Performance Evaluation of Clay Plastic Concrete of Cement and Epoxy Resin Composite as a Sustainable Construction Material in the Durability Process

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Mix Design and Sample Preparation

2.3. Testing Methods and Required Parameters

3. Results and Discussion

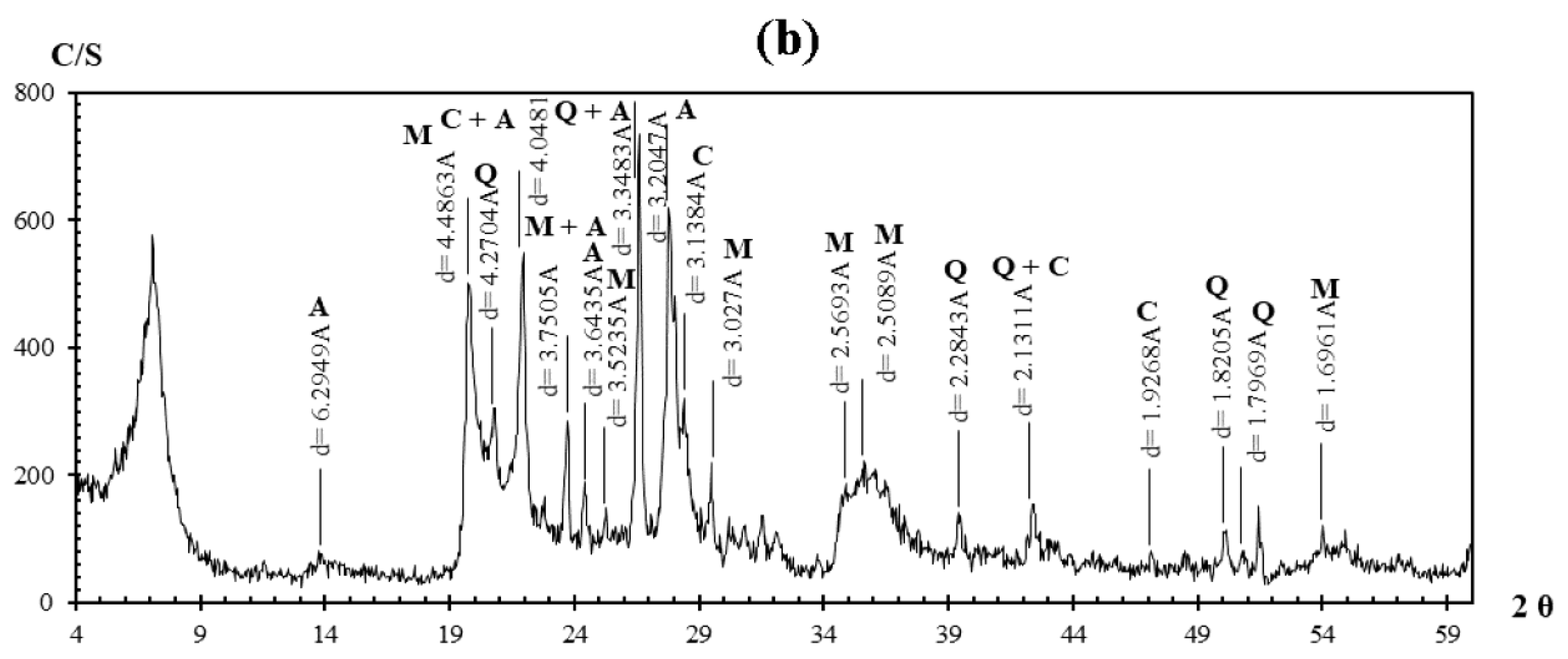

3.1. Mineral Identification and Analysis of Bentonite Soil Using XRD and SEM Tests

3.2. Cement Stabilization

