Experimental Study on the Negative Skin Friction of Piles in Collapsible Loess

Abstract

:1. Introduction

2. Methodology

2.1. Similarity Ratio Design

2.2. Synthetic Collapsible Loess

2.3. Model Piles

2.4. Experimental Design and Procedures

- (1)

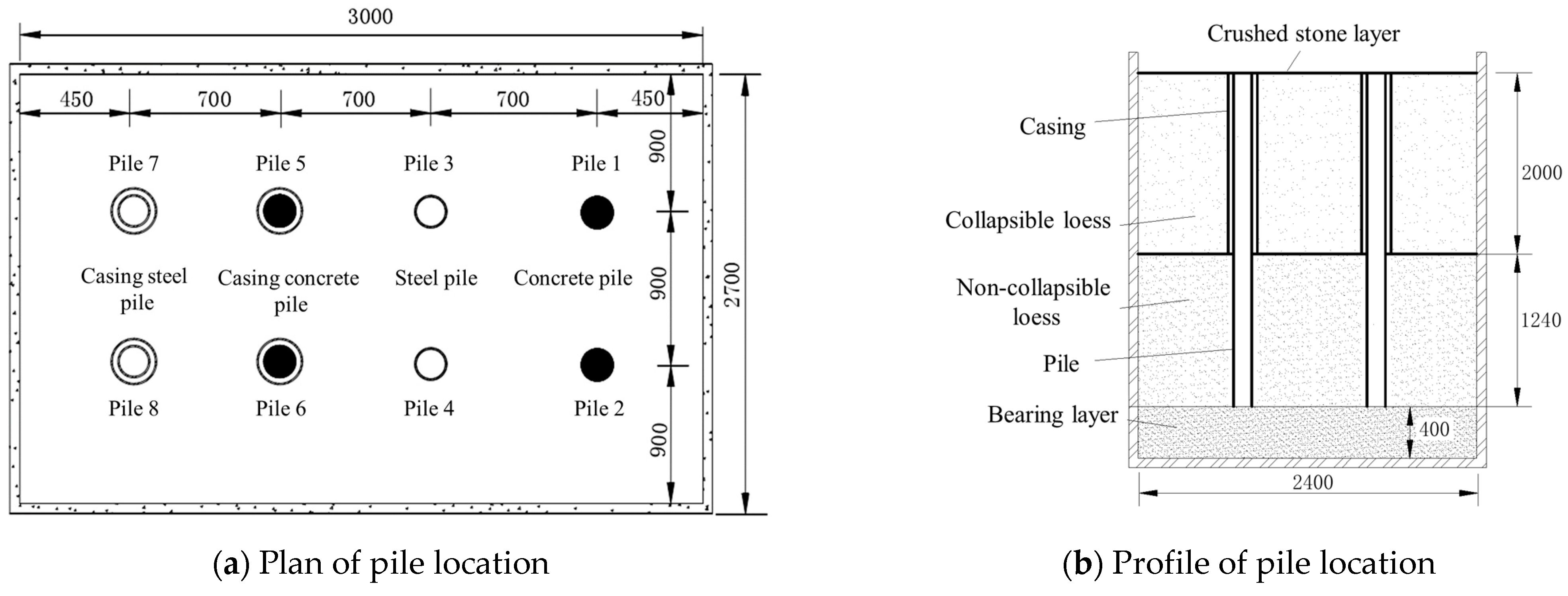

- At the bottom of the model tank, a 400 mm-thick sand bearing layer was filled. An electric compactor was used to slightly compress the sand every 110 mm to reach a density of 1.7 g/cm3. The prefabricated model piles were suspended in the design position using ropes. The verticality of each pile was ensured by using the heavy hammer suspension method. A layer of mixed sand and loess with a thickness of 1240 mm was filled, and followed by a layer of synthetic collapsible loess with a thickness of 2000 mm (Figure 2b). The compaction degree was controlled of 0.95 by using a ring cutter method. In addition, a 100 mm thick crushed stone was applied on the surface of synthetic collapsible loess to ensure the uniform penetration of water during immersion.

- (2)

