- APEAL. Life Cycle Assessment on Tinplate (Leaflet). 2012. Available online: www.apeal.org/wp-content/uploads/2012/04/APEAL-LCA_summary_paper11.pdf (accessed on 27 August 2020).

- World Steel Association. Life Cycle Inventory Study 2018; World Steel Association: Belgium, Brussels, 2018; Available online: https://worldsteel.org/publications/bookshop/life-cycle-inventory-report-2018/ (accessed on 11 March 2019).

- Simon, B.; Amor, M.B.; Földényi, R. Life cycle impact assessment of beverage packaging systems: Focus on the collection of post-consumer bottles. J Clean. Prod. 2016, 112, 238–248. [Google Scholar] [CrossRef]

- Stotz, P.M.; Niero, M.; Bey, N.; Paraskevas, D. Environmental screening of novel technologies to increase material circularity: A case study on aluminium cans. Resour. Conserv. Recycl. 2017, 127, 96–106. [Google Scholar] [CrossRef]

- European Environmental Agency. Greenhouse Gas Emission Intensity of Electricity Generation in Europe. Available online: https://www.eea.europa.eu/ims/greenhouse-gas-emission-intensity-of-1 (accessed on 25 March 2022).

- International Energy Agency. Available online: https://www.iea.org/data-and-statistics/charts/carbon-intensity-of-electricity-generation-in-selected-regions-in-the-sustainable-development-scenario-2000-2040 (accessed on 1 April 2020).

- World Resources Institute. Sustainability Dashboard Methodology. Available online: https://www.wri.org/sustainability-wri/dashboard/methodology (accessed on 12 January 2023).

- UK Government GHG Conversion Factors for Company Reporting: Conversion Factors 2017. Available online: https://www.gov.uk/government/publications/greenhouse-gas-reporting-conversion-factors-2017 (accessed on 1 February 2023).

- CE-Delft. Chain Emissions Electricity (Update Energy Mix 2019); CE Delft: Delft, The Netherlands, 2022. [Google Scholar]

- Müller, A.; Friedrich, L.; Reichel, C.; Herceg, S.; Mittag, M.; Neuhaus, D.H. A comparative life cycle assessment of silicon PV modules: Impact of module design, manufacturing location and inventory. Sol. Energy Mater. Sol. Cells 2021, 230, 111277. [Google Scholar] [CrossRef]

- Evans, J.A.; Foster, A.M.; Huet, J.M.; Reinholdt, L.; Fikiin, K.; Zilio, C.; Houska, M.; Landfeld, A.; Bond, C.; Scheurs, M.; et al. Specific energy consumption values for various refrigeratedfood cold stores. Energy Build. 2014, 74, 141–151. [Google Scholar] [CrossRef]

- Nemecek, T.; Weiler, K.; Plassmann, K.; Schnetzer, J. Geographical Extrapolation of Environmental Impact of Crops by the MEXALCA Method. Unilever-ART Project No. CH-2009-0362 “Carbon and Water Data for Bio-based Ingredients”: Final Report of Phase 2: Application of the Method and Results; Agroscope Reckenholz-Tänikon Research Station ART: Zurich, Switzerland, 2011. [Google Scholar]

- Clune, S.; Crossin, E.; Verghese, K. Systematic review of greenhouse gas emissions for different fresh food categories. J. Clean. Prod. 2017, 140, 766–783. [Google Scholar] [CrossRef]

- Wilkes, A.; Wassie, S.; Odhong’, C.; Fraval, S.; van Dijk, S. Variation in the carbon footprint of milk production on smallholder dairy farms in central Kenya. J. Clean. Prod. 2020, 265, 121780. [Google Scholar]

- WRI/Food Loss & Waste Protocol, Connecting Food Loss and Waste to Greenhouse Gas Emissions: Guidance for Companies. Available online: https://www.flwprotocol.org/flw-standard/tools-resources/ (accessed on 13 April 2023).

- Tromp, S.O.; Haijema, R.; Rijgersberg, H.; van der Vorst, J.G. A systematic approach to preventing chilled-food waste at the retail outlet. Int. J. Prod. Econ. 2016, 182, 508–518. [Google Scholar] [CrossRef]

- Lore, T.; Omore, A.; Staal, S. Types, Levels and Causes of Post-Harvest Milk and Dairy Losses in Sub-Saharan Africa and the Near East: Phase Two Synthesis Report; ILRI: Nairobi, Kenya, 2005. [Google Scholar]

- Ndungu, M.M.; Lagat, J.K.; Langat, J.K. Determinants and causes of postharvest milk losses among milk producers in Nyandarua North subcounty, Kenya. East Afr. Agric. For. J. 2019, 83, 269–280. [Google Scholar] [CrossRef]

- Xiao, R.; Zhang, Y.; Liu, X.; Yuan, Z. A life-cycle assessment of household refrigerators in China. J. Clean. Prod. 2015, 95, 301–310. [Google Scholar] [CrossRef]

- Brito de Figueirêdo, M.C.; Kroeze, C.; Potting, J.; da Silva Barros, V.; Sousa de Aragão, F.A.; Sonsol Gondim, R.; de Lima Santos, T.; de Boer, I.J.M. The carbon footprint of exported Brazilian yellow melon. J Clean. Prod. 2013, 47, 404–414. [Google Scholar] [CrossRef]

- Bayer. 2023. Available online: https://www.bayer.com/en/news-stories/how-we-can-counter-climate-change-by-reducing-food-loss-and-waste (accessed on 27 February 2023).