3.2.1. Strength Parameter Evaluation

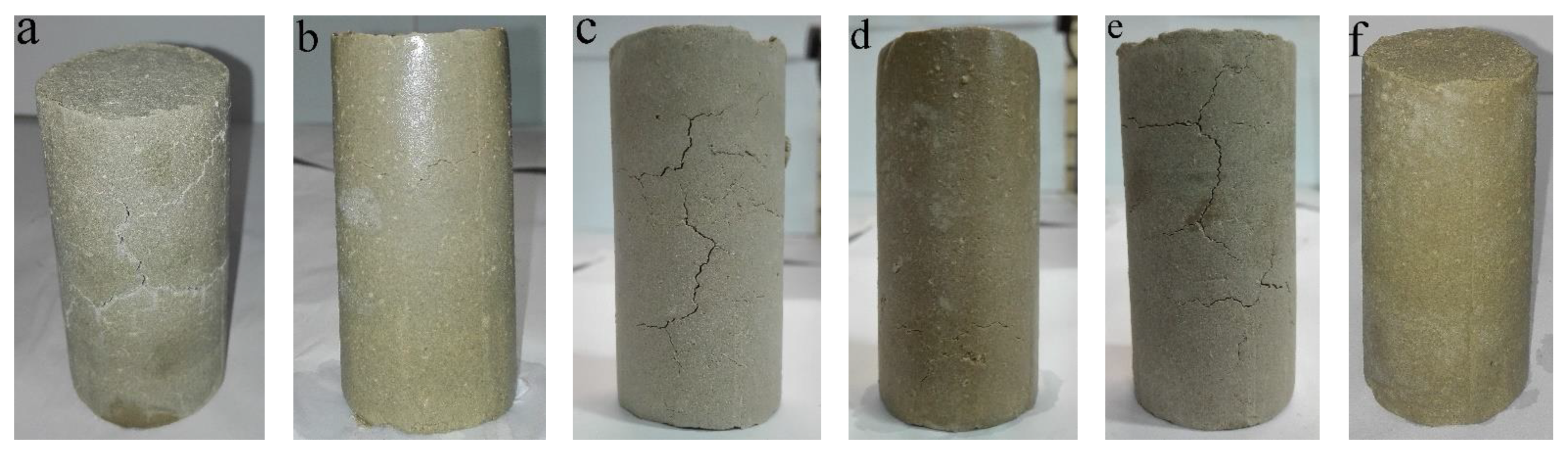

3.2.2. Evaluation of Durability against W/D Cycles

3.3. Stabilization with Cement and Epoxy Resin

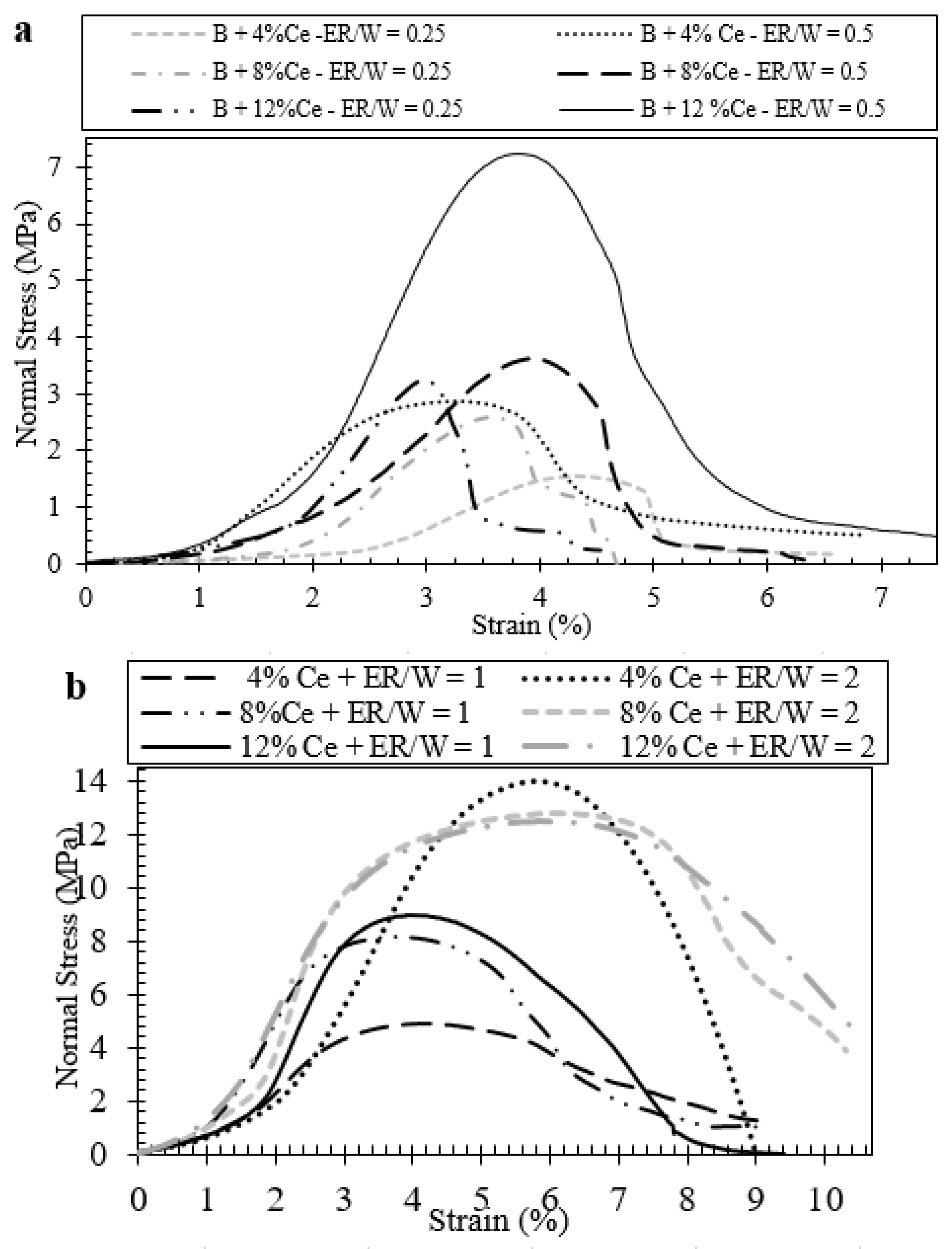

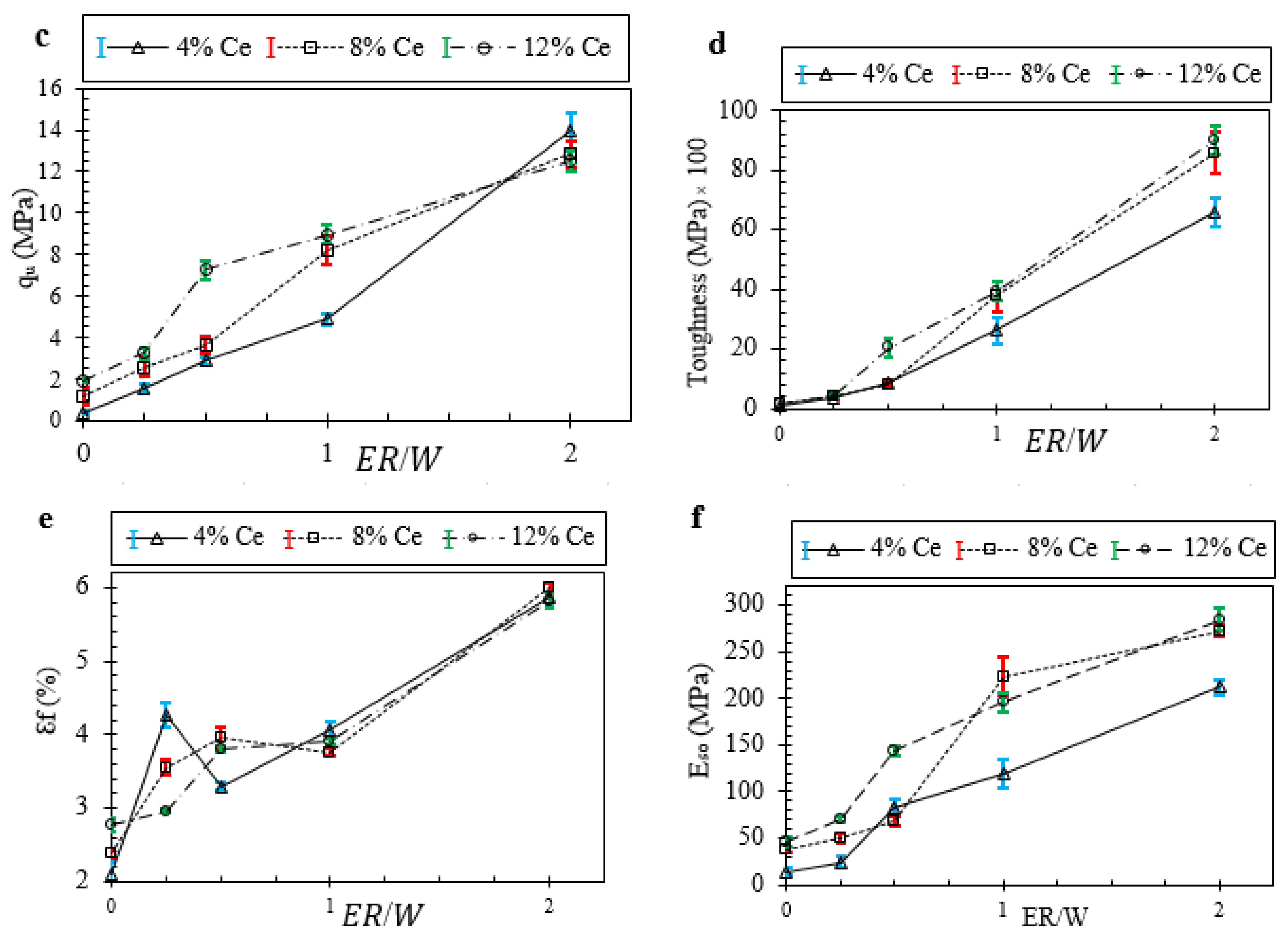

3.3.1. Investigation of the Strength Parameters after 7 Days of Curing

- Cement and epoxy resin with an ER/W ratio equal to 1:4

- Cement and epoxy resin with an ER/W ratio equal to 1:2

- Cement and epoxy resin with an ER/W ratio equal to 1:1