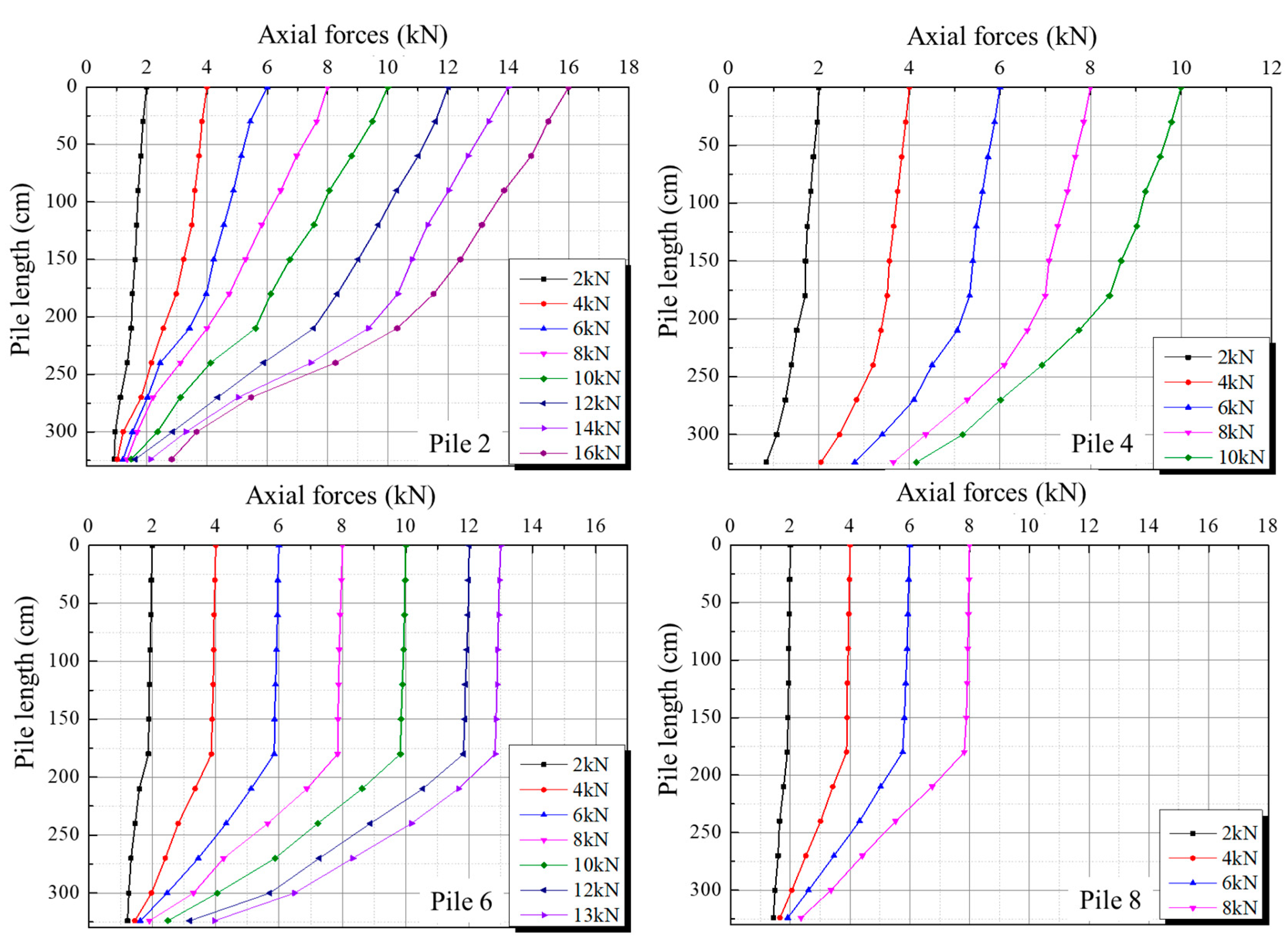

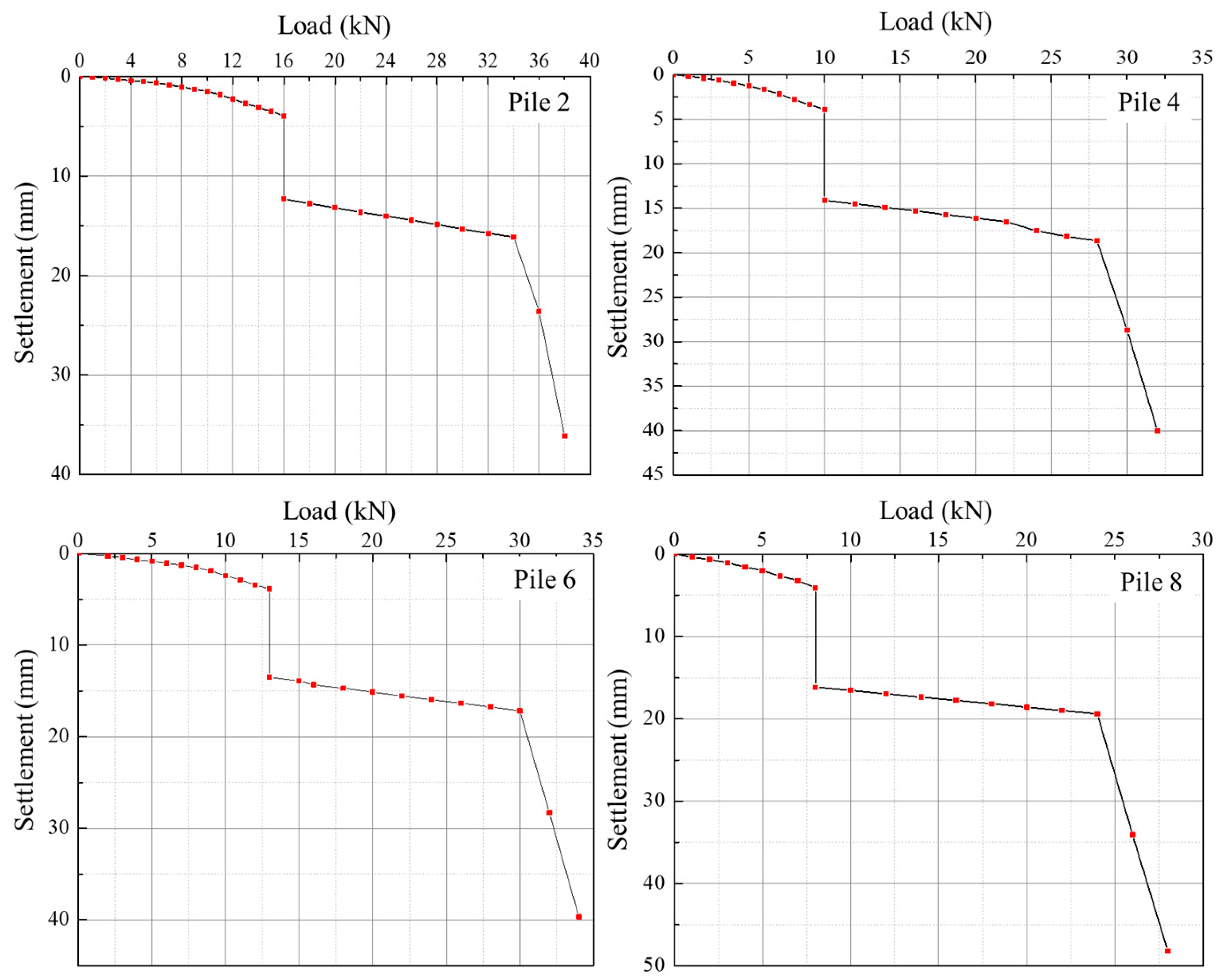

- A slow load maintenance method was used to load piles 2, 4, 6, and 8. The loading system employed a reaction beam and jacks, and the test load was gradually loaded. Each stage was loaded with 1.0 kN.

