Greenhouse Gas Emission Reduction Based on Social Recycling: A Case Study with Waste Picker Cooperatives in Brasília, Brazil

Abstract

:1. Introduction

2. Methodology

2.1. Location of the Study Sites

2.2. Data Collection

2.3. Data Analysis

- ERy = Reduction of emissions per year y (tCO2 eq);

- BEy = Baseline emissions per year y (tCO2 eq);

- PEy = Project emissions per year y (tCO2 eq) and

- LEy = Leakage emissions per electricity consumption per year (tCO2 eq).

- BEy = Baseline Emissions per year y (tCO2 eq y−1);

- i = Indexes for the type of material i (i = 1,2,3 for HDPE, LDPE and PET);

- Qi,y = Quantity of type i plastic recycled per year t (t y−1);

- Li = Adjustment factor to compensate for material quality degradation and material losses in the product manufacturing process using recycled material;

- SECBl,i = Specific consumption of electricity for the production of virgin material type i (MWh t−1);

- EFel,y = Emission factor of the electricity generation network, according to the most recent version (tCO2 MWh−1);

- SFCBl,i = Specific fuel consumption for the production of type i virgin material (GJ t−1) and

- EFff,CO2 = CO2 emission factor for fossil fuel (tCO2 GJ−1).

- BEvpp = Baseline emissions per year y (tCO2/y)

- Qi,y = Quantity of material i recycled per year y (t/y)

- Li = Adjustment factor to cover material quality degradation and material loss in the production process of the final product using the recycled material (use 0.88)

- SECBl,i = Specific consumption of electricity for the production of raw materials (MWh/t).

- EF el,y = Electricity generation network emission factor, according to the most recent version (tCO2 MWh−1) and

- EFff,CO2 = CO2 emission factor for fossil fuel (tCO2 GJ−1).

- Qi,y = Quantity of material i recycled per year y (t/y);

- SECrec = Specific electricity consumption for a recycled resource (MWh/t) and

- EFel,y = Emission factor of the electricity generation network, according to the most recent version (tCO2 MWh−1).

- LEEC,Y = Leakage emissions from electricity consumption per year y (tCO2/y).

- Use 0.001–0.0026;

- ECLE,l,y = Net increase in electricity consumption from source l in year y as a result of leakage (use 0.19);

- EFEF,l,y = Emission factor for electricity generation for source l in year y (tCO2/MWh) (use 0.22–0.38) and

- TDLl,y = Average technical transmission and distribution losses to supply electricity to source l in year y (use 0.03) (default data according to the methodology).

3. Results

4. Discussion

4.1. Waste Picker Cooperatives—Agents for GHG Emission Reduction

4.2. Environmental Contributions of Waste Picker Cooperatives

4.3. Remaining Challenges

4.4. Certification for GHG Emission Reductions

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Intergovernmental Panel on Climate Change (IPCC). Global Warming of 1.5 °C. 2018. Available online: https://www.ipcc.ch (accessed on 19 March 2023).

- Intergovernmental Panel on Climate Change (IPCC). Climate Change 2022: Impacts, Adaptation and Vulnerability. 2022. Available online: https://www.ipcc.ch/report/ar6/wg2/ (accessed on 19 March 2023).

- King, M.; Gutberlet, J. Contribution of Cooperative Sector Recycling to Greenhouse Gas Emissions Reduction: A Case Study of Ribeirão Pires, Brazil. Waste Manag. 2013, 33, 2771–2780. [Google Scholar] [CrossRef] [PubMed]

- Gautam, M.; Agrawal, M. Greenhouse gas emissions from municipal solid waste management: A review of global scenario. In Carbon Footprint Case Studies: Municipal Solid Waste Management, Sustainable Road Transport and Carbon Sequestration; Springer: Singapore, 2021; pp. 123–160. [Google Scholar]

- Wünsch, C.; Kocina, R. Global development of greenhouse gas emissions in the waste management sector. Detritus 2019, 7, 104–118. [Google Scholar] [CrossRef]

- Ebi, K.L.; Hess, J.J. Health Risks Due To Climate Change: Inequity In Causes And Consequences: Study examines health risks due to climate change. Health Aff. 2020, 39, 2056–2062. [Google Scholar] [CrossRef] [PubMed]