- Cement and epoxy resin with an ER/W ratio equal to 2:1

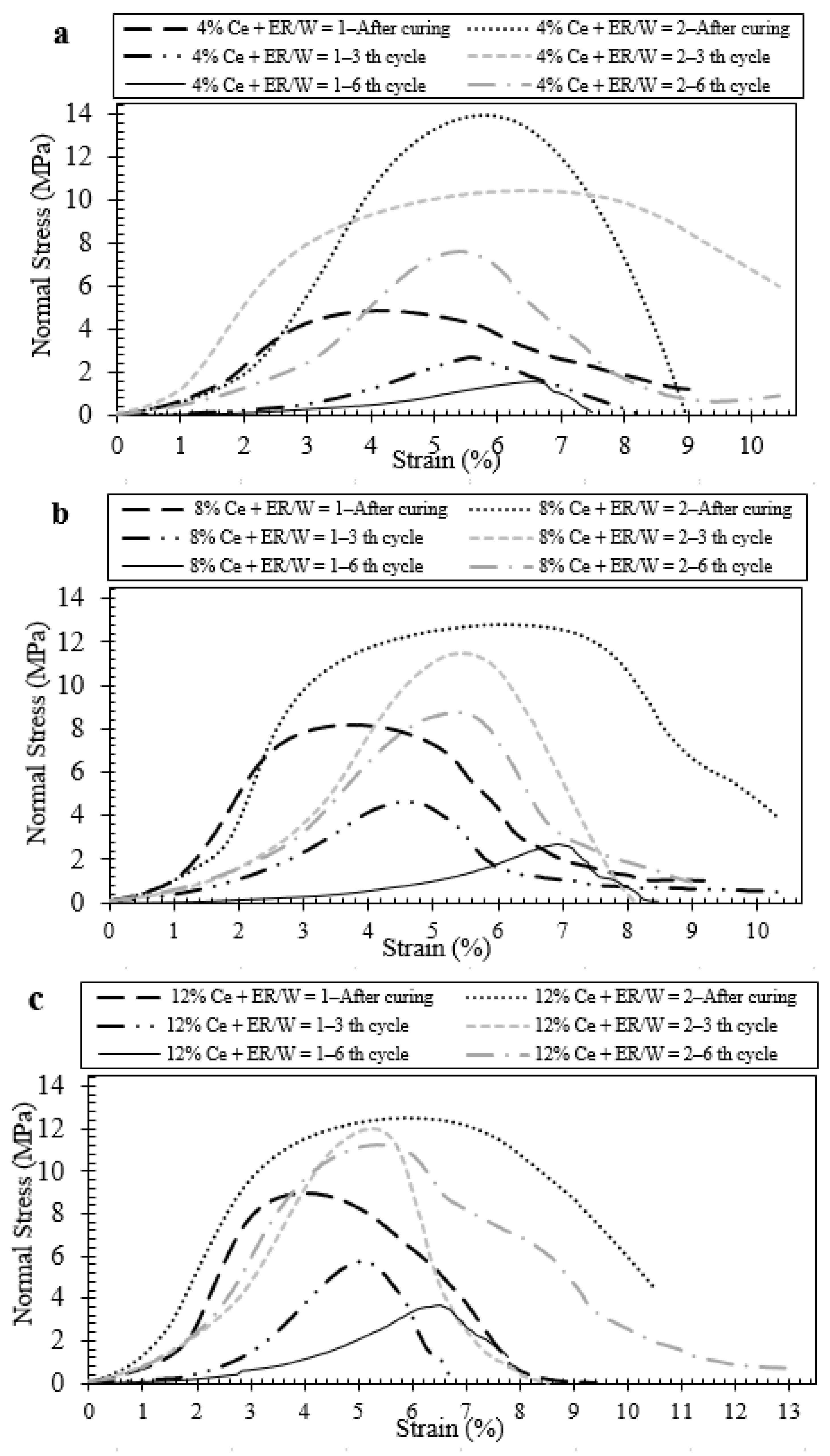

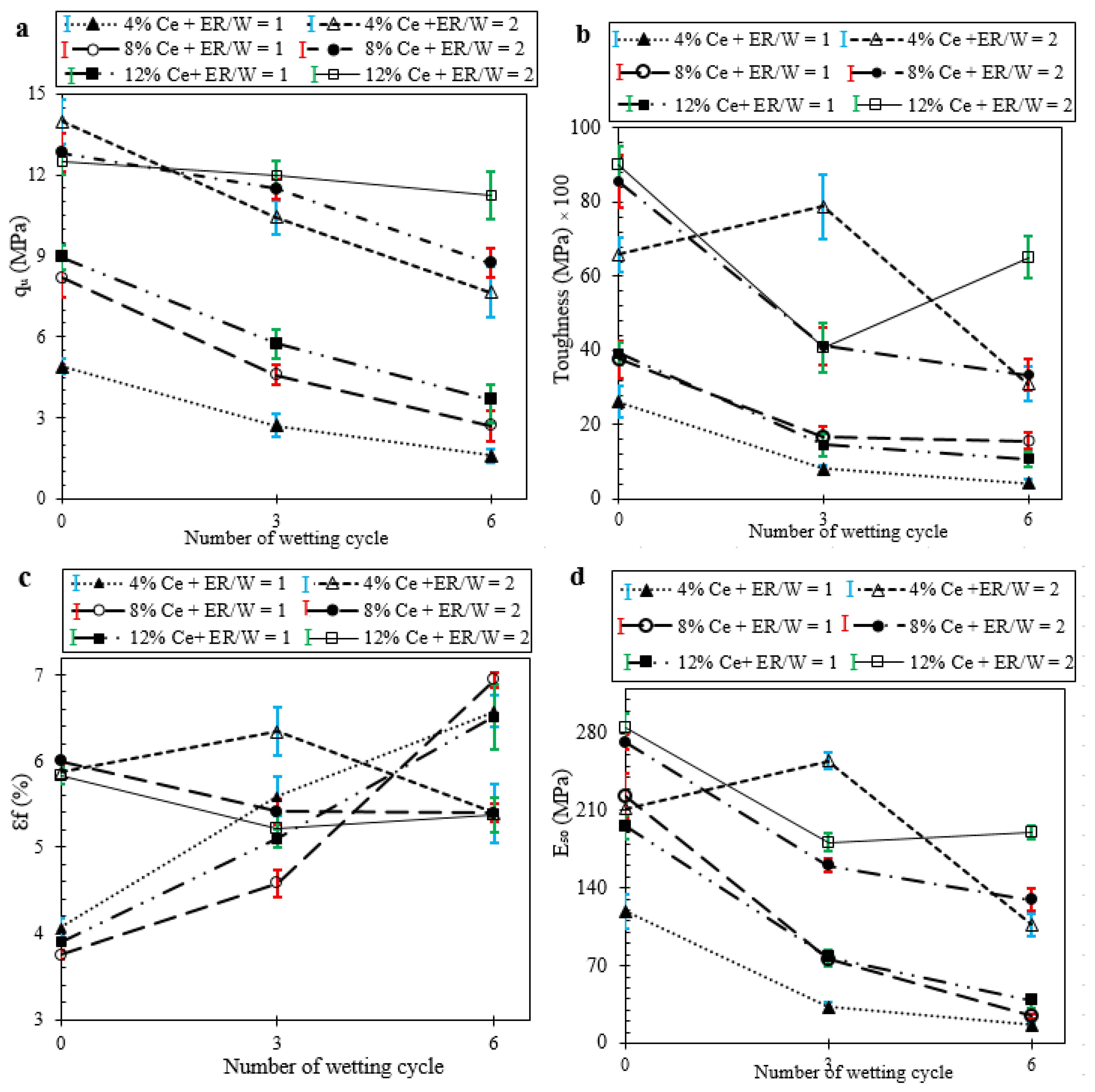

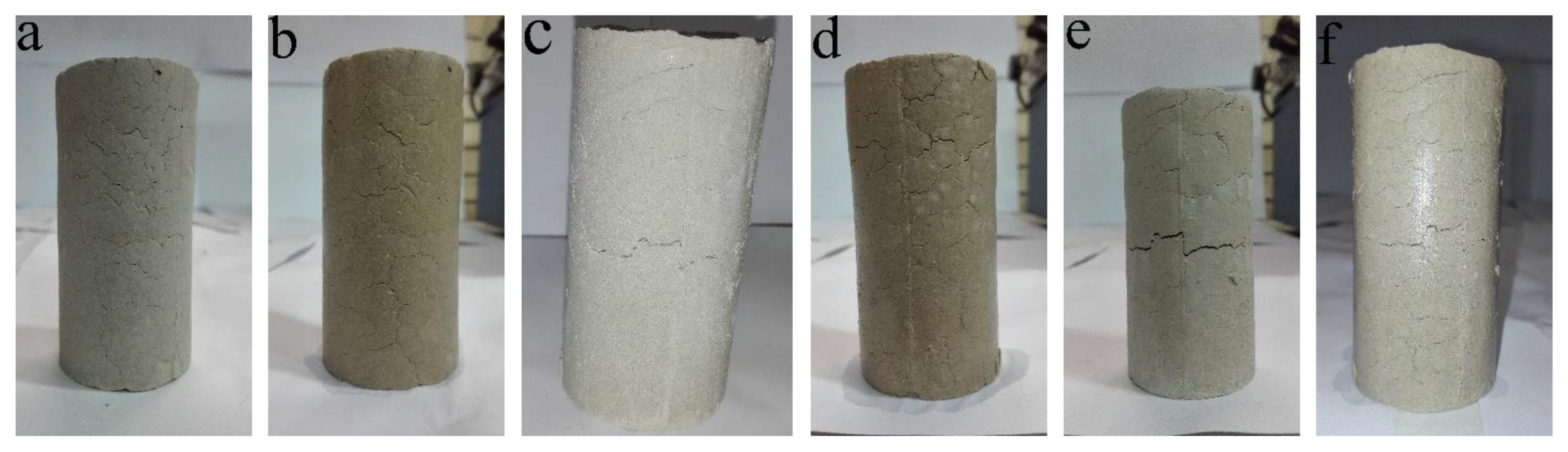

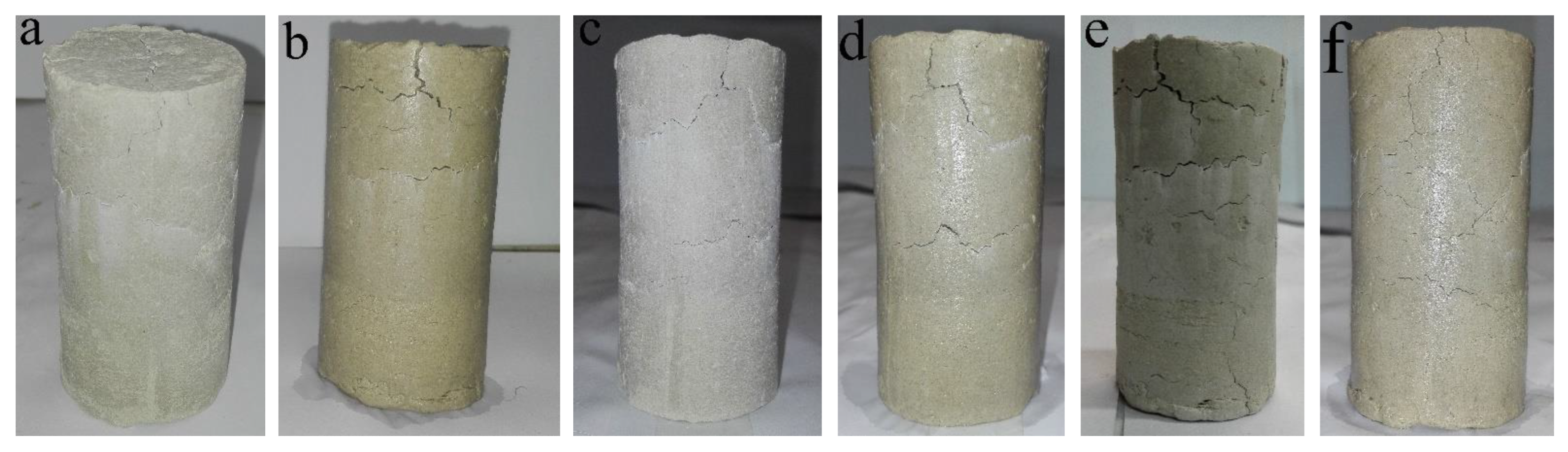

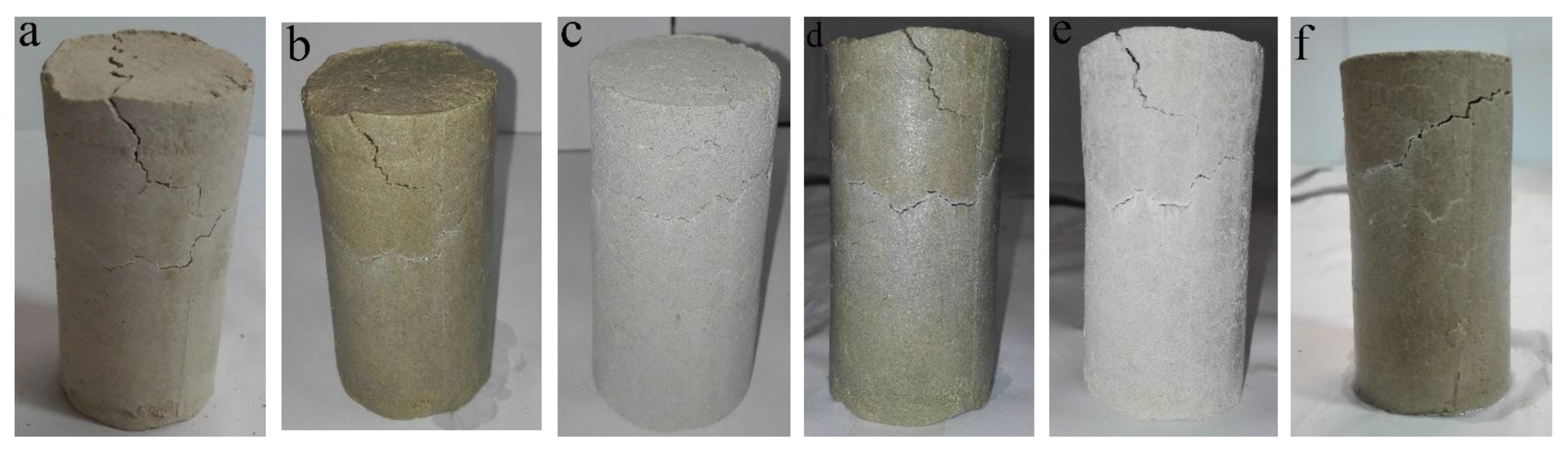

3.3.2. Evaluation of Durability against W/D Cycles

- Cement and epoxy resin with ER/W ratios of 1:4 and 1:2

- Indirect estimation of the swelling–shrinkage potential of bentonite soil