- (3)

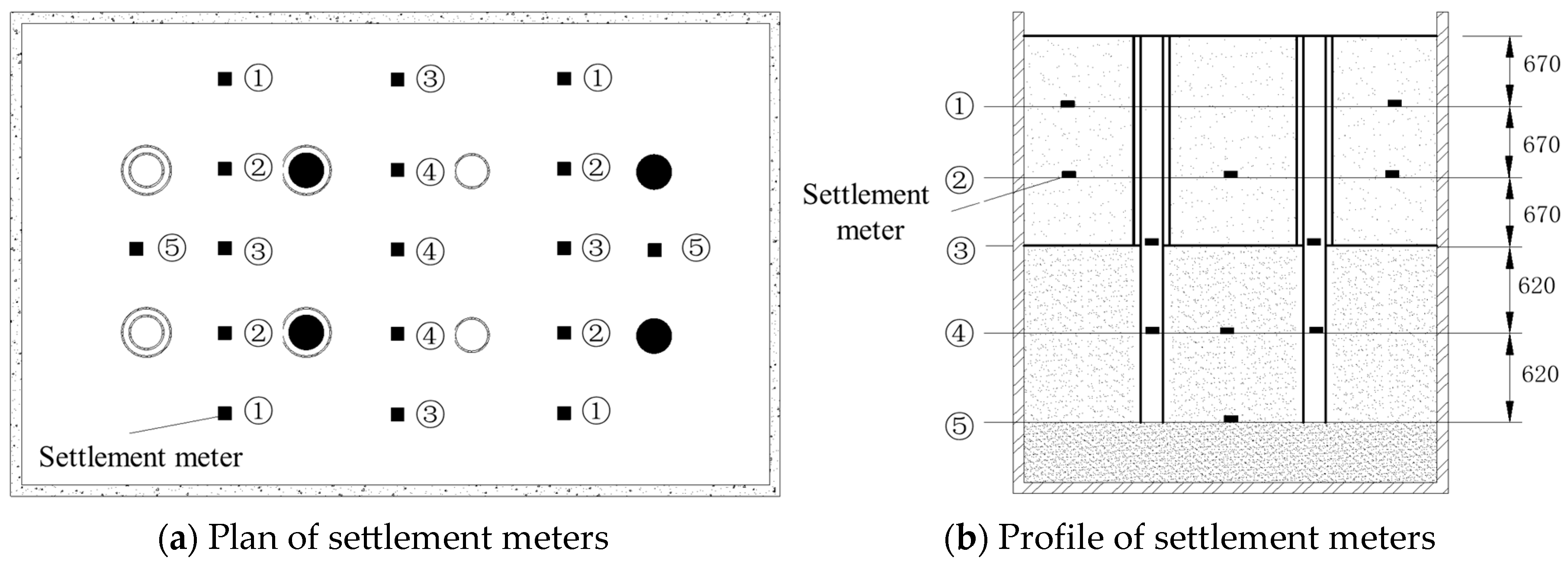

- After applying the load, the experiment started by gradually flooding with water. The impact of adding water on the settlement of each piles and the settlement of the soil itself were observed by settlement meters. The settlement at the pile top was measured at 5, 15, and 30 min after water immersion, and then measured every 30 min after accumulating 1.0 h. The measured data was transferred to the computer.

- (4)

- The next stage of load was applied after the previous stage of load had reached a relatively stable state (the settlement was less than 0.1 mm per hour and occurred twice in succession). The load was increased until the lateral soil of the pile was damaged, and then the load was gradually unloaded until it reached zero.