- Associação Brasileira das Empresas de Limpeza Pública (ABRELPE). Panorama dos Resíduos Sólidos No Brasil 2018/2019; ABRELPE: São Paulo, Brazil, 2019. [Google Scholar]

- De Almeida, R.; De Souza, R.G.; Campos, J.C. Lessons and challenges for the recycling sector of Brazil from the pandemic outbreak of COVID-19. Waste Dispos. Sustain. Energy 2021, 3, 145–154. [Google Scholar] [CrossRef] [PubMed]

- Barcellos, C.; Monteiro, A.M.W.; Corvalán, C.; Gurgel, H.C.; Sá Carvalho, M.; Artaxo, P.; Hacon, S.; Ragoni, V. Mudanças climáticas e ambientais e as doenças infecciosas: Cenários e incertezas para o Brasil. Epidemiol. Serv. Saúde 2009, 18, 285–304. [Google Scholar] [CrossRef]

- Serviço de Limpeza Urbana (SLU). Construindo um Novo Modelo de Gestão dos Resíduos Sólidos do Distrito Federal, Relatório de Atividades SLU, 2016, 1st ed.; Governo do Distrito Federal: Brasília, Brazil, 2017.

- Serviço de Limpeza Urbana (SLU). Relatório de Atividades SLU, 2018, 1st ed.; Governo do Distrito Federal: Brasília, Brazil, 2019.

- IPEA. Situação Social das Catadoras e dos Catadores de Material Reciclável e Reutilizável–Brasil; Instituto de Pesquisa Econômica Aplicada–IPEA: Brasília, Brazil, 2013. [Google Scholar]

- Serviço de Limpeza Urbana (SLU). Relatório de Atividades SLU, 2017, 1st ed.; Governo do Distrito Federal: Brasília, Brazil, 2018.

- Prates, C.I. Tem Algo Podre no Lixo? A Coleta do Lixo em Hospitais Públicos de Brasília. Doctoral Dissertation, Escola Nacional de Saúde Pública Sergio Arouca, Rio de Janeiro, Brazil, 2011. [Google Scholar]

- Gutberlet, J.; Carenzo, S. Waste Pickers at the Heart of the Circular Economy: A Perspective of Inclusive Recycling from the Global South. Worldw. Waste J. Interdiscip. Stud. 2020, 3, 6. [Google Scholar] [CrossRef]

- Silva, S.P. A Organização Coletiva de Catadores de Material Reciclável no Brasil: Dilemas e Potencialidades sob a Ótica da Economia Solidária; Texto para Discussão; Instituto de Pesquisa Econômica Aplicada (IPEA): Rio de Janeiro, Brazil; Brasília, Brazil, 2017. [Google Scholar]

- Diário Oficial da União (2023) Portaria nº 2, de 5 de Janeiro de 2023. Published on 06/01/2023, Edition 5, Section 2, Page 1. Órgão: Presidência da República/Secretaria-Geral. Available online: https://www.in.gov.br/web/dou/-/portaria-n-2-de-5-de-janeiro-de-2023-456348699 (accessed on 19 March 2023).

- Lowe, E. Economic Solutions. In Environmental Solutions; Agardy, F.J., Nemerow, N.L., Eds.; Elsevier: Amsterdam, The Netherlands, 2005; pp. 61–114. [Google Scholar]

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the circular economy: An analysis of 114 definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Gutberlet, J.; Carenzo, S.; Kain, J.-H.; de Azevedo, A.M.M. Waste Picker Organizations and Their Contribution to the Circular Economy: Two Case Studies from a Global South Perspective. Resources 2017, 6, 52. [Google Scholar] [CrossRef]

- Prajapati, H.; Kant, R.; Shankar, R. Bequeath life to death: State-of-art review on reverse logistics. J. Clean. Prod. 2019, 211, 503–520. [Google Scholar] [CrossRef]

- Rebehy, P.C.P.W.; dos Santos Lima, S.A.; Novi, J.C.; Salgado, A.P., Jr. Reverse logistics systems in Brazil: Comparative study and interest of multistakeholders. J. Environ. Manag. 2019, 250, 109223. [Google Scholar] [CrossRef]

- Brazil (2010) Law No. 12305–Brazilian National Policy on Solid Waste. Brazilian NR Health, Safety and Environment (HSE) in Brazil. Available online: https://www.braziliannr.com/brazilian-environmental-legislation/law-no-12305-brazilian-national-policy-solid-waste/ (accessed on 19 March 2023).