- Cement and epoxy resin with an ER/W ratio equal to 1:1

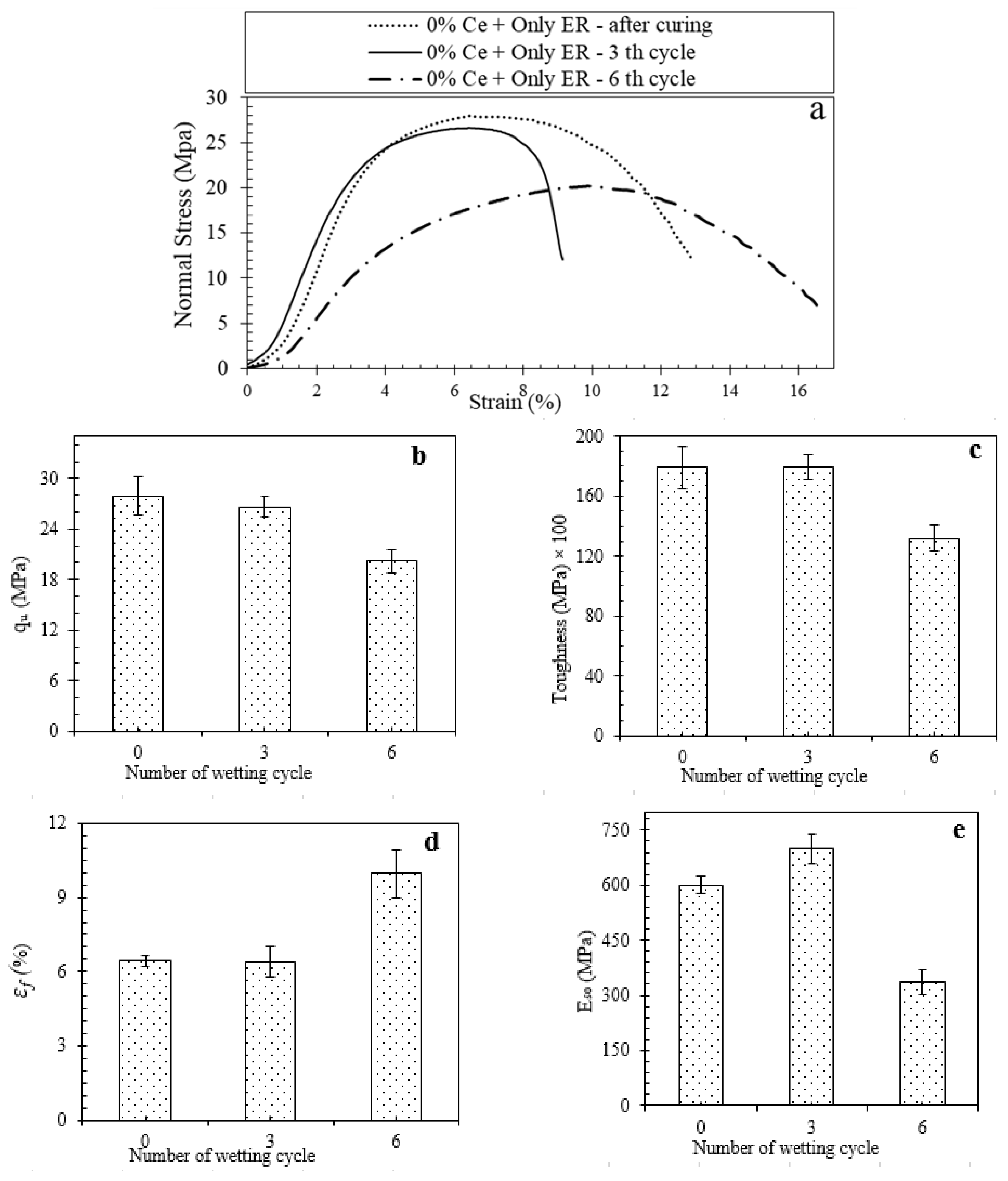

- Cement- and epoxy resin-stabilized samples with an ER/W ratio equal to 2:1

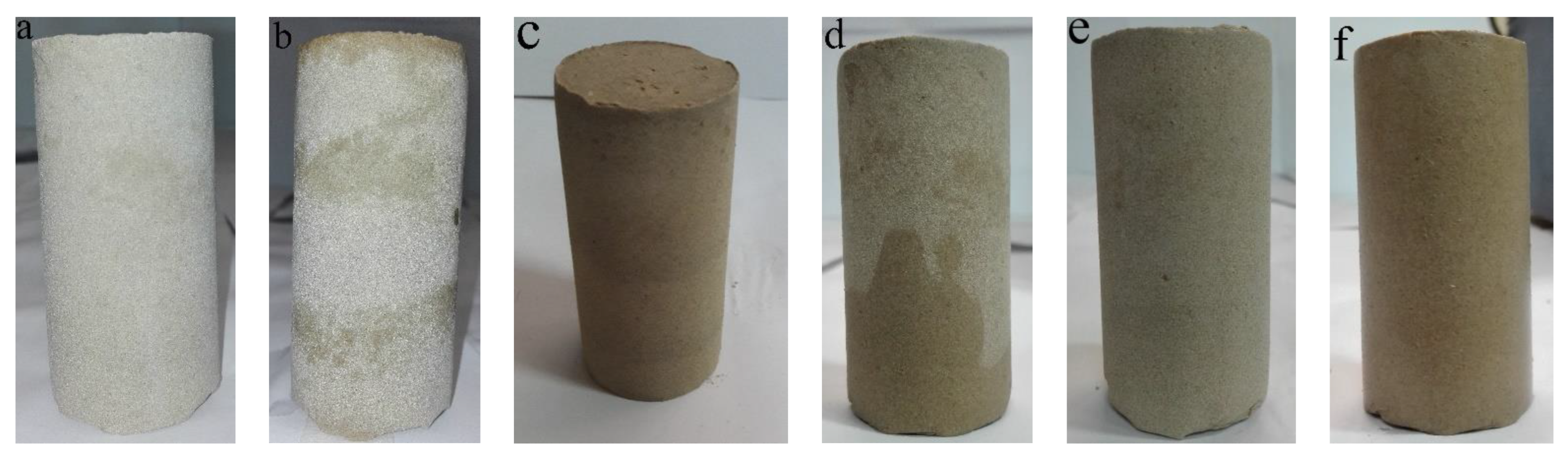

3.4. Evaluation of Epoxy Resin-Stabilized Bentonite Soil without Cement and Water

3.4.1. Evaluation of the Strength Parameters after 7 Days of Curing

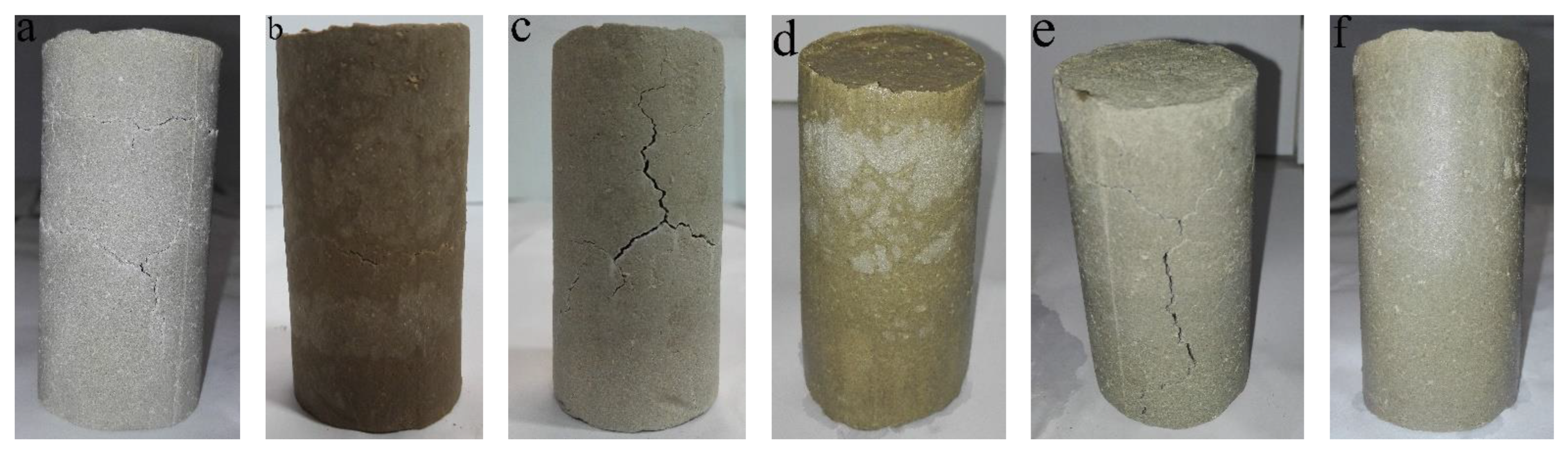

3.4.2. Evaluation of Durability against W/D Cycles

3.5. Geoenvironmental Assessment of Clay Plastic Concrete and Progress in Sustainability

4. Conclusions

- By adding epoxy resin at ER/W ratios equal to 1:4 and 1:2 and for different percentages of cement, the ductility of the samples improved noticeably relative to the samples stabilized with cement and without epoxy resin. Although at these ER/W ratios of less than 1:1, the stabilized samples had better performance in durability by adding cement, they eventually lasted for up to two cycles.