3. Results and Discussion

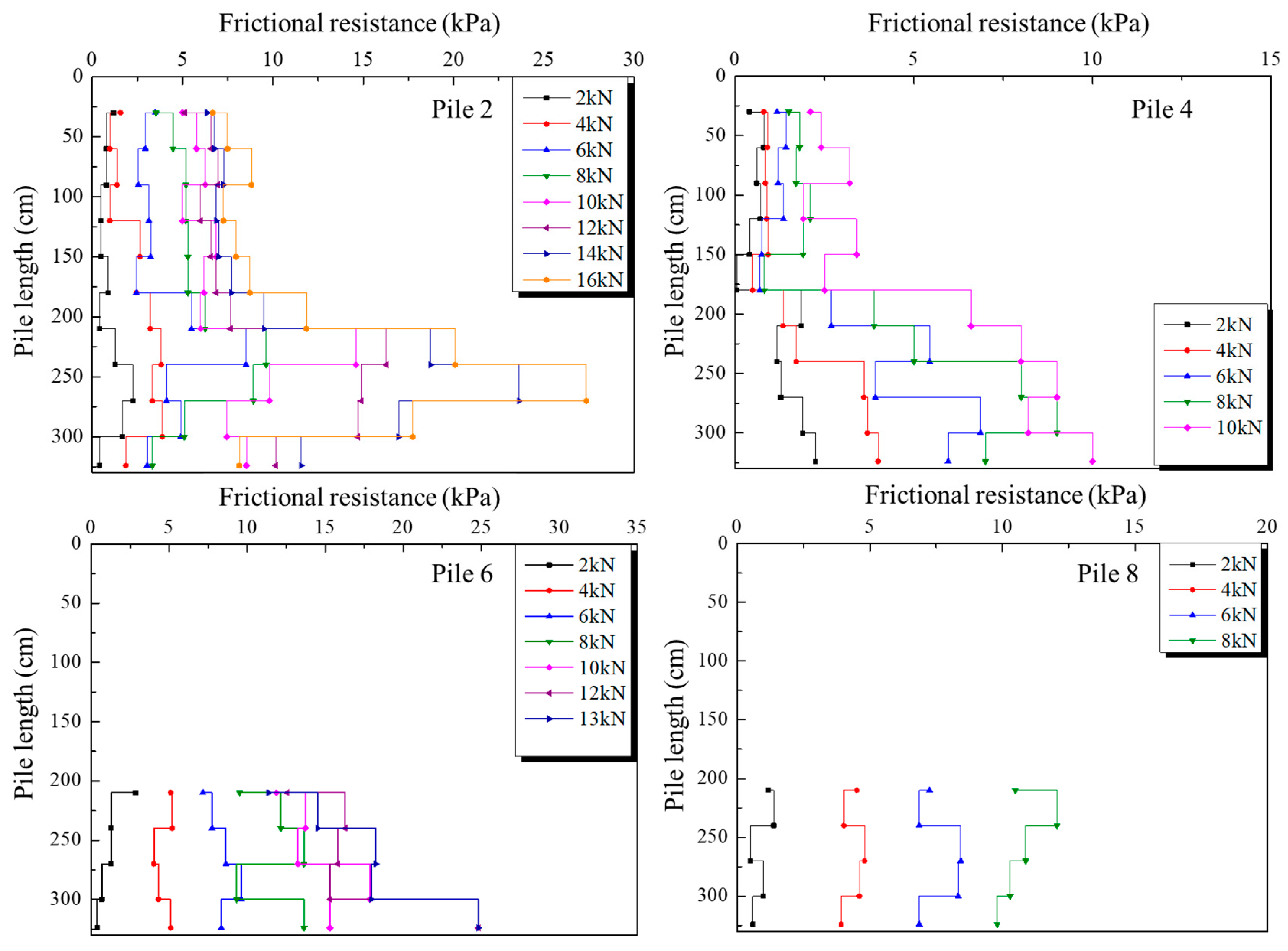

3.1. Bearing Characteristics of Model Piles (Non-Immersion Condition)

3.2. Layered Settlement of Soils (Water Immersion Condition)

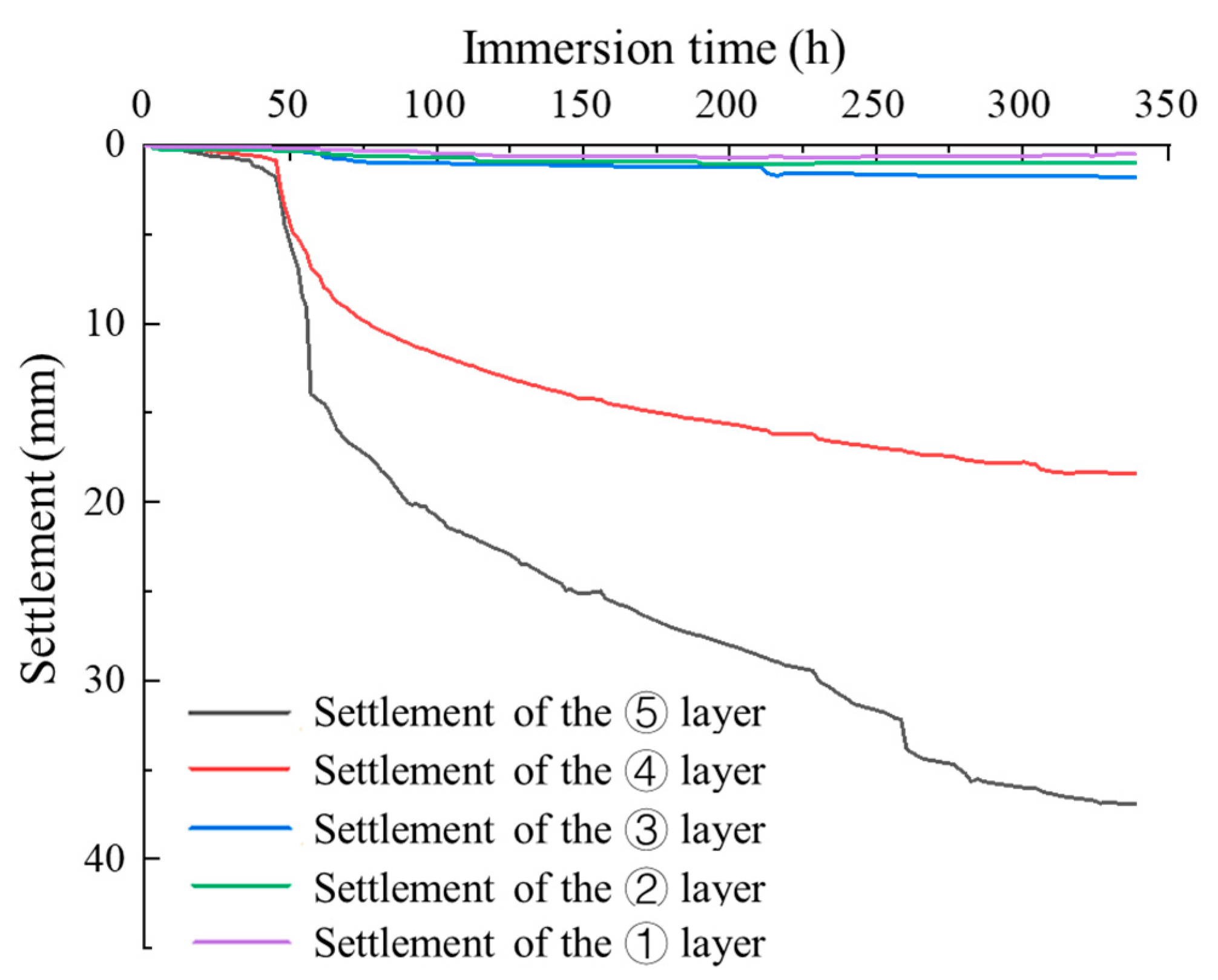

- (1)

- Initial gentle stage: during the initial 50 h after immersion, the upper synthetic collapsible loess layer experienced gradual settlement, while the middle and lower non-collapsible soil layers remained almost stable with minimal settlement.

- (2)

- Rapid drop stage: With the infiltration of water from the shallow to deep parts of the soil layer, a steep drop period of settlement deformation occurred in different parts along the depth of soil layers. The settlement of the upper synthetic collapsible loess layer developed rapidly, and the settlement amount of the middle and lower non-collapsible soil layers also increased gradually. After about 150 h of immersion, the cumulative settlement amount at each soil layer reached almost 70% of the total settlement amount. This result indicated that the settlement of loess became stable and the lateral friction of piles tended to be fully exerted.

- (3)

- Later gentle stage: after 150 h of immersion, the settlement rate gradually decreased, and the settlement–immersion time curve gradually flattened until the settlement reached relative stability.