- PlasticsEurope. Plastics–The Facts 2018: An Analysis of European Plastics Production, Demand and Waste Data; Association of Plastics Manufacturers and EPRO: Brussels, Belgium, 2018. [Google Scholar]

- Gall, M.; Wiener, M.; De Oliveira, C.C.; Lang, R.W.; Hansen, E.G. Building a circular plastics economy with informal waste pickers: Recyclate quality, business model, and societal impacts. Resour. Conserv. Recycl. 2020, 156, 104685. [Google Scholar] [CrossRef]

- Gutberlet, J.; Besen, G.R.; Morais, L.P. Participatory solid waste governance and the role of social and solidarity economy: Experiences from São Paulo, Brazil. Detritus 2020, 13, 167–180. [Google Scholar] [CrossRef]

- Maia, P.B. A Economia ambiental proporcionada através da reciclagem pela associação Montes Claros de catadores de recicláveis–Montesul. Rev. Verde Gd. Geogr. Interdiscip. 2020, 2, 105–113. [Google Scholar]

- Gutberlet, J. Grassroots waste picker organizations addressing the UN sustainable development goals. World Dev. 2021, 13, 105195. [Google Scholar] [CrossRef]

- Gutberlet, J.; Sorroche, S.; Martins Baeder, A.; Zapata, P.; Zapata Campos, M.J. Waste pickers and their insurgent practices of environmental stewardship. J. Environ. Dev. 2021, 30, 369–394. [Google Scholar] [CrossRef]

- King, M. Evaluating the Contribution of Cooperative Sector Recycling to the Reduction of Greenhouse Gas Emissions: An Opportunity for Recycling Cooperatives in São Paulo to Engage in Carbon Credit Market. Master’s Thesis, Department of Geography at the University of Victoria, Victoria, BC, Canada, 2012. [Google Scholar]

- CODEPLAN (Companhia de Planejamento do Distrito Federal) Pesquisa Distrital por Amostras de Domicílios 2018. Available online: https://www.codeplan.df.gov.br/pdad/ (accessed on 19 March 2023).

- EPE Anuário Estatístico de Energia Elétrica 2020-ano Base 2019. 2020 Statistical Yearbook of Electricity 2019 Baseline Year. Brasilia. Available online: https://www.epe.gov.br/sites-pt/publicacoes-dados-abertos/publicacoes/PublicacoesArquivos/publicacao-160/topico-168/Anu%C3%A1rio%20Estat%C3%ADstico%20de%20Energia%20El%C3%A9trica%202020.pdf (accessed on 19 March 2023).

- United Nations. Framework Convention on Climate Change (UNFCCC). AMS-III.A.J.: Recovery and Recycling of Materials from Solid Wastes-Version 9.0 UNFCCC; United Nations: New York, NY, USA, 2022. [Google Scholar]

- Fearnside, P. Tropical Hydropower in the Clean Development Mechanism: Brazil’s Santo Antônio Dam as an example of the need for change. Clim. Chang. 2015, 131, 575–589. [Google Scholar] [CrossRef]

- Dones, R.; Heck, T.; Hirschberg, S. Greenhouse gas emissions from solid wastes: Development of the wasted model. Waste Manag. 2004, 26, 886–901. [Google Scholar]

- Pimenteira, C.A.P.; Pereira, A.S.; Oliveira, L.B.; Rosa, L.P.; Reis, M.M.; Henriques, R.M. Energy conservation and CO2 emission reductions due to recycling in Brazil. Waste Manag. 2004, 24, 889–897. [Google Scholar] [CrossRef]

- Gomes, H.P.; Nóbrega, C.C. Economic viability study of a separate household waste collection in a developing country. J. Mater. Cycles Waste Manag. 2005, 7, 116–123. [Google Scholar] [CrossRef]

- Rigamonti, L.; Grosso, M.; Giugliano, M. Life cycle assessment for optimising the level of separated collection in integrated MSW management systems. Waste Manag. 2009, 29, 934–944. [Google Scholar] [CrossRef]

- Merrild, H.; Damgaard, A.; Christensen, T.H. Life cycle assessment of waste paper management: The importance of technology data and system boundaries in assessing recycling and incineration. Resour. Conserv. Recycl. 2009, 52, 1391–1398. [Google Scholar] [CrossRef]