- The minimum ER/W ratio for different percentages of cement in bentonite soil samples that lasted for up to six cycles of W/D was equal to 1:1. However, at this ratio, the W/D cycles had devastating effects on the samples. The development of cracks on the samples’ surfaces during drying and water penetration into the samples during the wetting in each cycle caused their strength parameter values after six cycles of W/D to drop by more than 70%. The optimum amount of cement for them was 8%.

- At an ER/W ratio of 1:1 and for different percentages of cement, the after-curing failure strain value was approximately 4%. At the end of wetting in the sixth cycle, it reached about 7%. At an ER/W ratio of 2:1, the after-curing failure strain was approximately 6%, while its value changed slightly after wetting in the sixth cycle. By doubling the ER/W ratio, an extensive plastic region in the stress–strain curve was achieved at the strain interval with a length of approximately 3%. The ductility, stiffness, and strength values of the samples increased so that the effects of W/D cycles on them considerably decreased.

- Increasing the cement content at an ER/W ratio equal to 2:1 had significant effects on improving the performance of the samples in the durability process, and the optimum amount of cement was 12%.

- The qu value of bentonite soil stabilized with only epoxy resin and without cement and water reached the range of OPC concrete. At the same time, the failure strain value became 32 times greater, and the plastic region of the stress–strain curve expanded over a wide range of strain with a length of approximately 5%. Its ductility and toughness against failure were substantially higher than those of OPC concrete, which was much lighter. The shrinkage potential of bentonite soil was overcome by this stabilization, and no crack development was seen in the drying phase of each cycle on the sample surface. However, the strength parameters still decreased after six cycles of W/D.

- In order to make the bentonite soil samples completely impenetrable and overcome the swelling potential in the wetting phase of each cycle, it was predicted that the (qu)e, (E50)e, and (toughness)e values of bentonite soil after stabilization should reach at least 38.6, 1074, and 2.45 MPa, respectively. It was necessary to increase the ductility and strength to values much greater than those of OPC concrete. Thus, the strength parameters do not decrease during the wetting phase in each cycle.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Firoozi, A.A.; Firoozi, A.A.; Baghini, M.S. A review of physical and chemical clayey. J. Civ. Eng. Urban. 2017, 6, 64–71. [Google Scholar]

- Karim, M.R.; Rahman, M.M.; Nguyen, H.B.K.; Kazmi, S.; Devkota, B.; Karim, R.; Rahman, M.; Bao, H.; Nguyen, K. Accounting for Expansive Soil Movement in Geotechnical Design— A State-of-the-Art Review. Sustainability 2022, 14, 15662. [Google Scholar] [CrossRef]

- Chen, F.H. Foundations on Expansive Soils; Elsevier Scientific Publishing Company: New York, NY, USA, 1975; p. 280. [Google Scholar]

- Jones, D.E., Jr.; Holtz, W.G. Expansive soils-the hidden disaster. J. Soil Mech. Found. Div. ASCE 1973, 43, 49–51. [Google Scholar]

- Singh, V.K.; Bommireddy, D.B.; Phanikumar, B.R. Innovative Techniques in Road and Rail Construction on Expansive Soils. Int. J. Civ. Eng. 2016, 3, 119–126. [Google Scholar] [CrossRef]

- Song, W.K.; Cui, Y.J. Modelling of water evaporation from cracked clayey soil. Eng. Geol. 2020, 266, 105465. [Google Scholar] [CrossRef]

- Day, R.W. Swell-shrink behavior of compacted clay. J. Geotech. Eng. 1994, 120, 618–623. [Google Scholar] [CrossRef]

- Samuel, R.; Puppala, A.; Radovic, M. Sustainability Benefits Assessment of Metakaolin-Based Geopolymer Treatment of High Plasticity Clay. Sustainability 2020, 12, 10495. [Google Scholar] [CrossRef]

- Zumrawi, M.M.E. Performance and Design of Expansive Soils as Road Subgrade. Ph.D. Thesis, Chang’an University, Xi’an, China, 2000. [Google Scholar]

- Yazdandoust, F.; Yasrobi, S.S. Effect of cyclic wetting and drying on swelling behavior of polymer-stabilized expansive clays. Appl. Clay Sci. 2010, 50, 461–468. [Google Scholar] [CrossRef]

- Al-Rawas, A.A.; Goosen, M.F.A. Expansive soils: Recent advances in characterization and treatment. Proc. Monogr. Eng. Water Earth Sci. 2006, 130, 391–402. [Google Scholar]

- Kou, H.; Jing, H.; Wu, C.; Ni, P.; Wang, Y.; Horpibulsuk, S. Microstructural and mechanical properties of marine clay cemented with industrial waste residue-based binder (IWRB). Acta Geotech. 2022, 17, 1859–1877. [Google Scholar] [CrossRef]

- Naeini, S.A.; Ghorbanali, M. Effect of wet and dry conditions on strength of silty sand soils stabilized with epoxy resin polymer. J. Appl. Sci. 2010, 10, 2839–2846. [Google Scholar] [CrossRef]

- Zandieh, A.R.; Yasrobi, S.S. Retracted article: Study of factors affecting the compressive strength of sandy soil stabilized with polymer. Geotech. Geol. Eng. 2010, 28, 139–145. [Google Scholar] [CrossRef]

- Anagnostopoulos, C.A.; Papaliangas, T.; Manolopoulou, S.; Dimopoulos, T. Physical and mechanical properties of chemically grouted sand. Tunn. Undergr. Space Technol. 2011, 26, 718–724. [Google Scholar] [CrossRef]

- Anagnostopoulos, C.A.; Papaliangas, T.T. Experimental investigation of epoxy resin and sand mixes. J. Geotech. Geoenviron. Eng. 2012, 138, 841–849. [Google Scholar] [CrossRef]

- Rahmannejad, M.; Toufigh, V. Influence of curing time and water content on unconfined compressive strength of sand stabilized using epoxy resin. Int. J. Eng. 2018, 31, 1187–1195. [Google Scholar]

- Ajayi, M.A.; Grissom, W.A.; Smith, L.S.; Jones, E.E. Epoxy–resin–based chemical stabilization of a fine, poorly graded soil system. Transp. Res. Rec. 1991, 1295, 95–108. [Google Scholar]

- Liu, J.; Shi, B.; Jiang, H.; Huang, H.; Wang, G.; Kamai, T. Research on the stabilization treatment of clay slope topsoil by organic polymer soil stabilizer. Eng. Geol. 2011, 117, 114–120. [Google Scholar] [CrossRef]

- Gilazghi, S.T.; Huang, J.; Rezaeimalek, S.; Bin-Shafique, S. Stabilizing sulfate-rich high plasticity clay with moisture activated polymerization. Eng. Geol. 2016, 211, 171–178. [Google Scholar] [CrossRef]

- Vyas, S.; Phougat, N.; Sharma, P.; Ratnam, M. Stabilization of dispersive soil by blending polymers. Int. J. Earth Sci. Eng. 2011, 4, 42–54. [Google Scholar]

- Estabragh, A.R.; Beytolahpour, I.; Javadi, A.A. Effect of resin on the strength of soil-cement mixture. J. Mater. Civ. Eng. 2011, 23, 969–976. [Google Scholar] [CrossRef]

- Hamidi, S.; Marandi, S.M. Clay concrete and effect of clay minerals types on stabilized soft clay soils by epoxy resin. Appl. Clay Sci. 2018, 151, 92–101. [Google Scholar] [CrossRef]

- Hamidi, S.; Marandi, S.M. Effect of clay mineral types on the strength and microstructure properties of soft clay soils stabilized by epoxy resin. Geomech. Eng. 2018, 15, 729–738. [Google Scholar] [CrossRef]

- Anagnostopoulos, C.A. Strength properties of an epoxy resin and cement-stabilized silty clay soil. Appl. Clay Sci. 2015, 114, 517–529. [Google Scholar] [CrossRef]