3.3. Bearing Characteristics of Model Piles (Water Immersion Condition)

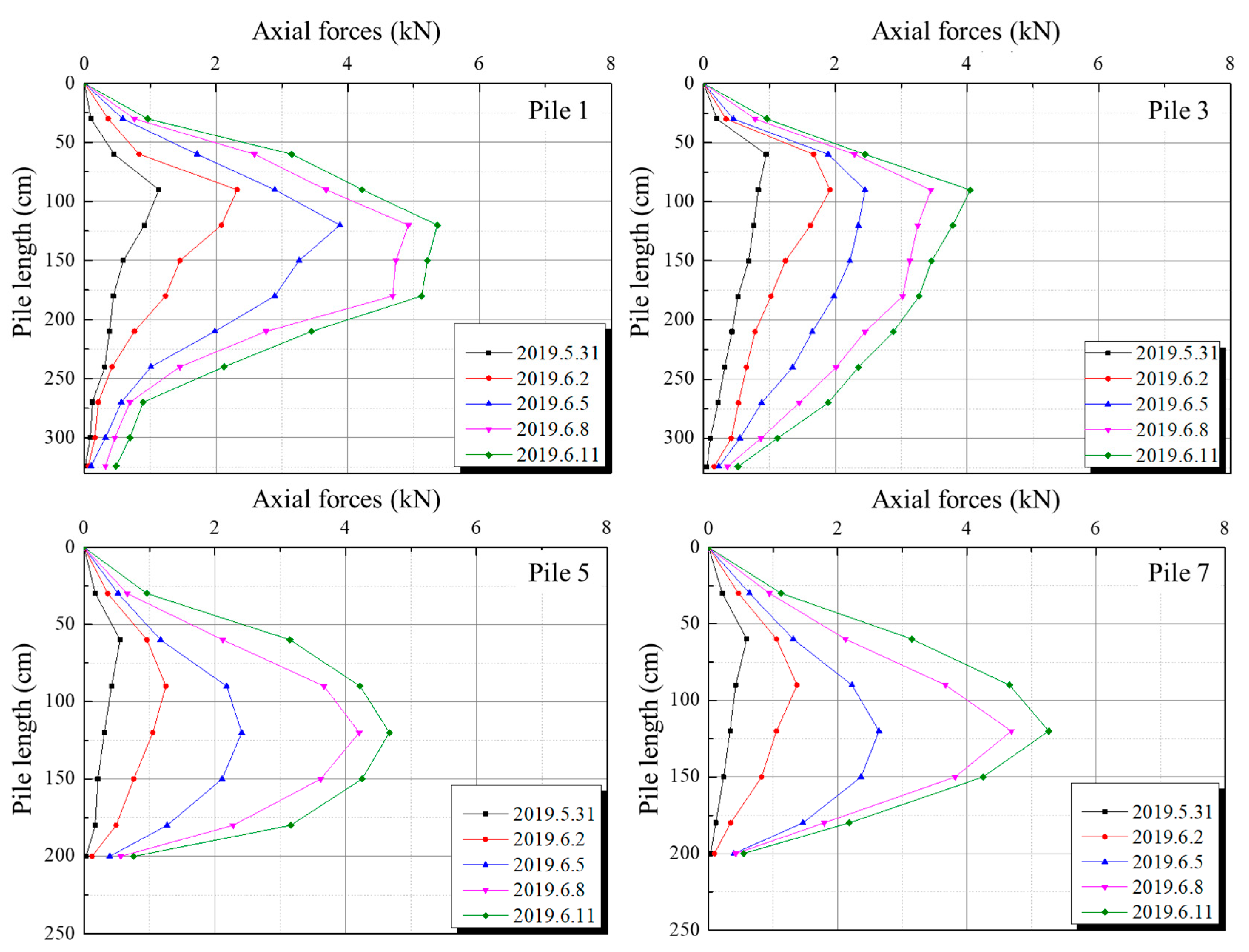

3.3.1. Without Additional Surface Loading

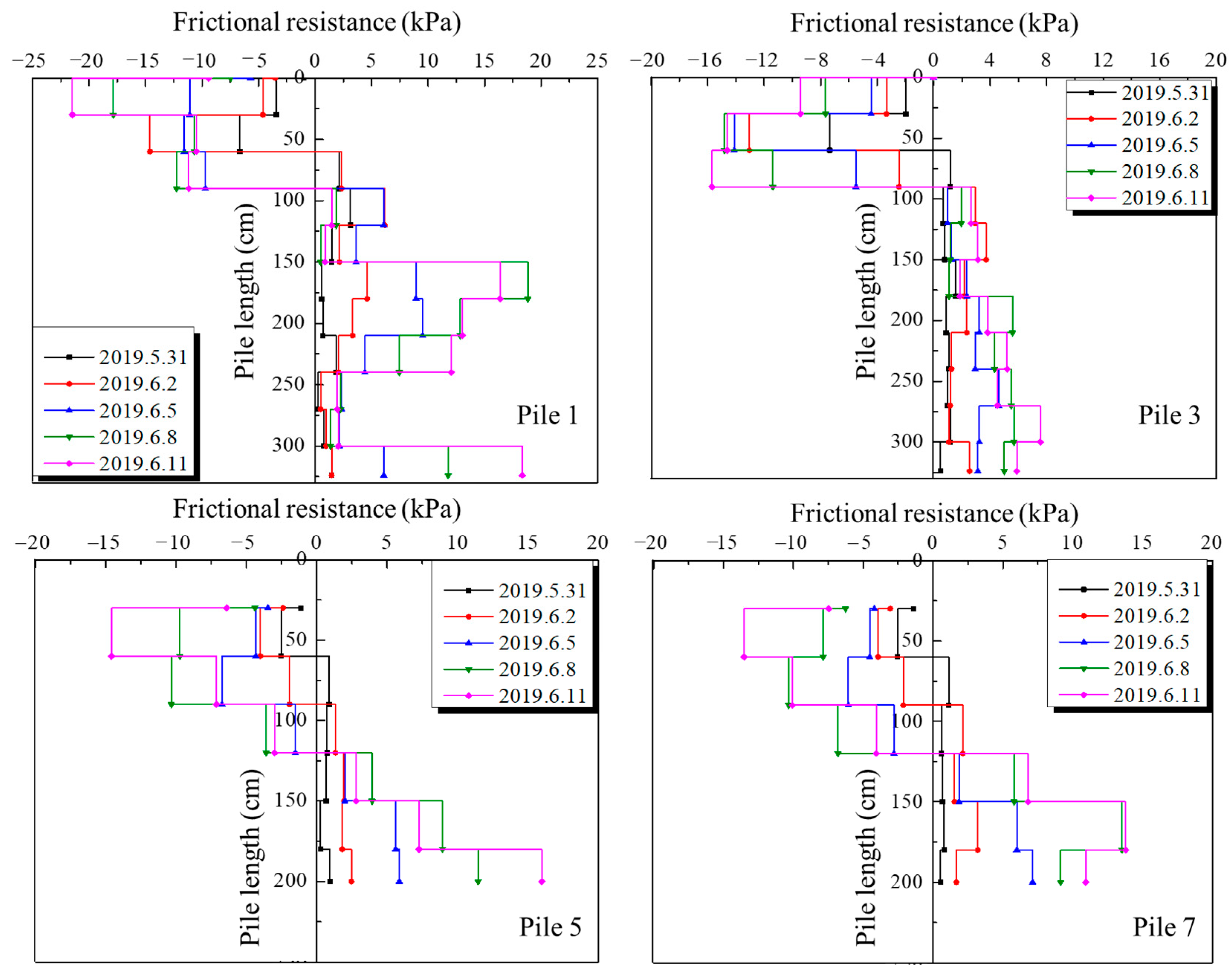

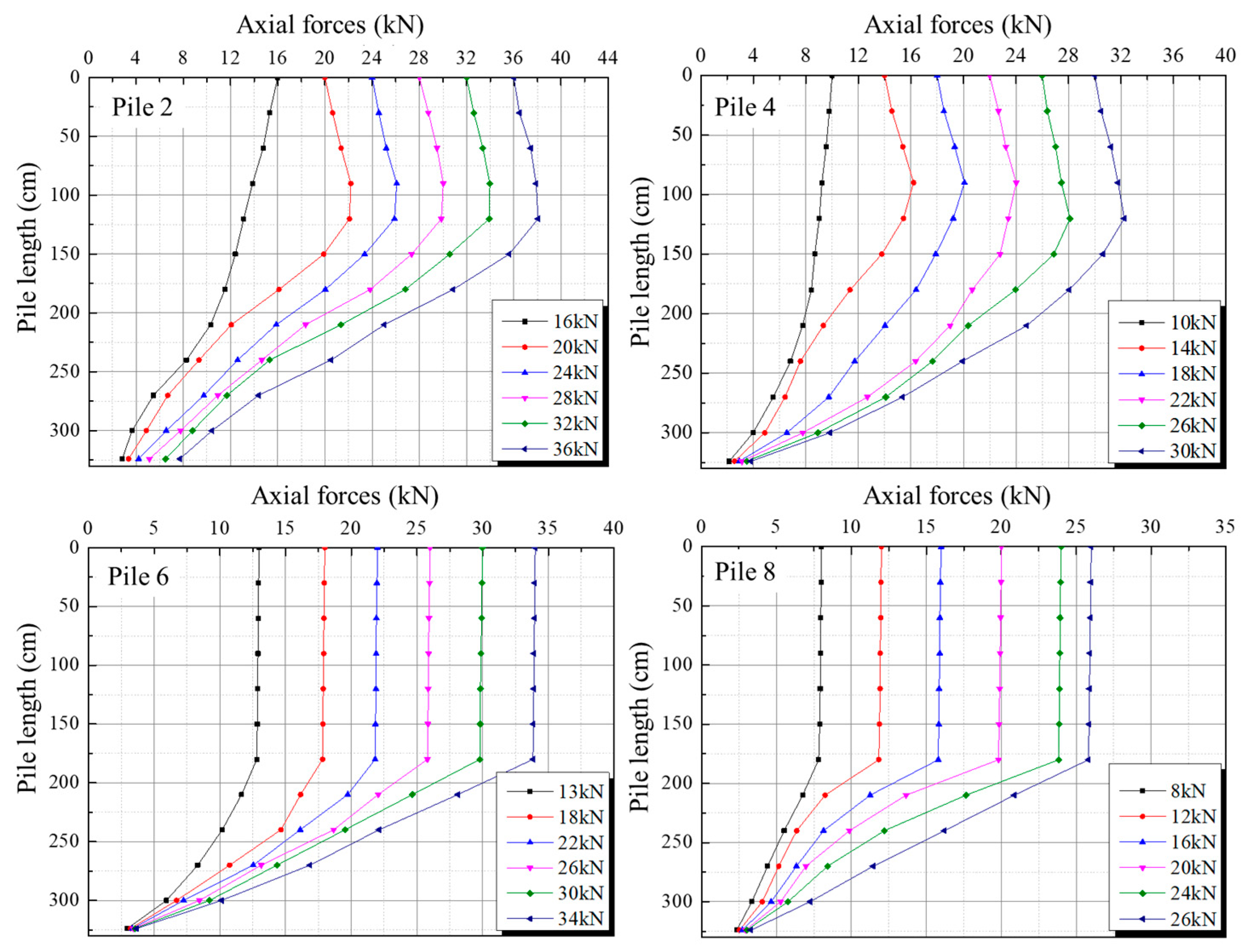

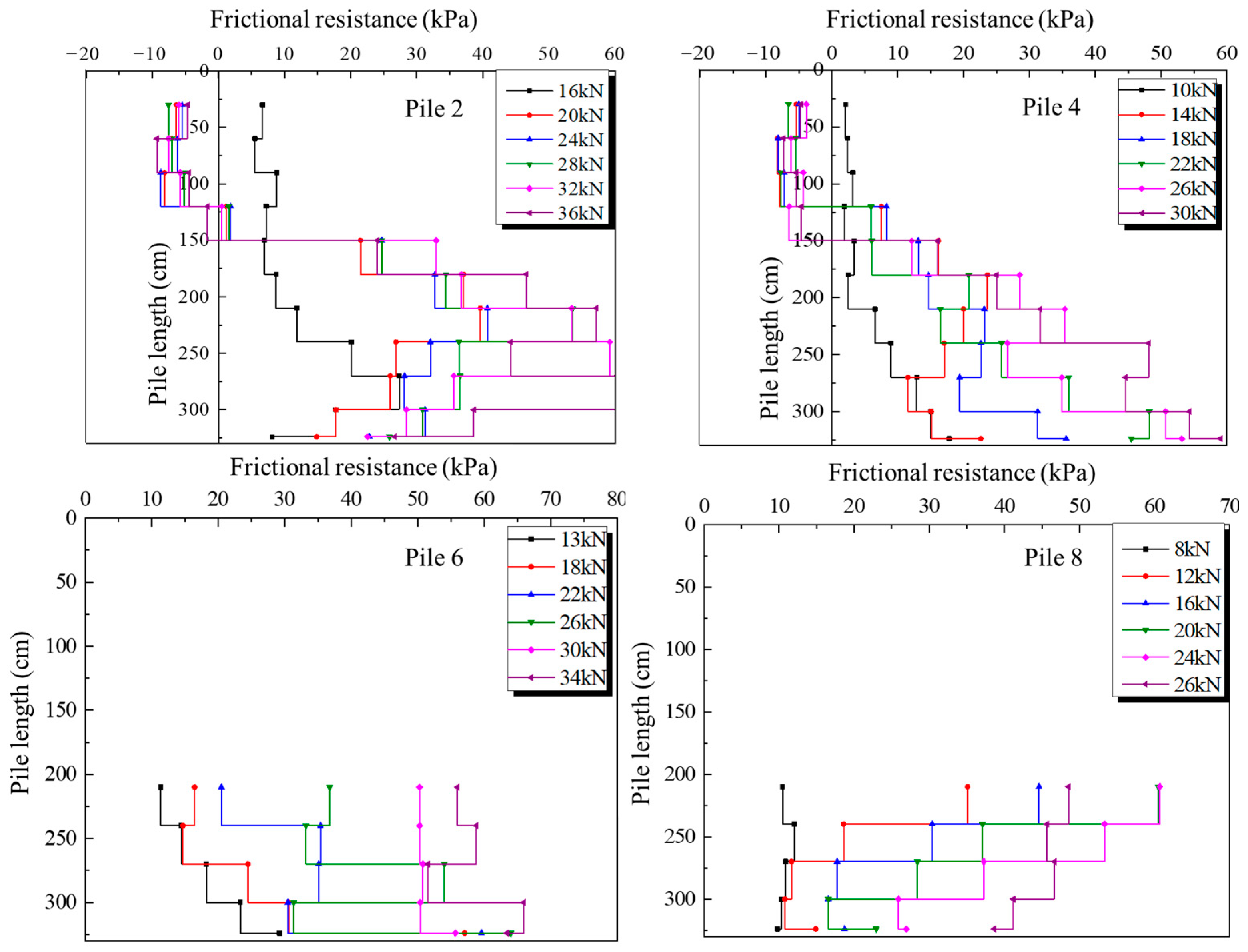

3.3.2. With Additional Surface Loading

4. Conclusions

- (1)

- Under the non-immersion condition, the settlement of model piles increased with the increasing pile top load. The ultimate bearing capacity of piles with casing was smaller than piles without casing. The axial force gradually decreased along the pile length for piles without casing. The axial force attenuation of the casing section of casing piles was almost negligible due to the isolating frictional resistance effect of casing.

- (2)

- The settlement of each soil layer increased with the increase in immersion time due to the collapsibility of loess. The settlement process was divided into three stages: initial gradual stage, rapid drop stage, and later gradual stage. The settlement of each soil layer first increased slowly, then rapidly dropped before stabilizing at a steady rate in the later gradual stage.