- Damgaard, A.; Larsen, A.W.; Christensen, T.H. Recycling of metals: Accounting of greenhouse gases and global warming contributions. Waste Manag. Res. 2009, 27, 773–780. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- United Nations. Framework Convention on Climate Change (UNFCCC) AMS-III.A.J.: Recovery and Recycling of Materials from Solid Wastes-Version 3.0 UNFCCC; United Nations: New York, NY, USA, 2010. [Google Scholar]

- United Nations. Framework Convention on Climate Change (UNFCCC). AMS-III.A.J.: Tool to Calculate the Emission Factor for an Electricity System-Version 2.2.1 UNFCCC; United Nations: New York, NY, USA, 2010. [Google Scholar]

- United Nations. Framework Convention on Climate Change (UNFCCC). AMS-III.A.J.: Tool to Calculate Baseline, Project Line and/or Leakage Emissions from Electricity Consumption. Version 1 UNFCCC; United Nations: New York, NY, USA, 2010. [Google Scholar]

- ICF Consulting. Determination of the Impact of Waste Management Activities on Greenhouse Gas Emission: 2005 Update; Final Report; ICF Consulting: Reston, VA, USA, 2005. [Google Scholar]

- Gichamo, T.; Gökçekuş, H. Interrelation between climate change and solid waste. J. Environ. Pollut. Control. 2019, 2, 104. [Google Scholar]

- Pereira Neto, J.T. Quanto Vale Nosso Lixo; Independente, Ed.; IEF/UNICEF: Viçosa, Brazil, 1995. [Google Scholar]

- Godecke, M.V. A Inserção da Reciclagem nos Mercados de Carbono: Avaliação da Situação Brasileira e Estudo de caso do Município de Porto Alegre. Ph.D. Thesis, Universidade Feevale, Feevale, Brazil, 2013. [Google Scholar]

- WIEGO. Financiamento de Carbono para Organizações de Catadores. Viabilidade e Outras Questões; Cidades Inclusivas; WIEGO: Manchester, UK, 2013; Available online: https://www.wiego.org/sites/default/files/resources/files/wiego-fact-sheet-carbon-finance-for-wastepicker-organizations-portugues.pdf (accessed on 19 March 2023).

- Guimarães, R.L. Compreendendo o Mecanismo de Desenvolvimento Limpo. In Boletim da Sociedade Brasileira de Economia Ecológica; Instituto de Economia (NEA); Unicamp: Campinas, Brazil, 2007. [Google Scholar]

- CBI. Climate Bonds Standard Version 3.0. International Best Practice for Labelling Green Investments. Climate Bonds Initiative, December 2019. Available online: https://www.climatebonds.net/files/files/climate-bonds-standard-v3-20191210.pdf (accessed on 19 March 2023).

- Gold Standard. Gold Standard for the Global Goals Fee Schedule. 2023. Available online: https://globalgoals.goldstandard.org/fees/ (accessed on 19 March 2023).

- VERRA. Program Fee Schedule. V4.2. 2023. Available online: https://verra.org/wp-content/uploads/2022/12/Program-Fee-Schedule-v4.2-OFFICIAL-Q4-2022-FINAL.pdf (accessed on 19 March 2023).

- Brasil. Senado Federal. Projeto de Lei No 412/2022. Regulamenta o Mercado Brasileiro de Redução de Emissões (MBRE), Brasília. 2022. Available online: https://legis.senado.leg.br/sdleg-getter/documento?dm=9076205&ts=1675309979726&disposition=inline (accessed on 19 March 2023).

- Besen, G.R.; Günther, W.M.R.; Ribeiro, H.; Jacobi, P.R. Gestão da Coleta Seletiva e de Organizações de Catadores: Indicadores e Índices de Sustentabilidade; Fundação Nacional de Saúde; Universidade de São Paulo; WIEGO; Faculdade de Saúde Pública/USP: São Paulo, Brazil, 2017. [Google Scholar]

| Material (i) | Raw Material SECBl,i | Recycled Material SECrec | Adjustment Factor Li | |