- Wang, Q.; Su, W.; Cui, Y.J.; Ye, W.M.; Chen, Y.G. Residual lateral stress effect on the swelling pressure measurements of compacted bentonite/claystone mixture. Eng. Geol. 2021, 295, 106437. [Google Scholar] [CrossRef]

- Yigzaw, Z.G.; Cuisinier, O.; Massat, L.; Masrouri, F. Role of different suction components on swelling behavior of compacted bentonites. Appl. Clay Sci. 2016, 120, 81–90. [Google Scholar] [CrossRef]

- Widomski, M.K.; Musz-Pomorska, A.; Franus, W. Hydraulic and Swell-Shrink Characteristics of Clay and Recycled Zeolite Mixtures for Liner Construction in Sustainable Waste Landfill. Sustainability 2021, 13, 7301. [Google Scholar] [CrossRef]

- Song, Y.; Geng, Y.; Dong, S.; Ding, S.; Xu, K.; Yan, R.; Liu, F. Study on Mechanical Properties and Microstructure of Basalt Fiber-Modified Red Clay. Sustainability 2023, 15, 4411. [Google Scholar] [CrossRef]

- Yuan, S.; Liu, X.; Sloan, S.W.; Buzzi, O.P. Multi-scale characterization of swelling behaviour of compacted Maryland clay. Acta Geotech. 2016, 11, 789–804. [Google Scholar] [CrossRef]

- Ramadji, C.; Messan, A.; Sore, S.O.; Prud’homme, E.; Nshimiyimana, P. Microstructural Analysis of the Reactivity Parameters of Calcined Clays. Sustainability 2022, 14, 2308. [Google Scholar] [CrossRef]

- Isaksson, R.; Rosvall, M.; Babaahmadi, A.; Buregyeya, A.; Hazarika, A.; Marangu, J.M.; Olonade, K.; Ramanathan, S.; Rucukye, A.; Valentini, L. Supplementary Cementitious Materials in Building Blocks—Diagnosing Opportunities in Sub-Saharan Africa. Sustainability 2023, 15, 5822. [Google Scholar] [CrossRef]

- Gedik, E.; Atmaca, A. An experimental study investigating the effects of bentonite clay on mechanical and thermal properties of concrete. Constr. Build. Mater. 2023, 383, 131279. [Google Scholar] [CrossRef]

- Mohamad, N.; Muthusamy, K.; Embong, R.; Kusbiantoro, A.; Hashim, M.H. Environmental impact of cement production and Solutions: A review. Mater. Today Proc. 2022, 48, 741–746. [Google Scholar] [CrossRef]

- Ige, O.E.; Olanrewaju, O.A.; Duffy, K.J.; Collins, O.C. Environmental Impact Analysis of Portland Cement (CEM1) Using the Midpoint Method. Energies 2022, 15, 2708. [Google Scholar] [CrossRef]

- Taklymi, S.M.Q.; Rezaifar, O.; Gholhaki, M. Investigating the Properties of Bentonite and Kaolin Modified Concrete as a Partial Substitute to Cement. SN Appl. Sci. 2020, 2, 2023. [Google Scholar] [CrossRef]

- Rangrazian, M.; Madandoust, R.; Mahjoub, R.; Raftari, M. Reduction of CO2 environmental pollution from concrete, by adding local mineral pozzolan as a part of cement replacement in concrete: A case study on engineering properties. Nanotechnol. Environ. Eng. 2023, 8, 253–268. [Google Scholar] [CrossRef]

- United Nations. Kyoto Protocol to the United Nations Framework Convention on Climate Change; UN: New York, NY, USA, 1998. [Google Scholar]

- Tam, V.W.; Butera, A.; Le, K.N.; Li, W. Utilising CO2 technologies for recycled aggregate concrete: A critical review. Constr. Build. Mater. 2020, 250, 118903. [Google Scholar] [CrossRef]

- Liang, C.; Pan, B.; Ma, Z.; He, Z.; Duan, Z. Utilization of CO2 Curing to Enhance the Properties of Recycled Aggregate and Prepared Concrete: A Review. Cem. Concr. Compos. 2020, 105, 103446. [Google Scholar] [CrossRef]

- Guo, H.; Shi, C.; Guan, X.; Zhu, J.; Ding, Y.; Ling, T.C.; Zhang, H.; Wang, Y. Durability of recycled aggregate concrete—A review. Cem. Concr. Compos. 2018, 89, 251–259. [Google Scholar] [CrossRef]

- Liu, M.; Wu, H.; Yao, P.; Wang, C.; Ma, Z. Microstructure and Macro Properties of Sustainable Alkali-Activated Fly Ash Mortar with Various Construction Waste Fines as Binder Replacement up to 100%. Cem. Concr. Compos. 2022, 134, 104733. [Google Scholar] [CrossRef]

- Ma, Z.; Shen, J.; Wang, C.; Wu, H. Characterization of sustainable mortar containing high-quality recycled manufactured sand crushed from recycled coarse aggregate. Cem. Concr. Compos. 2022, 132, 104629. [Google Scholar] [CrossRef]

- Wu, H.; Hu, R.; Yang, D.; Ma, Z. Micro-macro characterizations of mortar containing construction waste fines as replacement of cement and sand: A comparative study. Constr. Build. Mater. 2023, 383, 131328. [Google Scholar] [CrossRef]

- Singh, N.B. Clays and Clay Minerals in the Construction Industry. Minerals 2022, 12, 301. [Google Scholar] [CrossRef]

- Ahmad, J.; Kontoleon, K.J.; Al-Mulali, M.Z.; Shaik, S.; Hechmi El Ouni, M.; El-Shorbagy, M.A. Partial Substitution of Binding Material by Bentonite Clay (BC) in Concrete: A Review. Buildings 2022, 12, 634. [Google Scholar] [CrossRef]

- Alujas Diaz, A.; Almenares Reyes, R.S.; Hanein, T.; Irassar, E.F.; Juenger, M.; Kanavaris, F.; Maier, M.; Marsh, A.T.; Sui, T.; Thienel, K.-C. Properties and Occurrence of Clay Resources for Use as Supplementary Cementitious Materials: A Paper of RILEM TC 282-CCL. Mater. Struct. 2022, 55, 139. [Google Scholar] [CrossRef]

- Georgopoulos, G.; Aspiotis, K.; Badogiannis, E.; Tsivilis, S.; Perraki, M. Influence of mineralogy and calcination temperature on the behavior of palygorskite clay as a pozzolanic supplementary cementitious material. Appl. Clay Sci. 2023, 232, 106797. [Google Scholar] [CrossRef]

- Khandelwal, S.; Rhee, K.Y. Evaluation of Pozzolanic Activity, Heterogeneous Nucleation, and Microstructure of Cement Composites with Modified Bentonite Clays. Constr. Build. Mater. 2022, 323, 126617. [Google Scholar] [CrossRef]

- Al-Hammood, A.A.; Frayyeh, Q.J.; Abbas, W.A. Thermally activated bentonite as a supplementary cementitious material–a review. Eng. Technol. J. 2021, 39, 206–213. [Google Scholar] [CrossRef]

- Ghiyas, S.M.R.; Bagheripour, M.H. Stabilization of oily contaminated clay soils using new materials: Micro and macro structural investigation. Geomech. Eng. 2020, 20, 207–220. [Google Scholar] [CrossRef]

- Fathollah, S. Effect of curing regime and temperature on the compressive strength of cement-slagmortars. Constr. Build. Mater. 2012, 36, 549–556. [Google Scholar] [CrossRef]

- Mousa, M.I.; Mahdy, M.G.; Abdel-Reheem, A.H.; Yehia, A.Z. Mechanical properties of self-curing concrete (SCUC). HBRC J. 2015, 11, 311–320. [Google Scholar] [CrossRef]

- ASTM C938-97; Standard Practice for Proportioning Grout Mixtures for Preplaced-Aggregate Concrete. American Society for Testing and Materials: West Conshohocken, PA, USA, 1997.