- (3)

- Under the immersion condition and without additional pile top load, all model piles were in a tension state and the axial force curve exhibited a “D-shape”. The positive and negative skin frictions of piles were alternately distributed in the range of pile length, and increased with the increasing immersion time.

- (4)

- Under the immersion condition and with additional pile top load, the settlement of the pile top increased slowly with increasing load and then entered a stage of significant decrease. The maximum axial force of piles without casing exceeded the peak load at the pile top. The peak values of both negative and positive skin frictions increased with the increasing load.

- (5)

- The presence of steel casing isolated the friction force of loess soil on the upper part of piles, and reduced the failure of the pile foundation in collapsible loess areas.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, P.; Vanapalli, S.; Li, T.L. Review of collapse triggering mechanism of collapsible soils due to wetting. J. Rock Mech. Geotech. Eng. 2016, 8, 256–274. [Google Scholar] [CrossRef]

- Shah, M.M.; Shahzad, H.M.; Khalid, U.; Farooq, K.; Rehman, Z.U. Experimental study on sustainable utilization of ckd for improvement of collapsible soil. Arab. J. Sci. Eng. 2013, 48, 5667–5682. [Google Scholar] [CrossRef]

- Wang, X.L.; Zhu, Y.P.; Huang, X.F. Field tests on deformation property of self-weight collapsible loess with large thickness. Int. J. Geomech. 2014, 14, 04014001. [Google Scholar] [CrossRef]

- Chiou, J.S.; Wei, W.T. Numerical investigation of pile-head load effects on the negative skin friction development of a single pile in consolidating ground. Acta Geotech. 2021, 16, 1867–1878. [Google Scholar] [CrossRef]

- Tan, S.A.; Fellenius, B.H. Negative skin friction pile concepts with soil–structure interaction. Geotech. Res. 2016, 3, 137–147. [Google Scholar] [CrossRef]

- Mashhour, I.; Hanna, A. Drag load on end-bearing piles in collapsible soil due to inundation. Can. Geotech. J. 2016, 53, 2030–2038. [Google Scholar] [CrossRef]

- El-Mossallamy, Y.M.; Hefny, A.M.; Demerdash, M.A.; Morsy, M.S. Numerical analysis of negative skin friction on piles in soft clay. HBRC J. 2013, 9, 68–76. [Google Scholar] [CrossRef]