|---|---|---|---|---|

| Metal # | 6.84 | 1.78 | 0.84 | |

| Aluminium # | 17.6 | 0.7 | 0.9–1.0 * | |

| Glass # | 4.83 | 4.19 | 0.88–1.0 * | |

| Paper and cardboard # | 4.98 | 1.47 | 0.82 | |

| SFCBl,i | SECBl,i | |||

| PEAD & | 4.17 | 0.83 | 0.83 | 0.75 |

| PEBD & | 4.17 | 1.67 | 0.83 | 0.75 |

| PET & | 4.17 | 1.11 | 0.83 | 0.75 |

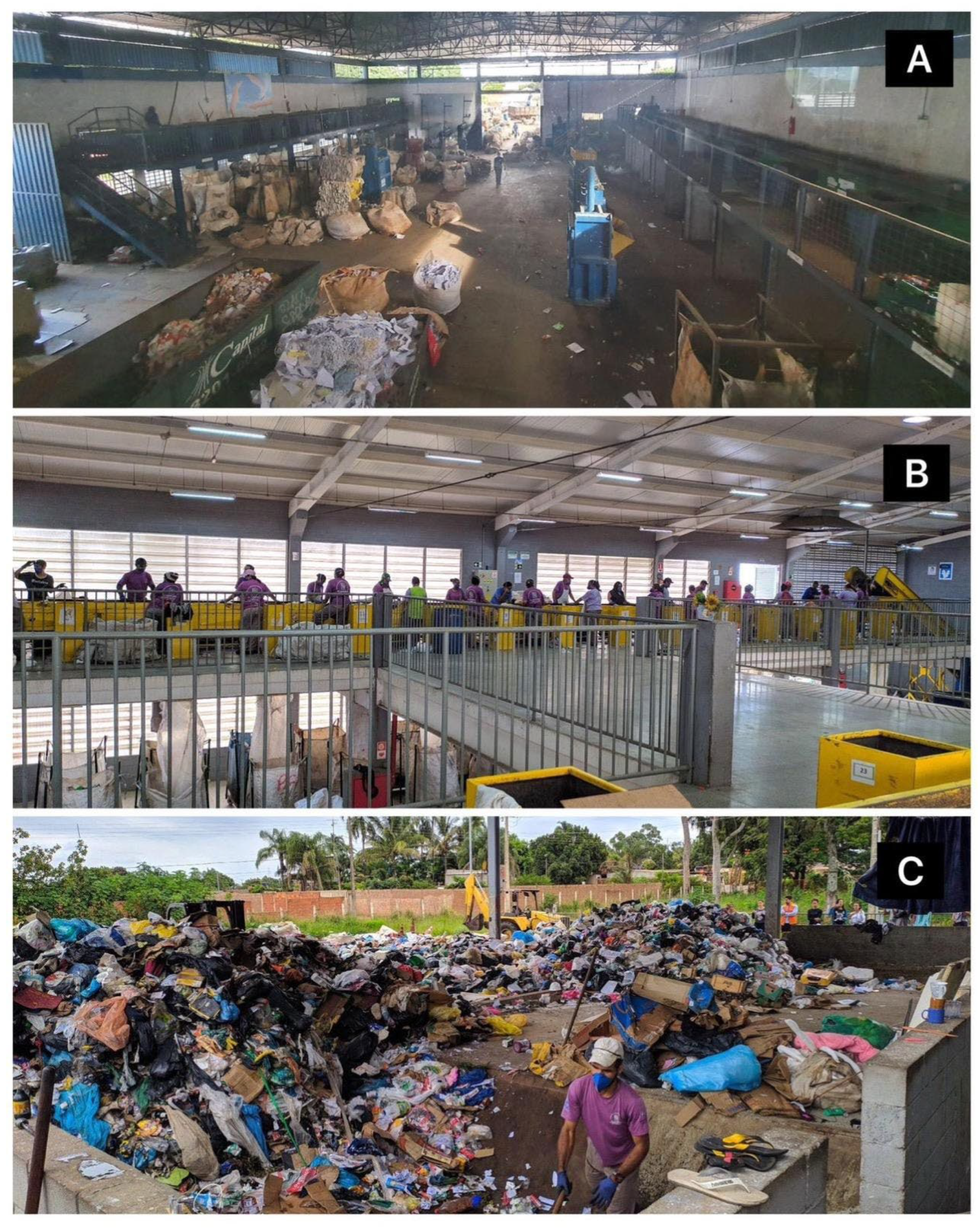

| Cooperative Name | |||

|---|---|---|---|

| Characteristics | Recicle a Vida (A) | Plasferro (B) | Coopere (C) |

| Number of workers | 85 | 100 | 65 |

| Average age (in years) | 38 | 40 | 37 |

| Women (%) | 56 | 61 | 54 |

| Total working hours per week | 45 | 75 (2 work shifts) | 75 (2 work shifts) |

| Source of material | Recyclables from selected businesses, neighborhoods, public departments | Recyclables from selected neighborhoods, using a truck owned by Plasferro and mixed solid waste collected by SLU | Mixed solid waste collected by SLU |