- ASTM D559-03; Standard Test Methods for Wetting and Drying Compacted Soil–Cement Mixtures. American Society for Testing and Materials: West Conshohocken, PA, USA, 2003. [CrossRef]

- Aldaood, A.; Bouasker, M.; Al-Mukhtar, M. Impact of wetting–drying cycles on the microstructure and mechanical properties of lime-stabilized gypseous soils. Eng. Geol. 2014, 174, 11–21. [Google Scholar] [CrossRef]

- ASTM D2166; Standard Test Method for Unconfined Compressive Strength of Cohesive Soil. ASTM International, i, 1–7: West Conshohocken, PA, USA, 2013. [CrossRef]

- Carlson, L. Bentonite Mineralogy. Part 1. Methods of Investigation—A Literature Review & Part 2. Mineralogical Research of Selected Bentonites. Posiva Oy, Olkiluoto. Working Report. 2004. Available online: https://www.yumpu.com/en/document/view/12090884/bentonite-mineralogy-part-1-methods-of-investigation-posiva (accessed on 4 May 2013).

- Al-Ani, T.; Sarapaa, O. Clay and Clay Mineralogy: Physical-Chemical Properties and Industrial Uses. 2008. Available online: https://www.researchgate.net/publication/292706105_Clay_and_clay_mineralogy (accessed on 30 June 2008).

- Khalifa, A.Z.; Cizer, Ö.; Pontikes, Y.; Heath, A.; Patureau, P.; Bernal, S.A.; Marsh, A.T. Advances in alkali-activation of clay minerals. Cem. Concr. Res. 2020, 132, 106050. [Google Scholar] [CrossRef]

- Peethamparan, S.; Olek, J.; Diamond, S. Mechanism of stabilization of Na-montmorillonite clay with cement kiln dust. Cem. Concr. Res. 2009, 39, 580–589. [Google Scholar] [CrossRef]

- Allam, M.M.; Sridharan, A. Effect of wetting and drying on shear strength. J. Geotech. Eng. Div. Proc. ASCE 1981, 107, 421–438. [Google Scholar] [CrossRef]

- Lin, L.C.; Benson, C.H. Effect of wet-Dry cycling on swelling and hydraulic conductivity of GCLs. J. Geotech. Geoenviron. Eng. 2000, 126, 40–49. [Google Scholar] [CrossRef]

- Pedarla, A.; Chittoori, S.; Puppala, A.J. Influence of mineralogy and plasticity index on the stabilization effectiveness of expansive clays. Transp. Res. Rec. 2011, 2212, 91–99. [Google Scholar] [CrossRef]

- Prusinski, J.R.; Bhattacharja, S. Effectiveness of Portland cement and lime in stabilizing clay soils. Transp. Res. Rec. 1999, 1652, 215–227. [Google Scholar] [CrossRef]

- Mitchell, J.K.; Soga, K. Fundamentals of Soil Behaviour, 3rd ed.; John Wiley and Sons Inc.: New York, NY, USA, 2005. [Google Scholar]

- Chittoori, B.C.S. Clay Mineralogy Effects on Long-Term Performance of Chemically Treated Expansive Clays. Ph.D. Thesis, University of Texas: Arlington, TX, USA, 2008. [Google Scholar]

- Little, D.; Thompson, M.; Terrell, R.; Epps, J.; Barenberg Dallas, E.N. Soil Stabilization for Roadways and Airfields; Engineering & Services Laboratory Air Force Engineering & Services Center: Tyndall Air Force Base, FL, USA, 1987. [Google Scholar]

- Papatzani, S.; Badogiannis, E.G.; Paine, K. The Pozzolanic Properties of Inorganic and Organomodified Nano-Montmorillonite Dispersions. Constr. Build Mater. 2018, 167, 299–316. [Google Scholar] [CrossRef]

- Li, M.; Wu, Z. Preparation, Characterization, and Humidity-Control Performance of Organobentonite/Sodium Polyacrylate Mortar. J. Macromol. Sci. Part B 2012, 51, 1647–1657. [Google Scholar] [CrossRef]

- Liu, L. Prediction of Swelling Pressures of Different Types of Bentonite in Dilute Solutions. Colloids Surf. A Physicochem. Eng. Asp. 2013, 434, 303–318. [Google Scholar] [CrossRef]

- Anh, T.N.; Ngoc, T.N. Soft ground improvement below bridge approach foundation using cement deep mixing columns combined with geotextile. J. Appl. Eng. Sci. 2023, 2, 1–10. [Google Scholar] [CrossRef]

| Property | Liquid Limit (%) | Plastic Limit (%) | Plasticity Index (%) | Sand (%) | Silt (%) | Clay (%) | United Soil Classification | Colour |

|---|---|---|---|---|---|---|---|---|

| 396.2 | 40 | 356.2 | 0 | 22 | 78 | CH | White |

| Cement Type | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | SO3 | Free CaO | Alkalies (Na2O% + 0.658K2O%) | L.O.I | Insoluble Residue |

|---|---|---|---|---|---|---|---|---|---|---|

| II | 21.50 | 4.95 | 3.97 | 63.52 | 1.75 | 2.20 | 1.4 | 1 | 1.19 | 0.5 |

| Appearance | Color | The Combination Ratio of the Resin to the Hardener | Composition Time of the Components | Curing Time at Room Temperature | Density | Viscosity of the Compound at 25 °C |

|---|---|---|---|---|---|---|

| Liquid | Clear colorless | 2:1 | 5 min | 360 min | 1.1 gr/cm3 | 440 cp |

| Symbol | Description | Symbol | Description |

|---|---|---|---|

| ER | The homogenous combination of epoxy resin and hardener with a ratio of 2:1 | The strength parameter of the stabilized bentonite sample with cement and epoxy resin after 24 h of wetting in the sixth cycle | |

| W | Distilled water | ||

| qu | Ultimate compressive strength in the UCS test | ||

| εf | Failure strain | (qu)e | The estimated ultimate compressive strength |

| E50 | The secant elastic modulus at 50% of the ultimate compressive strength | (E50)e | The estimated secant elastic modulus |

| The strength parameter of the stabilized bentonite sample with cement and epoxy resin after 7 days of curing | (Toughness)e | The estimated toughness |

| Montmorillonite (%) | Quartz (%) | Albite (%) | Cristobalite (%) |

|---|---|---|---|

| Ca0.2(Al,Mg)2Si4O10(OH)2,xH2O | SiO2 | (Na,Ca)(Si,Al)4O8 | SiO2 |

| 45 | 14 | 26 | 12 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Soltaninejad, S.; Marandi, S.M.; BP, N. Performance Evaluation of Clay Plastic Concrete of Cement and Epoxy Resin Composite as a Sustainable Construction Material in the Durability Process. Sustainability 2023, 15, 8987. https://doi.org/10.3390/su15118987

Soltaninejad S, Marandi SM, BP N. Performance Evaluation of Clay Plastic Concrete of Cement and Epoxy Resin Composite as a Sustainable Construction Material in the Durability Process. Sustainability. 2023; 15(11):8987. https://doi.org/10.3390/su15118987

Chicago/Turabian StyleSoltaninejad, Sanaz, Seyed Morteza Marandi, and Naveen BP. 2023. "Performance Evaluation of Clay Plastic Concrete of Cement and Epoxy Resin Composite as a Sustainable Construction Material in the Durability Process" Sustainability 15, no. 11: 8987. https://doi.org/10.3390/su15118987

APA StyleSoltaninejad, S., Marandi, S. M., & BP, N. (2023). Performance Evaluation of Clay Plastic Concrete of Cement and Epoxy Resin Composite as a Sustainable Construction Material in the Durability Process. Sustainability, 15(11), 8987. https://doi.org/10.3390/su15118987