- Poulos, H.G.; Davis, E.H. The development of negative friction with time in end-bearing piles. Aust. Geomech. J. 1969, G2, 11–20. [Google Scholar]

- Gao, D.H.; Zhao, K.Y.; Jin, S.L.; Xing, Y.C.; Chu, W.S.; Fan, Z.F.; Zhu, Q. Method for calculating negative skin friction of pile foundation in large-thickness self-weight collapsible loess sits. Chin. J. Geotech. Eng. 2022, 44 (Suppl. S1), 232–235. [Google Scholar]

- Kim, H.J.; Mission, J.L.; Park, T.W.; Dinoy, P.R. Analysis of negative skin-friction on single piles by one-dimensional consolidation model test. Int. J. Civ. Eng. 2018, 16, 1445–1461. [Google Scholar] [CrossRef]

- Zhao, M.; Cao, W.P. A new approach for calculating negative skin friction of piles in collapsible loess soils. J. Civ. Environ. Eng. 2022. [Google Scholar] [CrossRef]

- Liu, J.; Gao, H.; Liu, H. Finite element analyses of negative skin friction on a single pile. Acta Geotech. 2012, 7, 239–252. [Google Scholar] [CrossRef]

- Zhao, Z.F.; Ye, S.H.; Zhu, Y.P.; Tao, H.; Chen, C.L. Scale model test study on negative skin friction of piles considering the collapsibility of loess. Acta Geotech. 2022, 17, 601–611. [Google Scholar] [CrossRef]

- Zhu, B.E.; Qi, C.G.; Bao, J.L. Field test study of load transfer mechanism of plastic tube pile under embankment loading. Chin. J. Rock Soil Mech. 2016, 2, 658–664. [Google Scholar]

- Feng, Z.J.; Hu, H.B.; Dong, Y.X. Indoor simulation tests on reducing negative skin friction of pile foundation. Chin. J. Geotech. Eng. 2019, 41, 45–48. [Google Scholar]

- Bjerrum, L.; Johannessen, I.J.; Eide, O. Reduction of negative skin friction on steel piles to rock. In Proceedings of the 7th International Conference on Soil Mechanics and Foundation Engineering, Mexico City, Mexico, 1969; pp. 27–34. [Google Scholar]

- Yang, K.B. Study on the Bearing Characteristics of a New Type of Steel Pipe Composite Pile in Collapsible Loess Area. Master’s Thesis, Lanzhou University of Technology, Lanzhou, China, 2018. [Google Scholar]

- Dong, J.H.; Zheng, Y.L.; Wu, X.L. Study and development of caterpillar pile for reducing negative friction resistance and analysis of its mechanical properties. Chin. J. Rock Mech. Eng. 2023, 42, 1–14. [Google Scholar]

- Zhu, C.Q.; Cheng, H.L.; Bao, Y.J.; Chen, Z.Y.; Huang, Y. Shaking table tests on the seismic response of slopes to near-fault ground motion. Geomech. Eng. 2022, 29, 133–143. [Google Scholar]

- Rehman, Z.U.; Zhang, G. Shear coupling effect of monotonic and cyclic behavior of the interface between steel and gravel. Can. Geotech. J. 2019, 56, 876–884. [Google Scholar] [CrossRef]

| Physical Quantities | Similarity Relation | Similarity Ratio |

|---|---|---|

| Strain, ε | Cε = 1.0 | 1 |

| Stress, σ | Cσ = CE | 1/3.6 |

| Elastic modulus, E | CE | 1/3.6 |

| Poission’s ratio, μ | Cμ = 1.0 | 1 |

| Density, ρ | Cρ | 1 |

| Length, l | Cl | 1/10 |

| Area, S | CS = Cl2 | 1/100 |

| Linear displacement, X | CX = Cl | 1/10 |

| Concentrated force, p | Cp = CECl2 | 1/360 |

| Surface load, q | Cq = CE | 1/3.6 |

| ρd (g/cm3) | Gs | e | Wl (%) | Wp (%) | PI | w (%) | ρdmax (g/cm3) |

|---|---|---|---|---|---|---|---|

| 1.30 | 2.66 | 1.04 | 26.7 | 15.5 | 11.1 | 16.1 | 1.73 |

| c (kPa) | φ (°) | E (MPa−1) | Es (MPa) |

|---|---|---|---|

| 64.24 | 25.45 | 0.43 | 4.75 |

| Number of Piles | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | |

| Type | concrete | concrete | steel | steel | concrete | concrete | steel | steel | |

| Diameter (mm) | 108 | 108 | 108 | 108 | 108 | 108 | 108 | 108 | |

| Length (mm) | 3240 | 3240 | 3240 | 3240 | 3240 | 3240 | 3240 | 3240 | |

| Casing | Type | / | / | / | / | steel | steel | steel | steel |

| Length (mm) | / | / | / | / | 2000 | 2000 | 2000 | 2000 | |

| Diameter(mm) | / | / | / | / | 158 | 158 | 158 | 158 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chai, Q.; Chen, T.; Li, Z.; Shen, D.; Wu, C. Experimental Study on the Negative Skin Friction of Piles in Collapsible Loess. Sustainability 2023, 15, 8893. https://doi.org/10.3390/su15118893

Chai Q, Chen T, Li Z, Shen D, Wu C. Experimental Study on the Negative Skin Friction of Piles in Collapsible Loess. Sustainability. 2023; 15(11):8893. https://doi.org/10.3390/su15118893

Chicago/Turabian StyleChai, Qing, Tianlei Chen, Zuoyong Li, Danyi Shen, and Chuangzhou Wu. 2023. "Experimental Study on the Negative Skin Friction of Piles in Collapsible Loess" Sustainability 15, no. 11: 8893. https://doi.org/10.3390/su15118893

APA StyleChai, Q., Chen, T., Li, Z., Shen, D., & Wu, C. (2023). Experimental Study on the Negative Skin Friction of Piles in Collapsible Loess. Sustainability, 15(11), 8893. https://doi.org/10.3390/su15118893