| Type of work | Collection and sorting | Collection and sorting | Sorting |

| Type of contract | No contract | Contract with SLU for collection and sorting | Contract with SLU for sorting |

| Source of the recyclable material | Operates own selective waste collection | Receives material from garbage collection transferred by SLU | Receives material from both the selective waste collection and the garbage collection operated by SLU |

| Material separated per year (in tons) | 327 | 1309.01 | 1237.75 |

| Facility | Own property | SLU owned property | SLU owned property |

| Rejected material (%) | 16.6 | 80.3 | 75.3 |

| Cooperative | Recicle a Vida (A) (T) | Plasferro (B) (T) | Coopere (C) (T) |

|---|---|---|---|

| Type of Material | |||

| PEAD | 22.5 | 127.57 | 0 |

| PEBD | 19 | 0 | 47.33 |

| PET | 20 | 209.38 | 142 |

| Paper and cardboard | 208 | 709.52 | 726.73 |

| Glass | 28 | 161.79 | 195.03 |

| Aluminium | 2.6 | 0.3 | 45.39 |

| Steel | 27 | 100.45 | 81.27 |

| Total | 327 | 1309.01 | 1237.75 |

| Cooperative | Fuel (m3) (Diesel and LPG in m3) | Eletricity (GWh) |

|---|---|---|

| Recicle a Vida (A) | 5.182 m3 | 0.045 GWh |

| Plasferro (B) | 21.147 m3 | 0.028 GWh |

| Coopere (C) | 20.806 m3 | 0.028 GWh |

| Cooperative | Rejected Materials (in Tons)/Year |

|---|---|

| Recicle a Vida (A) | 65.36 |

| Plasferro (B) | 4015.20 |

| Coopere (C) | 2007.60 |

| EFel,y (tCO2/MWh) | 0.22 | 0.38 | 0.22 | 0.38 | 0.22 | 0.38 |

|---|---|---|---|---|---|---|

| Type of Material | Baseline Emissions BEy | Projected Emissions PEy | Emission Reduction ERy | |||

| PEBD | 42.8 | 52.3 | 8.6 | 14.9 | 34.2 | 37.4 |

| PET | 115.4 | 134.3 | 25.9 | 44.7 | 89.5 | 89.5 |

| Paper and cardboard | 652.8 | 1127.7 | 235.0 | 405.9 | 417.8 | 721.7 |

| Glass | 182.3 | 315.0 | 179.7 | 310.5 | 2.5 | 4.4 |

| Aluminium | 175.7 | 303.5 | 6.9 | 12.0 | 168.7 | 291.4 |

| Steel | 102.7 | 177.4 | 31.8 | 54.9 | 70.9 | 122.4 |

| Total | 1272.0 | 2110.4 | 488.1 | 843.2 | 783.8 | 1267.2 |

| EFel,y (tCO2/MWh) | 0.22 | 0.38 | 0.22 | 0.38 | 0.22 | 0.38 |

|---|---|---|---|---|---|---|

| Type of Material | Baseline Emissions BEy | Projected Emissions PEy | Emission Reduction ERy | |||

| PEAD | 97.8 | 110.5 | 23.2 | 40.2 | 74.5 | 70.3 |

| PET | 170.2 | 198.1 | 38.2 | 66.0 | 132.0 | 132.1 |

| Paper and cardboard | 637.4 | 1101.0 | 229.4 | 396.3 | 407.9 | 704.6 |

| Glass | 151.2 | 261.3 | 149.1 | 257.6 | 2.1 | 3.7 |

| Aluminium | 1.1 | 2.0 | 0.0 | 0.0 | 1.1 | 1.9 |

| Steel | 126.9 | 219.3 | 39.3 | 67.9 | 87.6 | 151.3 |

| Total | 1184.9 | 1892.3 | 479.5 | 828.2 | 705.4 | 1064.1 |

| EFel,y (tCO2/MWh) | 0.22 | 0.38 | 0.22 | 0.38 | 0.22 | 0.38 |

|---|---|---|---|---|---|---|

| Type of Material | Baseline Emissions BEy | Projected Emissions PEy | Emission Reduction ERy | |||