- Axmann, H.; Soethoudt, H.; Van Dao, T.; Kok, M.; Nguyễn Anh, P.; Broeze, J. Roadmap Post Harvest Loss Reduction in Selected Vietnamese Value Chains: Phase 1: Hotspots and Feasible Interventions in Dragon Fruit and Longan; Report Wageningen Food & Biobased Research, No. 2161; Wageningen Food & Biobased Research: Wageningen, The Netherlands, 2021. [Google Scholar] [CrossRef]

| Factors | Value | Source/Comment |

|---|---|---|

| Bovine meat GHG emission factor | 22.9 kg CO2-eq./kg product | [1] |

| Processing/packaging loss factor | 5% | [1] |

| Retail shelf loss factor | Cooling at 7 °C: 3% Cooling at 4 °C: 1% | Estimated with the method presented by [46] for a representative supply chain in the Netherlands |

| Chain Configuration Parameters | Value | Source/Comment |

|---|---|---|

| Processing energy use | - | GHG emissions up to meat processing are included in the product’s GHG emission factor and, thus, should not be added to the calculations. |

| Refrigerated storage duration in processing/packaging stage | 1.3 days | practical expert estimate |

| Packaging plastics | 0.03 kg plastics per kg meat | measured from practical samples (random samples from a supermarket) |

| Transport from the packaging station to the distribution center | 80 km, large truck | practical expert estimate |

| Refrigerated storage duration in the distribution center | 0.5 days | practical expert estimate |

| Transport from distribution center to retail shop | 50 km, large truck | practical expert estimate |

| average Refrigerated retail display duration | Cooling at 7 °C: 40 h Cooling at 4 °C: 45 h | Estimated with the method presented by [46] for representative supply chain in The Netherlands |

| Factors | Value | Source/Comment |

|---|---|---|

| Vegetable production GHG emission factor | 0.84 kg CO2-eq./kg product | [1] |

| Handling and storage loss factor | 7.3% | [1] |

| Processing/packaging loss factor | 2.0% | [1] |

| Retail shelf loss factor | Cooling at 7 °C: 3% Cooling at 4 °C: 1% | Estimated with the method presented by [46] for a representative supply chain in the Netherlands |

| Packaging plastics | 0.01 kg plastics per kg product | Practical samples measurement |

| Parameter | Value and Further Specification |

|---|---|

| Crop GHG emission factor | 0.27 kg CO2-eq. per kg crop [50] |

| Trucking distance from the orchard to the packing house | 15 km (non-refrigerated medium size truck) |

| Operations in the packaging station | Cooling down Cold storage for an average of 2 days Packaging |

| Packaging material use | Carton: 80 g per kg melon Plastic (optional): 4 g per kg melon |

| Intercontinental transport (refrigerated reefer container) | Large truck: 386 km Container ship: 8760 km Large truck: 20 km |

| Losses (rejects) at point of arrival | Scenario without packaging: 17.5% Scenario with modified atmosphere packaging: 3.5% |

| Reference Hybrid Variety | Variety with Improved Yield (Ayushman) | Variety with Improved Shelf Life (Ansal) | |

|---|---|---|---|

| Average annual yield (ton/ha) | 39 | 43.5 | 45 |

| Crop GHG emission factor (kg CO2-eq. per kg crop) | 0.032 | 0.029 | 0.028 |

| Farmer grading: rejects | 20% | 3–5% | 3–5% |

| Buyer grading: rejects | 1% | 1% | 1% |

| Loss during long-distance transportation and on market | 20–25% | 34–39% | 8–10% |

| Transportation from field to collection center | 20 km; small truck | 20 km; small truck | 20 km; small truck |

| Transportation from collection center to market | 500 km; medium size truck | 500 km; medium size truck | 500 km; medium size truck |

| Scenario 1. Current Supply Chain: From Mekong Delta to Amsterdam (By Air) | Scenario 2. Supply Chain: From Mekong Delta to Rotterdam (By Sea, Reefer Container) | Scenario 3: Equal to Scenario 2, Supplemented with Cold Storage Directly after Picking | |

|---|---|---|---|

| Total food losses (measured/estimated) | 15% | 44% | 13% |

| Crop production GHG intensity * | 14.3 kg CO2-eq./kg | 14.3 kg CO2-eq./kg | 14.3 kg CO2-eq./kg |

| Emissions due to cooling energy use in the collection chain | - | - | ≪ 0.1 kg CO2-eq./kg |

| Emissions due to international transport * | 11 kg CO2-eq./kg | 0.6 kg CO2-eq. per kg | 0.5 kg CO2-eq. per kg |

| Emissions due to post-harvest losses ** | 1.1 kg CO2-eq./kg | 9.0 kg CO2-eq./kg | 0.4 kg CO2-eq./kg |

| TOTAL emissions per kg product on end market | 26.5 kg CO2-eq./kg | 24 kg CO2-eq./kg | 15 kg CO2-eq./kg |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Broeze, J.; Guo, X.; Axmann, H. Trade-Off Analyses of Food Loss and Waste Reduction and Greenhouse Gas Emissions in Food Supply Chains. Sustainability 2023, 15, 8531. https://doi.org/10.3390/su15118531

Broeze J, Guo X, Axmann H. Trade-Off Analyses of Food Loss and Waste Reduction and Greenhouse Gas Emissions in Food Supply Chains. Sustainability. 2023; 15(11):8531. https://doi.org/10.3390/su15118531

Chicago/Turabian StyleBroeze, Jan, Xuezhen Guo, and Heike Axmann. 2023. "Trade-Off Analyses of Food Loss and Waste Reduction and Greenhouse Gas Emissions in Food Supply Chains" Sustainability 15, no. 11: 8531. https://doi.org/10.3390/su15118531

APA StyleBroeze, J., Guo, X., & Axmann, H. (2023). Trade-Off Analyses of Food Loss and Waste Reduction and Greenhouse Gas Emissions in Food Supply Chains. Sustainability, 15(11), 8531. https://doi.org/10.3390/su15118531