| PEAD | 17.2 | 19.4 | 4.1 | 7.0 | 13.1 | 12.4 |

| PEBD | 17.2 | 21.0 | 3.4 | 5.9 | 13.7 | 15.0 |

| PET | 16.2 | 18.9 | 3.6 | 6.3 | 12.6 | 12.6 |

| Paper and cardboard | 186.8 | 322.7 | 67.2 | 116.1 | 119.5 | 206.5 |

| Glass | 26.1 | 45.2 | 25.8 | 44.5 | 0.3 | 0.6 |

| Aluminium | 10.0 | 17.3 | 0.4 | 0.6 | 9.6 | 16.6 |

| Steel | 34.1 | 58.9 | 10.5 | 18.2 | 23.5 | 40.6 |

| Total | 307.9 | 503.7 | 115.2 | 199.1 | 192.6 | 304.6 |

| EFel,y (tCO2/MWh) | 0.22 | 0.38 | 0.22 | 0.38 | 0.22 | 0.38 |

|---|---|---|---|---|---|---|

| Type of material | Recicle a Vida | Coopere | Plasferro | |||

| PEAD | 76.1 | 63.5 | 0 | 0 | 76.1 | 63.6 |

| PEBD | 79.8 | 71.4 | 79.8 | 71.4 | 0 | 0 |

| PET | 77.5 | 66.6 | 77.5 | 66.6 | 77.5 | 66.6 |

| Paper and cardboard | 64.0 | 64.0 | 64.0 | 64.0 | 64.0 | 64.0 |

| Glas | 1.41 | 1.41 | 1.4 | 1.4 | 1.4 | 1.4 |

| Aluminium | 96.0 | 96.0 | 96.0 | 96.0 | 95.9 | 95.9 |

| Steel | 69.5 | 69.01 | 69.0 | 69.0 | 69.0 | 69.0 |

| Total | 62.5 | 60.4 | 61.6 | 60.0 | 59.5 | 56.2 |

| 1 tCO2e = 1 Carbon Credit | EFel,y = 0.2 | Estimated Commercial Value USD 4.69/Credit | EFel,y = 0.38 | Estimated Commercial Value USD 4.69/Credit |

|---|---|---|---|---|

| WPO | Credit Unit | USD | Credit Unit | USD |

| Coopere | 783.8 | 3676.02 | 1267.2 | 5943.17 |

| Plasferro | 705.4 | 3308.33 | 1064.1 | 4990.63 |

| Recicle a Vida | 192.6 | 903.29 | 304.6 | 1428.57 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mesquita, J.L.C.; Gutberlet, J.; de Araujo, K.P.; Cruvinel, V.R.N.; Duarte, F.H. Greenhouse Gas Emission Reduction Based on Social Recycling: A Case Study with Waste Picker Cooperatives in Brasília, Brazil. Sustainability 2023, 15, 9185. https://doi.org/10.3390/su15129185

Mesquita JLC, Gutberlet J, de Araujo KP, Cruvinel VRN, Duarte FH. Greenhouse Gas Emission Reduction Based on Social Recycling: A Case Study with Waste Picker Cooperatives in Brasília, Brazil. Sustainability. 2023; 15(12):9185. https://doi.org/10.3390/su15129185

Chicago/Turabian StyleMesquita, Julia Luz Camargos, Jutta Gutberlet, Katiuscia Pereira de Araujo, Vanessa Resende Nogueira Cruvinel, and Fabiano Harada Duarte. 2023. "Greenhouse Gas Emission Reduction Based on Social Recycling: A Case Study with Waste Picker Cooperatives in Brasília, Brazil" Sustainability 15, no. 12: 9185. https://doi.org/10.3390/su15129185

APA StyleMesquita, J. L. C., Gutberlet, J., de Araujo, K. P., Cruvinel, V. R. N., & Duarte, F. H. (2023). Greenhouse Gas Emission Reduction Based on Social Recycling: A Case Study with Waste Picker Cooperatives in Brasília, Brazil. Sustainability, 15(12), 9185. https://doi.org/10.3390/su15129185